1. Introduction

Mega construction projects (MCPs) refer to “super” projects with mega infrastructure projects as carriers [

1]. The Development Bureau of Hong Kong in China believes that MCPs should contract for work worth more than HKD 1 billion [

2]. Many MCPs, such as the Qinghai–Tibet Railway, the Quebec Bridge, and the Hong Kong–Zhuhai–Macao Bridge, have been built worldwide. They involve significant capital investment and human resources, widely impacting local economic and social development. Due to the complex nature of MCPs, multiple stakeholders, high innovation requirements, and complex technological demands, this leads to mega construction project risks (MCPRs) [

3,

4]. MCPs usually involve multiple links and cooperation with various stakeholders, such as designers, contractors, suppliers, regulators, and investors [

5]. Issues such as poor communication, asymmetric information, and unstable cooperative relationships can arise in this context and increase MCPRs. Technical factors, such as the aging of components, the failure of control systems, and nonlinear effects, can also cause engineering accidents and MCPRs.

Technological innovation cooperation (TIC) plays a vital role in solving MCPRs. Information sharing and knowledge exchange are the foundation of TIC [

6]. Stakeholders improve the project team’s awareness and understanding of MCPRs by jointly researching, discussing, and solving technical challenges and potential risks [

7]. Improving the project’s innovative ability and technical level can reduce MCPRs and costs. It helps to realize the economic and social benefits of MCPs. However, due to the uncertainty around TIC, stakeholders must overcome many obstacles to prevent and solve technological innovation risks (TIRs). TIRs may lead to project failure, delay, cost overruns, and poor sustainability during the TIC process.

TIC in MCPs is a dynamic process, including pre-planning, technological research, engineering design, construction implementation, operation, and maintenance. In this process, all stakeholders work together and support each other to reduce MCPRs. However, scholars have not yet studied the interactive relationship between MCPRs and TIC. In order to better understand and explain it, this study aims to build a conceptual framework. Specifically, the knowledge gaps include: (1) How do MCPRs affect TIC?; (2) How does TIC help to solve MCPRs?; (3) What roles do TIRs play? This study will broaden the behavior, psychology, and management research into MCPs and enrich the knowledge on engineering technology innovation. In addition, the related suggestions will be provided to stakeholders according to the conceptual framework.

The structure of this study is organized as follows: We discuss the related literature review in

Section 2.

Section 3 discusses how MCPRs affect TIC. In

Section 4, this study expounds on how to solve MCPRs through TIC. Finally,

Section 5 constructs the research framework and

Section 6 concludes this study.

2. The Literature Review

2.1. Mega Construction Project Risks

Due to the characteristics of large-scale, high investment, and long construction periods, MCPs face various risks [

8]. These risks are highly uncertain and potentially harmful. In recent years, with the in-depth study of engineering risk management by scholars and the accumulation of engineering practice, the cognition and management of MCPRs have gradually become an essential issue in engineering management [

9,

10].

MCPRs are complex issues involving many disciplines. Many scholars have classified and identified MCPRs. One is the natural environment, such as earthquakes, floods, and typhoons [

11]. Another is related to the characteristics of MCPs, such as the uncertainty of the geological conditions, and safety-related accidents during the construction process [

12]. In addition, funding, policies, and regulations are considered risk factors that cannot be ignored.

A risk assessment is essential to MCPRs. Scholars have put forward a variety of risk assessment methods, such as fuzzy comprehensive assessment, and risk matrix assessment [

13,

14]. Others define a structured framework through a spatial decision support system, based on an innovative model, to carry out an effective risk assessment [

15]. These methods aim to quantify MCPRs and their potential impact through informing decisionmakers. With the rapid development of information technology, big data, and artificial intelligence, such technologies have gradually received attention in the context of MCPRs. Technology improves the accuracy of risk identification and the efficiency of the risk assessment, and provides technical support for real-time monitoring and early warning systems [

16,

17].

Although the current research on MCPRs has made some achievements, there are still many limitations. For example, the research on specific types of engineering risk still needs to be more in-depth, and the accuracy and practicability of risk assessment methods still need to be improved. Future research can explore new risk identification technology, improve risk assessment systems, and develop more effective risk management tools and methods.

2.2. Technological Innovation Cooperation

TIC refers to the process through which innovation stakeholders, such as enterprises, universities, and research institutions, carry out technological innovation by jointly investing resources, knowledge, and capabilities to achieve technological breakthroughs, product innovation, and market expansion [

18,

19]. Such cooperation usually involves a close cooperative relationship, which requires deep integration and collaborative innovation in technology, resources, and talent [

20,

21]. Many forms of technological innovation cooperation exist, including industry–university–research cooperation, enterprise–enterprise cooperation, and enterprise–research institution cooperation [

22,

23,

24]. Based on common goals and interests, stakeholders work together to address technological challenges through complementary advantages and resource sharing.

Generally speaking, TIC is manifested as mutual help, encouragement, and support. In particular, in the process of technological innovation, cooperative behavior brings different degrees of economic, social, and ecological benefits to these units [

25]. Different interest demands lead to conflicts of interest, resulting in different states of cooperative behavior, including: non-cooperation, antagonistic cooperation, simple cooperation, and collaborative cooperation [

26]. According to the theory of planned behavior, the emergence of multi-agent cooperative behavior directly depends on the willingness to cooperate [

27]. The bidding for MCPs needs to go through a strict review and bidding process to ensure technological innovation capability and fundamental social responsibility, and the stakeholders may choose to cooperate after participating in technological innovation.

In this regard, many studies have suggested TIC requires stakeholders with different professional backgrounds to participate in technology research, development, transformation, and industrialization [

28]. The complex relationships among owners, contractors, universities, research institutes, and design units form a technological innovation network. In this network, technology, talent, the economy, and the organization are essential factors worthy of attention [

29]. Owners and contractors extensively gather superior resources and promote the integrated development of technological innovation. They intuitively understand the technical difficulties and provide direct feedback on site. Universities and research institutes are bases for original innovation and agglomeration innovation. They play an essential role in cultivating innovative talent. According to the characteristics of MCPs, stakeholders may set up technological innovation centers and build technological innovation platforms based on engineering planning and development requirements.

