Abstract

Construction supervision is a key task that can confirm and inspect the project execution and support the creation of successful results. For the efficient performance of construction supervision, collecting various information necessary for the supervisor’s decision-making is a prerequisite, and the use of digital technology has recently been proposed as an alternative. Accordingly, the purpose of this study is to present a roadmap for the step-by-step use of digital technology to improve the efficiency of construction supervision. This study was limited to the supervision of construction projects, which have a high proportion of contract volumes in the Korean construction industry and can directly affect people’s lives. This study reclassified Korea’s construction supervision works, collected data on the urgency and effectiveness of detailed works from various stakeholders, and derived a final roadmap using importance–performance analysis. The results of this study are expected to serve as basic guidelines that can be used when reviewing digital technologies that can be applied step by step to improve the efficiency of construction supervision work.

1. Introduction

Construction supervision is defined as the act of checking whether the contractor’s production processes are carried out according to the design documents and supervising management activities in terms of process, cost, safety, and quality [1,2,3,4]. This work is carried out in a third position separate from the contractor and can contribute to the successful completion of the project and the creation of high-quality results [4,5,6,7]. In particular, in the case of building projects, considering that most of the users are ordinary citizens [6] and that they account for a high proportion of the annual public contract volume, the importance of construction supervision work to ensure the safety and quality of the results can be said to be very high. In fact, in the case of Korea, the proportion of building project contract volumes in public has been reviewed to be approximately 72% [8]. Considering the importance of construction supervision in building projects, countries such as the United States, the United Kingdom, and Japan have implemented related laws such as the Building Act. Korea also operates the legal regulations as a notification of the Ministry of Land, Infrastructure, and Transport (MOLIT) [1,2,3,9].

The prerequisite for the efficient performance of construction supervision in building projects is the collection of various on-site information that can support decision-making for management and confirmation [4,6,10,11,12]. However, the current work system has limitations in that it is performed based on a small amount of information, such as reports prepared by site managers or photos and videos collected from some workspaces on the site [6,10,12]. In addition, considering the unique characteristics of construction projects in which each work is performed simultaneously over a wide range of sites, supervisors have realistic limitations in securing sufficient data for supervision work [6,11]. Furthermore, the lack of a real-time communication system between supervisors and site managers has been pointed out as a cause of lower work efficiency. This situation can cause serious problems such as process delay and reduced safety in the construction phase, and in fact, the problems of limited information and lack of communication among stakeholders have been found to be the main causes of building collapse accidents in Korea [13].

The use of digital technology is an attractive alternative that can solve the limitations of obtaining the information necessary for supervisors to perform their work and support communication with various stakeholders. The application of digital technology at the industrial level began to be activated with the emergence of the fourth industrial revolution as a global agenda [14,15], and various previous studies have been conducted on the advanced equipment or systems that can contribute to improving the work efficiency of construction supervision, as follows: (1) convergence equipment such as a drone and helmet with information collection devices (e.g., 360 camera) capable of on-site monitoring [16,17,18,19,20]; (2) visualization and monitoring system linked to digital technologies such as Building Information Modeling (BIM) that can supervise actual construction results against design documents [21,22,23,24,25]; and (3) an advanced system that can present various analysis and prediction results and share the information using big data and Artificial Intelligence (AI) [26,27,28,29,30]. The application of digital technologies in construction supervision may be accompanied by limitations such as increased initial costs compared to conventional work systems, and this can be a major influence factor hindering the practical use of advanced technology. However, previous studies have analyzed cases by applying digital technology to some types of building construction processes or focused on evaluating the priority of the technology that can be utilized, so studies on establishing actual master plans to apply digital technology are relatively insufficient.

Therefore, the purpose of this study is to present a roadmap for the step-by-step use of digital technology that can contribute to improving the efficiency of construction supervision in building projects, focusing on the Korean case. A roadmap, which is the result of this study, was derived by comprehensively considering the urgency and effectiveness of adoption evaluated by various stakeholders for digital technologies that can be used in each supervision work. Therefore, the results of this study are expected to be used as guidelines for applying digital technology in construction supervision.

2. Methods

The research procedures are as follows: First, through the preliminary review, the construction supervision system of Korean building projects, the types of applicable digital technology, and the direction of connection between supervision works and digital technologies were examined. In particular, Korea’s construction supervision system is based on the Building Act and Housing Act, and there are complex differences in the resident status of the supervisor and detailed work contents depending on the project scale and building type [1,2,3,6]. Accordingly, this study summarized and presented information on the projects subject to supervision and types of work based on the resident status of the supervisor (as shown in Table 1).

Table 1.

Organization of construction supervision for building projects in Korea.

Second, through a review process, such as a focus group interview (FGI) with experts, the construction supervision work of building projects operated in Korea was reclassified. The FGI is a qualitative research tool that originated in social science in the 1920s and is used to collect experts’ opinions in various academic fields, such as education and political science [31,32,33]. In research related to the construction industry, it is used as a way to derive results and confirm appropriateness [34,35,36,37,38]. In order to ensure the reality of the research results, this study selected experts in FGI based on their related work careers in order to collect realistic opinions on digital technologies that can be used for construction supervision of building projects. The experts consisted of people belonging to research institutes, industries, and academia. In particular, experts from the industrial sector were divided into experts from construction companies and supervision firms, which are entities directly connected to construction supervision. Details about the experts’ careers are as follows: (1) experts in research institutes and academia were people who have received philosophy of doctoral degrees in the field of construction management and have continuously conducted research and development projects (R&D) and published research articles on digital construction; (2) expert belonging to a construction company not only has many careers carrying out practical overall tasks for the construction phase of a building project and conducting project control with supervisors, but is also a person who is included as a developer in patents related to digital construction technology; and (3) experts belonging to a supervision firm has careers performing numerous supervision and management tasks for building construction projects of various sizes and types. This study constructed a reclassification system for construction supervision by reflecting the review opinions of experts with practical work careers. For example, considering the similarity of work, pre-confirmation of processes subject to the work permit system, which is a detailed work within on-site construction management, and confirmation of major works were reclassified as a detailed work of safety management. In addition, it is expected that it will be necessary to integrate works that have similar characteristics among works that are classified as separate in the conventional system. For example, considering that the following works review contract-related issues in the supervision process, it is believed that they can be integrated within a new major classification called contract management: (1) confirmation of the appropriateness of subcontracts; (2) confirmation of the appropriateness of design changes; and (3) review of the contractor’s request for interim and final payment.

