Development of a Heat Consumption Model Group and Analysis of Economic Adjustments and Carbon Reduction Efforts in Centralized Heating Upgrades in the Beijing Urban–Rural Fringe

Abstract

1. Introduction

2. Literature Review

3. Analysis of Modeling Methods and Heating Characteristics

3.1. Conventional Statistical Modeling Methods

3.2. Research Framework

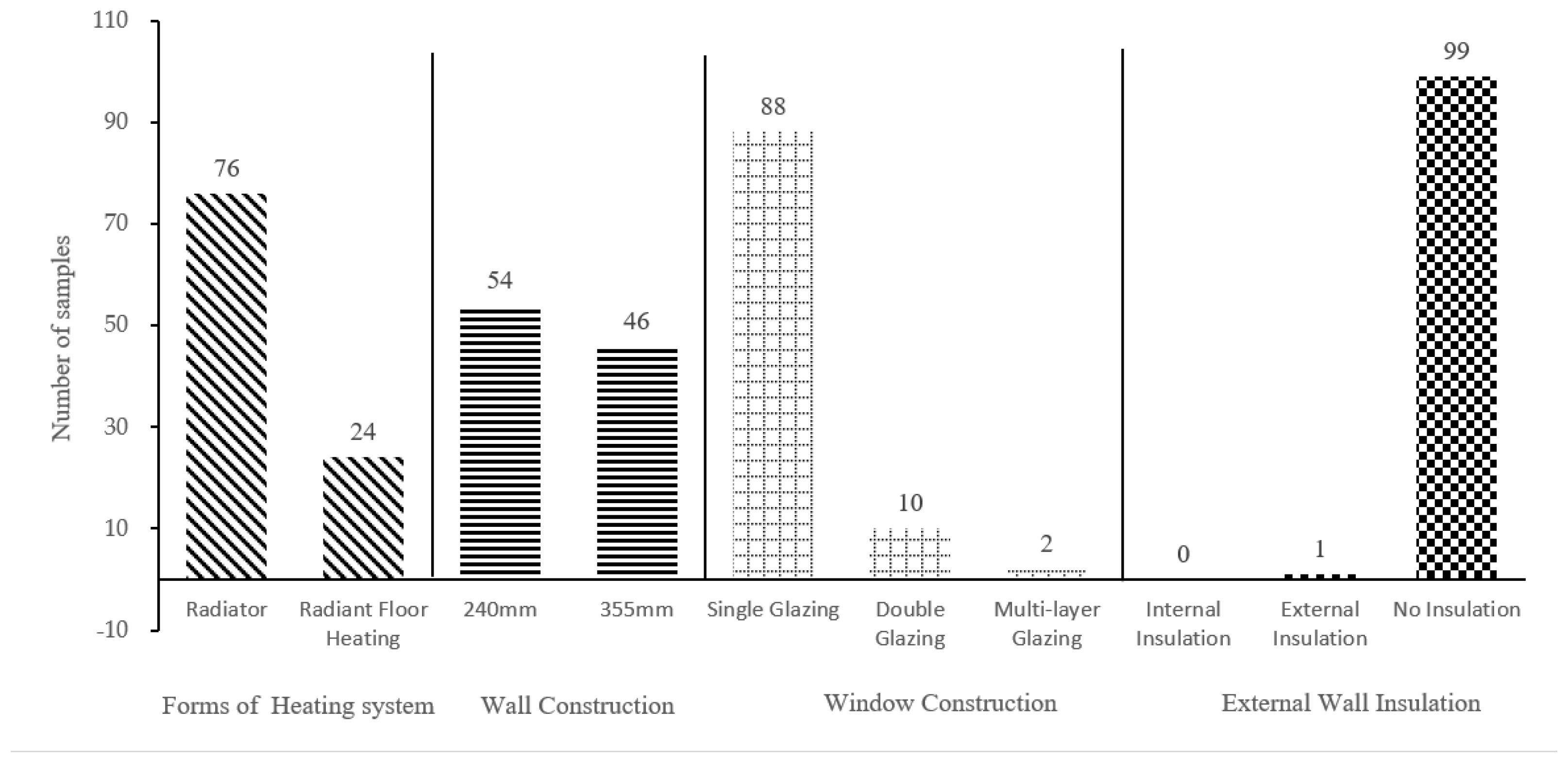

3.3. Analysis of Building and Heating Characteristics

4. Analysis of Heat-Affecting Factors and Testing Contents

4.1. Investigation of Heat-Affecting Factors

4.2. Analysis of Affecting Factors

4.3. Testing Method for Affecting Factors

4.4. Analysis of Testing Results and Selection of Affecting Factors

5. Establishment and Verification of Heat Consumption Prediction Model Group

