Research Development and Key Issues of Pervious Concrete: A Review

Abstract

1. Introduction

2. Raw Materials for PC

2.1. Aggregate

2.2. Gradation and Grain Size

2.3. Water–Cement Ratio

2.4. Cement Admixtures and Additives

3. Preparation of PC

3.1. Design of Mix Proportion

3.2. Mixing and Moulding

4. Strength Characteristics of PC

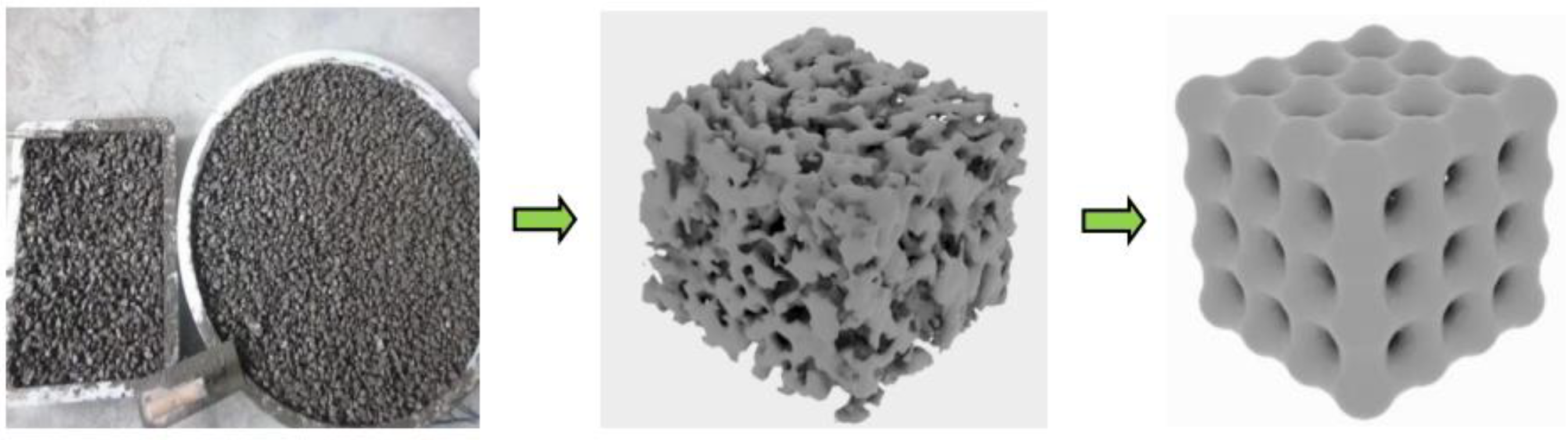

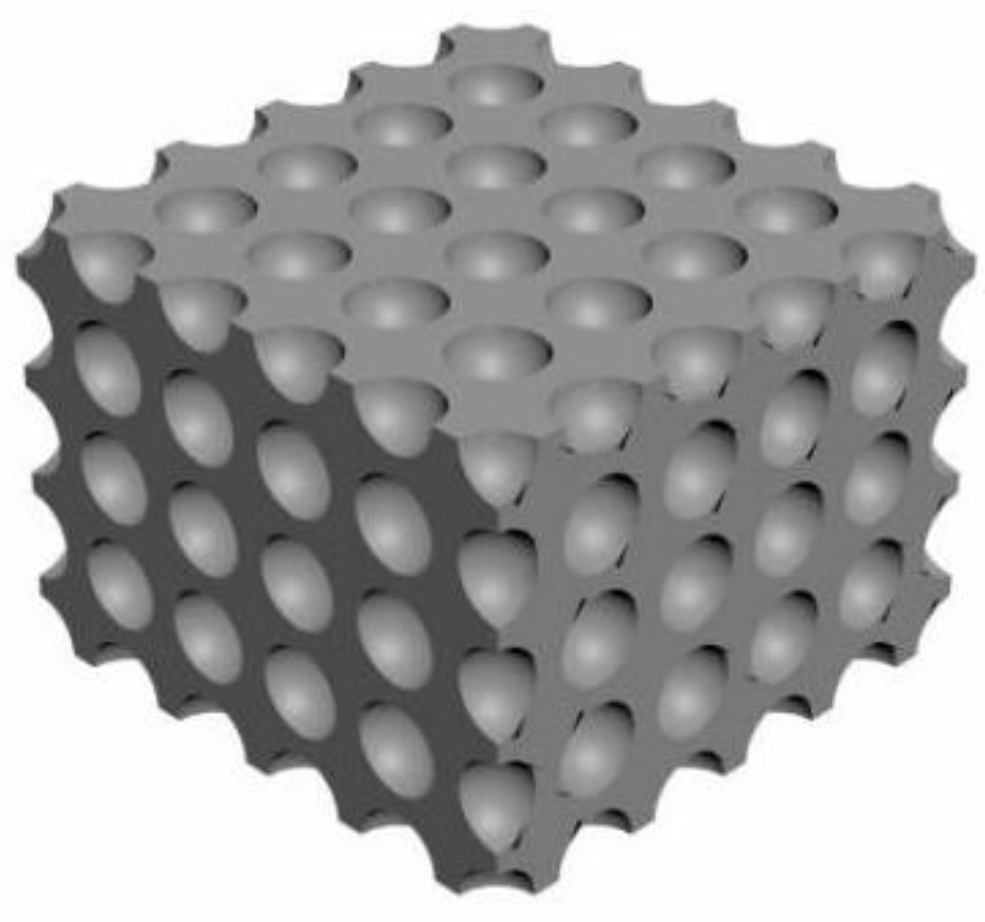

5. Porosity, Permeability, and Characteristics

5.1. Factors Affecting Porosity

5.2. Effective Stress Principle and Pore Structure

- (1)

- Reducing the friction head loss by doping surfactant.

- (2)

- Reducing impingement, vortexing and bypassing resistance loss by changing the shape of the coarse aggregate by special mechanism sand.

- (3)

- An appropriate increase in aggregate particle size by using modified cementitious materials without reducing strength.

6. Durability of PC

6.1. Blockage Resistance

6.2. Freeze Thaw Durability

6.3. Abrasion Resistance

7. Discussions

- 1.

- In terms of research results, there is currently insufficient research in the literature on the correlation between various influencing factors, and there are even contradictory research results on some influencing factors.

- 2.

- In terms of the mechanism of damage, the cracking law and mechanism of the performance of permeable recycled aggregate concrete under multi factor coupling are worthy of in-depth study. In addition, it is necessary to study the reinforcement mechanism of high-strength cementitious materials at the micro level.

- 3.

- In terms of preparation and testing, there is no unified standard for the preparation and testing of PC, and there are still some shortcomings in the existing preparation process. The strength and permeability of PC cannot be effectively predicted through mix design, and the reliability is poor, with many technical defects.

- 4.

- In terms of sustainable adsorption, it is still unclear whether the pollutants removed by physical adsorption, chemical binding, biological retention, photocatalysis, etc. are in a stable state. Further research is needed to achieve sustainable pollutant removal and optimise pollutant removal efficiency.

- 5.

- In terms of the concept of green development, research topics and application technologies related to the use of plant-based PC for water storage and crop irrigation in arid and water scarce areas are still insufficient.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yiwo, E.; Tamayo, P.; Jato-Espino, D.; García Del Angel, G.; Thomas, C. The Effect of Untreated Dura-Palm Kernel Shells as Coarse Aggregate in Lightweight Pervious Concrete for Flood Mitigation. Buildings 2023, 13, 1588. [Google Scholar] [CrossRef]

- Liu, W.; Ma, K.; Zhang, C.; Long, G.; Xie, Y.; Bian, W. Research progress on the purification principle of water permeable concrete on pollutants in urban stormwater runoff. Mater. Rep. 2019, 33, 293–299. [Google Scholar]