Third, digital technologies that can be used in construction supervision were investigated through analysis of policy reports and previous research, and the technologies that could be used in reclassified works were selected by reflecting the review opinions of experts who performed FGI. Detailed information on the analysis targets for deriving applicable digital technologies is as follows: (1) policy reports are the most recently released by the MOLIT, the ministry that oversees Korea’s construction industry, taking into account the characteristics that they include digital technologies that have been reviewed by the ministry from the past to the present; and (2) previous researches consist of articles presenting digital technologies that can be used in the construction industry and future strategy reports published by various organizations [16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,37,39,40,41,42,43,44,45,46,47,48,49,50,51,52]. Among them, research that presented overlapping technologies was excluded, and the final analysis targets were selected. At this phase, this study excluded the following technologies that were assessed to have a low direct connection with construction supervision work: (1) technologies aimed at improving the existing construction production system rather than technologies that support the management and supervision of production activities (e.g., automated construction system, and modular construction methods); (2) automated equipment that supports workers’ work; and (3) automated robots that can collect a variety of field information but are expensive to use for construction supervision. Targeting the derived digital technologies, this study established the following concepts of technologies that can be used in construction supervision through a consultation process with experts who performed FGI: (1) provision of various information for supervisors to perform confirmation and guidance; (2) presentation of various analysis and prediction results based on collected information; (3) provision of visualization data that allows intuitive confirmation of analysis and prediction results; and (4) support for communication between stakeholders and sharing of related information. Based on these concepts, this study established digital technologies that can be used in construction supervision for building projects and matched the technologies with reclassified works that can be used. In other words, this study can be summarized as reflecting the review opinions of experts and establishing digital technologies that can practically support the work of supervisors through data collection, analysis, and communication between stakeholders. The derived digital technologies were matched with the reclassified works, and the appropriateness of the matching results was evaluated by collecting opinions from experts other than those who performed the FGI. The purpose of this procedure is to reconfirm the adequacy of the hierarchy for deriving results by distinguishing between experts who collected opinions to derive matching results between digital technologies and reclassified works.

Fourth, this study investigated the urgency and effectiveness of applicable digital technologies for each reclassified work as perceived by various stakeholders through a survey. The survey model presented the results of reclassifying the current supervision system and digital technologies applicable to each work. In addition, in order to prevent bias in collected data, the anonymity of responses based on statistical law was guaranteed in the survey model, and numbers for each digital technology were not marked to prevent the perception that numbers may be highly related to reclassified works. Furthermore, the survey target was set to stakeholders who had experience performing actual construction supervision or using digital technologies at actual sites, and responses were investigated on a 4-point Likert scale, excluding the intermediate scale to measure clear perception.

Fifth, a roadmap for applying digital technologies to the construction supervision of building projects was presented based on the analysis results using the importance–performance analysis (IPA) method. IPA is a method used to determine efficient operational direction within limited conditions and has the characteristic of expressing results in 4-quadrants that simultaneously consider the relative importance and performance of the analysis subject [53,54,55]. Due to its characteristics, it has been used in a variety of previous studies in the construction field, such as analyzing conditions for successful completion of projects and setting directions for revising regulations to ensure worker safety [56,57,58,59,60,61]. Namely, considering that the purpose of this study is to derive a roadmap for applying digital technologies to improve the efficiency of construction supervision work, the method that can simultaneously consider the urgency and effectiveness of available technologies is judged to be appropriate.

Finally, to ensure the reliability of a roadmap, expert advice was conducted, and implications for the final results were presented.

3. Preliminary Review

3.1. Construction Supervision System of Building Projects in Korea

Construction supervision for building projects in Korea is performed based on related acts, and specific contents are presented in the MOLIT’s Notice No. 2020-1011, Detailed Construction Supervision Standards [1,2,3]. The project stages at which supervision is performed are defined as pre-construction, construction, and post-construction stages, and the supervisor’s work is divided into basic and non-basic work. In addition, supervision objects are classified based on criteria such as building type, floor area, total floor area, and construction cost, and the operation types can be divided into non-resident supervision, resident supervision, and responsible supervision. For example, in the case of “safety management”, which is classified as a major basic work, there is a difference in that the middle-level works of non-resident supervision are composed of 2 works, and the resident and responsible supervision are composed of 14 works. In detail, the middle-level works of non-resident supervision consist of the following: (1) reviewing whether technical guidance is provided by an accident prevention guidance agency and (2) checking whether safety managers are deployed to the construction site. On the other hand, resident and responsible supervision consist of 14 middle-level works, including the 2 works of non-resident supervision, such as reviewing whether safety plans for hazardous locations and work are established and checking whether safety signs are attached. Table 1 shows the composition and structure of construction supervision work for Korean building projects, summarized based on the information provided in relevant laws [1,2,3].

3.2. Review of Applicable Digital Technologies

In previous studies, government reports, and future strategy reports, digital technologies applicable to the construction industry have been presented in various categories, such as fully automated construction systems, AI, and BIM [16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,37,39,40,41,42,43,44,45,46,47,48,49,50,51,52]. Among various references, this study set eight references as the analysis target, excluding those that presented overlapping digital technologies [6,14,25,26,27,28,48,50]. The analysis results are shown in Table 2.

Table 2.

Analysis results of applicable digital technologies.

Among the derived technologies, this study filtered digital technologies that are expected to directly support the essential roles of construction supervision of building projects, such as comparison of design documents and construction results and management of process, safety, and quality. Namely, the technologies excluded by filtering are aimed at changing the conventional production system rather than improving the efficiency of construction supervision, and representative examples include 3D printing, robotic systems, and advanced construction methods (e.g., modular construction). Digital technologies that can be used in the construction supervision of the building project set up in this study were verified through experts’ reviews.

3.3. Direction of Connection with Supervision Works and Digital Technologies

First, the construction supervision works of current Korean building projects have a very complex structure. If this structure is used as in this study, the survey will inevitably consist of a large number of questions that stakeholders must assess, which will have a negative impact on securing data consistency. Accordingly, this study collected expert review opinions through FGI and established a reclassified structure based on similarity for each work.

Second, there are bound to be differences in the digital technologies that can be applied to each supervisory work. For example, image recognition and drones can be used as technologies for collecting information in the work of verifying consistency with design documents. However, in works such as checking the adequacy of the contractor’s request for interim and final payment, information can be collected through the use of communication and information-sharing technologies rather than the corresponding technologies.

Considering the above characteristics, this study reclassified supervision works that had similarities and established an analysis structure by linking the digital technologies available for each reclassified work.

4. Roadmap for Application of Digital Technologies

4.1. Reclassification of Construction Supervision Work

This study reclassified conventional construction supervision work to facilitate data collection and ensure the reliability of analysis results. The reclassification of work was performed through three rounds of FGI targeting six experts from industry, academia, and research institutes with an average career of about 23 years, as shown in Table 3. As mentioned above, this study collected opinions from experts who have experience in conducting construction supervision of building projects or in conducting related research. In particular, the experts are composed of those who have earned master’s degrees and doctoral degrees in academic fields such as construction management, so it is believed that a high level of understanding of the scope of this study has been secured.

Table 3.

Experience of experts participating in FGI.