To sum up, TIC in MCPs still needs to be deeply explored. Combined with the characteristics of MCPs, this study is helpful to understand the advantages and limitations of TIC and provides guidance for optimizing the design and implementation phases.

2.3. Technological Innovation Risks

Technological innovation is the process of resource integration to achieve the goals of MCPs by tapping into the technological potential [

30]. Intelligent construction and building information modeling technology can promote decision making, construction, and operation of MCPs [

31]. Compared with technological innovation in enterprises, the technological innovation in MCPs pays more attention to ensuring that the construction of engineering projects meets the design requirements.

At the same time, difficulties such as a lack of funds, a shortage of talent, the uneven coordination of interests, and unstable organization mean that the technological innovation within MCPs has an intense ambiguity, resulting in technological innovation activities failing to meet expectations [

32]. The ability to meet expectations may significantly reduce the possibility of technological innovation performance, resulting in the interruption or even failure of innovation projects in MCPs [

7]. Therefore, it is significant to identify the TIRs.

Considering the impact of technological innovation on the success or failure of engineering construction projects, it is necessary to focus on management’s role and the risks in the technological innovation process. In addition, based on the technological innovation process, technological innovation is mainly divided into research and application, without considering the market expansion of the technology. Therefore, the TIRs in MCPs can be roughly divided into three categories: technology research and development (R&D) risk, innovation management risk, and technology application risk.

3. How do MCPRs Affect TIC?

MCPs are faced with various risks during the project lifecycle. In order to manage MCPRs effectively, it is necessary to promote technological innovation and optimize cooperative behavior among the stakeholders. However, how do MCPRs drive technological innovation and positively guide TIC?

3.1. MCPRs Drive Technological Innovation

Risk control is the key to the management of MCPRs [

33]. The core purpose of risk control is to identify the MCPRs faced in process of achieving the project’s objectives. It involves the assessment of various uncertainties that may affect the MCP. When risks are identified, resources are required to be deployed to address them. These resources can be allocated according to risk sharing schemes to ensure maximum benefit and efficiency [

34]. If risks are effectively controlled, technological innovation objectives, such as concerning the quality, safety, and duration of a project, will likely be achieved. MCPRs spawn the demand for technological innovation and lead the research direction. When uncertainty impacts the design scheme or construction technology, relevant staff must assess the MCPRs, make a feasibility study, and optimize technical solutions [

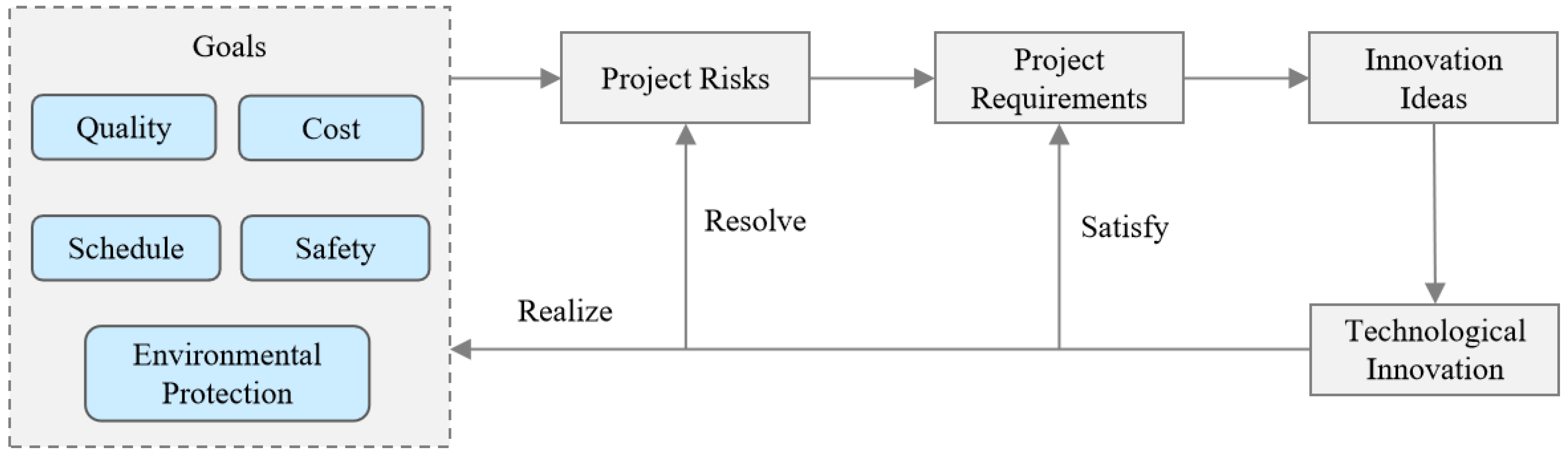

35]. Therefore, this study discusses the goals of MCPs from five perspectives, namely the quality risks, cost risks, schedule risks, safety risks, and environmental protection risks. The process of risk consideration during MCPRs and the role of technological innovation are shown in

Figure 1.

3.1.1. Quality Risks

Quality risks in MCPs refer to the possibility of quality defects involving structural safety and essential functions [

36,

37]. The Qinghai–Tibet Railway, with its complex geographical environment (sensitive ecological environment, complex terrain, harsh climatic conditions, and plateau of frozen soil), encountered great difficulties during the construction of the railways. There are also natural disasters, such as earthquakes, landslides, and mudslides in the region, which may affect the quality of the railway. The construction of the railway involved the building of lots of bridges and tunnels. The stability and safety of these engineering structures are crucial to the quality of the railway. Due to the particularity of the geographical environment, the engineering techniques employed are complicated and require a superb level of technical expertise and rich practical experience. Therefore, quality risks mainly come from the geographical environment and engineering technology challenges. In order to meet these challenges, a series of risk management measures and technical means need to be adopted. Some scholars have proposed that technological innovations, such as establishing precision measurement in the control network and improving the construction mechanization level can solve design, construction, and maintenance puzzles. At the same time, enterprise management informatization modules can be established to check aspects of MCPs and improve project quality.

