Abstract

The aim of this study is to provide an overview of the current state of Industry 4.0 (IR 4.0) with regard to construction in Australia and to identify the key factors that are driving and hindering its adoption. A literature review and desktop review were conducted to extract mainstream topics, followed by a two-folded workshop designed with a multidisciplinary team of academics, as well as representatives of mainstream firms and peak bodies from the construction value chain. Our study has highlighted the importance of considering both technological and human-related factors in the adoption of IR 4.0 to address barriers that have been traditionally overlooked, and work towards a more successful and holistic implementation of this transformative paradigm. By considering the social aspects of construction, prioritizing data-driven approaches with a focus on privacy and ethics, and emphasizing integration, these facilitators contribute to the effective implementation and success of IR 4.0 in the construction industry. The findings of this study have significant implications for the construction industry in Australia. Addressing the barriers to digital construction adoption and embracing IR 4.0 technologies can help the industry to improve productivity, reduce costs, and enhance sustainability. Additionally, investing in education and training can help to build the necessary skills and capabilities needed to drive the industry forward in the digital age.

1. Introduction

Construction has been consistently lagging behind other industries in terms of innovation and technology adoption [1,2,3]. Despite being one of the largest global industries, the Australian construction sector has been slow to adopt digital technologies and practices [4,5,6], resulting in lower productivity rates and increased project costs. This can be attributed to a multitude of reasons, including the industry’s traditional and fragmented structure [7,8], resistance to change and hesitation to adoption [9,10], and lack of incentives to invest in technology [11]. To address such shortcomings, the construction industry must identify and attend to the key areas that need immediate attention. Furthermore, the gaps in the industry need to be aligned with emerging technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), Digital Twin processes and technology-enabled methods and approaches including Big Data, Building Information Modelling (BIM) and Extended Reality technologies to achieve a more efficient and productive construction sector, known as IR 4.0 technologies [12,13,14]. IR 4.0, or the fourth industrial revolution, refers to the integration of physical and digital environments, driven by trends in connectivity, advanced technology, and collaborative networks, leading to new design principles, business opportunities, and challenges in IT capabilities and data security throughout the project lifecycle [15].

Integrating IR 4.0 technologies and enhancing real-time collaboration and communication among stakeholders are vital for optimizing the performance of the entire project lifecycle. There are numerous research avenues to explore the application and integration of these digital technologies to maximize their benefits. The German government embarked on the introduction of the Industry 4.0 paradigm as a means to enhance productivity through the bolstering of automation mechanisms. Similarly, countries such as France, the USA, the UK, Japan, and China have formulated strategic agendas and embarked upon technological revolutions to propel the uptake of Industry 4.0 technologies within their manufacturing sectors. The Indonesian government has unveiled a roadmap towards the widespread integration of Industry 4.0 principles. The impetus for this strategic direction primarily rests on enhancing competitiveness to allure an increased number of manufacturing entities to adopt this transformative framework [16].

Australia has undertaken several initiatives aimed at promoting the adoption and implementation of Industry 4.0 in the Architecture, Engineering, and Construction (AEC) sector. One noteworthy effort is the establishment of the Building 4.0 Cooperative Research Centre, a research initiative driven by industry stakeholders and co-funded by the Australian Government, initiated in 2020-2021 to facilitate this transition. [11] argue while the existing studies in other contexts do contain valuable insights, they are hampered by several limitations, including:

- Utilization of unknown, insufficient, or biased population sampling and data collection methodologies.

- Failure to distinguish between software acquisitions and genuine adoption.

- Overlooking the non-software facets intrinsic to IR 4.0 adoption.

- Absence of identification of market gaps in the Australian context or incorporation of market-specific criteria.

- Inability to serve as a tool for policymakers seeking to promote IR 4.0 adoption in Australia, given the distinct industry roles and regulatory landscape. Moreover, the absence of a legislative mandate in Australia further complicates matters, rendering the outcomes of other studies inapplicable to the Australian context.

- Lack of in-depth explorations of the perspectives of major stakeholders in the construction process, who can significantly contribute to improving digitalization in the construction sector.

This study aims to evaluate the current status quo of the Australian market that pertain to IR 4.0 readiness and adoption. This paper will also examine the challenges facing the Australian construction industry and how they can be addressed by leveraging emerging technologies. We will explore the potential impact of IR 4.0 technologies in the construction sector and the key gaps that must be addressed to enable their effective implementation. By doing so, this paper aims to provide recommendations for the construction industry to transform into a more innovative, productive, and sustainable sector.

2. Background

2.1. Industry 4.0 in Construction Industry

The emergence of Construction 4.0 within the construction industry signifies a pivotal shift catalyzed by the principles of Industry 4.0, highlighted in the recent studies. Heidenwolf and Szabo [17] illuminate this transition by highlighting how the digital industrial revolution of Industry 4.0 disrupts the traditionally labor-intensive and male-dominated construction sector. This shift is exemplified through the promise of automation facilitated by technologies like Building Information Modeling (BIM), effectively streamlining processes and transforming industry dynamics. Taking a more holistic approach, Baduge, et al. [18] present a comprehensive overview of the applications of Artificial Intelligence (AI), Machine Learning (ML), and Deep Learning (DL) within the realm of Construction 4.0. Their investigation traverses architectural design, structural analysis, offsite manufacturing, construction management, building operations, and sustainability. This expansive review underscores the transformative potential of AI-driven technologies in revolutionizing construction practices and propelling the industry towards a digitally integrated future. Shafei, et al. [19] examine the integration of Construction 4.0 technologies and decision-making processes. Their systematic review identifies gaps in the prior research and underscores the potential of Industry 4.0 to positively impact sustainability in construction. By analysing themes such as strengths, weaknesses, opportunities, and threats, the study underscores the critical role of digital transformation in enhancing decision-making within the construction ecosystem.

Further examinations investigate the intricate interplay of technologies within the construction domain. Osunsanmi, et al. [20] investigates the integration of deep learning and digital twins (DDT) as a means to fortify the resilience of construction supply chains. Their study highlights DDT’s potential as an interoperable tool for real-time interpretation and decision-making support, crucial for navigating disruptions such as the COVID-19 pandemic. Kor, et al. [21] explores the integration of deep learning and digital twins within the Construction 4.0 framework. Their conceptual model accentuates digital twins’ cognitive capabilities in optimizing complex processes, underlining their potential to revolutionize traditional construction practices through adaptability and enhanced decision-making. Expanding beyond immediate operational aspects, Ghobakhloo [22] articulates the synergy between Industry 4.0 and sustainability. The author emphasizes how advanced digital technologies embedded within Industry 4.0, such as IoT and AI, have the potential to contribute to sustainability goals. By enhancing resource efficiency, economic development, and environmental protection, Industry 4.0 presents a pathway towards holistic sustainability.