FGI was conducted face-to-face with all experts in attendance, and the negotiated opinions collected during each interview were shared with experts via e-mail and reviewed for appropriateness. The main opinions reviewed through FGI are as follows: First, it was reviewed that it would be reasonable to reclassify the supervision work system into two composition levels, identical to the conventional system. In other words, by reclassifying the composition level of conventional work in more detail, various results related to applicable digital technologies can be confirmed. However, when targeting such a detailed composition of work, a large number of survey questions on the urgency and effectiveness of digital technologies may be included, which may have a negative impact on securing data consistency. Therefore, experts’ opinions were derived that it is reasonable for the composition level of reclassified work to be the same as the conventional work system.

Second, it was agreed that the reclassified works at the major level would be comprised of six categories as follows: (1) confirmation of implementation according to design documents; (2) process management; (3) contract management; (4) safety management; (5) quality management; and (6) records and retention. For example, “review of process achievement rate against the plan”, a detailed work of “on-site construction management and confirmation of major works”, which was classified as a major work in the conventional system, was included as a detailed work of “process management” among the six major categories reorganized considering the similarity of work. In addition, as mentioned above, the suitability review work for a subcontract, design change, and interim and final payment were formed as detailed works in a new major category called “contract management”.

Finally, a comprehensive review was conducted on the results of the reclassification of construction supervision work for the building project setup, as shown in Table 4. As a result, the composition of the reclassified works was reviewed to ensure appropriateness for experts with high expertise in construction supervision, and this study reviewed digital technologies applicable to the system.

Table 4.

Final composition of reclassification works.

4.2. Deduction of Applicable Digital Technologies

This study classified digital technologies that can be used in construction supervision into aspects such as data collection, analysis and prediction, visualization, and communication, reflecting the review opinions of six experts in FGI. FGI was conducted in two rounds using the same process as work reclassification, and digital technologies applicable to the reclassified works were matched and verified.

Reflecting the opinions of experts, this study organized the types of digital technologies that can be used into four major categories and nine middle categories, as shown in Table 5. The negotiated concepts of digital technology in each major category are as follows: First, data collection is the technology that supports the collection of various types of information on-site required to perform construction supervision. Second, result analysis and prediction is the technology that applies advanced techniques (e.g., AI, artificial neural networks, and machine learning) based on collected information to review the adequacy of the construction process and derive possible risk factors (e.g., process delays). Third, visualization is defined as the technology that can streamline the supervisor’s review and guidance work by visualizing information collected in the field. Finally, communication and information sharing are defined as technologies that can convert collected information into a database and share that information with various stakeholders.

Table 5.

Final composition of applicable digital technologies.

The digital technologies selected through this process were matched by collecting opinions from experts on their practical usability in each reclassified supervision work.

4.3. Establishment of Final Analysis Hierarchy

To ensure the appropriateness of the matching results between reclassified works and digital technologies, this study collected additional review opinions from five experts other than those who performed FGI. The experts consisted of people with expertise in the direction of utilizing smart and digital technologies in the construction industry, of which two were from research institutes and three were from academia. The affiliated research institutes of two experts are located in Seoul and Gyeonggi-do and are government-funded and private institutes that perform various research related to the Korean construction industry. In addition, the academic expert’s affiliation is with three universities located in Seoul and Gangwon-do, and the experts were reviewed to have experience conducting research on construction management and cutting-edge technology. All five experts had doctoral degrees in construction management or architectural engineering, and their average experience was approximately 14.8 years.

As a result of collecting review opinions from experts, the matching results established through FGI were reviewed as overall reasonable. However, the following opinions were gathered that adjustments in technologies were necessary for some reclassified works: (1) In the case of “B3. Review of process achievement rate against plan”, communication and information-sharing technologies were excluded from the results matched through FGI, but it was considered necessary to add the technology because information on achievement against plan is a matter of interest to all project participants; and (2) In the case of “E1. Inspection of materials brought into site”, the results matched through FGI included a drone for the purpose of initial inspection of materials. However, drones were excluded, reflecting the opinion that initial inspection using a drone may not be able to confirm detailed materials and that image recognition technology is the digital technology that can support detailed inspection of various materials. Table 6 shows the types of digital technologies available for each reclassified work based on the results of experts’ reviews. In the table, the number of digital technologies is shown in Table 5. Based on the matching results of digital technologies applicable to each reclassified work, this study analyzed the urgency and effectiveness of applying the technologies to each work and derived the final results.

Table 6.

Final analysis hierarchy.

4.4. Overview of Data Analysis

This study collected data through a survey targeting various stakeholders to derive the types of digital technologies that can be used to improve the efficiency of construction supervision for building projects. In order to investigate clear perceptions, this study investigated the urgency and efficiency of applying digital technologies for each work on a 4-point Likert scale. The purpose of using this scale in this study can be said to be to prevent the limitation that mid-point answers such as ‘normal’ can be used to avoid giving correct answers to sensitive questions [62,63].

In this study, urgency refers to the degree of priority applied to ensure the efficiency of the conventional work system, and effectiveness is defined as the degree of improvement in the efficiency of conventional work through the use of digital technologies. The definitions of the four quadrants in this study are as follows: (1) technologies in the first quadrant contain items with high urgency and effectiveness to improve the efficiency of construction supervision; (2) technologies in the second quadrant have high urgency but are relatively low in effectiveness in terms of improving work efficiency; (3) technologies in the third quadrant contain items reviewed with low values in terms of urgency and effectiveness; and (4) technologies in the fourth quadrant are items that have low urgency but are highly effective in improving work efficiency.

Accordingly, the roadmap presented in this study can be defined as a step-by-step plan to utilize digital technologies that can be used to improve the efficiency of construction supervision work for building projects, considering both the urgency and efficiency of each technology. It is expected that a roadmap can be used as basic data for the selection of digital technologies that can create high effectiveness within a limited budget for performing construction supervision. In addition, the IPA used in this study is expected to be an appropriate method for this study in that it has been used not only to establish master plans in various academic fields [53,54,55,56,57,58,59,60,61] but also to add ways to utilize smart safety products within the occupational safety standards of the Korean construction industry [64,65].

4.5. Data Collection and Refinement

This study collected data through a survey over a period of approximately two months, and an overview of the survey participants is shown in Table 7.

Table 7.

Career of survey participants.

Data were collected from a total of 89 stakeholders, and in detail, they were reviewed to consist of 37 stakeholders from industry, 27 from research institutes, and 25 from academia. In addition, the average experience of stakeholders was approximately 17.3 years, which can be interpreted as ensuring an understanding of the scope of this study. To ensure the reality and reliability of the collected data through the survey, industry participants were selected as those who had experience performing construction management and supervision on at least two building projects. In addition, participants in research and academia consisted of people who held a master’s degree or higher and had careers conducting research or projects on construction supervision and digital technology. Among the collected data, incomplete questionnaires were considered outliers and excluded from the scope of analysis, and this study set the final analysis data responded to by 71 stakeholders.

