Evaluation of Carbon Emission Efficiency in the Construction Industry Based on the Super-Efficient Slacks-Based Measure Model: A Case Study at the Provincial Level in China

Abstract

:1. Introduction

2. Research Methods and Models

2.1. Carbon Emissions Accounting Model

2.1.1. DCE Accounting Model

2.1.2. ICE Accounting Model

2.1.3. The CEICI Accounting Model

2.2. The Static CEECI Measurement Model

2.2.1. Factor Selection and Data Source

2.2.2. Super-Efficient SBM Models including Non-Desired Outputs

2.3. The Dynamic CEECI Measurement Model

2.3.1. The ML Index Model

2.3.2. ML Exponential Decomposition

3. Empirical Results

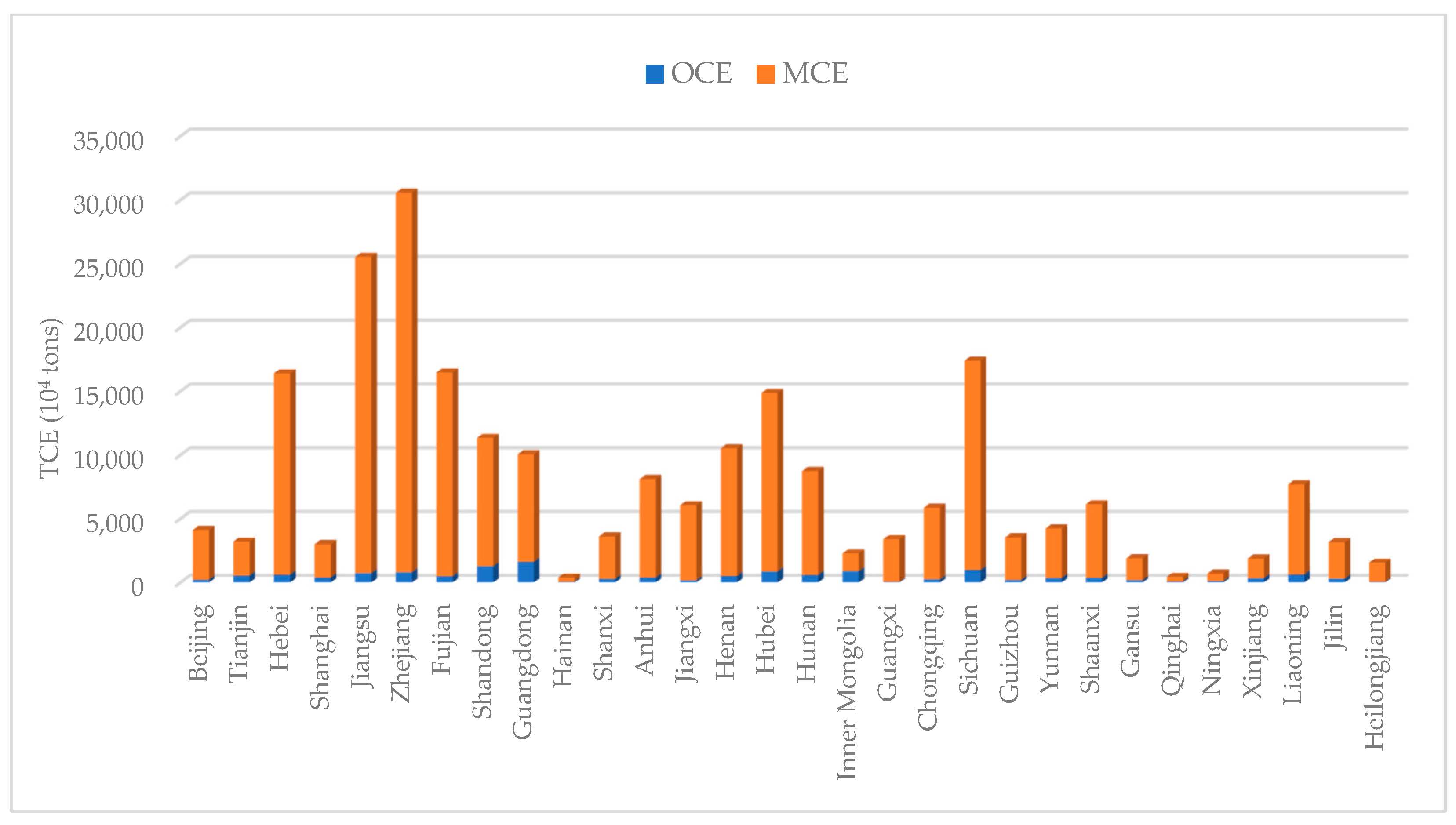

3.1. Carbon Emissions from the Construction Industry

3.1.1. Results of the TCEs

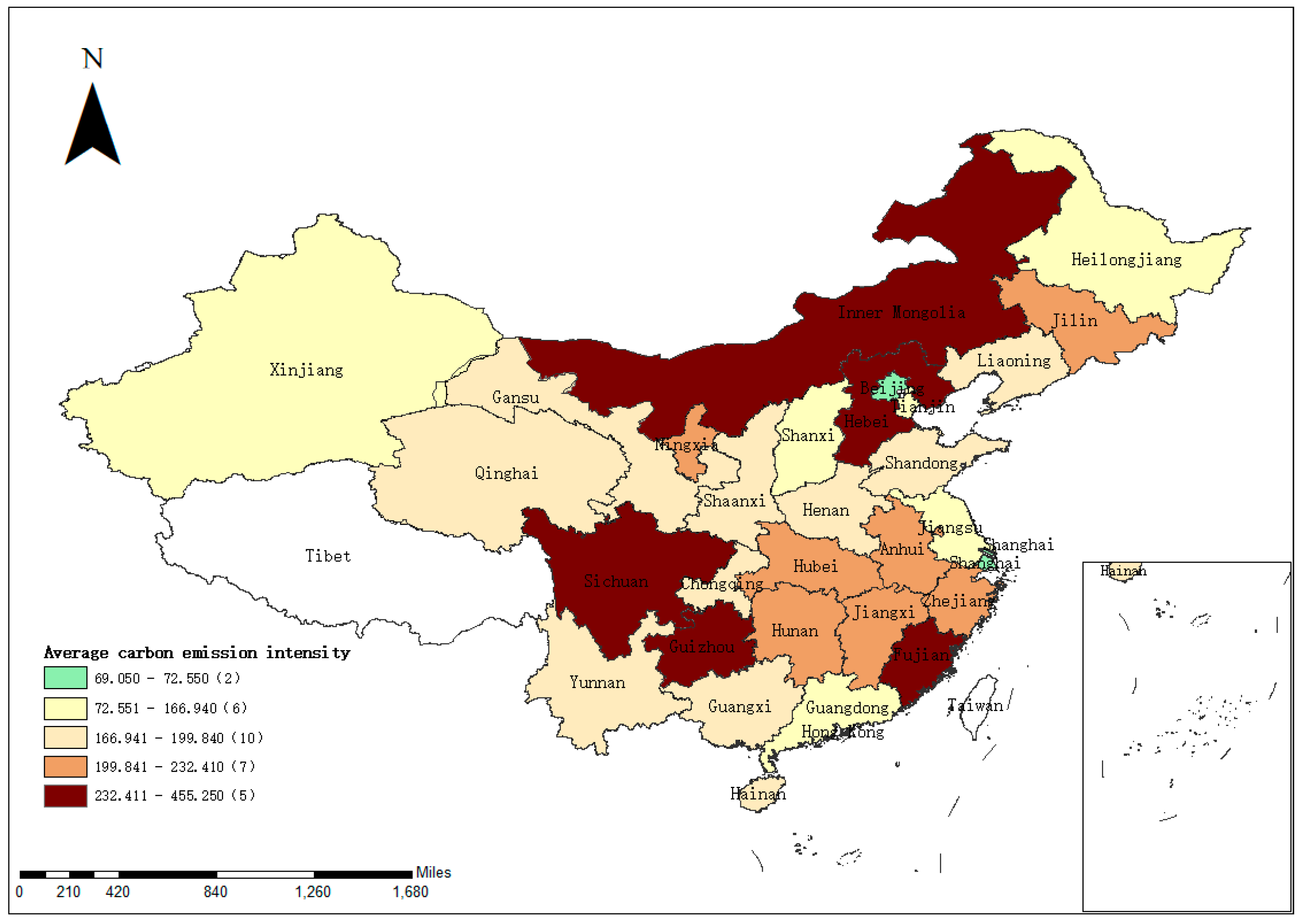

3.1.2. Results of the CEICI

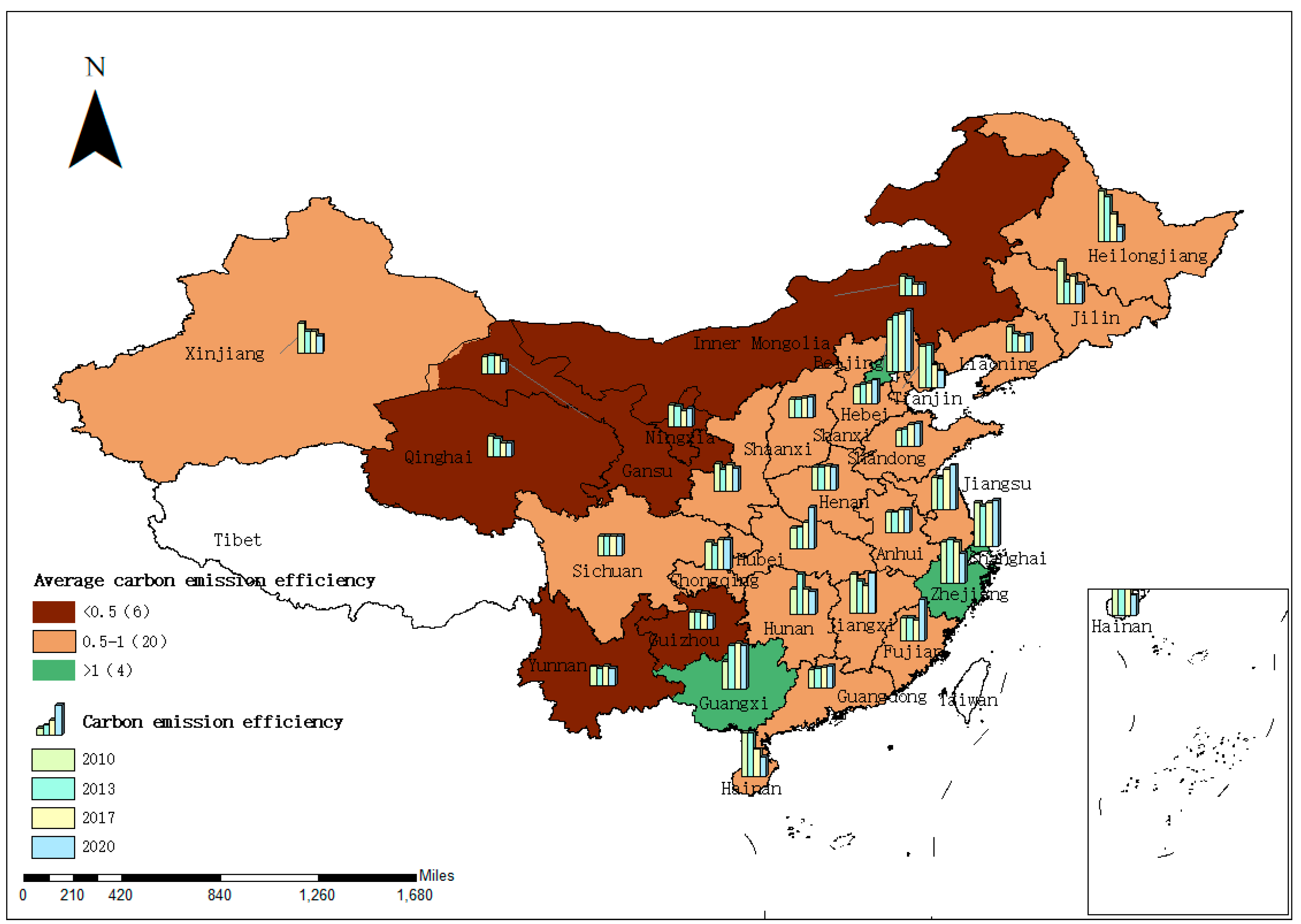

3.2. The Static CEECI

3.2.1. Results of the CEECI