3.1.2. Cost Risks

Technological innovation plays a vital role in reducing cost risks in MCPs. In order to ensure construction safety and quality control, the construction unit of the Hong Kong–Zhuhai–Macao Bridge adopted intelligent monitoring technology. The technology can monitor the construction site in real time and find potential safety hazards and quality problems. It helps to avoid increased costs due to accidents or quality problems. Through technological innovation, construction units effectively reduce cost risks related to safety and quality. China Railway Construction Corporation Limited lost CNY 4 billion due to excessive cost risks involving the Mecca Light Railway project. These risks can be avoided if the project incorporates technological innovation in line with the project requirements, which can realize cost compression and monitor real-time costs [

38]. The direct economic losses caused by cost risks damages the interests of each participant. Cost risks can be resolved by using technological innovation [

39].

3.1.3. Schedule Risks

In MCPs, schedule risks are common problems [

40]. Various factors, such as project complexity, resource allocation, environmental conditions, and technical difficulties, usually cause them. They can damage the interests of the relevant stakeholders, and it is necessary to resolve schedule risks to guarantee the viability of MCPs. Technological innovation is an effective solution to reduce these risks. The Hong Kong–Zhuhai–Macao Bridge has introduced BIM (building information modeling). The technology can be used to conduct detailed simulations of the entire project before construction, predict possible problems, and formulate solutions in advance. This dramatically reduces the possibility of unexpected situations during the construction phase, thus reducing delays in the construction period. The project team also adopted technology to assemble prefabricated bridge segments. By prefabricating the bridge section in the factory, the site construction time can be greatly shortened, and the impact of weather, the environment, and other factors on the construction schedule can be reduced. Automated and intelligent construction equipment is used, such as intelligent concrete pump trucks and excavators. These devices can work continuously in harsh environments, significantly improving the efficiency of construction and, thus, reducing the schedule risks [

41,

42].

3.1.4. Safety Risks

In recent decades, attention has been paid to the safety risks in MCPs [

3]. Safety-related accidents can have a severe economic impact on society and can even lead to casualties. The physical condition of construction personnel, the selection of construction equipment, the inspection of construction materials, the applicability of construction methods, and the construction environment will affect the safety risks in MCPs. Due to the high safety risks in the Qinghai–Tibet Railway tunnel project, the project team carried out technological innovation by introducing advanced geological forecasting technology, an automated monitoring system, and new tunnel construction methods. Advanced geological forecasting technology can determine the geological conditions ahead of tunnel construction, such as whether there are caves, faults, and other safety hazards. This helps avoid sudden geological disasters during construction, reducing safety risks. The automatic monitoring system can monitor the stability of the surrounding rock in the tunnel construction process in real time, find abnormal situations in a certain timeframe, and take corresponding measures. It avoids collapse accidents caused by the instability of the surrounding rock and further guarantees the safety of construction personnel. The new tunnel construction method improves the stability and durability of the tunnel structure by improving the construction technology and materials. It reduces safety risks due to tunnel structural issues, while also reducing maintenance costs. These examples fully demonstrate the importance of technological innovation in MCPs. In similar projects in the future, more innovative technologies and methods can be introduced to improve the safety, stability, and reliability of projects further [

43,

44].

3.1.5. Environmental Protection Risks

Environmental protection risks include resource loss risks, environmental pollution risks, construction environmental protection risks, and environmental protection management system risks. Due to their enormous scale, MCPs must pay more attention to protecting the ecological environment. During the construction process of the Three Gorges Water Hub Project, low noise and low vibration construction equipment was used to minimize the damage to the surrounding ecology. At the same time, the wastewater generated by the construction was properly treated to ensure that it did not pollute the surrounding environment. Before and during construction, environmental monitoring equipment was installed to monitor various indicators in the surrounding environment in real time, such as air quality, water quality, and biodiversity. Once abnormalities are found, immediate measures are taken to intervene and prevent further deterioration of the environment. After the completion of the construction, ecological restoration, such as vegetation restoration and water purification, will be carried out in the affected area. Through these technical means, the influence of hydropower station construction on the surrounding environment can be reduced, as much as possible. Technological innovation can not only improve the economic and social benefits of the project, but also effectively reduce the negative impact on the environment. In the future, more attention should be paid to assessing and controlling environmental protection risks, and innovative technologies should be actively adopted to achieve the harmonious development of engineering construction and environmental protection.

3.2. The Technological Innovation Goals Guide TIC

The technological innovation goals of MCPs are the general program for technological innovation. Stakeholders will carry out innovation work according to the goals. At the same time, the goals provide a reference for the performance evaluation of the technological innovation and the direction of technological innovation, which is conducive to improving the quality of the technological innovation in MCPs [

