Structural Behaviour and Mechanical Characteristics of BlueDeck Profiled Steel Sheeting for Use in Composite Flooring Systems

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.2. Specimen Design and Test Setup

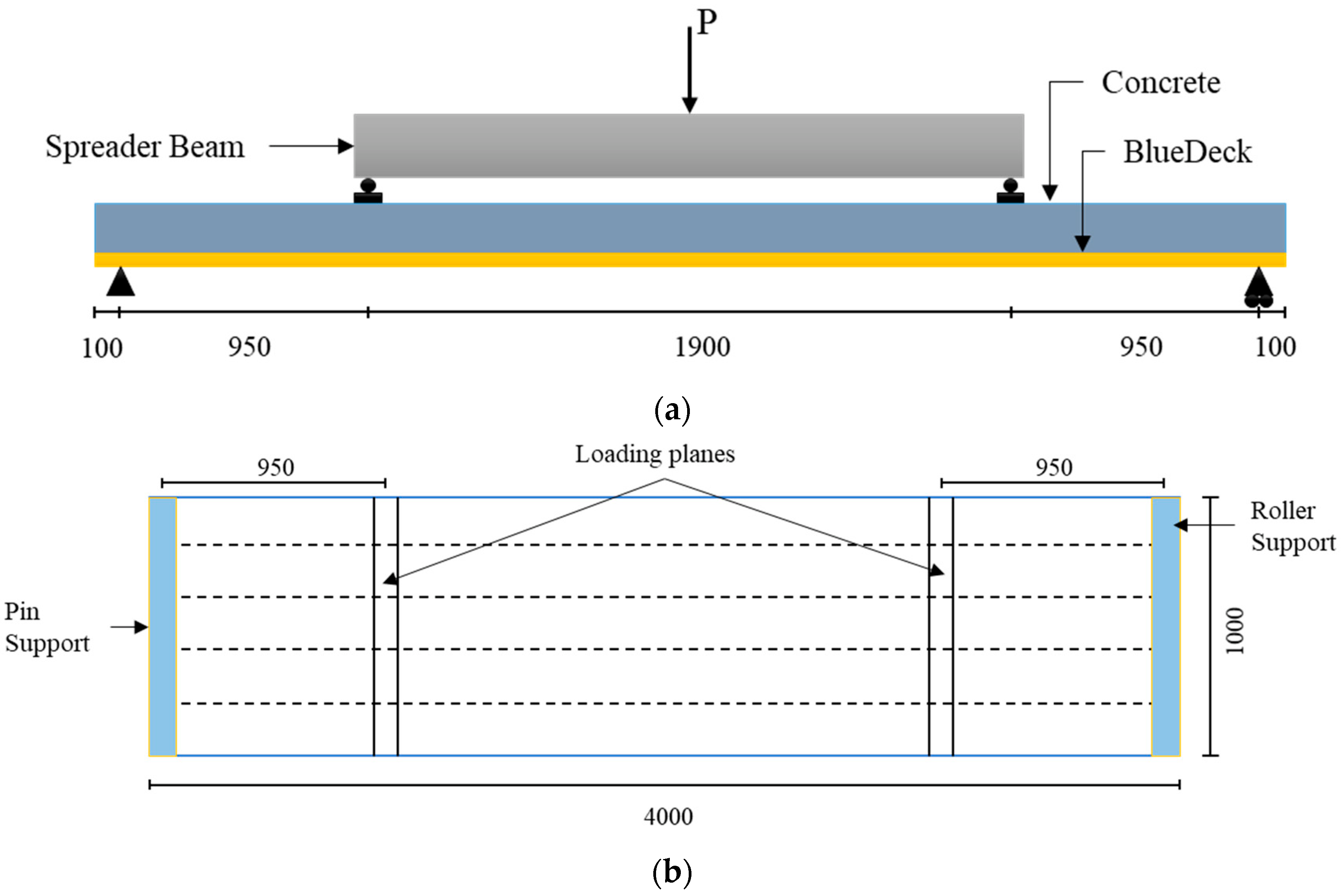

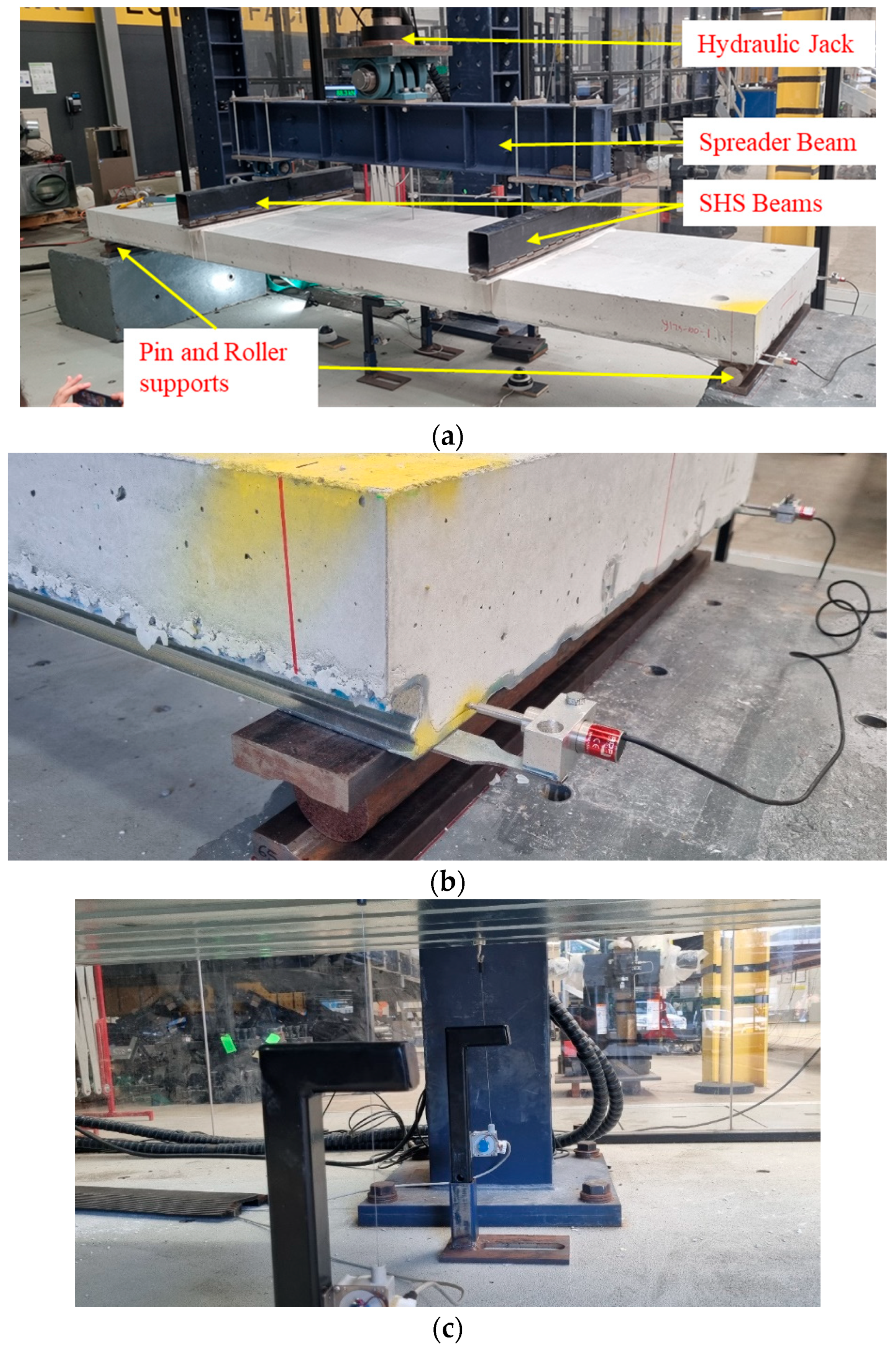

2.2.1. Four-Point Bending Tests

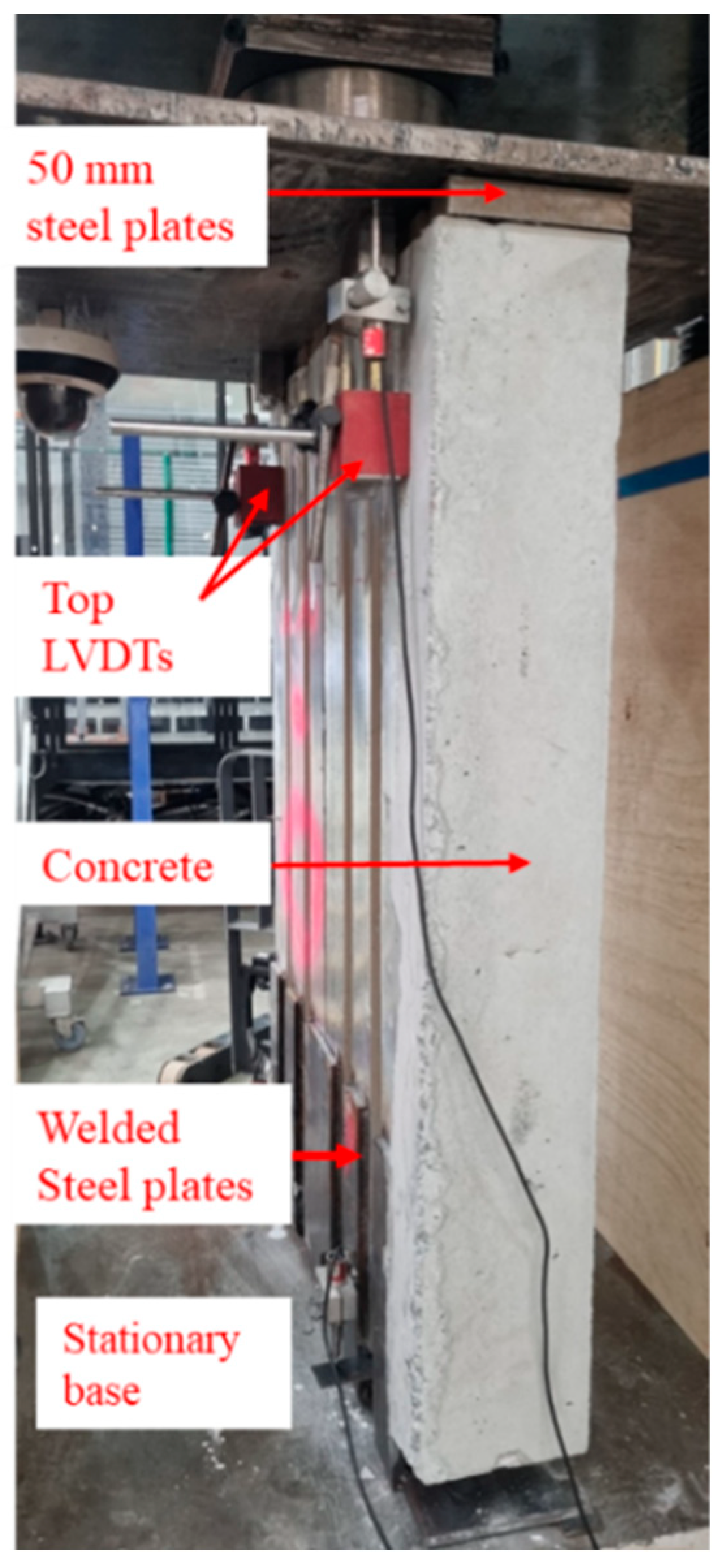

2.2.2. Shear Tests

3. Test Results and Discussion

3.1. Four-Point Bending Tests

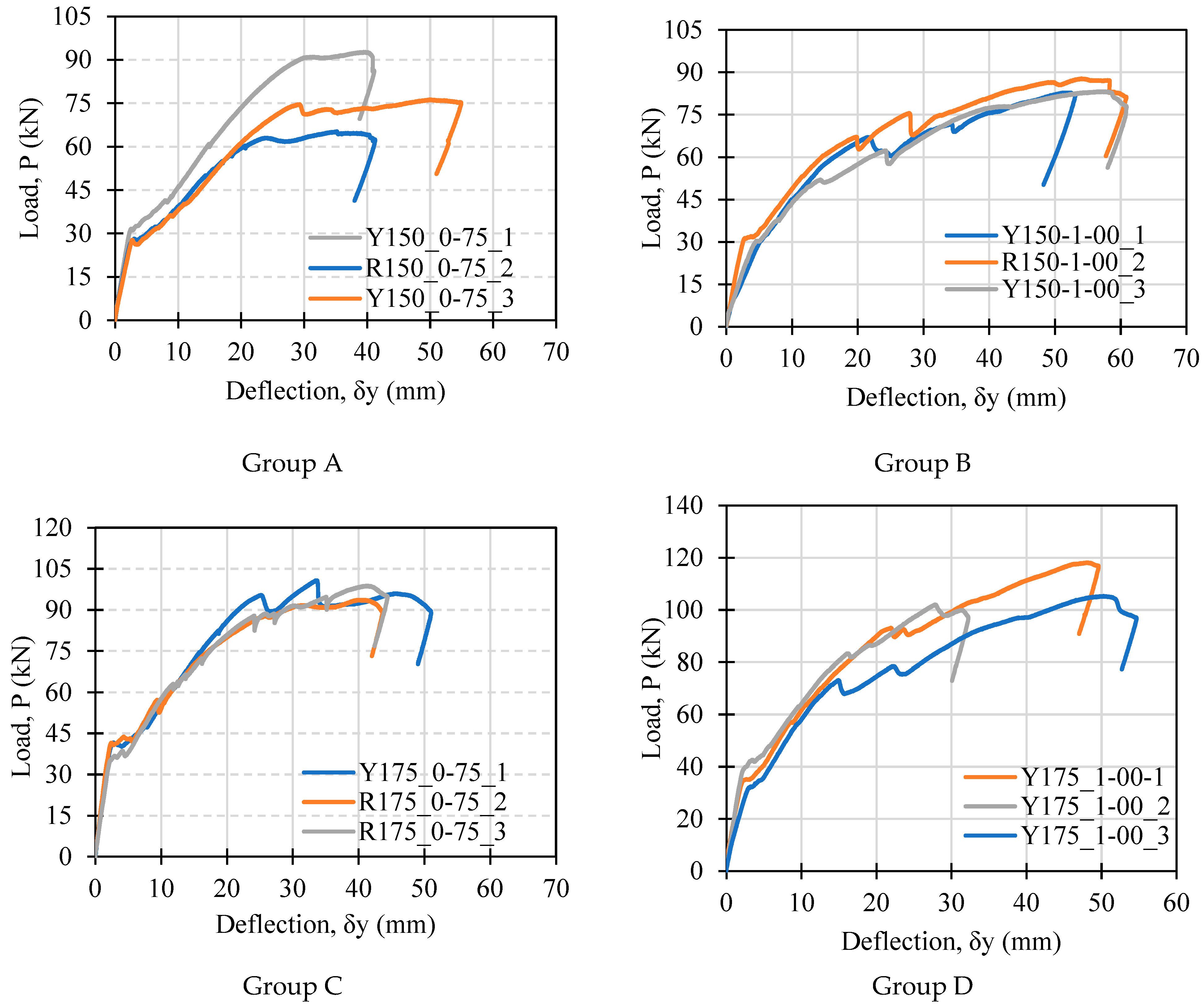

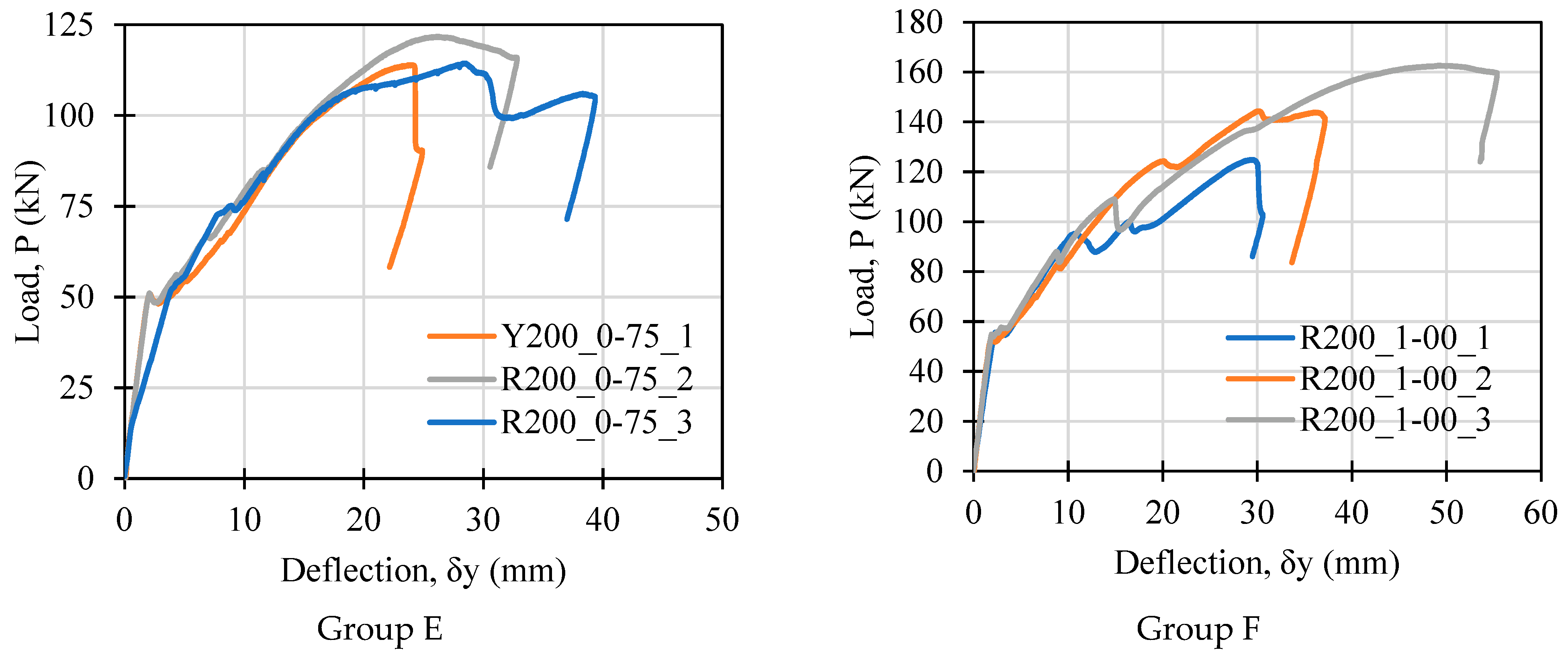

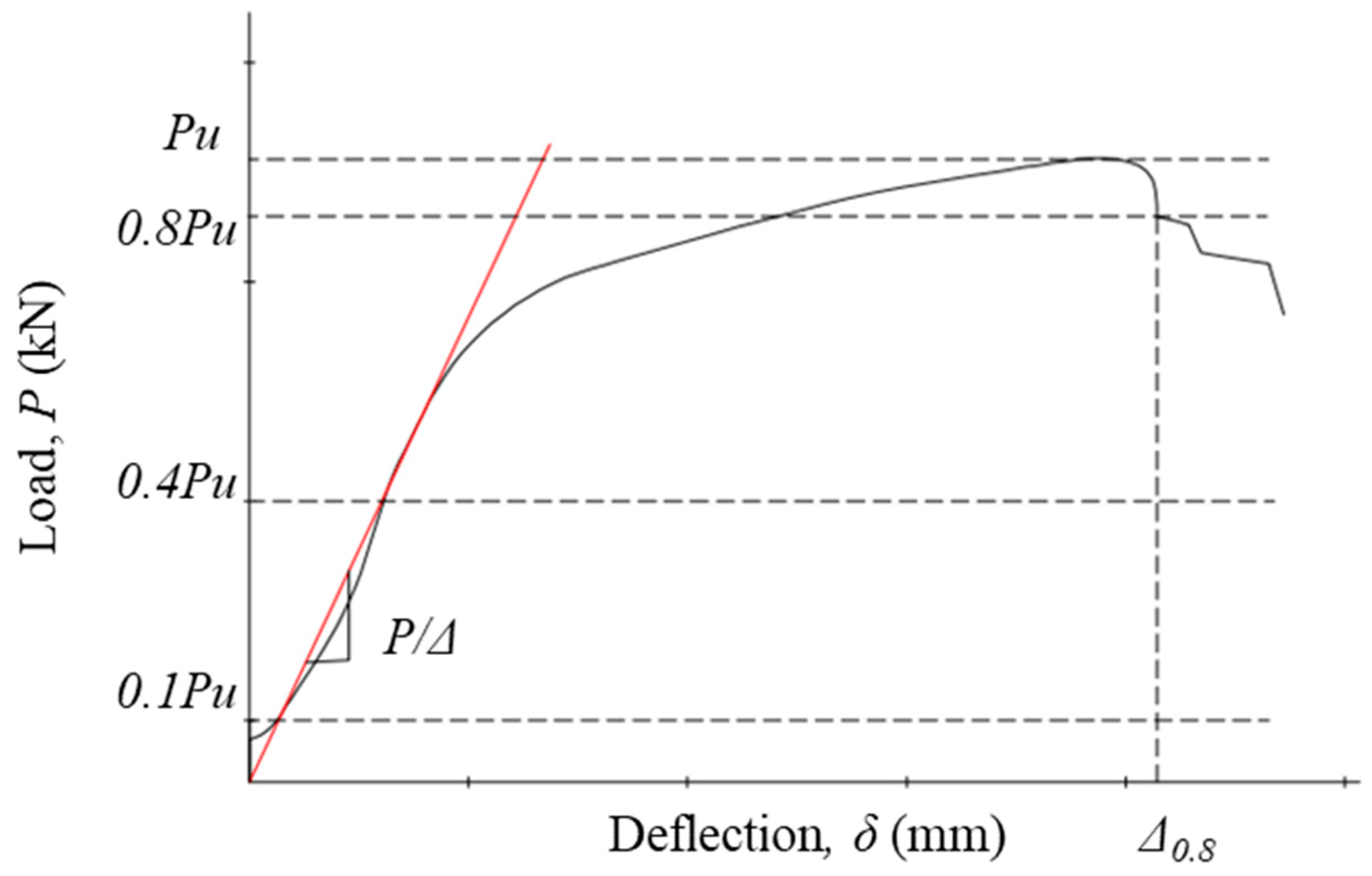

3.1.1. Load–Deflection Behaviour

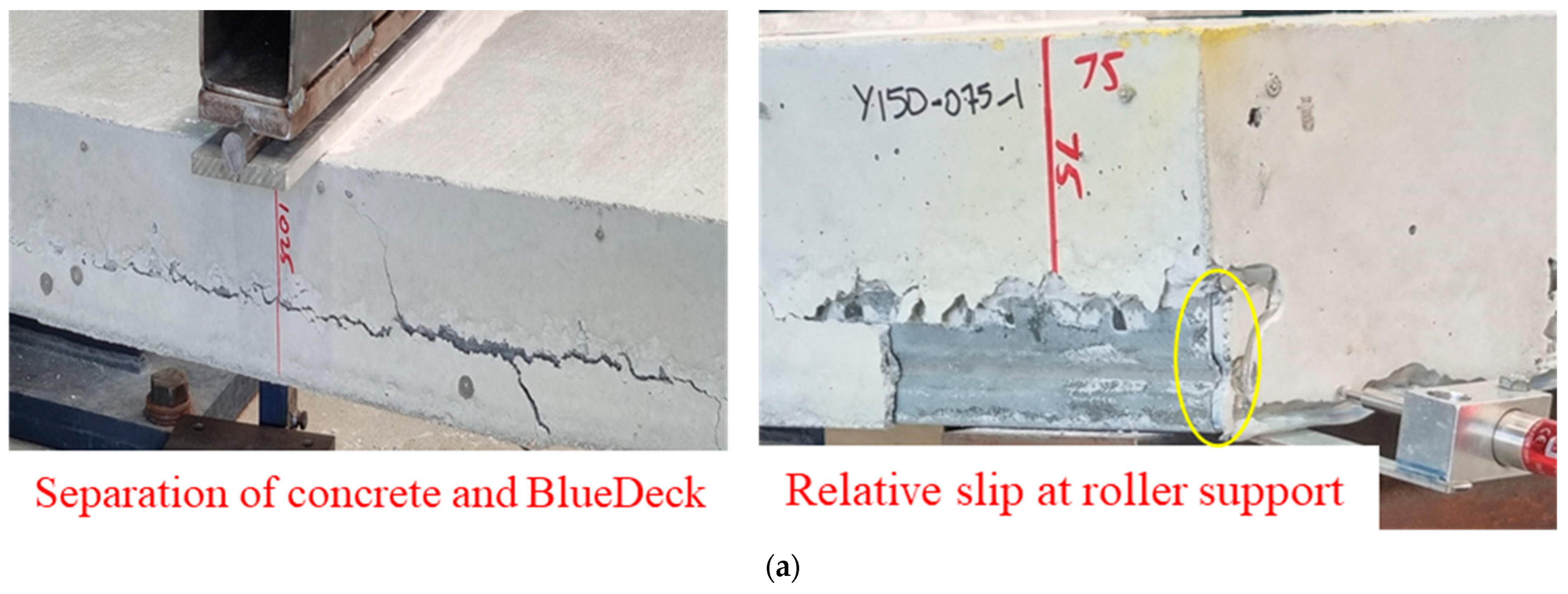

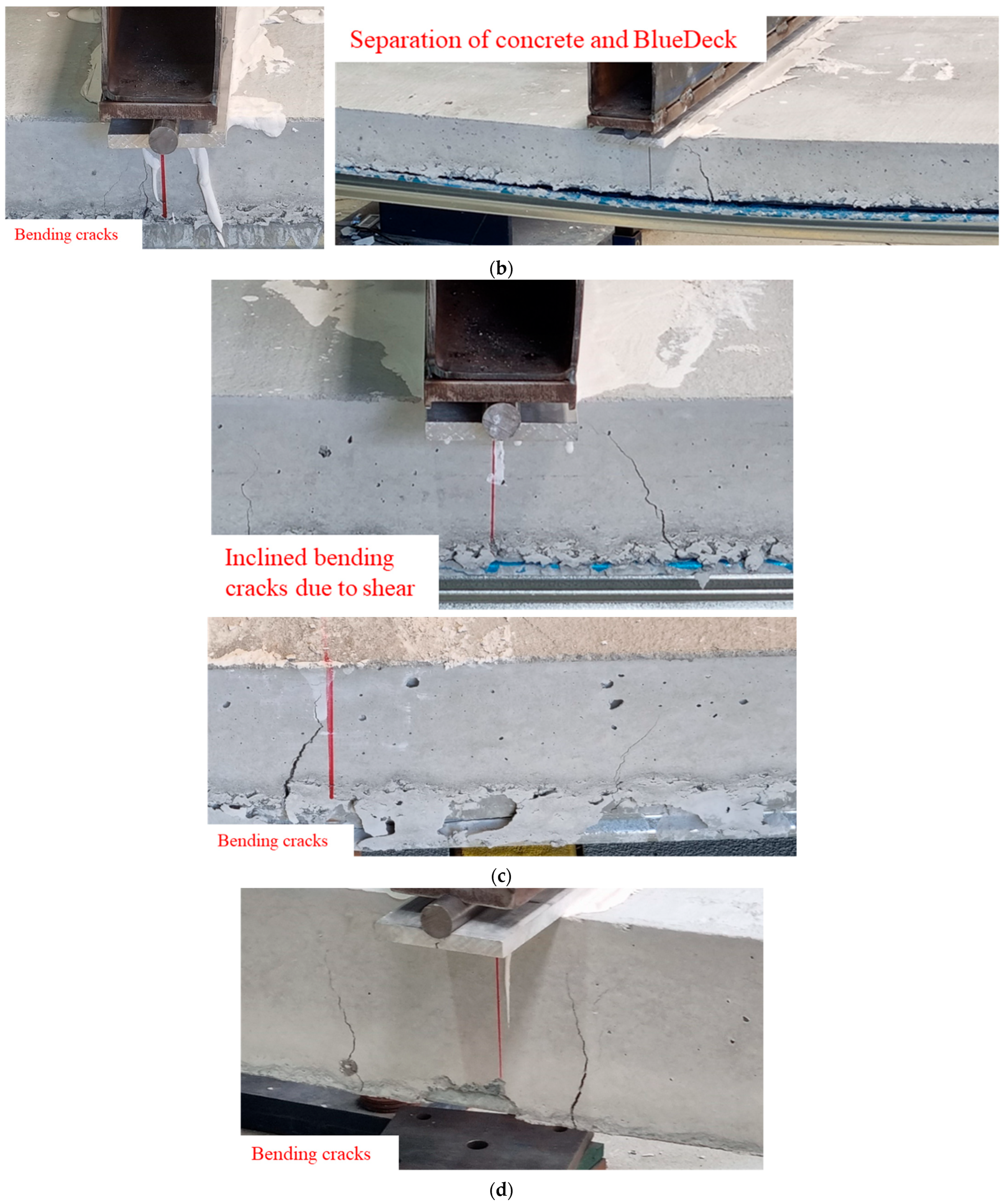

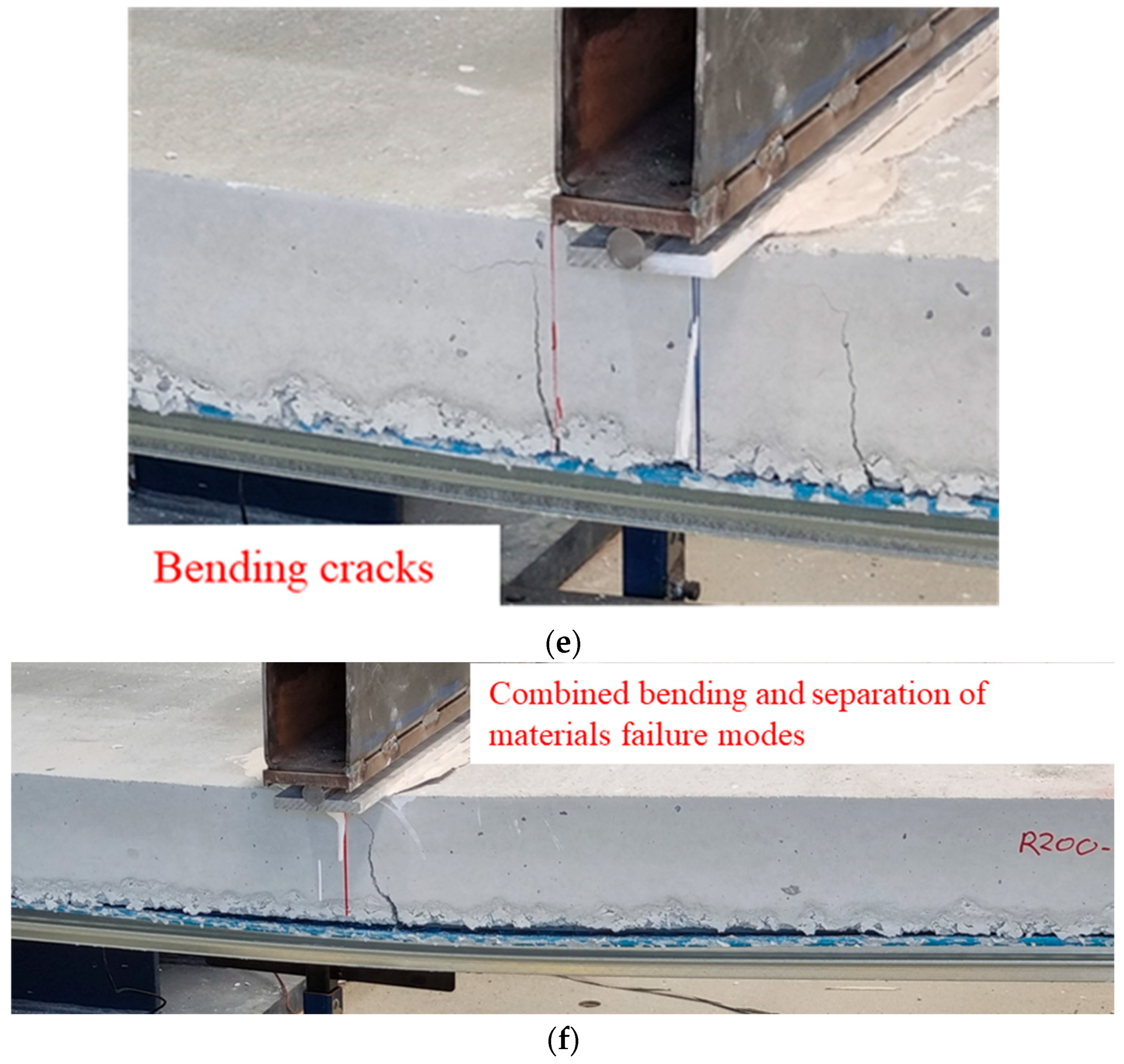

3.1.2. Failure Modes

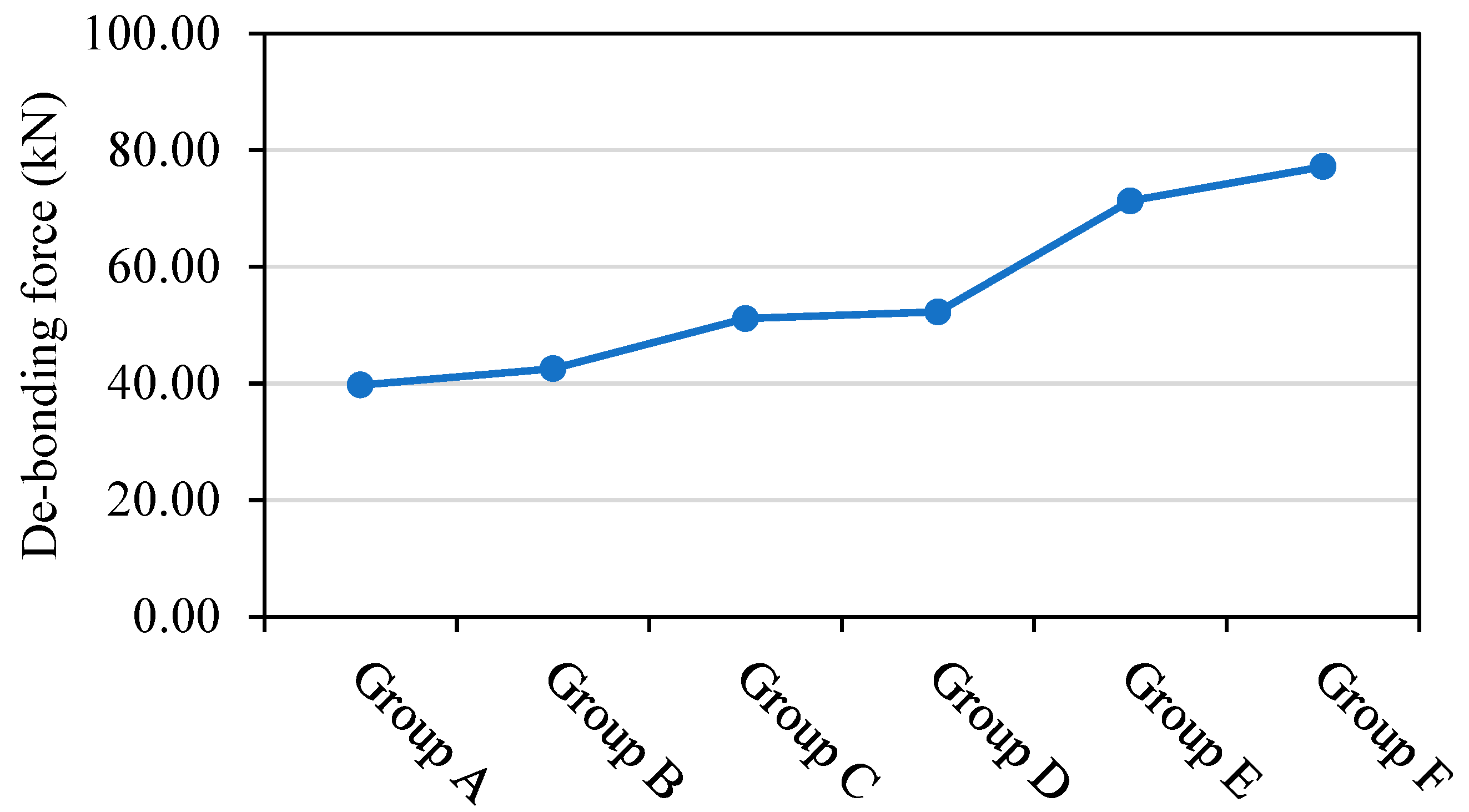