A wide range of technological advancements has driven the evolution of IR 4.0, leading to significant transformations in various industries [23]. Industries such as manufacturing, retailing, and banking have embraced digital technologies to enhance their operations [24]. The concept of IR 4.0 has gained significant attention in recent years [25], offering benefits such as enhanced collaboration, improved decision-making accuracy, and better quality and safety in digital construction [25,26,27]. However, different countries are in different maturity stages and adoption levels when it comes to digitalization and adoption of ICT. For example, the adaptation rate of BIM in the Australian construction industry is a little behind the countries like Germany, USA, UK while advanced automation and robotics have yet to infiltrate traditional construction in Australia, due to a lack of knowledge, competence, and adequate training [28]. Barriers to technology implementation in Australia include poor interoperability, industry fragmentation, high costs, resistance to change, and limited resources for small and medium enterprises [29].

Although Australia has benefited from IR 4.0 advancements and initiatives like IR 4.0 Testlabs [30] and the Advanced Manufacturing Growth Centre [31], many industries in the country still struggle to fully embrace the potential of these technologies [32]. The construction industry, being complex and dynamic, is a significant contributor to Australia’s economy but faces challenges in technology deployment and productivity improvement compared to other sectors [2,33]. Factors such as high costs, lack of incentives, poor interoperability, industry complexity, and resistance to change contribute to this situation [29]. For example, as noted by Australian Constructors Association (2022), although BIM can deliver considerable efficiencies during the entire project lifecycle, the benefits are rarely valued since the cost of implementation is significantly high. Further, some companies are reluctant to apply these technologies due to the less understanding of potential benefits and impacts. In such context, more in-depth explorations are needed to distinctly identify the challenges to adopt IR 4.0 technologies within the Australian construction industry and possible opportunities to overcome those challenges, by assessing the current status of implementation. Since the research studies particularly on IR 4.0 for Australian construction industry is scarce and still in early stages, a dearth in existing literature could be identified in this domain.

Given the scarcity of research on IR 4.0 in the Australian construction industry, a more comprehensive exploration is needed to identify challenges and opportunities for technology adoption [24,34,35,36]. While some studies have examined technological implementations through different methodologies and countries, there is limited research specifically focused on the Australian context [11,37,38]. Thus, further research is essential to assess the current state, address challenges, and propose solutions to enable a digitalized construction environment in Australia.

2.2. Technological Readiness and Adoption

Technological readiness pertains to comprehending the level of readiness exhibited by individuals, teams, or entire organizations to adopt novel innovations. This ensures they remain well-informed about market requirements within their operating environment. Consequently, for any change management initiative to succeed within an organization or project team, it is imperative to cultivate a state of collective readiness at the individual, group, or organizational levels within a market. Additionally, the preparedness of digital technologies capable of propelling digital transformation is influenced by two primary factors: the technology’s availability and individuals’ competencies to utilize it to enhance performance [39]. According to [40], in order to empower individuals within organizations or sectors to enhance their technological skills, it becomes essential to pinpoint the specific competencies that must be acquired, applied in practical scenarios, and evaluated to enhance overall performance. The paper initially presents various taxonomies and conceptual models that provide clarity on how individual competencies can be sifted, categorized, and consolidated into a foundational competency inventory. These competency elements are then inputted into a specialized knowledge engine, yielding adaptable evaluation tools, learning modules, and procedural workflows. The process of identifying and structuring generic competencies not only facilitates the adoption of digital technologies but also sheds light on the intricate tasks carried out during multidisciplinary collaborations. These competencies encompass the skills needed for modelling, collaboration, and integration activities, remaining relevant across project lifecycles, industry sectors, disciplines, and specialties.

No organization operates autonomously from its clients, partners, competitors, government entities, professional associations, trade counterparts, and other pertinent industry stakeholders. Consequently, organizations are subjected to and swayed by the dynamics present within their external milieu. Striving to grasp the ramifications of external pressures on the integration of digital technology within the construction sector, institutional theory furnishes a comprehensive perspective [41].

According to institutional theory, external pressures manifest as isomorphic pressures and operate through coercive, mimetic, and normative isomorphism. The assertions of this study are predicated on the sway of these isomorphic pressures on the adoption process of IR 4.0 technologies within the Australian Architecture, Engineering, and Construction (AEC) sector. This study contends that these pressures exert their influence on organizations within the market, subsequently affecting the awareness of IR 4.0 technologies and consequent decisions regarding their adoption. Coercive pressures encompass both formal and informal influences compelling firms towards isomorphism. These influences may manifest as persuasion or compulsion, including governmental mandates to employ IR 4.0 technologies or policies that incentivize the adoption of IR 4.0 technologies within the industry. The degree to which organizations rely on other entities correlates with their susceptibility to coercive isomorphism. This notion resonates particularly with small and medium-sized enterprises (SMEs) that constitute a significant portion of the construction industry’s supply chain and often rely on other organizations for collaboration and support. Consequently, coercive pressures are likely to impact awareness and influence the adoption of IR 4.0 technologies within these SMEs. In contrast, mimetic pressures stem from the emulation of successful and legitimate organizations by others.

The theory of diffusion of innovation also offers comprehensive understandings regarding both technology readiness and adoption [42]. This theory proposes that to enhance awareness for the adoption of innovative technology, key criteria such as relative advantage (demonstrating superiority over existing solutions), compatibility (alignment with current practices and values), and trialability and observability (achievable through pilot projects or showcasing successful case studies) should be emphasized. In this context, effective communication channels serve as the primary facilitators.

3. Methodology

The underpinning methodology of this research adopts a qualitative approach within the framework of the interpretive paradigm, which postulates various assumptions about the nature of the world. According to the interpretive paradigm, social reality is shaped by human experiences within specific social contexts [43]. Another key assumption is that individuals within a social organization are knowledgeable agents who possess expertise in their respective domains and possess full awareness of their intentions, thoughts, and actions. By prioritizing the perspectives and voices of these actors, new concepts and insights can emerge throughout the entire research process, including data collection, analysis, and the reporting of findings [44]. While there are studies that approach this topic through methods such as systematic literature review [45,46], case studies [10], and surveys [47], a qualitative approach centred around multidisciplinary experts view is rather a less-explored, particularly in an Australian context.