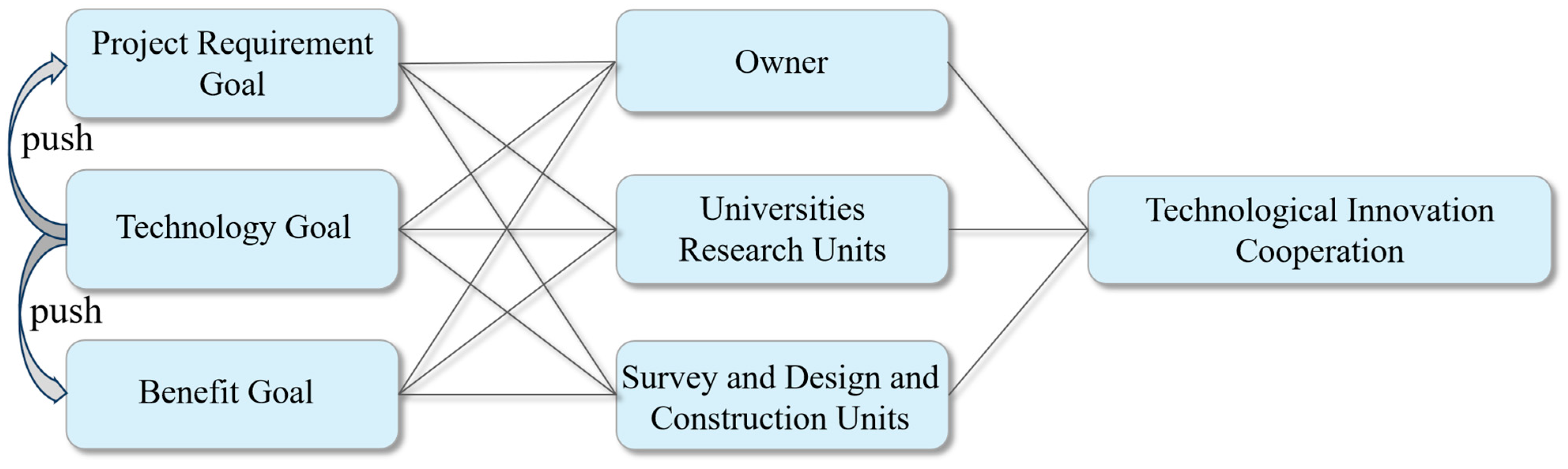

45]. It divides the technological innovation goals of MCPs into project requirement goals, technological goals, and benefit goals. Due to the complexity of MCPs and the uncertainty of technological innovation, stakeholders must cooperate to achieve the technological innovation goals. The relationship is shown in

Figure 2.

The technological innovation in MCPs is typically subject to demand orientation. The original intention of project innovation is to overcome the difficulties encountered in the construction process, such as that seen during the construction of the Hong Kong–Zhuhai–Macao Bridge tunnel on the deep sea floor and the Qinghai–Tibet Railway on the icy plateau [

46]. The miracle, in the history of human architecture, is to overcome many difficulties through technological innovation to meet the needs of project construction. We can only realize the significance of MCPs’ technological innovation by meeting their requirements. In order to meet these goals, participants need to timely feedback the requirements. Universities and research institutes carry out technological research by counting the construction unit requirements. Only by jointly implementing the feedback mechanism and applying the technological innovation results to the construction process can the MCPs be completed.

Realizing technology goals is the key to the success of technological innovation. Technology goals provide working guidelines for the technical activities. The goals require stakeholders to cooperate. The construction unit shall put forward the technical requirements and coordinate to ensure the effective use of resources. The research institutes and universities should actively explore new technologies and solutions, dare to make breakthroughs, and provide theoretical support and practical experience for the technological innovation. The production units must fully cooperate with the technological innovation activities, transform theoretical knowledge into actual products or solutions, and solve problems and challenges encountered in the implementation process. Technical goals can be achieved through the joint efforts and coordinated innovation of construction units, research institutes, universities, and production units. Stakeholders should clarify their respective roles and responsibilities, give full play to their advantages, strengthen communication and collaboration, and jointly address the problems and challenges encountered during the application of technological innovation. In addition, technological innovation also needs to pay attention to market demands and economic benefits, as only when we meet market demands and create economic benefits can technological innovation be widely used and sustainable development achieved.

Due to the different roles, responsibilities, and resources of stakeholders in MCPs, their interest-related objectives will be different. Construction units usually focus on the project’s overall and economic benefits. They hope to improve quality and efficiency through technological innovation and reduce costs and risks to obtain more profits. Research institutes and universities pay attention to the output of scientific research results and the promotion of their academic reputation. They hope that by participating in the technological innovation in MCPs, they can accumulate practical experience, promote scientific research progress, and cultivate more talent with innovative spirit and practical ability. Production units focus on technological innovation to improve products or services and enhance market competitiveness. They hope to improve the production process, improve product quality and performance, and reduce costs through technological innovation to obtain more market share and profits. Although there are differences in the interests of the participating units, mutual benefit and win–win results can be achieved through practical cooperation and coordination. Through full communication and consultation, stakeholders can clarify their respective needs and expectations, find common ground and a space for cooperation, and jointly promote the development and application of technological innovation. At the same time, the government also encourages and promotes the cooperation and collaborative innovation of the participating units through policy guidance, financial support, and other measures to achieve the overall benefits from technology innovation.

4. How to Solve MCPRs through TIC?

4.1. Negative Feedback Regulation of TIRs

Technological innovation in MCPs involves complex engineering. The resource input in MCPs promotes TIC, but brings with it TIRs. Under certain resource constraints, technological innovation is the key to achieving innovative benefits in MCPs [