3.1.3. Relative Slip and De-Bonding Force

3.1.4. Flexural Stiffness

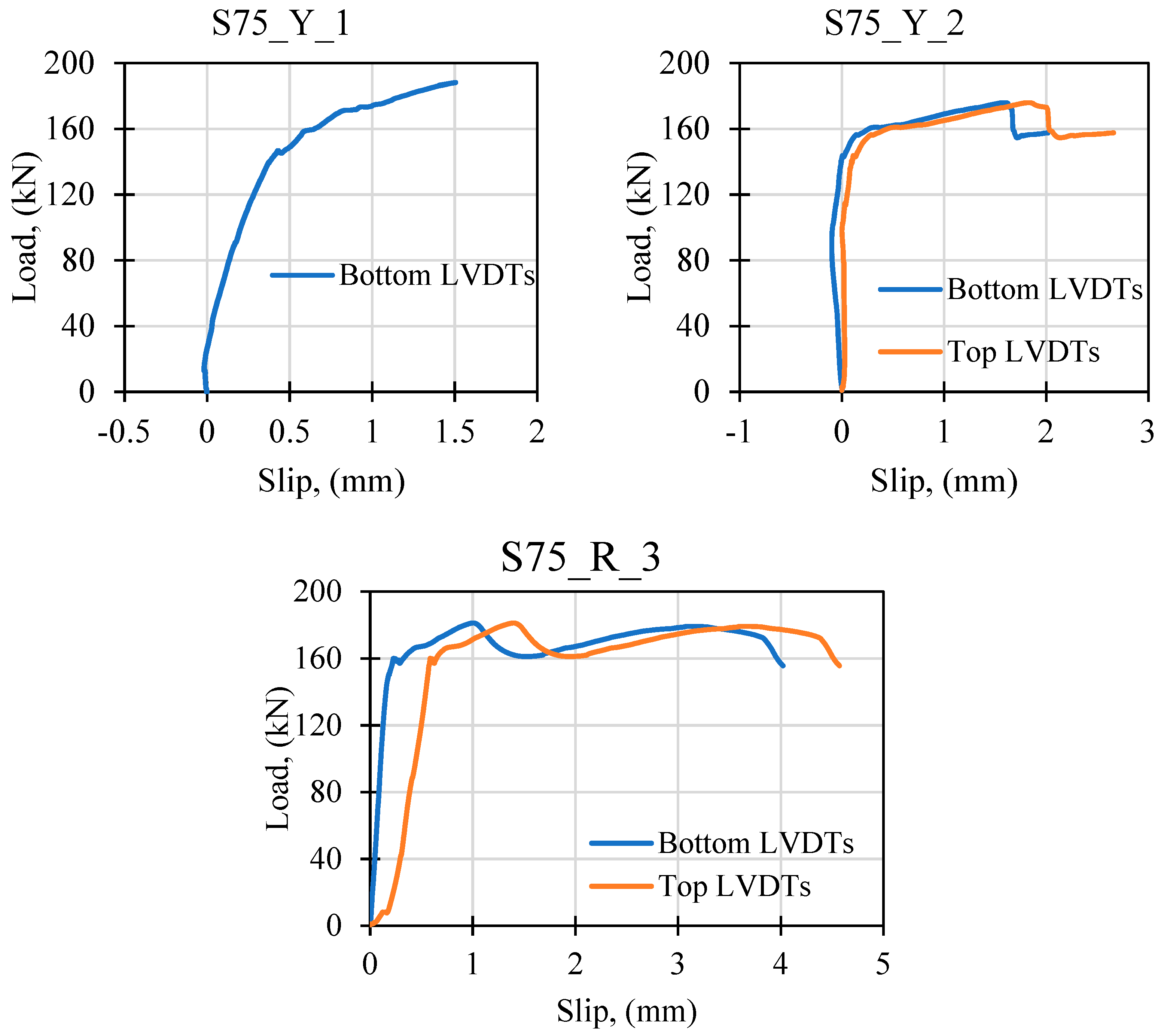

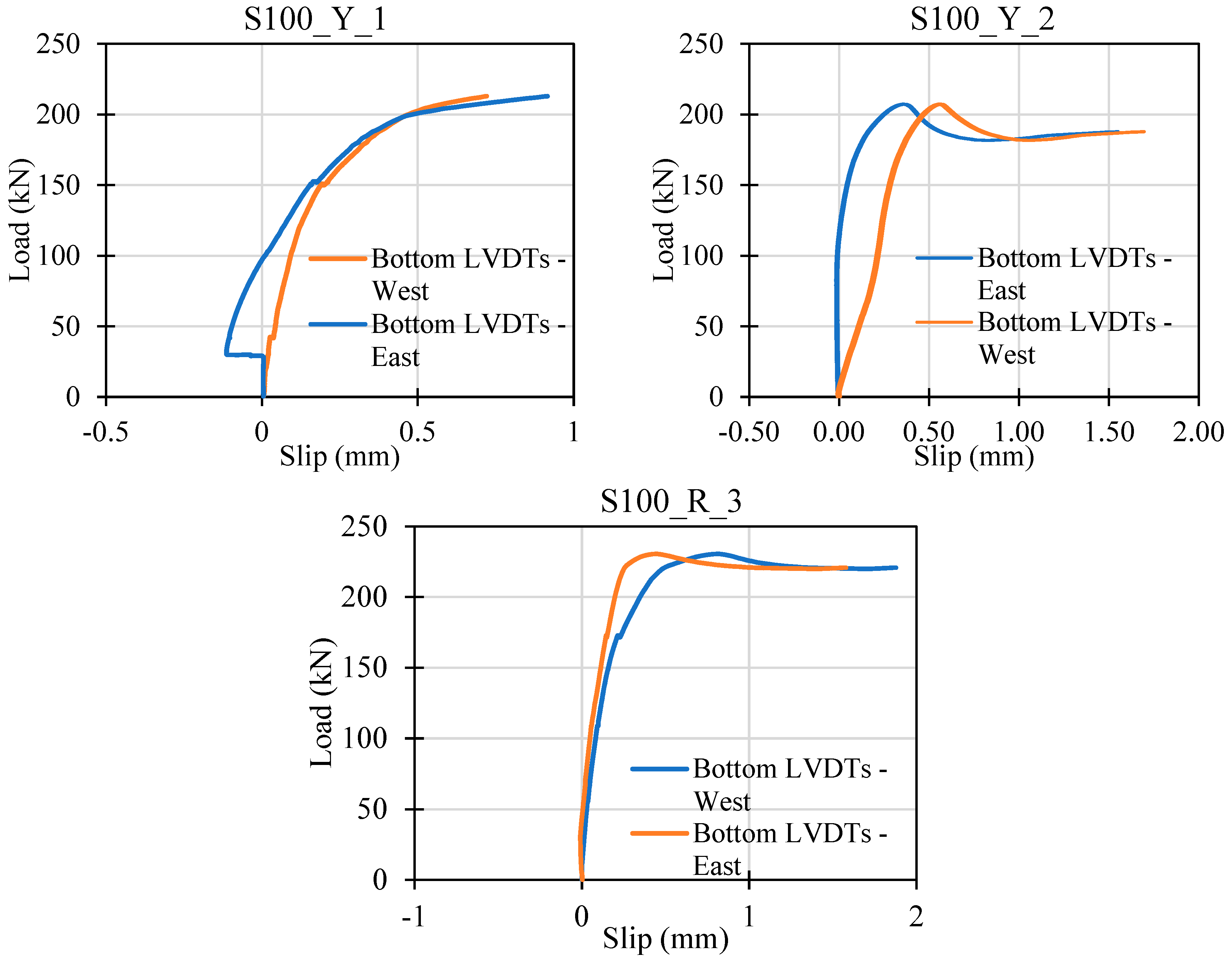

3.2. Shear Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, X.; Far, H.; Saleh, A. Structural Behaviour and Mechanical Properties of Welded Steel I-Girders with Corrugated Webs. Int. J. Steel Struct. 2019, 19, 1342–1352. [Google Scholar] [CrossRef]

- Chourasia, A.; Singhal, S.; Manivannan. Prefabricated volumetric modular construction: A review on current systems, chal-lenges, and future prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar] [CrossRef]

- Haydar, H.; Far, H.; Saleh, A. Portal steel trusses vs. portal steel frames for long-span industrial buildings. Steel Constr. 2018, 11, 205–217. [Google Scholar] [CrossRef]

