1. Introduction

Concrete is formed by a mixture of cement, coarse, and fine aggregate with water. Cement in this mixture plays an essential role by connecting aggregates, filling the space between them [

1]. No building can be imagined without the use of concrete, and for this reason, concrete is the most widely used building material. Good concrete properties are primarily reflected in extremely high compressive strength, market availability, pourability into various forms, price, etc. However, despite its good properties, this material has high cracking sensitivity due to its limited tensile strength. For this reason, it is often combined with steel reinforcement, which allows it to bear certain tensile loads. However, steel reinforcement cannot prevent crack formation but can only limit crack width. Cracks that appear over time are the result of various environmental influences to which building structures are exposed. Various aggressive liquids and gases can penetrate the cement matrix through these cracks. In the worst-case scenario, when the steel reinforcement is exposed to environmental influences, it can corrode and get severely damaged at the crack site. Such severe damages to building structures require repairs, which makes maintenance even more expensive. According to available data for Great Britain, the annual costs of maintenance and repair of building structures exceed 40 billion pounds, while the USA plans to invest about 4.59 billion dollars in the next three years for their repairs [

2,

3,

4,

5]. In addition to the economic impact, this also raises the issue of environmental protection through the conservation of resources and waste problems. However, the occurrence of damage does not necessarily cause major problems. Even a minor cost reduction in repairing cracks and damage to building structures makes a difference in the economy and ecology of every country, especially if performed without human intervention [

6,

7,

8,

9,

10,

11].

For more than fifty years, there has been the idea of finding new, smart, cement-based materials that have the ability to increase the self-healing properties of concrete. Self-healing materials should be cheap and not affect the properties of concrete structures and the most important thing, is that they should be active for a long time, as cracks usually do not appear immediately after installation. These materials could at least partially if not completely, reduce the appearance of damage while maintaining the initial structure properties and prevent the formation of subsequent permanent cracks that would further weaken the building [

3,

4,

5,

6].

The basic concept of self-healing materials in construction is to restore concrete strength, porosity, workability, and waterproofing [

12]. Certainly, using building materials with self-healing properties would require more significant financial investments at the very beginning but they would still bring savings over time [

13].

The self-healing phenomenon is defined by the material’s ability to heal small cracks on its own without external human intervention [

13,

14].

Self-healing of concrete can be greatly contributed by the presence of certain mineral additives such as fly ash, blast furnace slag, silica fume, limestone powder, geomaterials, etc. These materials are added as additives, since they stimulate autogenous healing, especially in the later phase due to the slower pozzolanic reaction of non-hydrated binders [

13,

15]. In the presence of water, pozzolanic materials react with portlandite (Ca(OH)

2), forming binding products, and calcium carbonate [

15].

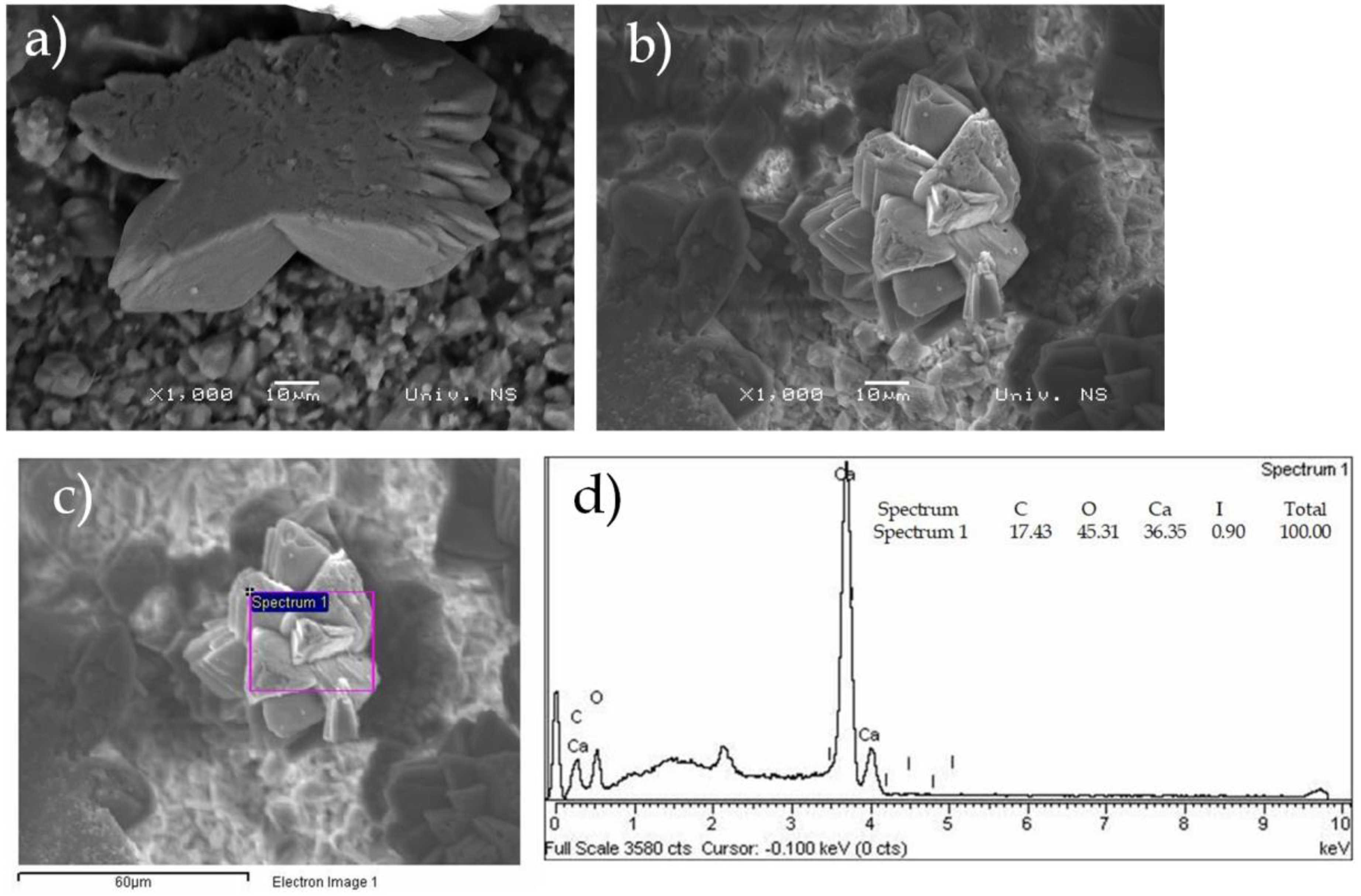

Granulated blast furnace slag and fly ash, as industrial by-products, are an inexhaustible research topic as cement additives, and the reason for this is primarily their pozzolanic activity. In their cement matrix self-healing experiments, Li et al. (2020) only used granulated blast furnace slag in different mass ratios, with added crystalline admixtures. Their results showed that mortar with 10% granulated blast furnace slag and crystal additives demonstrated self-healing properties where calcium carbonate was the product that healed the crack [

16,

17].

Moreover, calcium carbonate precipitation is a common natural phenomenon. In addition to being found in nature (earth crust, sea, and fresh water), calcium carbonate is a raw material for obtaining cement, which makes it one of the most useful building materials. Besides that they form a wide range of minerals, carbonates are known to be produced by certain microorganisms, especially bacteria, and due to their crack-filling efficiency, they are used as one of the significant external self-healing methods for cement materials. Metabolic activities in the bacterial self-healing process lead to carbonate production, when carbonate ions react with calcium ions from the material, resulting in calcium carbonate formation due to system oversaturation [

18]. In this way, cracks and gaps created as a result of concrete structure damage are filled. Introducing microorganisms into the self-healing process requires great care since many factors affect their metabolic activity. For example, a lack of sufficient moisture and a high pH are destructive to the bacteria metabolic activity [

1].

Since concrete structures are designed to last over 100 years, the bacteria should survive and remain active during that period in a highly alkaline environment. In their investigation, Renée and Henk (2012) presented the conclusions of Jose-Luis and Aylin (1996) about bacterial viability over a long period and under different conditions. Based on extensive research, it was found that bacteria are produced from thick-walled spores. These spores are resistant to chemical and mechanical influences and can remain dormant for a very long time. In conditions of concrete structure cracks with food and water present, the spores germinate and transform into active bacteria and their metabolic products can fill the free crack space [

6,

19].

In recent years, a special approach to research through connecting experiments with numerical simulations and modeling has attracted a lot of attention from researchers, whether it is classical or artificial intelligence methods (such as forming mathematical equations that describe the trend of crack healing, predicting the effectiveness of crack healing based on their dimensions, the classification of data based on the appearance of samples, etc.) [

8,

10,

20,

21].

