Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM

Abstract

1. Introduction

- A greater cost of manufacture as a result of the inclusion of a higher amount of cement and polymeric fiber [14].

2. Materials and Methods

2.1. Materials

2.2. Design of RSM Mixes and Material Proportions

2.3. Mixing and Sample Testing Procedures

2.3.1. Mixing

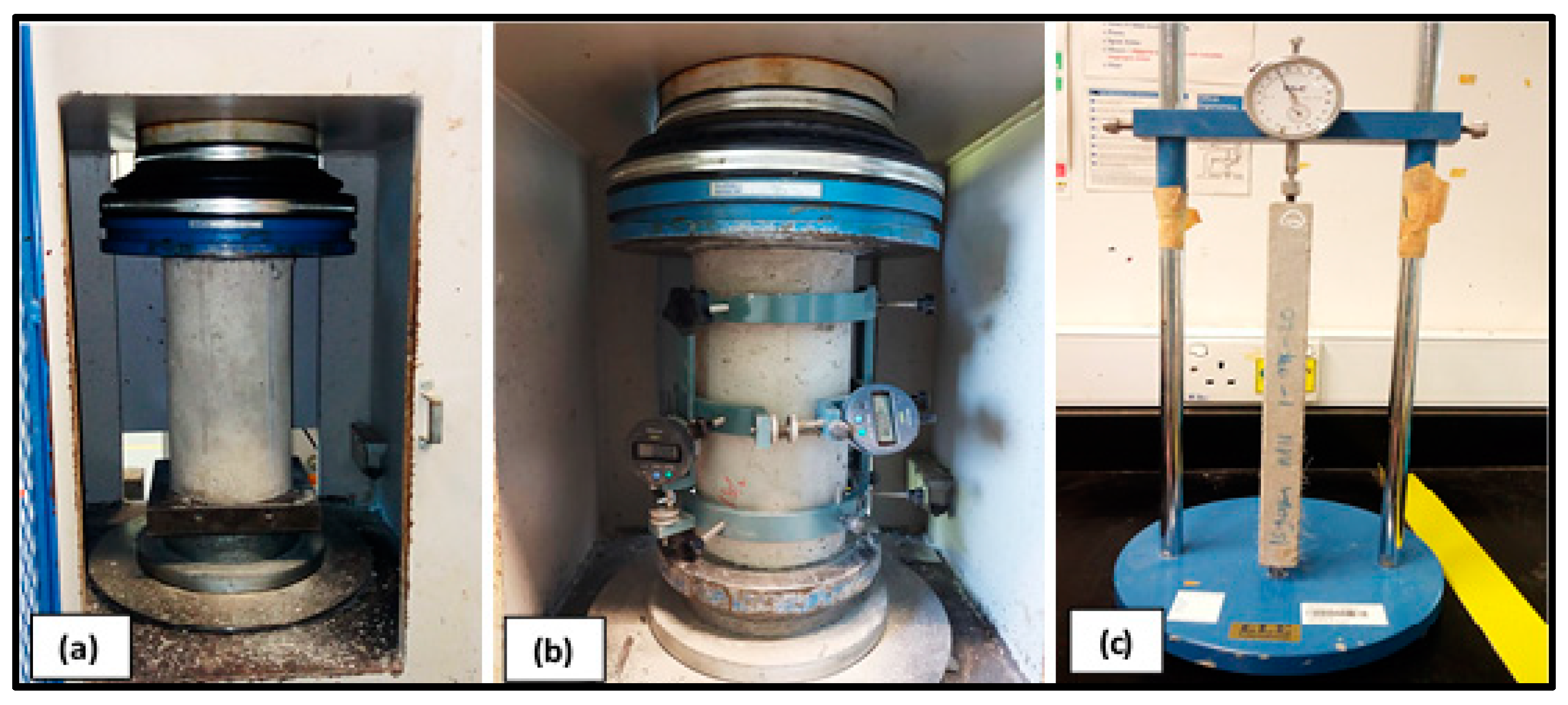

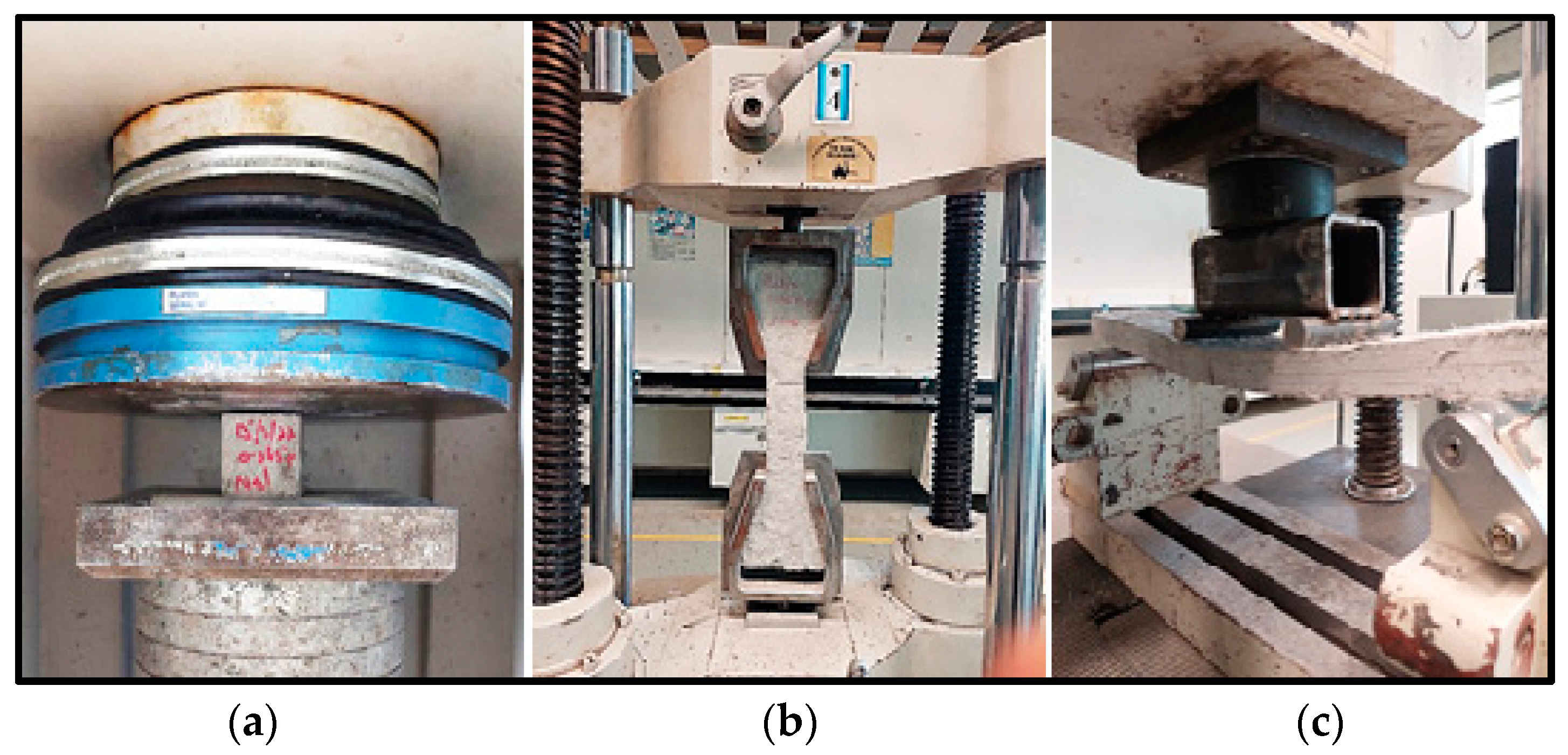

2.3.2. Mechanical Properties Tests

2.3.3. Deformation Properties Tests

- E is Young’s modulus of elasticity, MPa;

- σ2 is the Stress corresponding to 40% of the ultimate load or ultimate Stress, MPa;

- σ1 is the Stress corresponding to a longitudinal strain of 0.000050, MPa;

- is Poisson’s ratio;

- is the lateral strain at mid-height of the specimen at a Stress, σ2;

- is the lateral strain at mid-height of the specimens under Stress, σ1.

