Evaluating the Effects of RA on the Rheological Properties and Aging Susceptibility of RAM Asphalt

Abstract

:1. Introduction

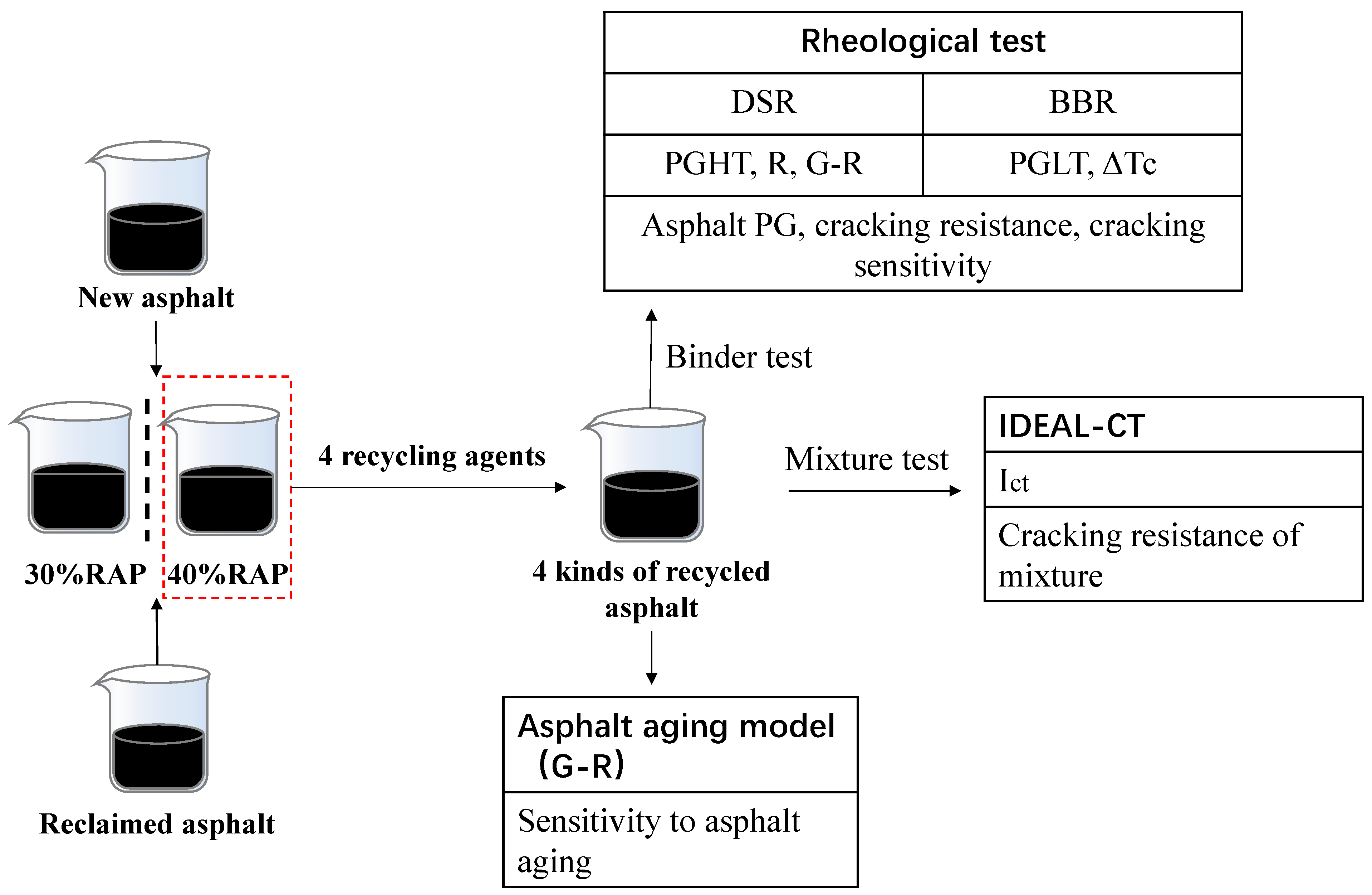

2. Materials and Method

2.1. Materials

2.2. Preparation

2.2.1. Aged Asphalt Recovery

2.2.2. Aging of Asphalt

2.3. Laboratory Testing of Rheological Properties of Recycled Asphalt