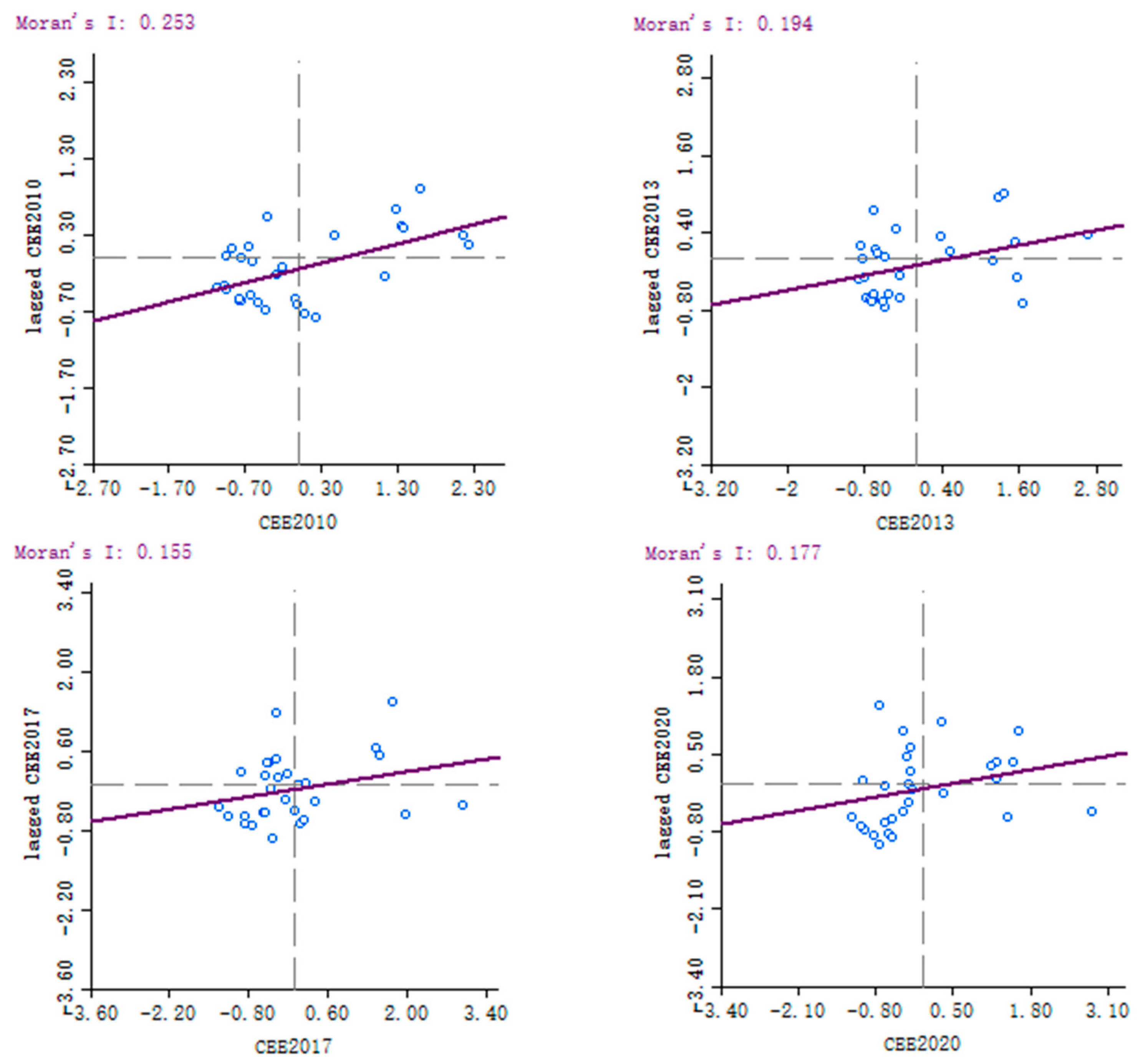

3.2.2. Spatial Correlation Analysis

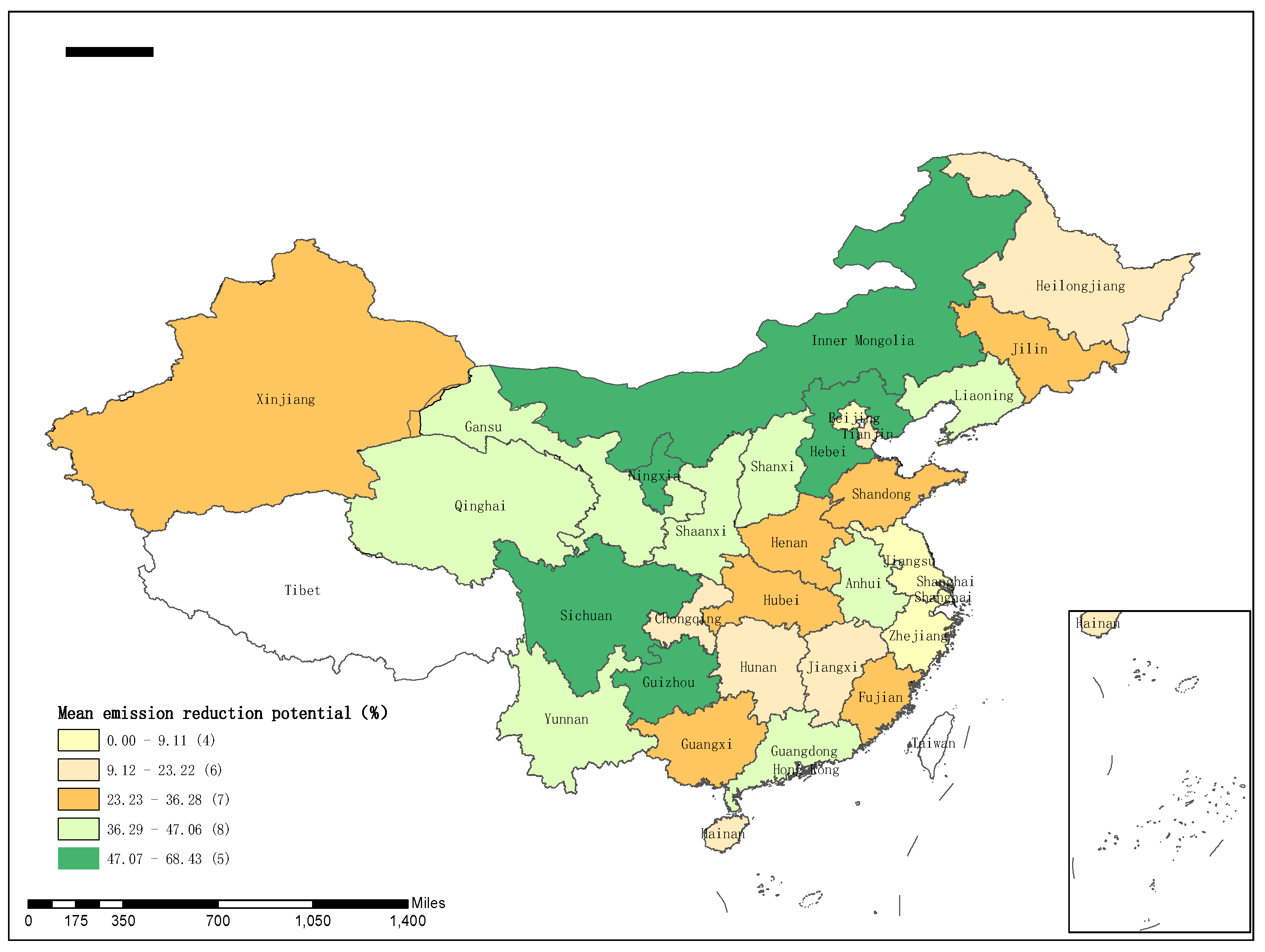

3.2.3. Results of the CRPCI

3.3. The Dynamic CEECI

4. Discussion

4.1. Discussion and Analysis of TCEs

4.2. Discussion and Analysis of the Static CEECI

4.3. Discussion and Analysis of the CRPCI

4.4. Discussion and Analysis of the Dynamic CEECI

5. Conclusions and Policy Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Provinces | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Beijing | 4141.10 | 4247.77 | 3435.60 | 3855.11 | 3991.27 | 3858.62 | 3655.28 | 3876.19 | 4616.35 | 4977.63 | 4636.69 | 4117.42 |

| Tianjin | 2180.10 | 2962.44 | 2921.30 | 3827.69 | 5124.88 | 3377.18 | 3066.20 | 2683.86 | 3917.30 | 2345.50 | 2887.00 | 3208.49 |

| Hebei | 11,931.56 | 50,978.83 | 50,098.14 | 18,619.91 | 8787.23 | 9145.52 | 6541.50 | 7026.63 | 5645.86 | 6563.21 | 5100.96 | 164,03.58 |