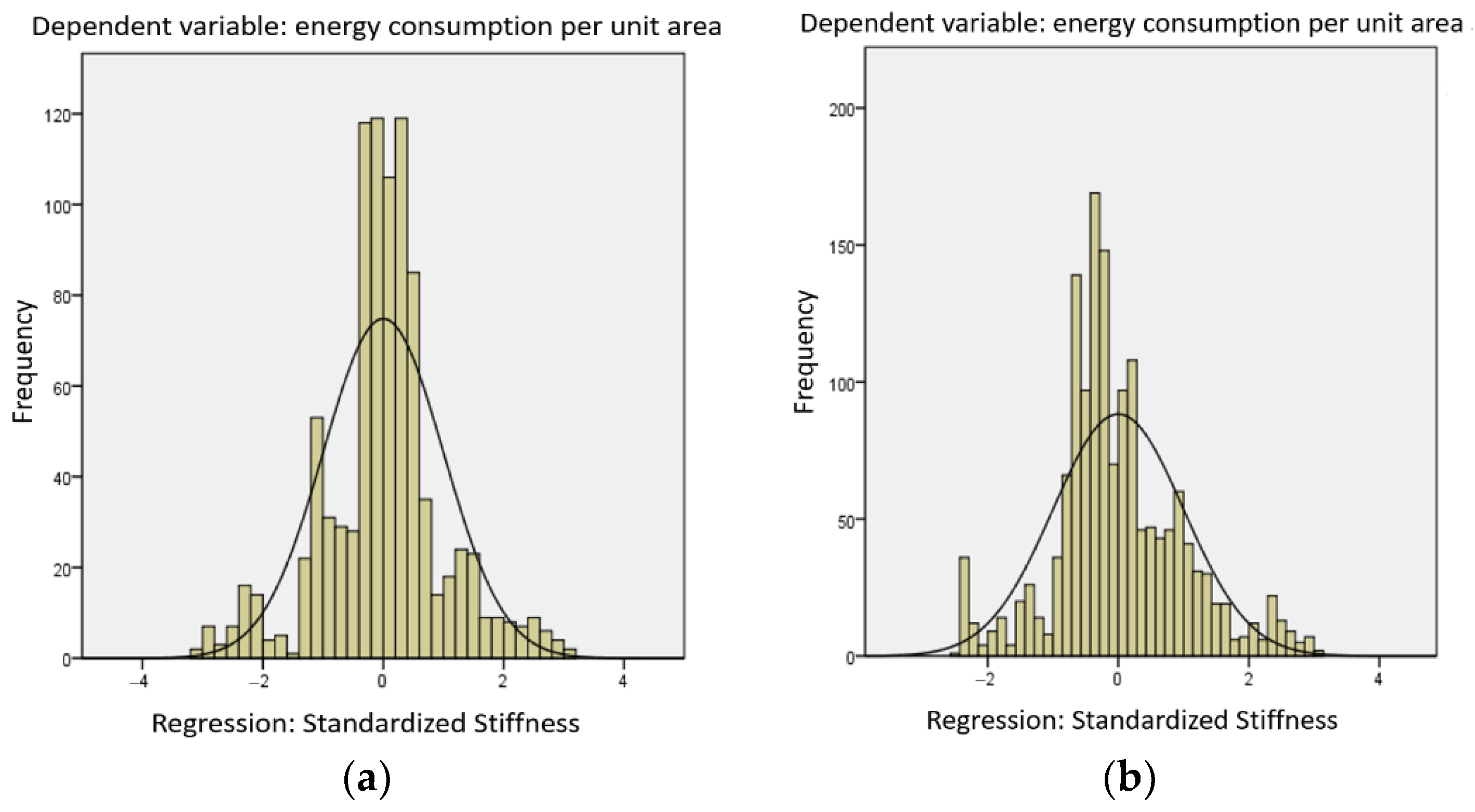

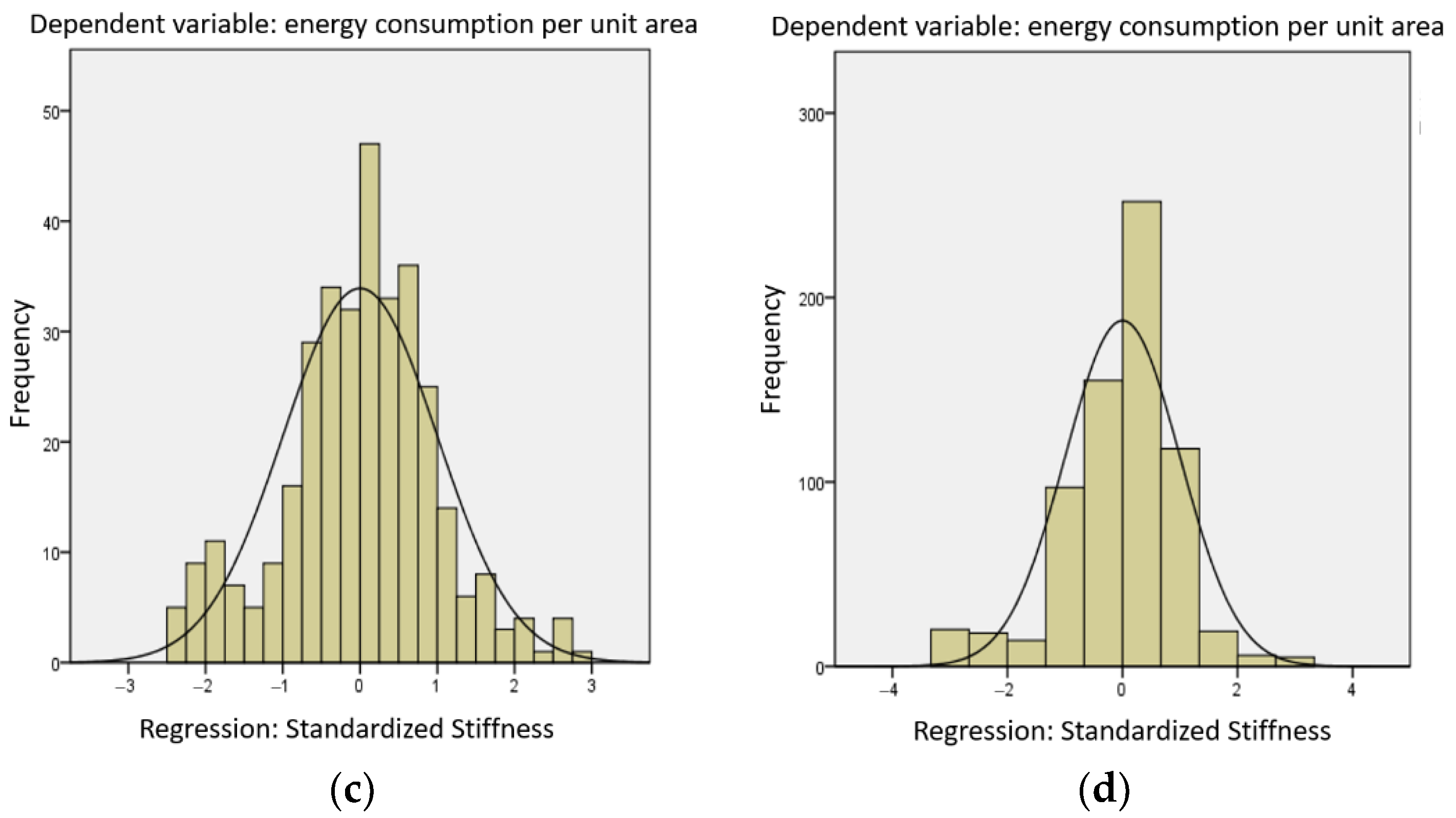

5.1. Process of Building the Model Groups

5.2. Establishment and Validation of the Prediction Model Group for Heat Consumption

- —Hourly heat consumption per unit area (kJ/m2);

- —Hourly average indoor temperature (°C);

- —Hourly average outdoor temperature (°C).