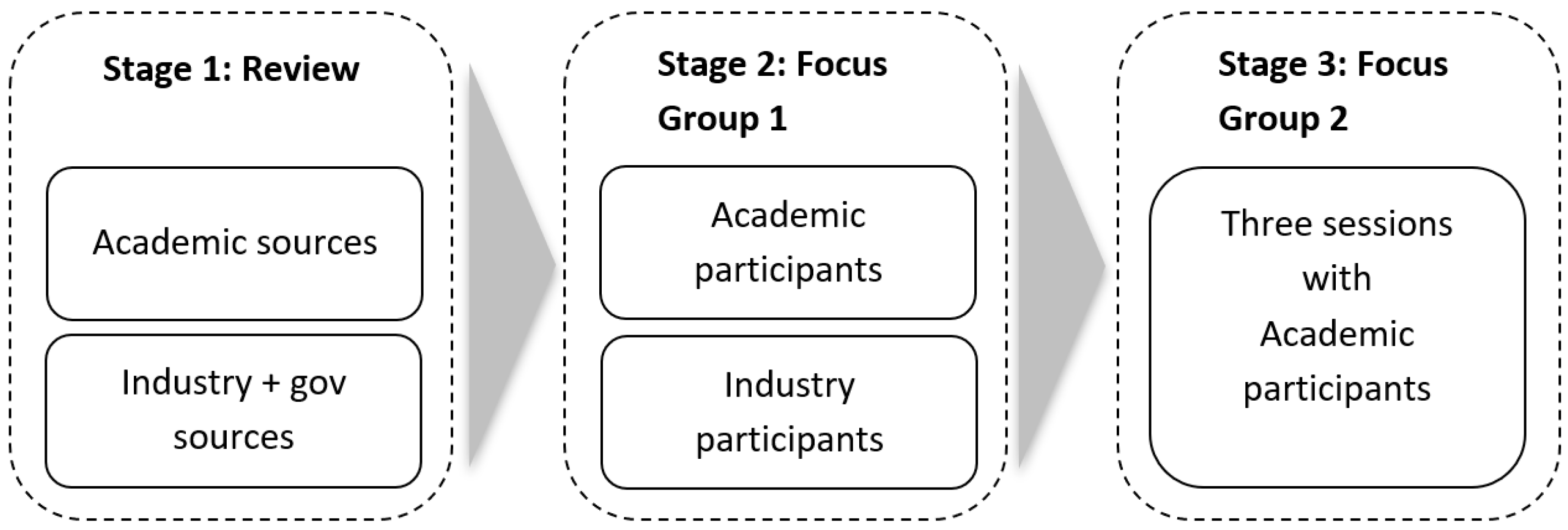

The multiple methods employed in this study encompass an initial content analysis of a focused literature review and industry reports to explore the emerging themes in the construction industry as it undergoes digitalization and industrialization. Secondly, an in-depth analysis of a series of focus group discussions enabled a thorough examination of the key topics. To ensure the credibility of the results, we have conducted member-checking, inter-coder agreement, and a rich description of the topics. The following sub-sections will describe the data collection process in detail in stages (Figure 1), as well as a systematic analysis of the results, to highlight the main findings and outcomes of this study.

Figure 1.

Research process.

3.1. Data Collection and Analysis

3.1.1. Stage One: Focused Literature and Market Review

The review was centred around the academic articles, industry and government reports, guidelines, and white papers addressing the digitalisation of the construction industry in Australia with the emergence of IR 4.0. The purpose of this focused review was to provide a comprehensive analysis and synthesis of existing knowledge to inform the second stage of the study.

The initial search on Scopus using the keywords “IR 4.0” OR “industrialised revolution 4” OR “industrialized revolution 4” AND construction AND Australia yielded only 11 articles, indicating a scarcity of research in this specific area within the Australian context. Consequently, conducting a systematic review would not be appropriate for addressing our query effectively. Furthermore, the search for white papers also produced a limited number of publications. However, by combining insights from both scholarly articles and practical white papers, we were able to obtain sufficient insights aligned with the study’s objectives, encompassing both scholarly and practical perspectives.

Table 1 and Table 2 outline the key sources with a summary of the existing trends and top takeaways to inform the future directions of the research within IR 4.0.

Table 1.

Summary of the scholarly sources.

Table 2.

Summary of white papers and industry reports.

To address these challenges and promote the adoption of IR 4.0 in the construction industry, several key gaps need to be addressed. These gaps are aligned with the key emerging technologies, such as Building Information Modelling (BIM), Internet of Things (IoT), and Artificial Intelligence (AI) and Extended Reality (XR) technologies. These gaps include the need for an upskilling and reskilling of the workforce to enable them to effectively use these technologies, the need for collaboration among stakeholders to overcome the fragmentation of the industry, the need for regulations to ensure the safety and security of these technologies, and the need for industry awareness and engagement to promote the benefits of these technologies.

3.1.2. Stage Two: Focus Group Studies

To refine and complement the list of identified topics, two sets of focus group studies were curated with participants from two distinct groups—academics and industry experts, each arranged in a different session. The academic group comprised twenty participants from five IT, Business, Engineering, Law, and Art, Design and Architecture faculties. The industry group consisted of the representative of a cross-section of construction firms from the construction value chain.

Focus Group 1 included a general introduction of digitalization in the construction industry and a discussion on IR 4.0. Participants were asked about their perception of IR 4.0 in their respective fields, and the conversation was directed towards the important lessons for the construction industry from other sectors and fields of research. The extracted topics from stage one were presented, and participants discussed the priority and importance of the topics and suggested other critical or missing topics.

The focus group transcripts underwent a rigorous qualitative analysis using the Gioia methodology [14] via NVivo software 20.3, complemented with the manual extraction and categorisation of the codes and themes. In the first stage, the transcripts were carefully coded and categorized based on similarities in their content. This allowed for a comprehensive understanding of the data and facilitated the identification of recurring themes and patterns. The relationships between these themes and sub-themes were thoroughly explored, leading to the identification of primarily participant-driven themes. These themes were then classified into main categories, as shown in Table 3, providing a holistic view of the key topics discussed in the workshops.

Table 3.

Extracted topics and themes from the primary analysis.

A second-order analysis was conducted, aiming at identifying and synthesising the recurring topics among both groups of participants, leading to a further refinement of the results with the following categorisation (Table 4):

Table 4.

Extracted topics and themes from the second-order analysis.

- Socio-technological approaches in the construction industry;

- Data-driven construction and automation;

- Integrated approaches, platforms, and processes in construction.

The above final themes are presented in the order of their recurrences in the database. Focus Group 2 was centred around these topics with the same multidisciplinary academic group. Each session was structured into two parts: an introduction of the topic area to set the scene for the upcoming discussion, and an interactive session with questions and prompts presented to the participants. The results of Focus Group 2 were analysed using the same method as Focus Group 1.