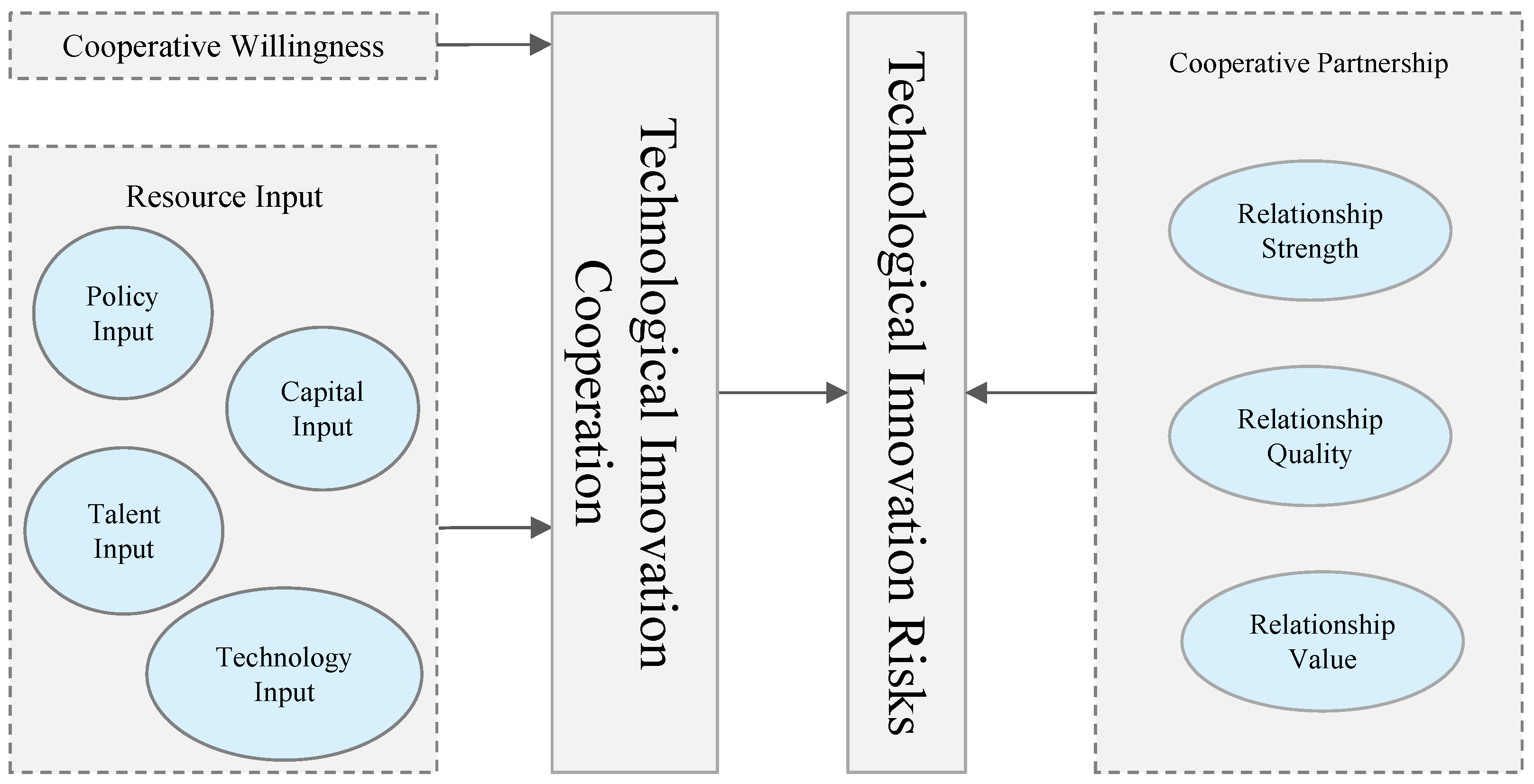

47]. The fundraising ability, technical strength, management level, credit rating, and performance ability of technological innovation entities affect the progress and quality of MCPs, involving many risks. The resolution of these risks depends on the resource input (i.e., policy input, capital input, talent input, and technology input) in technological innovation. At the same time, cooperative willingness has an essential influence on TIC. Suppose the stakeholders lack the cooperative willingness, or do not clearly understand the goal and significance of cooperation. In that case, it will affect the process and results of the technological innovation. The establishment and development of TIC will also be affected by various factors. For example, misaligned goals, asymmetric information, and unequal resource inputs, may undermine cooperative willingness. In addition, the cooperative relationship’s strength, quality, and value impact the TIRs. When involved in technological innovation, stakeholders should attach importance to establishing and maintaining a cooperative relationship and reduce the uncertainty of technological innovation by strengthening cooperative relationships, improving the quality of the cooperation, and rationally distributing the benefits. The negative feedback regulation of TIRs is shown in

Figure 3.

Policy resources are an essential means to guide TIC. The government can guarantee TIC and promote stakeholders’ enthusiasm to cooperate by formulating relevant policies. If the policy is not properly formulated or implemented, it may lead to distortion or inefficiency of TIC. Capital resources are essential for TIC. Funds can be used to support research and development, testing, promotion, and other links, to provide the necessary material foundation for TIC. The risk from capital concerns liquidity problems and high financing costs. Talent resources are the core element of TIC. The input of talent resources can provide intellectual support for TIC. On the one hand, the flow of talent may lead to technology leaks or intellectual property disputes. On the other hand, the unreasonable allocation of talent resources or imperfect incentive mechanisms may lead to brain drain. Technology resources are the foundation of TIC. The input from technology resources can provide the necessary technical support for TIC. However, the acquisition of technology resources may require a high price to be paid, and the necessary transformation and application are uncertain, resulting in the outcome that the technology-related TIC cannot reach the expected goal.

Cooperative willingness usually refers to the motivation of stakeholders to engage in TIC and their willingness to put in much effort to cooperate [

48]. In recent years, the positive effect of cooperative willingness has been proven in many fields, such as sociology and psychology. To some extent, the stronger the cooperative willingness, the more effort stakeholders will make in MCPs. Cooperative willingness directly determines TIC.

When stakeholders show positive cooperative willingness, such as efforts to actively increase the frequency of TIC, striving to extend the duration of TIC, and fully implementing the tasks necessary for TIC, it means that stakeholders have a certain level of risk perception, risk judgment, and risk prevention capabilities related to technological innovation in MCPs. From the perspective of the entire process, a strong cooperative willingness is beneficial for stakeholders to identify and eliminate potential risks in advance and can reduce the probability of and losses from TIRs. In addition, after TIRs occur, stakeholders with strong cooperative willingness can take timely and correct actions to optimize the technological innovation content in MCPs.

TIC by stakeholders requires practical cooperation, active investment, and mutual collaboration to achieve the established goals and tasks [

49]. The strength, quality, and value of cooperative relationships are essential indicators of TIC and have a significant inhibitory effect on TIRs.

A high level of intensity of stakeholders’ cooperative relationships implies multiple instances of repeated collaboration activities and close connections [

50]. The higher the level of interaction among stakeholders, the easier it is to develop a shared vision to pursue future goals, reducing conflicts arising from knowledge disparities and information asymmetry, and promoting TIC.

The quality of diversified stakeholder relationships can increase trust in the technical abilities and characters involved, and a high level of trust can also help create a good atmosphere and cooperative willingness [

51]. In the context of technological innovation, the quality of cooperative relationships can be explained by factors such as satisfaction with existing cooperative relationships, fulfillment of contractual cooperation relationships, and trust protection in interpersonal cooperative relationships to enhance trust when facing risks.

The value of cooperative relationships involves a recognition of TIC, which includes the belief that the relationships’ stability will not be disrupted. The main body of technological innovation in MCPs is the sustainable growth organization, and growth requires the creation of high value through TIC among the central subjects. It reduces environmental regulatory pressure for technological innovation, making partners willing to establish longer, more stable interactions, and reduces potential risks [

52].