- Sun, L. Experimental study on acoustic absorption performance of pervious concrete. Concrete 2019, 11, 159–162. [Google Scholar] [CrossRef]

- Chen, S.; Gao, Y.; Liang, C.; Desire, R.; Shao, X. Research progress of water permeable recycled aggregate concrete. Silic. Bull. 2020, 39, 150–156. [Google Scholar] [CrossRef]

- Sukcharoen, T.; Kositgittiwong, D.; Ekkawatpanit, C.; Tran, T.N.H.; Tangchirapat, W. Assessment of the solitary wave attenuation through pervious concrete breakwater. Constr. Build. Mater. 2024, 411, 134457. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, K.; Yin, Z.; Zhou, J. Deterioration Performance of Recycled Aggregate Pervious Concrete under Freezing–Thawing Cycle and Chloride Environment. Buildings 2023, 13, 645. [Google Scholar] [CrossRef]

- Dong, S.; Li, J.; Xiao, P.; Guo, Q.; Feng, L.; You, M. Research progress of recycled aggregate pervious concrete in sponge city construction. Rural. Econ. Technol. 2020, 31, 327–328. [Google Scholar]

- Xie, H.; Li, J.; Li, G.; Liu, F. Progress of research on the performance and application of water-permeable concrete. In Proceedings of the 20th National Symposium on Modern Structural Engineering, Shijiazhuang, China, 19 September 2020. [Google Scholar]

- Jiang, Y.; Niu, Y.; Jia, L.; Qiao, H.; Yang, S. Experimental research on high-strength pervious concrete. New Build. Mater. 2017, 44, 16–19. [Google Scholar]

- Xie, H.Z.; Li, L.G.; Liu, F.; Kwan, A.K.H. Recycling Old Concrete as Waste Concrete Powder for Use in Pervious Concrete: Effects on Permeability, Strength and Eco-Friendliness. Buildings 2022, 12, 2172. [Google Scholar] [CrossRef]

- Fan, W. Research progress on permeable concrete. Mater. Rep. 2017, 31, 413–416. [Google Scholar]

- GB/T 14685; Pebbles and Crushed Stone for Construction. Chinese National Standard: Beijing, China, 2022.

- Wang, Y.; Yu, F.; Zheng, G. Compressive strength and water permeability of pervious concrete with recycled aggregates. J. Fuzhou Univ. (Nat. Sci. Ed.) 2019, 47, 538–543. [Google Scholar]

- Fan, Q.; Shi, C. Current status of research on recycled aggregate pervious concrete. Concrete 2023, 9, 141–144+54. [Google Scholar] [CrossRef]

- Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious geopolymer concrete using recycled aggregates. Constr. Build. Mater. 2013, 42, 33–39. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H. Comprehensive assessment of engineering and environmental attributes of geopolymer pervious concrete with natural and recycled aggregate. J. Clean. Prod. 2024, 468, 143138. [Google Scholar] [CrossRef]

- Yap, S.; Chen, P.; Goh, Y.; Ibrahim, H.; Mo, K.; Yuen, C. Characterization of pervious concrete with blended natural aggregate and recycled concrete aggregates. J. Clean. Prod. 2018, 181, 155–165. [Google Scholar] [CrossRef]

- Kasulanati, M.L.; Pancharathi, R.K. Optimizing multi-recycled concrete for sustainability: Aggregate gradation, surface treatment methods and life cycle impact assessment. Constr. Build. Mater. 2024, 449, 138510. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Density, Relative Density. ASTM International: West Conshohocken, PA, USA, 2017.