2.3.4. Microstructural Tests

3. Results and Discussions

3.1. Mechanical Properties

3.1.1. Compressive Strength

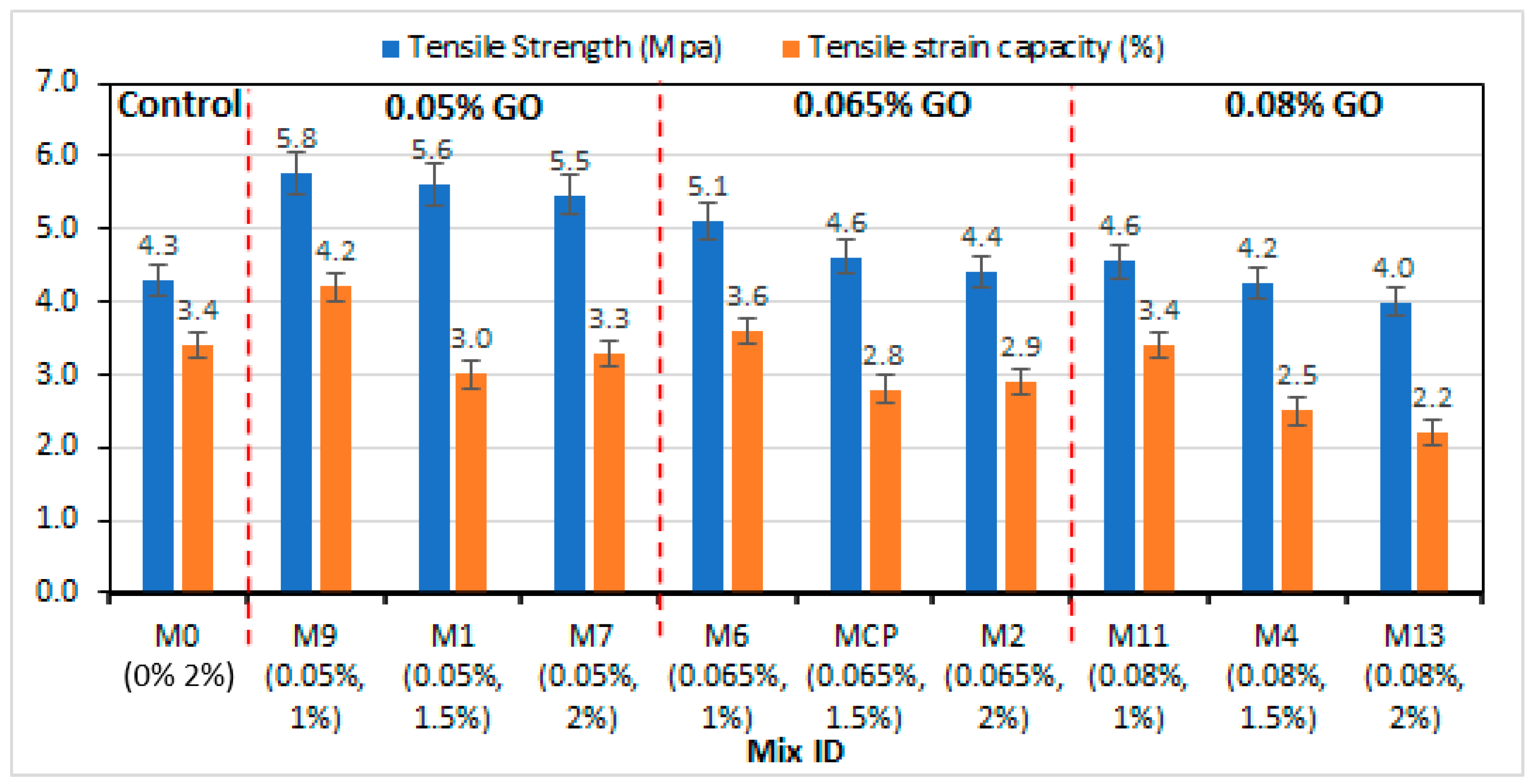

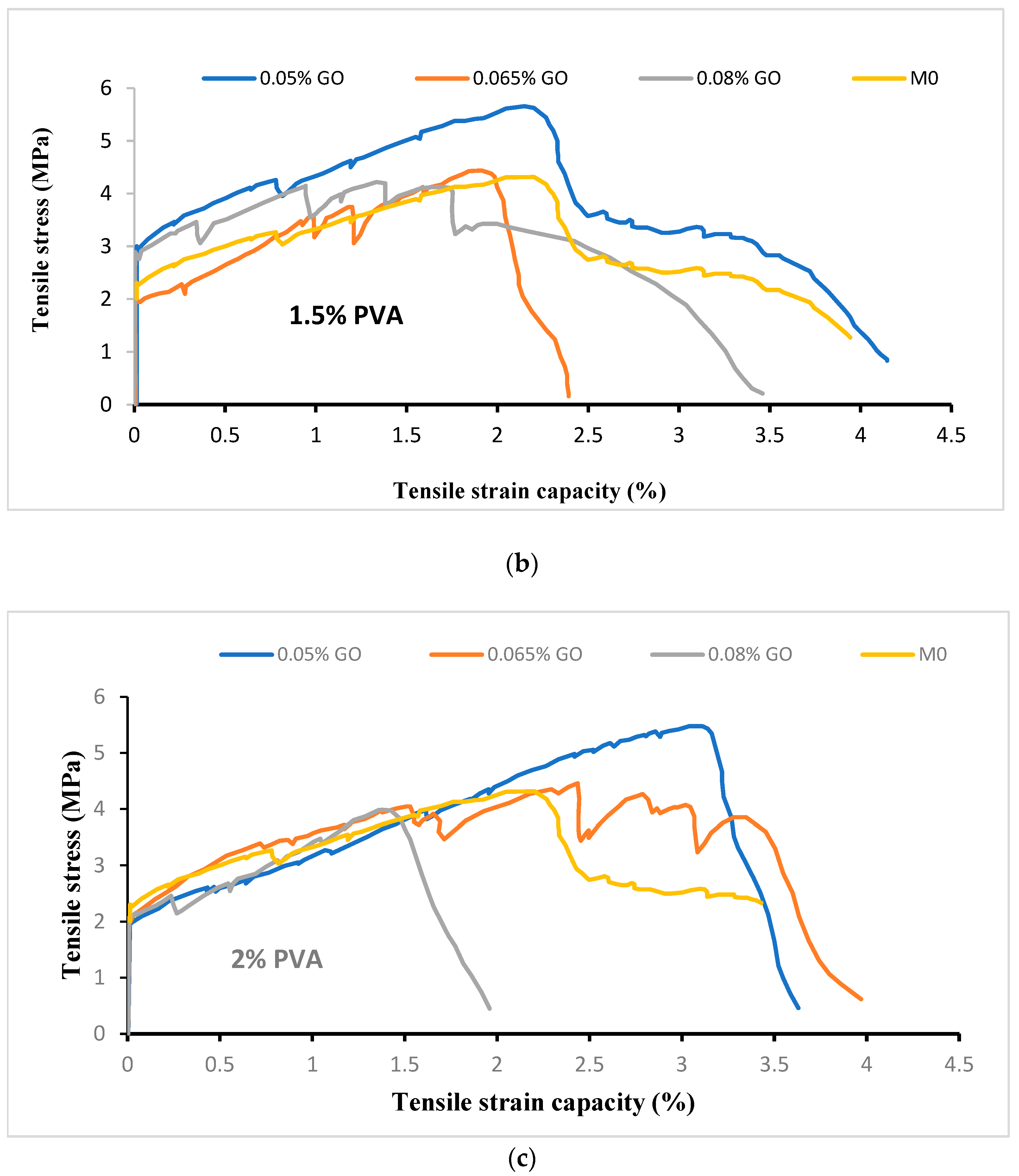

3.1.2. Tensile Properties

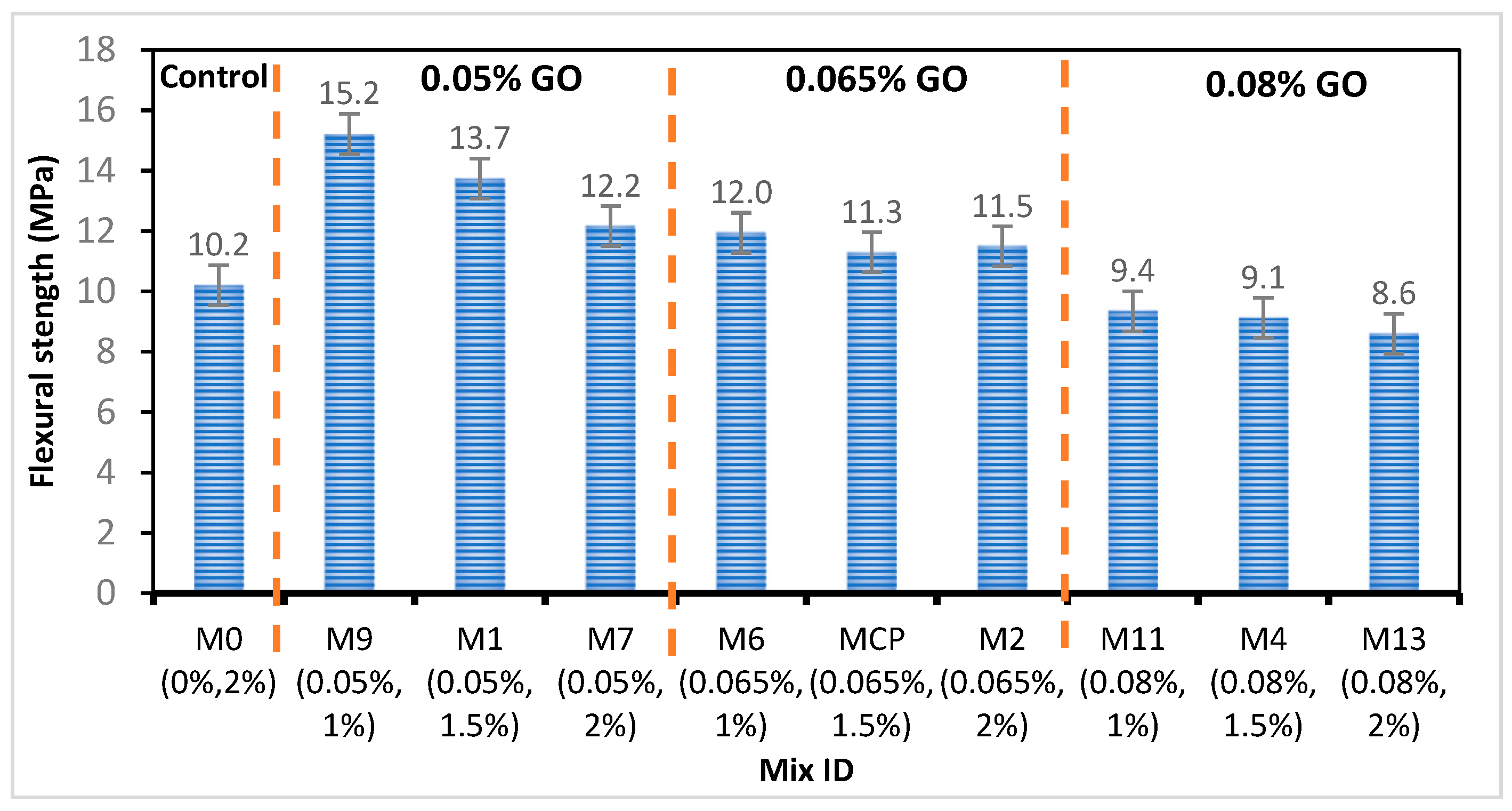

3.1.3. Flexural Properties

3.2. Deformation Properties

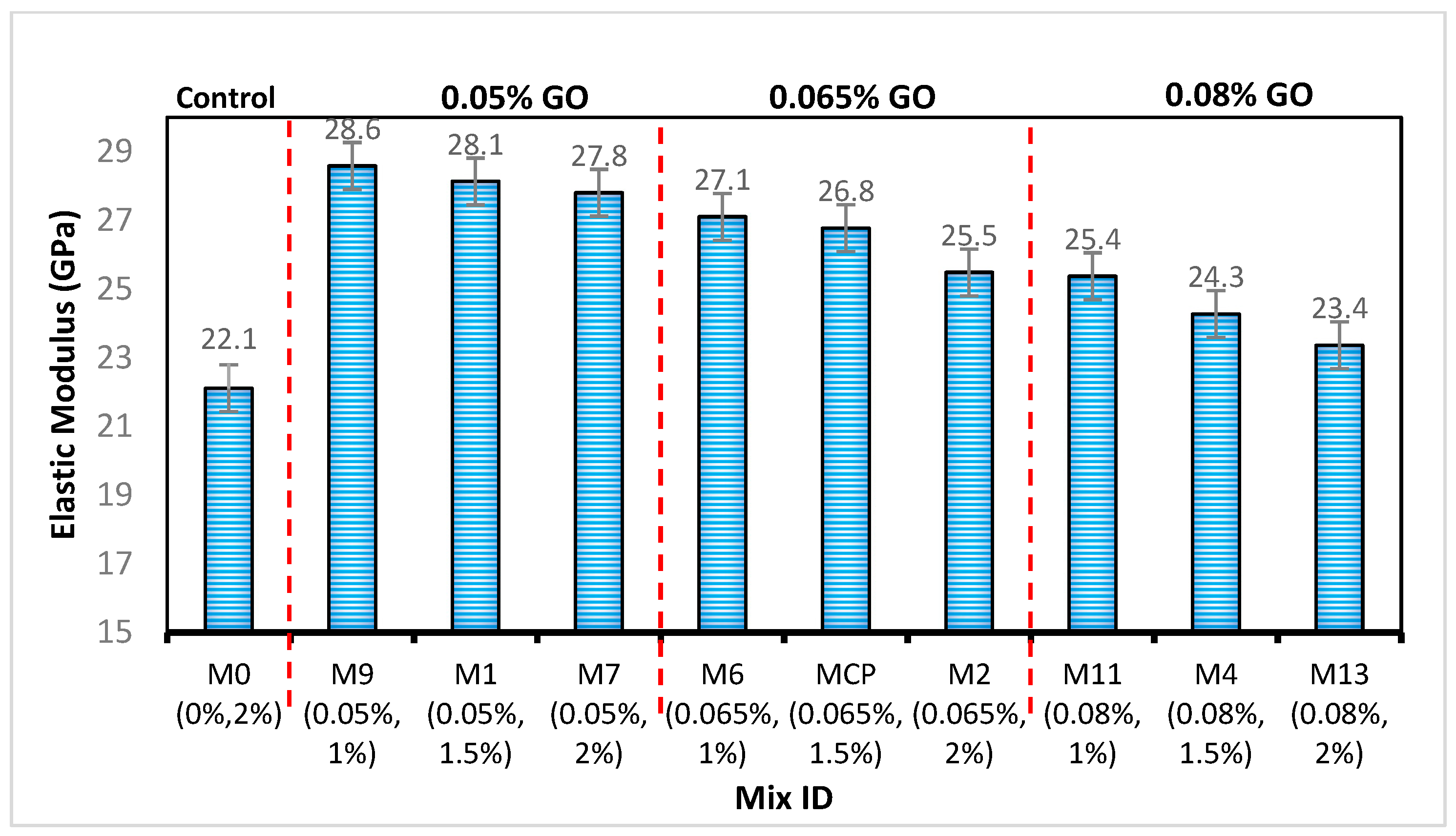

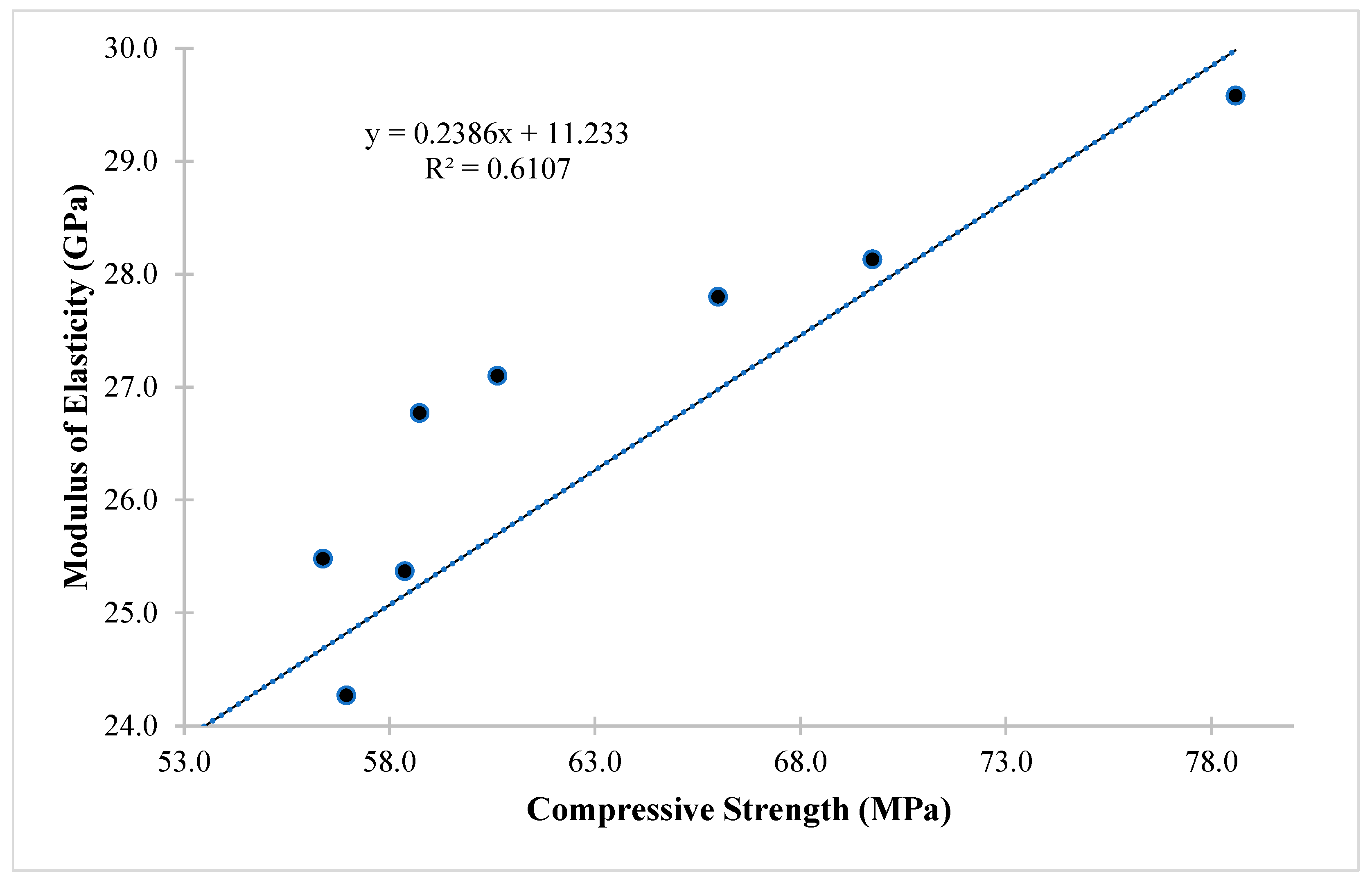

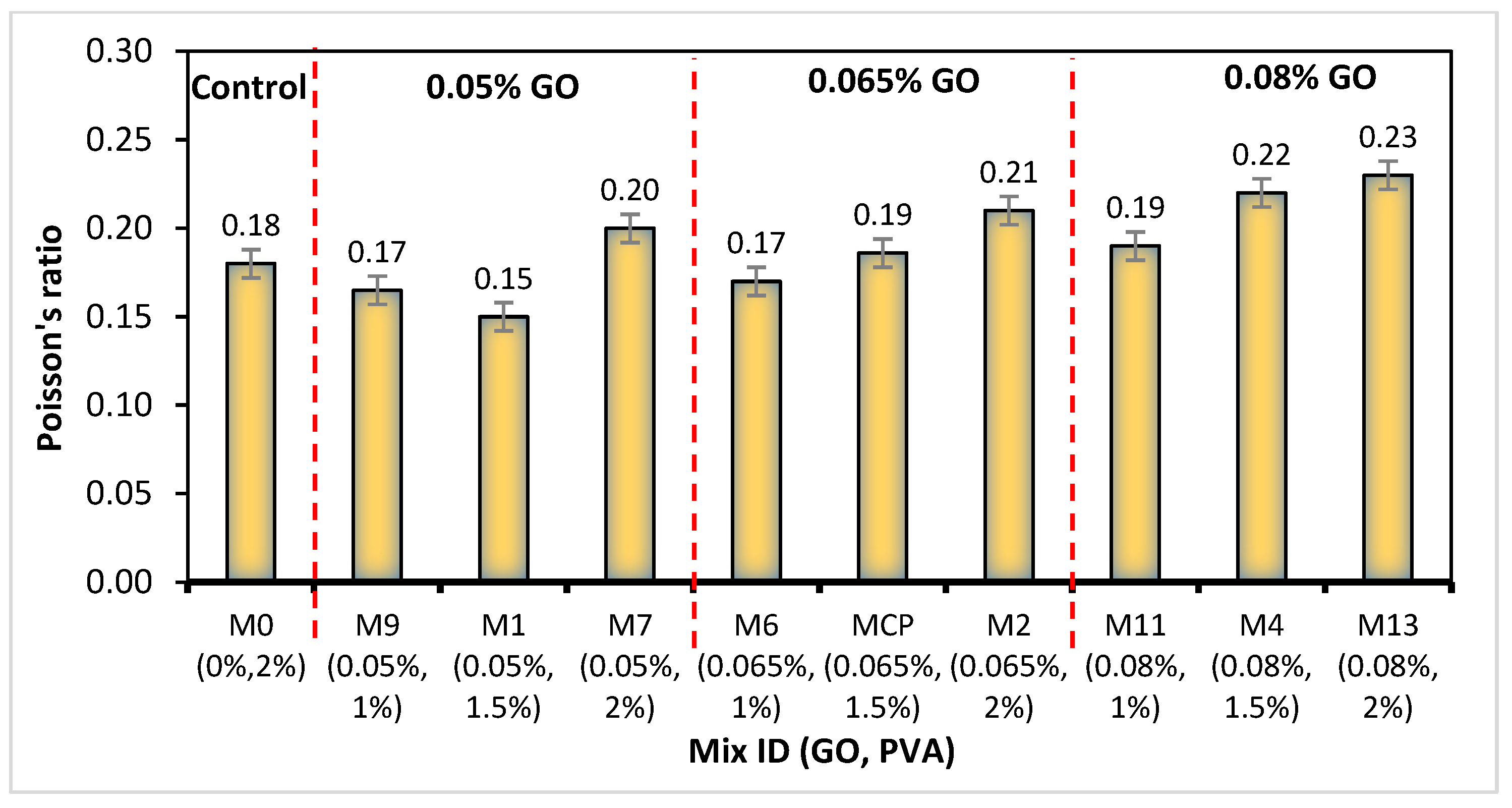

3.2.1. Modulus of Elasticity (ME) and Poisson’s ratio (PR)

3.2.2. Drying Shrinkage

3.3. Microstructural Properties

3.3.1. FESEM Analysis

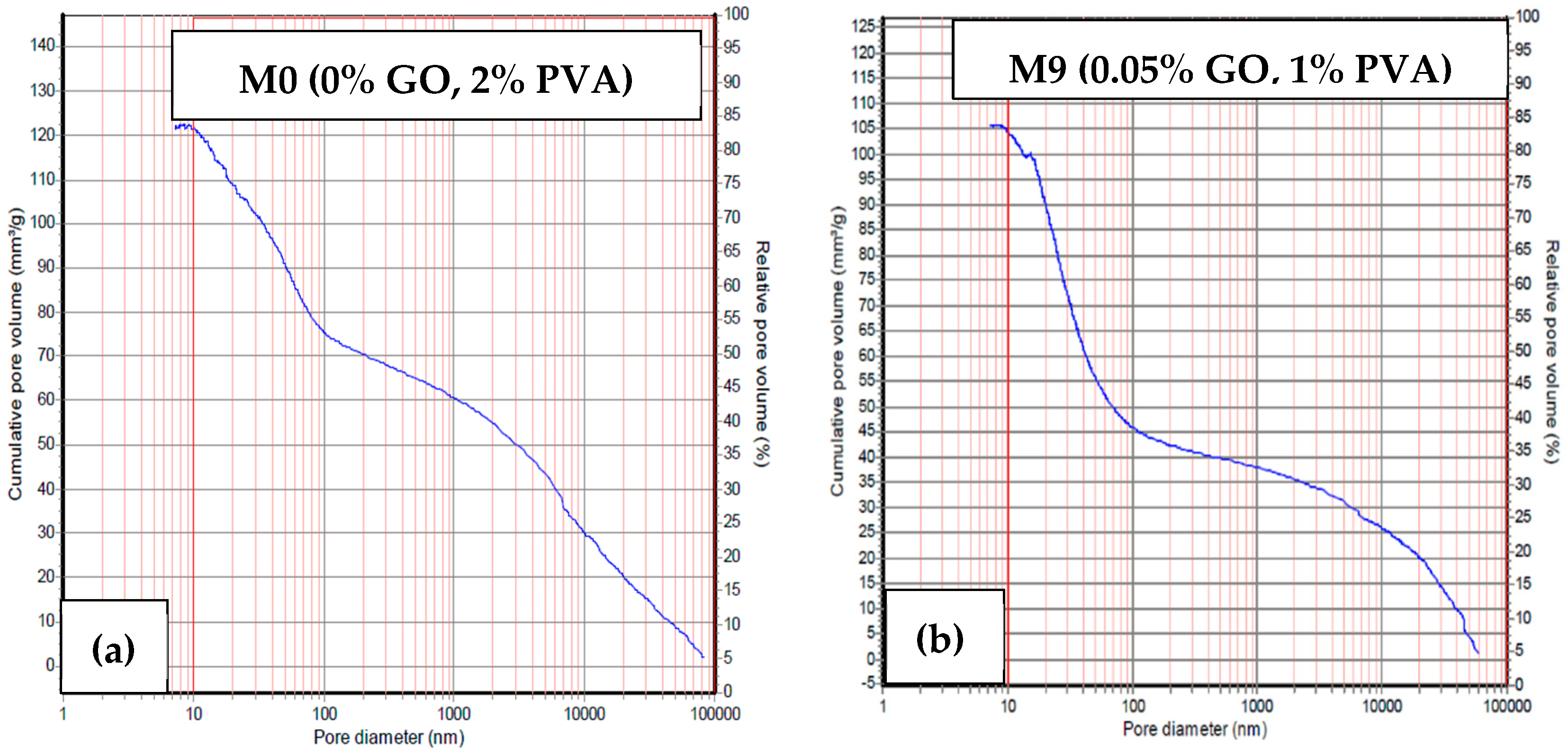

3.3.2. MIP Analysis

4. Response Surface Methodology (RSM) Analysis

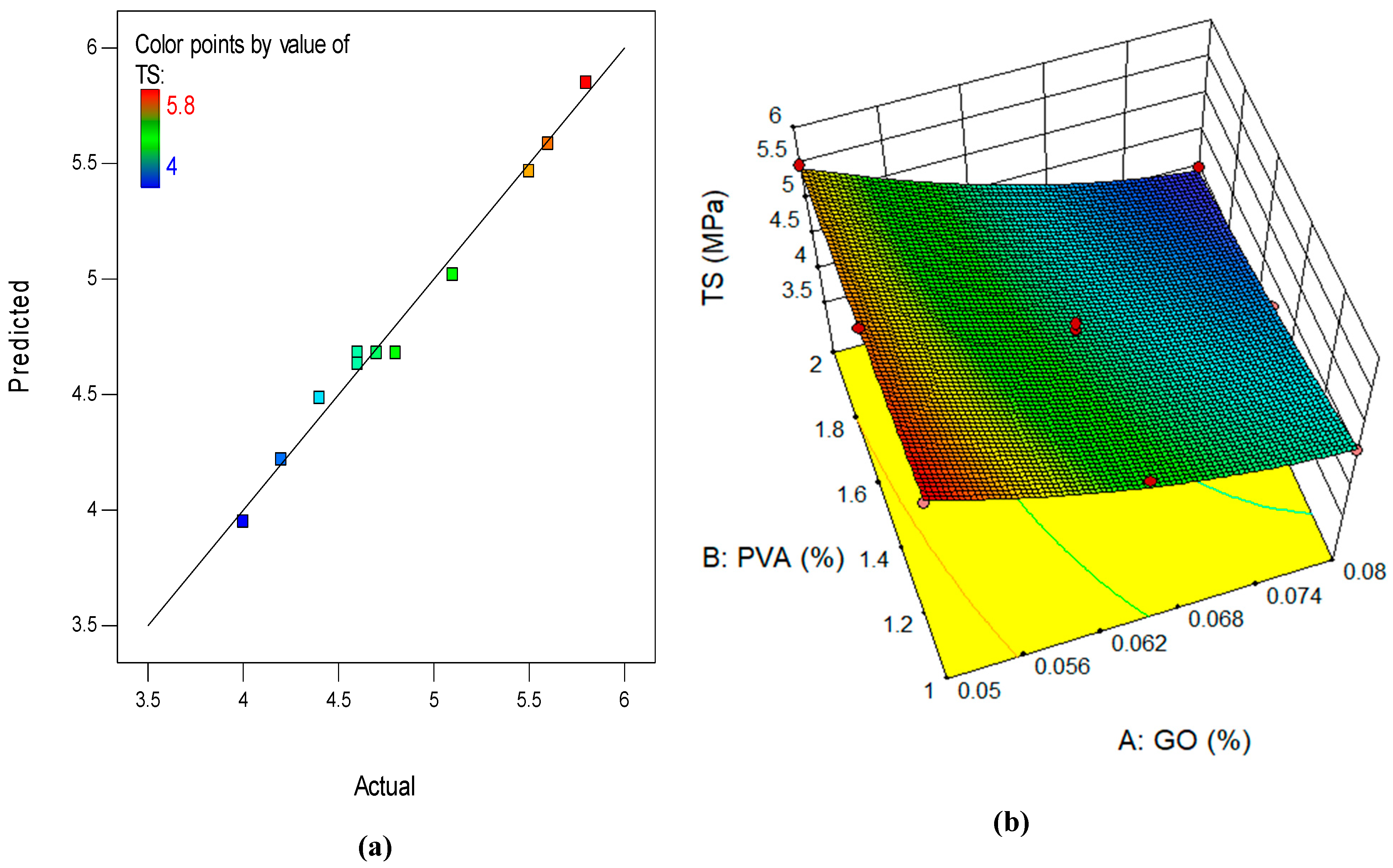

4.1. Response Surface Model Development and ANOVA

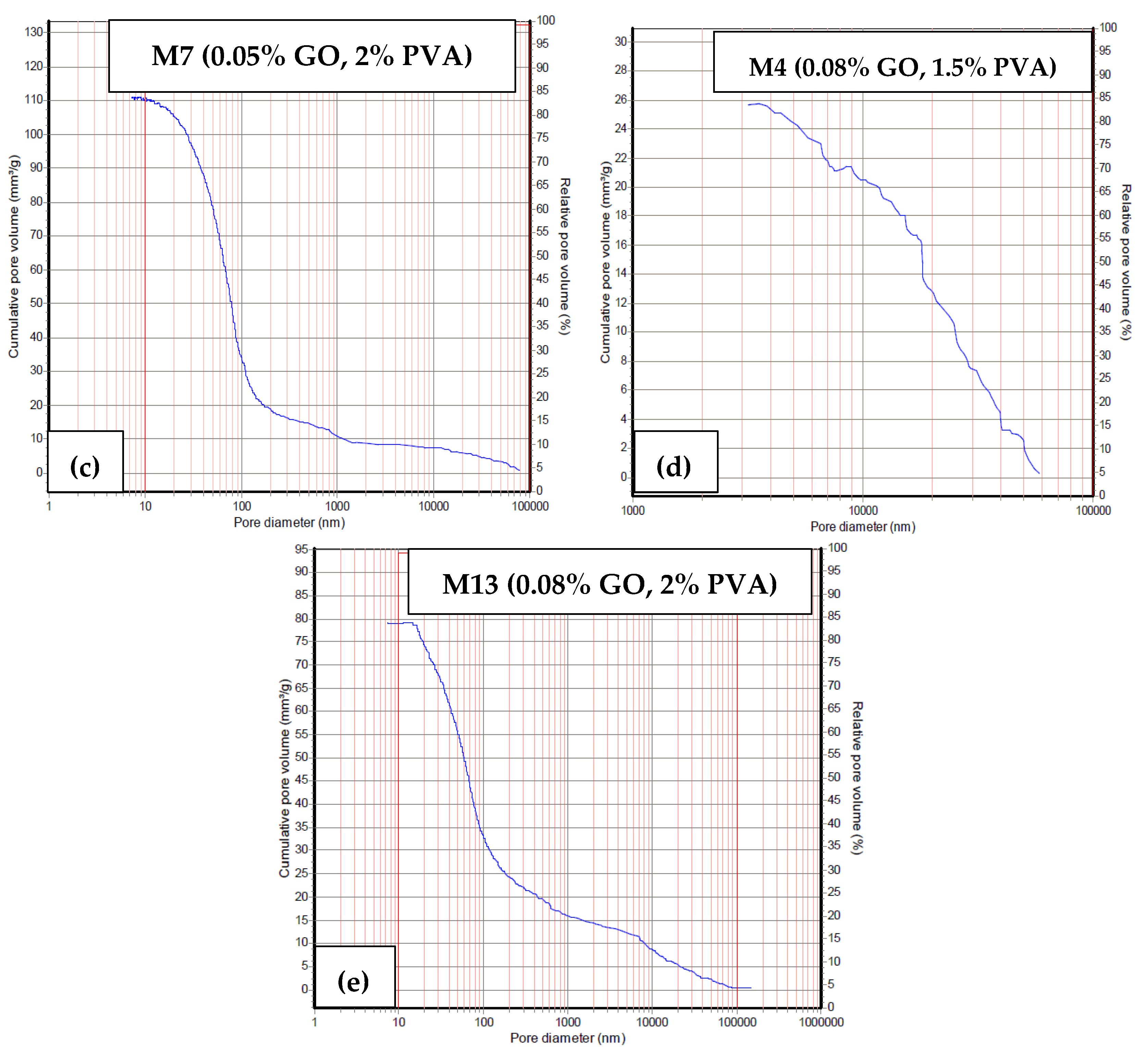

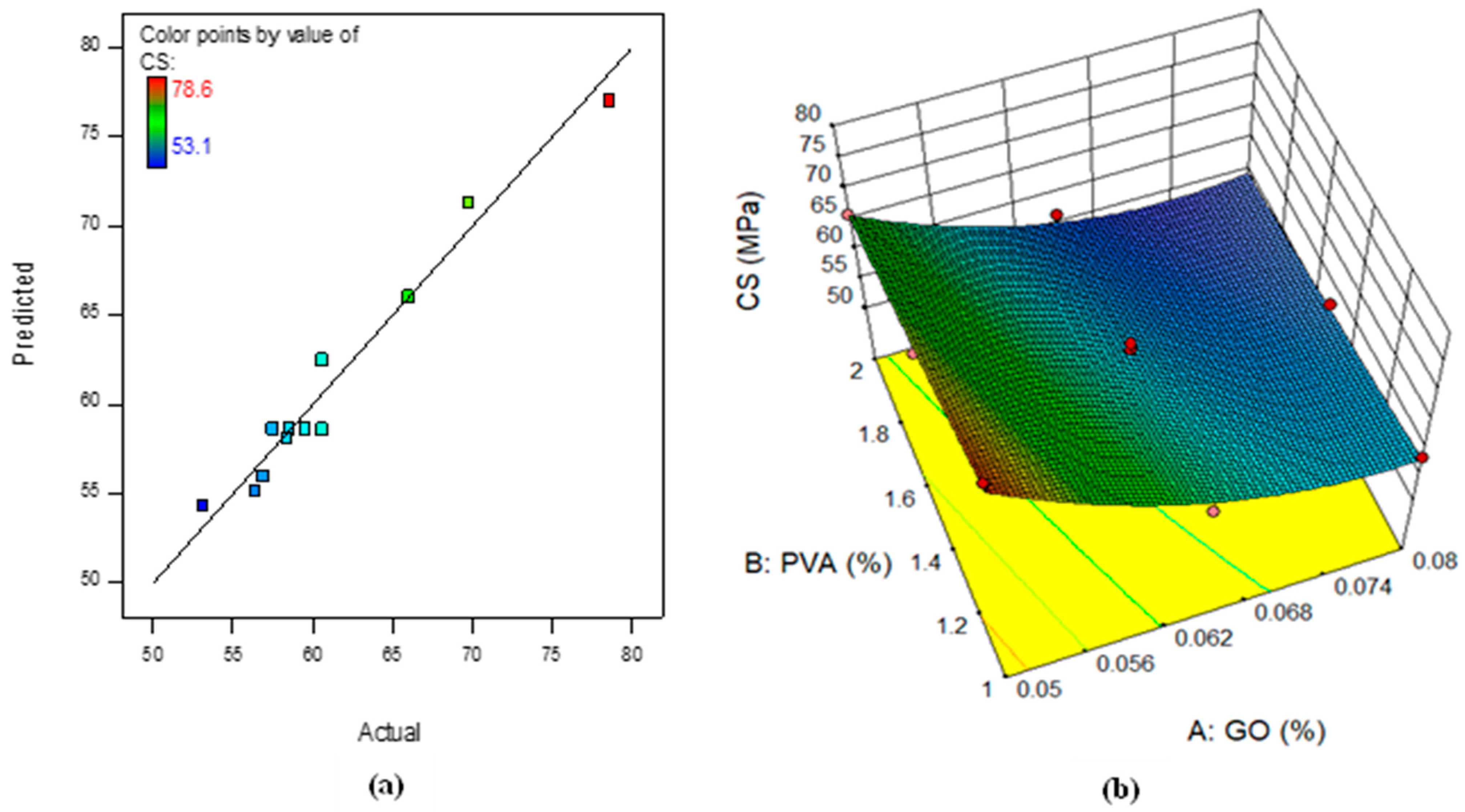

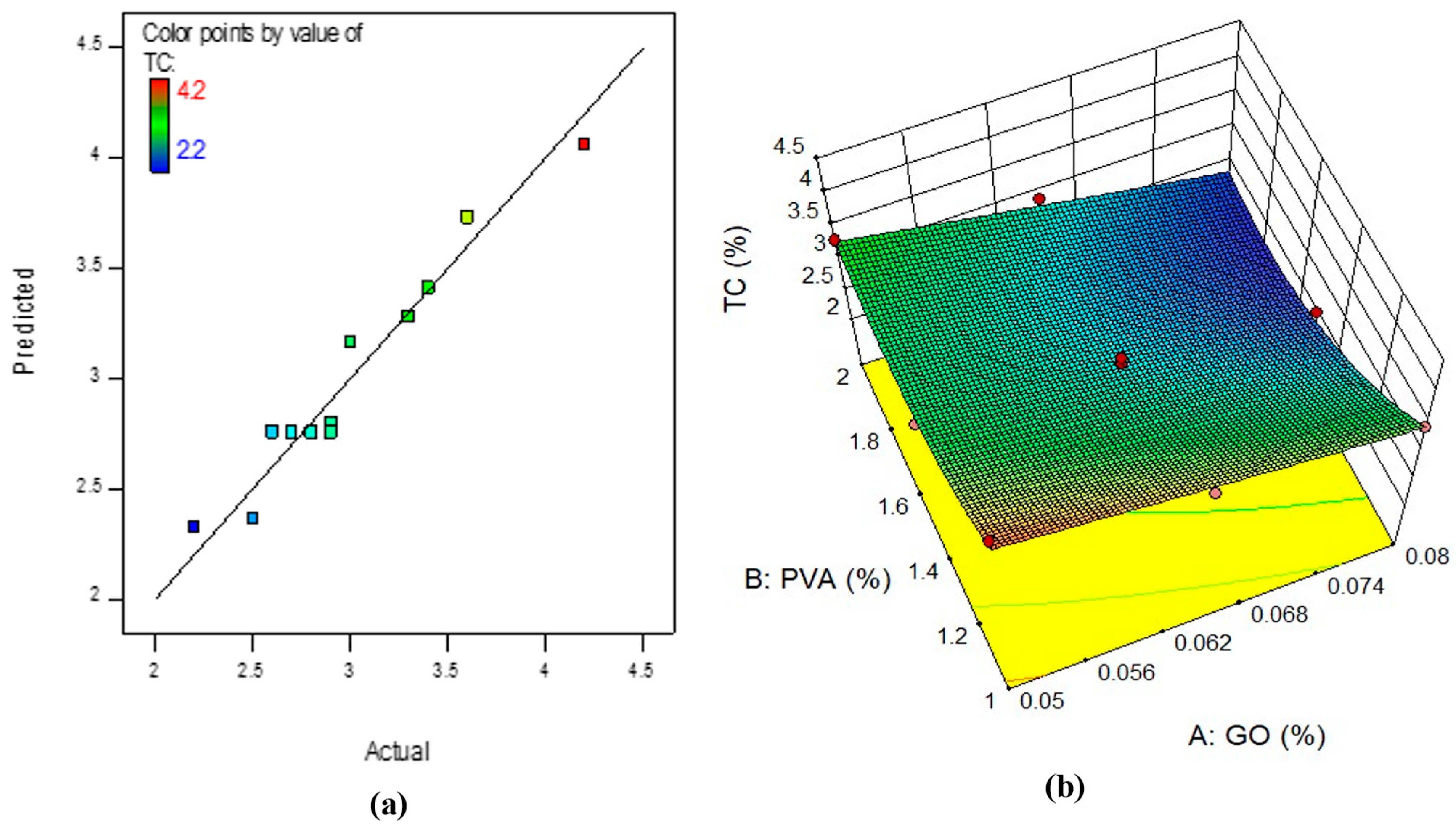

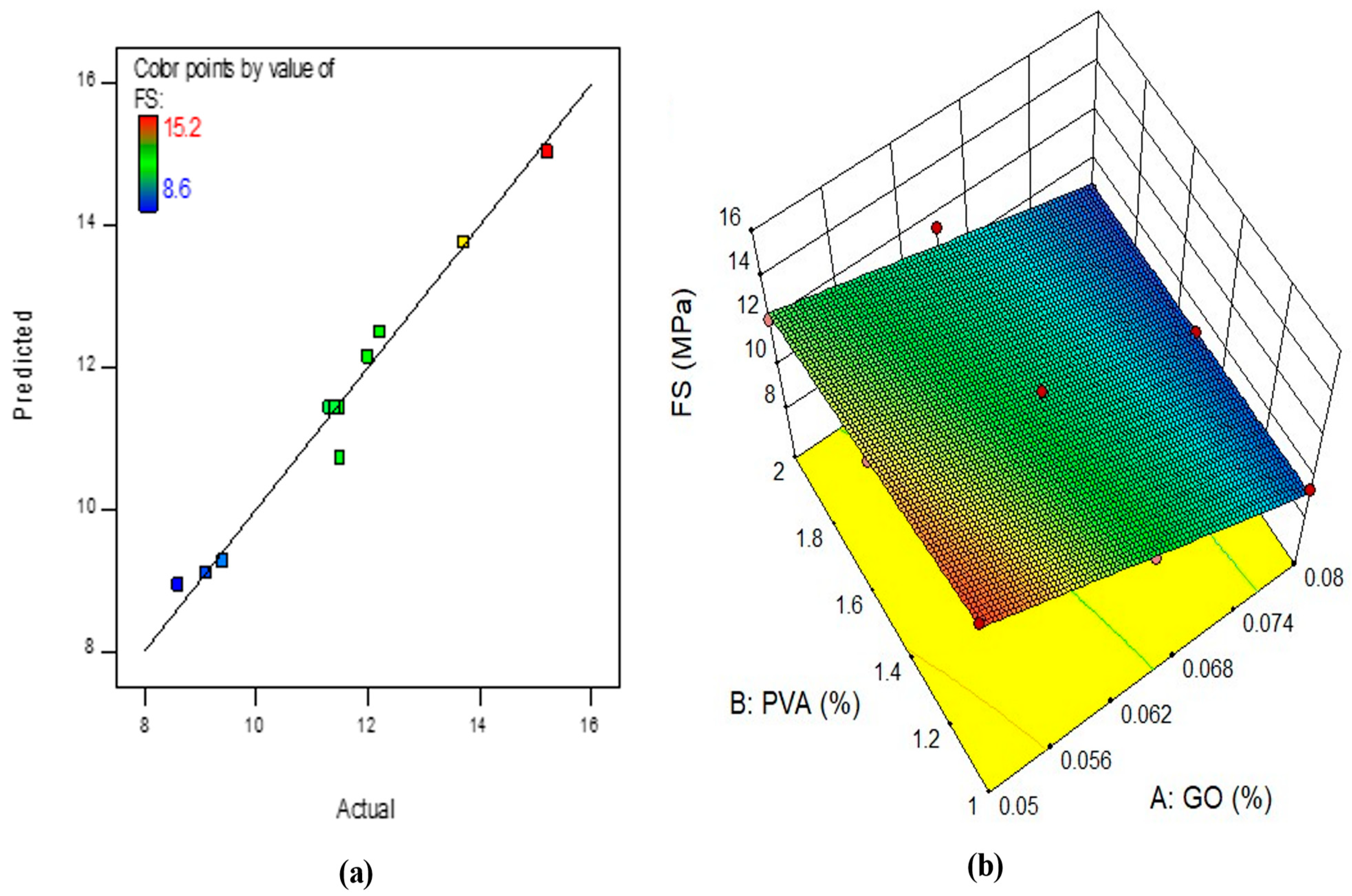

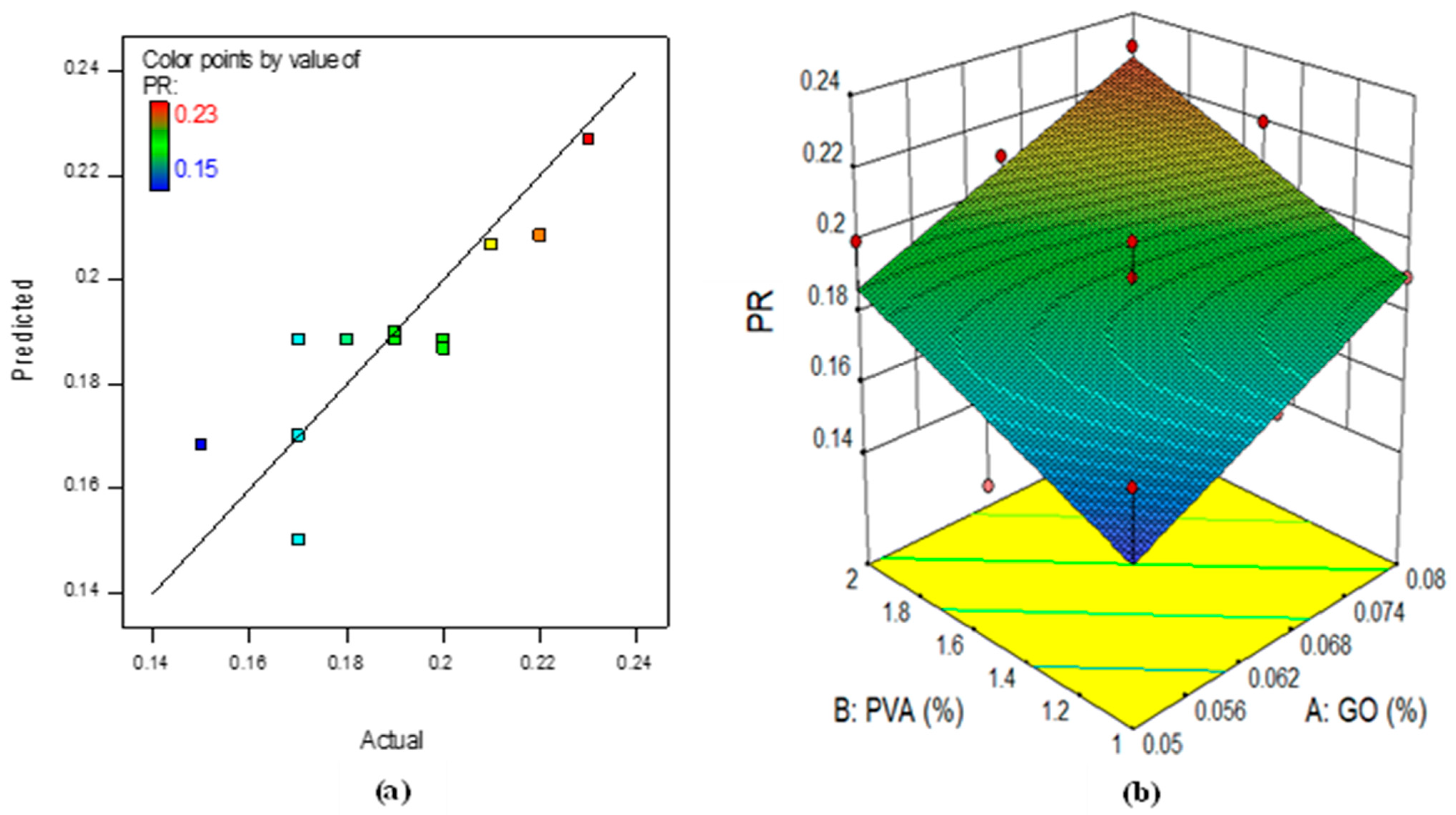

4.2. Model Diagnostics and Response Surface Plots

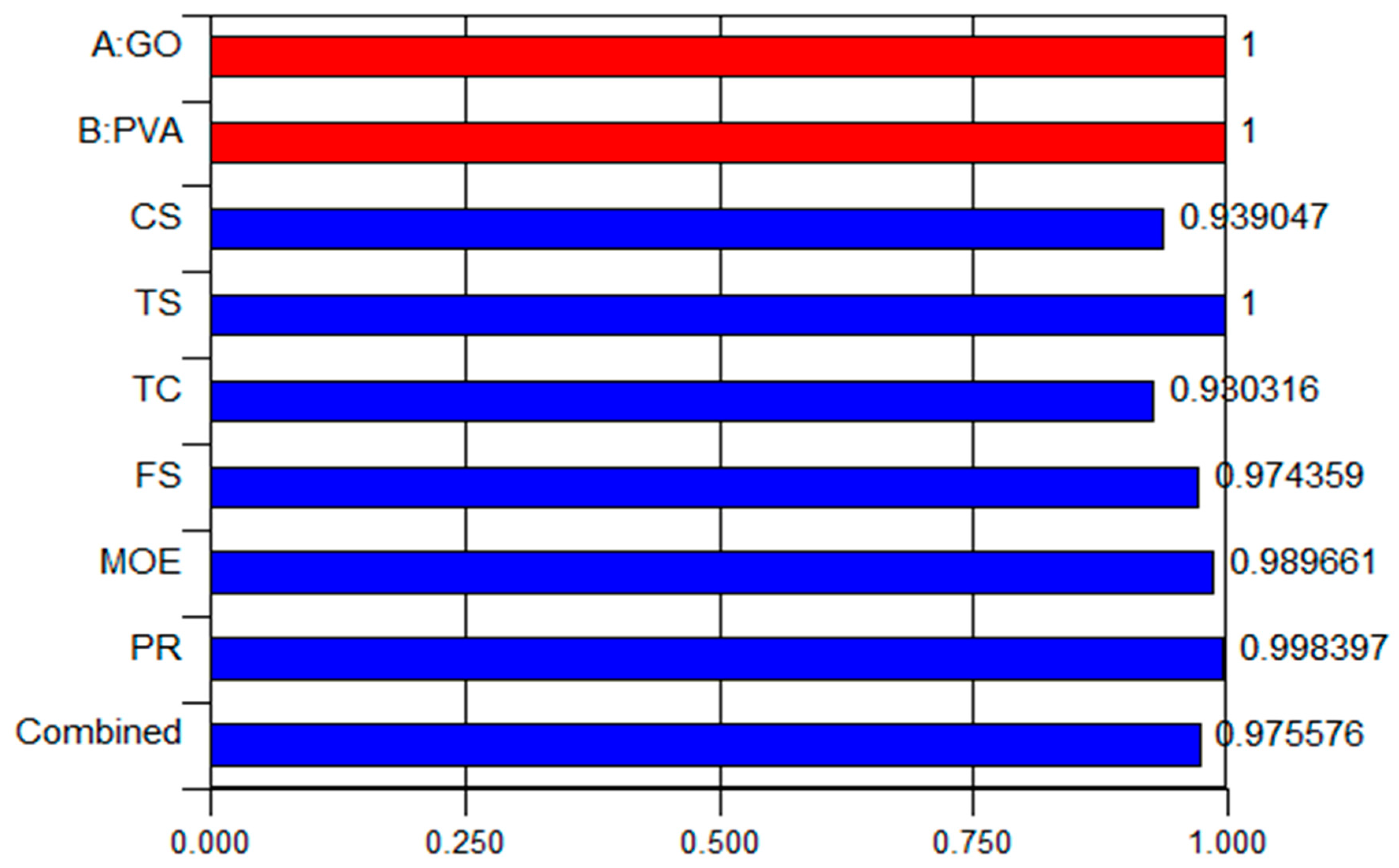

4.3. Multi-Objective Optimization

4.4. Experimental Validation

5. Conclusions

- The mechanical characteristics of ECCs, including compressive, tensile, flexural, and tensile capacity, are greatly improved with a 0.05% and 1% addition of GO and PVA fibers, respectively. When 0.05% and 1% PVA fiber additions were used, the compressive, tensile, and flexural strengths increased by 30%, 35%, and 49%, respectively, when compared to the control. However, boosting the GO and PVA fiber fractions over the ideal levels severely harmed the characteristics. Furthermore, all of the mixes demonstrated normal strain-hardening behavior, with tensile capacities ranging from 2.2 to 4.2%.

- Incorporating 0.05% GO and 1% to 1.5% PVA fiber volume fraction increased the modulus of elasticity and the PR of GO–ECC combinations. With a maximum value of 29.4 GPa, the obtained MOE values were extremely high. The PR values were kept between 0.15 and 0.23, which is a desirable range.