Considering that there are bridges of exceptional cultural, historical, and symbolic value, the state of damage of their concrete structures in real conditions was the subject of many authors, especially after natural disasters caused by earthquakes. Mangalathu et al. (2019) proposed a methodology that includes a rapid assessment of the state of damage using the capabilities of machine learning techniques (e.g., Discriminant Analysis (QDA), K-Nearest Neighbors (KNN), Decision Trees (DT), Random Forests (RF), and Naïve Bayes (NB)). The Random Forest algorithm showed the highest accuracy (from 73% to 82%) for column damage of bridges. Cosgun (2023) considered four machine learning techniques for cracks in buildings caused by earthquakes: Artificial Neural Networks (ANN), Support Vector Machine (SVM), as well as RF and DT techniques. The Random Forest (RF) methodology also showed the highest accuracy here, with a value of 100%. In their study, Chen and Dagli (2023) obtained the accuracy of ANN seismic classifiers varying from 92% to 99%, with different damage indices not affecting this value [

22,

23,

24].

Following damage on bridges, Mirbod and Shoar (2023) proposed ANN as the best model that can specifically distinguish images with cracks from images without cracks. The efficiency of this ANN model is 84.88% [

25].

Cardellicchio et al. (2023) proposed existing algorithms of Convolutional Neural Networks (CNN) using two visualization techniques that are based on the Class Activation Map (CAM) and allow the observation of the activation zone and the type of specific defect in the analyzed image. The conclusion they reached refers to precise preparatory work. That is, attempting to increase the number of images explained for each defect as much as possible in order to avoid poor data balancing [

26].

In a slightly different approach, Abubakr et al. (2023) performed image classification using Xception & Vanilla models based on Convolutional Neural Networks (CNN) to detect the five most common damages of RC bridges (cracks, corrosion, efflorescence, spalling, and steel reinforcement exposed to ambient influence). The Xception model in defect classification showed an accuracy of 94.95%, and the Vanilla model had an accuracy of 85.71% [

27].

Apart from bridges in real conditions, it is also important to monitor the condition of the roads, which was the subject of research by some authors. Deng et al. (2023) developed a new algorithm for the automatic detection, segmentation, and measurement of cracks on the road surface using the Iou Only Look One (IOLOv5) and Residual Unity Networking (Res-Unet) algorithms. They found out that the crack damage detection based on the IOLOv5 method achieves a mean average accuracy of 91%; modified Res-UNet achieves 87%, and their developed new algorithm has an accuracy of 95% [

28]. Crack width classification using machine learning is also useful when sufficient image resolution is not available, as stated by Mir et al. (2022). In this case, SVM gave better classification accuracy than the method using arbitrary features [

29].

The latest study by Yun et al. (2023) proposes a modified deep learning network (VGG) method and a method based on Generative Adversarial Networks (GAN) for the classification of asphalt crack images. The crack prediction accuracy of the improved VGG model compared to the original VGG model increased by 5.9% and the F1-score also increased by 5.78%. The obtained F1-score value is higher than the same one in GoogLeNet, ResNet18, and AlexNet [

30].

In a similar way, Iraniparast et al. (2023) developed a method for the automatic identification of cracks in images as the help for the assessment of the condition of concrete structures. They proposed two transfer learning scenarios used to train five pre-trained CNN models (AlexNet, GoogleNet, SqueezeNet, MobileNet, and ResNet-18). Among them, ResNet showed the best performance [

31].

In addition to the macroscopic sizes of the cracks, microscopic cracks in real conditions were also processed in related studies [

32,

33]. For example, Guzmán-Torres et al. (2022) chose micro and macro cracks on concrete structures as the subject of their investigation, applying DL architecture based on the significantly improved VGG-16 model. This technique achieved an accuracy of 99.5% while the F1-score was 100% [

33]. In addition, Tang et al. (2023) proposed a machine vision-based methodology for the definition of crack width, which combines the macroscale and microscale characteristics of the backbone [

32].

Ali et al. (2021) compared the performance of the proposed Convolutional Neural Network (CNN) model with pre-trained networks, VGG-16, VGG-19, ResNet-50, and Inception V3. All models showed satisfactory performances, however, VGG-16 stood out, having better accuracy in the phases of training, validation, and testing [

34].

A recent study predicting the degree of crack healing of cement mortars with fly ash, limestone powder, and silica fume additives has used Gene Expression Programming (GEP) models. This study was conducted by Althoey et al. (2022). Compared to linear regression models, the GEP model shows the highest correlation coefficient and the lowest error check [

21].

In accordance with the aforementioned facts, this paper represents an expansion of existing ideas and current thinking, reduced to the framework of laboratory research, and analyzes the possibility of incorporating waste materials from the industrial process into new types of cement, which is especially important for building structures that will be used in river conditions. In addition, the process of self-healing mortar with bacteria was monitored through precipitation under the conditions of sterile demineralized and Danube river water. To the best of our knowledge, no study has been conducted to investigate bio-stimulated healing phenomena under the natural river (Danube) water yet. In our work, we use this water based on the fact that the Danube river is the second longest river in Europe. By considering a set of recorded images after healing, in conditions with and without the presence of bacterial culture, their classification was performed. For this purpose, a deep learning methodology was chosen, i.e., a technique based on Convolutional Neural Networks and ResNet50, which according to the available literature has not been applied to this type of research. According to some authors, ResNet50 provides the best performance compared to VGG16 and VGG 19 [

35]. In their research, Dabović and Tartalja (2017) compared five different CNN networks: AlexNet, ZF Net, VGG Net, GoogLeNet, and ResNet50. The following classification errors were found: 15.4%; 13.5%; 7.4%; 6.7%, and 3.6%, respectively. Due to how in this case, the ResNet50 network showed the best performance [

36], it was chosen for this study.

Although still under development, this type of analytical support in the crack healing process can significantly help engineers in their work. Through the developed model and simulation of the bio-stimulated healing mortar phenomenon, useful information can be obtained. Model results affect the direction and cost reduction of subsequent research, save materials and time, and represent a key addition to the experimental part of the research, with the aim of solving the problem as best as possible [

37].

2. Materials and Methods

The materials used in this research include CEM I cement from Lafarge BFC d.o.o. Beočin, Serbia, a member of Holcim Group (alite cement), granulated blast furnace slag from HBIS GROUP Serbia Iron & Steel d.o.o. Belgrade—Serbia (slag), standard three-fraction sand as aggregate, suspension of Sporosarcina pasteurii DSM 33 as a means for external healing of cracks of new cement mixtures, sterile demineralized water, and Danube riverwater.