| Shanghai | 2683.57 | 2862.43 | 2711.69 | 2771.60 | 2850.15 | 2352.96 | 2424.72 | 2659.57 | 2582.21 | 5715.11 | 3413.71 | 3002.52 |

| Jiangsu | 17,446.34 | 29,870.23 | 32,186.46 | 24,667.14 | 26,506.67 | 24,510.53 | 24,102.46 | 24,053.74 | 25,803.79 | 24,940.07 | 26,773.66 | 25,532.83 |

| Zhejiang | 22,551.46 | 27,728.49 | 29,545.27 | 33,489.57 | 34,282.08 | 34,412.04 | 34,716.80 | 37,087.15 | 31,773.29 | 25,682.84 | 24,995.17 | 30,569.47 |

| Fujian | 6784.00 | 6664.42 | 8351.58 | 11,196.03 | 14,788.44 | 15,257.24 | 17,283.81 | 21,591.42 | 25,139.66 | 27,867.68 | 26,267.89 | 16,472.02 |

| Shandong | 9632.56 | 9778.67 | 22,368.62 | 10,686.56 | 11,149.21 | 10,562.08 | 9843.76 | 9792.52 | 10,052.95 | 11,333.09 | 9600.75 | 11,345.53 |

| Guangdong | 7009.04 | 10,127.94 | 10,306.67 | 9755.95 | 10,390.67 | 8726.73 | 8005.24 | 10,334.96 | 10,671.74 | 12,435.93 | 12,798.55 | 10,051.22 |

| Hainan | 268.49 | 430.32 | 415.05 | 515.16 | 405.61 | 266.53 | 302.59 | 331.99 | 454.03 | 465.23 | 393.19 | 386.20 |

| Shanxi | 4494.84 | 3095.55 | 3138.88 | 3297.47 | 3857.80 | 3518.09 | 3427.76 | 3630.51 | 3882.76 | 3787.12 | 3537.35 | 3606.19 |

| Anhui | 4519.68 | 4863.35 | 4905.01 | 6093.21 | 6607.09 | 5599.87 | 6943.01 | 8886.85 | 10,135.06 | 18,269.11 | 12,359.16 | 8107.40 |

| Jiangxi | 2285.25 | 3530.82 | 3801.32 | 4651.75 | 2297.18 | 6068.00 | 6466.47 | 8027.91 | 9170.38 | 10,437.02 | 9898.34 | 6057.68 |

| Henan | 7087.71 | 7281.73 | 8859.62 | 8525.09 | 11,723.72 | 8563.09 | 10,555.01 | 11,561.57 | 16,238.15 | 12,341.31 | 12,957.67 | 10,517.70 |

| Hubei | 4824.10 | 9355.86 | 16,766.38 | 15,564.60 | 18,350.34 | 14,754.54 | 19,784.64 | 17,360.74 | 17,852.62 | 14,421.98 | 14,508.45 | 14,867.66 |

| Hunan | 6142.03 | 6000.92 | 6912.98 | 7275.36 | 7619.36 | 7962.16 | 8714.58 | 9489.04 | 11,208.90 | 12,309.58 | 12,425.32 | 8732.75 |

| Inner Mongolia | 2063.54 | 2376.58 | 2290.73 | 2114.21 | 2085.44 | 2207.67 | 2553.85 | 3316.38 | 2515.35 | 1794.59 | 1811.30 | 2284.51 |

| Guangxi | 1907.17 | 2156.22 | 2940.48 | 3169.30 | 3533.47 | 3114.67 | 3957.46 | 4445.54 | 3766.46 | 4456.99 | 3960.43 | 3400.75 |

| Chongqing | 5007.53 | 5428.01 | 4810.03 | 5721.15 | 5850.80 | 5749.34 | 6325.33 | 6374.27 | 6328.41 | 6573.56 | 6385.13 | 5868.51 |

| Sichuan | 10,775.14 | 13,150.94 | 19,530.44 | 21,545.78 | 23,840.78 | 11,331.86 | 12,908.92 | 16,079.06 | 20,112.77 | 20,516.96 | 21,457.48 | 17,386.38 |

| Guizhou | 1040.72 | 1318.54 | 1624.78 | 2784.48 | 3403.56 | 4407.27 | 7880.68 | 3703.11 | 4292.21 | 4622.59 | 3836.98 | 3537.72 |

| Yunnan | 2347.06 | 2078.75 | 2576.87 | 5915.49 | 6472.38 | 3208.55 | 3807.53 | 4192.47 | 4956.26 | 5176.64 | 5747.87 | 4225.44 |

| Shaanxi | 3788.10 | 6280.58 | 4513.80 | 4821.53 | 5515.13 | 5627.84 | 6204.58 | 6354.95 | 7734.02 | 8005.90 | 8752.45 | 6145.35 |

| Gansu | 975.35 | 2122.99 | 1682.12 | 2090.38 | 2279.04 | 1988.81 | 2132.31 | 1862.40 | 1938.57 | 1647.23 | 2190.77 | 1900.91 |

| Qinghai | 573.40 | 330.01 | 346.55 | 366.79 | 396.53 | 391.06 | 416.94 | 507.48 | 519.98 | 463.93 | 503.29 | 437.81 |

| Ningxia | 506.34 | 646.52 | 633.60 | 821.17 | 953.18 | 702.07 | 628.94 | 626.39 | 693.35 | 909.82 | 558.23 | 698.15 |

| Xinjiang | 1144.42 | 1671.97 | 1927.40 | 2078.28 | 2602.63 | 1955.34 | 1928.41 | 1909.97 | 1693.89 | 1875.38 | 1910.06 | 1881.61 |

| Liaoning | 6602.81 | 10,681.55 | 9277.68 | 16,766.37 | 16,541.03 | 6068.53 | 5681.10 | 3467.76 | 3314.42 | 3084.19 | 3153.76 | 7694.47 |

| Jilin | 1741.40 | 2005.27 | 4815.41 | 7033.20 | 7466.20 | 2607.52 | 1857.23 | 1547.13 | 2251.32 | 2182.85 | 1243.56 | 3159.19 |

| Heilongjiang | 1432.66 | 2111.97 | 1653.23 | 1704.99 | 1736.29 | 1274.77 | 1270.41 | 1186.11 | 1199.92 | 2057.54 | 1428.20 | 1550.55 |

| Provinces | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Beijing | 5196.02 | 6046.22 | 6588.30 | 7407.09 | 8209.80 | 8436.73 | 8841.19 | 9736.71 | 10,939.76 | 11,999.36 | 12,905.87 | 8755.18 |

| Tianjin | 2424.49 | 2986.45 | 3258.57 | 3670.53 | 4123.49 | 4488.90 | 4891.81 | 4262.35 | 3791.10 | 4096.50 | 4388.79 | 3853.00 |

| Hebei | 3231.46 | 3972.66 | 4865.09 | 5203.92 | 5625.75 | 5252.57 | 5517.69 | 5655.96 | 5740.25 | 5847.97 | 5948.09 | 5169.22 |

| Shanghai | 4300.19 | 4586.28 | 4843.44 | 5102.84 | 5499.94 | 5652.47 | 6046.19 | 6426.42 | 7072.21 | 7812.47 | 8277.04 | 5965.41 |

| Jiangsu | 12,405.92 | 15,122.85 | 18,423.55 | 21,712.16 | 24,592.93 | 24,785.81 | 25,791.76 | 27,956.71 | 30,846.66 | 33,099.18 | 35,251.64 | 24,544.47 |

| Zhejiang | 12,007.89 | 14,907.42 | 17,332.74 | 20,066.42 | 22,668.19 | 23,980.59 | 24,989.37 | 27,235.83 | 28,756.20 | 20,390.20 | 20,938.61 | 21,206.68 |

| Fujian | 2935.94 | 3692.62 | 4424.54 | 5459.41 | 6689.21 | 7605.81 | 8531.45 | 9993.65 | 11,548.82 | 13,164.42 | 14,118.01 | 8014.90 |

| Shandong | 5496.59 | 6482.90 | 7281.33 | 8332.70 | 9313.46 | 9381.72 | 10,087.43 | 11,477.75 | 12,898.29 | 14,269.29 | 14,947.30 | 9997.16 |

| Guangdong | 4715.46 | 5774.01 | 6514.43 | 7729.24 | 8356.50 | 8865.68 | 9652.31 | 11,372.05 | 13,714.37 | 16,633.41 | 18,429.84 | 10,159.75 |

| Hainan | 199.48 | 255.47 | 283.11 | 285.31 | 276.33 | 278.63 | 307.76 | 322.76 | 339.22 | 365.98 | 391.37 | 300.49 |

| Shanxi | 2143.46 | 2324.91 | 2668.17 | 2983.81 | 3103.49 | 2931.26 | 3318.47 | 3566.57 | 4071.46 | 4653.28 | 5113.64 | 3352.59 |

| Anhui | 2864.96 | 3597.26 | 4230.44 | 4970.34 | 5482.93 | 5695.94 | 6047.29 | 6829.67 | 7888.45 | 8503.26 | 9365.12 | 5952.33 |

| Jiangxi | 1690.02 | 2095.47 | 2789.57 | 3459.53 | 4122.63 | 4602.49 | 5179.03 | 6166.81 | 6993.40 | 7944.80 | 8649.16 | 4881.17 |

| Henan | 4400.61 | 5279.36 | 6009.08 | 7082.37 | 7911.89 | 8047.65 | 8807.99 | 10,086.58 | 11,360.52 | 12,701.68 | 13,122.56 | 8619.12 |

| Hubei | 4345.20 | 5586.45 | 7043.42 | 8343.40 | 10,059.59 | 10,592.86 | 11,862.40 | 13,390.73 | 15,133.87 | 16,979.67 | 16,136.11 | 10,861.24 |

| Hunan | 3161.73 | 3915.02 | 4407.92 | 5255.98 | 6020.97 | 6630.82 | 7304.22 | 8423.00 | 9581.44 | 10,800.62 | 11,864.03 | 7033.25 |

| Inner Mongolia | 1125.58 | 1394.68 | 1441.00 | 1540.48 | 1402.93 | 1123.47 | 1220.81 | 1122.19 | 1040.12 | 1086.06 | 1134.44 | 1239.25 |

| Guangxi | 1222.31 | 1553.07 | 1867.06 | 2271.39 | 2608.91 | 2953.42 | 3449.19 | 4210.07 | 4671.72 | 5407.31 | 5853.24 | 3278.88 |

| Chongqing | 2534.36 | 3328.83 | 3975.67 | 4731.88 | 5552.21 | 6256.94 | 7035.81 | 7605.66 | 7819.42 | 8222.96 | 8974.97 | 6003.52 |