- With a greater addition of GO, the rate of shrinkage decreased dramatically. The shrinkage values for GO–ECC range from 0.00043 mm to 0.0009 mm, which is significantly less than the shrinkage value for the control sample (0.00122 mm). The drying shrinkage decreases by 66.4% between the control (M0) and the GO–ECC mixture with the smallest drying shrinkage value (M11). Due to the GO’s effect of densification, the matrix’s pore structure is diminished and refined, resulting in a decrease in drying shrinkage.

- The microstructural properties of the GO–ECC mixes investigated through FESEM and MIP analyses showed an improved and refined microstructure with an increase in the GO. The pore-refining effect through the pore filling and crystallization of hydration products by the GO was attributed to this. However, the MIP results show the growth in the porosity of the mixtures, with a rise in the PVA fiber attributed to the clumping effect and the ITZ openings.

- The development and validation of response-predictive models applying ANOVA and experimentation. The developed models have a coefficient of determination (R2) values between 70 and 99 percent. Multi-objective optimization determined the optimal input variables for the GO and PVA fibers to be 0.05% and 1%, respectively, with a 97% desirability value.

- Due to the 2D planar nature of the GO nanosheets, which behave like nanofibers in the composite, a comparatively low content of PVA fiber is required to obtain the optimal GO–ECC properties. This reduces the need for higher fiber content in mixtures.

6. Future Recommendations

- It has been recommended that the addition of 0.05% of GO as a nanoscale material provides good outcomes for structural applications in the field of civil engineering.

- The impact of GO on the long-term durability behavior and time-dependent deformations, such as fatigue and the creep behavior of ECCs, must thus be studied.

- It is also feasible to carry out studies on the chemical interactions and behavior of GO when combined with other additives, such as metakaolin, coconut shell ash, groundnut shell ash, wheat straw ash, and other nanoparticles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thacker, S.; Adshead, D.; Fay, M.; Hallegatte, S.; Harvey, M.; Meller, H.; O’Regan, N.; Rozenberg, J.; Watkins, G.; Hall, J.W. Infrastructure for Sustainable Development. Nat. Sustain. 2019, 2, 324–331. [Google Scholar] [CrossRef]