- Zhang, P.; Wang, W.; Zheng, Y.; Hu, S. Effect of Recycled Aggregate and Slag as Substitutes for Natural Aggregate and Cement on the Properties of Concrete: A Review. J. Renew. Mater. 2022, 11, 1853–1879. [Google Scholar] [CrossRef]

- Ichino, H.; Kuwahara, N.; Beppu, M.; Williamson, E.B.; Himi, A. Effects of the shape, size, and surface roughness of glass coarse aggregate on the mechanical properties of two-stage concrete. Constr. Build. Mater. 2024, 411, 134296. [Google Scholar] [CrossRef]

- Shen, C.; Wang, H.; Tang, D.; Lyu, Z.; Zhang, H.; Yu, L.; Zhang, H.; Yu, L.; Yang, C. Investigating the influence of coarse aggregate characteristics and fiber dispersion on the flexural performance of ultra-high performance concrete (UHPC). J. Build. Eng. 2024, 97, 110738. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Liu, Z.; Zhang, W.; Pang, B.; Zhang, Y.; Wang, D. Quantitative surface quality evaluation for 3D-printed concrete with coarse aggregate through 3D scanning. Case Stud. Constr. Mater. 2024, 20, e03077. [Google Scholar] [CrossRef]

- Zhao, H.; Geng, Q.; Ren, W. Research progress of permeable concrete based on solid waste. Appl. Chem. Eng. 2023, 52, 261–265. [Google Scholar]

- Wu, C. Experimental Study on the Preparation of Functional Permeable Concrete by Gangue Synergistic Multi-Level Utilization of Multi-Source Solid Waste. Ph.D. Thesis, Shandong University, Jinan, China, 2023. [Google Scholar]

- Xu, X. Properties and microscopic morphology analysis of recycled aggregate concrete with waste rock excavated by mining method. Concrete 2023, 7, 177–180+87. [Google Scholar] [CrossRef]

- Wu, S.; Xie, P.; Qiao, S.; Zhao, F.; Liao, L. Experimental study on the preparation of permeable concrete from iron tailings aggregate. Min. Res. Dev. 2022, 42, 100–105. [Google Scholar] [CrossRef]

- Huang, Z.-W.; Xue, Z.-L.; Guo, L.; Chen, S.-K. Influence of aggregate gradation on the properties of recycled pervious concrete. People’s Yellow River 2021, 43, 147–150+54. [Google Scholar]

- Tan, Y.; Tan, Y.; Xiao, H.; Zhu, Y.; Peng, Y. Experimental study on the strength of water permeable concrete. Concrete 2020, 5, 126–128+35. [Google Scholar] [CrossRef]

- Yang, L.-X.; Song, X.-F.; Lu, M.-R.; Xia, Y.-H. Study on the effect of aggregate gradation on the performance of recycled aggregate permeable concrete. Concrete 2021, 12, 83–88. [Google Scholar] [CrossRef]

- Chen, P.; Li, B.; Zeng, B. Effect of recycled coarse aggregate particle size on mechanical and durability properties of concrete. Silic. Bull. 2023, 42, 3679–3687+94. [Google Scholar] [CrossRef]

- Miao, R.; Fan, H.; Liu, S.; Yang, H. Porosity study of pervious concrete based on image analysis. Concrete 2021, 40–43. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, Y.; Yang, T.; Huang, W.; Li, Y.; Li, Z.; Chen, Y.; Xiao, Y. Control mechanism of particle crushing and interfacial damage on the strength of water-stabilized recycled aggregate permeable base material. J. Cent. South Univ. (Nat. Sci. Ed.) 2023, 54, 4777–4792. [Google Scholar]

- Claudino, G.O.; Rodrigues, G.G.O.; Rohden, A.B.; Mesquita, E.F.T.; Garcez, M.R. Mix design for pervious concrete based on the optimization of cement paste and granular skeleton to balance mechanical strength and permeability. Constr. Build. Mater. 2022, 347, 128620. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Li, X.; Huo, G.; Xie, L.; Meng, Z.; Gao, Y.; Cao, Y. Analysis of pore structure and mechanical properties of fully-replaced recycled concrete with coarse aggregates. Silic. Bull. 2024, 43, 3005–3016+3033. [Google Scholar] [CrossRef]