4. Results

The following subsections are organized to reflect the main themes and topics that emerged from the findings of our multi-staged analysis (refer to Table 1, Table 2, Table 3 and Table 4). As such, we have classified and aggregated the results into barriers and challenges, as well as research trends, benefits, opportunities, and enablers related to the adoption of Industry 4.0 in the Australian construction industry.

4.1. Challenges and Barriers of Adopting IR 4.0

The results of our analysis show that implementing IR 4.0 in the construction industry presents various challenges, particularly regarding standardisation, data collection, and conflicting priorities among stakeholders. However, by identifying the value of IR 4.0 and determining suitable technologies for adoption, these challenges can be mitigated. Even if a technology has already been invented, it must be reinterpreted within the relevant context to be effectively implemented. Another important consideration is the selection of appropriate IR 4.0 technologies, and whether clients, designers, and other stakeholders perceive their value. It is necessary to assess both individual projects and long-term compatibility across different software suites used by various parties involved in construction.

The concept of considering systems of systems in IR 4.0 becomes particularly significant in the construction industry, where standardisation is challenging due to the individualisation of building designs and circumstances, as well as the multitude of involved processes. A holistic approach to standardising the construction process can bring significant benefits, including the automation of data and integration to support the entire building life cycle. However, fragmentation exists in construction processes, such as stakeholder communication and collaboration. The market is segmented, and changes are typically agreed upon within specific segments. Different construction processes require different compatibilities. Therefore, implementing IR 4.0 should be approached incrementally, addressing the specificities of each process and accommodating differences. While building processes are already standardised in isolation, less attention has been given to the interfaces between them (systems of systems). Standardisation could help overcome compatibility challenges arising from the use of different software by different parties involved in construction. Conflicting priorities further hinder standardisation and the implementation of IR 4.0, as builders prioritise completing their work while building managers require specific data that only builders can collect.

Given the ever-evolving nature of the construction industry, a holistic approach to standardisation is necessary. Connecting actors within the construction industry, including designers, consultants, developers, suppliers, and assemblers, through a digital ecosystem of data, processes, and manufacturing can bring significant benefits.

The participants also recommended considering larger scales, such as the construction of newly developed areas, instead of focusing solely on individual buildings. It is important to strike a balance between the cost of adopting IR 4.0 and the current methods. The workshop also emphasised the importance of not only focusing on manufacturing efficiency, but also considering the environmental impact and people’s attitudes towards the adoption of these technologies. Lastly, the potential of extending and interconnecting the traditional project lifecycle to encompass asset use was highlighted, underscoring the significance of stakeholder engagement and inclusion.

4.2. Construction Readiness and Awareness

The results emphasise the significance of construction readiness, stressing the need for readiness and adaptability to market changes. The importance of meeting market demands and ensuring that the company is equipped to fulfil clients’ needs were also highlighted. It was also noted that clarifying the cost–benefit analysis of implementing IR 4.0 technologies is crucial to demonstrate their value to the market. Relating the value of these technologies to the Australian context was identified as essential. The participants emphasised the importance of client and designer awareness, urging stakeholders to recognise the value of IR 4.0 technologies.

Data accessibility was brought up as a critical factor, ensuring that captured data are easily accessible to relevant parties; however, companies may drop the proper documentation when it becomes too expensive to maintain.

The participants emphasised the importance of incremental improvement in implementing new technologies, highlighting the need to contextualise them within the specific construction context. They also noted the lack of infrastructure in the industry that must be addressed when integrating IR 4.0. The construction market is segmented, and while some segments may be willing to embrace significant changes, the adoption of IR 4.0 technologies needs to consider the industry as a whole. The differences across the value chain were highlighted, where off-site construction may operate at a lower level of industrialisation compared to on-site operations.

Thinking about design and quality for minimising waste, sharing data, and knowledge exchange for better implementation can also help in raising awareness. Demonstration of the tech adoption and its value through case studies is also essential. Companies may have reservations about collecting some data for liability issues, but a synthetic approach is better than single improvements.

4.3. Inter-Sectoral Knowledge Transfer

The construction industry is known for being highly competitive, with different construction teams competing against each other. This can lead to a lack of sharing knowledge and information. The workshop discussed how this issue could be overcome by creating a culture of sharing knowledge and information. By doing this, the industry can learn from each other and improve its processes and systems.

The construction industry can learn from other sectors and industries that have successfully implemented innovative solutions to similar problems. The construction industry can benefit from more collaborative and data-driven approaches, which can drive continuous improvement and optimise building performance. By learning from other industries and adopting best practices, the construction industry can improve project management, reduce costs, and deliver better outcomes.

For example, DFMA (Design for Manufacture and Assembly) is a method used in manufacturing that emphasises simplicity, standardisation, and the use of modular designs. The participants discussed how the construction industry could benefit from learning from other sectors and methods like DFMA, especially when it comes to data. By using meaningful data, the construction industry can gain valuable insights and knowledge that can be used to improve its processes and systems.

4.4. Enablers of IR 4.0 in Australian Construction Industry

The second-order analysis (Table 4) led to three clear factors that are critical to facilitating the uptake of IR 4.0 in the Australian construction industry, which will be elaborated in the following sub-sections.

4.4.1. Socio-Technological Approaches in Construction

Construction is a complex industry that involves multiple stakeholders and has a significant impact on a wide range of social groups, including workers, customers, suppliers, and the local community, to promote social well-being and development. This includes prioritising human rights and culture, diversity and inclusion, health and safety, wellbeing, collaboration, and community impact in construction projects.

During the focus group session, the industry’s shortcomings in diversity, gender equity, and construction workers’ wellbeing were highlighted through statistics, and case studies from around the world were presented to provide a global perspective. The participants identified current social hurdles in the industry such as a lack of cultural studies, and fast-changing technologies leading to knowledge and skill gaps. According to our findings, effective engagement with these stakeholders is essential for building trust, fostering loyalty, and creating value. It is no longer adequate for construction companies to focus solely on the bottom line; they must also prioritise their social and environmental impact.

Different disciplines perceive and define the social element of construction differently, and each considers its importance based on its unique perspective. There are several dimensions to explore when considering the social element of construction. In the industry, stakeholder collaboration, construction workers’ engagement, upskilling, regulations, technology, and digitalisation are crucial areas of engagement. End-users or clients require effective engagement, updates, communication, feedback, and supervision to ensure satisfaction. In the community, engagement focuses on safety considerations, impact, involvement, and communication.