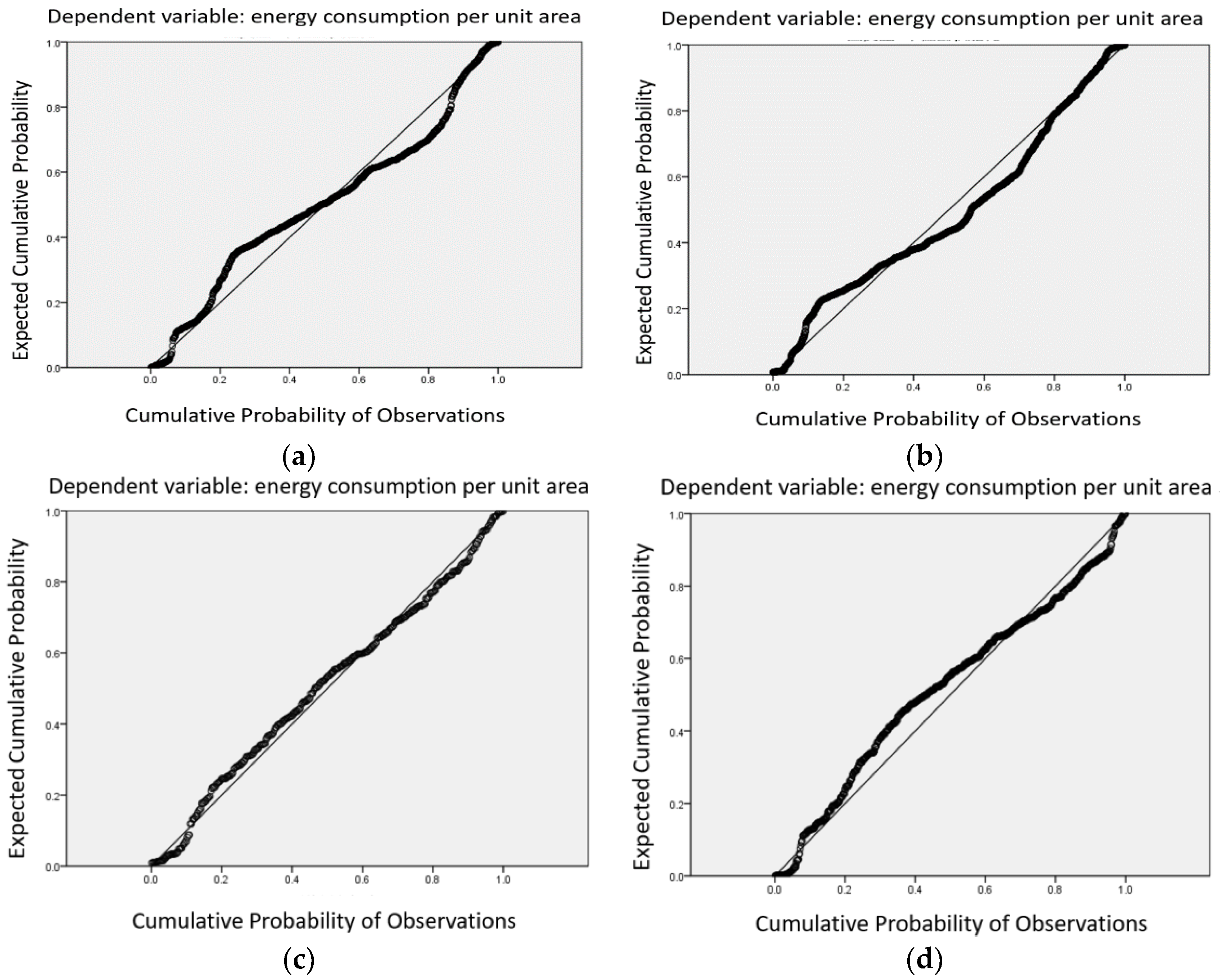

5.3. Validation of the Heat Consumption Prediction Model Group

6. Analysis of the Economy and Carbon Reduction in Rural Centralized Heating Upgrades

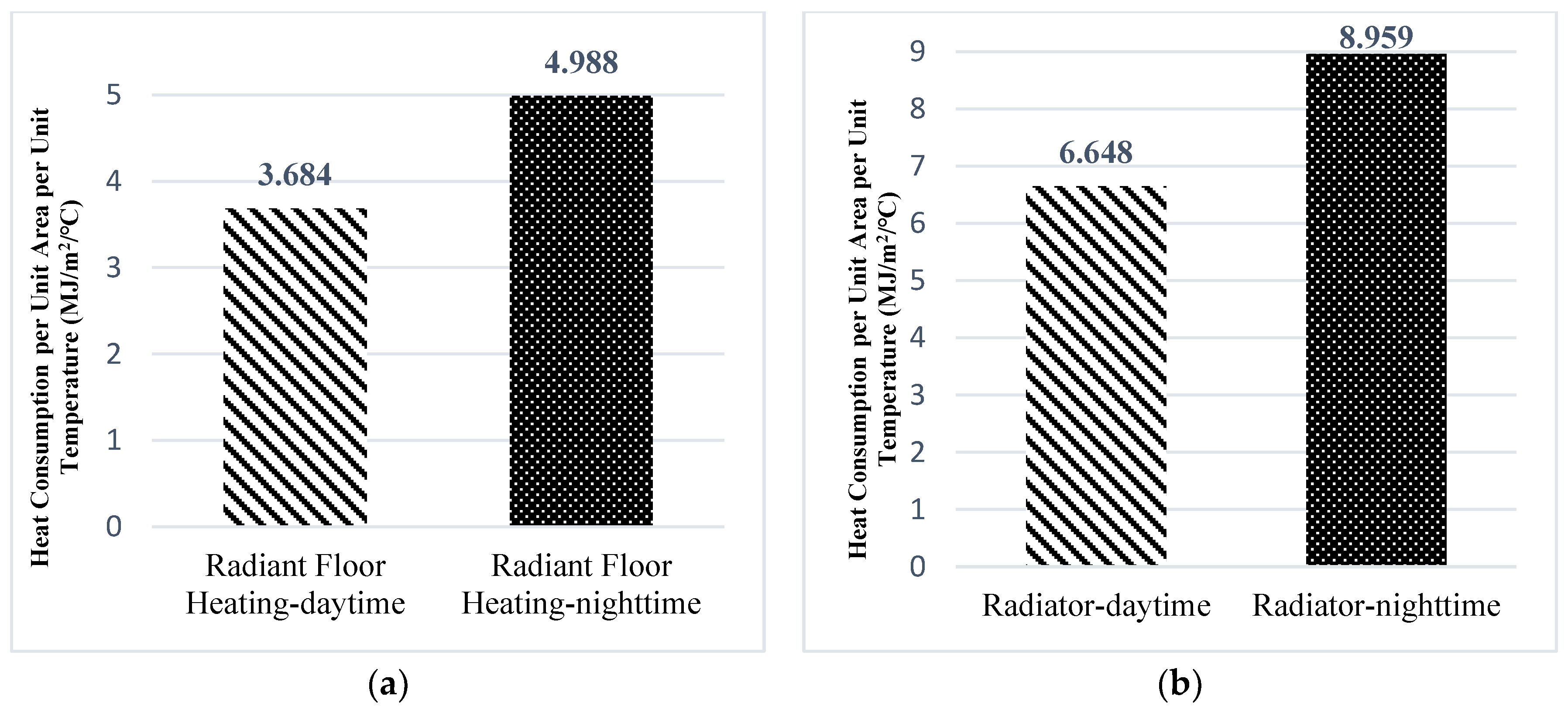

6.1. Heat Consumption Analysis of Different Heating Methods

6.2. Analysis of CO2 Reduction in Rural Centralized Heat Upgrades

- —CO2 emissions (ton);

- —Heat consumption (GJ);

- —Efficiency of boiler;

- —Carbon content per unit of calorific value (ton/GJ);

- —Carbon oxidation rate.

6.3. Analysis of Economic Impacts of Rural Centralized Heating Upgrades

- —Primary energy consumption (ton or 10,000 m3);

- —Heat consumption (GJ);

- —Efficiency of boiler;

- —QDW of anthracite and natural gas (GJ/ton or GJ/10,000 m3).

- —Annual operation cost (RMB 10,000);

- —Primary energy consumption (ton or 10,000 m3);

- —Primary energy price (RMB/ton or RMB/m3);

- —CO2 emission reduction compared with small coal-burning boilers (ton);

- —CO2 price in Beijing (RMB/ton).

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, Y.; Han, S.; Tian, Z.; Yao, J.; Chen, W.; Zhang, Q. Review on occupancy detection and prediction in building simulation. Build. Simul. 2022, 15, 333–356. [Google Scholar] [CrossRef]

- Hou, X.; Tian, Z.; Niu, J.; Wu, X.; Lu, Y. Research on design day generation method for air-conditioning system design considering the coincidence of hourly variation coefficient. Energy Build. 2022, 270, 112300. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Wang, H. Influencing factors regression analysis of heating energy consumption of rural buildings in China. Procedia Eng. 2017, 205, 3585–3592. [Google Scholar] [CrossRef]

- Building Energy Conservation Research Center, Tsinghua University. China Building Energy Efficiency Annual Development Report in 2016; China Building Industry Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Ma, R.; Mao, C.; Shan, M.; Zhang, L.; Yang, X. Occupant control patterns of low temperature air-to-air heat pumps in Chinese rural households based on field measurements. Energy Build. 2017, 154, 157–165. [Google Scholar] [CrossRef]

- Yuan, P.; Duanmu, L.; Wang, Z. Coal consumption prediction model of space heating with feature selection for rural residences in severe cold area in China. Sustain. Cities Soc. 2019, 50, 101643. [Google Scholar] [CrossRef]

- Meredydd, E.; Sha, Y.; Bo, S.; Deng, Q.; Liu, J.; Delgado, A. Building energy efficiency in rural China. Energy Policy 2014, 64, 243.e51. [Google Scholar]