| Sichuan | 4163.07 | 5256.65 | 6240.33 | 7239.49 | 8066.66 | 8768.24 | 9959.68 | 11,400.34 | 12,983.75 | 14,668.15 | 15,612.70 | 9487.19 |

| Guizhou | 622.96 | 824.72 | 1039.22 | 1365.00 | 1640.24 | 1947.74 | 2362.95 | 2932.96 | 3329.98 | 3714.89 | 4080.24 | 2169.17 |

| Yunnan | 1510.96 | 1868.40 | 2383.66 | 2888.82 | 3054.67 | 3268.93 | 3867.22 | 4726.36 | 5458.52 | 6122.09 | 6724.82 | 3806.77 |

| Shaanxi | 3063.61 | 3216.63 | 3529.39 | 3993.81 | 4557.71 | 4752.61 | 5329.23 | 6227.47 | 7120.15 | 7883.89 | 8501.13 | 5288.69 |

| Gansu | 751.99 | 925.84 | 1364.63 | 1708.27 | 1814.52 | 1849.02 | 1947.24 | 1825.42 | 1796.43 | 1916.35 | 2049.28 | 1631.73 |

| Qinghai | 279.61 | 319.42 | 325.76 | 396.39 | 432.91 | 409.51 | 410.62 | 406.93 | 435.14 | 460.72 | 512.24 | 399.02 |

| Ningxia | 342.69 | 427.92 | 466.95 | 564.66 | 625.16 | 524.53 | 511.25 | 549.21 | 565.04 | 601.41 | 641.81 | 529.15 |

| Xinjiang | 963.72 | 1320.37 | 1622.31 | 2071.52 | 2306.28 | 2255.74 | 2258.24 | 2418.70 | 2110.05 | 2278.17 | 2693.12 | 2027.11 |

| Liaoning | 4690.31 | 6217.52 | 7547.39 | 8743.37 | 7851.12 | 5413.76 | 3926.71 | 3688.33 | 3528.41 | 3554.45 | 3815.32 | 5361.52 |

| Jilin | 1348.78 | 1626.65 | 1990.43 | 2200.15 | 2521.00 | 2216.31 | 2283.56 | 2218.37 | 2183.63 | 1863.10 | 2005.78 | 2041.62 |

| Heilongjiang | 1769.70 | 2029.16 | 2373.96 | 2450.57 | 2150.75 | 1680.39 | 1716.61 | 1560.07 | 1194.28 | 1181.35 | 1206.37 | 1755.75 |

| Provinces | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Beijing | 1.300 | 1.370 | 1.396 | 1.428 | 1.405 | 1.475 | 1.460 | 1.452 | 1.465 | 1.479 | 1.553 | 1.435 |

| Tianjin | 1.043 | 1.101 | 1.054 | 1.065 | 1.065 | 1.002 | 1.018 | 0.569 | 0.384 | 0.452 | 0.423 | 0.834 |

| Hebei | 0.446 | 0.451 | 0.415 | 0.505 | 0.676 | 0.540 | 0.593 | 0.540 | 0.538 | 0.623 | 0.599 | 0.539 |

| Shanghai | 1.125 | 1.114 | 1.033 | 1.036 | 1.038 | 1.126 | 1.138 | 1.120 | 1.180 | 1.267 | 1.165 | 1.122 |

| Jiangsu | 0.825 | 0.679 | 0.628 | 0.789 | 0.805 | 1.013 | 1.036 | 1.041 | 1.060 | 1.089 | 1.134 | 0.918 |

| Zhejiang | 1.064 | 1.097 | 1.089 | 1.111 | 1.117 | 1.086 | 1.086 | 1.058 | 1.105 | 0.739 | 0.751 | 1.028 |

| Fujian | 0.587 | 0.695 | 0.610 | 0.593 | 0.552 | 0.567 | 0.561 | 0.531 | 0.497 | 1.032 | 1.043 | 0.661 |

| Shandong | 0.408 | 0.455 | 0.359 | 0.447 | 0.524 | 0.552 | 0.556 | 0.571 | 0.601 | 0.650 | 0.589 | 0.519 |

| Guangdong | 0.467 | 0.520 | 0.414 | 0.492 | 0.523 | 0.552 | 0.554 | 0.525 | 0.488 | 0.656 | 0.548 | 0.522 |

| Hainan | 1.111 | 1.233 | 1.225 | 1.125 | 0.682 | 1.017 | 1.006 | 0.696 | 0.521 | 0.534 | 0.509 | 0.878 |

| Shanxi | 0.487 | 0.542 | 0.459 | 0.490 | 0.514 | 0.506 | 0.524 | 0.510 | 0.506 | 0.622 | 0.549 | 0.519 |

| Anhui | 0.522 | 0.605 | 0.497 | 0.501 | 0.545 | 0.685 | 0.630 | 0.568 | 0.535 | 0.512 | 0.585 | 0.562 |

| Jiangxi | 1.005 | 0.900 | 1.032 | 0.825 | 1.171 | 0.774 | 0.781 | 0.710 | 0.661 | 1.018 | 1.021 | 0.900 |

| Henan | 0.585 | 0.661 | 0.506 | 0.603 | 0.619 | 0.605 | 0.633 | 0.612 | 0.521 | 0.662 | 0.580 | 0.599 |

| Hubei | 0.533 | 0.585 | 0.464 | 0.538 | 0.620 | 0.647 | 0.707 | 0.675 | 1.048 | 1.064 | 1.048 | 0.721 |

| Hunan | 0.622 | 1.027 | 0.669 | 1.015 | 1.027 | 0.642 | 0.655 | 0.623 | 0.581 | 0.632 | 0.575 | 0.733 |

| Inner Mongolia | 0.495 | 0.500 | 0.421 | 0.428 | 0.380 | 0.334 | 0.332 | 0.294 | 0.243 | 0.290 | 0.278 | 0.363 |

| Guangxi | 0.719 | 1.012 | 1.020 | 1.121 | 1.141 | 1.099 | 1.152 | 1.180 | 1.040 | 1.110 | 1.108 | 1.064 |

| Chongqing | 0.690 | 0.690 | 0.590 | 0.605 | 0.759 | 0.848 | 0.830 | 0.754 | 0.750 | 0.783 | 0.762 | 0.733 |

| Sichuan | 0.494 | 0.545 | 0.468 | 0.493 | 0.502 | 0.595 | 0.562 | 0.506 | 0.482 | 0.583 | 0.490 | 0.520 |

| Guizhou | 0.438 | 0.534 | 0.458 | 0.431 | 0.458 | 0.422 | 0.354 | 0.403 | 0.354 | 0.367 | 0.336 | 0.414 |

| Yunnan | 0.490 | 0.576 | 0.423 | 0.442 | 0.437 | 0.530 | 0.513 | 0.517 | 0.488 | 0.571 | 0.456 | 0.495 |

| Shaanxi | 0.691 | 0.707 | 0.593 | 0.559 | 0.550 | 0.620 | 0.639 | 0.653 | 0.596 | 0.656 | 0.584 | 0.622 |

| Gansu | 0.447 | 0.470 | 0.442 | 0.477 | 0.486 | 0.569 | 0.546 | 0.454 | 0.392 | 0.383 | 0.328 | 0.454 |

| Qinghai | 0.527 | 0.575 | 0.396 | 0.460 | 0.463 | 0.468 | 0.390 | 0.338 | 0.316 | 0.367 | 0.347 | 0.422 |

| Ningxia | 0.557 | 0.615 | 0.535 | 0.533 | 0.540 | 0.484 | 0.464 | 0.420 | 0.424 | 0.449 | 0.471 | 0.499 |

| Xinjiang | 0.760 | 0.813 | 0.667 | 0.541 | 0.568 | 0.549 | 0.744 | 0.550 | 0.389 | 0.414 | 0.428 | 0.584 |

| Liaoning | 0.641 | 0.804 | 0.643 | 0.482 | 0.555 | 0.511 | 0.400 | 0.421 | 0.423 | 0.487 | 0.450 | 0.529 |

| Jilin | 1.067 | 1.013 | 0.433 | 0.540 | 1.019 | 0.593 | 0.673 | 0.681 | 0.523 | 0.451 | 0.493 | 0.681 |

| Heilongjiang | 1.277 | 1.122 | 1.187 | 1.147 | 1.110 | 1.007 | 1.011 | 0.702 | 0.436 | 0.406 | 0.394 | 0.891 |

References

- Du, M.B.; Zhang, X.L.; Xia, L.; Libin, C.; Zhe, Z.; Li, Z.; Heran, Z.; Cai, B.F. The China Carbon Watch (CCW) system: A rapid accounting of household carbon emissions in China at the provincial level. Renew. Sustain. Energy Rev. 2022, 155, 111825. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liu, X.; Yang, L.; Zhang, Y.; He, J. How does future climatic uncertainty affect multi-objective building energy retrofit decisions? Evidence from residential buildings in subtropical Hong Kong. Sustain. Cities Soc. 2023, 92, 104482. [Google Scholar] [CrossRef]

- Liu, X.; He, J.; Xiong, K.; Liu, S.; He, B.-J. Identification of factors affecting public willingness to pay for heat mitigation and adaptation: Evidence from Guangzhou, China. Urban Clim. 2023, 48, 101405. [Google Scholar] [CrossRef]

- Ma, C.B.; Atakelty, H.; You, C.Y. A critical review of distance function based economic research on China’s marginal abatement cost of carbon dioxide emissions. Energy Econ. 2019, 84, 104533. [Google Scholar] [CrossRef]

- The Catalyst Review Newsletter Group. Bp’s Statistical Review of World Energy 2021. Catal. Rev. Newsl. 2021, 34, 3. [Google Scholar]

- Jiao, J.L.; Yang, Y.F.; Bai, Y. The impact of inter-industry R&D technology spillover on carbon emission in China. Nat. Hazards 2018, 91, 913–929. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, D. The Spatial-Temporal Evolution of China’s Carbon Emission Intensity and the Analysis of Regional Emission Reduction Potential under the Carbon Emissions Trading Mechanism. Sustainability 2022, 14, 7442. [Google Scholar] [CrossRef]

- Shen, L.; Song, X.; Wu, Y.; Liao, S.; Zhang, X. Interpretive Structural Modeling based factor analysis on the implementation of Emission Trading System in the Chinese building sector. J. Clean. Prod. 2016, 127, 214–227. [Google Scholar] [CrossRef]

- Zhang, M.N.; Li, L.S.; Cheng, Z.H. Research on carbon emission efficiency in the Chinese construction industry based on a three-stage DEA-Tobit model. Environ. Sci. Pollut. Res. 2021, 28, 51120–51136. [Google Scholar] [CrossRef]

- Ma, N.; Li, H.J.; Tang, R.W.; Dong, D.; Shi, J.L.; Wang, Z. Structural analysis of indirect carbon emissions embodied in intermediate input between Chinese sectors: A complex network approach. Environ. Sci. Pollut. Res. 2019, 26, 17591–17607. [Google Scholar] [CrossRef]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: https://www.osti.gov/etdeweb/biblio/20880391 (accessed on 20 March 2023).