The participants question the cultural implications of IR 4.0 technologies and how they could bridge the gap between off-site and on-site work. The gender pay-gap was identified as an immediate issue after graduation, and it was discussed how women in engineering typically leave the industry within five years. In this context, IR 4.0 could create transitional environments to bridge the gap of culture between off-site and on-site work.

In this context, from personal experiences, they discussed the behavioural changes when women are present in male-dominated areas; male co-workers are more cautious and less welcoming/friendly. They pointed out that women with the same job are usually more welcoming. In this, it is clear that by entering a male-dominated industry, these women are strongly influenced to behave less feminine, which is quite a cultural problem.

Older workers in the construction industry encounter difficulties due to constantly evolving technology. They may experience anxiety from having to keep learning new technologies without being given adequate opportunities to do so, leading to poor performance. Consequently, there are barriers to adopting many new systems to achieve IR 4.0. These include a lack of perceived benefits, a high turnover rate of experienced workers due to the complexity of many technologies, a loss of the knowledge of implementation, and new employees having to learn the systems from scratch.

There are several potential solutions to the social challenges faced by the construction industry. Given the large number of small businesses in the industry, it may be necessary for the government to drive a shift in culture through regulations. In addition to incremental changes, such as promoting diversity by forming all-female construction crews, there is also the potential for new, small businesses to emerge that are radically different from the norm. Another promising opportunity is the use of collaborative robotics, which have fewer physical requirements and are more computer-based. This technology is friendlier to female workers and has already helped to close the gender gap in the aerospace industry. University programs are difficult to change due to accreditation requirements. However, there are opportunities in considering requirements for postgraduate training. Another mitigating factor is mixing or separating the teaching of technical skills with soft skills. That is, teaching the foundations behind performing a task versus teaching how to do the task with a specific technology; e.g., teaching someone how to do FEA by hand VS teaching how to use a particular FEA software.

Teaching the foundations allows students to learn new technologies when the old ones become obsolete. This also enables the innovation itself that results in new/improved software and is not restricted to methods that are outside of the abilities of current software. It also includes teaching students to design within the limitations of the software, which reduces their ability to adapt to other software, and induces bias in designs. It can be used to abstract the complexities and teach an understanding of higher-level principles, as higher-level principles are important foundational knowledge too.

Moreover, teaching higher-level principles is equally important as it provides a better understanding of the complexities and allows for an abstraction of the complexities. Thus, it enables students to learn the foundational knowledge that is necessary for them to be successful in the construction industry, as well as in other industries.

4.4.2. Data-Driven Technologies and Processes in Construction

Another important enabler of IR 4.0 in construction is data-driven construction (DDC). Building upon the interest generated in previous sessions, participants delved into the potential of IoT and data analytics to revolutionise the construction industry. The benefits of a data-driven approach include a better management of technology usage and a more efficient adoption and deployment of digital tools. The practical considerations involved in implementing DDC, including readiness factors from various perspectives such as regulations, technicalities, and skills, were pointed out, as well as the impact of DDC on different stakeholders, including companies, the government, and society at large.

During the discussion, several crucial points were raised regarding the adoption of a data-driven approach in the construction industry. Firstly, it was emphasized that defining the robustness and frequency of data collection and effectively communicating this information within the team is essential. Additionally, managing and integrating multiple data types and structures beyond traditional reports is crucial. A shared understanding of the data-driven approach among stakeholders, including the site team, was identified as a key factor for success. The influence of clients in shaping the adoption of the data-driven approach was also highlighted. It was suggested that raising awareness is necessary, which involves considering the benefits of data-driven design, minimizing waste, and promoting knowledge sharing. A clear identification of data sources and ensuring their accountability and reliability is vital. Learning from the Construction Resource Integration Project (CRIP) was encouraged to enhance data-driven practices. Developing a well-defined data management plan that addresses data needs, collection methods, usage, and value demonstration is crucial. Communicating the adoption and value of data-driven technologies through case studies and real-world examples was seen as an effective strategy. A specific case study was mentioned, involving the implementation of a tracking system to understand waste generation and propose optimization methods. The challenge of managing overwhelming data and the importance of a shared understanding of data were discussed. Liability concerns may lead companies to be reluctant to collect certain data, such as waste data. Therefore, it is essential to think deeply about the purpose and problems at hand and develop well-defined problem statements. Avoiding overly detailed and complex data while adopting a holistic approach rather than isolated improvements were also suggested. Finally, exploring IT solutions to understand previous failures in data-driven approaches was recommended. These points highlight the challenges, considerations, and potential solutions associated with the successful adoption of a data-driven approach in the construction industry.

The adoption of DDC poses several challenges to the industry, which can hinder its widespread implementation. Workers from different roles have different perspectives on what DDC is, resulting in a lack of shared understanding among stakeholders. The high cost of trialling new technologies can slow down projects and cause frustration among workers. Fragmentation in organisational structures can also create barriers to adoption, as communication and collaboration between different teams can be difficult, resulting in the need to start from scratch with new systems for each project.

To overcome these challenges, a clear data management plan is essential, as well as a shared understanding of the data-driven approach across all stakeholders. Defining the data needed, its robustness and frequency of collection, and communicating it within the team can also help. Clients can play a crucial role in the implementation of the data-driven approach, as they need to think about the purpose and problems more deeply before making decisions. Investigating the root cause of problems and showing how data can help tackle them can improve awareness and facilitate adoption.

Before adopting DDC, companies should address critical questions about data providers, data selection, and data accessibility. Small companies may face challenges with data collection and analytics systems, while excessive unnecessary data can be costly and difficult to process. The overall impact and integration of point solutions should be considered, along with the long- and short-term effects of data collection methods. Prerequisites for DDC extend beyond technology and encompass new processes and organizational structures. These prerequisites include understanding user perceptions, employing co-design and bottom-up decision making, and complying with data regulations and standards. Learning from other industries, identifying success factors, and understanding user needs are also crucial. Flexibility in readiness factors and the establishment of a shared collaborative work environment are necessary for successful DDC implementation.

DDC has the potential to reframe data in different ways, such as using existing timesheet data to improve the culture of long working hours or using material tracking data to measure and reduce waste. However, there are challenges to adoption, such as a lack of regulations, which can increase costs. It is important to note that DDC can have an impact on all three Ps: people, process, and product. However, the impact on the environment and the social aspects of construction are often overlooked. Therefore, it is essential to consider the broader implications of DDC and ensure that its implementation is sustainable and socially responsible.

