The Effect of Length of Service in a Thermal Environment on Thermal Comfort and Mental Stress

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants

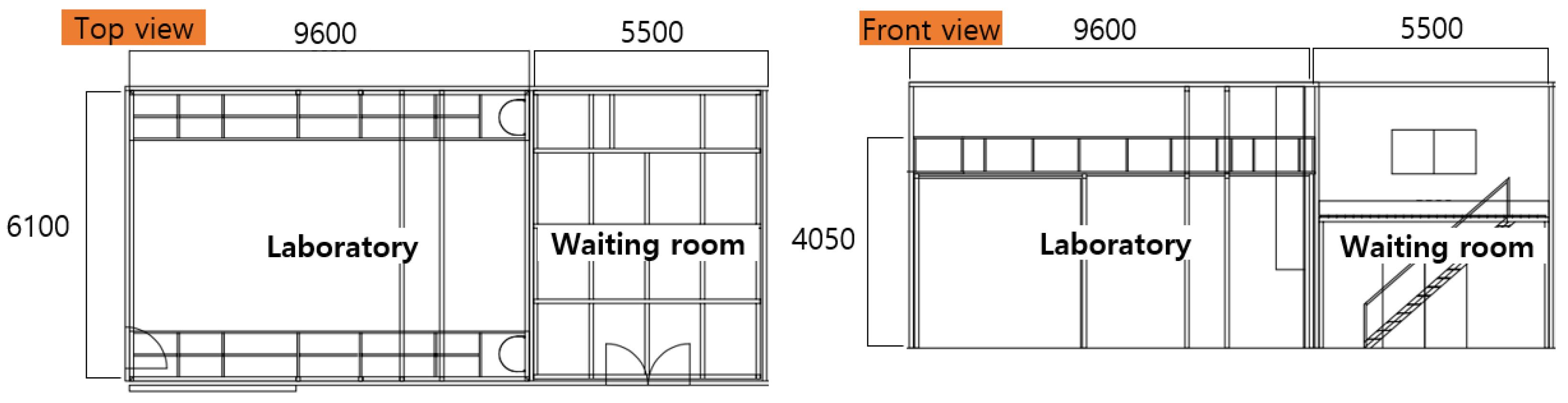

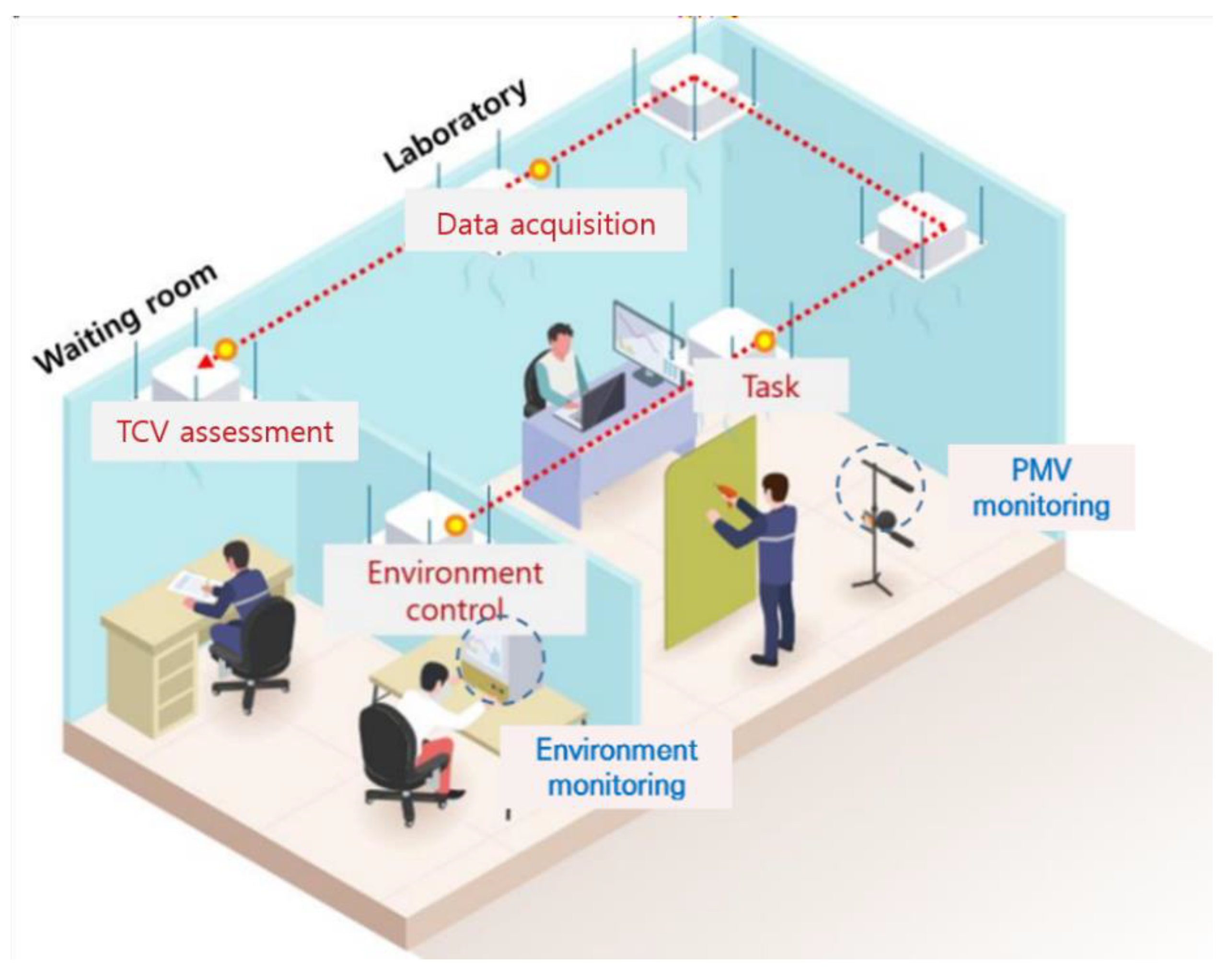

2.2. Experimental Environment

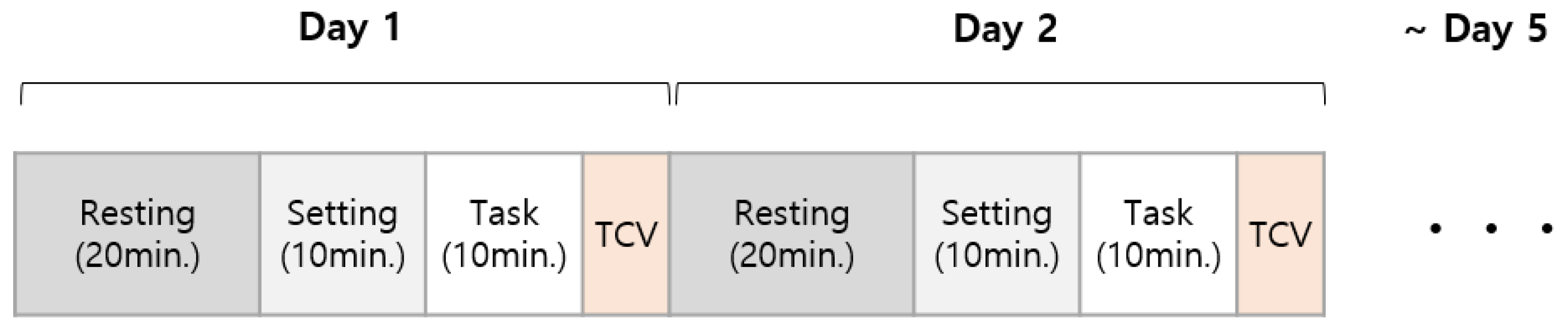

2.3. Experimental Procedure

2.4. Measurement

2.5. Data Analysis

2.6. Statistics

3. Results

3.1. LF/HF Ratio Analysis Results

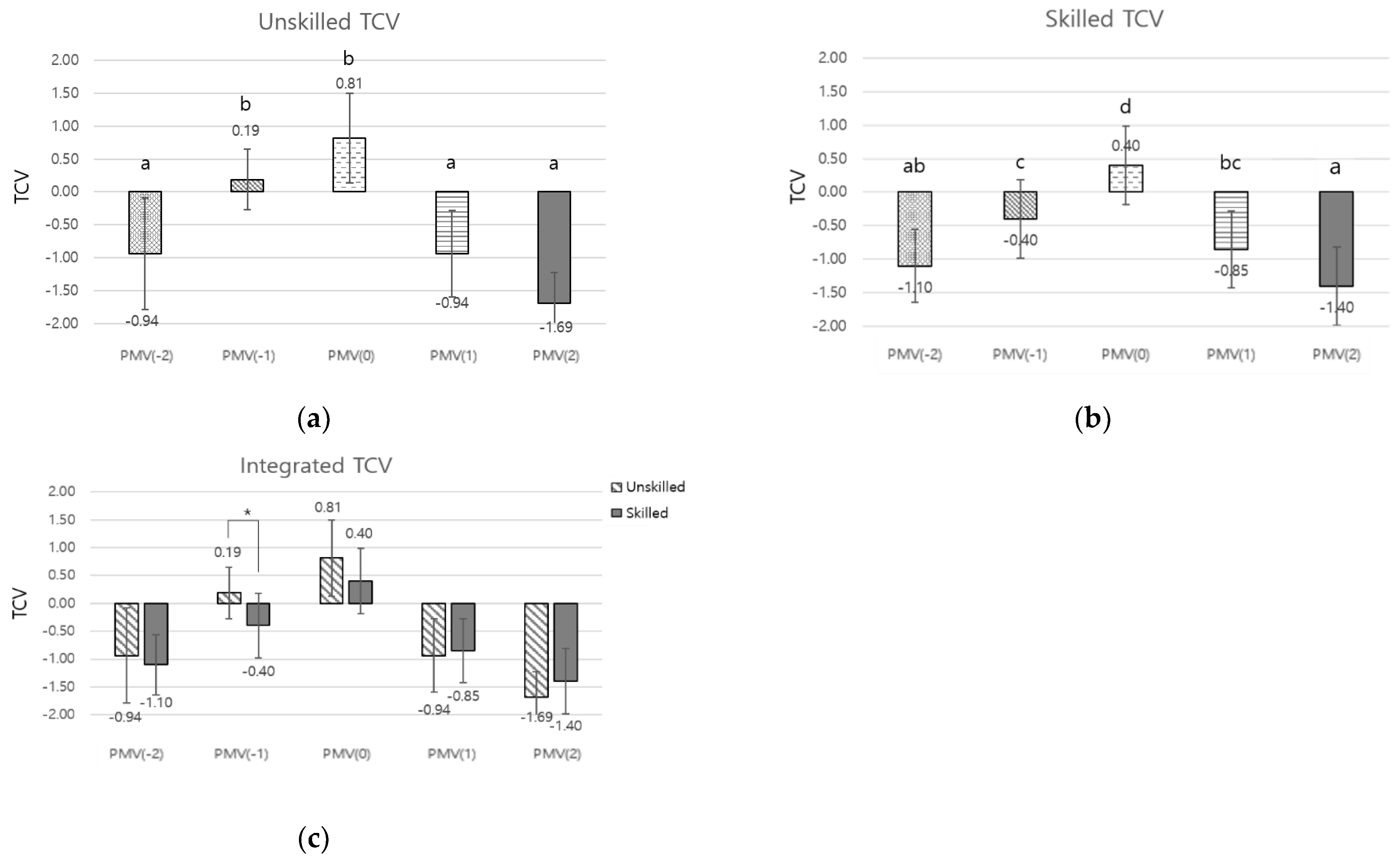

3.2. TCV Analysis Results

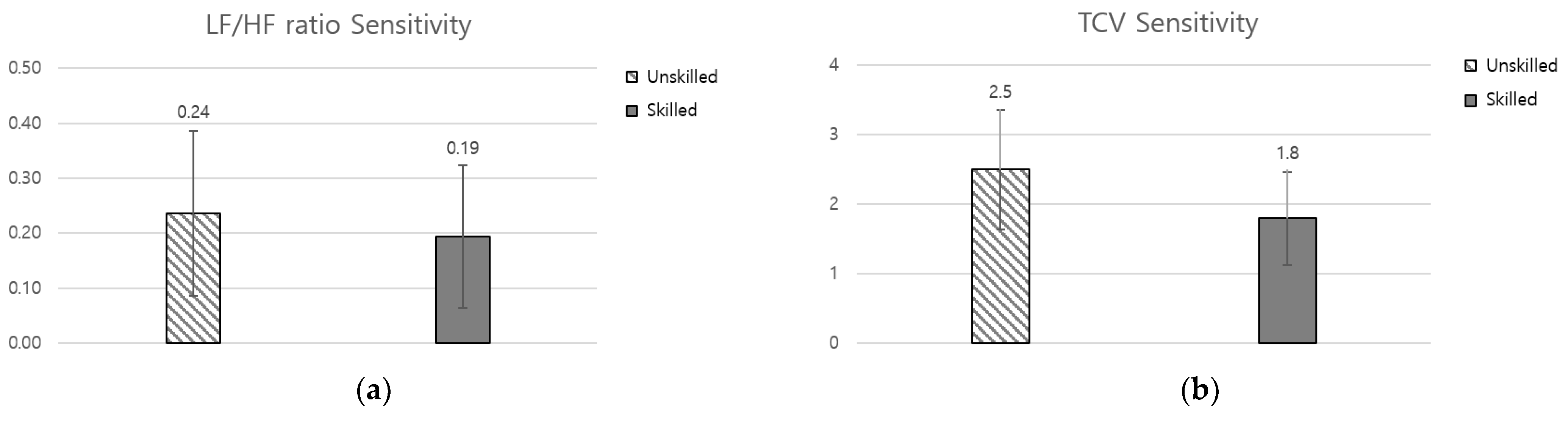

3.3. Thermal Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Labor Organization. Sectoral Activities Department (SECTOR), Geneva. 2012. Available online: https://www.ilo.org/sector/lang--en/index.htm (accessed on 13 November 2022).