- Zhou, W.Z.; Yu, W.H. Regional Variation in the Carbon Dioxide Emission Efficiency of Construction Industry in China: Based on the Three-Stage DEA Model. Discret. Dyn. Nat. Soc. 2021, 2021, 4021947. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, Z.; Huang, B.; Li, X. Embodied Carbon Emissions in China’s Building Sector: Historical Track from 2005 to 2020. Buildings 2023, 13, 211. [Google Scholar] [CrossRef]

- Sun, Y.H.; Hao, S.Y.; Long, X.F. A study on the measurement and influencing factors of carbon emissions in China’s construction sector. Build. Environ. 2023, 229, 109912. [Google Scholar] [CrossRef]

- Nicholas, G.R.; Wassily, L.W. The Structure of the American economy, 1919–1939: An empirical application of equilibrium analysis. Econometrica 1951, 19, 351–353. [Google Scholar]

- Pan, W.; Pan, W.; Shi, Y.; Liu, S.; He, B.; Hu, C.; Tu, H.; Xiong, J.; Yu, D. China’s inter-regional carbon emissions: An in-put-output analysis under considering national economic strategy. J. Clean. Prod. 2018, 197, 794–803. [Google Scholar] [CrossRef]

- Long, Y.; Yoshida, Y.; Fang, K.; Zhang, H.; Dhondt, M. City-level household carbon footprint from purchaser point of view by a modified input-output model. Appl. Energy 2019, 236, 379–387. [Google Scholar] [CrossRef]

- Acquaye, A.A.; Duffy, A.P. Input–output analysis of Irish construction sector greenhouse gas emissions. Build. Environ. 2009, 45, 784–791. [Google Scholar] [CrossRef]

- Feng, B.; Wang, X.; Liu, B. Provincial Variation in Energy Efficiency Across China’s Construction Industry with Carbon Emission Considered. Resour. Sci. 2014, 36, 1256–1266. [Google Scholar]

- Li, Y.; Wang, J.F.; Liu, B.; Li, H.Y.; Guo, Y.M.; Guo, X.R. Regional green total factor performance analysis of China’s construction industry based on a unified framework combining static and dynamic indexes. Environ. Sci. Pollut. Res. 2022, 30, 26874–26888. [Google Scholar] [CrossRef]

- Solow, R.M. Technical change and the aggregate production function. Rev. Econ. Stat. 1957, 39, 554–562. [Google Scholar] [CrossRef]

- Hu, J.-L.; Wang, S.-C. Total-factor energy efficiency of regions in China. Energy Policy 2006, 34, 3206–3217. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Liu, J.; Zhang, H. Total-factor carbon emission efficiency of China’s provincial industrial sector and its dynamic evolution. Renew. Sustain. Energy Rev. 2018, 94, 330–339. [Google Scholar] [CrossRef]

- Yang, Z.; Ying, K.; Tuo, Z. The spatial and temporal evolution of provincial eco-efficiency in China based on SBM modified three-stage data envelopment analysis. Environ. Sci. Pollut. Res. 2020, 27, 8557–8569. [Google Scholar]

- Sun, W.; Huang, C.C. Predictions of carbon emission intensity based on factor analysis and an improved extreme learning machine from the perspective of carbon emission efficiency. J. Clean. Prod. 2022, 338, 130414. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Chen, P.Y. Industrialization, urbanization, and carbon emission efficiency of Yangtze River Economic Belt-empirical analysis based on stochastic frontier model. Environ. Sci. Pollut. Res. 2021, 28, 66914–66929. [Google Scholar] [CrossRef]

- Yang, Z.; Fang, H.; Xue, X.S. Sustainable efficiency and CO2 reduction potential of China’s construction industry: Application of a three-stage virtual frontier SBM-DEA model. J. Asian Arch. Build. Eng. 2022, 21, 604–617. [Google Scholar] [CrossRef]

- Anze, Z.; Yuan, Q. Research on Energy Efficiency Evaluation and Emission Reduction Strategy of Construction Industry Based on DEA and Improved FAA. IOP Conf. Ser. Earth Environ. Sci. 2018, 199, 022065. [Google Scholar] [CrossRef]

- Yao, X.; Feng, W.; Zhang, X.; Wang, W.; Zhang, C.; You, S. Measurement and decomposition of industrial green total factor water efficiency in China. J. Clean. Prod. 2018, 198, 1144–1156. [Google Scholar] [CrossRef]

- Yu, Y.G.; Yan, Y.N.; Shen, P.Y.; Li, Y.T.; Ni, T.H. Green financing efficiency and influencing factors of Chinese listed construction companies against the background of carbon neutralization: A study based on Three-Stage DEA and system GMM. Axioms 2022, 11, 467. [Google Scholar] [CrossRef]

- Sun, C.; Yan, X.; Zhao, L. Coupling efficiency measurement and spatial correlation characteristic of water–energy–food nexus in China. Resour. Conserv. Recycl. 2021, 164, 105151. [Google Scholar] [CrossRef]

- Thompson, M.; Dahab, M.F.; Williams, R.E.; Dvorak, B. Improving energy efficiency of small water-resource recovery facilities: Opportunities and barriers. J. Environ. Eng. 2021, 146, 05020005. [Google Scholar] [CrossRef]

- Zhou, Z.B.; Li, K.; Liu, Q.; Tao, Z.; Lin, L. Carbon footprint and eco-efficiency of China’s regional construction industry: A life cycle perspective. J. Oper. Res. Soc. 2021, 72, 2704–2719. [Google Scholar] [CrossRef]

- Yang, W.; Li, L. Analysis of Total Factor Efficiency of Water Resource and Energy in China: A Study Based on DEA-SBM Model. Sustainability 2017, 9, 1316. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.Y. Carbon emission efficiency measurement and influencing factor analysis of nine provinces in the Yellow River basin: Based on SBM-DDF model and Tobit-CCD model. Environ. Sci. Pollut. Res. 2022, 29, 33263–33280. [Google Scholar] [CrossRef]

- Hua, L.; Min, Z. Carbon emission efficiency of construction industry in Hunan province and measures of carbon emission reduction. Nat. Environ. Pollut. Technol. 2019, 18, 1005–1010. [Google Scholar]

- Song, M.L.; Chen, Y.; An, Q.X. Spatial econometric analysis of factors influencing regional energy efficiency in China. Environ. Sci. Pollut. Res. 2018, 25, 13745–13759. [Google Scholar] [CrossRef]

- Du, Q.; Deng, Y.G.; Zhou, J.; Wu, J.; Pang, Q.Y. Spatial spillover effect of carbon emission efficiency in the construction industry of China. Environ. Sci. Pollut. Res. 2021, 29, 2466–2479. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Liu, W.L.; Lv, X.Y.; Chen, X.H.; Shen, M.H. Investigating interior driving factors and cross-industrial linkages of carbon emission efficiency in China’s construction industry: Based on Super-SBM DEA and GVAR model. J. Clean. Prod. 2019, 241, 118322. [Google Scholar] [CrossRef]

- Jiang, X.H.; Ma, J.X.; Zhu, H.Z.; Guo, L.C.; Huang, Z.G. Evaluating the Carbon Emissions Efficiency of the Logistics Industry Based on a Super-SBM Model and the Malmquist Index from a Strong Transportation Strategy Perspective in China. Int. J. Environ. Res. Public Health 2020, 17, 8459. [Google Scholar] [CrossRef]

- Tian, J.J.; Song, X.Q.; Zhang, J.S. Spatial-Temporal Pattern and Driving Factors of Carbon Efficiency in China: Evidence from Panel Data of Urban Governance. Energies 2022, 15, 2536. [Google Scholar] [CrossRef]

- Xu, G.; Zhao, T.; Wang, R. Research on Carbon Emission Efficiency Measurement and Regional Difference Evaluation of China’s Regional Transportation Industry. Energies 2022, 15, 6502. [Google Scholar] [CrossRef]

- Zhou, Y.W. Total factor productivity of Hubei transportation industry under environmental constraint. Ekoloji Dergisi. 2019, 107, 1591–1597. [Google Scholar]

- Zhang, N.; Zhou, P.; Kung, C. Total-factor carbon emission performance of the Chinese transportation industry: A boot-strapped non-radial Malmquist index analysis. Renew. Sustain. Energy Rev. 2015, 41, 584–593. [Google Scholar] [CrossRef]

- Lin, B.; Fei, R. Regional differences of CO2 emissions performance in China’s agricultural sector: A Malmquist index approach. Eur. J. Agron. 2015, 70, 33–40. [Google Scholar] [CrossRef]

- Liu, M.; Yang, L. Spatial pattern of China’s agricultural carbon emission performance. Ecol. Indic. 2021, 133, 108345. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, K.; Zhou, X. Analysis of regional differences and dynamic mechanisms of agricultural carbon emission efficiency in China’s seven agricultural regions. Environ. Sci. Pollut. Res. 2022, 29, 38258–38284. [Google Scholar] [CrossRef]

- Yao, X.; Guo, C.; Shao, S.; Jiang, Z. Total-factor CO2 emission performance of China’s provincial industrial sector: A meta-frontier non-radial Malmquist index approach. Appl. Energy 2016, 184, 1142–1153. [Google Scholar] [CrossRef]

- Oathout, J.M. Determining the Dynamic Efficiency with which wiping Materials Remove Liquids from Surfaces. Int. Nonwovens J. 2000, OS-9(1). [Google Scholar] [CrossRef]

- Lu, X.; Xu, C. The difference and convergence of total factor productivity of inter-provincial water resources in China based on three- stage DEA-Malmquist index model. Sustain. Comput. Inform. Syst. 2019, 22, 75–83. [Google Scholar] [CrossRef]

- Woo, C.; Chung, Y.; Chun, D.; Seo, H.; Hong, S. The static and dynamic environmental efficiency of renewable energy: A Malmquist index analysis of OECD countries. Renew. Sustain. Energy Rev. 2015, 47, 367–376. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, R. Carbon emissions in the construction sector based on input-output analyses. J. Tsinghua Univ. (Sci. Technol.) 2013, 53, 53–57. [Google Scholar]

- State Statistical Bureau (SSB; Now NBS). China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2022. Available online: http://www.shujuku.org/china-energy-statistical-yearbook.html (accessed on 20 November 2022).