As a result of the descriptive statistics analysis of the data collected through the survey, the overall average for urgency was 3.18, the standard deviation was 0.10, the overall average for effectiveness was 3.25, and the standard deviation was 0.12. Accordingly, stakeholders are highly aware of the contribution of digital technology to improving the work efficiency of construction supervision of building projects, and the difference in opinion among stakeholders regarding this perception can also be interpreted as low.

4.6. Analysis Results

This study used the analysis process used in previous studies [57,61] to derive research results: (1) calculate the average value of urgency and effectiveness of all digital technologies available at level 2 work and set it as a standard for dividing into four quadrants, and (2) draw a diagram using the average value of urgency and effectiveness for each technology as coordinates. The analysis results for each reclassified work are as follows:

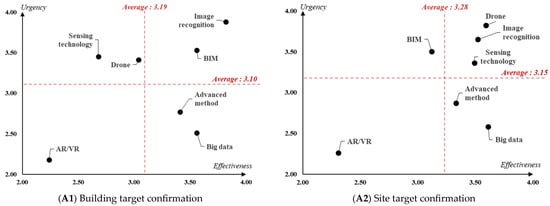

First, the analysis results of available digital technologies for ‘A. confirmation of implementation according to design documents’ are shown in Figure 1. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) image recognition, (2) drones, (3) sensing technology, (4) big data, (5) advanced methods, and (6) BIM.

Figure 1.

Results of IPA for “A. confirmation of implementation according to design documents”.

The detailed analysis results are as follows: First of all, image recognition technology was analyzed as a technology that can be commonly applied in the short term. These results are believed to reflect the recognition that the technology can provide key results that can support supervisors’ decision-making by comparing actual on-site progress with design documents. Next, BIM yielded different results in Level 2 works, and these results are expected to reflect the perception that supervision of external sites is highly variable and difficult to apply in the short term compared to confirming building targets. In addition, the drone was evaluated as a digital technology that can be used in the short term to perform supervision work on external sites, reflecting the characteristic that it is difficult to operate inside the building. However, through technological advancement, it is expected that when developing drones that can be operated in indoor spaces, it will be possible to use them to improve the efficiency of construction supervision in the long term. In the case of big data and advanced methods, their effectiveness when utilized was analyzed to be high, but the various work-related information required to use the technologies in actual work is currently insufficient, so it was evaluated that they can be utilized in the medium term.

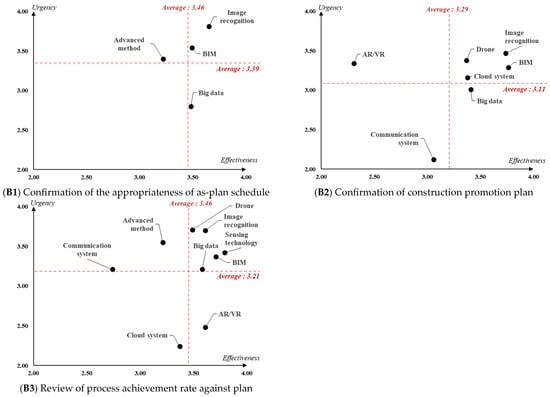

Second, the analysis results of available digital technologies for ‘B. Process management’ are shown in Figure 2. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) image recognition, (2) drones, (3) sensing technology, (4) big data, (5) advanced methods, (6) AR/VR, (7) BIM, and (8) cloud systems.

Figure 2.

Results of IPA for “B. process management”.

First of all, the results of the analysis of digital technologies available in the short term are expected to reflect the recognition that collecting information generated in the field and deriving various review results based on this is a prerequisite for successful process management. Next, big data and advanced methods, which were evaluated as technologies that can be used in the medium- to long-term, are believed to have taken into account the characteristic that the establishment of actual process management plans is conducted by benchmarking past similar project cases. In other words, it is possible to derive the best practice for successful process management of projects that perform supervision using the relevant technologies, and it is expected that the best practice can be used as a prerequisite to support the successful performance of construction supervision. In addition, AR/VR, which is evaluated as a medium-term usable technology, is expected to be used as a way to confirm process interference in connection with BIM after securing reliability.

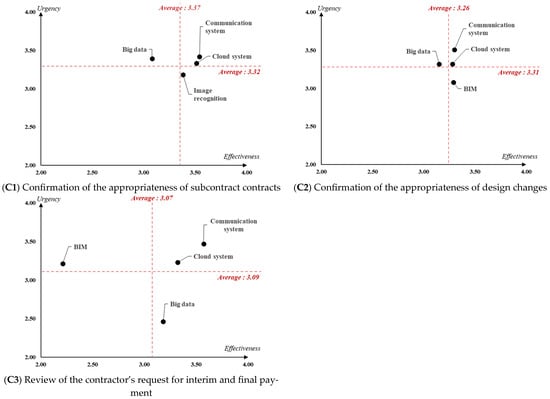

Third, the analysis results of available digital technologies for ‘C. contract management’ are shown in Figure 3. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) communication system, (2) cloud system, (3) BIM, (4) big data, and (5) image recognition.

Figure 3.

Results of IPA for “C. contract management”.

In detail, communication systems and cloud systems were commonly evaluated as technologies that needed to be utilized in the short term. This is expected to be a result of the recognition that collecting opinions from various stakeholders participating in the project in real-time and sharing the results of reflecting the information in the project execution system is the basis for successful construction supervision. In addition, it was analyzed that technologies that can be utilized in the medium- to long-term differ depending on the characteristics of each detailed work. For example, in the case of “C2. confirmation of the appropriateness of design changes”, BIM was reviewed as a usable technology considering the nature of the work, which involves examining the appropriateness of design changes. In order to perform BIM-based work, it is expected that real-time reflection of various information related to design changes (e.g., changes in shape and quantity) must be assumed, and it is judged to be evaluated as a technology that can be used in the medium term.

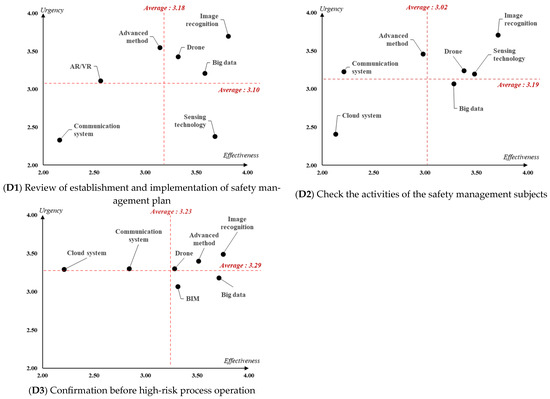

Fourth, the analysis results of available digital technologies for ‘D. safety management’ are shown in Figure 4. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) image recognition, (2) drones, (3) sensing technology, (4) big data, (5) advanced methods, (6) AR/VR, (7) BIM, (8) communication systems, and (9) cloud systems.

Figure 4.

Results of IPA for “D. safety management”.