- Korea Occupational Safety and Health Agency. Physical Activity Risk Factor Exposure; KOSHA: Seoul, Republic of Korea, 2022. [Google Scholar]

- Veitch, J.A.; Charles, K.E.; Farley, K.M.; Newsham, G.R. A model of satisfaction with open-plan office conditions: COPE field findings. J. Environ. Psychol. 2007, 27, 177–189. [Google Scholar] [CrossRef]

- Cheung, S.S.; Lee, J.K.; Oksa, J. Thermal stress, human performance, and physical employment standards. Appl. Physiol. Nutr. Metab. 2016, 41, S148–S164. [Google Scholar] [CrossRef] [PubMed]

- Hancock, T. Creating environments for health—20 years on. Promot. Educ. 2007, 7–8, 27. [Google Scholar] [CrossRef]

- Pilcher, J.J.; Nadler, E.; Busch, C. Effects of hot and cold temperature exposure on performance: A meta-analytic review. Ergonomics 2002, 45, 682–698. [Google Scholar] [CrossRef] [PubMed]

- Najafi, N.; Movahed, K.; Barzegar, Z.; Samani, S. The effect of thermal comfort on stress in female high school students. Int. J. Sch. Health 2018, 5, 1–6. [Google Scholar]

- Yan, T.; Jin, H.; Jin, Y. The mediating role of emotion in the effects of landscape elements on thermal comfort: A laboratory study. Build Environ. 2023, 233, 110130. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, Y.; Mao, Y.; Yang, Y.; Fu, C.; Fang, Z. Analysis of SET* and PMV to evaluate thermal comfort in prefab construction site offices: Case study in South China. Case Stud. Therm. Eng. 2021, 26, 101137. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, H.T.; Kim, H.S.; Kuwak, W.T.; Kim, J.H. A study on the effects of PMV thermal environment and illumination on visual performance. Sci. Emot. Sensib. 2014, 17, 55–62. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Ter Mors, S.; Hensen, J.L.; Loomans, M.G.; Boerstra, A.C. Adaptive thermal comfort in primary school classrooms: Creating and validating PMV-based comfort charts. Build Environ. 2011, 46, 2454–2461. [Google Scholar] [CrossRef]

- Wu, Y.C.; Mahdavi, A. Assessment of thermal comfort under transitional conditions. Build Environ. 2014, 76, 30–36. [Google Scholar] [CrossRef]