- State Administration for Market Regulation. General Rules for Calculation of the Comprehensive Energy Consumption; National Standard of the People’s Republic of China, 2020. Available online: http://ft.panzhihua.gov.cn/uploadfiles/202108/12/2021081217202347802674.pdf (accessed on 20 January 2023).

- National Development and Reform Commission. Guidelines for the Preparation of Provincial Greenhouse Gas Inventories (Trial); National Development and Reform Commission: Beijing, China, 2011.

- Ministry of Ecology and Environment. Accounting Methods and Reporting Guidelines for Greenhouse Gas Emissions of Enterprises; China Energy Information Platform, 2015. Available online: http://big5.mee.gov.cn/gate/big5/www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202212/W020221221671986519778.pdf (accessed on 20 December 2022).

- Construction Statistics National Bureau of Statistics. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2022; Available online: http://www.shujuku.org/china-construction-statistical-yearbook.html (accessed on 20 January 2023).

- Cui, P.; Li, D.; Ang, S.; Li, Q. Study on the life-cycle eco-efficiency evaluation method of residential building. Constr. Econ. 2013, 11, 96–99. [Google Scholar]

- Li, Z. Study on calculation method of life cycle energy consumption for recyclable materials. J. Basic Sci. Eng. 2006, 1, 50–58. [Google Scholar]

- Wang, L. Re-discussing CO2 reduction in China’s cement industry. China Cem. 2008, 2, 36–39. [Google Scholar]

- Li, X.; Xu, H. Life cycle evaluation of steel based on GaBi software. Environ. Prot. Circ. Econ. 2009, 29, 15–18. [Google Scholar]

- Lin, B.Q. Qualitative Change of China’s Energy Conservation and Emission Reduction Policy: From Energy Intensity to Carbon Intensity. China Daily. 2009. Available online: http://www.chinadaily.com.cn/zgrbjx/2009-11/05/content_9089221.htm (accessed on 20 February 2023).

- Fang, L.; Lu, T.; Kai, C.; Li, J.; Ping, S. Spatial distribution and regional difference of carbon emissions efficiency of industrial energy in China. Sci. Rep. 2021, 11, 19419. [Google Scholar]

- National Bureau of Statistics (NBS; formerly State Statistical Bureau). China Statistical Yearbook; China Statistics Press: Beijing, China, 2022. Available online: http://www.stats.gov.cn/sj/ndsj/ (accessed on 20 January 2023).

- Cheng, G. Data Envelopment Analysis Methodology and MaxDEA Software; Intellectual Property Publishing House: Beijing, China, 2014. [Google Scholar]

- Sten, M. Index numbers and indifference surfaces. Trab. Estad. 1953, 4, 209–242. [Google Scholar]

- Färe, R.; Margaritis, S.; Margaritis, D. Malmquist productivity indexes and DEA. In Handbook on Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2011; pp. 127–149. [Google Scholar]

- Zhang, C.; Liu, H.; Bressers, H.T.A.; Buchanan, K.S. Productivity growth and environmental regulations—Accounting for undesirable outputs: Analysis of China’s thirty provincial regions using the Malmquist–Luenberger index. Ecol. Econ. 2011, 70, 2369–2379. [Google Scholar] [CrossRef]

- Du, J.; Chen, Y.; Huang, Y. A Modified Malmquist-Luenberger Productivity Index: Assessing Environmental Productivity Performance in China. Eur. J. Oper. Res. 2018, 269, 171–187. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef]

- Du, Q.; Zhou, J.; Pan, T.; Sun, Q.; Wu, M. Relationship of carbon emissions and economic growth in China’s construction industry. J. Clean. Prod. 2019, 220, 99–109. [Google Scholar] [CrossRef]

- Du, Q.; Lu, X.; Yi, L.; Min, W.; Li, B.; Ming, Y. Carbon emissions in China’s construction industry: Calculations, factors and regions. Int. J. Environ. Res. Public Health 2018, 15, 1220. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Sun, W.; Li, G.; Cui, P.; Wu, W.; Jin, B. Temporal and spatial heterogeneity of carbon intensity in China’s construction industry. Resour. Conserv. Recycl. 2017, 126, 162–173. [Google Scholar] [CrossRef]

- Monidipa, D.; Ghosh, S.K. Measuring Moran’s I in a cost-efficient manner to describe a land-cover change pattern in large-scale remote sensing imagery. IEEE J.-Stars. 2017, 10, 2631–2639. [Google Scholar]

- Chen, H.; Lu, X.; Gao, T.; Chang, Y. Identifying hot-spots of metal contamination in campus dust of Xi’an, China. Int. J. Environ. Res. Public Health 2016, 13, 555. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.C.; Xia, N.N.; Varga, L.; Tan, Y.T.; Hua, X.J.; Li, Q.M. Sustainable international competitiveness of regional construction industry: Spatiotemporal evolution and influential factor analysis in China. J. Clean. Prod. 2022, 337, 130592. [Google Scholar] [CrossRef]

- Du, K.; Lu, H.; Yu, K. Sources of the potential CO2 emission reduction in China: A nonparametric metafrontier approach. Appl. Energy 2014, 115, 491–501. [Google Scholar] [CrossRef]

- Lu, C.-C.; Chiu, Y.-H.; Shyu, M.-K.; Lee, J.-H. Measuring CO2 emission efficiency in OECD countries: Application of the Hybrid Efficiency model. Econ. Model. 2013, 32, 130–135. [Google Scholar] [CrossRef]

- Wang, K.; Wei, Y.-M. China’s regional industrial energy efficiency and carbon emissions abatement costs. Appl. Energy 2014, 130, 617–631. [Google Scholar] [CrossRef]

- Tan, X.; Lai, H.; Gu, B.; Zeng, Y.; Li, H. Carbon emission and abatement potential outlook in China’s building sector through 2050. Energy Policy 2018, 118, 429–439. [Google Scholar] [CrossRef]

- Hou, H.; Feng, X.; Zhang, Y.; Bai, H.; Ji, Y.; Xu, H. Energy-related carbon emissions mitigation potential for the construction sector in China. Environ. Impact Assess. Rev. 2021, 89, 106599. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, L.; Fan, Y.; Xie, B. Evaluation of potential reductions in carbon emissions in Chinese provinces based on en-vironmental DEA. Energy Policy 2011, 39, 2352–2360. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B. Research on the life-cycle CO2 emission of China’s construction sector. Energy Build. 2016, 112, 244–255. [Google Scholar] [CrossRef]

- Beijing Municipal Commission of Housing and Urban-rural Development; Beijing Municipal Commission of Planning and Natural Resources; Beijing Municipal Finance Bureau. Beijing prefabricated buildings, green buildings, green ecological demonstration zone project municipal incentive funds management Interim measures. Gaz. People’s Gov. Beijing Munic. 2020, 38, 11–23. [Google Scholar]

- Development and Reform Commission, Department of Housing and Urban-Rural Development. Guangxi: Issued a green building action plan. Informatiz. China Constr. 2013, 22, 6. [Google Scholar]

- Xiao, H.; Wei, Q.; Wang, H. Marginal abatement cost and carbon reduction potential outlook of key energy efficiency technologies in China’s building sector to 2030. Energy Policy 2014, 69, 92–105. [Google Scholar] [CrossRef]

- Bian, Y.; Lv, K.; Yu, A. China’s regional energy and carbon dioxide emissions efficiency evaluation with the presence of recovery energy: An interval slacks-based measure approach. Ann. Oper. Res. 2015, 255, 301–321. [Google Scholar] [CrossRef]

- Zhang, J.; Zeng, W.; Wang, J.; Yang, F.; Jiang, H. Regional low-carbon economy efficiency in China: Analysis based on the Super-SBM model with CO2 emissions. J. Clean. Prod. 2017, 163, 202–211. [Google Scholar] [CrossRef]

- GB/T 50378-2019; Assessment Standard for Green Building. National Standard of the People’s Republic of China: Beijing, China, 2019.

- Report on Building Energy Efficiency and Green Building Policy and Development of Shanghai. Shanghai Build. Mater. 2014, 4, 1–6.

- Shanghai Housing and urban and rural Construction Management Committee requires that new civil and industrial buildings should be fabricated. Build. Technol. Dev. 2019, 46, 143.

- Cheng, Z.; Li, L.; Liu, J. Industrial structure, technical progress and carbon intensity in China’s provinces. Renew. Sustain. Energy Rev. 2018, 81, 2935–2946. [Google Scholar] [CrossRef]

- Yan, D.; Lei, Y.; Li, L.; Song, W. Carbon emission efficiency and spatial clustering analyses in China’s thermal power industry: Evidence from the provincial level. J. Clean. Prod. 2017, 156, 518–527. [Google Scholar] [CrossRef]

| Energy Type | NCVi (TJ/104 Tons) | Ci (Tons/TJ) | Oi |

|---|---|---|---|

| Raw coal | 209.08 | 26.37 | 0.94 |

| Washed refined coal | 263.44 | 25.41 | 0.96 |

| Other washed coal | 83.63 | 25.41 | 0.96 |

| Briquette | 174.60 | 33.60 | 0.90 |

| Coal gangue | 83.63 | 27.30 | 0.98 |

| Coke | 284.35 | 29.50 | 0.93 |

| Coke oven gas | 292.71 | 13.60 | 0.99 |

| Other gas | 522.70 | 12.20 | 0.99 |

| Crude oil | 418.16 | 20.10 | 0.98 |

| Gasoline | 430.70 | 18.90 | 0.98 |

| Kerosene | 430.70 | 19.50 | 0.98 |

| Diesel oil | 426.52 | 20.20 | 0.98 |

| Fuel oil | 418.16 | 21.10 | 0.98 |

| Naphtha | 439.07 | 20.00 | 0.98 |

| Lubricant | 413.98 | 20.00 | 0.98 |

| Petroleum asphalt | 389.31 | 22.00 | 0.98 |

| Petroleum coke | 319.47 | 27.50 | 0.98 |

| Liquefied petroleum gas | 501.79 | 17.20 | 0.98 |

| Refinery dry gas | 460.55 | 18.20 | 0.98 |

| Other petroleum products | 409.80 | 20.00 | 0.98 |

| Natural gas | 292.54 | 15.30 | 0.99 |

| Name of the Grid | Coverage of Provinces | Carbon Emission Factor (kgCO2/kWh) |

|---|---|---|

| North China region | Beijing, Tianjin, Hebei, Shanxi, Shandong, and Inner Mongolia | 0.8843 |

| Central China region | Henan, Hubei, Hunan, Jiangxi, Sichuan, and Chongqing | 0.5257 |