- Far, H. Flexural Behavior of Cold-Formed Steel-Timber Composite Flooring Systems. J. Struct. Eng. 2020, 146, 06020003. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Khan, K.; Chen, Z.; Liu, J.; Javed, K. State-of-the-art on technological developments and adaptability of prefabricated industrial steel buildings. Appl. Sci. 2023, 13, 685. [Google Scholar] [CrossRef]

- Srisangeerthanan, S.; Hashemi, M.J.; Rajeev, P.; Gad, E.; Fernando, S. Review of performance requirements for inter-module connections in multi-story modular buildings. J. Build. Eng. 2020, 28, 101087. [Google Scholar] [CrossRef]

- Srisangeerthanan, S.; Hashemi, M.J.; Rajeev, P.; Gad, E.; Fernando, S. Development of an innovative boltless connection for multistory modular buildings. J. Struct. Eng. 2022, 148, 04022085. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- AL Hunaity, S.A.; Far, H.; Saleh, A. Vibration behaviour of cold-formed steel and particleboard composite flooring systems. Steel Compos. Struct. 2022, 43, 403–417. [Google Scholar]

- Karki, D.; Al-Hunaity, S.; Far, H.; Saleh, A. Composite connections between CFS beams and plywood panels for flooring systems: Testing and analysis. Structures 2022, 40, 771–785. [Google Scholar] [CrossRef]

- Loss, C.; Frangi, A. Experimental investigation on in-plane stiffness and strength of innovative steel-timber hybrid floor diaphragms. Eng. Struct. 2017, 138, 229–244. [Google Scholar] [CrossRef]

- Pan, W.; Yang, Y.; Yang, L. High-rise modular building: Ten-year journey and future development. Constr. Res. Congr. 2018, 2018, 523–532. [Google Scholar]