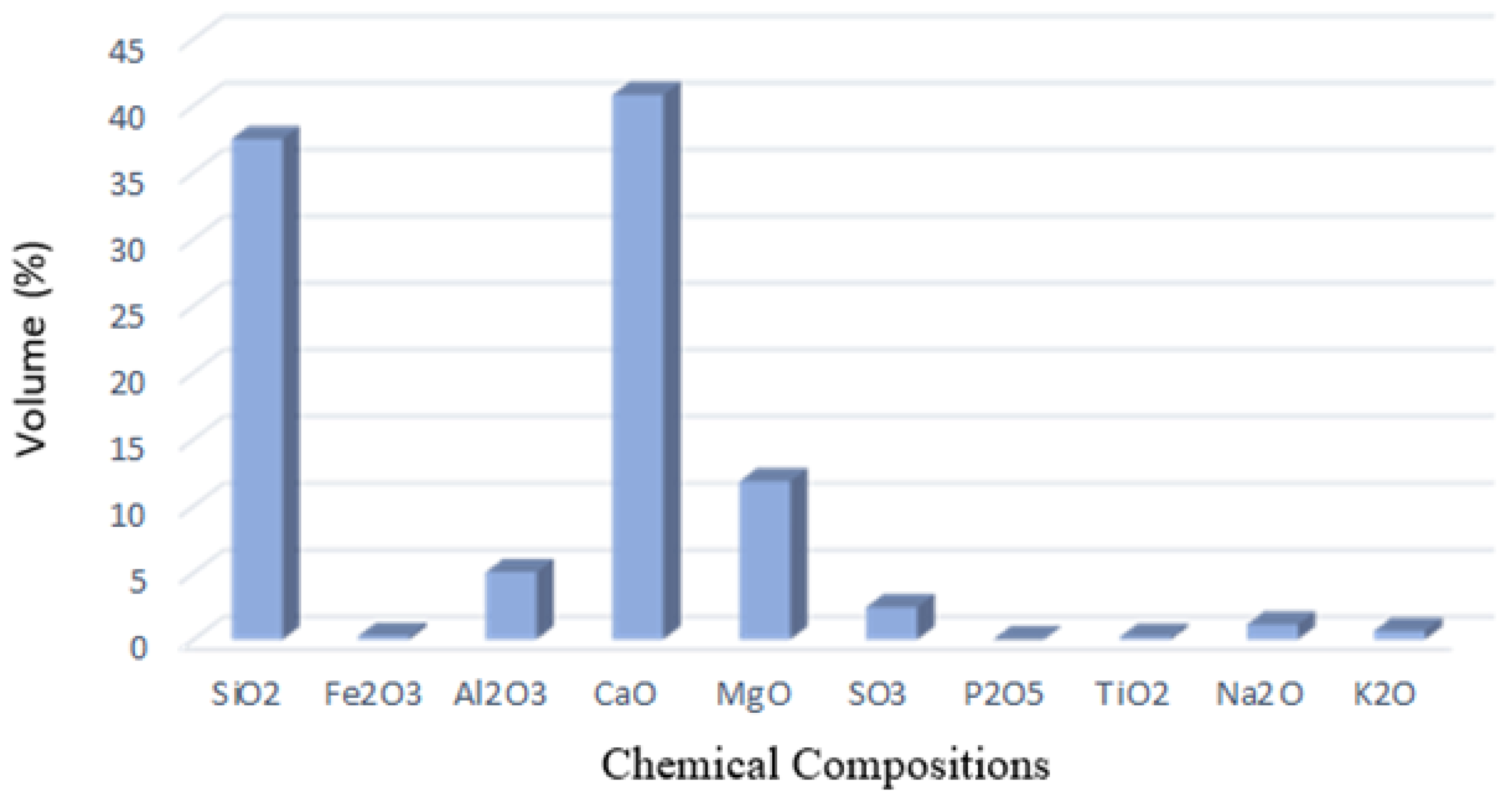

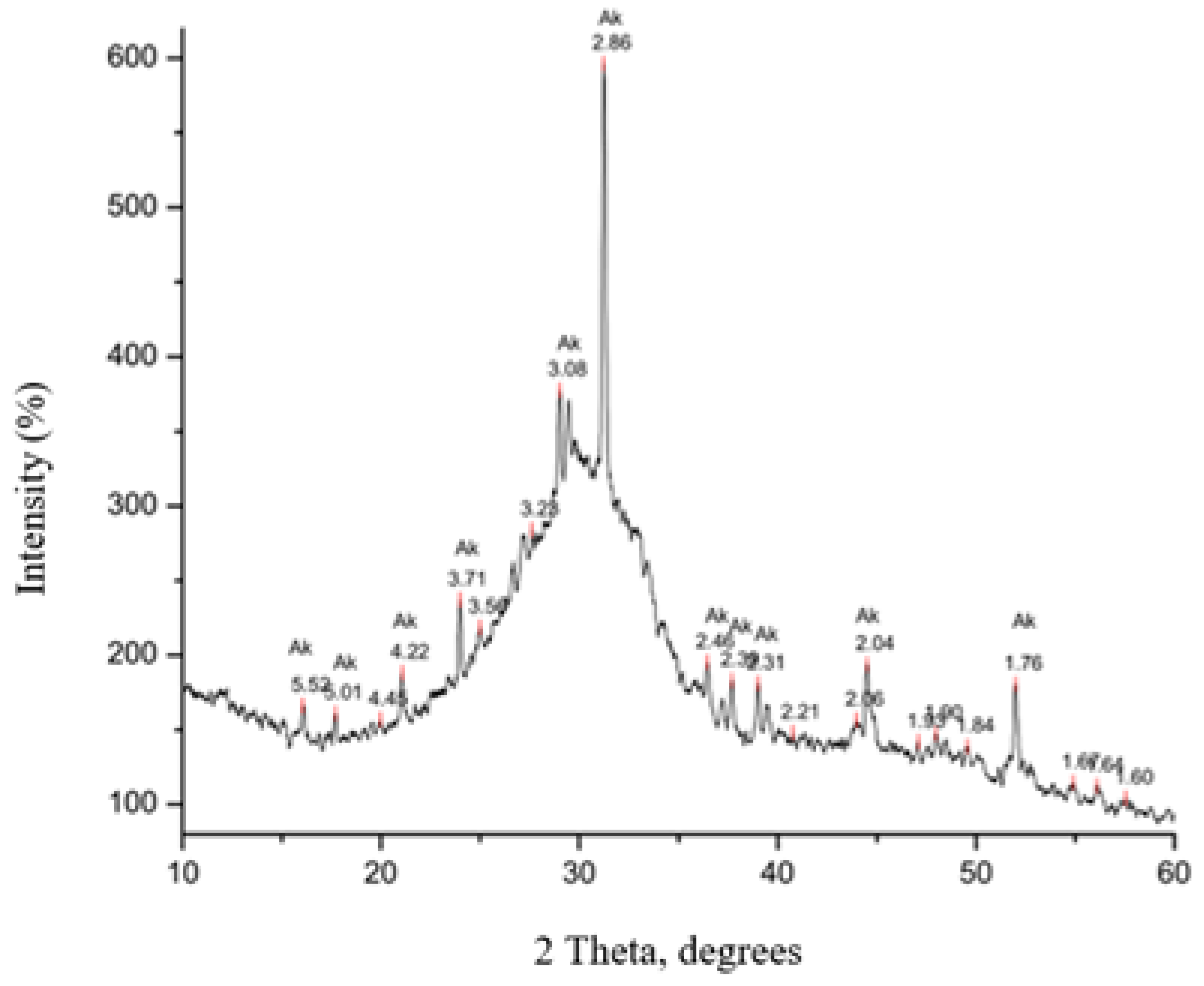

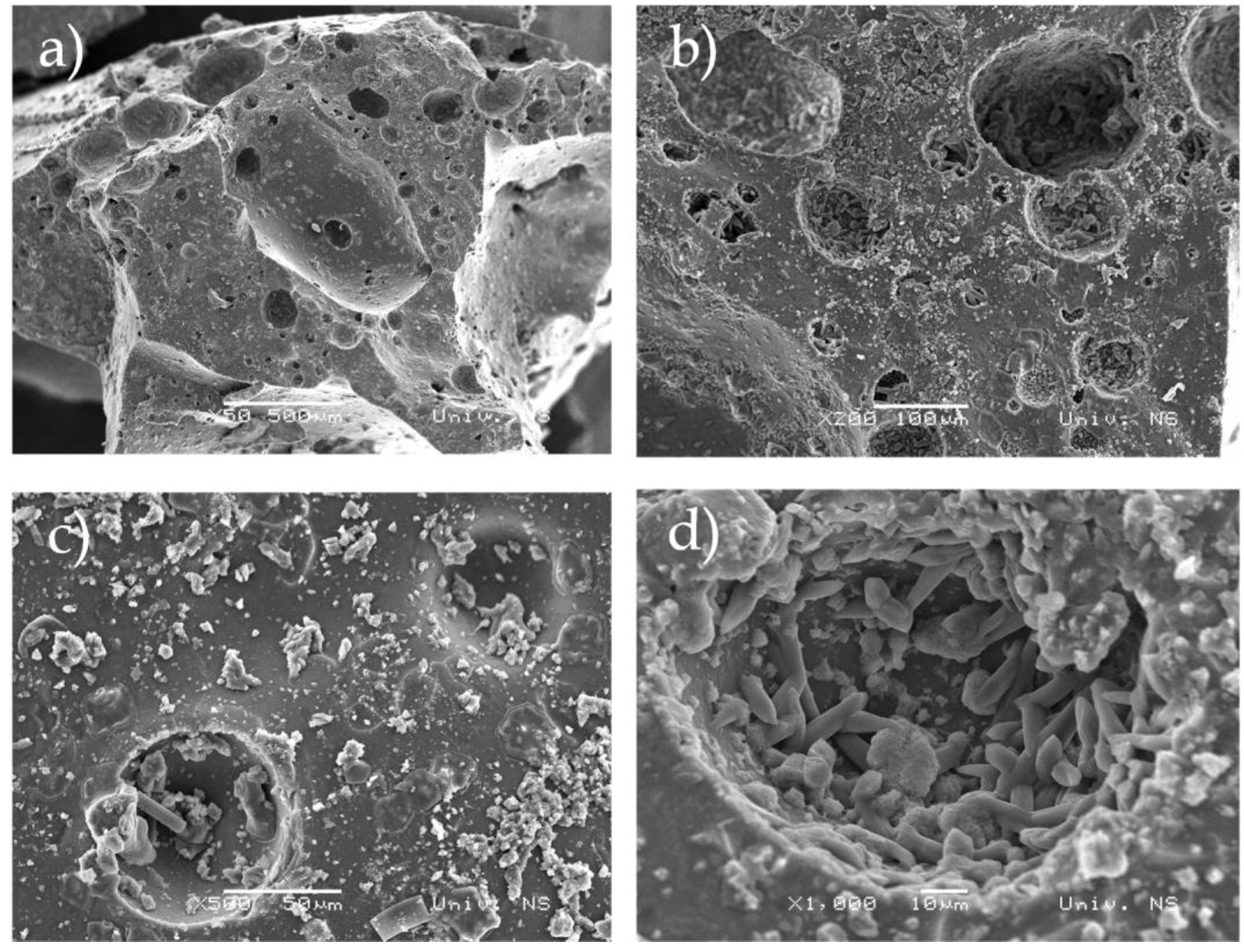

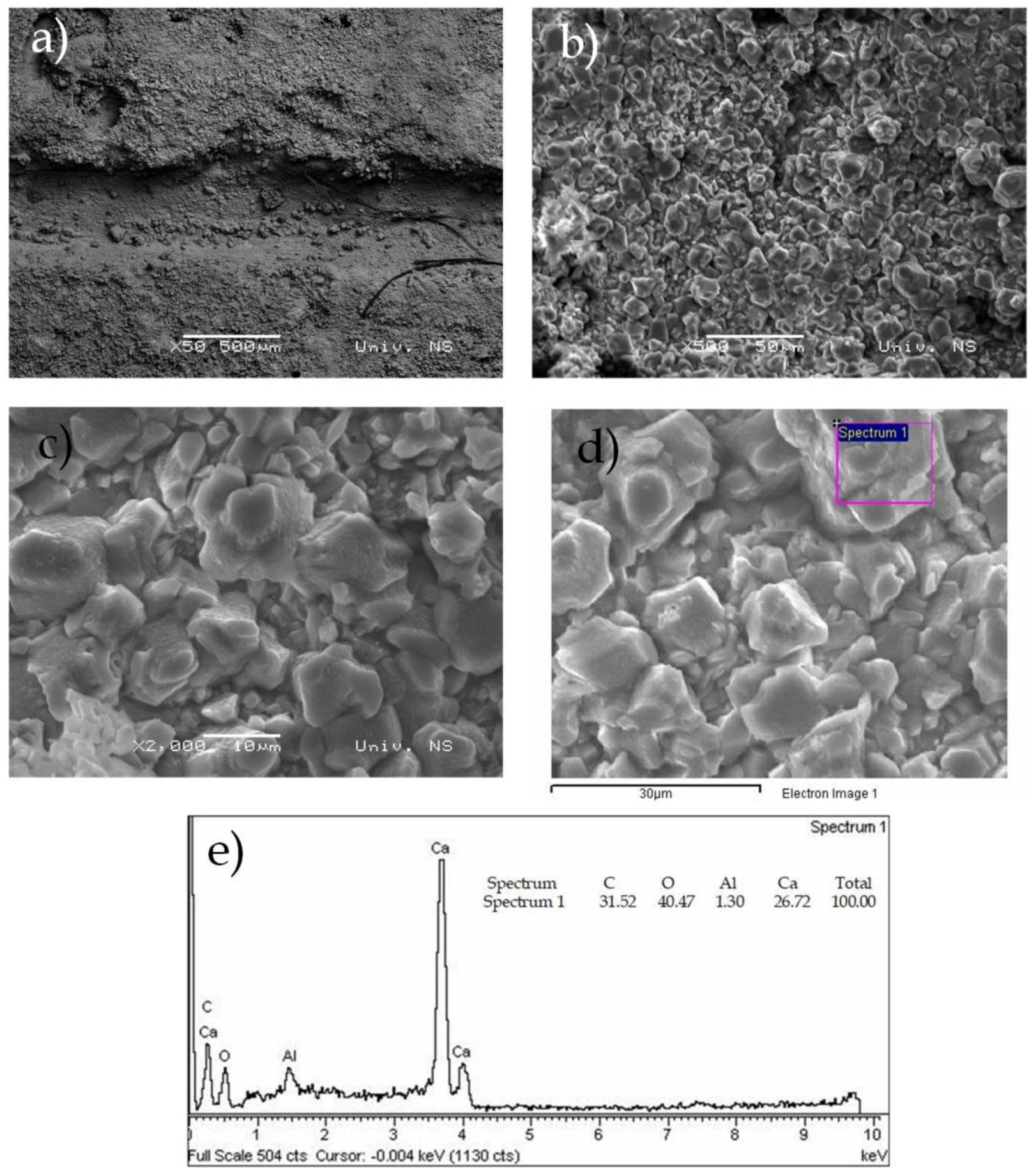

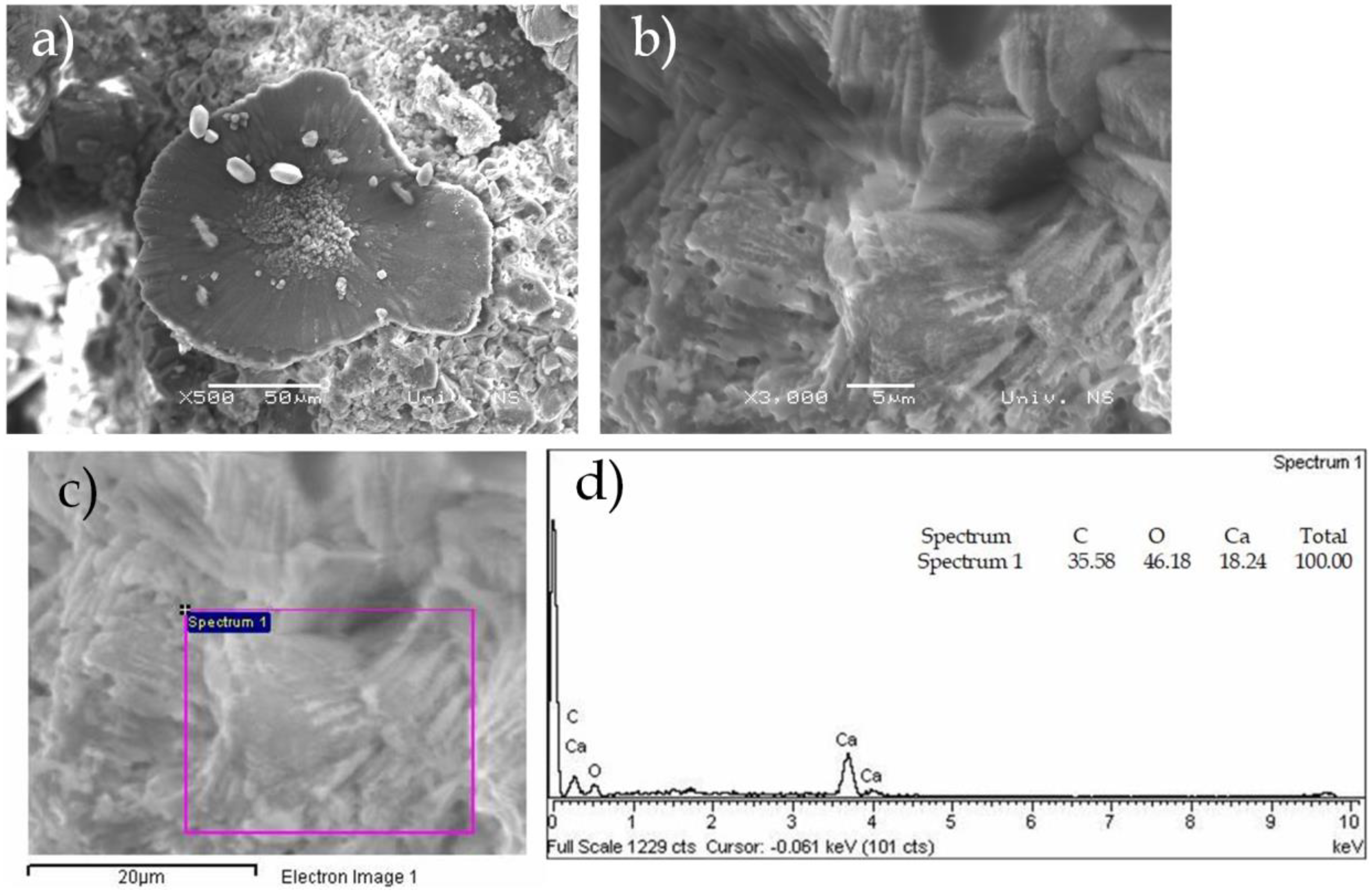

2.1. Characterization of the Initial Slag Sample

For the preparation of new cement mixtures, a slag sample was characterized in detail to select the optimal quantities of material for alite cement replacement. The slag characterization involved determining physical and chemical properties, using standard methods that included particle size analysis, pH value, chemical composition, specific weight, X-ray diffraction analysis—XRD, and scanning electron microscopy—SEM. A more detailed description of these methodologies is given below.