| East China region | Shanghai, Jiangsu, Zhejiang, Anhui, and Fujian | 0.7035 |

| Northeast China region | Liaoning, Jilin, and Heilongjiang | 0.7769 |

| Northwest China region | Shaanxi, Gansu, Qinghai, Ningxia, and Xinjiang | 0.6671 |

| Southern China region | Guangdong, Guangxi, Yunnan, Guizhou, and Hainan | 0.5271 |

| Construction Materials | Carbon Emission Factor | Recovery Factor |

|---|---|---|

| Steel | 1.789 kg/kg | 0.8 |

| Wood | 10.45 kg/m3 | - |

| Cement | 0.822 kg/kg | - |

| Glass | 35.78 kg/weight box | - |

| Aluminum | 2.6 kg/kg | 0.85 |

| Category | Elements | Specific Indicators | Data Source |

|---|---|---|---|

| Input elements | Energy | Total energy consumption in the construction industry (104 tons) | China Energy Statistics Yearbook [54] |

| Labor | Year-end number of employees in the construction industry (104 people) | China Statistical Yearbook [65] | |

| Capital | Construction industry enterprise assets (108 RMB) | China Statistical Yearbook on Construction [58] | |

| Mechanical equipment | Total power of own construction mechanical equipment at the end of the year (104 kilowatts) | China Statistical Yearbook on Construction [58] | |

| Expected output | Total industry output | Total construction industry output (108 RMB) | China Statistical Yearbook on Construction [58] |

| Non-desired output | Carbon emissions | Carbon emissions from the construction industry (104 tons) | Calculated by Equations (1)–(5) |

| Year | Moran’s I | p-Value | Z-Value | E[I] | Mean | sd |

|---|---|---|---|---|---|---|

| 2010 | 0.2529 | 0.023 | 2.3583 | −0.0357 | −0.0344 | 0.1218 |

| 2011 | 0.1625 | 0.056 | 1.6087 | −0.0357 | −0.0344 | 0.1224 |

| 2012 | 0.1130 | 0.108 | 1.2471 | −0.0357 | −0.0359 | 0.1194 |

| 2013 | 0.1937 | 0.036 | 1.9185 | −0.0357 | −0.0364 | 0.1199 |

| 2014 | 0.2220 | 0.028 | 2.1057 | −0.0357 | −0.0379 | 0.1235 |

| 2015 | 0.2410 | 0.016 | 2.3652 | −0.0357 | −0.0391 | 0.1185 |

| 2016 | 0.2213 | 0.026 | 2.1764 | −0.0357 | −0.0407 | 0.1204 |

| 2017 | 0.1554 | 0.056 | 1.7155 | −0.0357 | −0.0427 | 0.1155 |

| 2018 | 0.1983 | 0.035 | 2.0591 | −0.0357 | −0.0438 | 0.1176 |

| 2019 | 0.2049 | 0.022 | 2.1295 | −0.0357 | −0.0452 | 0.1174 |

| 2020 | 0.1772 | 0.040 | 1.9105 | −0.0357 | −0.0453 | 0.1165 |

| Provinces | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inner Mongolia | 60.11 | 38.24 | 62.47 | 56.84 | 63.45 | 80.77 | 83.02 | 87.25 | 86.08 | 58.88 | 75.65 | 68.43 |

| Guizhou | 51.54 | 36.43 | 57.88 | 69.04 | 55.91 | 66.07 | 66.69 | 71.09 | 79.35 | 58.06 | 71.33 | 62.13 |

| Ningxia | 50.48 | 38.72 | 52.73 | 55.96 | 53.08 | 57.48 | 68.59 | 64.57 | 67.80 | 55.35 | 48.99 | 55.80 |

| Sichuan | 70.25 | 56.39 | 78.90 | 78.10 | 54.83 | 28.59 | 39.31 | 28.47 | 37.51 | 49.01 | 62.04 | 53.04 |

| Hebei | 78.07 | 88.68 | 92.00 | 79.61 | 35.97 | 35.51 | 27.35 | 40.05 | 34.99 | 27.64 | 43.29 | 53.02 |

| Liaoning | 42.49 | 22.49 | 39.35 | 69.29 | 59.27 | 44.95 | 70.04 | 51.40 | 56.59 | 16.84 | 44.90 | 47.06 |

| Qinghai | 60.52 | 15.73 | 36.56 | 28.97 | 27.82 | 41.78 | 56.66 | 70.32 | 74.27 | 39.00 | 64.68 | 46.94 |

| Gansu | 37.58 | 54.69 | 44.91 | 45.96 | 56.22 | 26.12 | 24.70 | 42.35 | 60.44 | 35.61 | 66.40 | 45.00 |

| Shanxi | 61.39 | 31.42 | 41.22 | 44.80 | 44.86 | 32.80 | 57.51 | 58.07 | 55.39 | 9.94 | 40.45 | 43.44 |

| Yunnan | 47.88 | 23.62 | 38.06 | 68.53 | 65.52 | 36.10 | 39.11 | 35.01 | 39.91 | 25.24 | 56.79 | 43.25 |

| Guangdong | 56.82 | 56.53 | 54.32 | 49.22 | 48.90 | 34.65 | 26.77 | 34.41 | 39.99 | 2.83 | 36.74 | 40.11 |

| Anhui | 48.68 | 23.83 | 41.69 | 45.90 | 54.15 | 13.99 | 25.90 | 30.41 | 26.47 | 65.11 | 59.00 | 39.56 |

| Shaanxi | 21.61 | 40.37 | 47.69 | 46.13 | 39.97 | 26.00 | 34.16 | 31.02 | 41.90 | 33.21 | 56.60 | 38.06 |

| Xinjiang | 28.75 | 14.62 | 40.84 | 45.06 | 44.15 | 38.79 | 19.96 | 33.75 | 58.94 | 25.23 | 49.03 | 36.28 |

| Shandong | 53.80 | 30.13 | 77.00 | 45.77 | 38.01 | 35.02 | 24.99 | 21.00 | 17.08 | 8.92 | 18.68 | 33.67 |

| Guangxi | 30.98 | 35.34 | 33.91 | 34.27 | 35.63 | 38.30 | 34.16 | 35.63 | 28.49 | 30.09 | 25.40 | 32.93 |

| Hubei | 27.08 | 41.75 | 71.47 | 64.32 | 51.32 | 28.00 | 43.76 | 32.68 | 0.00 | 0.00 | 0.00 | 32.76 |

| Fujian | 40.55 | 11.38 | 34.39 | 39.52 | 38.57 | 36.35 | 39.43 | 53.45 | 55.79 | 0.00 | 0.00 | 31.77 |

| Jilin | 0.00 | 0.00 | 72.10 | 79.76 | 0.00 | 30.02 | 3.96 | 0.63 | 44.34 | 38.53 | 34.85 | 27.65 |

| Henan | 38.54 | 12.45 | 52.27 | 31.33 | 58.91 | 0.73 | 0.00 | 14.33 | 28.42 | 19.01 | 38.56 | 26.78 |

| Chongqing | 43.80 | 26.47 | 47.75 | 47.77 | 22.26 | 6.91 | 7.17 | 0.00 | 13.61 | 14.24 | 25.45 | 23.22 |

| Heilongjiang | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 21.75 | 62.86 | 66.62 | 66.65 | 19.81 |

| Jiangxi | 14.05 | 16.09 | 14.39 | 13.74 | 15.24 | 18.38 | 12.76 | 23.39 | 29.44 | 27.68 | 21.19 | 18.76 |

| Hunan | 44.25 | 0.00 | 13.81 | 11.78 | 0.00 | 11.76 | 10.88 | 9.16 | 15.89 | 31.59 | 38.95 | 17.10 |

| Hainan | 0.00 | 0.00 | 0.00 | 0.00 | 28.63 | 0.00 | 0.00 | 5.88 | 47.25 | 41.71 | 53.14 | 16.05 |

| Tianjin | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 38.35 | 70.60 | 12.10 | 48.59 | 15.42 |

| Jiangsu | 4.51 | 33.27 | 41.86 | 1.36 | 19.25 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 9.11 |

| Zhejiang | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Beijing | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Shanghai | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Provinces | 2010–2011 | 2011–2012 | 2012–2013 | 2013–2014 | 2014–2015 | 2015–2016 | 2016–2017 | 2017–2018 | 2018–2019 | 2019–2020 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Beijing | 1.142 | 1.131 | 1.019 | 0.988 | 1.009 | 0.993 | 0.996 | 1.004 | 0.993 | 1.188 | 1.047 |

| Tianjin | 1.081 | 0.838 | 0.984 | 0.899 | 0.555 | 1.228 | 0.597 | 0.728 | 1.062 | 1.117 | 0.909 |

| Hebei | 0.982 | 0.985 | 1.132 | 1.120 | 0.648 | 0.887 | 0.617 | 1.047 | 1.082 | 1.139 | 0.964 |

| Shanghai | 0.925 | 0.972 | 0.887 | 0.998 | 1.073 | 0.987 | 0.972 | 1.174 | 0.982 | 1.026 | 1.000 |

| Jiangsu | 0.690 | 1.036 | 1.126 | 0.983 | 1.008 | 0.939 | 1.027 | 0.971 | 1.010 | 0.938 | 0.973 |

| Zhejiang | 1.030 | 1.011 | 0.997 | 1.003 | 0.974 | 0.988 | 0.984 | 1.041 | 0.646 | 1.077 | 0.975 |

| Fujian | 1.148 | 0.936 | 0.930 | 0.904 | 0.989 | 0.955 | 0.984 | 0.933 | 0.981 | 0.997 | 0.976 |

| Shandong | 1.001 | 0.913 | 1.167 | 0.993 | 0.917 | 0.972 | 1.025 | 1.102 | 0.960 | 1.275 | 1.033 |

| Guangdong | 1.010 | 0.895 | 1.122 | 0.935 | 0.930 | 0.994 | 0.923 | 1.002 | 1.152 | 1.036 | 1.000 |

| Hainan | 1.073 | 0.992 | 0.769 | 0.589 | 0.961 | 0.832 | 0.678 | 0.822 | 0.945 | 1.128 | 0.879 |

| Shanxi | 1.030 | 0.973 | 1.001 | 0.932 | 0.776 | 1.034 | 0.950 | 1.072 | 1.061 | 1.094 | 0.992 |

| Anhui | 0.991 | 0.970 | 0.928 | 0.938 | 1.079 | 0.866 | 0.922 | 0.961 | 0.866 | 1.259 | 0.978 |

| Jiangxi | 0.859 | 1.061 | 0.878 | 1.399 | 0.623 | 0.935 | 0.958 | 0.918 | 1.210 | 1.005 | 0.985 |