4.2. Positive Feedback Regulation of TIRs on MCPRs

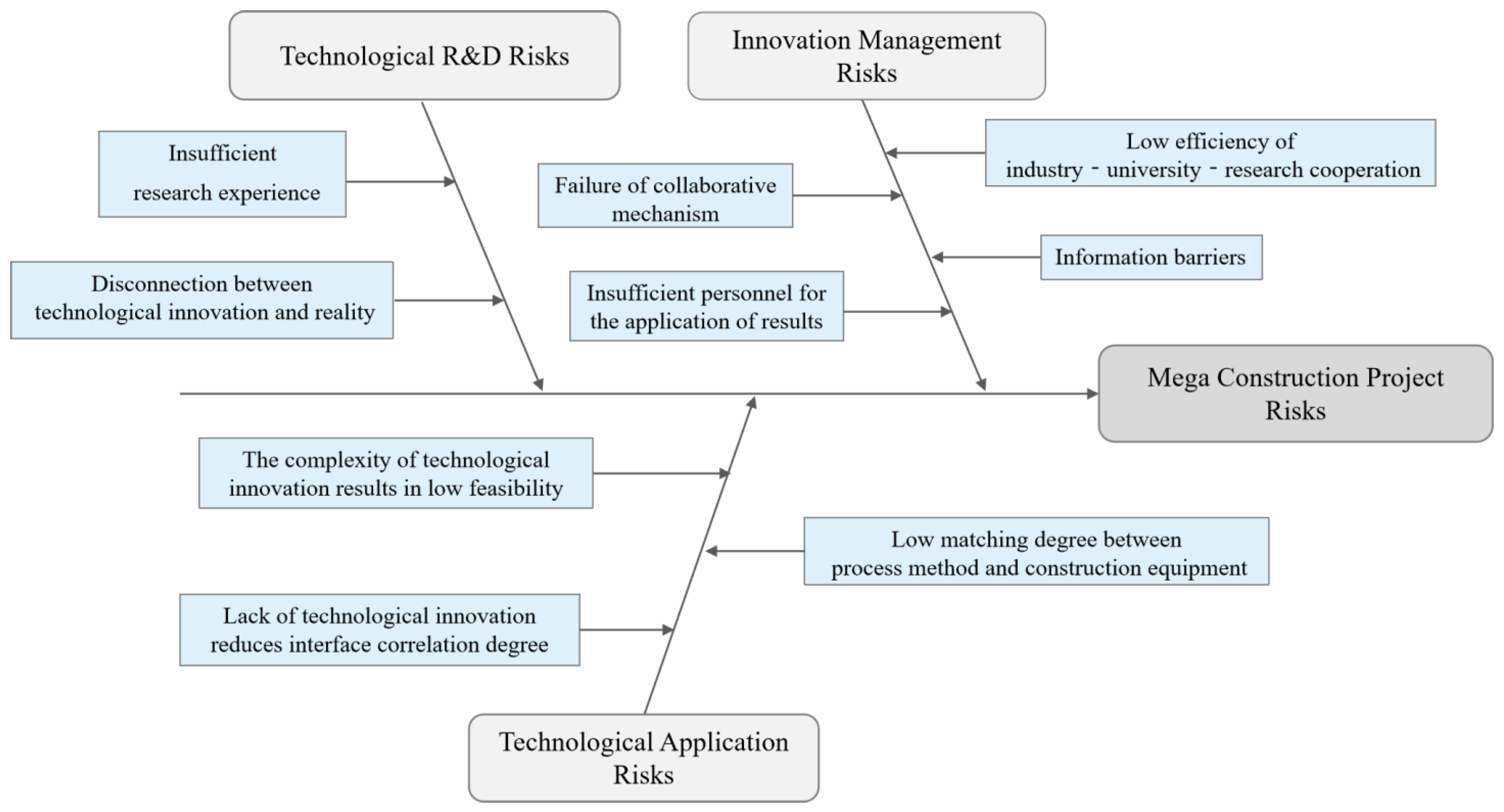

From the perspective of overall process management, technological innovation runs through multiple stages of decision making, construction, and operation. TIRs always exist in the process of technological innovation, causing MCPs to generate many risks (i.e., technological R&D risks, innovation management risks, and technological application risks) throughout their entire lifecycle. Therefore, the positive feedback process between TIRs and MCPRs is shown in

Figure 4.

TIRs may present many decision-making risks for MCPs, manifested as insufficient research and development experience in major scientific and technological projects, and a disconnect between technological innovation and reality. In response to engineering needs, new equipment for MCPs is usually recognized as the first mega technical equipment requirement. Due to the lack of market performance, this type of equipment faces the risk of failure in applying new technologies, leading to significant errors when selecting construction plans.

The confidentiality of on-site data and research information for MCPs poses challenges to technological innovation. The ambiguity and uncertainty around the stakeholders’ understanding of the on-site environment need resources. Technological innovation has led to a disconnect between technology and the actual situation faced by MCPs [

53]. The mismatch between information and TIC in MCPs leads to the irrationality of technological innovation, which can easily lead to decision-making errors.

TIRs involve multiple subjects and specialties, which brings many problems to the operation of MCPs, such as the failure of collaborative mechanisms, low efficiency of industry–university–research cooperation, insufficient talent allocation for application achievement, and information barriers. The collaborative mechanism formed among stakeholders in MCPs will be affected by TIRs and will lose effectiveness, making it difficult for MCPs to leverage the technological innovation advantages. It will somewhat hinder stakeholders from achieving resource integration and reduce the efficiency of industry–university–research cooperation. Considering the complex workload of MCPs and the insufficient talent for applying technological innovation achievements, it will harm the entire project operation process. In addition, information barriers are also a risk that urgently needs to be addressed in the operational process. Otherwise, it may also bring about the possibility of MCP failure.

