1. Introduction

Regarding recent trends in the structural health monitoring of buildings based on advanced computational and experimental techniques, works related to structural damage identification stand out. Recently, Wang, Kajita and Yang [

1] proposed a Bayesian RC-frame Finite Element Model Updating (FEMU) and damage state estimation approach using the nonlinear acceleration time history based on nested sampling. Another important research issue is the failure of joints, which can lead to structural collapse. Buka-Vaivade, Kurtenoks and Serdjuks [

2] proposed a novel method for the quality assessment of structural joints using coaxial correlation in 6D space. At the conclusion, the authors point to the importance of monitoring joint stiffness during operation to prevent such failures.

An approach that is rapidly gaining importance and adherence in the field of structural integrity studies is machine learning. To investigate the sensitivity of the overall mechanical performance of steel–concrete composite beam bridges (SCCBB) to different types of damage, Guo et al. [

3] proposed a method based on the extremely randomized trees (ET) algorithm in machine learning. Dyer et al. [

4] presented a comparative study of two machine learning models designed to assess the remaining useful life (RUL) of offshore platforms, a gradient boosted regression tree and a feedforward artificial neural network, with results that highlight the key factors associated with the platform RUL. Sarmadi [

5] used the vibration data of two full-scale bridges to perform a comparison of various machine learning methods (aiming to help engineers to choose the most appropriate technique), while also proposing automated approaches to hyperparameter optimization and variability level prediction. Pishro et al. [

6] applied artificial neural networks to predict and to evaluate the structural responses of externally bonded fiber-reinforced polymer-strengthened reinforced concrete T-beams under combined torsion and shear, with great consistency between the experimental and numerical results. Pishro et al. [

7] used a genetic algorithm and a physics-informed neural network to solve the inverse problem of the parallel micro element system on the local bond stress–slip relationship at the steel bar–ultra-high-performance concrete interface subjected to monotonic loading.

Lyapunov exponents are widely used to verify whether a given dynamical system presents instabilities and, particularly, deterministic chaotic behavior. For usual problems, the responses obtained through physical models, in general, are presented in a discrete way, modeled from approximation method solutions.

Over time, several methods for determining Lyapunov coefficients have been developed and published in the scientific literature. Wolf et al. [

8] presented, in an unprecedented way, a method to estimate the Lyapunov exponents from experimental time series, capable of working even in the presence of external noise. Sano and Sawada [

9] proposed a new method, which also can be used in experimentally obtained irregular signals, to determine a set of several Lyapunov exponents (including positive, zero, and even negative ones), from the observed time series of a single variable. Briggs [

10] presented an improved method, which remained close to the ideas of Wolf [

8] and Sano and Sawada [

9], but with the novelty of using a least-squares polynomial fitting in experimental data with the presence of noise, which generated better results. Abarbanel et al. [

11] generalized the notion of the Lyapunov spectrum, so that one can address the local variations in the growth rate of the instabilities across the attractor, with the idea that the local characteristics of a perturbation are more important in determining the predictability of a given state of the system. Dingwell [

12] and Sprott [

13] are good references that present these and other methods and strategies for obtaining Lyapunov coefficients from time series.

The increase in the number of methods for obtaining Lyapunov coefficients, as well as the increasing efficiency of such methods, has made their use more common and general. Its application is found in studies in astrophysics [

14] and climate systems [

15], among other areas that use the tools of dynamical systems. Recently, Fernandes [

16] and Barbosa et al. [

17] have made use of Lyapunov exponents for studies of lattice structures susceptible to chaotic behavior.

In recent years, several works have made use of tools from the field of dynamic systems, such as Lyapunov exponents and Poincaré maps, to monitor the integrity of structures such as bridges, viaducts, and mechanical elements, among others [

1,

2,

3,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17]. In general, such methods only identify the existence of damage, but are not capable of pointing out the magnitude or position of such degradation [

18]. It is important to point out that in these works, the use of the word damage only means an anomaly in the structural behavior, including all types of non-linearities and instabilities.

Casciati and Casciati [

19] presented the possibility of using Lyapunov exponents for structural monitoring by observing the variation in such parameters from an intact structure to a degraded structure, since before the occurrence of damage, the exponents were invariant. Jin, Jalinoos, and Livingston [

20] applied the Chaos Theory, using Lyapunov’s exponents, to analyze a real bridge, using experimental data and the results of a finite element model of the structure, having as a novelty the use of acceleration data instead of displacement data. The authors developed a geometric dynamics analytical process to reveal the relationship between the nonlinear invariants extracted from accelerations and displacements, thus enabling the direct use of the acceleration data to obtain the Lyapunov exponents. This is an interesting result, as it allows the direct use of experimental data collected from monitoring bridges with accelerometers in methods that use Lyapunov exponents to assess structural integrity, as is the purpose of the method presented in this work. However, Zhou, Chen and Yin [

21] point out that the number of samples and the duration of the analysis time are factors that influence the obtainment of the maximum Lyapunov exponents and, therefore, the integrity analysis of a structure. Rai and Kim [

22] propose a new approach for estimating the service life of rolling element bearings using the Lyapunov maximum exponent together with a probabilistic map of self-organization and the Gini-Simpson index; this method proved to be capable of predicting the growth of bearing damage.