- Li, V.C. Introduction to Engineered Cementitious Composites (ECC). In Engineered Cementitious Composites (ECC); Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–10. [Google Scholar] [CrossRef]

- Ma, H.; Yi, C.; Wu, C. Review and Outlook on Durability of Engineered Cementitious Composite (ECC). Constr. Build. Mater. 2021, 287, 122719. [Google Scholar] [CrossRef]

- Singh, S.B.; Munjal, P. Engineered Cementitious Composite and Its Applications. Mater. Today Proc. 2020, 32, 797–802. [Google Scholar] [CrossRef]

- Li, V.C. Advancesin ECCresearch. In ACI Special Publication on Concrete; Material Science to Applications: SP 206–23, Ed; American Concrete Institute: Farmington Hills, MI, USA, 2002; pp. 373–400. [Google Scholar]

- Li, V.C. On Engineered Cementitious Composites (ECC). A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Yu, J.; Xiao, J.; Xu, Q. Using Green Supplementary Materials to Achieve More Ductile ECC. Materials 2019, 12, 858. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Achara, B.E.; Nuruddin, M.F.; Yaw, M.; Zulkefli, M.Z. Properties of Nano-Silica-Modified Self-Compacting Engineered Cementitious Composites. J. Clean. Prod. 2017, 162, 1225–1238. [Google Scholar] [CrossRef]

- Achara, B.E. Modeling of Properties of Nano-Silica-Modified Self-Consolidating Engineered Cementitious Composites (ECC) Using Response Surface Methodology (RSM). Ph.D. Thesis, Universiti Teknologi PETRONAS (UTP), Seri Iskandar, Malaysia, 2018. [Google Scholar]

- Huang, B.T.; Zhu, J.X.; Weng, K.F.; Li, V.C.; Dai, J.G. Ultra-High-Strength Engineered/Strain-Hardening Cementitious Composites (ECC/SHCC): Material Design and Effect of Fiber Hybridization. Cem. Concr. Compos. 2022, 129, 104464. [Google Scholar] [CrossRef]