2.3.1. DSR Experiments

2.3.2. BBR Experiments

2.4. Experiments with Asphalt Mixtures

2.5. The Asphalt Aging Model

3. Results and Discussion

3.1. DSR Results

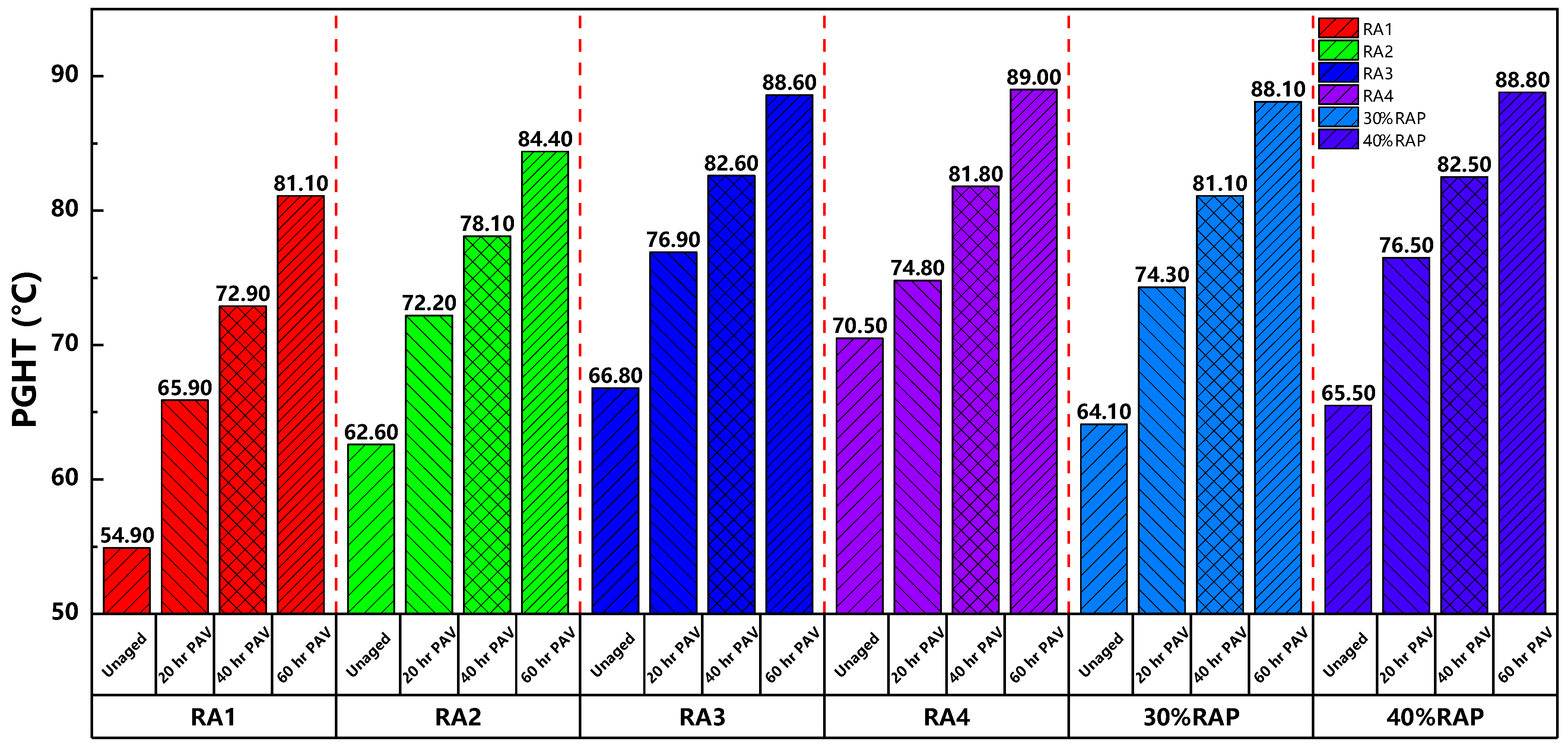

3.1.1. PGHT

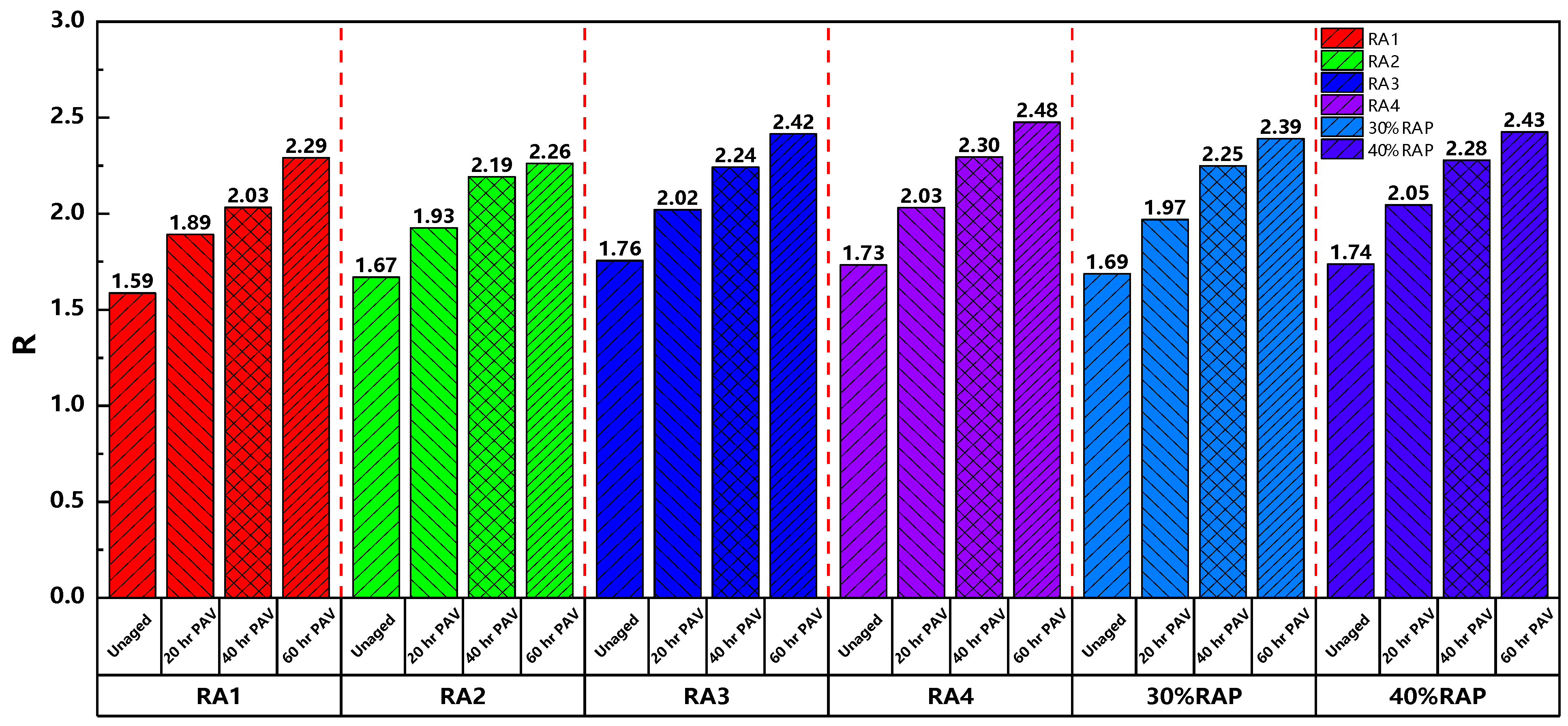

3.1.2. R Value

3.1.3. G − R

3.2. BBR Results