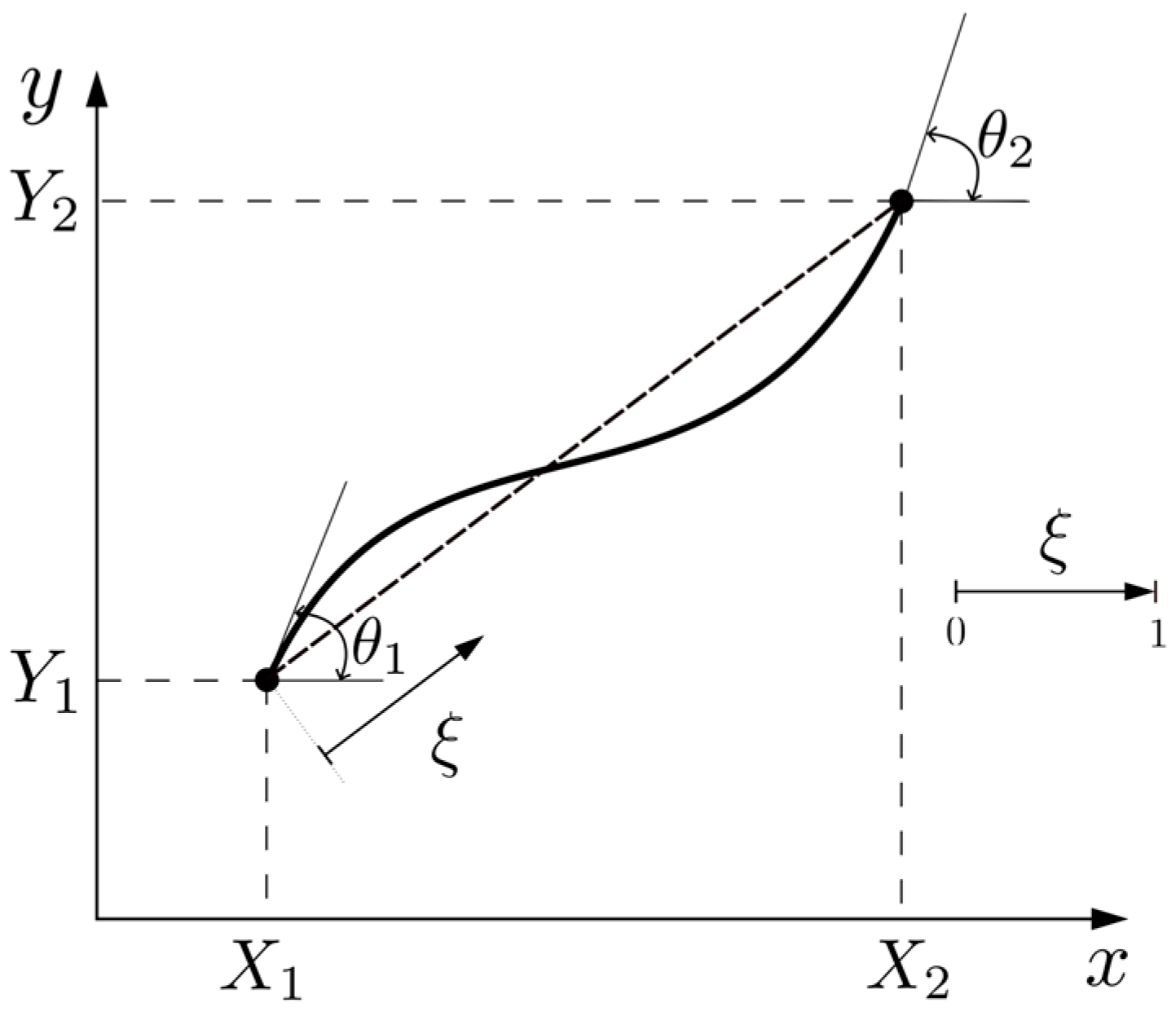

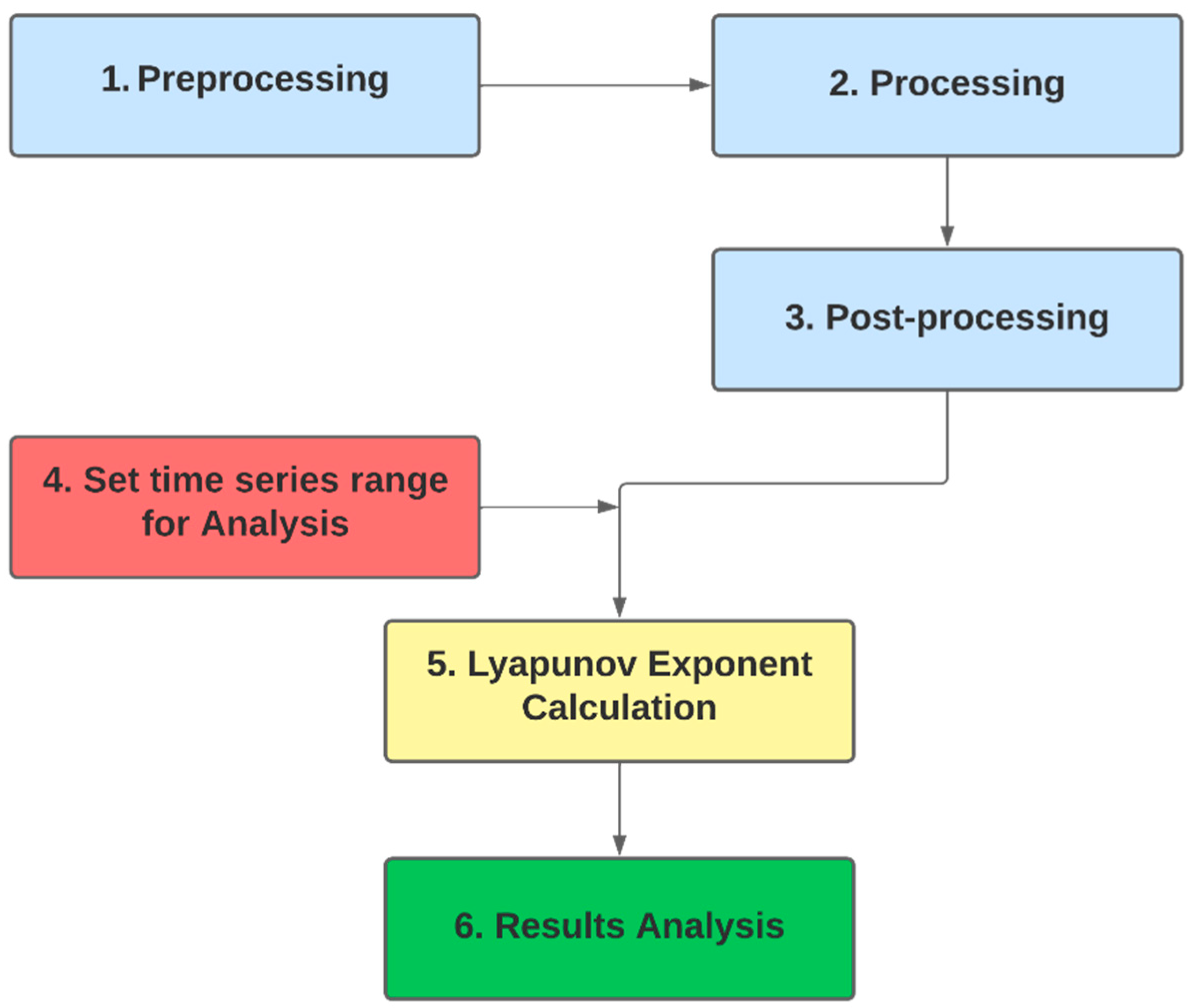

In the present study, the use of the Lyapunov exponents to evaluate the integrity of structures was achieved by examining a structural analysis that considers geometric and physical nonlinearities, aiming to ensure the applicability of the method in robust simulations. The algorithm used in the analysis was implemented by the authors, with the material nonlinearity modeled using the multilinear isotropic elastoplastic model together with a recently developed damage model, called FLHB [

23]. The nonlinear equilibrium equations solution was obtained using the positional finite element method. In this article, a numerical example of a frame structure was presented to illustrate the methodology applicability, even though the methodology could be applied to displacement/acceleration data resulting from any other type of analysis or experimental test.