In detail, image recognition, drones, sensing technology, big data, and advanced methods were evaluated as technologies that can be applied in the short term. These results are believed to reflect the recognition that occupational accidents that occurred in similar projects in the past can be used as meaningful basic data for successful safety management of high-risk processes performed at the site. Therefore, it is expected that the establishment of big data for successful safety management by continuously collecting information collected using various digital technologies in the short term will be necessary in the medium to long term. In addition, in the case of AR/VR, which was evaluated as a technology that can be used in the long term in detailed work named “D1. Review of establishment and implementation of a safety management plan”, the result is expected to reflect the recognition that it can contribute to predicting the possibility of occupational accidents occurring at the actual site. However, since this technology requires linkage with other digital technologies (e.g., big data) rather than a stand-alone technology, it seems reasonable to consider its use in the long term.

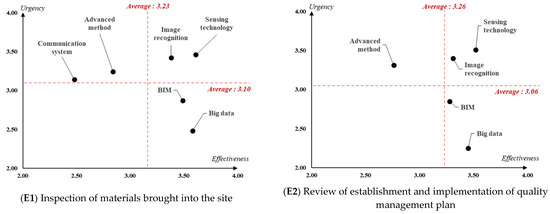

Fifth, the analysis results of available digital technologies for ‘E. quality management’ are shown in Figure 5. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) image recognition, (2) sensing technology, (3) big data, (4) advanced methods, and (5) BIM.

Figure 5.

Results of IPA for “E. quality management”.

In the case of quality management, image recognition, and sensing technology were selected as applicable technologies in the short term, reflecting the fact that inspection of materials brought into the field is the main purpose of this classification. In addition, it is expected that big data will be evaluated as a technology that can be applied in the medium term, reflecting the perception that quality management results information for each material brought in under various field conditions in the future can be used as basic data for establishing a customized management system for the project. In the long term, BIM and advanced methods were selected as applicable technologies. As mentioned above, it is expected that the quality management factors, as well as specifications of materials in BIM, are added, and if the system is maintained for a certain period of time, insights based on various advanced methods such as AI can be derived, reflecting the recognition that it will be possible to utilize.

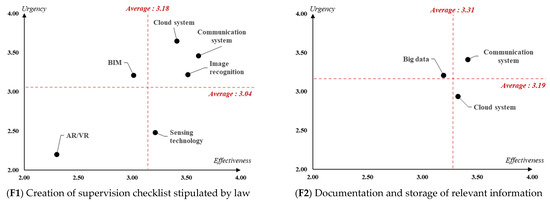

Finally, the analysis results of available digital technologies for ‘F. records and retention’ are shown in Figure 6. In this classification, digital technologies that can contribute to work efficiency were derived as follows: (1) communication system, (2) cloud system, (3) big data, (4) image recognition, (5) sensing technology, and (6) BIM.

Figure 6.

Results of IPA for “F. records and retention”.

In detail, communication systems and cloud systems were evaluated as technologies that can be applied in the short term to improve work efficiency. This is expected to reflect the perception that these technologies can support the supervisor’s work by reviewing the checklist items specified in the statute and writing reports based on them in the short term. In addition, image recognition and big data were evaluated as applicable technologies in the medium to long term. It is expected that this reflects the perception that text mining technologies can build big data on past projects if they are applied to related documents, and supervisors can utilize meaningful reference materials analyzed based on information about similar projects in the past.

A comprehensive summary of the above results is shown in Table 8. This study collected final review opinions from six experts who performed FGI to ensure the reliability of the configuration of digital technologies applicable to each work in the short, medium, and long term. As a result, the configuration framework of step-by-step digital technologies applicable to each work was reviewed as reasonable for the purpose of improving the efficiency of construction supervision work on building projects.

Table 8.

Configuration of digital technologies to each work by term.

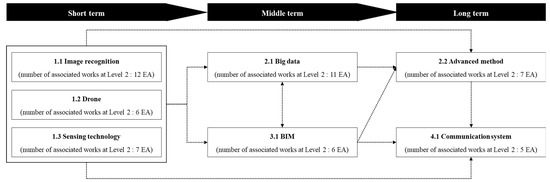

Based on the configuration of digital technologies, this study analyzed the number of works that can be used for each technology and selected technologies with high frequency. This type of analysis is intended to select technologies that can achieve maximum effectiveness through the application of a single technology, as the application of technology may entail an increase in the initial cost of performing supervision work. The analysis results are shown in Table 9, and the details are as follows: (1) in the short term, the average number of related works is 5, so 1.1 Image recognition, 1.2 Drone, and 1.3 Sensing technology, which can be applied to a higher number of works, can be evaluated as highly useful digital technologies; (2) in the medium term, technologies evaluated higher than the average for the number of works were selected as 2.1 Big data and 3.1 BIM; and (3) in the long term, technologies evaluated higher than the average for the total number of works were selected as 2.2 Advanced method and 4.1 Communication system.

Table 9.

Number of associated works at Level 2 by each digital technology.

The step-by-step relationship between digital technologies that can support multiple tasks can be schematized, as shown in Figure 7, and the details are as follows:

Figure 7.

A roadmap for application of digital technologies considering usability.

Above all, the selection of sub-category technologies for data collection in the short term is expected to reflect the stakeholders’ perception that the most important factor for efficient construction supervision work is the collection of various data generated on-site. In addition, it is expected that short-term technologies will be able to be operated in continuous connection with technologies that have been evaluated as having high utility in the medium and long term. For example, various on-site data collected in real-time using short-term technologies can be operated as a sequential linkage network that is linked to big data, a medium-term technology, and then to the advanced method, a long-term technology. Furthermore, it is believed that short-term technologies can be utilized through direct linkage with long-term technologies rather than sequential linkage. It is expected that these short-term technologies can be used as efficient alternatives to overcome the limitations of construction supervision work based on limited information.

Next, in the medium term, big data and BIM were evaluated as highly useful technologies. These results are expected to reflect the recognition that the collection of various data occurring on the site through the use of short-term technologies can be constituted as big data. For example, data collected using short-term technologies can be interpreted as the concept of big data in that various analyses are possible considering differences such as building types (e.g., public government buildings and cultural facilities), construction scales, and building shapes. In addition, it is expected that the various data that can be confirmed through big data can be used as a reference for supervisors when reviewing similar building projects in the future. In the case of BIM, it is believed that the fact that it was selected as a technology that can be used in the medium term was taken into consideration in light of the recognition that the use of short-term technologies must be used first in order to check actual on-site progress compared to design documents, which is the main work of construction supervision. Furthermore, it is expected that big data and BIM can be operated in conjunction with each other. For example, information related to design documents of various projects built on big data can be used to create a library for BIM, and BIM-based design documents are expected to become basic data for the continuous expansion of big data.