- Yaghmour, E.; Abu Qamar, M.A.; Yan, L.; Naito, C.; Suleiman, M.; Fox, J.; Romero, C.; Neti, S. Energy storage in lightweight aggregate and pervious concrete infused with phase change materials. Appl. Therm. Eng. 2024, 250, 123430. [Google Scholar] [CrossRef]

- Bao, J.-W.; Zhang, H.-R.; Fang, X.-L.; Zhang, P.; Qin, L.; Sun, J.-W. Research progress on the properties of recycled coarse aggregate concrete modified with nanosilica. J. Silic. 2023, 51, 2045–2053. [Google Scholar] [CrossRef]

- Ji, L.-P. Research on the performance and engineering application of water permeable concrete with recycled aggregates of metakaolin. Jiangxi Build. Mater. 2023, 12, 28–30+3. [Google Scholar]

- Bright Singh, S.; Murugan, M.; Chellapandian, M.; Dixit, S.; Bansal, S.; Sunil, K.; Gupta, M.; Maksudovna, K. Effect of fly ash addition on the mechanical properties of pervious concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Venkati, B.; Manjulavani, K. Variation of aggregate size using sensors based on impact strength of pervious concrete. Meas. Sens. 2024, 33, 101094. [Google Scholar] [CrossRef]

- Singh, T.; Siddique, R.; Sharma, S. Effectiveness of using Metakaolin and fly ash as supplementary cementitious materials in pervious concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 7359–7382. [Google Scholar] [CrossRef]

- Sun, J.; Song, N.; Yu, K.; Zhang, H. Study on the properties of recycled aggregate reinforced and recycled concrete. Concrete 2023, 8, 95–99. [Google Scholar] [CrossRef]

- Li, F.; Huang, Z.; Wang, Y.; Lu, J.; Liu, C. Progress on the effect of polymers on the performance of pervious concrete. Concrete 2024, 1, 45–49. [Google Scholar]

- Algaifi, H.A.; Bakar, S.A.; Sam, A.R.M.; Abidin, A.R.Z.; Shahir, S.; Al-Towayti, W.A.H. Numerical modeling for crack self-healing concrete by microbial calcium carbonate. Constr. Build. Mater. 2018, 189, 816–824. [Google Scholar] [CrossRef]

- Zhang, G.-Z.; Liu, C.; Cheng, P.-F.; Li, Z.; Han, Y.; Wang, X.-Y. Enhancing the interfacial compatibility and self-healing performance of microbial mortars by nano-SiO2-modified basalt fibers. Cem. Concr. Compos. 2024, 152, 105650. [Google Scholar] [CrossRef]

- Hari, R.K.M.M. Mechanical and clogging characteristics of SBR modified pervious concrete reinforced with geogrids—A Functional Data Analysis approach. Constr. Build. Mater. 2024, 412, 134780. [Google Scholar] [CrossRef]

- Luo, F.; Li, B.; Du, J.; Guo, Y.; Mai, J.; Zhang, T. Influence of Aggregate Types and Grades on the Abrasion Resistance of Pavement Concrete. Silic. Bull. 2022, 41, 1963–1972+2006. [Google Scholar] [CrossRef]

- Zhang, G.Q. Research on Experimental Properties of Permeable Concrete. Master’s Degree, Guangzhou University, Guangzhou, China, 2019. [Google Scholar]

- Liang, J. Research on the Performance of Permeable Concrete Based on High Strength Binder. Master’s Degree, Guangzhou University, Guangzhou, China, 2022. [Google Scholar]

- He, S.; Jiao, C.; Ou, X. Design and performance evaluation of high-strength frost-resistant pervious concrete. Mater. Guide 2023, 37, 136–142. [Google Scholar]