3. Results

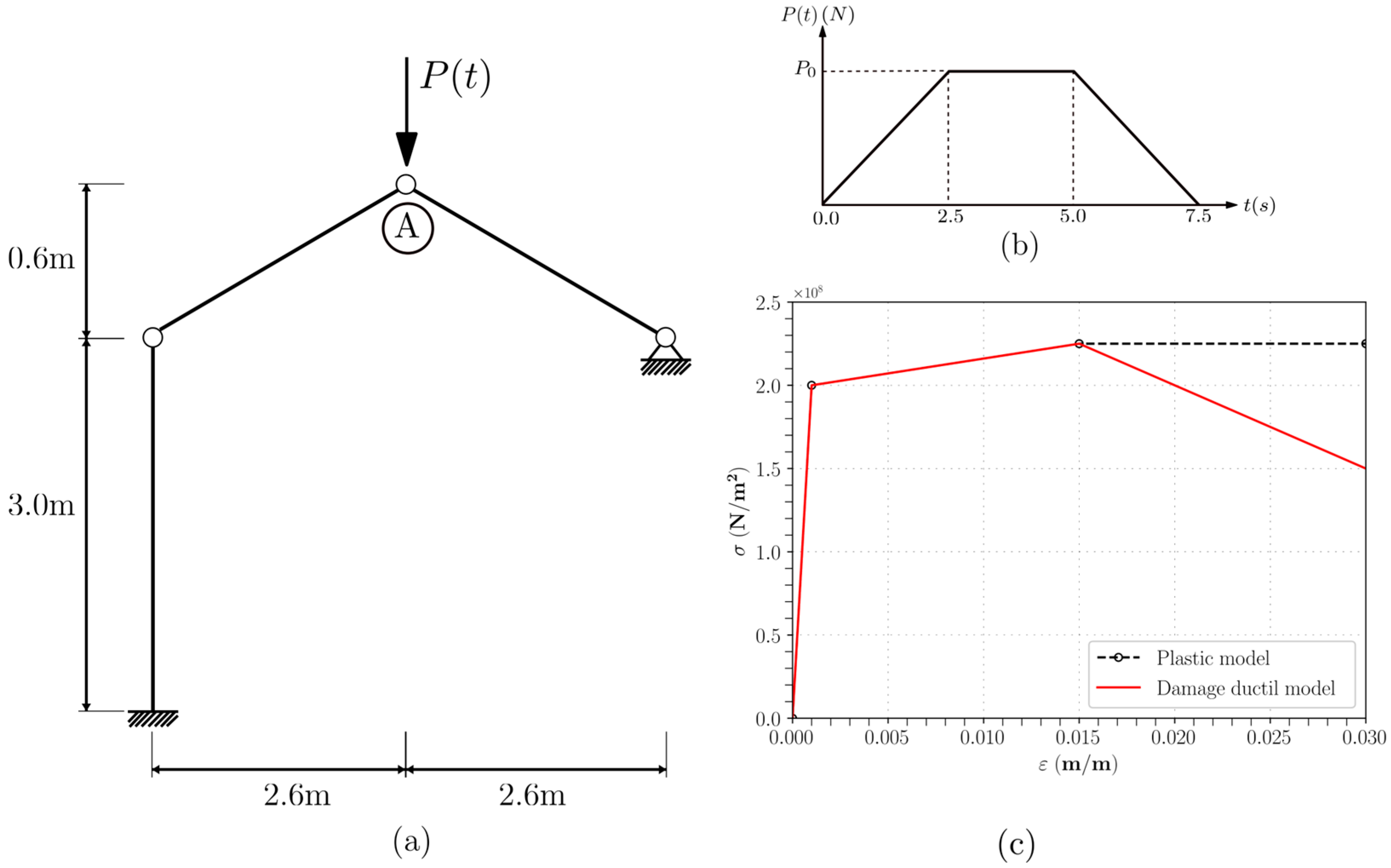

The numerical application consists of a framed structure with an upper section similar to a von Mises truss, as is shown in

Figure 3. The modulus of elasticity is

(steel), the cross-sectional area of the bars is equal to

and the moment of inertia of the bars is equal to

for the column and equal to

for the other bars. The specific mass is equal to

and the damping factor considered is equal to 0.05. The parameters of the ductile damage model are

,

,

,

and

. Regarding time integration, time increments of