Finally, long-term technologies were selected for their advanced methods and communication systems. The fact that the advanced method was selected as a long-term technology is believed to reflect the recognition that the practical use of the technology requires the collection of data with multiple attributes, like big data, which is a medium-term technology. In the case of the communication system, it is considered to have been selected as a long-term technology in that it serves as a platform for sharing the results of using other digital technologies. In the case of the communication system, it is considered to have been selected as a long-term technology in that it serves as a platform for sharing the results of using other digital technologies. In addition, it is expected that when the system is established in the future, it will be used as an alternative for project stakeholders to realistically review the results of construction supervision work.

5. Conclusions

This study presents a roadmap for applying digital technologies to improve the efficiency of construction supervision in Korean building projects. As a result, it was found that there are differences in digital technologies that require step-by-step application for each work. This can be interpreted as differences in digital technologies that can provide the information required by supervisors due to the characteristics of each work. Discussions of the research results are as follows:

First, this study considered both urgency and effectiveness and derived digital technologies that can be used step-by-step in construction supervision. However, in order to introduce realistic digital technologies, it is necessary to evaluate the economic feasibility of performing digital technology-based supervision compared to the existing system. Therefore, it is expected that economic analysis based on the initial cost of the application of digital technology will be needed for further study.

Second, it is expected that productivity analysis of construction supervision using digital technology compared to existing work systems is required. For example, digital technology-based construction supervision may be different in terms of work time for each unit of work required compared to the existing system. Therefore, if the review using an analysis methodology such as CYCLONE is carried out to compare the efficiency of the existing process and the improvement process, it is expected that it can be used as meaningful basic data for practically introducing and operating digital technologies in construction supervision. CYCLONE is a method that analyzes productivity by dividing the construction project process into work units, modeling them, and running simulations [66]. Previous studies have presented various results, such as analyzing the productivity of steel construction and comparing the productivity of processes based on advanced technology and conventional processes [67,68]. Therefore, if the method is used to compare productivity between supervision using digital technology and the existing supervision process, it is expected that it will be possible to review the quantitative effectiveness of the use of digital technology.

Third, in this study, the analysis was conducted on the assumption that digital technologies are used independently in each work, but there is a possibility that each technology has an interconnected relationship. For example, information collected through image recognition technology is stored in the cloud system, and the information on various projects stored in the cloud system is expanded into big data. Based on the information, when applying advanced methods (e.g., AI and machine learning), various results that can be used in construction supervision can be derived.

Finally, this study derived results by using opinions collected from various stakeholders as data. However, the fact that the data included relatively insufficient consideration of subjective factors that may differ for each stakeholder can be said to be a limitation of this study. For example, subjective factors such as the type of project performed by each stakeholder, experience in using digital technology, project implementation career, and affiliation can be said to be major factors that can affect decision-making. Therefore, based on the results of this study, it is expected that future research will need to develop a method that can differentially evaluate the opinions collected by stakeholders by reflecting subjective factors such as implementation career by project type. In addition, the relatively small number of data used in this study is expected to be a limitation in terms of securing the versatility of the research results. Therefore, in order to generalize the roadmap for utilizing digital technology, it is judged that the data collection target will be expanded to include owners and designers and that more data collection will be necessary.

This study presented a roadmap for step-by-step utilization of digital technology to improve work efficiency based on the opinions of various stakeholders and experts. It is expected that the analysis process of this study can be used as a method to support the digitalization of construction supervision and the decision-making of stakeholders when considered together with the above-mentioned improvement direction. In addition, considering that the performance of construction supervision based on digital technology can ultimately affect the performance of the project, further study of the mutual influence of the improved supervision process on the performance indicators of the project, such as productivity, economics, and safety efficiency, is needed.

Author Contributions

Conceptualization, C.-W.K. and B.g.K.; methodology, W.S.Y. and H.L.; formal analysis, H.L.; investigation, J.S.; data curation, W.S.Y. and J.S.; writing—original draft preparation, C.-W.K.; writing—review and editing, C.-W.K. and H.L.; supervision, B.g.K.; project administration, B.g.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a grant (RS-2022-00143493, project number: 1615012983) from the Digital-Based Building Construction and Safety Supervision Technology Research Program funded by the Ministry of Land, Infrastructure, and Transport of the Korean Government and by the Soonchunhyang University Research Fund.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors. The data are not publicly available due to the characteristics of some personal information included.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ministry of Land. Infrastructure and Transport. Building Act. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EA%B1%B4%EC%B6%95%EB%B2%95 (accessed on 27 September 2023).

- Ministry of Land. Infrastructure and Transport. Housing Act. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%A3%BC%ED%83%9D%EB%B2%95 (accessed on 27 September 2023).

- Ministry of Land. Infrastructure and Transport. Notice on Detailed Standards for Building Supervision. Available online: https://www.law.go.kr/%ED%96%89%EC%A0%95%EA%B7%9C%EC%B9%99/%EA%B1%B4%EC%B6%95%EA%B3%B5%EC%82%AC%EA%B0%90%EB%A6%AC%EC%84%B8%EB%B6%80%EA%B8%B0%EC%A4%80 (accessed on 25 September 2023).

- Rounds, J.L.; Segner, R.O. Construction Supervision; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Chang, L.; Wang, Y.; Feng, G.; Wang, L. Research on problems and solutions in construction quality supervision of construction projects. Smart Constr. Res. 2018, 2, 1–5. [Google Scholar] [CrossRef]

- Kim, C.W.; Yoo, W.S.; Lim, H. Priority analysis for applying digital technology to improve the efficiency of building supervision work. J. Korea Inst. Build. Constr. 2023, 23, 93–102. [Google Scholar]

- Halder, S.; Afsari, K.; Chiou, E.; Patrick, R.; Hamed, K.A. Construction inspection & monitoring with quadruped robots in future human-robot teaming: A preliminary study. J. Build. Eng. 2023, 65, 105814. [Google Scholar]

- Construction Association of Korea. Annual Contract Amount by Ordering Agency, Construction Scales, and Construction Project Type in Korea (2013–2021). Available online: https://kosis.kr/statHtml/statHtml.do?orgId=365&tblId=DT_365001_A051&conn_path=I3 (accessed on 4 October 2023).

- Park, H.P.; Oh, U.; Park, S.H. A Study on the improvement of the Supervision systems in the Housing Construction Projects. J. Archit. Inst. Korea 2004, 20, 177–185. [Google Scholar]

- Nguyen, L.; Koufakou, A.; Mitchell, C. A smart mobile app for site inspection and documentation. In Proceedings of the ICSC15-The Canadian Society for Civil Engineering 5th International/11th Construction Specialty Conference, Vancouver, BC, Canada, 7–10 June 2015. [Google Scholar]

- Kim, C.W.; Yoo, W.S.; Park, H.T. Development Direction of Performance Assessment System based on Building Supervision using Digital Technology. Build. Constr. 2022, 22, 16–21. [Google Scholar]

- Shin, H.J.; Cha, H.S. Proposing a Quality Inspection Process Model Using Advanced Technologies for the Transition to Smart Building Construction. Sustainability 2023, 15, 815. [Google Scholar] [CrossRef]

- Ministry of Land. Infrastructure and Transport. Press Release on the Collapse of Apartment under Construction by Hyundai Development Company. Available online: https://www.korea.kr/news/policyBriefingView.do?newsId=156499293 (accessed on 4 October 2023).