- -

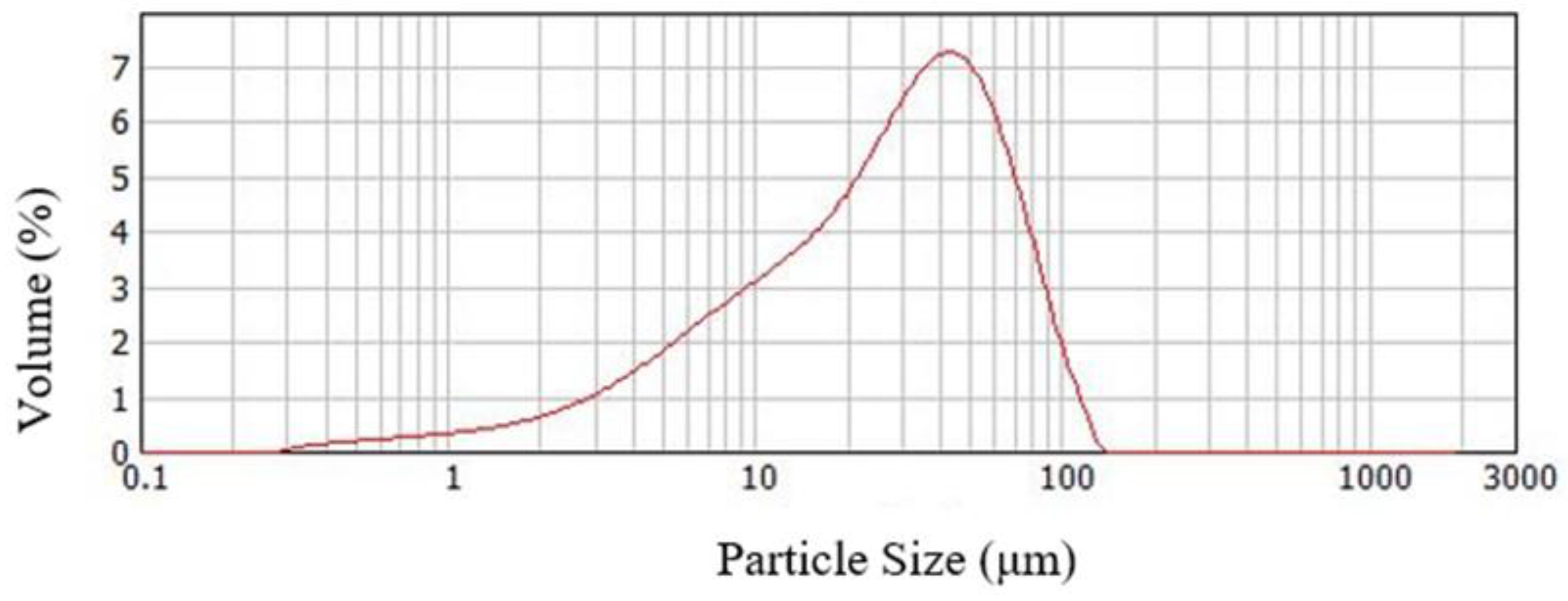

Particle size distribution after micronization to 70%—0.045 mm of the slag sample was confirmed by the laser light scattering method using Mastersizer Scirocco 2000 analyzer (Malvern Instruments, Malvern, UK) [

38].

- -

The chemical composition of the samples was presented through silicate analysis using the ICP-OES technique on a Varian 710-ES axial ICP-OES spectrometer (Varian, Houten, The Netherlands) [

39].

- -

XRD analysis of the pulverized slag sample was performed on a PHILIPS PW 1710 diffractometer (Malvern Instruments, Malvern, UK) under the following conditions: copper anticathode radiation with a wavelength of CuKa = 1.5 4178 Å, graphite monochromator tube operating voltage: U = 40 kV, current strength: I = 30 mA, test range: 10–60° 2Q, step/time (qualitative tests): 0.02°/2 s [

40].

SEM analysis confirmed the mineral composition of the slag sample. The equipment comprised:

- -

JEOL JSM 6460 LV, Tokyo, Japan, scanning microscope with EDS device Oxford INCA—digitized device, 3-of 4-nanometer resolution, magnification range 8–300,000×, and the possibility of working in a low vacuum to environment levels,

- -

BAL-TEC, SCD 005 SPUTTER COATER, Tokyo, Japan—vacuum device for preparing samples by vaporization with gold and carbon [

41].

2.2. Characterization of the Cement Sample

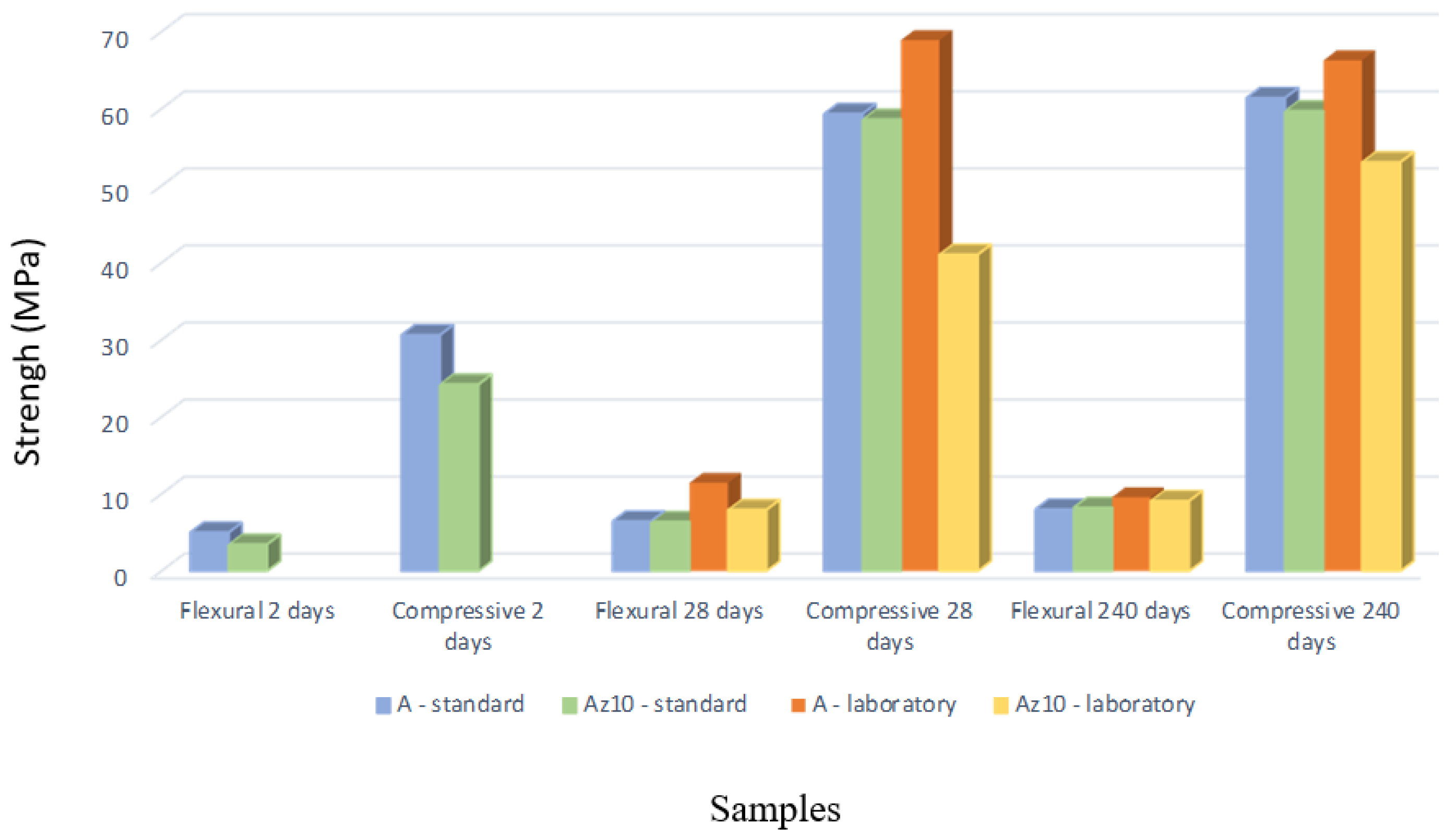

CEM I is a commercial product, therefore, no detailed characterization of the sample was performed except for the chemical, setting time, compressive, and flexural strength analyses.

- -

The chemical analysis methodology is described in the previous chapter.

- -

The cement mortars setting time was tested using a Vicat apparatus according to the SRPS EN 196-3:2017. The test room temperature should be 20 ± 2 °C and the relative humidity should be at least 50% [

42].

- -

Determination of flexural and compressive strength was described in SRPS EN 196-1:2017 [

43].

2.3. Characterization of Danube River Water

Water from the Danube river was tested using an ion chromatography method. Ion chromatography is a method of chromatographic separation of ions in a solution using a solid ion exchange material-filled column and it is ideal for determining very low concentrations of present ions. It is possible to simultaneously analyze a group of inorganic anions (fluorides, chlorides, nitrites, bromides, nitrates, phosphates, and sulfates) and cations of alkaline and alkaline earth metals in water, as well as ammonium ions. This method is used for analyzing all types of water, and it is most widely applied in drinking water analyses [

44].

2.4. Preparation and Bio-Stimulated Healing Mortar

Initial sample characterization was followed by the preparation of a new type of mortar and its characterization by examining the strengths, chemical composition, and setting time.

The new mortar system was prepared with a 10% slag replacement instead of alite cement using the method described in SRPS EN 196-1:2017. The sample prisms were of standard dimensions 40 × 40 × 160 mm and laboratory dimensions of 10 × 10 × 60 mm. Flexural and compressive strengths were tested after 2, 28, and 240 days of water curing on hydraulic presses by Tinius Olsen, Sari, England, a working force of up to 231 kN and VEB Thuringer Industriewerk Rauenstein, Weimar, Germany (standard prisms), as well as a working force of 0–5 kN and 25–50 kN (laboratory prisms). For this type of mortar, the setting time was also determined using a Vicat apparatus according to SRPS EN 196-3:2017. The mortar system composition is provided in

Table 1.