and

and

were adopted in the Newmark integration. The loading phases are presented in

Figure 3b.

The chosen example is conceptual by nature, serving the purpose of illustrating the verification sequence and evaluating the applicability of the proposed methodology. Despite this, the developed algorithm can receive the design parameters of real structures as its input.

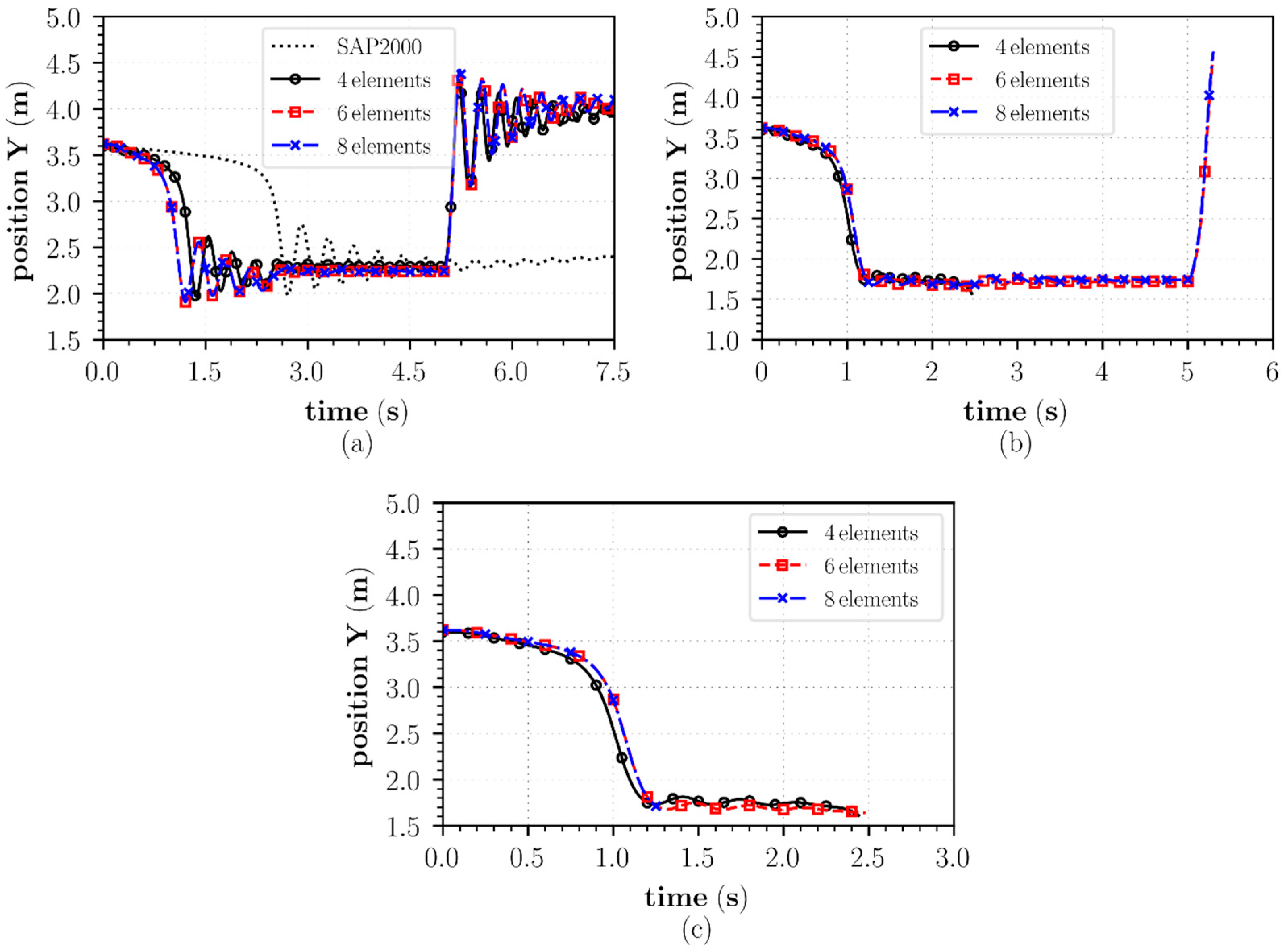

Three models were initially made with different meshes, considering four, six and eight elements per bar. The frequencies for the respective loops are shown in