- Shan, M.; Wang, P.; Li, J.; Yue, G.; Yang, X. Energy and environment in Chinese rural buildings: Situations, challenges, and intervention strategies. Build Environ. 2015, 91, 271.e82. [Google Scholar] [CrossRef]

- Wang, W.; Li, F. Study on substitutable value of electric heating instead of coal heating in northern China under carbon constraints. J. Clean. Prod. 2020, 260, 121155. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, Z.; Ngan, H.W.; Tan, Z. Sustainning China’s electricity market development. Energy Policy 2014, 73, 30–37. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Cheng, M.; Liu, S.; Xu, J.; He, Y.; Meng, F. The contribution of residential coal combustion to PM2.5 pollution over China’s Beijing-Tianjin-Hebei region in winter. Atmos. Environ. 2017, 159, 147–161. [Google Scholar] [CrossRef]

- Liu, J.; Mauzerall, D.L.; Chen, Q.; Zhang, Q.; Song, Y.; Peng, W.; Klimont, Z.; Qiu, X.; Zhang, S.; Hu, M.; et al. Air pollutant emissions from Chinese households: A major and underappreciated ambient pollution source. Proc. Natl. Acad. Sci. USA 2016, 113, 7756.e7761. [Google Scholar] [CrossRef] [PubMed]

- State Council. State Council Notice on Air Pollution Prevention and Control Action Plan 10 September 2013. Available online: http://www.gov.cn/zwgk/2013–09/12/content2486773.htm (accessed on 10 May 2020). (In Chinese)

- Beijing Municipal Government Beijing Municipal Government Notice on Clean Air Action Plan of 2013–2017. 11 September 2013. Available online: http://zhengwu.beijing.gov.cn/gzdt/gggs/t1324560.htm (accessed on 10 May 2020). (In Chinese)

- Kleinebrahm, M.; Weinand, J.M.; Naber, E.; McKenna, R.; Ardone, A. Analysing municipal energy system transformations in line with national greenhouse gas reduction strategies. Appl. Energy 2023, 332, 120515. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Liu, Y.; Wang, D.; Zhuang, Z.; Quan, M. Energy, exergy, and economic analysis of a centralized solar and biogas hybrid heating system for rural areas. Energy Convers. Manag. 2023, 276, 116591. [Google Scholar] [CrossRef]

- Al-Sakkaf, A.; Mohammed Abdelkader, E.; Mahmoud, S.; Bagchi, A. Studying energy performance and thermal comfort conditions in heritage buildings: A case study of murabba palace. Sustainability 2021, 13, 12250. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Oliveira, M.; Rubio-Bellido, C.; Marín, D. A comparative analysis of the international regulation of thermal properties in building envelope. Sustainability 2019, 11, 5574. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Sanchez-García, D.; Rubio-Bellido, C.; Marín-García, D. Potential of applying adaptive strategies in buildings to reduce the severity of fuel poverty according to the climate zone and climate change. Sustain. Cities Soc. 2021, 73, 103088. [Google Scholar] [CrossRef]

- Yan, H.; Yang, L.; Zheng, W.; Li, D. Influence of outdoor temperature on the indoor environment and thermal adaptation in Chinese residential buildings during the heating season. Energy Build. 2016, 116, 133–140. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, B. Simplified analysis methods for thermal responsive performance of passive solar house in cold area of China. Energy Build. 2013, 67, 445–452. [Google Scholar] [CrossRef]

- Cao, B.; Zhu, Y.; Li, M.; Ouyang, Q. Individual and district heating: A comparison of residential heating modes with an analysis of adaptive thermal comfort. Energy Build. 2014, 78, 17–24. [Google Scholar] [CrossRef]

- Lu, Y.; Tian, Z.; Zhou, R.; Liu, W. A general transfer learning-based framework for thermal load prediction in regional energy system. Energy 2021, 217, 119322. [Google Scholar] [CrossRef]

- Soltero, V.; Chacartegui, R.; Ortiz, C.; Velázquez, R. Potential of biomass district heating systems in rural areas. Energy 2018, 156, 132–143. [Google Scholar] [CrossRef]