- Yu, J.; Leung, C.K.Y. Strength Improvement of Strain-Hardening Cementitious Composites with Ultrahigh-Volume Fly Ash. J. Mater. Civ. Eng. 2017, 29, 104464. [Google Scholar] [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Sanjayan, J. Inclusion of Graphene Oxide in Cementitious Composites: State-of-the-Art Review. Aust. J. Civ. Eng. 2018, 16, 81–95. [Google Scholar] [CrossRef]

- Anwar, A. The Influence of Waste Glass Powder as a Pozzolanic Material in Concrete. Int. J. Civ. Eng. Technol. 2016, 7, 131–148. [Google Scholar]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.A. Advanced Engineered Cementitious Composites with Combined Self-Sensing and Self-Healing Functionalities. Constr. Build. Mater. 2018, 176, 313–322. [Google Scholar] [CrossRef]

- Khan, S.W.; Kamal, M.; Khan, F.A.; Gul, A.; Alam, M.; Shah, F.; Shahzada, K. Performance Evaluation of the Fresh and Hardened Properties of Different PVA-ECC Mixes: An Experimental Approach. Case Stud. Constr. Mater. 2023, 18, e01764. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, H.; Yu, J.; Liu, F. A Feasibility Study on Engineered Cementitious Composites Mixed with Coarse Aggregate. Constr. Build. Mater. 2022, 350, 128587. [Google Scholar] [CrossRef]

- Fischer, G.; Li, V.C. Deformation Behavior of Fiber-Reinforced Polymer Reinforced Engineered Cementitious Composite (ECC) Flexural Members under Reversed Cyclic Loading Conditions. ACI Struct. J. 2003, 100, 25–35. [Google Scholar] [CrossRef]

- Wang, S.; Li, V.C. Engineered Cementitious Composites with High-Volume Fly Ash. ACI Mater. J. 2007, 104, 233–241. [Google Scholar] [CrossRef]

- Zahid, M. Development and Mix Design Optimization of Fly Ash Based High Strength Engineered Geopolymer Composite. Ph.D. Thesis, Universiti Teknologi PETRONAS, Seri Iskandar, Malaysia, 2019. [Google Scholar]

- Jiang, T.; Cui, K.; Chang, J. Development of Low-Carbon Cement: Carbonation of Compounded C2S by β-C2S and γ-C2S. Cem. Concr. Compos. 2023, 139, 105071. [Google Scholar] [CrossRef]

- Wang, Q.; Yi, Y.; Ma, G.; Luo, H. Hybrid Effects of Steel Fibers, Basalt Fibers and Calcium Sulfate on Mechanical Performance of PVA-ECC Containing High-Volume Fly Ash. Cem. Concr. Compos. 2019, 97, 357–368. [Google Scholar] [CrossRef]