Table 1. In dynamic problems, excessive mesh refinement may not physically produce the best results, since high-order frequencies may spuriously influence the response. In general terms, the responses of all meshes were close, except in cases with inelasticity, in which six-element mesh achieved the expected responses from the physical point of view and over a longer analysis time. The other meshes studied failed in regard to this last consideration.

In

Figure 4, the responses of each material model with the mentioned meshes are presented. It can be observed that there is a convergence of responses between meshes with six and four elements for the elastic response (

Figure 4a) and the plastic response (

Figure 4b). In the damage model (

Figure 4c), the four-element and the six-element meshes present a longer-lasting response, but the responses slightly differ. Thus, the mesh with the longest period is the mesh with six elements, since in the plastic model the mesh with four elements presents a response only up to 2.46 s. There is also a discrepancy between the response presented by SAP2000 in the elastic model in relation to the responses of the present formulation. This difference can be explained, in theory, by the difference in the finite elements used by the SAP2000 and by the positional method. The data presented below were obtained considering the six-element mesh.

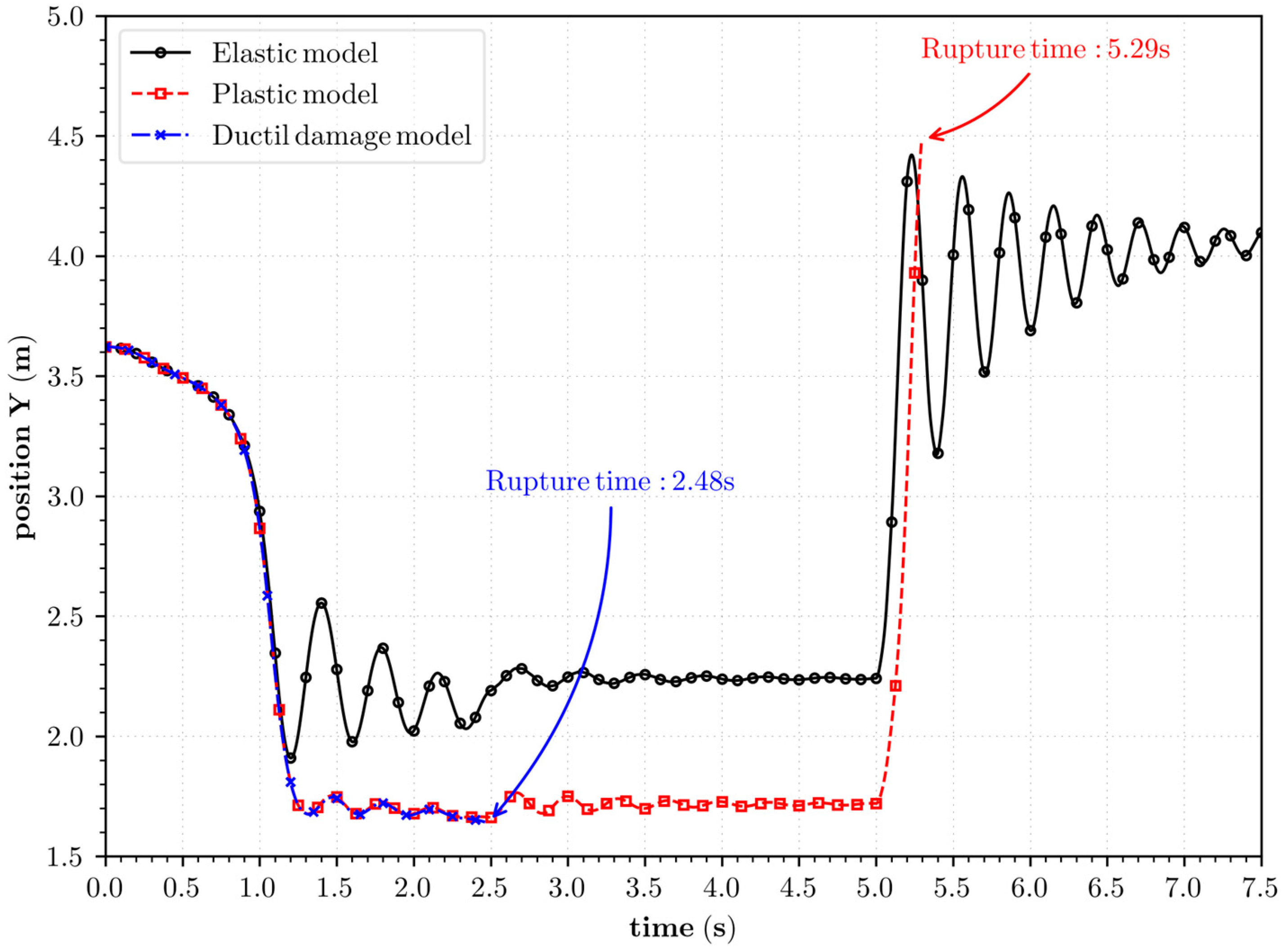

Figure 5 presents a comparison between responses for the six-element mesh of all material models. It can be noticed that there is an occurrence of snap-through in all models, but in the inelastic model the jump is more intense, taking node A up to approximately 1.6 m, while in the elastic model it approaches 1.8 m. In both models it occurs between 1.0 and 1.5 s. After the jump, oscillations of decreasing amplitude are observed in the elastic model, which cease around 3.0 s. This damping is observed practically instantaneously in the inelastic model after snap-through.