- Chowdhury, T.; Adafin, J.; Wilkinson, S. Review of digital technologies to improve productivity of New Zealand construction industry. J. Inf. Technol. Constr. 2019, 24, 569–587. [Google Scholar]

- Kim, T.; Lim, H.; Lee, M.; Cha, M.; Cho, K. Performance-Influencing Factors and Causal Relationships of Construction Projects Using Smart Technology. Buildings 2023, 13, 1431. [Google Scholar] [CrossRef]

- Khan, F.; Ellenberg, A.; Mazzotti, M.; Kontsos, A.; Moon, F.; Pradhan, A.; Bartoli, I. Investigation on bridge assessment using unmanned aerial systems. In Proceedings of the Structures Congress 2015, Portland, OR, USA, 23–25 April 2015; pp. 404–413. [Google Scholar]

- Almukhtar, A.; Saeed, Z.O.; Abanda, H.; Tah, J.H. Reality capture of buildings using 3D laser scanners. Civil Eng. 2021, 2, 214–235. [Google Scholar] [CrossRef]

- Afsari, K.; Halder, S.; Ensafi, M.; DeVito, S.; Serdakowski, J. Fundamentals and Prospects of Four-Legged Robot Application in Construction Progress Monitoring. EPiC Ser. Built Environ. 2021, 2, 274–283. [Google Scholar]

- Tan, Y.; Li, S.; Liu, H.; Chen, P.; Zhou, Z. Automatic inspection data collection of building surface based on BIM and UAV. Autom. Constr. 2021, 131, 103881. [Google Scholar] [CrossRef]

- Munawar, H.S.; Ullah, F.; Heravi, A.; Thaheem, M.J.; Maqsoom, A. Inspecting buildings using drones and computer vision: A machine learning approach to detect cracks and damages. Drones 2021, 6, 5. [Google Scholar] [CrossRef]

- Kwon, O.S.; Park, C.S.; Lim, C.R. A defect management system for reinforced concrete work utilizing BIM, image-matching and augmented reality. Autom. Constr. 2014, 46, 74–81. [Google Scholar] [CrossRef]

- Golparvar-Fard, M.; Pena-Mora, F.; Savarese, S. Automated progress monitoring using unordered daily construction photographs and IFC-based building information models. J. Comput. Civ. Eng. 2015, 29, 04014025. [Google Scholar] [CrossRef]

- Abbas, R.; Westling, F.A.; Skinner, C.; Hanus-Smith, M.; Harris, A.; Kirchner, N. BuiltView: Integrating LiDAR and BIM for Real-Time Quality Control of Construction Projects. In Proceedings of the International Symposium on Automation and Robotics in Construction, Kitakyshu, Japan, 27–28 October 2020; pp. 233–239. [Google Scholar]

- Ma, G.; Wu, M.; Wu, Z.; Yang, W. Single-shot multibox detector-and building information modeling-based quality inspection model for construction projects. J. Build. Eng. 2021, 38, 102216. [Google Scholar] [CrossRef]

- Ministry of Land. Infrastructure and Transport. Smart Construction Technology Roadmap to Innovate Construction Productivity and Enhance Safety. Available online: http://www.molit.go.kr/USR/NEWS/m_71/dtl.jsp?id=95081506 (accessed on 4 October 2023).

- Son, T.H.; Lee, G.P. Construction Issue Focus: Strategy for Utilizing Digital Technology in the Future Construction Industry; Construction & Economy Research Institute of Korea: Seoul, Republic of Korea, 2019. [Google Scholar]

- Ministry of Land. Infrastructure and Transport. Press Release for Promotion of Smart Construction Vitalization Plan. Available online: https://www.korea.kr/news/pressReleaseView.do?newsId=156517315 (accessed on 4 October 2023).

- Kim, W.Y. Construction Issue Focus: Digital Transformation Trends in the Construction Industry and Response Directions; Construction & Economy Research Institute of Korea: Seoul, Republic of Korea, 2022. [Google Scholar]

- Paduano, I.; Mileto, A.; Lofrano, E. A Perspective on AI-Based Image Analysis and Utilization Technologies in Building Engineering: Recent Developments and New Directions. Buildings 2023, 13, 1198. [Google Scholar] [CrossRef]

- Fang, J.; Hu, J.; Elzarka, H.; Zhao, H.; Gao, C. An Improved Inspection Process and Machine-Learning-Assisted Bridge Condition Prediction Model. Buildings 2023, 13, 2459. [Google Scholar] [CrossRef]

- Merton, R.E.; Kendall, P.L. The Focused Interview. Am. J. Sociol. 1946, 51, 541–557. [Google Scholar] [CrossRef]

- Munday, J. Identity in focus: The use of focus groups to study the construction of collective identity. Sociology 2006, 40, 89–105. [Google Scholar] [CrossRef]

- Smithson, J.; Focus Groups. The Sage Handbook of Social Research Methods; Sage Publication Ltd.: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Chan, I.Y.S.; Leung, M.; Yu, S.S.W. Managing the Stress of Hong Kong Expatriate Construction Professionals in Mainland China: Focus Group Study Exploring Individual Coping Strategies and Organizational Support. J. Constr. Eng. Manag. 2012, 138, 1150–1160. [Google Scholar] [CrossRef]

- Nyumba, T.O.; Wilson, K.; Derrick, C.J.; Mukherjee, N. The Use of Focus Group Discussion Methodology: Insights from Two Decades of Application in Conservation. Methods Ecol. Evol. 2018, 9, 20–32. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Dolla, T.; Delhi, V.S.K. Strategies for Digital Transformation in Construction Projects: Stakeholders’ Perceptions and Actor Dynamics for Industry 4.0. J. Inf. Technol. Constr. 2023, 28, 151–175. [Google Scholar] [CrossRef]

- Budayan, C.; Okudan, O. Assessment of Barriers to the Implementation of Smart Contracts in Construction Projects—Evidence from Turkey. Buildings 2023, 13, 2084. [Google Scholar] [CrossRef]

- Korea Agency for Infrastructure Technology Advancement. Technology Forecasting 2040: Land, Infrastructure and Transport. 2013. Available online: https://www.codil.or.kr/viewDtlConRpt.do?gubun=rpt&pMetaCode=OTKCRK130007 (accessed on 19 December 2023).

- Jawad, I. World’s Top Global Megatrends, Frost & Sullivan. 2014. Available online: https://store.frost.com/top-global-mega-trends-to-2025-and-implications-to-business-society-and-cultures-2014-edition-19883.html (accessed on 19 December 2023).