- Chen, Q. District or distributed space heating in rural residential sector? Empirical evidence from a discrete choice experiment in South China. Energy Policy 2021, 148, 111937. [Google Scholar] [CrossRef]

| No. | Investigated Factors | No. | Investigated Factors |

|---|---|---|---|

| 1 | Heat Consumption | 8 | Housing Rental Rates |

| 2 | Indoor Temperature | 9 | Whether the Vacant Rooms are Heated |

| 3 | Outdoor Temperature | 10 | Wall Construction |

| 4 | Orientations | 11 | Exterior Wall Insulation |

| 5 | Gross Floor Area (GFA) | 12 | Window Construction |

| 6 | Ways to Add Coal | 13 | Gross Window Area (GWA) |

| 7 | Whether the House is for Rent | 14 | Forms of Heating System |

| Factor Characteristic | Controllable | Uncontrollable |

|---|---|---|

| Directly available | Heat Consumption | Indoor Temperature Outdoor Temperature Gross Floor Area Gross Window Area |

| Indirectly available | Whether the House is for Rent Housing Rental Rates Whether Vacant Rooms are Heated | Ways to Add Coal Wall Construction Exterior Wall Insulation Window Construction Forms of Heating System Orientations |

| No. | Affecting Factors | Investigation and Testing Requirements and Methods |

|---|---|---|

| 1 | Heat Consumption | Test water flow and temperature of supply and return water; record data every 10 min for 3 days. |

| 2 | Indoor Temperature | Choose 5 measuring points at each building; record data every 10 min for 3 days. |

| 3 | Outdoor Temperature | Choose 2 measuring points of outdoor shelter; record data every 10 min for 3 days. |

| 4 | Gross Window Area | Sum all gross window areas. |

| 5 | Gross Floor Area | Sum all gross wall areas. |

| 6 | Forms of Heating System | Investigate radiant floor heating or radiator heating. |

| 7 | Wall Construction | Investigate wall construction: 370 mm or 240 mm. |

| 8 | Window Construction | Investigate window construction: single glazing, double glazing, or multi-layer glazing. |

| 9 | Exterior Wall Insulation | Investigate whether the building has exterior wall insulation. |

| Group No. | Forms of Heating System | GFA (m2) | Average Indoor Temperature (°C) | Average Outdoor Temperature (°C) | Heat Consumption (MJ) | Deviation |

|---|---|---|---|---|---|---|

| 1 | Radiator | 300 | 17 | −9.5 | 573.6 | 25.7% |

| Radiant Floor Heating | 320 | 16.5 | −9.5 | 425.9 | ||

| 2 | Radiator | 510 | 16.3 | −7.3 | 752.8 | 22.2% |

| Radiant Floor Heating | 500 | 16.6 | −7.3 | 585.5 | ||

| 3 | Radiator | 1000 | 16.5 | −10.1 | 2721.0 | 32.3% |

| Radiant Floor Heating | 930 | 16.7 | −10.1 | 1843.3 |

| Group No. | Wall Construction | GFA (m2) | Average Indoor Temperature (°C) | Average Outdoor Temperature (°C) | Heat Consumption (MJ) | Deviation |

|---|---|---|---|---|---|---|

| 1 | 240 mm | 300 | 16.3 | −8.8 | 516.3 | 2.34% |

| 370 mm | 330 | 16.7 | −8.8 | 528.7 | ||

| 2 | 240 mm | 513 | 17.3 | −5.6 | 620.2 | 1.16% |

| 370 mm | 540 | 16.9 | −5.6 | 627.5 | ||

| 3 | 240 mm | 1000 | 16.6 | −7.3 | 1568 | −2.83% |

| 370 mm | 970 | 16.9 | −7.3 | 1524.8 |

| Model | Original Data Quantity | Remaining Data Quantity (After Sifting) |

|---|---|---|

| Radiator—Daytime Model | 6172 | 4836 |

| Radiator—Nighttime Model | 7144 | 6780 |

| Radiant Floor Heating—Daytime Model | 2116 | 1584 |

| Radiant Floor Heating—Nighttime Model | 3244 | 3036 |

| Model | Radiator—Daytime Model | Radiator—Nighttime Model | Radiant Floor Heating—Daytime Model | Radiant Floor Heating—Nighttime Model |

|---|---|---|---|---|

| Adjust R2 | 0.696 | 0.801 | 0.695 | 0.896 |

| Model | Radiator—Daytime Model | Radiator—Nighttime Model | Radiant Floor Heating —Daytime Model | Radiant Floor Heating—Nighttime Model |

|---|---|---|---|---|

| F-value | 439.71 | 1384.87 | 157.18 | 3043.21 |

| Fα-value | 3.0 | 3.0 | 3.03 | 3.01 |

| F/Fα | 146.57 | 461.62 | 51.87 | 1011.03 |

| Model | Radiator—Daytime Model | Radiator—Nighttime Model | Radiant Floor Heating—Daytime Model | Radiant Floor Heating—Nighttime Model |