- Turk, K.; Nehdi, M.L. Coupled Effects of Limestone Powder and High-Volume Fly Ash on Mechanical Properties of ECC. Constr. Build. Mater. 2018, 164, 185–192. [Google Scholar] [CrossRef]

- Khed, V.C.; Mohammed, B.S.; Shahir Liew, M.; Alaloul, W.S.; Adamu, M. Hybrid Fibre Rubberized ECC Optimization for Modulus of Elasticity. Int. J. Civ. Eng. Technol. 2018, 9, 918–928. [Google Scholar]

- Wang, Z.; Zuo, J.; Zhang, X.; Jiang, G.; Feng, L. Stress-Strain Behaviour of Hybrid-Fibre Engineered Cementitious Composite in Compression. Adv. Cem. Res. 2020, 32, 53–65. [Google Scholar] [CrossRef]

- Sridhar, R.; Prasad, R. Study on Mechanical Properties of Hybrid Fiber Reinforced Engineered Cementitious Composites. Rev. Rom. Mater. Rom. J. Mater. 2019, 49, 424–433. [Google Scholar]

- Singh, M.; Saini, B.; Chalak, H.D. Appraisal of Hybrid Fiber Reinforced Engineered Cementitious Composite. In Proceedings of the International Conference on Civil, Structural and Transportation Engineering, Ottawa, ON, Canada, 11 June 2019. [Google Scholar]

- Liu, W.; Han, J. Experimental Investigation on Compressive Toughness of the PVA-Steel Hybrid Fiber Reinforced Cementitious Composites. Front. Mater. 2019, 6, 108. [Google Scholar] [CrossRef]

- Cui, K.; Lu, D.; Jiang, T.; Zhang, J.; Jiang, Z.; Zhang, G.; Chang, J.; Lau, D. Understanding the Role of Carbon Nanotubes in Low Carbon Sulfoaluminate Cement-Based Composite. J. Clean. Prod. 2023, 416, 137843. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano Reinforced Cement and Concrete Composites and New Perspective from Graphene Oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Pan, Z.; Duan, W.; Li, D.; Collins, F. Graphene Oxide Reinforced Cement and Concrete. WO Patent Application PCT/AU2012/001582, 21 December 2012. [Google Scholar]

- Yang, H.; Monasterio, M.; Cui, H.; Han, N. Experimental Study of the Effects of Graphene Oxide on Microstructure and Properties of Cement Paste Composite. Compos. Part A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- Yang, H.; Cui, H.; Tang, W.; Li, Z.; Han, N.; Xing, F. A Critical Review on Research Progress of Graphene/Cement Based Composites. Compos. Part A Appl. Sci. Manuf. 2017, 102, 273–296. [Google Scholar] [CrossRef]