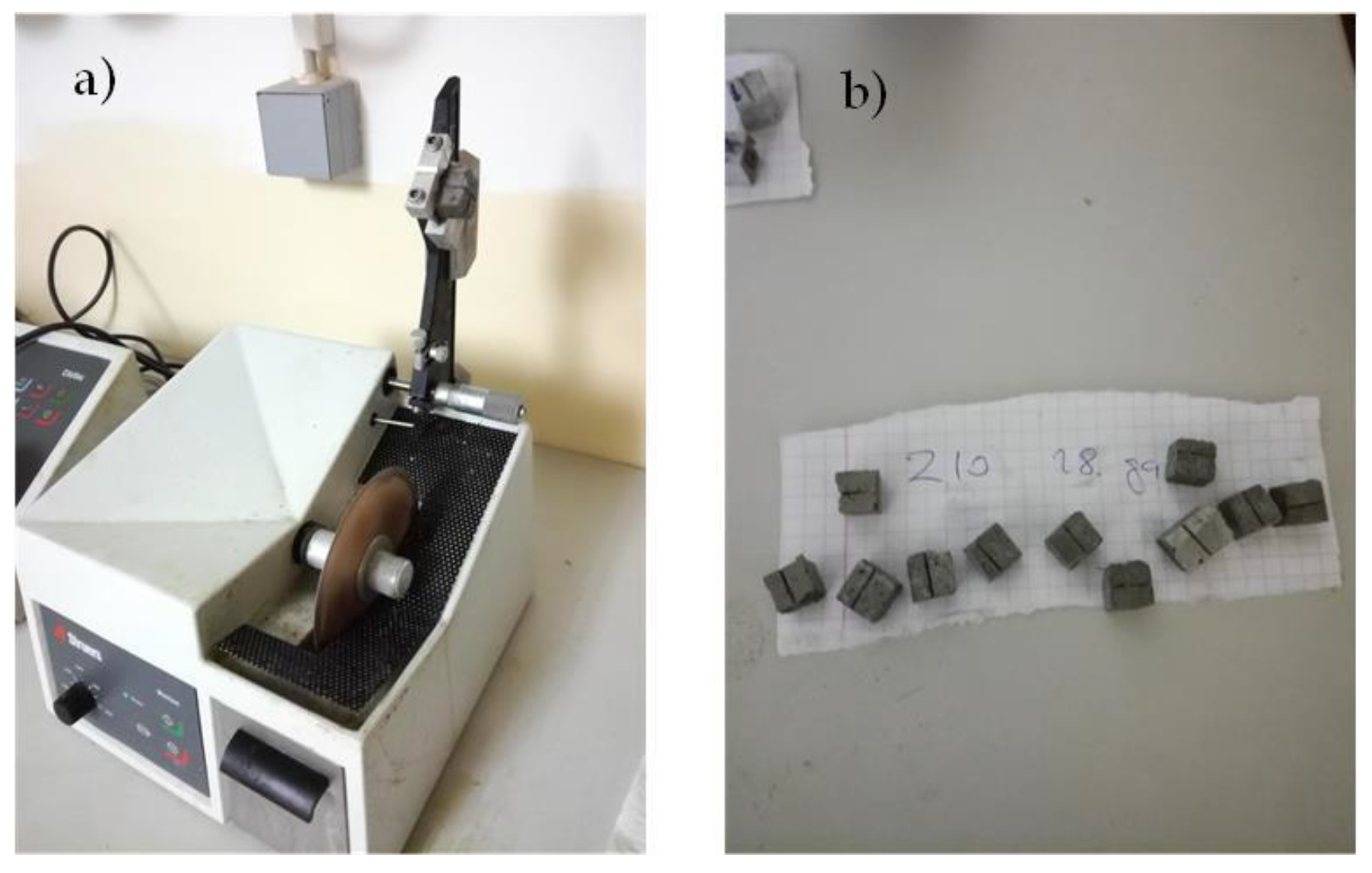

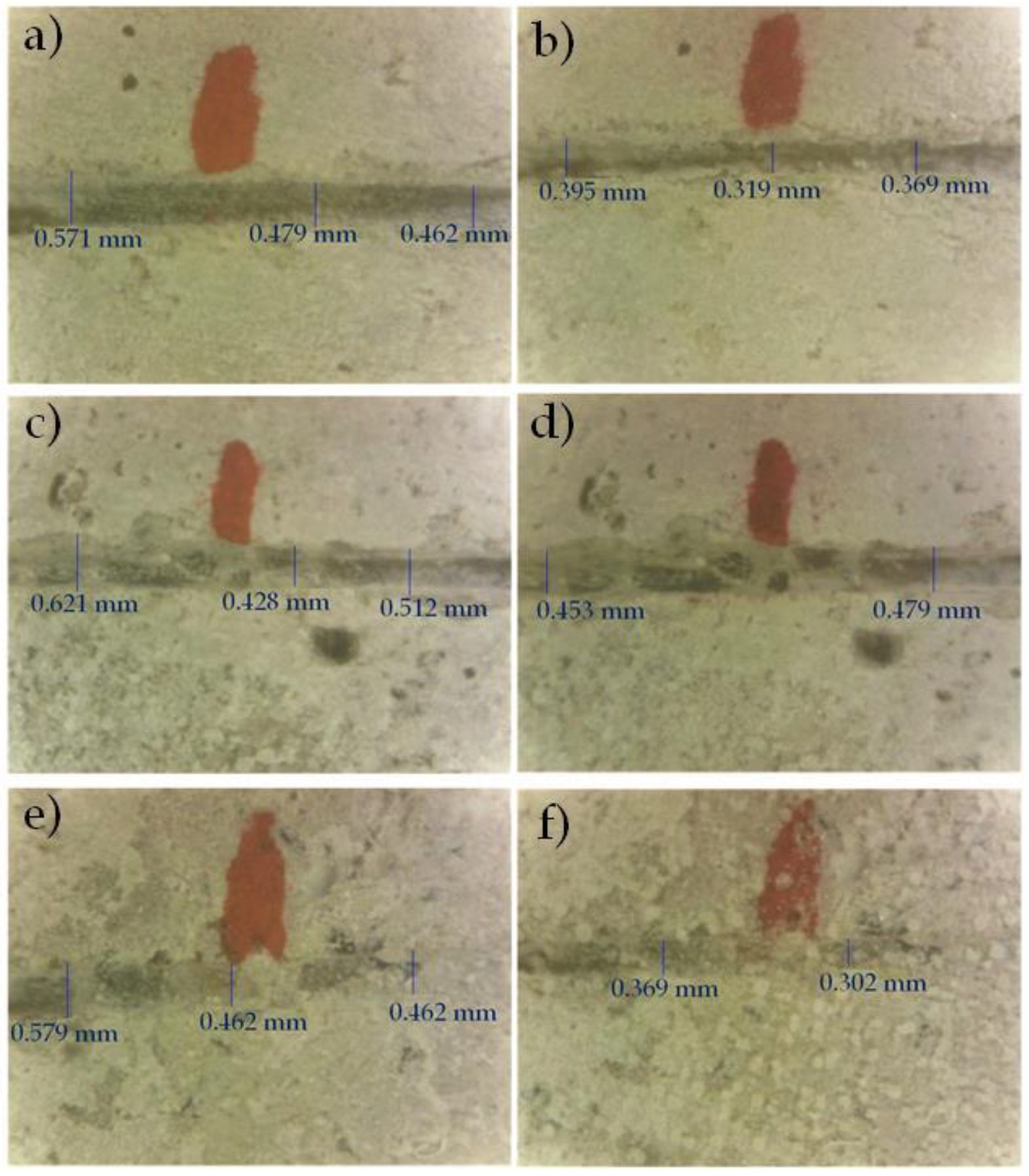

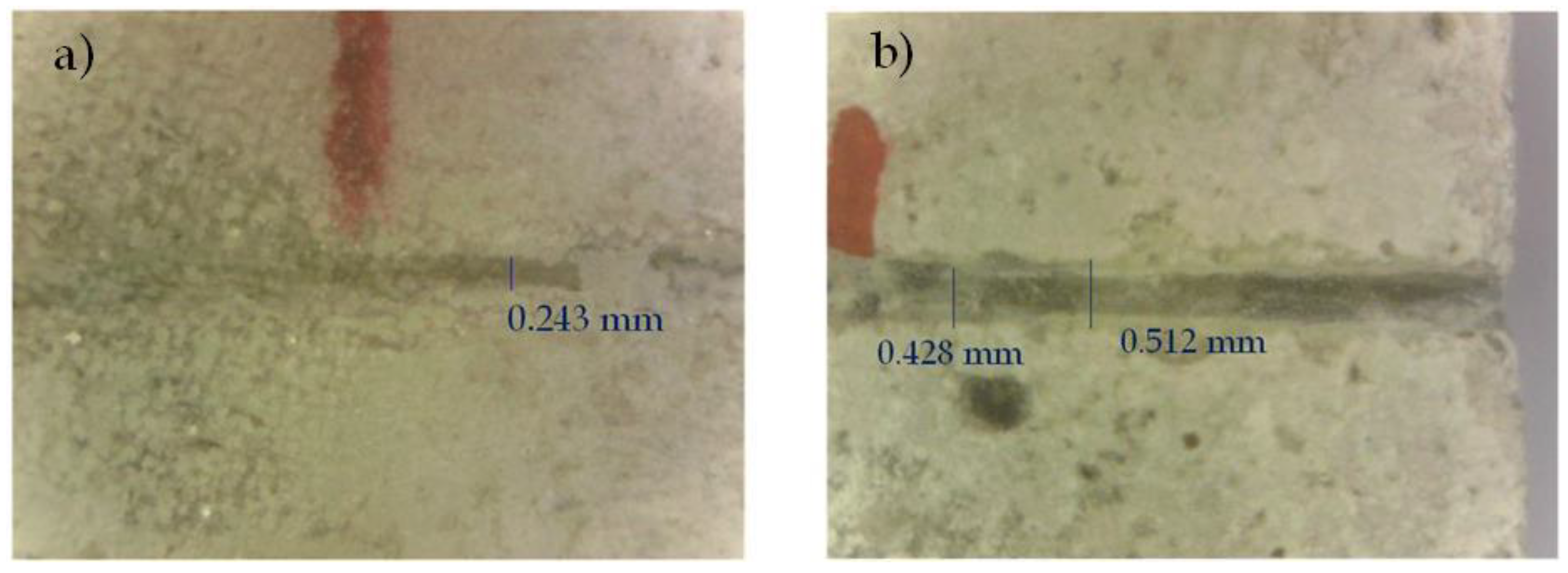

Determination of the strengths, setting time, and chemical composition of the new mortar type was followed by the preparation of laboratory sample prisms for the bacterial bio-stimulated healing experiment. After preparation and water curing for 28 days, sample prisms of laboratory dimensions were cut with a diamond knife (