- Barmjouse, P.W.; Srubar, W.V., III. Material characterization and hydraulic conductivity modeling of macroporous recycled-aggregate pervious concrete. Constr. Build. Mater. 2016, 110, 89–97. [Google Scholar]

- Yuan, W.; Ji, L.; Meng, L.; Fang, M.; Zhang, X. Inffuence of Mineral Admixtures on the Performance of Pervious Concrete and Microscopic Research. Buildings 2024, 14, 533. [Google Scholar] [CrossRef]

- Brasileiro, K.P.T.V.; Nahime, B.D.O.; Lima, E.C.; Alves, M.M.; Ferreira, W.P.; Santos, L.S.D.; Filho, C.P.B.; Reis, I.C.D. Influence of recycled aggregates and silica fume on the performance of pervious concrete. J. Build. Eng. 2024, 82, 108347. [Google Scholar] [CrossRef]

- Risson, K.D.D.; Sandoval, G.F.; Pinto, F.S.; Camargo, M.; De Moura, A.C.; Toralles, B.M. Molding Procedure for Pervious Concrete Specimens by Density Control. Case Stud. Constr. Mater. 2021, 15, e00619. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Yu, P.; Gao, Y.; Hou, Y. Study on the effect of molding method on the strength and water permeability of pervious concrete. Concrete 2020, 8, 143–146+50. [Google Scholar] [CrossRef]

- Wu, Y.; Pieralisi, R.; Sandoval, F.G.; López-Carreño, R.D.; Pujadas, P. Optimizing pervious concrete with machine learning: Predicting permeability and compressive strength using artificial neural networks. Constr. Build. Mater. 2024, 443, 137619. [Google Scholar] [CrossRef]

- Liao, L.; Wu, S.; Hao, R.; Zhou, Y.; Xie, P. The compressive strength and damage mechanisms of pervious concrete based on 2D mesoscale pore characteristics. Constr. Build. Mater. 2023, 386, 131561. [Google Scholar] [CrossRef]

- Supriya, A.; Murali, K. The development of the compressive strength of pervious concrete using sugarcane bagasse ash and flyash. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Park, S.; Ju, S.; Kim, H.-K.; Seo, Y.-S.; Pyo, S. Effect of the rheological properties of fresh binder on the compressive strength of pervious concrete. J. Mater. Res. Technol. 2022, 17, 636–648. [Google Scholar] [CrossRef]

- Gaedicke, C.; Torres, A.; Huynh, K.C.T.; Marines, A. A method to correlate splitting tensile strength and compressive strength of pervious concrete cylinders and cores. Constr. Build. Mater. 2016, 125, 271–278. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Behera, N. Performance assessment of pervious concrete road on strength and permeability by using silica fume. Mater. Today Proc. 2022, 60, 559–568. [Google Scholar] [CrossRef]

- Nazeer, M.; Kapoor, K.; Singh, S.P. Impact of recycled concrete aggregates on the strength and durability properties of pervious concrete. Mag. Concr. Res. 2023, 76, 272–291. [Google Scholar] [CrossRef]

- Chockalingam, T.; Vijayaprabha, C.; Leon Raj, J. Experimental study on size of aggregates, size and shape of specimens on strength characteristics of pervious concrete. Constr. Build. Mater. 2023, 385, 131320. [Google Scholar] [CrossRef]

- Putma, B.J.; Neptune, A.I. Comparison of test specimen preparation techniques for pervious concrete pavements. Constr. Build. Mater. 2011, 25, 3480–3485. [Google Scholar] [CrossRef]

- Yi, C.; Tan, Y.; Zhang, W.; Tan, Y.; Xiao, H. Experimental study on water permeability of pervious concrete. Concrete 2021, 1, 110–114. [Google Scholar] [CrossRef]

- Chen, S.; Lei, S.; Duan, P.; Zhang, Z.; Zhao, M.; Wang, L. Critical properties and prediction of water permeable concrete with recycled aggregate pipe holes. Concrete 2023, 2, 176–181. [Google Scholar] [CrossRef]