4.4.3. Integration across the Construction Sector

The integration of systems of systems in IR 4.0 was highlighted as a critical consideration in the construction industry. While individual building processes are already standardized, the interfaces between them lack integration. IR 4.0 should focus on addressing these interfaces, which would facilitate individualization and accommodate site-specific conditions. For example, if a logistics plan needs to be changed due to bad weather, IR 4.0 can facilitate the necessary adjustments. Several questions were posed to explore integration further, such as understanding the scope and components of integration and assessing the industry’s readiness for integration. The benefits of connecting machines, enabling real-time data-driven decision making, and reconciling people and machines were emphasized. Additionally, the potential of IR 4.0 in facilitating the construction of larger-scale developments rather than individual buildings was mentioned. The challenge of disparate software systems in the industry that do not communicate with each other and the associated costs of upgrading or changing them were discussed. The value of a shared collaborative information environment for production co-ordination, project lifecycle extension to asset use, and learning from user data was underscored. The lack of communication between different stakeholders, such as engineers, lawyers, and architects, was identified as a current issue. It was noted that making processes more thorough to learn from previous designs is challenging due to long product lifecycles and loosely coupled systems, exacerbated by subcontracting. The importance of bringing together different expertise and overcoming stakeholders’ tendencies to work in isolation was emphasized. These points highlight the need for integrated systems, collaboration, and improved processes to fully realize the potential of IR 4.0 in the construction industry.

5. Discussion

Our findings support the results of previous studies that have identified lack of industry awareness of benefits and adoption of IR 4.0 [9], data management competencies [34], hesitation to adopt, and high cost of adoption [10] as primary barriers to the adoption of IR 4.0. While most research and practical applications in the context of IR 4.0 tend to focus primarily on the technological aspects of adoption [54], our research places a strong emphasis on the “softer” human-centric factors that are crucial for successful technology uptake. For instance, while the lack of skilled labour is often acknowledged as a major obstacle, there has been relatively little emphasis on the importance of upskilling the current workforce. By investing in upskilling programs, organizations can overcome resistance to change and enhance industry awareness regarding the intricacies of technology adoption. This aligns with the findings of Succar, Sher and Williams [40], which underscore the importance of adopting a methodical approach to assess individuals’ competencies in the context of technological innovations. This comprehensive assessment should encompass essential core competencies like personal attributes and educational background, domain competencies such as technical proficiencies, and execution competencies that encompass on-site equipment handling. Additionally, the training prerequisites, informed by the outcomes of competency assessments, should encompass a combination of formal education and on-the-job training.

By taking a broader perspective on IR 4.0, our research provides a more comprehensive understanding of barriers, including legislative frameworks and regulations [34], which are typically cited as obstacles. The concept of isomorphism, particularly coercive isomorphism, can be applied to explain the barriers identified in this study. The lack of industry awareness, hesitation to adopt, and high adoption costs allude to the pressures exerted by external factors, such as government mandates or industry norms, which align with coercive isomorphism. These pressures can influence AEC organizations to conform to prevailing practices and norms within the industry. For instance, the adoption of IR 4.0 technologies might be driven by the need to comply with industry expectations or regulatory mandates. This can impact technology readiness by necessitating the adoption of new practices and technologies to align with industry standards. The absence of structured and systematic regulatory instructions can result in inconsistencies across industries, but it also presents opportunities for developing standards that facilitate effective implementation. Moreover, prior studies emphasize that awareness alone does not necessarily translate into the adoption of IR 4.0 technologies [55]. AEC firms must possess the necessary readiness, encompassing factors like infrastructure and competencies, to effectively embrace and implement IR 4.0 technologies.

Our research has identified three essential facilitators that are intertwined with the enablers of IR4.0, such as promoting equalities among construction stakeholders [49] and advanced analytics [56]. Firstly, it is crucial to focus on the social aspects of construction and their relationship with the uptake of technology. This includes raising awareness about the increasing involvement of the female workforce and the necessary cultural changes that accompany it. Recognizing the importance of equity is key to promoting well-being, safety, and collaboration among all stakeholders. The second significant facilitator is data-driven construction, which goes beyond simply adopting IR4.0 technologies. While many studies in this area primarily focus on the adoption of these technologies, our research highlights the importance of data management, structured data development, and collection [34], as well as cybersecurity. Additionally, our findings emphasize the significance of privacy and ethical considerations in gaining trust and driving organizational change. Lastly, our study underscores the imperative role of integrated approaches in enabling IR4.0. While there are various interpretations of integration, the nature of IR4.0 necessitates the establishment of common data environments and digital platforms. Achieving successful integration requires wide awareness and readiness at various levels and scales, encompassing technologies [57], systems, stakeholders [13], and projects. These findings are substantiated by the principles of the Diffusion of Innovation Theory, which suggest that establishing an environment conducive to IR 4.0 adoption entails cultivating efficient communication channels, harnessing social influence, and ensuring compatibility and relative advantages

6. Future Directions

The findings regarding the challenges, barriers, and enablers of IR 4.0 adoption in Australia has been discussed in the previous sections. We present a summary of the essential topics as emerged from this study, whether as the priorities or gaps and shortcomings, for future research:

- Education and training: understanding the best approaches to educate and train workers on IR 4.0 technologies and processes, including the use of virtual and augmented reality tools, gamification, and other innovative methods.

- Culture and gender equity, ethics, and data privacy: exploring how IR 4.0 technologies can be used to promote culture and gender equity, as well as address ethical considerations such as data privacy and ownership.

- Collaboration: exploring how collaboration among different stakeholders in the construction industry can be improved to support the adoption of IR 4.0 technologies, including upstream–downstream collaboration, and collaboration between expert and non-expert stakeholders.

- Industry awareness: understanding how to increase the awareness of IR 4.0 technologies and their potential benefits among industry stakeholders, including owners, contractors, and suppliers.

- Tech and digital literacy: exploring the role of upskilling and new training to improve the digital literacy of the stakeholders across the whole value chain.

- Regulation: examining the role of regulations in the adoption of IR 4.0 technologies in the construction industry, and how regulatory frameworks can be improved to support their adoption.

7. Conclusions

The construction industry in Australia needs to address several key gaps to promote the adoption of digital technologies and IR 4.0. These gaps are aligned with the key emerging technologies and include an upskilling and reskilling of the workforce, collaboration among stakeholders, regulations, and industry awareness and engagement, along with an increased focus on end-user needs and a shift towards a more human-centered approach to construction. By addressing these gaps, the construction industry can reap the benefits of digital construction and IR 4.0, and improve the efficiency, productivity, and quality of construction projects.