3.2.1. PGLT Value

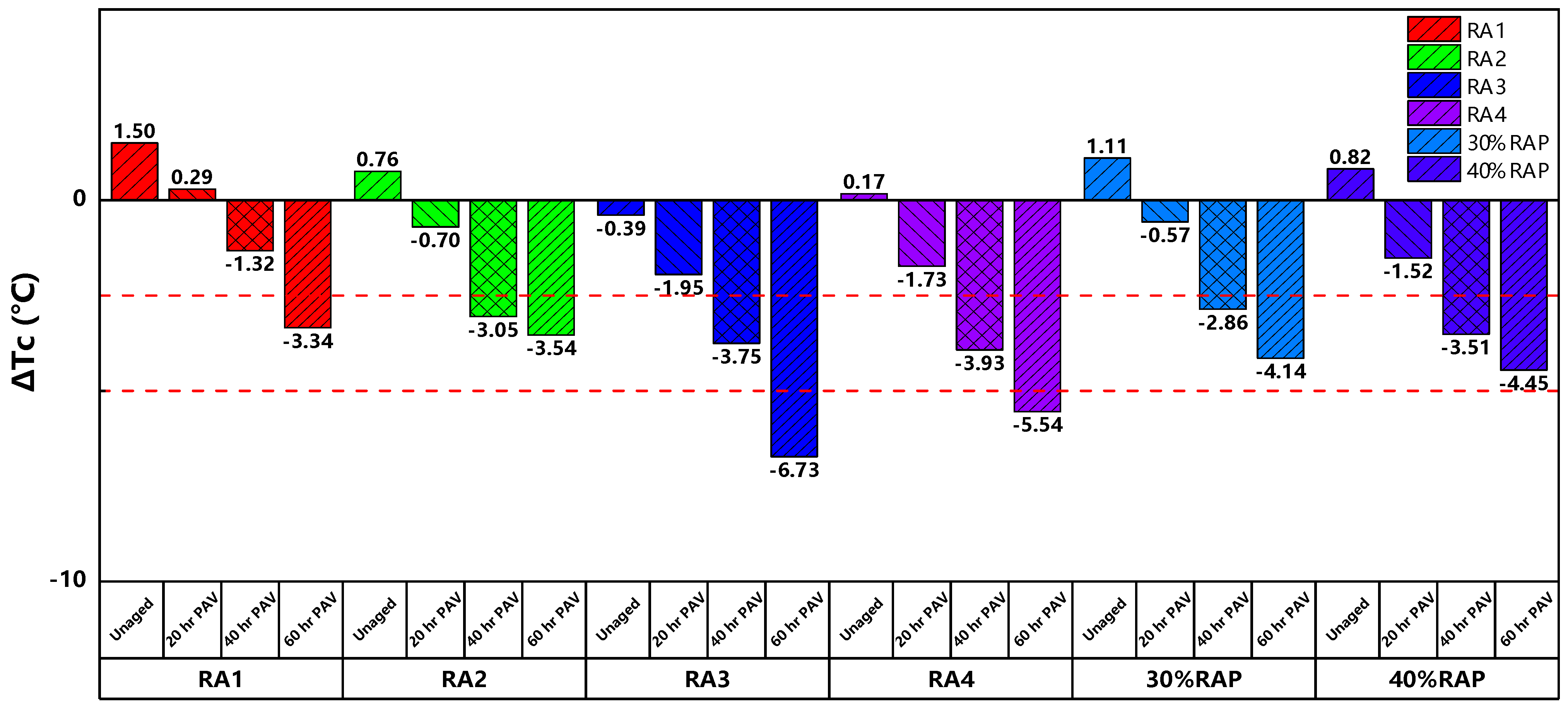

3.2.2. ΔTc

3.3. Mixture Test Results

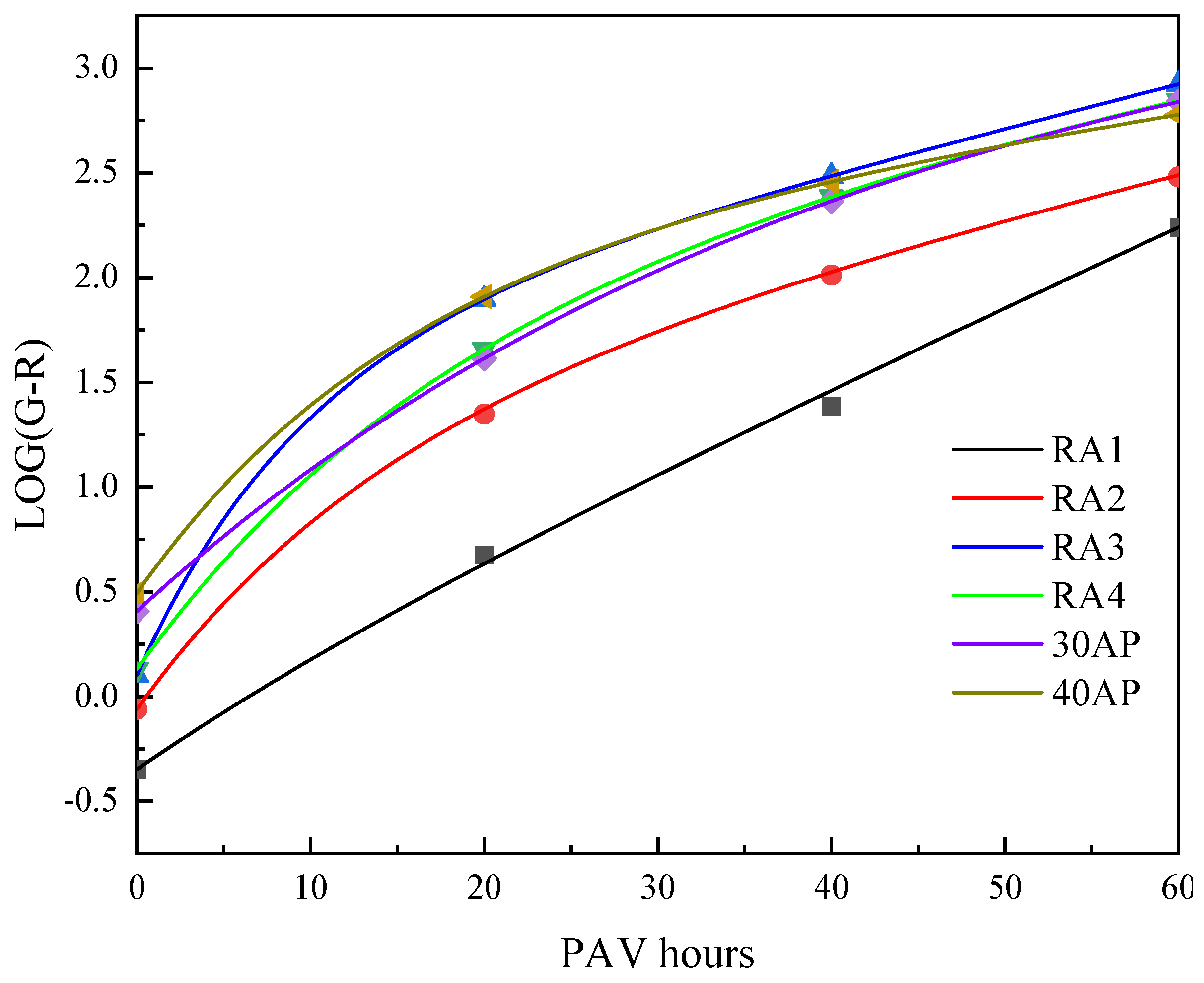

3.4. Aging Model Result

4. Conclusions

- (1)

- DSR results indicate that asphalt performance levels increase with aging time. RA1 and RA2 improved the recycled asphalt’s high-temperature performance, while RA3 and RA4 had a lesser effect on the reclaimed asphalt. The R value increased as the aging time of asphalt increased. The R values of the six asphalt samples were similar. The R value of RA1 was the lowest, indicating that the recycled asphalt with RA1 had the lowest cracking sensitivity. The G − R increased with the asphalt’s aging time. The modification effect of RA1 was the best, and the G − R value still did not reach the cracking warning value of asphalt after aging for 60 h. The modification effect of RA2 ranked second, and the addition of R3 and R4 had a detrimental impact on the anti-cracking performance.