- Lawson, R.; Ogden, R.; Pedreschi, R.; Grubb, P.; Ola, S.P. Developments in pre-fabricated systems in light steel and modular construction. Transport 2005, 35, 15. [Google Scholar]

- Fang, J.; Bao, W.; Ren, F.; Pang, L.; Jiang, J. Behaviour of composite beams with beam-to-girder end-plate connection under hogging moments. Eng. Struct. 2021, 235, 112030. [Google Scholar] [CrossRef]

- Guan, Y.; Wang, J.; Shi, Y.; Zhao, S.; Zhou, T.; Yao, X. Study on in-plane and out-of-plane bearing capacity of cold-formed steel composite floor with opening. J. Build. Eng. 2023, 70, 106246. [Google Scholar] [CrossRef]

- De Seixas, L.; Alberto, A.L.; De Miranda Batista, E. Experimental investigation of composite floor system with thin-walled steel trussed beams and partially prefabricated concrete slab. J. Constr. Steel Res. 2020, 172, 106172. [Google Scholar] [CrossRef]

- Dar, M.A.; Subramanian, N.; Dar, A.R.; Ghowsi, A.F.; Sidiqui, F.; Fayaz, S.; Mir, M.S. Comparison of various shear connectors for improved structural performance in CFS concrete composite slabs. Eng. Struct. 2020, 220, 111008. [Google Scholar] [CrossRef]

- Hassan, M.K.; Subramanian, K.B.; Saha, S.; Sheikh, M.N. Behaviour of prefabricated steel-concrete composite slabs with a novel interlocking system—Numerical analysis. Eng. Struct. 2021, 245, 112905. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Y.; Shi, L.; Hou, L.; Zhang, G. Current state of using prefabricated construction in Australia. Buildings 2022, 12, 1355. [Google Scholar] [CrossRef]

- AS/NZS 2327; Composite Structures—Composite Steel-Concrete Construction in Buildings. SAI Global: Sydney, Australia, 2017.

- AS 1397; Continuous Hot-Dip Metallic Coated Steel Sheet and Strip—Coatings of Zinc and Zinc Alloyed with Aluminium and Magnesium. SAI Global: Sydney, Australia, 2011.

- AS 3600; Concrete Structures. SAI Global: Sydney, Australia, 2018.

- AS/NZS 1170.1; Structural Design Actions Permanent, Imposed and Other Actions. SAI Global: Sydney, Australia, 2002.

- ASTM D198-15; Standard Test Methods of Static Tests of Lumber in Structural Sizes. ASTM International: West Conshohocken, PA, USA, 2015.

- BS EN 26891; Timber Structures—Joints Made with Mechanical Fasteners—General Principles for the Determination of Strength and Deformation Characteristics. British Standards Institution (BSI): London, UK, 1991.