Around the time instant of 5.0 s, another leap occurs, which is due to the characteristic of the dynamic applied force. After this new jump, node A, in the elastic model, presents oscillations that tend to 4.0 m at the end of the analysis. The plastic model does not provide results until the end, since the base of the column undergoes plastification and the structure collapses at 5.29 s. Structure failure in the ductile damage model is much more premature, occurring at 2.48 s of analysis. Due to the constitutive curve used in the example and the geometric characteristics of the structure, no substantial differences can be noticed between the responses of the inelastic models, except for the premature break in the damage model. It should be noted that the first plastification takes 0.59 s for analysis, while the first degradation takes 1.19 s.

Considering the acceleration responses, presented in

Figure 6, a slightly more accentuated tendency for the accelerations to decrease can be seen in the damage model in relation to the plastic model. It is interesting to note how the acceleration presents jumps; in the plastic and damage model, they are in the order of

, eight times greater than the elastic model. Near the second jump, an increase in acceleration is again observed, reaching

in the plastic model, again higher than the elastic model, which presents a maximum acceleration of

.

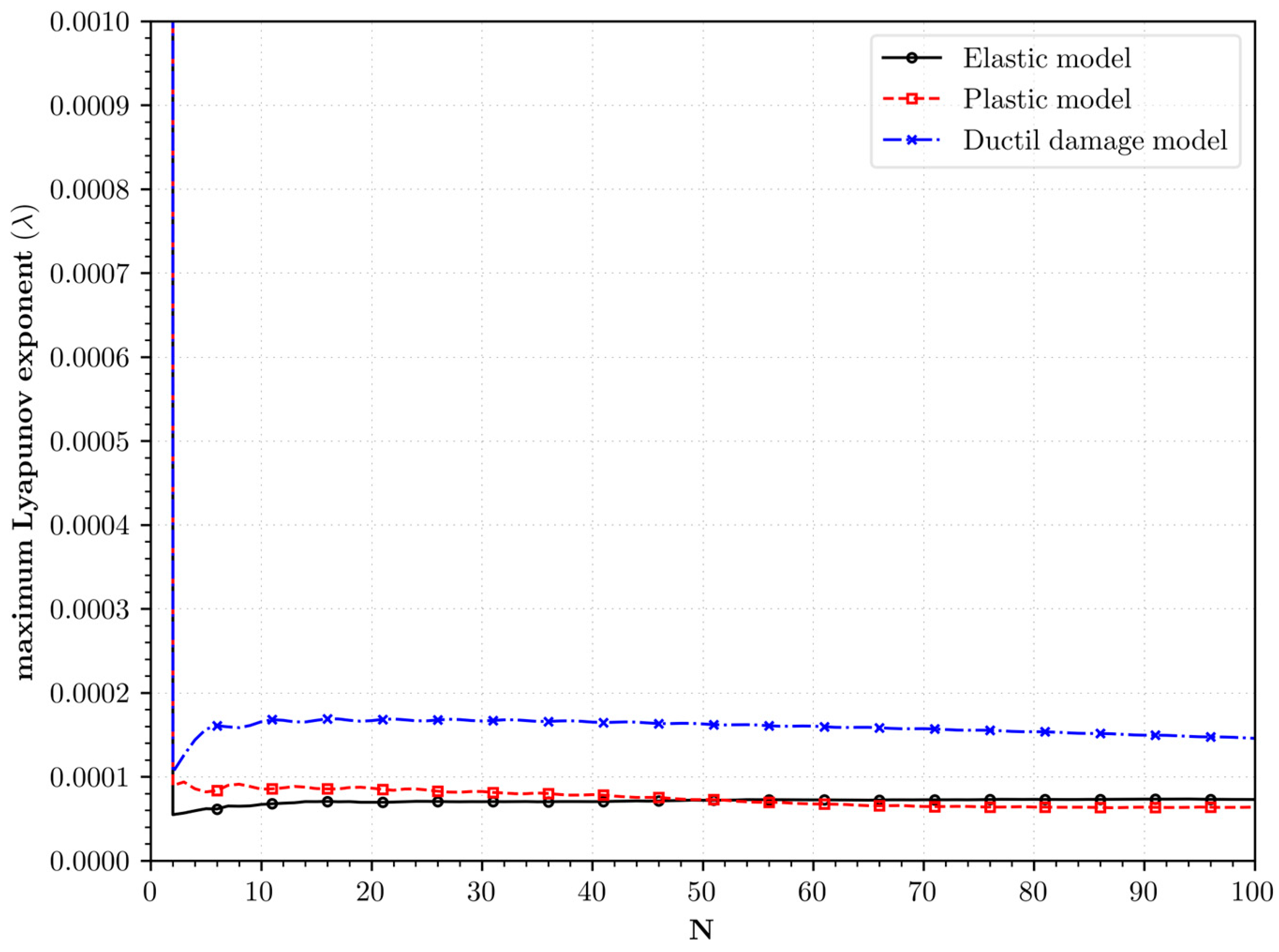

To obtain the largest Lyapunov exponent, three sets of time series were adopted, with the first set between 0 s and 1.3 s, the second, from 1.3 s to 5.0 s, and the third, from 5.0 s to the end of the analysis. Notably, the ductile damage model only provided results for the first and second spans.