While IR 4.0 is primarily focused on technology, it is important to recognize that successful implementation requires a human-centered approach that includes collaboration, stakeholder engagement, and consideration for end-use. In addition, the transition to IR 4.0 in construction will require education and training, as well as attention to cultural and gender equity, ethics, and data privacy. Regulations must also be considered, as well as the need for upskilling and awareness within the industry. It is important to recognize that the move towards IR 4.0 will not be an overnight process, but rather a journey that will require ongoing collaboration and engagement with all stakeholders. Ultimately, a successful transition to IR 4.0 will require a focus on people, processes, and technology, and a commitment to creating a more efficient and sustainable construction industry.

This study’s main limitation is the sample size of the participants, which may limit the generalisability of the findings. However, the study employed a rigorous data collection and analysis process, which enhances the validity and reliability of the study’s findings. The mixed-methods research design employed in this study allows for the triangulation of data, which increases the credibility of the study’s findings. While the mixed-methods approach contributes to a more comprehensive understanding, it is important to acknowledge the potential for methodological biases or discrepancies between qualitative and quantitative data. Furthermore, the study’s focus on the Australian construction industry could restrict the applicability of the findings to other geographical regions or industries. The dynamic nature of technology adoption and the rapidly evolving landscape of Industry 4.0 might result in certain findings becoming outdated in the relatively short term. Finally, although efforts were made to ensure data reliability and validity, inherent biases or inaccuracies could still exist due to factors such as participant recall, response bias, or contextual nuances that were not fully captured. Despite these limitations, the study provides valuable insights into the challenges and enablers of IR 4.0 adoption in the Australian construction sector.

Author Contributions

Conceptualization, S.S., D.M. and A.R.; Methodology, S.S., D.M. and A.R.; Software, S.S.; Validation, S.S.; Formal analysis, S.S.; Investigation, S.S., D.M. and A.R.; Resources, S.S.; Data curation, S.S. and D.M.; Writing—original draft, S.S.; Writing—review & editing, S.S., D.M. and A.R.; Supervision, D.M.; Funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

We would like to express our gratitude to the Building 4.0 Cooperative Research Centre (CRC) for their funding support.

Data Availability Statement

Not applicable.

Acknowledgments

We are grateful to all the participants who willingly shared their insights and expertise, as their contributions have significantly enriched this research. We would also like to extend our thanks to Brandon David Jones and Miyami Sinhala Pathiranage for their invaluable assistance throughout the research process.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fulford, R.G. The implications of the construction industry to national wealth. Eng. Constr. Archit. Manag. 2019, 26, 779–793. [Google Scholar] [CrossRef]

- Leviäkangas, P.; Paik, S.M.; Moon, S. Keeping up with the pace of digitization: The case of the Australian construction industry. Technol. Soc. 2017, 50, 33–43. [Google Scholar] [CrossRef]

- Nangia, I.; Brinded, T.; Tilahun, L.; Trueman, P.; Watson, B.; Joseph, S.; Sahulhameed, R. Australia’s Infrastructure Innovation Imperative; McKinsey and Company: New York, NY, USA, 2019. [Google Scholar]

- AMGC 2018. Industry 4.0: An Opportunity for Every Australian Manufacturer, Advanced Manufacturing and Growth Centre. Available online: https://www.amgc.org.au/wp-content/uploads/2018/11/AMGC_Industry-4.0-An-opportunity-for-every-Australian-Manufacturer-.pdf (accessed on 12 July 2023).

- Martin, L.; Perry, F. Sustainable construction technology adoption. In Sustainable Construction Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 299–316. [Google Scholar]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- London, K.; Pablo, Z. An actor–network theory approach to developing an expanded conceptualization of collaboration in industrialized building housing construction. Constr. Manag. Econ. 2017, 35, 553–577. [Google Scholar] [CrossRef]

- Martek, I.; Hosseini, M.R.; Shrestha, A.; Edwards, D.J.; Durdyev, S. Barriers inhibiting the transition to sustainability within the Australian construction industry: An investigation of technical and social interactions. J. Clean. Prod. 2019, 211, 281–292. [Google Scholar] [CrossRef]

- Das, P.; Perera, S.; Senaratne, S.; Osei-Kyei, R. Developing a construction business model transformation canvas. Eng. Constr. Archit. Manag. 2020, 28, 1423–1439. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Perera, S.; Jin, X.; Samaratunga, M.; Gunasekara, K. Drivers and Barriers to Digitalisation: A Cross-Analysis of the Views Of Designers And Builders In The Construction Industry. J. Inf. Technol. Constr. 2023, 28, 87–106. [Google Scholar] [CrossRef]

- Bartodziej, C.J.; Bartodziej, C.J. The Concept Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Gebhardt, M.; Kopyto, M.; Birkel, H.; Hartmann, E. Industry 4.0 technologies as enablers of collaboration in circular supply chains: A systematic literature review. Int. J. Prod. Res. 2022, 60, 6967–6995. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Thienen, S.V.; Binkhuysen, A.B.; Clinton, A.; Korte, R. Industry 4.0: An Introduction; Deloitte: Geneve, Switzerland; Amsterdam, The Netherlands, 2015. [Google Scholar]

- Fernando, Y.; Zainul Abideen, A.; Shaharudin, M.S. The nexus of information sharing, technology capability and inventory efficiency. J. Glob. Oper. Strateg. Sourc. 2020, 33, 327–351. [Google Scholar] [CrossRef]

- Heidenwolf, O.; Szabo, R. Construction 4.0. In Smart Business and Digital Transformation; Routledge: London, UK, 2023; pp. 165–170. [Google Scholar]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Shafei, H.; Radzi, A.R.; Algahtany, M.; Rahman, R.A. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings 2022, 12, 2206. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Thwala, W.D.D.; Molusiwa, R. Modelling construction 4.0 as a vaccine for ensuring construction supply chain resilience amid COVID-19 pandemic. J. Eng. Des. Technol. 2022, 20, 132–158. [Google Scholar] [CrossRef]

- Kor, M.; Yitmen, I.; Alizadehsalehi, S. An investigation for integration of deep learning and digital twins towards Construction 4.0. Smart Sustain. Built Environ. 2023, 12, 461–487. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the construction industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A. Construction 4.0: The future of the construction industry in South Africa. Int. J. Civ. Environ. Eng. 2018, 12, 206–212. [Google Scholar]

- Hossain, M.A.; Nadeem, A. Towards Digitizing the Construction Industry: State of the Art of Construction 4.0; ISEC Press: Fargo, ND, USA, 2019; pp. 1–6. [Google Scholar]

- Awais, M.; Henrich, D. Human-robot interaction in an unknown human intention scenario. In Proceedings of the 11th International Conference on Frontiers of Information Technology, Islamabad, Pakistan, 16–18 December 2013; pp. 89–94. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Stewart, R.A.; Mohamed, S.; Marosszeky, M. An empirical investigation into the link between information technology implementation barriers and coping strategies in the Australian construction industry. Constr. Innov. 2004, 4, 155–171. [Google Scholar] [CrossRef]

- Subic, A. Industry 4.0 Testlabs in Australia: Preparing for the Future. 2017. Available online: https://www.industry.gov.au/publications/industry-40-testlabs-australia-report (accessed on 29 June 2023).