- (2)

- Based on the experimental results of the BBR test, the recycled asphalt’s PGLT continued to increase as the aging time increased. All four RAs made the PGHT lower, and RA1 obtained the lowest PGLT. Test results for ΔTc showed that the ΔTc continued to be reduced as the aging time increased. RA1 and RA2 improved the asphalt cracking resistance the most. Recycled asphalt with the addition of RA1 did not reach the crack warning limit for ΔTc after aging for 40 h. RA3 and RA4 improved the cracking resistance of unaged recycled asphalt. Nevertheless, as the aging time increased, the cracking resistance of recycled asphalt with RA3 and RA4 was worse than that noted for 40% RAP.

- (3)

- The CT experimental results showed that RA1 and RA2 significantly increase the anti-cracking index Ict of asphalt mixtures. Its value increased approximately two-fold compared with that of 40% RAP recycled asphalt, and the addition of RA3 and RA4 had minimal influence on the crack-resistance index.

- (4)

- The recycled asphalt’s ability to resist short-term and long-term aging was better analyzed using an aging model. Analyzing the fitted parameters, it was found that RA1 had the best capability for short-term aging resistance, and RA3 had the worst ability to resist short-term aging. However, the ability of recycled asphalt with the addition of RA to resist long-term aging was worse than that noted for 30% RAP and 40% RAP. Among them, RA1 had the least resistance to long-term aging. The recycled asphalt with RA1 had the lowest G − R after 60 h of aging. However, according to the predicted trend, the G − R value of recycled asphalt with the addition of RA1 exceeded that of the other five asphalt samples as the aging time increased. This finding indicated that the crack resistance of recycled asphalt with the addition of RA1 would worsen after a longer aging time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Zhou, Z.; Gu, X.; Sun, L.; Wang, C. Laboratory evaluation of the performance of reclaimed asphalt mixed with composite crumb rubber-modified asphalt: Reconciling relatively high content of RAP and virgin asphalt. Int. J. Pavement Eng. 2023, 24, 2217320. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, X.; Cui, B.; Hu, D. Mechanism and Performance of Graphene Modified Asphalt: An Experimental Approach Combined with Molecular Dynamic Simulations. Case Stud. Constr. Mat. 2022, 18, e01749. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Z.; Sun, L.; Li, Z. Analysis of the viscosity and self-healing performance of warm-mix recycled asphalt: A method combining molecular dynamics simulations and laboratory tests. Case Stud. Constr. Mater. 2023, 19, e02593. [Google Scholar] [CrossRef]

- Arambula-Mercado, E.; Chavarro-Munoz, S.J.; Hu, S.; Epps, J.A.; Park, E.S.; Epps Martin, A. High Reclaimed Asphalt Pavement (RAP) Asphalt Mixes for Low Volume Roads; Texas A&M Transportation Institute: Bryan, TX, USA, 2018. [Google Scholar]

- Liu, Z.; Yang, Q.; Gu, X. Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar. Remote Sens. 2023, 15, 4620. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H.; Li, S.; Dong, Q. Permanent Deformation Monitoring and Remaining Life Prediction of Asphalt Pavement Combining Full-Scale Accelerated Pavement Testing and FEM. Struct. Control Health Monit. 2023, 2023, 6932621. [Google Scholar] [CrossRef]

- Daryaee, D.; Ameri, M.; Mansourkhaki, A. Utilizing of waste polymer modified bitumen in combination with rejuvenator in high reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 235, 117516. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Ameri, M.; Mirzaiyan, D.; Amini, A. Rutting resistance and fatigue behavior of gilsonite-modified asphalt binders. J. Mater. Civ. Eng. 2018, 30, 04018292. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H. Rutting prediction of asphalt pavement with semi-rigid base: Numerical modeling on laboratory to accelerated pavement testing. Constr. Build. Mater. 2023, 375, 130903. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Rea, R.; Reinke, G.; Haghshenas, D.F. Chemical characterization of recycling agents. J. Mater. Civ. Eng. 2020, 32, 06020005. [Google Scholar] [CrossRef]