The resolution of MCPRs cannot be separated from the close integration of technological innovation and engineering practice. TIRs may present problems such as a difficulty in applying new technologies, implementing new processes, and operating new equipment, resulting in low feasibility of technological innovation achievements. The matching degree between technology, construction methods, and construction equipment is low, and the correlation between technological innovation achievements and interfaces is insufficient, resulting in construction risks.

The technological innovation in MCPs largely stems from the practical problems encountered during the construction stage, which is carried out from a practical perspective. New equipment innovation originates from equipment development and design documents, which are biased towards technological innovation from a theoretical perspective. At present, practical demands come first, and theoretical R&D comes second, resulting in low matching between processes, methods, and construction equipment. If the construction robot is still in the R&D stage, its on-site application during the construction process is limited [

54]. We can optimize processes and construction methods and improve construction equipment by combining theory with practical innovation. Moreover, there may need to be more technical disclosure in applying technological innovation achievements. Due to the schedule requirements of MCPs, construction personnel will be unable to operate proficiently. The uncertainty in applying these innovative achievements is considered a newly emerging risk that hinders the construction in MCPs.

Throughout the entire process of technological innovation in MCPs, it is necessary to unify the organization, management, systems, platforms, and structures. The application of technological innovation achievements will generate much data that needs to be standardized through the platform to achieve practical benefits [

55]. If the interface correlation of technological innovation achievements is high, data are more accessible to convert into information, which may bring risks.

4.3. The Mediating Effect of Cooperative Performance

Cooperation performance represents the total number of achievements that stakeholders can achieve in the future [

56]. TIC positively affects cooperative performance. Stakeholders integrate internal and external resources to achieve a high level of cooperation performance through technological innovation. Resource integration is affected by the unique geographical conditions and complex terrain of MCPs. If the location is too concentrated, it will lead to fatigue and depolarization among stakeholders, leading to a severe decline in interactive learning and innovation efficiency. If the distance is too far, it will hinder the effectiveness of TIC [

57]. Cognitive proximity, technological proximity, relational proximity, and institutional proximity significantly reduce the communication costs and improve the cooperation performance [

58]. In addition, cooperative network relationships play an essential role in achieving the stable improvement of the performance [

59]. As the maturity of the technological innovation increases, the enthusiasm for TIC among stakeholders is fully mobilized. These beneficial relationships help to generate excellent cooperation performance [

60].

Cooperation performance has a positive effect on resolving MCPRs [

61]. In general, the higher the cooperation performance, the lower the MCPRs, and vice versa. On the one hand, high cooperation performance reduces the uncertainty of MCPRs [

62]. A high level of cooperation performance means that stakeholders have a similar understanding of the cultural customs, religious beliefs, and policy planning. When there is a positive history of interactions among stakeholders, the expectation of TIC is more accessible, thereby reducing the TIRs. On the other hand, a high level of cooperation performance enhances the ability to prevent MCPRs [

63]. The prevention of MCPRs is a complex, cumbersome, and continuous process. It requires accurate evaluation of the stakeholder cooperation performance and dynamic tracking of future development trends. The generation of a high level of cooperation performance can curb opportunistic behavior through risk prevention mechanisms.