- Liu, H.; Lian, Z.; Gong, Z.; Wang, Y.; Yu, G. Thermal comfort, vibration, and noise in Chinese ship cabin environment in winter time. Build Environ. 2018, 135, 104–111. [Google Scholar] [CrossRef]

- Van Craenendonck, S.; Lauriks, L.; Vuye, C.; Kampen, J. A review of human thermal comfort experiments in controlled and semi-controlled environments. Renew. Sust. Energ. Rev. 2018, 82, 3365–3378. [Google Scholar] [CrossRef]

- ASHRAE. ANSI/ASHRAE Addenda o, p, and q to ANSI/ASHRAE Standard 55-2010; ASHRAE: Atlanta, GA, USA, 2013; p. 7. [Google Scholar]

- ISO 7730:2005(E); Moderate Thermal Environments-Determination of the PMV and PPD Indices and Specification of the Conditions for Thermal Comfort. International Organization for Standardization: Geneva, Switzerland, 2005.

- Liu, C.; Zhou, G.; Li, H. Analysis of thermal environment in a hospital operating room. Procedia Eng. 2015, 121, 735–742. [Google Scholar] [CrossRef]

- Vilcekova, S.; Meciarova, L.; Burdova, E.K.; Katunska, J.; Kosicanova, D.; Doroudiani, S. Indoor environmental quality of classrooms and occupants’ comfort in a special education school in Slovak Republic. Build Environ. 2017, 120, 29–40. [Google Scholar] [CrossRef]

- Zhang, S.; He, W.; Chen, D.; Chu, J.; Fan, H.; Duan, X. Thermal comfort analysis based on PMV/PPD in cabins of manned submersibles. Build Environ. 2019, 148, 668–676. [Google Scholar] [CrossRef]

- Rehman, S.U.; Javed, A.R.; Khan, M.U.; Nazar Awan, M.; Farukh, A.; Hussien, A. Personalised comfort: A personalised thermal comfort model to predict thermal sensation votes for smart building residents. Enterp. Inf. Syst. 2022, 16, 1852316. [Google Scholar]

- Karjalainen, S. Gender differences in thermal comfort and use of thermostats in everyday thermal environments. Build Environ. 2007, 42, 1594–1603. [Google Scholar] [CrossRef]

- Modera, M. Skin temperature and evaporative heat loss variations for men and women in thermal comfort. ASHRAE Transact 1993, 99, 210–222. [Google Scholar]

- Young, A.J.; Lee, D.T. Aging and human cold tolerance. Exp. Aging Res. 1997, 23, 45–67. [Google Scholar] [CrossRef]

- Kurazumi, Y.; Ishii, J.; Fukagawa, K.; Kondo, E.; Aruninta, A. Ethnic differences in thermal responses between Thai and Japanese females in tropical urban climate. Am. J. Clim. Change 2016, 5, 52–68. [Google Scholar] [CrossRef]

- Nicol, J.F.; Humphreys, M. Understanding the adaptive approach to thermal comfort. ASHRAE Transact. 1998, 104, 991–1004. [Google Scholar]

- Meier, M.W.; Fischer, W.K.; Perruchoud, R.; Gauckler, L.J. Thermal shock of anodes-a solved problem? In Light Metals; Tomsett, A., Johnson, J., Eds.; Springer International Publishing: Cham, Switzerland, 1994; pp. 685–694. [Google Scholar]

- Kim, S.W.; Sohn, A.R.; Lee, J.S. The effects of job stress on musculoskeletal diseases among shipyard workers. Phys. Ther. Korea 2005, 12, 1–10. [Google Scholar]

- Korea Occupational Safety and Health Agency. Overall Disaster Status and Analysis—By Entry Period (Medium Classification by Industry); KOSHA: Seoul, Republic of Korea, 2023. [Google Scholar]

- EN ISO 8996:2021; Ergonomics of the Thermal Environment-Determination of Metabolic Rate. International Organization for Standardization: Geneva, Switzerland, 2021.