Figure 7 shows the convergence of the highest Lyapunov exponent, where

N is the number of points close to the analysis point for the first analysis set. Note the convergence of

for the elastic model in the order of 0.01. The inelastic models, however, present

tending to 0.001.

For the second set of data, from 1.3 s to 5 s, there is a certain stabilization of the structure at the new position after the snap presented in

Figure 8, as

is detected for all the models, which tends to

.

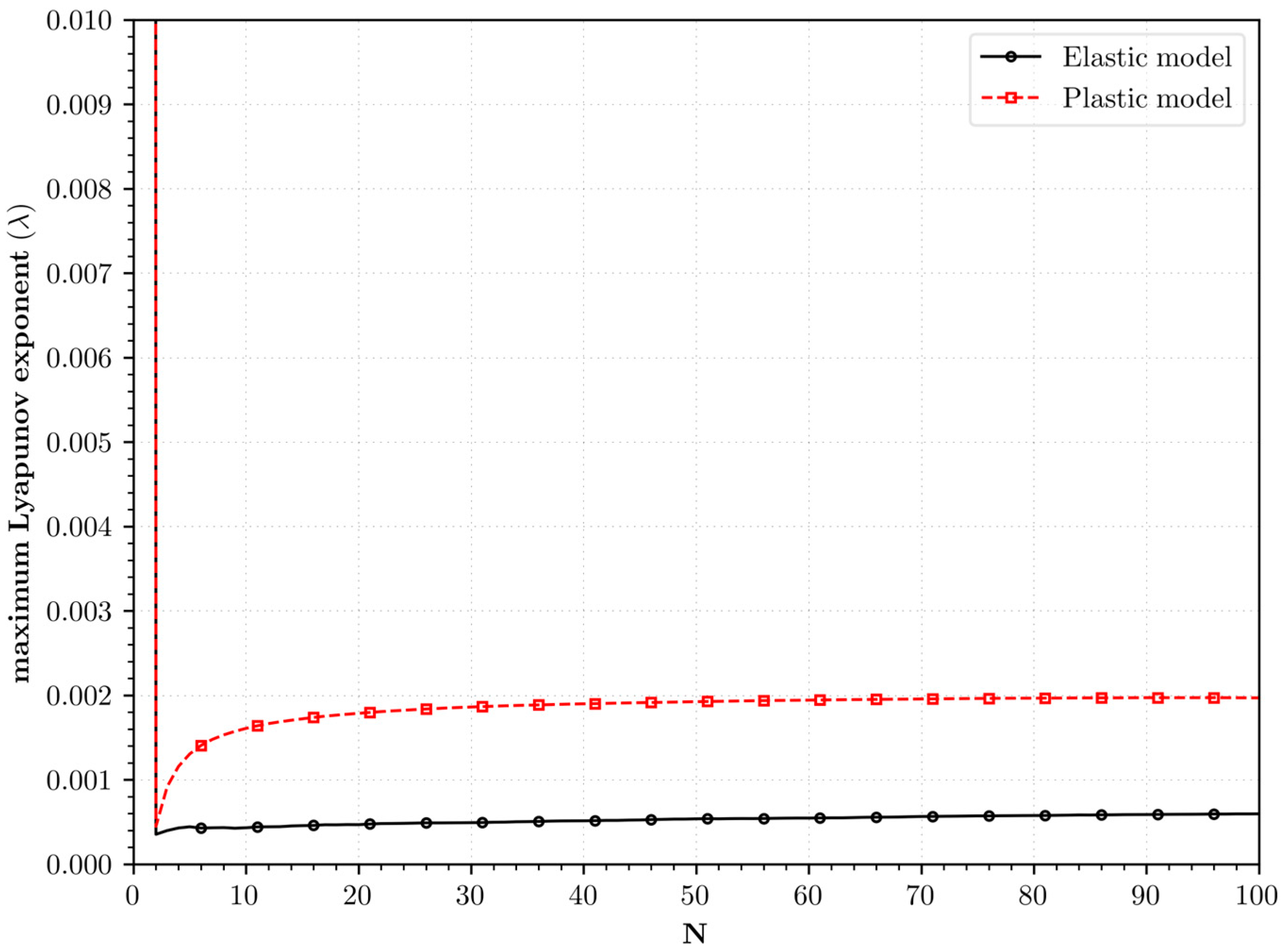

Finally, in the last part of the analysis, only the elastic and plastic models provide results, justifying the absence of the damage model in

Figure 9. For the elastic model,

tends to

, indicating the stabilization that occurs in the elastic model despite the jump. The plastic model, however, tends towards a high Lyapunov exponent of 0.002, justified by the sudden break in the jump.