- Dong, L.-L.; Chen, W.-G.; Deng, N.; Zheng, C.-H. A Novel Fabrication of Graphene by Chemical Reaction with a Green Reductant. Chem. Eng. J. 2016, 306, 754–762. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Mijowska, E.; Kalenczuk, R.J.; Aleksandrzak, M.; Mijowska, S. Nanocomposite of Cement/Graphene Oxide—Impact on Hydration Kinetics and Young’s Modulus. Constr. Build. Mater. 2015, 78, 234–242. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent Advances in Graphene Based Polymer Composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lu, C.; Liu, B.; Zhang, K.; Li, C. Influence of Graphene Oxide Additions on the Microstructure and Mechanical Strength of Cement. Carbon N. Y. 2015, 95, 1083–1084. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Graphene Oxide Impact on Hardened Cement Expressed in Enhanced Freeze–Thaw Resistance. J. Mater. Civ. Eng. 2016, 28, 04016072. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J. Hydration, Reinforcing Mechanism, and Macro Performance of Multi-Layer Graphene-Modified Cement Composites. J. Build. Eng. 2022, 57, 104880. [Google Scholar] [CrossRef]

- Pathak, A.K.; Borah, M.; Gupta, A.; Yokozeki, T.; Dhakate, S.R. Improved Mechanical Properties of Carbon Fiber/Graphene Oxide-Epoxy Hybrid Composites. Compos. Sci. Technol. 2016, 135, 28–38. [Google Scholar] [CrossRef]

- Bagheri, A.; Negahban, E.; Asad, A.; Abbasi, H.A.; Raza, S.M. Graphene Oxide-Incorporated Cementitious Composites: A Thorough Investigation. Mater. Adv. 2022, 3, 9040–9051. [Google Scholar] [CrossRef]

- Pu, Y.; Yang, S.; Qi, M.; Sheng, K.; Bi, J.; Fan, F.; Yuan, X. Synergistic Effect of Graphene Oxide and Hydroxylated Graphene on the Enhanced Properties of Cement Composites. RSC Adv. 2022, 12, 26733–26743. [Google Scholar] [CrossRef]

- Zheng, Q.; Han, B.; Cui, X.; Yu, X.; Ou, J. Graphene-Engineered Cementitious Composites: Small Makes a Big Impact. Nanomater. Nanotechnol. 2017, 7, 1847980417742304. [Google Scholar] [CrossRef]

- Verma, P.; Chowdhury, R.; Chakrabarti, A. Role of Graphene-Based Materials (GO) in Improving Physicochemical Properties of Cementitious Nano-Composites: A Review. J. Mater. Sci. 2021, 56, 19329–19358. [Google Scholar] [CrossRef]

- Li, W.; Qu, F.; Dong, W.; Mishra, G.; Shah, S.P. A Comprehensive Review on Self-Sensing Graphene/Cementitious Composites: A Pathway toward next-Generation Smart Concrete. Constr. Build. Mater. 2022, 331, 127284. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Jiang, Z.; Harris, D.K. Exploring Scalable Fabrication of Self-Sensing Cementitious Composites with Graphene Nanoplatelets. Smart Mater. Struct. 2018, 27, 115029. [Google Scholar] [CrossRef]

- Hu, Y.G.; Awol, J.F.; Chen, S.; Jiang, J.N.; Pu, X.; Jia, X.; Xu, X.Q. Experimental Study of the Electrical Resistance of Graphene Oxide-Reinforced Cement-Based Composites with Notch or Rebar. J. Build. Eng. 2022, 51, 104331. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuvaraj, A.; Di, J.; Qian, S. Matrix Design of Light Weight, High Strength, High Ductility ECC. Constr. Build. Mater. 2019, 210, 188–197. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Ali, M.O.A.; Liew, M.S. Effects of Graphene Oxide and Crumb Rubber on the Fresh Properties of Self-Compacting Engineered Cementitious Composite Using Response Surface Methodology. Materials 2022, 15, 2519. [Google Scholar] [CrossRef]

- Japan Society of Civil Engineers Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC). Concr. Eng. Ser. 2008, 82. Available online: https://books.google.com.my/books?id=3eWRYgEACAAJ (accessed on 28 May 2023).

- ASTM C469 Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM Stand. B 2002, 04, 469.

- ASTM C157/C157M-08. Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete. ASTM International: West Conshohocken, PA, USA, 2008.

- Abdulkadir, I.; Mohammed, B.S.; Liew, M.S.; Wahab, M.M.A. Modelling and Optimization of the Impact Resistance of Graphene Oxide Modified Crumb Rubber-ECC Using Response Surface Methodology. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Guntur, India, 25–26 June 2021; Volume 1197, p. 012043. [Google Scholar]

- Nguyen, H.D.; Zhang, Q.; Sagoe-Crentsil, K.; Duan, W. Graphene Oxide-Coated Sand for Improving Performance of Cement Composites. Cem. Concr. Compos. 2021, 124, 104279. [Google Scholar] [CrossRef]

- Mowlaei, R.; Lin, J.; Basquiroto de Souza, F.; Fouladi, A.; Habibnejad Korayem, A.; Shamsaei, E.; Duan, W. The Effects of Graphene Oxide-Silica Nanohybrids on the Workability, Hydration, and Mechanical Properties of Portland Cement Paste. Constr. Build. Mater. 2021, 266, 121016. [Google Scholar] [CrossRef]

- Shamsaei, E.; de Souza, F.B.; Yao, X.; Benhelal, E.; Akbari, A.; Duan, W. Graphene-Based Nanosheets for Stronger and More Durable Concrete: A Review. Constr. Build. Mater. 2018, 183, 642–660. [Google Scholar] [CrossRef]

- Young, R.J.; Liu, M.; Kinloch, I.A.; Li, S.; Zhao, X.; Vallés, C.; Papageorgiou, D.G. The Mechanics of Reinforcement of Polymers by Graphene Nanoplatelets. Compos. Sci. Technol. 2018, 154, 110–116. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Song, L.; Song, Y.; Dai, G.; Liu, J. An Intensive Review on the Role of Graphene Oxide in Cement-Based Materials. Constr. Build. Mater. 2020, 241, 117939. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Liew, M.S.; Wahab, M.M.A. Modelling and Multi-Objective Optimization of the Fresh and Mechanical Properties of Self-Compacting High Volume Fly Ash ECC (HVFA-ECC) Using Response Surface Methodology (RSM). Case Stud. Constr. Mater. 2021, 14, e00525. [Google Scholar] [CrossRef]

- Kang, D.; Seo, K.S.; Lee, H.Y.; Chung, W. Experimental Study on Mechanical Strength of GO-Cement Composites. Constr. Build. Mater. 2017, 131, 303–308. [Google Scholar] [CrossRef]

- Devi, S.C.; Khan, R.A. Compressive Strength and Durability Behavior of Graphene Oxide Reinforced Concrete Composites Containing Recycled Concrete Aggregate. J. Build. Eng. 2020, 32, 101800. [Google Scholar] [CrossRef]

- Long, W.J.; Li, H.D.; Mei, L.; Li, W.; Xing, F.; Khayat, K.H. Damping Characteristics of PVA Fiber-Reinforced Cementitious Composite Containing High-Volume Fly Ash under Frequency-Temperature Coupling Effects. Cem. Concr. Compos. 2021, 118, 103911. [Google Scholar] [CrossRef]

- Li, V.C. Mechanical Properties of Engineered Cementitious Composites (ECC). In Engineered Cementitious Composites (ECC); Springer: Berlin/Heidelberg, Germany, 2019; pp. 101–137. [Google Scholar] [CrossRef]

- Yu, K.; Wang, Y.; Yu, J.; Xu, S. A Strain-Hardening Cementitious Composites with the Tensile Capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Zhu, J.X.; Xu, L.Y.; Huang, B.T.; Weng, K.F.; Dai, J.G. Recent Developments in Engineered/Strain-Hardening Cementitious Composites (ECC/SHCC) with High and Ultra-High Strength. Constr. Build. Mater. 2022, 342, 127956. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, K.; Li, V.C. Sprayable Engineered Cementitious Composites (ECC) Using Calcined Clay Limestone Cement (LC3) and PP Fiber. Cem. Concr. Compos. 2021, 115, 103868. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.; Weng, J.; Yang, E.H. Micromechanics of Engineered Cementitious Composites (ECC): A Critical Review and New Insights. Constr. Build. Mater. 2023, 362, 129765. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.; Leung, C.K.Y. Effect of Graphene Oxide on the Mechanical Behavior of Strain Hardening Cementitious Composites. Constr. Build. Mater. 2016, 120, 457–464. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, F.; Ma, H.; Xu, L. Tailoring an Impact Resistant Engineered Cementitious Composite (ECC) by Incorporation of Crumb Rubber. Constr. Build. Mater. 2020, 262, 120116. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Liu, Y.; Li, W.; Dong, B.; Duan, W.H. Dispersion of Graphene Oxide Agglomerates in Cement Paste and Its Effects on Electrical Resistivity and Flexural Strength. Cem. Concr. Compos. 2018, 92, 145–154. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.M.; Li, W.G.; Li, C.Y.; Sanjayan, J.G.; Duan, W.H.; Li, Z. Effects of Graphene Oxide Agglomerates on Workability, Hydration, Microstructure and Compressive Strength of Cement Paste. Constr. Build. Mater. 2017, 145, 402–410. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Ye, G.; Copuroglu, O.; Van Breugel, K.; Li, V.C. Improved Fiber Distribution and Mechanical Properties of Engineered Cementitious Composites by Adjusting the Mixing Sequence. Cem. Concr. Compos. 2012, 34, 342–348. [Google Scholar] [CrossRef]

- Ali, M.A.E.M.; Soliman, A.M.; Nehdi, M.L. Hybrid-Fiber Reinforced Engineered Cementitious Composite under Tensile and Impact Loading. Mater. Des. 2017, 117, 139–149. [Google Scholar] [CrossRef]

- Khed, V.C.; Mohammed, B.S.; Liew, M.S.; Abdullah Zawawi, N.A.W. Development of Response Surface Models for Self-Compacting Hybrid Fibre Reinforced Rubberized Cementitious Composite. Constr. Build. Mater. 2020, 232, 117191. [Google Scholar] [CrossRef]

- Adesina, A.; Das, S. Performance of Engineered Cementitious Composites Incorporating Crumb Rubber as Aggregate. Constr. Build. Mater. 2021, 274, 122033. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q. Matrix Tailoring of Engineered Cementitious Composites (ECC) with Non-Oil-Coated, Low Tensile Strength PVA Fiber. Constr. Build. Mater. 2018, 161, 420–431. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, C.; Guo, Z.; Zhang, M. Engineered Cementitious Composite with Characteristic of Low Drying Shrinkage. Cem. Concr. Res. 2009, 39, 303–312. [Google Scholar] [CrossRef]

- Li, G.; Zhang, L.W. Microstructure and Phase Transformation of Graphene-Cement Composites under High Temperature. Compos. Part B Eng. 2019, 166, 86–94. [Google Scholar] [CrossRef]

- Yu, K.; Li, L.; Yu, J.; Wang, Y.; Ye, J.; Xu, Q.F. Direct Tensile Properties of Engineered Cementitious Composites: A Review. Constr. Build. Mater. 2018, 165, 346–362. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, Y.; Qi, M.; Bi, J.; Yang, S.; Yuan, X. The Role of Sucrose on Enhancing Properties of Graphene Oxide Reinforced Cement Composites Containing Fly Ash. Constr. Build. Mater. 2021, 293, 123507. [Google Scholar] [CrossRef]