- Von Rosenberg, W.; Chanwimalueang, T.; Adjei, T.; Jaffer, U.; Goverdovsky, V.; Mandic, D.P. Resolving ambiguities in the LF/HF ratio: LF-HF scatter plots for the categorization of mental and physical stress from HRV. Front. Physiol. 2017, 8, 360. [Google Scholar] [CrossRef] [PubMed]

- Hjortskov, N.; Rissén, D.; Blangsted, A.K.; Fallentin, N.; Lundberg, U.; Søgaard, K. The effect of mental stress on heart rate variability and blood pressure during computer work. Eur. J. Appl. Physiol. 2004, 92, 84–89. [Google Scholar] [CrossRef] [PubMed]

- Minakuchi, E.; Ohnishi, E.; Ohnishi, J.; Sakamoto, S.; Hori, M.; Motomura, M.; Hoshino, J.; Murakami, K.; Kawaguchi, T. Evaluation of mental stress by physiological indices derived from finger plethysmography. J. Physiol. Anthrop. 2013, 32, 17. [Google Scholar] [CrossRef] [PubMed]

- Sato, N.; Miyake, S. Cardiovascular reactivity to mental stress: Relationship with menstrual cycle and gender. J. Physiol. Anthropol. Appl. Hum. Sci. 2004, 23, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Subahni, A.R.; Xia, L.; Malik, A.S. Association of mental stress with video games. In Proceedings of the 2012 4th International Conference on Intelligent and Advanced Systems (ICIAS2012), Kuala Lumpur, Malaysia, 12–14 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 82–85. [Google Scholar]

- Tao, D.; Tan, H.; Wang, H.; Zhang, X.; Qu, X.; Zhang, T. A systematic review of physiological measures of mental workload. Int. J. Environ. Res. Public Health 2019, 16, 2716. [Google Scholar] [CrossRef]

- Tarvainen, M.P.; Niskanen, J.P.; Lipponen, J.A.; Ranta-Aho, P.O.; Karjalainen, P.A. Kubios HRV–heart rate variability analysis software. Comp. Methods Programs Biomed. 2014, 113, 210–220. [Google Scholar] [CrossRef]

- Kosonen, R.; Tan, F. Assessment of productivity loss in air-conditioned buildings using PMV index. Energy Build. 2004, 36, 987–993. [Google Scholar] [CrossRef]

| Sample | Age (Years) | Height (cm) | Weight (kg) | BMI (kg/m2) | LoS (Years) | |

|---|---|---|---|---|---|---|

| Unskilled | 16 | 33.4 (9.8) | 174.4 (4.7) | 73.3 (8.5) | 24.9 (2.6) | - |

| Skilled | 20 | 36.6 (7.6) | 172.9 (8.9) | 74.1 (9.9) | 24.8 (3.2) | 11.8 (4.8) |

| Variables | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 |

|---|---|---|---|---|---|

| PMV | −2 | −1 | 0 | 1 | 2 |

| Air temperature | 18 °C | 22.5 °C | 27.5 °C | 32 °C | 36.5 °C |

| Air velocity | 2.1 m/s | 0.2 m/s | |||

| Relative humidity | 50% (±5) | ||||

| Clothing insulation | 0.73 clo | ||||

| Metabolic rate | 1.7 met | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, Y.-S.; Ko, J.-B.; Cha, D.-A.; Hong, J.-S. The Effect of Length of Service in a Thermal Environment on Thermal Comfort and Mental Stress. Buildings 2024, 14, 99. https://doi.org/10.3390/buildings14010099

Shin Y-S, Ko J-B, Cha D-A, Hong J-S. The Effect of Length of Service in a Thermal Environment on Thermal Comfort and Mental Stress. Buildings. 2024; 14(1):99. https://doi.org/10.3390/buildings14010099

Chicago/Turabian StyleShin, Young-Sub, Jeong-Bae Ko, Dong-An Cha, and Jae-Soo Hong. 2024. "The Effect of Length of Service in a Thermal Environment on Thermal Comfort and Mental Stress" Buildings 14, no. 1: 99. https://doi.org/10.3390/buildings14010099

APA StyleShin, Y.-S., Ko, J.-B., Cha, D.-A., & Hong, J.-S. (2024). The Effect of Length of Service in a Thermal Environment on Thermal Comfort and Mental Stress. Buildings, 14(1), 99. https://doi.org/10.3390/buildings14010099