- Yang, Y.F. Influence of Pore Characteristics on the Performance of Pervious Concrete. Master’s Thesis, Beijing University of Architecture, Beijing, China, 2024. [Google Scholar]

- Lee, M.-G.; Wang, Y.-C.; Wang, W.-C.; Chien, H.-J.; Cheng, L.-C. Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete. Buildings 2023, 13, 2880. [Google Scholar] [CrossRef]

- Kapicová, A.; Bílý, P.; Fládr, J.; Šeps, K.; Chylík, R.; Trtík, T. Development of sound-absorbing pervious concrete for interior applications. J. Build. Eng. 2024, 85, 108697. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Z. Heavy metal ion adsorption properties of carbon nanotube pervious concrete. Funct. Mater. 2019, 50, 7111–7114. [Google Scholar] [CrossRef]

- Li, Y.; Huang, C.; Zhang, Z.; Lin, Y.; Wang, Y. Research progress of recycled aggregate permeable concrete under the concept of sponge city. China Build. Met. Struct. 2023, 22, 65–67. [Google Scholar] [CrossRef]

- Sathiparan, N.; Jeyananthan, P.; Subramaniam, D.N. Surface response regression and machine learning techniques to predict the characteristics of pervious concrete using non-destructive measurement: Ultrasonic pulse velocity and electrical resistivity. Measurement 2024, 225, 114006. [Google Scholar] [CrossRef]

- Zhang, J.; Ming, R.; Dai, Z.; Meng, G.; Cui, X.; Ma, G.; She, R. A review of permeability properties of pervious concrete and clogging research. Concrete 2019, 7, 94–99. [Google Scholar] [CrossRef]

- Elango, K.S.; Saravanakumar, R.; Annadurai, S.; Vivek, D.; Rajeshkumar, K.; Karthikeyan, S. Comparative analysis of infiltration and pore clogging effects in pervious concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, K.; Zhao, Y. Frost durability test of recycled aggregate pervious concrete based on pore structure characteristics. Silic. Bull. 2020, 39, 756–761+78. [Google Scholar] [CrossRef]

- Xiang, J.; Song, H.; Leng, M.; Gui, F. Analysis on the causes of freeze-thaw spalling of permeable concrete. Silic. Bull. 2021, 40, 2215–2224. [Google Scholar] [CrossRef]

- Gong, L.; Liang, Y.; Gong, X.; Li, Y.; Jia, Z. Study on frost durability and interface microstructure of recycled concrete under sulfate environment. J. Basic Appl. Eng. Sci. 2023, 31, 1006–1017. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Liu, H.; Zhang, W. Experimental study on frost resistance of 3D printed recycled coarse aggregate concrete. Funct. Mater. 2023, 54, 7001–7009. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Tavakoli, D.; El-Mir, A.; Dehkordi, R.S. Synergistic effect of recycled aggregate, waste glass and slag on the properties of pervious concrete. Built Environ. Dev. 2023, 15, 100189. [Google Scholar] [CrossRef]

- Sandoval, G.F.B.; Pieralisi, R. Effect of sustainable aggregates on the abrasion resistance of pervious concrete. Results Eng. 2023, 20, 101384. [Google Scholar] [CrossRef]

- Nazeer, M.; Kapoor, K.; Singh, S.P. Strength, durability and microstructural investigations on pervious concrete made with fly ash and silica fume as supplementary cementitious materials. J. Build. Eng. 2023, 69, 106275. [Google Scholar] [CrossRef]

- Luo, Y.; Lv, Y.; Wang, D.; Jiang, Z.; Xue, G. The influence of coarse aggregate gradation on the mechanical properties, durability, and plantability of geopolymer pervious concrete. Constr. Build. Mater. 2023, 382, 131246. [Google Scholar] [CrossRef]