- Sun, L.; Wen, Y.; Liu, Q.; Li, D.; Lyu, L.; Pei, J.; Zhang, J.; Li, R. A laboratory investigation into the effect of waste non-tire rubber particles on the performance properties of terminal blend rubberized asphalt binders. Constr. Build. Mater. 2021, 313, 125409. [Google Scholar] [CrossRef]

- Shen, J.; Ohne, Y. Determining rejuvenator content for recycling reclaimed asphalt pavement by SHRP binder specifications. Int. J. Pavement Eng. 2002, 3, 261–268. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% reclaimed Asphalt pavement mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Li, J.; Ni, F.; Huang, Y.; Gao, L. New additive for use in hot in-place recycling to improve performance of reclaimed asphalt pavement mix. Transp. Res. Rec. 2014, 2445, 39–46. [Google Scholar] [CrossRef]

- Zhang, R.; Dave, E.V.; Sias, J.E.; Tabatabaee, H.A.; Sylvester, T.; Wang, Z. Evaluation of the state of practice asphalt binder and mixture tests for assessing the compatibility of complex asphalt materials. Road Mater. Pavement Des. 2023, 24, 451–470. [Google Scholar] [CrossRef]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E.; Daniel, J.S.; Salari, S. Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.; Dave, E.; Hanz, A.; Reinke, G.; Wang, Z. Comprehensive Laboratory Evaluation of Recycling Agent Treated Plant-Produced Asphalt Mixtures. Transp. Res. Rec. 2022, 2676, 620–634. [Google Scholar] [CrossRef]

- Cao, W.; Barghabany, P.; Mohammad, L.; Cooper III, S.B.; Balamurugan, S. Chemical and rheological evaluation of asphalts incorporating RAP/RAS binders and warm-mix technologies in relation to crack resistance. Constr. Build. Mater. 2019, 198, 256–268. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, H.; Guo, H.; Zhou, M.; Jiandong, H. Development of a prior model to predict the cracking performance of asphalt mixture in general for asphalt material selection and mix design. Int. J. Pavement Eng. 2023, 24, 2251080. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, Q. Permanent Deformation Evaluation and Instability Prediction of Semi-rigid Pavement Structure Using Accelerated Pavement Testing and Finite Element Method. J. Test. Eval. 2024, 52. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X. Performance Evaluation of Full-scale Accelerated Pavement using NDT and Laboratory Tests: A case study in Jiangsu, China. Case Stud. Constr. Mat. 2023, 18, e02083. [Google Scholar] [CrossRef]

- Behnia, B.; Ahmed, S.; Dave, E.V.; Buttlar, W.G. Fracture Characterization of Asphalt Mixtures with Reclaimed Asphalt. Int. J. Pavement Res. Technol. 2010, 3, 72–78. [Google Scholar]

- Sun, L.; Gu, X.; Hu, D.; Zhou, Z.; Wang, G. Anti-aging mechanism and rheological properties of lignin, quercetin, and gallic acid as antioxidants in asphalt. Constr. Build. Mater. 2023, 369, 130560. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M.O.; Williams, R.C.; Clyne, T.R. Effect of reclaimed asphalt pavement (proportion and type) and binder grade on asphalt mixtures. Transp. Res. Rec. 2008, 2051, 90–97. [Google Scholar] [CrossRef]

- ASTM D2172; Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM D1856; Standard Test Method for Recovery of Asphalt from Solution by Abson Method. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2012.