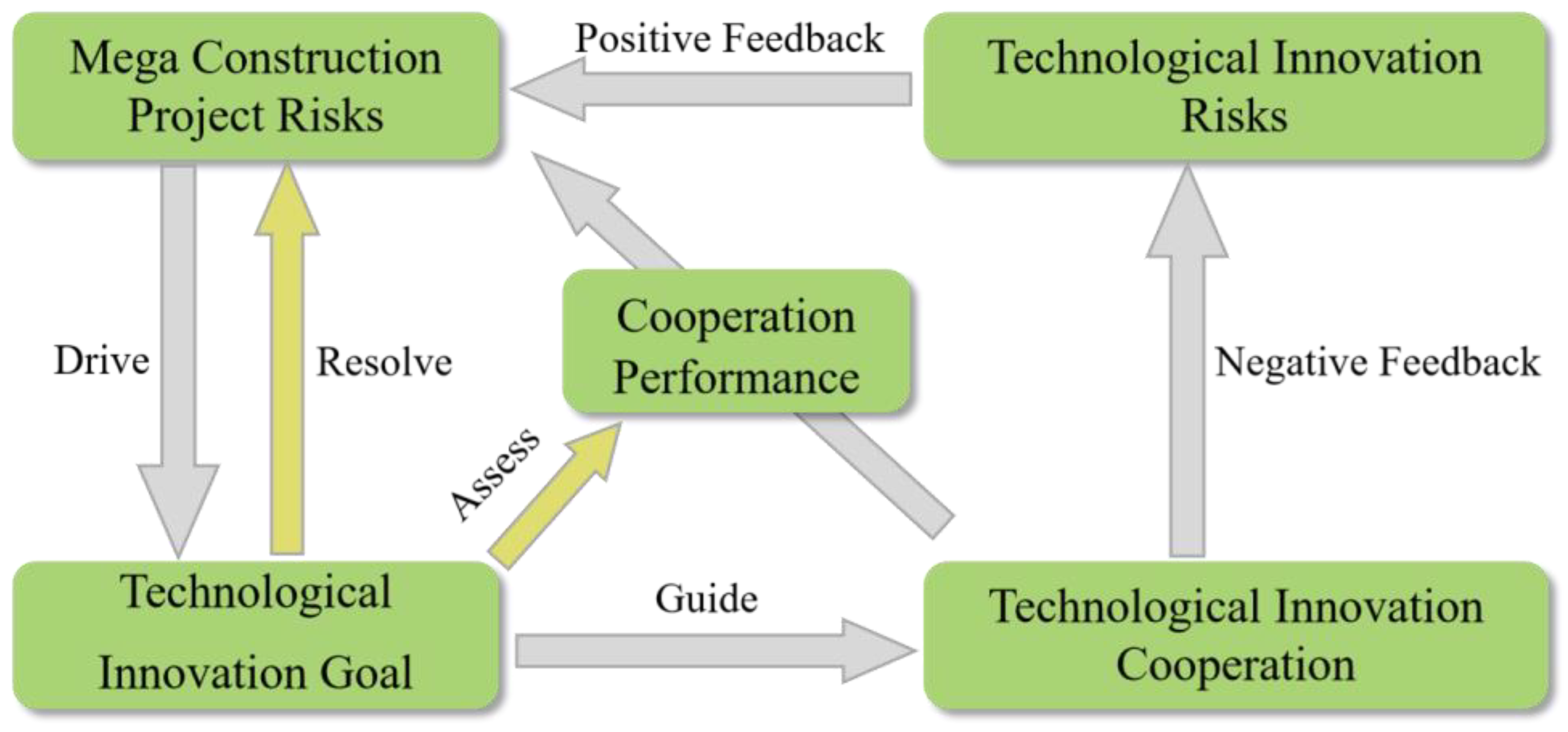

5. Conceptual Framework

In MCPs, stakeholders should emphasize cooperation, actively seek partners, jointly promote technological innovation, and achieve mutual benefits and win–win results. Considering technological innovation goals and TIRs, we propose the conceptual framework on the relationship between MCPRs and TIC, as shown in

Figure 5. Guided by the engineering requirements, MCP quality, cost, schedule, safety, and environmental protection, risks drive stakeholders to carry out TIC. Influenced by the complexity of MCPs, technological innovation goals guide TIC. Technological innovation is inherently uncertain and risky. Even under cooperative conditions, avoiding the risks of technological failure and market changes are difficult. The differences between cooperative stakeholders at the technical level, resource input, and interest demands may lead to coordination difficulties and interest conflicts during cooperation, thus leading to risks. Uncertainties and changes in the external environment may also pose risks to TIC. These risks further affect MCPRs. TIC also affects MCPRs through cooperative performance.

Due to various risks and challenges, stakeholders are encouraged to actively seek technological innovation to solve problems in engineering and reduce MCPRs. Technological innovation can improve construction efficiency, safety, and the reliability of MCPs. The driving force of technological innovation comes from the challenge of MCPRs and the demand to cope with them, which is an essential driving force for the continuous development of MCPs. For example, introducing intelligent construction equipment can improve construction efficiency and reduce costs. Project management efficiency and quality can be improved by adopting a new project management mode and introducing an information management system. By improving and optimizing the process flow, the quality of the project can be improved, and the risk in the construction process can be reduced. Introducing preventive maintenance concepts and technologies (i.e., condition monitoring and fault diagnosis techniques) into MCPs can identify potential problems in advance and reduce MCPRs.

In MCPs, technological innovation goals are the core elements guiding TIC. These goals define the direction and focus of cooperation and provide a common value pursuit and measurement standard for stakeholders. Through the guiding role of the goals, stakeholders can better integrate resources, give full play to their advantages, concentrate on overcoming critical technical problems, and achieve breakthroughs in technological innovation. At the same time, clear objectives also reduce communication barriers and conflicts of interest that impact cooperation. Therefore, we should always adhere to goal orientation to ensure a smooth cooperation process and to achieve innovative results.

TIC is a double-edged sword, which may bring both technological innovation breakthroughs and TIRs. When TIC generates risks, these risks will be further transmitted and amplified and will profoundly impact MCPs. Imagine that complex problems or obstacles are encountered during the cooperation. In that case, it may delay the project’s progress and even interrupt or cancel the entire technological innovation plan. It means that the resources invested in the early stage may be lost and may trigger a chain reaction, affecting the progress and efficiency of the entire project. TIRs may also lead to project quality problems. During technological innovation, if the risks cannot be effectively controlled, it may lead to developing new technologies or new products with defects or deficiencies. It may cause safety issues, social responsibility issues, severe damage to the reputation of those involved, and may jeopardize long-term development.

Cooperation performance plays a mediating role between TIC and MCPRs. If the cooperation efficiency is high and the results are remarkable, the technological innovation is more likely to succeed, thus reducing MCPRs. On the contrary, if the cooperation performance is poor, it may lead to the failure of technological innovation or an effect that is not ideal. Good cooperation performance means that all parties have good coordination and high efficiency, which helps speed up the project’s progress and reduces costs. If TIC can produce technological achievements with social value, such as improving resource utilization efficiency and reducing environmental pollution, it will help reduce the social and environmental risks to the project.

6. Conclusions

Based on a literature review of existing studies, the conceptual framework facilitates an understanding of MCPRs and TIC through an analytical approach. The framework emphasizes the driving role of MCPRs for technological innovation and the guiding role of technological innovation goals for TIC. However, TIC is not always successful in resolving TIRs and can sometimes damage TIRs. Furthermore, TIRs have a positive effect on MCPRs, which increases the risk level of the project. This study improves and develops the theoretical system of risk management and TIC in MCPs and reveals the internal relationships and mechanisms. It deepens the understanding of MCPRs and TIC and provides a valuable reference for theoretical research on MCPs.

In practice, the implications of this study are significant. First of all, project managers and technological innovation teams can better identify, evaluate, and manage risks to improve the project success rate and efficiency. Secondly, the research points out that MCPRs promote technological innovation, and technological innovation goals guide TIC, which provides new ideas and methods for engineering practice. In addition, the research also points out that TIC has a negative impact on solving TIRs, and TIRs have a positive impact on MCPRs. This discovery reminds us that we should pay attention to establishing and improving cooperation mechanisms in engineering practice and reduce MCPRs and TIRs through reasonable cooperation modes and management means. In order to better understand this complex relationship, cooperation performance is introduced as a mediating variable. The level of cooperation performance will directly affect the relationship between TIC and MCPRs. Improving cooperation performance helps reduce engineering risk and vice versa. It provides a new perspective and method for risk management.

After explaining the results, some limitations should be noted.

On the one hand, this study points out that TIC is affected by many factors. It is worthy of in-depth analysis on how to overcome the hindrance factors and maximize the expected benefits. On the other hand, there have been many static and qualitative analyses on TIC, and dynamic and quantitative evaluation is essential. Evolutionary game theory is a standard dynamic research method for solving cooperation problems [

64]. In the future, evolutionary game analysis will help explore the sensitivity of stakeholders to various factors through simulation.