Figure 1a)) to 10 × 10 mm for easier manipulation, and a groove was artificially made on each sample as a real crack simulation (

Figure 1b)). In this way, enough samples were prepared for the needs of further experiments.

For the bio-stimulated healing process, the

S. pasteurii DSM 33 strain was selected, which is characterized by a high capacity of continuous production of carbonate and bicarbonate ions through ureolysis [

11,

45]. Considering that the selected bacterial strain

S. pasteurii DSM 33 is highly sensitive to environmental conditions [

45], the pH value had to be reduced to a value below 10, which was achieved by alternating immersion in distilled water and drying in a dryer for 2 h each. After 20 washing cycles, the pH value was lowered from 14 to 9.

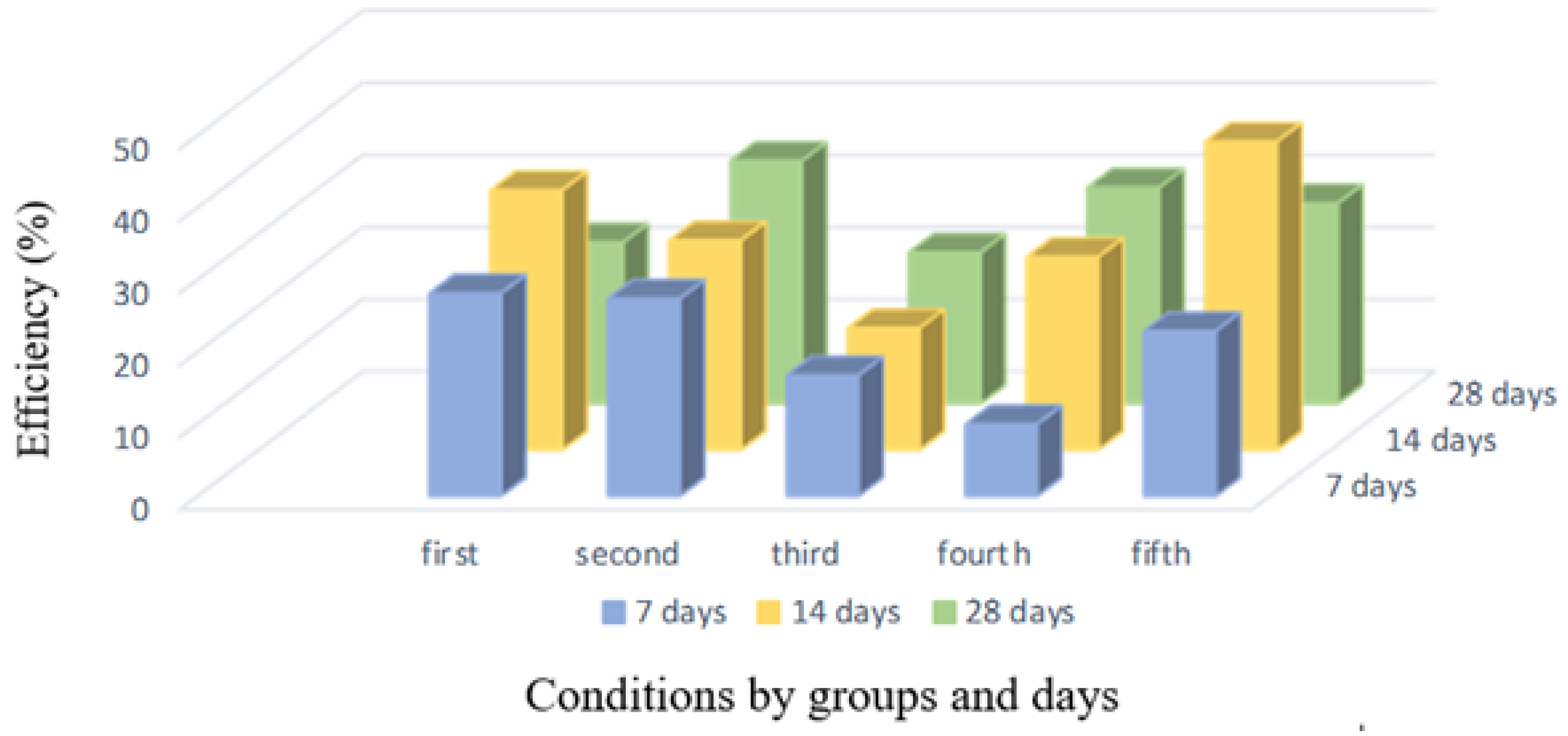

According to the established experiment program, 45 samples were singled out. The system was divided into five groups that were treated under different conditions, as shown in

Table 2. Conditions 2 to 4 are those in control.

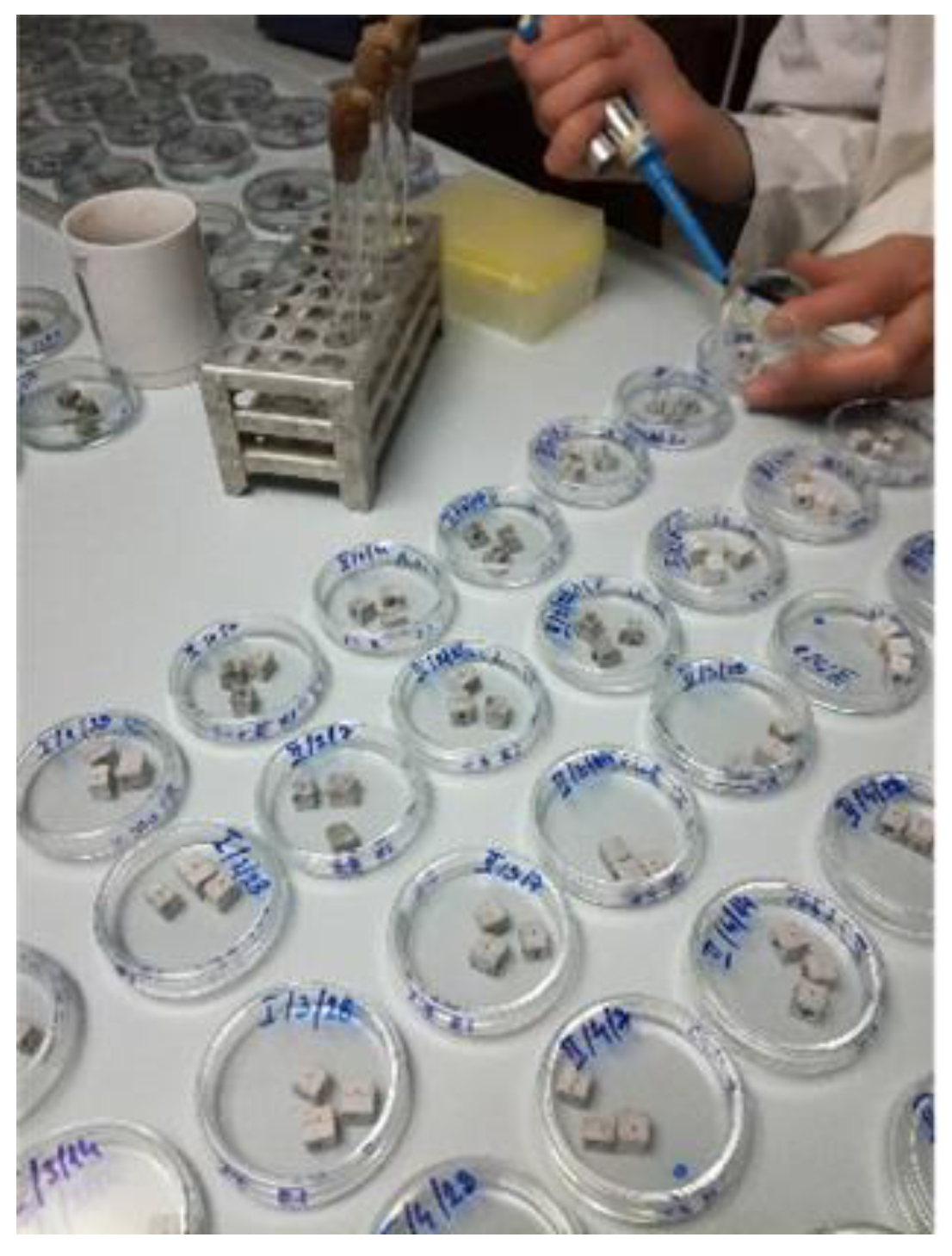

The samples were placed in Petri dishes so that the crack was on the upper side of the sample for easier healing agent application, with three repetitions in each group. Petri dishes with samples were sterilized for 1 h at 160 °C to eliminate any possibility of contamination. After sterilization, bacteria were applied in a laboratory at a constant temperature of 25 °C, which favors bacterial growth.