- Manikanta, D.; Ravella, D.P. Mechanical and Durability Characteristics of High Performance Self-Compacting Concrete Containing Flyash, Silica Fume and Graphene Oxide. Mater. Today Proc. 2020, 43, 2361–2367. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Pannem, R.M.R. Strength Properties of Graphene Oxide Cement Composites. Mater. Today Proc. 2019, 45, 3971–3975. [Google Scholar] [CrossRef]

| Materials | Compound (%) | Specific Gravity | Blaine Fineness (m2/Kg) | Loss on Ignition | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | MnO | CaO | MgO | Na2O | K2O | T2O | ||||

| FA | 57.01 | 20.96 | 4.15 | 0.033 | 9.79 | 1.75 | 2.23 | 1.53 | 0.68 | 2.38 | 290 | 1.25 |

| Cement | 20.76 | 5.54 | 3.35 | - | 61.4 | 2.48 | 0.19 | 0.78 | - | 3.15 | 325 | 2.20 |

| Type | Grade | Length | Diameter | Aspect Ratio (l/d) | Tensile Strength | Modulus of Elasticity | Specific Gravity |

|---|---|---|---|---|---|---|---|

| PVA | REC S-15 | 12 mm | 40 µm | 462 | 1600 MPa | 41 GPa | 1.3 |

| Mix ID | Materials (%) | Quantity of Materials Used in ECC Mixture (kg/m3) | ||||

|---|---|---|---|---|---|---|

| GO | PVA | PC | Fly Ash | Sand | Water | |

| M0 | 0.00 | 2 | 583 | 700 | 467 | 385 |

| M1 | 0.05 | 1.5 | 583 | 700 | 467 | 385 |

| M2 | 0.065 | 2 | 583 | 700 | 467 | 385 |

| M3 | 0.065 | 1.5 | 583 | 700 | 467 | 385 |

| M4 | 0.08 | 1.5 | 583 | 700 | 467 | 385 |

| M5 | 0.065 | 1.5 | 583 | 700 | 467 | 385 |

| M6 | 0.065 | 1 | 583 | 700 | 467 | 385 |

| M7 | 0.05 | 2 | 583 | 700 | 467 | 385 |

| M8 | 0.065 | 1.5 | 583 | 700 | 467 | 385 |

| M9 | 0.05 | 1 | 583 | 700 | 467 | 385 |

| M10 | 0.065 | 1.5 | 583 | 700 | 467 | 385 |

| M11 | 0.08 | 1 | 583 | 700 | 467 | 385 |

| M12 | 0.065 | 1.5 | 583 | 700 | 467 | 385 |

| M13 | 0.08 | 2 | 583 | 700 | 467 | 385 |

| Mix ID | Input Factors (%) | Responses | ||||||

|---|---|---|---|---|---|---|---|---|

| A: GO | B: PVA | CS (MPa) | TS (MPa) | TC (%) | FS (MPa) | MOE (GPa) | PR | |

| 9 | 0.05 | 1 | 78.6 | 5.8 | 4.2 | 15.2 | 29.6 | 0.17 |

| 1 | 0.05 | 1.5 | 69.8 | 5.6 | 3 | 13.7 | 28.1 | 0.15 |

| 7 | 0.05 | 2 | 66.0 | 5.5 | 3.3 | 12.2 | 27.8 | 0.2 |

| 6 | 0.065 | 1 | 60.6 | 5.1 | 3.6 | 12 | 27.1 | 0.17 |

| 3 | 0.065 | 1.5 | 57.5 | 4.7 | 2.8 | 11.5 | 26.7 | 0.17 |

| 5 | 0.065 | 1.5 | 59.5 | 4.6 | 2.7 | 11.4 | 27 | 0.2 |

| 8 | 0.065 | 1.5 | 57.5 | 4.6 | 2.8 | 11.3 | 26.8 | 0.19 |

| 10 | 0.065 | 1.5 | 58.5 | 4.7 | 2.6 | 11.3 | 26.6 | 0.18 |

| 12 | 0.065 | 1.5 | 60.6 | 4.8 | 2.9 | 11.4 | 27.1 | 0.17 |

| 2 | 0.065 | 2 | 56.4 | 4.4 | 2.9 | 11.5 | 25.5 | 0.21 |

| 11 | 0.08 | 1 | 58.4 | 4.6 | 3.4 | 9.4 | 25.4 | 0.19 |

| 4 | 0.08 | 1.5 | 56.9 | 4.2 | 2.5 | 9.1 | 24.3 | 0.22 |

| 13 | 0.08 | 2 | 53.1 | 4 | 2.2 | 8.6 | 23.4 | 0.23 |

| Response | Source | Sum of Squares | Df | Mean Square | F-Value | p-Value > F | Significance |

|---|---|---|---|---|---|---|---|

| CS | Model | 531.60 | 5 | 106.32 | 37.94 | <0.0001 | significant |

| A-GO | 351.82 | 1 | 351.82 | 125.53 | <0.0001 | significant | |

| B-PVA | 81.69 | 1 | 81.69 | 29.15 | 0.0010 | significant | |

| AB | 13.30 | 1 | 13.30 | 4.75 | 0.0658 | not significant | |

| A2 | 70.25 | 1 | 70.25 | 25.07 | 0.0016 | significant | |

| B2 | 0.11 | 1 | 0.11 | 0.039 | 0.8487 | not significant | |

| Residual | 19.62 | 7 | 2.80 | ||||

| Lack of Fit | 12.65 | 3 | 4.22 | 2.42 | 0.2062 | not significant | |

| Pure Error | 6.97 | 4 | 1.74 | ||||

| Cor Total | 551.22 | 12 | |||||

| TS | Model | 3.47 | 5 | 0.69 | 97.70 | <0.0001 | significant |

| A-GO | 2.80 | 1 | 2.80 | 394.73 | <0.0001 | significant | |

| B-PVA | 0.43 | 1 | 0.43 | 60.11 | 0.0001 | significant | |

| AB | 0.022 | 1 | 0.022 | 3.17 | 0.1182 | not significant | |

| A2 | 0.14 | 1 | 0.14 | 19.25 | 0.0032 | significant | |

| B2 | 0.014 | 1 | 0.014 | 2.04 | 0.1962 | not significant | |

| Residual | 0.050 | 7 | 7.098 × 10−3 | ||||

| Lack of Fit | 0.022 | 3 | 7.228 × 10−3 | 1.03 | 0.4679 | not significant | |

| Pure Error | 0.028 | 4 | 7.000 × 10−3 | ||||

| Cor Total | 3.52 | 12 | |||||

| TC | Model | 3.13 | 5 | 0.63 | 27.17 | 0.0002 | significant |

| A-GO | 0.96 | 1 | 0.96 | 41.69 | 0.0003 | significant | |

| B-PVA | 1.31 | 1 | 1.31 | 56.75 | 0.0001 | significant | |

| AB | 0.022 | 1 | 0.022 | 0.98 | 0.3558 | not significant | |

| A2 | 1.314 × 10−4 | 1 | 1.314 × 10−4 | 5.705 × 10−3 | 0.9419 | not significant | |

| B2 | 0.71 | 1 | 0.71 | 30.82 | 0.0009 | significant | |

| Residual | 0.16 | 7 | 0.023 | ||||

| Lack of Fit | 0.11 | 3 | 0.036 | 2.80 | 0.1727 | not significant | |

| Pure Error | 0.052 | 4 | 0.013 | ||||

| Cor Total | 3.29 | 12 | |||||

| FS | Model | 37.08 | 5 | 7.42 | 64.38 | <0.0001 | significant |

| A-GO | 32.67 | 1 | 32.67 | 283.59 | <0.0001 | significant | |

| B-PVA | 3.08 | 1 | 3.08 | 26.75 | 0.0013 | significant | |

| AB | 1.21 | 1 | 1.21 | 10.50 | 0.0142 | significant | |

| A2 | 0.092 | 1 | 0.092 | 0.80 | 0.4006 | not significant | |

| B2 | 0.077 | 1 | 0.077 | 0.67 | 0.4398 | not significant | |

| Residual | 0.81 | 7 | 0.12 | ||||

| Lack of Fit | 0.78 | 3 | 0.26 | 37.06 | 0.0022 | significant | |

| Pure Error | 0.028 | 4 | 7.0 × 10−3 | ||||

| Cor Total | 37.89 | 12 | |||||

| MOE | Model | 30.49 | 2 | 15.24 | 141.01 | <0.0001 | significant |

| A-GO | 25.63 | 1 | 25.63 | 237.06 | <0.0001 | significant | |

| B-PVA | 4.86 | 1 | 4.86 | 44.96 | <0.0001 | significant | |

| Residual | 1.08 | 10 | 0.11 | ||||

| Lack of Fit | 0.91 | 6 | 0.15 | 3.52 | 0.1216 | not significant | |

| Pure Error | 0.17 | 4 | 0.043 | ||||

| Cor Total | 31.57 | 12 | |||||

| PR | Model | 4.417 × 10−3 | 2 | 2.208 × 10−3 | 11.31 | 0.0027 | significant |

| A-GO | 2.400 × 10−3 | 1 | 2.40 × 10−3 | 12.29 | 0.0057 | significant | |

| B-PVA | 2.017 × 10−3 | 1 | 2.017 × 10−3 | 10.33 | 0.0093 | significant | |

| Residual | 1.953 × 10−3 | 10 | 1.953 × 10−4 | ||||

| Lack of Fit | 1.273 × 10−3 | 6 | 2.121 × 10−4 | 1.25 | 0.4339 | not significant | |

| Pure Error | 6.800 × 10−4 | 4 | 1.70 × 10−4 | ||||

| Cor Total | 6.369 × 10−3 | 12 |

| Model Verification Constraints | CS | TS | TC | FS | MOE | PR |

|---|---|---|---|---|---|---|

| Std. Dev. | 1.67 | 0.084 | 0.15 | 0.34 | 0.33 | 0.014 |

| Mean | 61.03 | 4.82 | 2.99 | 11.43 | 26.57 | 0.19 |

| C.V. % | 2.74 | 1.75 | 5.07 | 2.97 | 1.24 | 7.41 |

| PRESS | 137.19 | 0.26 | 1.18 | 7.56 | 1.64 | 3.556 × 10−3 |

| −2 Log Likelihood | 42.24 | −35.48 | −20.18 | 0.75 | 4.56 | −77.55 |

| R-Squared | 0.9644 | 0.9859 | 0.9510 | 0.9787 | 0.9658 | 0.6934 |

| Adj R-Squared | 0.9390 | 0.9758 | 0.9160 | 0.9635 | 0.9589 | 0.6321 |

| Pred R-Squared | 0.7511 | 0.9256 | 0.6398 | 0.8006 | 0.9482 | 0.4417 |

| Adeq Precision | 19.954 | 33.196 | 16.814 | 26.458 | 37.566 | 11.421 |

| BIC | 57.63 | −20.09 | −4.79 | 16.14 | 12.26 | −69.86 |

| AICc | 68.24 | −9.48 | 5.82 | 26.75 | 13.23 | −68.89 |

| Factors | Input Factors (%) | Responses (Output Factors) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| GO (%) | PVA (%) |

CS

(MPa) |

TS

(MPa) |

TC

(%) |

FS

(MPa) |

MOE

(GPa) | PR | ||

| Value | Min. | 0.05 | 1 | 53.1 | 4.0 | 2.2 | 8.61 | 23.36 | 0.15 |

| Max | 0.08 | 2 | 78.6 | 5.8 | 4.2 | 15.20 | 29.59 | 0.23 | |

| Goal | Min. | In range | Max. | Max. | Max. | Max. | Max. | Min. | |

| Results | 0.05 | 1.0 | 77.0 | 5.8 | 4.1 | 15 | 29.54 | 0.15 | |

| Desirability | 0.973 (97%) | ||||||||

| Response | Experimental Result | Predicted Result | Percentage Error (%) |

|---|---|---|---|

| CS (MPa) | 80.11 | 77.0 | 4.0 |

| TS (MPa) | 6.01 | 5.8 | 3.6 |

| TC (%) | 3.8 | 4.1 | 7.3 |

| FS (MPa) | 16.2 | 15.0 | 8.0 |

| MOE (GPa) | 31.5 | 29.4 | 7.1 |

| PR | 0.16 | 0.15 | 6.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bheel, N.; Mohammed, B.S.; Abdulkadir, I.; Liew, M.S.; Zawawi, N.A.W.A. Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM. Buildings 2023, 13, 2018. https://doi.org/10.3390/buildings13082018

Bheel N, Mohammed BS, Abdulkadir I, Liew MS, Zawawi NAWA. Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM. Buildings. 2023; 13(8):2018. https://doi.org/10.3390/buildings13082018

Chicago/Turabian StyleBheel, Naraindas, Bashar S. Mohammed, Isyaka Abdulkadir, M. S. Liew, and Noor Amila Wan Abdullah Zawawi. 2023. "Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM" Buildings 13, no. 8: 2018. https://doi.org/10.3390/buildings13082018

APA StyleBheel, N., Mohammed, B. S., Abdulkadir, I., Liew, M. S., & Zawawi, N. A. W. A. (2023). Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM. Buildings, 13(8), 2018. https://doi.org/10.3390/buildings13082018