- Gallagher, S. Industry 4.0 Testlabs in Australia Preparing for the Future. Hawthorn: Swinburne Research; Swinburne Research: Hawthorn, Australia, 2017. [Google Scholar]

- Cheng, C.-T.; Bab-Hadiashar, A.; Lai, C.; Chan, J.; Peszynski, K.; Vidoni, M.; Kajtaz, M.; Whiteside, N.; Houshyar, S.; Koddam, S.; et al. Demystifying Industry 4.0—Helping SMEs Lay the Tracks for Australia’s Digitalisation Express Train; RMIT University: Melbourne, Australia, 2020. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating major challenges for industry 4.0 adoption among construction companies. Eng. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Atuahene, B.T.; Kanjanabootra, S.; Gajendran, T. Benefits of big data application experienced in the construction industry: A case of an Australian construction company. In Proceedings of the 36th Annual Association of Researchers in Construction Management (ARCOM) Conference, Leeds, UK, 7 September 2020; pp. 346–355. [Google Scholar]

- Bajpai, A.; Misra, S.C. Barriers to implementing digitalization in the Indian construction industry. Int. J. Qual. Reliab. Manag. 2022, 39, 2438–2464. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Thwala, W.D.; Rillie, I. Industry 4.0 deployment in the construction industry: A bibliometric literature review and UK-based case study. Smart Sustain. Built Environ. 2021, 10, 557–580. [Google Scholar] [CrossRef]

- Kozlovska, M.; Klosova, D.; Strukova, Z. Impact of industry 4.0 platform on the formation of construction 4.0 concept: A literature review. Sustainability 2021, 13, 2683. [Google Scholar] [CrossRef]

- Talbi, A.; Souad, S.B. Industry 4.0 in construction organization of a mega projects: A bibliometric analysis. Procedia Comput. Sci. 2022, 204, 524–531. [Google Scholar] [CrossRef]

- Jafari-Sadeghi, V.; Garcia-Perez, A.; Candelo, E.; Couturier, J. Exploring the impact of digital transformation on technology entrepreneurship and technological market expansion: The role of technology readiness, exploration and exploitation. J. Bus. Res. 2021, 124, 100–111. [Google Scholar] [CrossRef]

- Succar, B.; Sher, W.; Williams, A. An integrated approach to BIM competency assessment, acquisition and application. Autom. Constr. 2013, 35, 174–189. [Google Scholar] [CrossRef]

- DiMaggio, P.J.; Powell, W.W. The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. Am. Sociol. Rev. 1983, 48, 147–160. [Google Scholar] [CrossRef]

- Rogers, E. Diffusion of Innovations, 5th ed.; Rezvani, Z., Jansson, J., Eds.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Lincoln, Y.S.; Guba, E.E. Research, evaluation, and policy analysis: Heuristics for disciplined inquiry. Rev. Policy Res. 1986, 5, 546–565. [Google Scholar] [CrossRef]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ. Res. Methods 2012, 16, 15–31. [Google Scholar] [CrossRef]

- Perera, S.; Jin, X.; Das, P.; Gunasekara, K.; Samaratunga, M. A strategic framework for digital maturity of design and construction through a systematic review and application. J. Ind. Inf. Integr. 2023, 31, 100413. [Google Scholar] [CrossRef]

- Smith, K.; Sepasgozar, S. Governance, Standards and Regulation: What Construction and Mining Need to Commit to Industry 4.0. Buildings 2022, 12, 1064. [Google Scholar] [CrossRef]

- Elghaish, F.; Hosseini, M.R.; Talebi, S.; Abrishami, S.; Martek, I.; Kagioglou, M. Factors driving success of cost management practices in integrated project delivery (IPD). Sustainability 2020, 12, 9539. [Google Scholar] [CrossRef]

- Chan, T.K. Comparison of precast construction costs—Case studies in Australia and Malaysia. In Proceedings of the 27th Annual ARCOM Conference, Bristol, UK, 12 September 2011; pp. 3–12. [Google Scholar]

- Sepasgozar, M.E.; Shirowzhan; Loosemore, M. Information asymmetries between vendors and customers in the advanced construction technology diffusion process. Constr. Innov. 2021, 21, 857–874. [Google Scholar] [CrossRef]

- Ghosh, A.; Abawajy, J.; Chowdhury, M. Redefining the construction managerial landscape to facilitate Industry 4.0 implementation: Scientometric mapping of research frontiers. Constr. Innov. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Fakher, R.A.; Anandh, K.S. An Exploratory Study to Utilize Construction 4.0 Technologies in Enhancing Communication to Get Quality Human Resources; Loon, L.Y., Subramaniyan, M., Gunasekaran, K., Eds.; Springer Nature: Singapore, 2022; pp. 465–479. [Google Scholar]

- Bok, B.; Hayward, P.R.; Voros, J.G. Construction 2030—A Roadmap of R&D Priorities for Australia’s Built Environment. Sustainable Built Environment National Research Centre, Brisbane. 2012. Available online: https://www.academia.edu/61255580/CONSTRUCTION_2030_A_Roadmap_of_R_and_D_Priorities_for_Australias_Built_Environment (accessed on 29 June 2023).

- Ribeirinho, M.; Mischke, J.; Strube, G.; Sjödin, E.; Blanco, J.; Palter, R.; Biörck, J.; Rockhill, D.; Andersson, T. The next normal in construction, Mckinsey, Company. IOP Pub. 2020, 1, 012011. [Google Scholar]

- Schlaepfer, R.C.; Koch, M.; Merkofer, P. Industry 4.0: Challenges and Solutions for the Digital Transformation and Use of Exponential Technologies; Deloitte: Switzerland, The Netherlands, 2015. [Google Scholar]

- Saka, A.B.; Chan, D.W.; Ajayi, S.O. Institutional isomorphism and adoption of building information modelling (BIM) in small and medium-sized enterprises (SMEs) of the Nigerian Construction Industry. Eng. Constr. Archit. Manag. 2022. [Google Scholar] [CrossRef]

- Development, QDoS 2016. Queensland Advanced Manufacturing 10-Year Roadmap and Action Plan [2016 and 2018]. Available online: https://cabinet.qld.gov.au/documents/2016/Dec/AdvMan/Attachments/Roadmap.PDF (accessed on 29 June 2023).

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).