- BS EN 12512; Timber Structures—Test Methods—Cyclic Testing of Joints Made with Mechanical Fasteners. British Standards Institution (BSI): London, UK, 2001.

| Thickness (mm) | Mass (kg/m) | Yield Strength (MPa) | Cross-Sectional Area (mm2) | Moment of Inertia (mm4) | Section Modulus (mm3) | Elastic Centroid (mm) |

|---|---|---|---|---|---|---|

| 0.75 | 9.06 | 550 | 1153.86 | 408,220 | 31,353 | 13.02 |

| 1.00 | 11.87 | 550 | 1511.93 | 535,085 | 39,057 | 13.70 |

| Batch No. | Code | Compressive Strength, f′c (MPa) | Density (kN/m3) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|

| 1 | R | 36.80 | 2400 | 30,670 |

| 2 | Y | 39.00 | 2400 | 31,573 |

| Specimen ID | BlueDeck Thickness (mm) | Concrete Depth (mm) | Concrete Compressive Strength (MPa) |

|---|---|---|---|

| Group A samples | |||

| Y150_0-75_1 | 0.75 | 150.00 | 39.00 |

| R150_0-75_2 | 0.75 | 150.00 | 36.80 |

| Y150_0-75_3 | 0.75 | 150.00 | 39.00 |

| Group B samples | |||

| Y150_1-00_1 | 1.00 | 175.00 | 39.00 |

| R150_1-00_2 | 1.00 | 150.00 | 36.80 |

| Y150_1-00_3 | 1.00 | 175.00 | 39.00 |

| Group C samples | |||

| Y175_0-75_1 | 0.75 | 175.00 | 39.00 |

| R175_0-75_2 | 0.75 | 175.00 | 36.80 |

| R175_0-75_3 | 0.75 | 175.00 | 36.80 |

| Group D samples | |||

| Y175_1-00_1 | 1.00 | 175.00 | 39.00 |

| Y175_1-00_2 | 1.00 | 175.00 | 39.00 |

| Y175_1-00_3 | 1.00 | 175.00 | 39.00 |

| Group E samples | |||

| Y200_0-75_1 | 0.75 | 200.00 | 39.00 |

| R200_0-75_2 | 0.75 | 200.00 | 36.80 |

| R200_0-75_3 | 0.75 | 200.00 | 36.80 |

| Group F samples | |||

| R200_1-00_1 | 1.00 | 200.00 | 36.80 |

| R200_1-00_2 | 1.00 | 200.00 | 36.80 |

| R200_1-00_3 | 1.00 | 200.00 | 36.80 |

| Specimen ID | BlueDeck Thickness (mm) | Concrete Depth (mm) | Concrete Compressive Strength (MPa) |

|---|---|---|---|

| Set A | |||

| S75_R_1 | 0.75 | 150.00 | 36.80 |

| S75_Y_2 | 0.75 | 150.00 | 39.00 |

| S75_Y_3 | 0.75 | 150.00 | 39.00 |

| Set B | |||

| S100_R_1 | 1.00 | 150.00 | 36.80 |

| S100_Y_2 | 1.00 | 150.00 | 39.00 |

| S100_Y_3 | 1.00 | 150.00 | 39.00 |

| Specimen ID | Peak Load (kN) | Load at Initial De-Bonding (kN) | Max. Deflection (mm) | Max. Slip–Pin Support (mm) | Max. Slip–Roller Support (mm) |

|---|---|---|---|---|---|

| Group A | |||||

| Y150_0-75_1 | 92.71 | 44.78 | 40.86 | 0.87 | 4.05 |

| R150_0-75_2 | 65.25 | 38.35 | 41.06 | 0.87 | 4.05 |

| Y150_0-75_3 | 76.27 | 36.04 | 56.16 | 1.64 | 4.67 |

| Average | 78.08 | 39.72 | 46.02 | 1.13 | 4.26 |

| Standard dev | 11.28 | 3.70 | 7.17 | 0.37 | 0.29 |

| Group B | |||||

| Y150_1-00_1 | 82.82 | 45.00 | 52.88 | 1.69 | 5.80 |

| R150_1-00_2 | 87.80 | 45.00 | 60.85 | -2.07 | 7.60 |

| Y150_1-00_3 | 83.22 | 37.59 | 61.17 | 2.50 | 1.40 |

| Average | 84.61 | 42.53 | 58.30 | 0.71 | 4.93 |

| Standard dev | 2.26 | 3.49 | 3.83 | 1.99 | 2.60 |

| Group C | |||||

| Y175_0-75_1 | 100.78 | 54.60 | 51.85 | 3.21 | 5.71 |

| R175_0-75_2 | 93.67 | 45.00 | 43.58 | 6.14 | 3.79 |

| R175_0-75_3 | 98.78 | 53.73 | 44.13 | 3.15 | 4.36 |

| Average | 97.75 | 51.11 | 46.52 | 4.17 | 4.62 |

| Standard dev | 3.00 | 4.33 | 3.78 | 1.40 | 0.81 |

| Group D | |||||

| Y175_1-00_1 | 118.15 | 58.03 | 48.65 | 1.48 | 6.39 |

| Y175_1-00_2 | 102.04 | 44.38 | 32.70 | 1.66 | 3.97 |

| Y175_1-00_3 | 105.34 | 54.40 | 55.04 | 1.92 | 9.19 |

| Average | 108.51 | 52.27 | 45.47 | 1.69 | 6.52 |

| Standard dev | 6.95 | 5.77 | 9.39 | 0.18 | 2.13 |

| Group E | |||||

| Y200_0-75_1 | 114.02 | 65.26 | 24.43 | 0.33 | 2.28 |

| R200_0-75_2 | 121.81 | 74.73 | 32.71 | 4.26 | 0.96 |

| R200_0-75_3 | 114.46 | 73.92 | 39.20 | 0.54 | 7.38 |

| Average | 116.76 | 71.30 | 32.12 | 1.71 | 3.54 |

| Standard dev | 3.57 | 4.29 | 6.04 | 1.81 | 2.77 |

| Group F | |||||

| R200_1-00_1 | 124.89 | 88.31 | 29.93 | 1.84 | 3.81 |

| R200_1-00_2 | 144.38 | 69.83 | 37.95 | 2.73 | 4.12 |

| R200_1-00_3 | 162.67 | 73.49 | 55.57 | 3.90 | 9.53 |

| Average | 143.98 | 77.21 | 41.15 | 2.82 | 3.94 |

| Standard dev | 15.42 | 7.99 | 10.71 | 0.84 | 2.62 |

| Specimen ID | Ultimate Shear Strength (kN) | Ultimate Slip (mm) |

|---|---|---|

| Set A | ||

| S75_Y_1 | 188.23 | 1.50 |

| S75_Y_2 | 175.97 | 3.08 |

| S75_R_3 | 181.25 | 4.03 |

| Average | 181.82 | 2.87 |

| Set B | ||

| S100_Y_1 | 213.01 | 0.92 |

| S100_Y_2 | 207.31 | 2.80 |

| S100_R_3 | 216.95 | 1.16 |

| Average | 212.42 | 1.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Far, H.; Nejadi, S.; Al-Hunaity, S.A. Structural Behaviour and Mechanical Characteristics of BlueDeck Profiled Steel Sheeting for Use in Composite Flooring Systems. Buildings 2024, 14, 3204. https://doi.org/10.3390/buildings14103204

Far H, Nejadi S, Al-Hunaity SA. Structural Behaviour and Mechanical Characteristics of BlueDeck Profiled Steel Sheeting for Use in Composite Flooring Systems. Buildings. 2024; 14(10):3204. https://doi.org/10.3390/buildings14103204

Chicago/Turabian StyleFar, Harry, Shami Nejadi, and Suleiman A. Al-Hunaity. 2024. "Structural Behaviour and Mechanical Characteristics of BlueDeck Profiled Steel Sheeting for Use in Composite Flooring Systems" Buildings 14, no. 10: 3204. https://doi.org/10.3390/buildings14103204

APA StyleFar, H., Nejadi, S., & Al-Hunaity, S. A. (2024). Structural Behaviour and Mechanical Characteristics of BlueDeck Profiled Steel Sheeting for Use in Composite Flooring Systems. Buildings, 14(10), 3204. https://doi.org/10.3390/buildings14103204