The bacterial suspension was freshly prepared with sterile demineralized water. The nutrient medium was also freshly prepared from urea, NaHCO3, NH4Cl, and sterile demineralized water.

The nutrient medium and bacterial suspension were applied using a sterile pipette in the crack mid-line. Each sample of the first, second, and fifth groups was first given 50 μL of nutrient medium. After absorbing the nutrient medium, 50 μL of bacterial suspension was applied to each sample of the first and fifth groups (

Figure 2). Finally, the sterile demineralized water was added with a sterile pipette for up to 1/3 of the sample height in the first, second, and third groups, while the fresh Danube river water was added also for up to 1/3 of the sample height in the fourth and fifth group (10 mL for smaller 6 cm diameter Petri dishes and 15 mL for larger 10 cm diameter Petri dishes). This amount of water was optimal for maintaining system humidity. After setting up the system, the Petri dishes with the samples were transferred to the Binder Climate Chamber KBWF 240, Tuttlingen, Germany. In the climate chamber, the systems were kept under controlled conditions of a temperature of 30 °C and humidity of 70% until testing.

The tests’ durations were 7, 14, and 28 days after the experiments’ setup. Non-destructive methods were selected to monitor changes in the bio-stimulated healing process, portable microscope imaging (described below—

Section 2.5), and SEM analysis, as already described in

Section 2.1.

2.5. Identification of Cracks

Cracks were identified and non-destructively recorded using a portable Vitiny PRO10-3 microscope, Greenville, South Carolina Greenville, South Carolina, USA, which can operate at 10 to 30× magnifications. The crack width was measured with the existing integrated microscope software.

2.6. Image Classification

Image classification was performed in the MATLAB 2023A programming language using the Convolutional Neural Networks methodology—ResNet 50, which has already been pretrained to extract features from digital images based on the RGB model.

2.6.1. Basic Characteristics of the Convolutional Neural Networks (CNN) Model

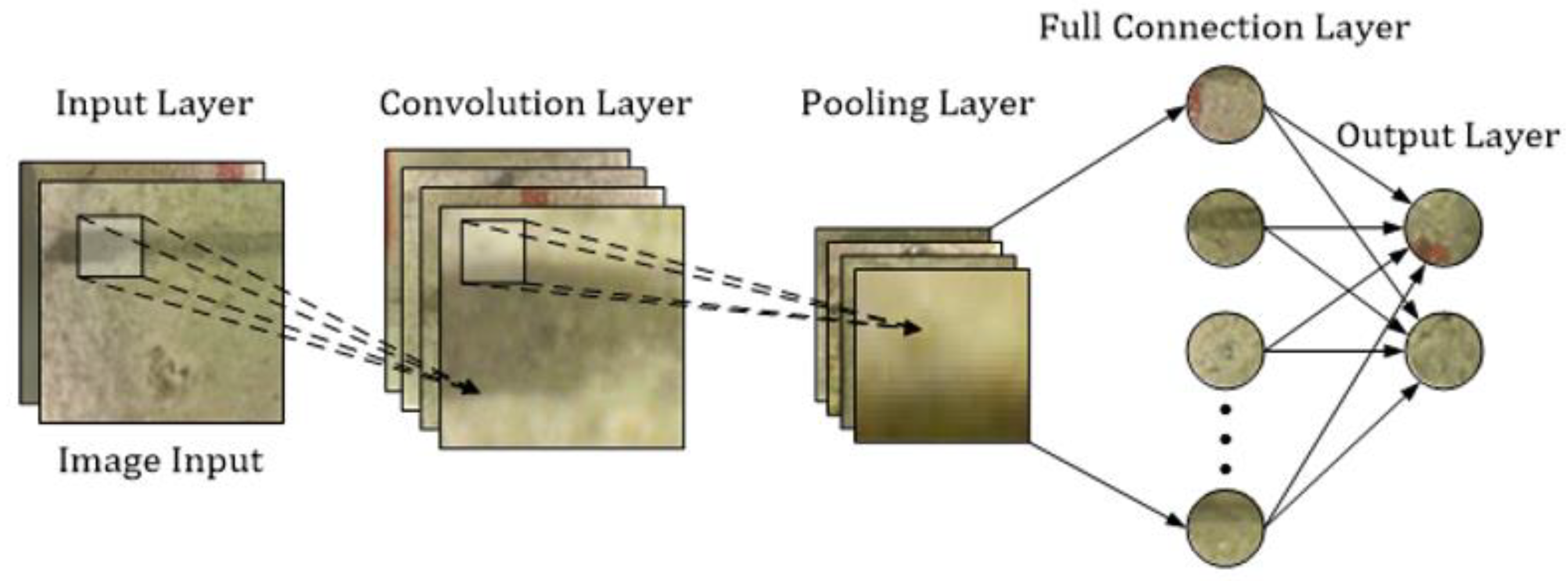

Convolutional Neural Networks are an extended model of multi-layer artificial neural networks, which are developed by the addition of a new type of layer. They are predominantly used for image analysis (recognition and classification) [

46].

Convolutional Neural Networks mimic the human visual system and may recognize complicated image features gradually. In the first layers of this network, simple attributes such as edges are detected. Based on what was detected in the previous, contours are recognized in the next layer. Contour detection is followed by the recognition of specific parts of the object so that the object can be classified in the final layer [

47].

The principle behind Convolutional Neural Networks is reflected in the direct input of image data in raw pixels, for example, as a width of 32, height of 32, and depth of 3. The first task of a convolutional neural network model is to transform the image it receives into a computer-understandable format. More precisely, the input data is represented as a two-dimensional pixel intensity matrix in the case of a single-channel image or as a multi-dimensional matrix in the case of a multi-channel image. As a whole, in the input layer, the image data is entered into the network, and each entered pixel represents an input characteristic. Each pixel is described by its color as a color imaging system [

48,

49].

Data entry is followed by several alternating convolutional layers and pooling layers, for which alternation reduces their dimensions. The end result is images that are very small in size, each representing one matrix. The matrix values are arranged into a vector that represents the input to the fully connected network [

46,

47,

50,

51]. A schematic representation of the basic convolutional neural network on the example of a cement prism crack image from this research is shown in

Figure 3.

2.6.2. Convolutional Layer

The convolutional layer serves to extract the features of the input data using the filters located inside the convolutional layer [

50].

The filter window moving starts from the upper left corner of the image and goes to the right by the same value. When we reach the edge, we move it downward, repeating the process. The size of the subsample depends on the size of the filter. In this study, the output volume is obtained based on several filters that make up this layer and are grouped along the axis [

50,

51,

53,

54].

2.6.3. ReLu Layer

The ReLu layer is introduced after the convolutional layer as an additional layer to increase image non-linearity and reduce the calculation time. This layer serves to break the linearity imposed by passing the image through the convolutional layer [

50,

51].

2.6.4. Pooling Layer

The convolutional layer is followed by the pooling layer, in which the data dimension is reduced. This layer also has filters, but they have no weight here, unlike in the convolutional layer. Here, the role of the filter is to select the pixel that is within the dimensions covered by this layer in a given way. The maximum is often used as it works better in practice, although average values are also acceptable. The pooling layer reduces the dimension of the feature maps while retaining the most important sample information. After pooling, the image feature map is aligned in one column, resulting in a vector. The long vector obtained in this way serves as the input to the artificial neural network, which is also the final step [

36,

53].

In this study, both (max and average) methodologies are used as the pooling functions. The microscopic images from this experimental research showing bacterial healing in sterile demineralized water and Danube river water are visually very similar and can be classified into the same data set (Class 1). For the second data set (Class 2), images from mortar samples with sterile demineralized water without nutrient and bacterial culture were selected.

Considering that these are laboratory experiments, 51 images for each class were selected for the initial data set. This data set was augmented by rotating the images by 180°. Validation was performed on a completely new dataset consisting of 18 images for each class.

Validation success can also be shown computationally through a precision expression adapted from [

55]:

where:

TP—True Positive

FP—False Positive

TN—True Negative

FN—False Negative

F1-score and accuracy are used to precisely assess model performance, where F1-score takes into account precision and recall and it is calculated for both classes while accuracy represents the proportion of correct recognition of the entire sample.