- Ministry of Land. Infrastructure and Transport. Establishment of Vision 2045: Land, Infrastructure and Transport. 2016. Available online: https://www.codil.or.kr/viewDtlConRpt.do?gubun=rpt&pMetaCode=OTKCRK180120 (accessed on 19 December 2023).

- The Strategic Future Group. Global Trends 2040: A More Contested World. 2021. Available online: https://www.dni.gov/files/ODNI/documents/assessments/GlobalTrends_2040.pdf (accessed on 19 December 2023).

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Kim, C.W.; Kim, T.; Lee, U.K.; Cho, H.; Kang, K.I. Advanced steel beam assembly approach for improving safety of structural steel workers. J. Constr. Eng. Manag. 2016, 142, 05015019. [Google Scholar] [CrossRef]

- Lim, H.; Lee, J.W.; Kim, T.; Cho, K.; Cho, H. Economic analysis of USN-based data acquisition systems in tall building construction. Sustainability 2017, 9, 1360. [Google Scholar] [CrossRef]

- Lim, H.; Kim, T.; Teizer, J. Smartphone-based data collection system for repetitive concrete temperature monitoring in high-rise building construction. Sustainability 2019, 11, 5211. [Google Scholar] [CrossRef]

- Korea Institute of S&T Evaluation and Planning. Report of Preliminary Feasibility Study for Smart Construction Technology Development Project. Available online: https://www.kistep.re.kr/board.es?mid=a10305080000&bid=0002&act=view&list_no=25500&tag=&nPage=14 (accessed on 4 October 2023).

- Bouabdallaoui, Y.; Lafhaj, Z.; Yim, P.; Ducoulombier, L.; Bennadji, B. Predictive maintenance in building facilities: A machine learning-based approach. Sensors 2021, 21, 1044. [Google Scholar] [CrossRef]

- Park, D.H.; Jeon, H.R. Issue Monitor: Preparing for the Future Construction Industry Digitally; KPMG Economic Research Center of Korea: Seoul, Republic of Korea, 2021. [Google Scholar]

- Ghannad, P.; Lee, Y.-C. Automated modular housing design using a module configuration algorithm and a coupled generative adversarial network (CoGAN). Autom. Constr. 2022, 139, 104234. [Google Scholar] [CrossRef]

- Yan, K.; Zhou, X.; Yang, B. Editorial: AI and IoT applications of smart buildings and smart environment design, construction and maintenance. Build. Environ. 2023, 229, 109968. [Google Scholar] [CrossRef]

- Martilla, J.A.; James, J.C. Importance-performance analysis. J. Mark. 1997, 41, 77–79. [Google Scholar] [CrossRef]

- Susanty, M.; Ningsih, T.W.; Rissa, M.F. Analysis of customer satisfaction with Importance Performance Analysis (IPA) method in one of the banking industries. Int. J. Innov. Sci. Res. Technol. 2019, 4, 421–425. [Google Scholar]

- Vieira, E.; Ferreira, J.J.; São João, R. Creation of value for business from the importance-performance analysis: The case of health clubs. Meas. Bus. Excell. 2019, 23, 199–215. [Google Scholar] [CrossRef]

- Kang, S.H.; Huh, Y.K.; Kim, D.Y. Analysis of Construction Safety Planning Tasks for Performance Improvement Using Importance Performance Analysis (IPA) Method. J. Korea Inst. Build. Constr. 2020, 20, 545–554. [Google Scholar]

- Jang, J.; Cho, K.W.; Koo, C.; Lee, C.; Kim, T. Importance and Performance Analysis on Factors of PC Component Allocation and Loading Planning. Korean J. Constr. Eng. Manag. 2021, 22, 53–62. [Google Scholar]

- Kim, H.; Jung, M.; Jang, H. Analyzing the ODA Construction Project Competence based on IPA. Korean J. Constr. Eng. Manag. 2021, 22, 66–72. [Google Scholar]

- Jung, D.; Seo, Y.J.; Shin, S.; Kim, D. Analyzing the relationship between the critical safety management tasks and their effects for preventing construction accidents using IPA method. Korean J. Constr. Eng. Manag. 2022, 23, 77–86. [Google Scholar]

- Lim, S.; Won, J.H.; Seo, J.; Jeon, S.; Kim, C.W. A roadmap to improve usage items to enhance the operational effectiveness of occupational safety and health management expense in Korean construction. Ind. Health 2022, 61, 158–170. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J.H. A Study on Critical Success Factors of Off-Site Construction—By Importance Performance Analysis. Korean J. Constr. Eng. Manag. 2023, 24, 24–36. [Google Scholar]

- Jang, D.H.; Cho, S.K. Is the mid-point of a likert-type scale necessary? Comparison between the scales with or without the mid-point. Sur. Res. 2017, 18, 1–24. [Google Scholar] [CrossRef]

- Lim, H.; Seo, J.; Yoo, W.S.; Kim, C.W. Critical impact factors affecting the performance of domestic construction projects through megatrend analysis. J. Korea Inst. Build. Constr. 2022, 22, 207–218. [Google Scholar]

- Ministry of Employment and Labor. Notice on Calculation and Usage Standards for Occupational Safety and Health Expense in the Construction Industry. Available online: https://www.law.go.kr/%ED%96%89%EC%A0%95%EA%B7%9C%EC%B9%99/%EA%B1%B4%EC%84%A4%EC%97%85%EC%82%B0%EC%97%85%EC%95%88%EC%A0%84%EB%B3%B4%EA%B1%B4%EA%B4%80%EB%A6%AC%EB%B9%84%EA%B3%84%EC%83%81%EB%B0%8F%EC%82%AC%EC%9A%A9%EA%B8%B0%EC%A4%80 (accessed on 5 December 2023).

- Kim, C.W.; Oh, S.; Seo, J.; Hong, Y. A Study for the Improvement on Use and Transparency of Occupational Safety and Health Expenses in Construction. 2021. Available online: https://oshri.kosha.or.kr/oshri/publication/researchReportSearch.do?mode=view&articleNo=427917&article.offset=0&articleLimit=5&srSearchVal=%EA%B9%80%EC%B0%BD%EC%9B%90&srSearchKey=etc_text1 (accessed on 19 December 2023).

- Hong, T.; Hastak, M. Simulation study on construction process of FRP bridge deck panels. Autom. Constr. 2007, 16, 620–631. [Google Scholar] [CrossRef]

- Jeong, S.; Cho, K.; Hyun, C.T. A study on the productivity analysis of deck plate installation work in steel structure construction. J. Korea Inst. Build. Constr. 2010, 10, 73–79. [Google Scholar] [CrossRef][Green Version]

- Kim, T.; Lim, H.; Cho, H.; Kang, K.I. Automated lifting system integrated with construction hoists for table formwork in tall buildings. J. Constr. Eng. Manag. 2014, 140, 04014049. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).