- Adamu, M.; Ayeni, K.O.; Haruna, S.I.; Ibrahim Mansour, Y.E.-H.; Haruna, S. Durability performance of pervious concrete containing rice husk ash and calcium carbide: A response surface methodology approach. Case Stud. Constr. Mater. 2021, 14, e00547. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar] [CrossRef]

- Taheri, B.M.; Ramezanianpour, A.M.; Sabokpa, S.; Gapele, M. Experimental evaluation of freeze-thaw durability of pervious concrete. J. Build. Eng. 2021, 33, 101617. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Boutouil, M.; Sebaibi, N.; Baraud, F.; Leleyter, L. Durability of pervious concrete using crushed seashells. Constr. Build. Mater. 2017, 135, 137–150. [Google Scholar] [CrossRef]

| Specification | Dry-Rodded Unit Weight, kg/m3 | Relative Density (Specific Gravity) | Absorption Capacity | Size Range |

|---|---|---|---|---|

| Natural coase aggregate (NCA) | 1449 | 2.73 | 0.5% | 0.3–12.5 mm |

| Recycled concrete aggregate (RCA) | 1284 | 2.35 | 5.5% |

| Processing Processes | Pending Items | Equipment Used | Achieve the Goal |

|---|---|---|---|

| Crushing and Screening | Waste Concrete | Screening Equipment | Separate Aggregates |

| Removing Pollutants | Aggregate | Water Flotation Separators, Separators, and Magnets | Remove Impurities |

| Plastic Surgery Treatment | Recycled Aggregate | Mechanical Grinding Equipment | Improve Performance |

| Calcination and Grinding | Recycled Aggregate | Rotary Kiln | Remove Impurities |

| Final Programme | The calcined aggregate can be further processed into the required particle size through grinding equipment. | ||

| Factors | Water–Cement Ratio | Porosity | Recycled Aggregate Particle Size and Grading | Replacement Rate of Recycled Aggregate | Molding Methods | Addition of Fibers | Freeze–Thaw Cycle | |

|---|---|---|---|---|---|---|---|---|

| Strength | ||||||||

| Changes in compressive strength | ↗↘ | ↘ | ↗↘ | ↘ | ↗ | ↗↘ | ↘ | |

| Changes in tensile strength | ↗↘ | ↘ | ↗↘ | ↘ | ↗ | ↗↘ | ↘ | |

| Changes in flexural strength | ↗↘ | ↘ | ↗↘ | ↘ | ↗ | ↗↘ | ↘ | |

| Factors | Water–Cement Ratio | Porosity | Recycled Aggregate Particle Size | Replacement Rate of Recycled Aggregate | Coefficient of Thermal Expansion of Aggregate | Addition of Rubber or Fibre | |

|---|---|---|---|---|---|---|---|

| Durability | |||||||

| Wear resistance changes | ↗ | ↘ | ↗ | ↘ | ↗ | ↗ | |

| Changes in freeze–thaw damage | ↘ | ↘ | ↗ | ↘ | ↗ | ↗ | |

| Resistance to sulfuric acid erosion changes | ↘ | ↘ | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, B.; Luo, A.; Zhang, X.; Huang, P. Research Development and Key Issues of Pervious Concrete: A Review. Buildings 2024, 14, 3419. https://doi.org/10.3390/buildings14113419

Cui B, Luo A, Zhang X, Huang P. Research Development and Key Issues of Pervious Concrete: A Review. Buildings. 2024; 14(11):3419. https://doi.org/10.3390/buildings14113419

Chicago/Turabian StyleCui, Bo, Aizhong Luo, Xiaohu Zhang, and Ping Huang. 2024. "Research Development and Key Issues of Pervious Concrete: A Review" Buildings 14, no. 11: 3419. https://doi.org/10.3390/buildings14113419

APA StyleCui, B., Luo, A., Zhang, X., & Huang, P. (2024). Research Development and Key Issues of Pervious Concrete: A Review. Buildings, 14(11), 3419. https://doi.org/10.3390/buildings14113419