- Liu, Z.; Sun, L.; Gu, X.; Wang, X.; Dong, Q.; Zhou, Z.; Tang, J. Characteristics, mechanisms, and environmental LCA of WMA containing sasobit: An analysis perspective combing viscosity-temperature regression and interface bonding strength. J. Clean. Prod. 2023, 391, 136255. [Google Scholar] [CrossRef]

- Rowe, G.M.; Sharrock, M. Alternate shift factor relationship for describing temperature dependency of viscoelastic behavior of asphalt materials. Transp. Res. Rec. 2011, 2207, 125–135. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.E.; Dave, E.V. Using mix design information for modelling of fundamental viscoelasticity of asphalt mixtures. Constr. Build. Mater. 2022, 329, 127029. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.Y.; Ren, H.; Wang, X.; Dong, Q. Three-dimensional finite element analysis for structural parameters of asphalt pavement: A combined laboratory and field accelerated testing approach. Case Stud. Constr. Mat. 2022, 17, e01221. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.E.; Dave, E.V. Comparison and correlation of asphalt binder and mixture cracking parameters incorporating the aging effect. Constr. Build. Mater. 2021, 301, 124075. [Google Scholar] [CrossRef]

- ASTM D6648; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). ASTM International: West Conshohocken, PA, USA, 2018.

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–664. [Google Scholar]

- ASTM D8225-2019; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM International: West Conshohocken, PA, USA, 2019.

- Zhang, R.; Sias, J.E.; Dave, E.V. Development of a rheology-based mixture aging model for asphalt material cracking performance evaluation. Mater. Struct. 2021, 54, 150. [Google Scholar] [CrossRef]

- Petersen, J.C.; Harnsberger, P.M. Asphalt aging: Dual oxidation mechanism and its interrelationships with asphalt composition and oxidative age hardening. Transp. Res. Rec. 1998, 1638, 47–55. [Google Scholar] [CrossRef]

- Petersen, J.; Harnsberger, P.; Robertson, R. Factors affecting the kinetics and mechanisms of asphalt oxidation and the relative effects of oxidation products on age hardening. Prepr. Pap. Am. Chem. Soc. Div. Fuel Chem. 1996, 41, 212. [Google Scholar]

| PGLT | Unaged | 20 h PAV | 40 h PAV | 60 h PAV |

|---|---|---|---|---|

| RA1 | −38.4 | −33.8 | −30.2 | −26.1 |

| RA2 | −33.7 | −28.3 | −26.0 | −23.7 |

| RA3 | −30.5 | −25.8 | −22.9 | −19.2 |

| RA4 | −33.2 | −28.4 | −24.3 | −21.5 |

| 30% RAP | −31.5 | −28.1 | −24.5 | −21.5 |

| 40% RAP | −31.6 | −26.6 | −24.0 | −22.1 |

| G − R | RA1 | RA2 | RA3 | RA4 | 30% RAP | 40% RAP |

|---|---|---|---|---|---|---|

| RS | 0.347 | 0.060 | 0.102 | 0.130 | 0.407 | 0.493 |

| K | 0.316 | 1.367 | 1.571 | 1.795 | 2.962 | 1.596 |

| Ra | 0.060 | 0.067 | 0.105 | 0.055 | 0.025 | 0.067 |

| Rb | 0.038 | 0.020 | 0.021 | 0.016 | 0.002 | 0.012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Liu, Z.; Wang, R.; Sun, L.; Zhang, R. Evaluating the Effects of RA on the Rheological Properties and Aging Susceptibility of RAM Asphalt. Buildings 2024, 14, 18. https://doi.org/10.3390/buildings14010018

Yang Q, Liu Z, Wang R, Sun L, Zhang R. Evaluating the Effects of RA on the Rheological Properties and Aging Susceptibility of RAM Asphalt. Buildings. 2024; 14(1):18. https://doi.org/10.3390/buildings14010018

Chicago/Turabian StyleYang, Qifeng, Zhen Liu, Rui Wang, Lijun Sun, and Runhua Zhang. 2024. "Evaluating the Effects of RA on the Rheological Properties and Aging Susceptibility of RAM Asphalt" Buildings 14, no. 1: 18. https://doi.org/10.3390/buildings14010018

APA StyleYang, Q., Liu, Z., Wang, R., Sun, L., & Zhang, R. (2024). Evaluating the Effects of RA on the Rheological Properties and Aging Susceptibility of RAM Asphalt. Buildings, 14(1), 18. https://doi.org/10.3390/buildings14010018