4. Discussion

The responses of the inelastic models used in this article were theoretically consistent, both presenting energy dissipation characterized by a decrease in oscillation. The loss of stiffness was also observed, due to ruptures before the end of the analysis time, as well as more flexible responses when compared to the elastic model. Failure in cross-sections with low levels of oscillation or increased stress in the structure highlights the structural response of the damage model, characterized by a strong decrease in material stiffness. Thus, such models are useful for describing the behavior of structures under strong non-linearities that may occur in real situations such as buildings, bridges, transmission towers, industrial structures or structures in general in a situation of progressive collapse.

In addition to the presented numerical results, phase figures related to the position and velocity of the top central node are presented in

Figure 10. The analyses of the results of the elastic model, elastoplastic model and ductile damage model are also presented. The initial vertical position is the same for three analyses, i.e.,

(with null velocity). It is clearly possible to note two point attractors in the elastic response (the first one at the left and the second one at the right). Two dynamic snap-throughs are noted (initial position to the left attractor and left attractor to the right attractor). For elastoplastic response, only the left attractor is noted, but two snap-throughs are observed. For the ductile damage model, only one attractor and one snap-through are noted. Inelastic models present smaller oscillation amplitudes and more stable trajectories on phase figures. For the modeling of realistic building structures, inelastic effects analyses are advisable. These effects can mask instability identification.

Phase figures related to the position and acceleration of the top central node are presented in

Figure 11. Again, analyses results of the elastic model, elastoplastic model and ductile damage model are presented. But, contrary to the velocity phase figure, trajectories, snap-through and attractors are not so evident. Only for the ductile damage model it is possible to note instabilities when central node position reaches the position close to

The use of Lyapunov exponents in monitoring the integrity of the analyzed structure has been proven to be promising, since it was able to detect the occurrence of the destabilization of the structure with the dynamic jump and the presence of material failures by means of a comparison between the responses of undamaged/stabilized and damaged/unstabilized structures. However, as pointed out by the technical literature on the subject [

18], it is not possible to differentiate the phenomena just by observing the maximum Lyapunov exponent, leaving this level of detail to other essays/analyses. The use of only one time series is a characteristic to be highlighted in the technique for obtaining the Lyapunov exponent via the non-linear predictor, decreasing the computational cost and analysis time. Thus, a limitation that must be pointed out is the absence of negative exponents, making it difficult to immediately detect any structural failure, thus requiring an additional step of analysis since comparison with other response excerpts is necessary.

The chosen numerical example has different levels of damage in all elements (global), as well local damage next to the column base. Moreover, due to initial/boundary conditions, there occurs a dynamic snap-through depending on the considered constitutive model (elastic, elastoplastic or elastoplastic with damage).

Possible Directions for Future Studies

The presented methodology to assess structural integrity using the Lyapunov exponents is compatible with any damage model. The FLHB ductile-damage model used here has some restrictions in its applicability to concrete structures. It can be used only in situations that involve pure tensile or pure compressive loading, for instance. Thus, the next step of the research is to include a damage model capable of simulating the responses in brittle materials in a more general manner. One of the first options for concrete modeling is to use the concrete damaged plasticity (CDP) model [

37]. The CDP is a modification of the Drucker–Prager model and considers the degradation of the elastic stiffness induced by plastic deformation, both for tensile stresses and for compressive stresses.

A promising application of the presented methodology is its use with experimental data instead of the data acquired, simulating a numerical example. Now that the methodology has shown itself capable of verifying the structural integrity, the practical use with experimental data is an interesting application, remembering that, as explained in the introduction, one can use data collected from accelerometers installed in real structures. As an example, Toloue et al. [

38] used accelerometers to assess the damage of aluminum spatial frames. The authors used the damage load vectors (DLV) method in association with the application of the Markov matrix to the noisy accelerometer data, enabling the exclusive inclusion of the most useful signals.

Another possible work to be conducted is the comparison of the presented method, which uses the Lyapunov coefficients, with other methods of structural integrity verification. A comparison of Lyapunov exponent analysis with the evolution of damage indexes, as developed by Park and Ang [

39] and applied by Karayannis and Goliath [

40] for studying the structural performance parameters of concrete structures strengthened with carbon fiber reinforced, is a good example.

Finally, reliability and robustness analyses of the methodology should be performed in future studies, i.e., to assess the sensitivity to changes in input parameters, such as material properties and loading conditions.

5. Conclusions

This article presents a methodology, based on the use of Lyapunov exponents, to assess stability and structural integrity. A frame structure was used as numerical example to illustrate the applicability of the methodology. The structural analysis performed integrated the positional finite element method to address geometric nonlinearity, and the isotropic elastoplastic model together with the recently developed FLHB damage model were used to evaluate material nonlinearities. The equilibrium trajectories obtained with and without the consideration of material nonlinearities were examined, and the relevant differences revealed through a qualitative and quantitative analysis demonstrated the importance of using robust simulations that consider the nonlinearities.

An important feature of the methodology is the non-linear predictor that needs a single data series, which proved to be an efficient technique for obtaining the Lyapunov exponents. This consists of an important result because it facilitates the applicability of the presented methodology due to its lower computational cost.

The results obtained through the application of the proposed methodology showed that it is possible to identify the loss of structural stiffness, even if it is related only to stability or if it involves physical nonlinearity phenomena such as plastification and damage. It can also be concluded that the Lyapunov exponents can be used as indicative parameters of structural integrity, as their analysis was able to detect the occurrence of the destabilization of the structure with the dynamic jump and the presence of material failures. Overall, the methodology presented here to monitor structural integrity was shown to be a promising alternative.