| Henan | 0.930 | 0.907 | 1.033 | 0.895 | 0.841 | 0.954 | 1.014 | 0.864 | 1.168 | 0.984 | 0.959 |

| Hubei | 0.984 | 0.908 | 1.082 | 0.987 | 0.759 | 1.010 | 0.804 | 1.600 | 1.109 | 0.990 | 1.023 |

| Hunan | 1.666 | 0.655 | 1.004 | 1.025 | 0.573 | 0.955 | 0.985 | 0.953 | 1.000 | 0.962 | 0.978 |

| Inner Mongolia | 0.985 | 0.876 | 0.962 | 0.819 | 0.793 | 0.997 | 0.878 | 0.908 | 1.165 | 1.076 | 0.946 |

| Guangxi | 1.028 | 1.138 | 1.123 | 0.995 | 0.962 | 1.030 | 1.061 | 0.882 | 0.996 | 1.026 | 1.024 |

| Chongqing | 0.907 | 1.067 | 0.979 | 1.095 | 1.178 | 0.876 | 0.956 | 0.988 | 0.971 | 1.204 | 1.022 |

| Sichuan | 1.018 | 0.976 | 1.012 | 0.927 | 1.100 | 0.919 | 0.908 | 0.985 | 1.119 | 0.951 | 0.991 |

| Guizhou | 1.088 | 1.009 | 0.892 | 0.931 | 0.871 | 0.813 | 1.121 | 0.943 | 0.988 | 1.001 | 0.966 |

| Yunnan | 1.051 | 0.877 | 0.970 | 0.862 | 1.076 | 0.945 | 0.997 | 0.994 | 1.063 | 0.919 | 0.975 |

| Shaanxi | 0.995 | 0.768 | 0.879 | 0.849 | 0.778 | 0.994 | 1.027 | 0.941 | 1.010 | 0.993 | 0.923 |

| Gansu | 0.930 | 1.100 | 1.004 | 0.881 | 0.999 | 0.922 | 0.829 | 0.915 | 0.884 | 0.959 | 0.942 |

| Qinghai | 0.984 | 0.821 | 1.079 | 0.874 | 0.864 | 0.834 | 0.852 | 1.000 | 1.069 | 1.093 | 0.947 |

| Ningxia | 1.039 | 1.004 | 0.917 | 0.891 | 0.639 | 0.957 | 0.876 | 1.114 | 1.001 | 1.217 | 0.966 |

| Xinjiang | 1.014 | 0.894 | 0.952 | 1.005 | 0.844 | 0.817 | 0.775 | 0.533 | 0.935 | 1.247 | 0.902 |

| Liaoning | 1.270 | 0.958 | 1.161 | 0.509 | 0.616 | 0.778 | 1.032 | 1.087 | 1.007 | 1.113 | 0.953 |

| Jilin | 0.980 | 0.453 | 1.173 | 1.265 | 0.552 | 1.104 | 0.992 | 0.832 | 0.789 | 1.681 | 0.982 |

| Heilongjiang | 0.878 | 1.087 | 0.924 | 0.956 | 0.725 | 0.997 | 0.690 | 0.642 | 0.882 | 1.064 | 0.884 |

| Provinces | 2010–2011 | 2013–2014 | 2016–2017 | 2019–2020 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MLTC | MLPEC | MLSEC | MLTC | MLPEC | MLSEC | MLTC | MLPEC | MLSEC | MLTC | MLPEC | MLSEC | |

| Beijing | 1.084 | 1.049 | 1.005 | 1.004 | 0.980 | 1.004 | 1.002 | 0.992 | 1.002 | 1.130 | 1.049 | 1.001 |

| Tianjin | 1.019 | 1.052 | 1.003 | 0.900 | 0.999 | 1.001 | 0.981 | 0.574 | 0.973 | 1.193 | 0.922 | 1.016 |

| Hebei | 0.970 | 0.932 | 1.086 | 0.837 | 1.010 | 1.325 | 0.989 | 0.894 | 1.017 | 1.185 | 0.957 | 1.004 |

| Shanghai | 0.935 | 0.990 | 1.000 | 0.996 | 0.999 | 1.003 | 0.988 | 0.984 | 1.000 | 1.116 | 0.916 | 1.004 |

| Jiangsu | 0.838 | 0.920 | 0.894 | 0.963 | 0.984 | 1.037 | 1.022 | 1.017 | 0.988 | 0.901 | 0.984 | 1.058 |

| Zhejiang | 0.999 | 1.043 | 0.989 | 0.997 | 1.018 | 0.988 | 1.010 | 0.982 | 0.992 | 1.059 | 1.031 | 0.986 |

| Fujian | 0.970 | 1.193 | 0.992 | 0.972 | 0.942 | 0.988 | 1.039 | 0.972 | 0.974 | 0.986 | 0.991 | 1.019 |

| Shandong | 0.898 | 1.058 | 1.054 | 0.848 | 1.031 | 1.136 | 0.998 | 1.054 | 0.974 | 1.407 | 0.965 | 0.939 |

| Guangdong | 0.907 | 1.088 | 1.024 | 0.880 | 0.961 | 1.105 | 0.974 | 0.947 | 1.000 | 1.240 | 1.287 | 0.649 |

| Hainan | 0.967 | 0.670 | 1.657 | 0.971 | 1.063 | 0.571 | 0.978 | 1.145 | 0.604 | 1.184 | 1.141 | 0.835 |

| Shanxi | 0.926 | 1.086 | 1.025 | 0.888 | 1.049 | 1.000 | 0.976 | 0.982 | 0.991 | 1.240 | 0.883 | 1.000 |

| Anhui | 0.854 | 1.089 | 1.065 | 0.863 | 0.955 | 1.139 | 1.022 | 0.912 | 0.989 | 1.102 | 1.226 | 0.932 |

| Jiangxi | 0.959 | 0.991 | 0.904 | 0.986 | 1.175 | 1.207 | 1.055 | 0.910 | 0.998 | 1.002 | 1.006 | 0.997 |

| Henan | 0.823 | 1.391 | 0.812 | 0.873 | 0.866 | 1.185 | 1.049 | 1.013 | 0.954 | 1.123 | 1.000 | 0.876 |

| Hubei | 0.896 | 0.988 | 1.110 | 0.857 | 1.011 | 1.140 | 0.834 | 0.957 | 0.997 | 1.006 | 0.996 | 0.989 |

| Hunan | 1.009 | 1.650 | 1.001 | 1.017 | 1.011 | 1.001 | 1.035 | 0.981 | 0.970 | 1.057 | 1.163 | 0.783 |

| Inner Mongolia | 0.976 | 1.020 | 0.989 | 0.921 | 0.913 | 0.973 | 0.994 | 0.894 | 0.987 | 1.123 | 0.951 | 1.007 |

| Guangxi | 0.730 | 1.043 | 1.349 | 0.978 | 1.060 | 0.960 | 1.036 | 1.025 | 0.999 | 1.028 | 0.942 | 1.059 |

| Chongqing | 0.907 | 0.993 | 1.007 | 0.873 | 1.186 | 1.058 | 1.052 | 0.945 | 0.962 | 1.238 | 1.022 | 0.952 |

| Sichuan | 0.922 | 1.032 | 1.071 | 0.910 | 0.977 | 1.042 | 1.008 | 0.931 | 0.968 | 1.133 | 0.901 | 0.932 |

| Guizhou | 0.892 | 1.159 | 1.052 | 0.875 | 1.072 | 0.992 | 0.985 | 1.103 | 1.032 | 1.096 | 0.922 | 0.991 |

| Yunnan | 0.894 | 1.179 | 0.997 | 0.871 | 0.988 | 1.001 | 0.988 | 0.996 | 1.013 | 1.152 | 0.803 | 0.993 |

| Shaanxi | 0.997 | 1.284 | 0.797 | 0.863 | 0.978 | 1.006 | 1.006 | 1.007 | 1.015 | 1.115 | 0.894 | 0.997 |

| Gansu | 0.883 | 0.994 | 1.060 | 0.864 | 1.017 | 1.002 | 0.995 | 0.853 | 0.976 | 1.121 | 0.845 | 1.013 |

| Qinghai | 0.902 | 1.165 | 0.936 | 0.870 | 0.829 | 1.213 | 0.982 | 0.885 | 0.981 | 1.155 | 0.985 | 0.961 |

| Ningxia | 0.941 | 0.621 | 1.778 | 0.880 | 1.091 | 0.929 | 0.968 | 0.934 | 0.969 | 1.161 | 1.120 | 0.936 |

| Xinjiang | 1.156 | 0.817 | 1.307 | 0.883 | 1.032 | 1.017 | 0.846 | 0.761 | 0.972 | 1.204 | 1.013 | 1.022 |

| Liaoning | 1.012 | 0.998 | 1.258 | 0.873 | 1.328 | 0.868 | 0.980 | 1.067 | 0.987 | 1.206 | 0.920 | 1.004 |

| Jilin | 1.034 | 0.973 | 0.976 | 0.670 | 1.873 | 1.007 | 0.980 | 1.022 | 0.990 | 1.536 | 1.128 | 0.970 |

| Heilongjiang | 0.999 | 0.859 | 1.024 | 0.988 | 0.954 | 1.014 | 0.994 | 0.978 | 0.711 | 1.095 | 1.007 | 0.965 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhang, Y.; Chen, Y.; Wang, J.; Zhao, L.; Chen, M. Evaluation of Carbon Emission Efficiency in the Construction Industry Based on the Super-Efficient Slacks-Based Measure Model: A Case Study at the Provincial Level in China. Buildings 2023, 13, 2207. https://doi.org/10.3390/buildings13092207

Zhang J, Zhang Y, Chen Y, Wang J, Zhao L, Chen M. Evaluation of Carbon Emission Efficiency in the Construction Industry Based on the Super-Efficient Slacks-Based Measure Model: A Case Study at the Provincial Level in China. Buildings. 2023; 13(9):2207. https://doi.org/10.3390/buildings13092207

Chicago/Turabian StyleZhang, Jun, Ying Zhang, Yunjie Chen, Jinpeng Wang, Lilin Zhao, and Min Chen. 2023. "Evaluation of Carbon Emission Efficiency in the Construction Industry Based on the Super-Efficient Slacks-Based Measure Model: A Case Study at the Provincial Level in China" Buildings 13, no. 9: 2207. https://doi.org/10.3390/buildings13092207

APA StyleZhang, J., Zhang, Y., Chen, Y., Wang, J., Zhao, L., & Chen, M. (2023). Evaluation of Carbon Emission Efficiency in the Construction Industry Based on the Super-Efficient Slacks-Based Measure Model: A Case Study at the Provincial Level in China. Buildings, 13(9), 2207. https://doi.org/10.3390/buildings13092207