|---|---|---|---|---|

| p-value of Indoor Temperature | 9.91 × 10−27 | 2.20 × 10−53 | 2.23 × 10−49 | 1.05 × 10−87 |

| p-value of Outdoor Temperature | 1.22 × 10−36 | 1.13 × 10−88 | 2.90 × 10−22 | 3.12 × 10−33 |

| Model | Heat Consumption of Intermittent Heating (GJ) | Heat Consumption of Continuous Heating (GJ) |

|---|---|---|

| Radiator—Daytime Model | 163,216.6 | 292,520.8 |

| Radiator—Nighttime Model | 462,120.7 | 533,422.1 |

| Radiant Floor Heating—Daytime Model | 48,035.1 | 85,899.9 |

| Radiant Floor Heating—Nighttime Model | 144,958.5 | 167,401.9 |

| Sum | 818,330.9 | 1,079,244.8 |

| Heating Modes | Type of Energy | Heat Consumption (GJ) | Carbon Content per Unit of Calorific Value (ton/GJ) | Carbon Oxidation Rate | Efficiency of Boiler | CO2 Emissions (ton) |

|---|---|---|---|---|---|---|

| Small Coal-Burning Boiler | Anthracite | 818,330.9 | 26.18 × 10−3 | 85% | 80% | 83,464.0 |

| Intermittent Heating from Centralized Heat | Natural Gas | 818,330.9 | 15.3 × 10−3 | 99% | 90% | 50,499.2 |

| Continuous Heating from Centralized Heat | Natural Gas | 1,079,244.8 | 15.3 × 10−3 | 99% | 90% | 66,600.2 |

| Heating Modes | Heat Consumption (GJ) | Type of Energy | Efficiency of Boiler | QDW of Primary Energy (GJ/ton or GJ/10,000 m3) | Primary Energy Consumption (ton or 10,000 m3) |

|---|---|---|---|---|---|

| Small Coal-Burning Boiler | 818,330.9 | Anthracite | 80% | 20.304 | 50,379.9 |

| Intermittent Heating from Centralized Heat | 818,330.9 | Natural Gas | 90% | 389.31 | 2335.6 |

| Continuous Heating from Centralized Heat | 1,079,244.8 | Natural Gas | 90% | 389.31 | 3080.2 |

| Heating Modes | Primary Energy Consumption (ton or 10,000 m3) | Primary Energy Price (RMB/ton or RMB/m3) | CO2 Emission Reduction (ton) | CO2 Price in Beijing (RMB/ton) | Annual Operation Cost (RMB 10,000) |

|---|---|---|---|---|---|

| Small Coal-Burning Boiler | 50,379.9 | 1500 | 0 | 120 | 7557.0 |

| Intermittent Heating from Centralized Heat | 2335.6 | 2.88 | 32,964.8 | 120 | 6330.8 |

| Continuous Heating from Centralized Heat | 3080.2 | 2.88 | 16,863.8 | 120 | 8668.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Tian, Z.; Cao, Y.; Cen, Y.; Qiao, Q.; Wang, X. Development of a Heat Consumption Model Group and Analysis of Economic Adjustments and Carbon Reduction Efforts in Centralized Heating Upgrades in the Beijing Urban–Rural Fringe. Buildings 2023, 13, 1821. https://doi.org/10.3390/buildings13071821

Liu Y, Tian Z, Cao Y, Cen Y, Qiao Q, Wang X. Development of a Heat Consumption Model Group and Analysis of Economic Adjustments and Carbon Reduction Efforts in Centralized Heating Upgrades in the Beijing Urban–Rural Fringe. Buildings. 2023; 13(7):1821. https://doi.org/10.3390/buildings13071821

Chicago/Turabian StyleLiu, Yimin, Zhe Tian, Yong Cao, Yue Cen, Qing Qiao, and Xiaolin Wang. 2023. "Development of a Heat Consumption Model Group and Analysis of Economic Adjustments and Carbon Reduction Efforts in Centralized Heating Upgrades in the Beijing Urban–Rural Fringe" Buildings 13, no. 7: 1821. https://doi.org/10.3390/buildings13071821

APA StyleLiu, Y., Tian, Z., Cao, Y., Cen, Y., Qiao, Q., & Wang, X. (2023). Development of a Heat Consumption Model Group and Analysis of Economic Adjustments and Carbon Reduction Efforts in Centralized Heating Upgrades in the Beijing Urban–Rural Fringe. Buildings, 13(7), 1821. https://doi.org/10.3390/buildings13071821