A Performance-Based Design Framework for Enhanced Asphalt Concrete in the Caribbean Region

Abstract

1. Introduction

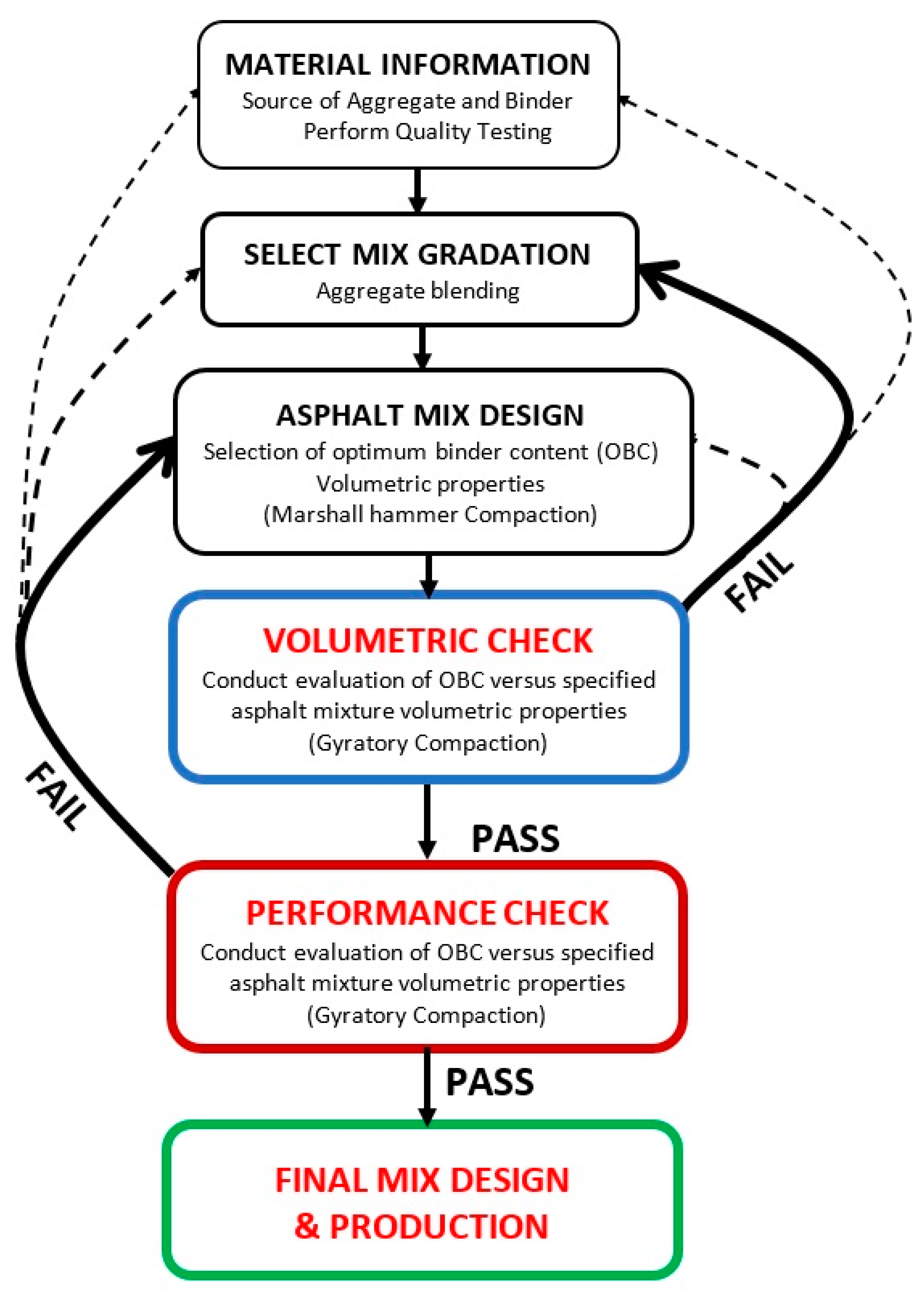

2. Methodology

2.1. Case Studies

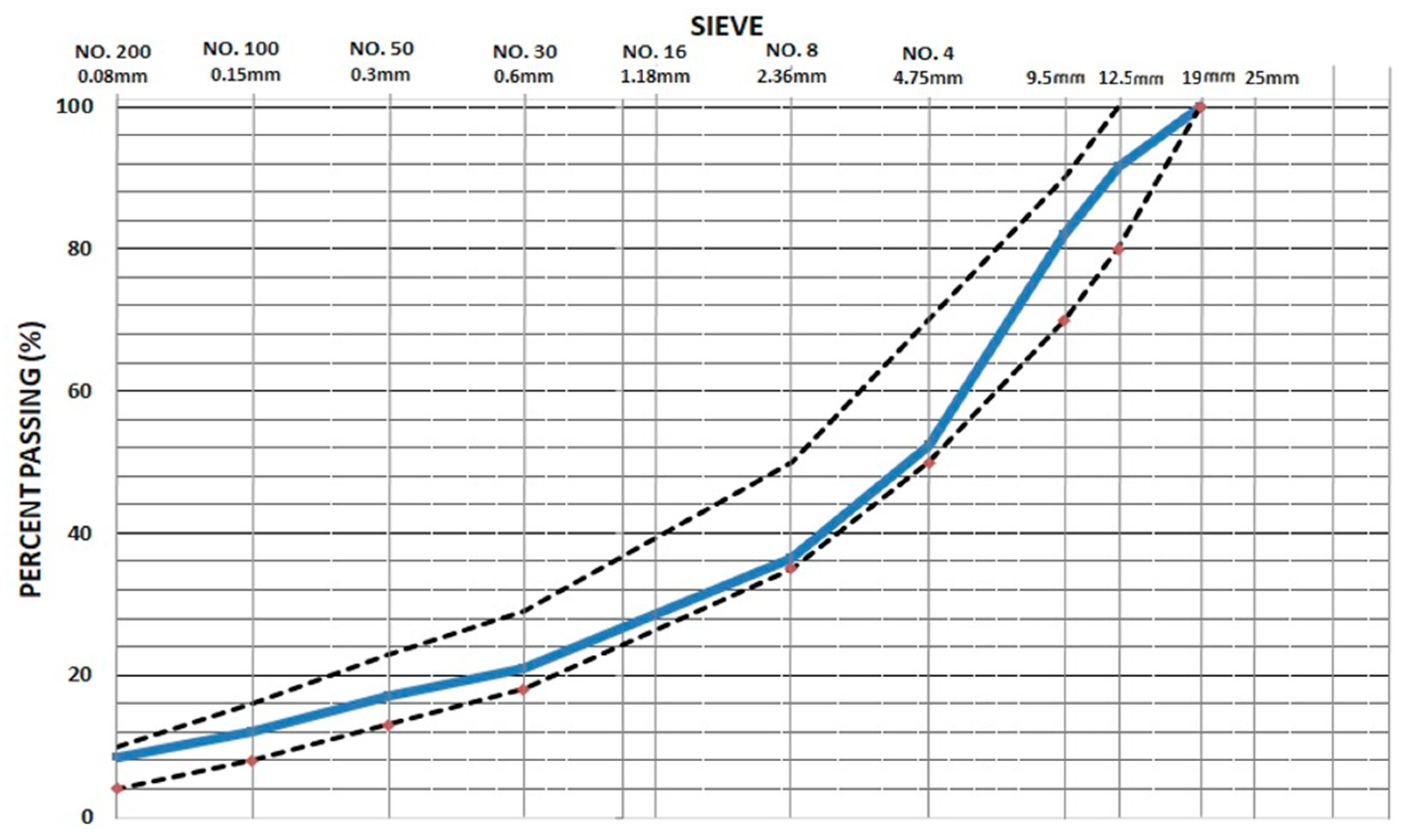

2.2. Materials and Laboratory Experimental Framework

- CONTROL MIX 1: Utilized 4.1% TLA Blend 60/75 bitumen

- CONTROL MIX 2: Utilized 4.7% TLA Blend 60/70 modified bitumen

2.3. Mix Performance Test Criteria and Description

- PBMD MIX 1: Utilized 5.1% TLA Blend 60/75 bitumen (+1% of control mix 1%)

- PBMD MIX 2: Utilized 5.7% TLA Blend 40/55 bitumen

- (a)

- Indirect Tensile Fatigue Test (ITFT)—The EN 12697-24 test is commonly used to as a quick decision-making tool in the design of asphalt mixes. The method consists of characterizing asphalt mix fatigue behavior under repeated loads with constant stress using indirect tensile (ITT). Diametral compression force is applied to a cylindrical specimen followed by rest time, with the test being down at ambient to low temperatures.

- (b)

- Repeated Load Axial Test (RLAT)—The EN 12697-25, which is sometimes referred to as the Flow Number procedure, uses a cylindrical specimen with a diameter of 100 mm or 150 mm and a thickness preferably between 40 mm and 100 mm. A repeated load is applied axially, while the vertical deformation of the specimen is measured by two LVDTs. The pulsating load consists of a square waveform with a frequency of 0.5 Hz, which simulates the slow-moving traffic that leads to the majority of deformation visible on real roads. The input parameters for testing are temperature, specimen thickness and diameter, and stress and number of load pulses, including those for the conditioning stage. The standard test uses a vertical stress of 100–250 kPa at a temperature of 60 °C up to 3600 pulses. During testing, if the specimen deforms more than 10 mm before reaching the specified number of pulses, the test is then terminated. The test output consists of vertical deformations of the specimen plotted against a number of load cycles. The lower the axial permanent percent strain, the more resistance the sample has to rutting/deformation.

- (c)

- Indirect Tensile Stiffness Modulus (ITSM)—The stiffness of bituminous material can be measured quickly and easily using the EN 12697-26 non-destructive method. This testing method uses cylindrical specimens that may be prepared in the laboratory or sampled from the field. The load is applied in the vertical plane while the strain/deformation is measured in the horizontal plane. When applying the load in the vertical plane, the horizontal plane experiences extension (indirectly, tension), which is where the test’s name is derived from. The average resilient stiffness modulus of the sample is calculated. Samples with stiffness modulus values above 3000 MPa are considered to have adequate resistance to rutting and cracking.

- (d)

- Tensile Strength Ratio (TSR)—This is a moisture susceptibility test that uses the ratio of the indirect tensile strength of wet conditioned specimens to that of dry specimens.

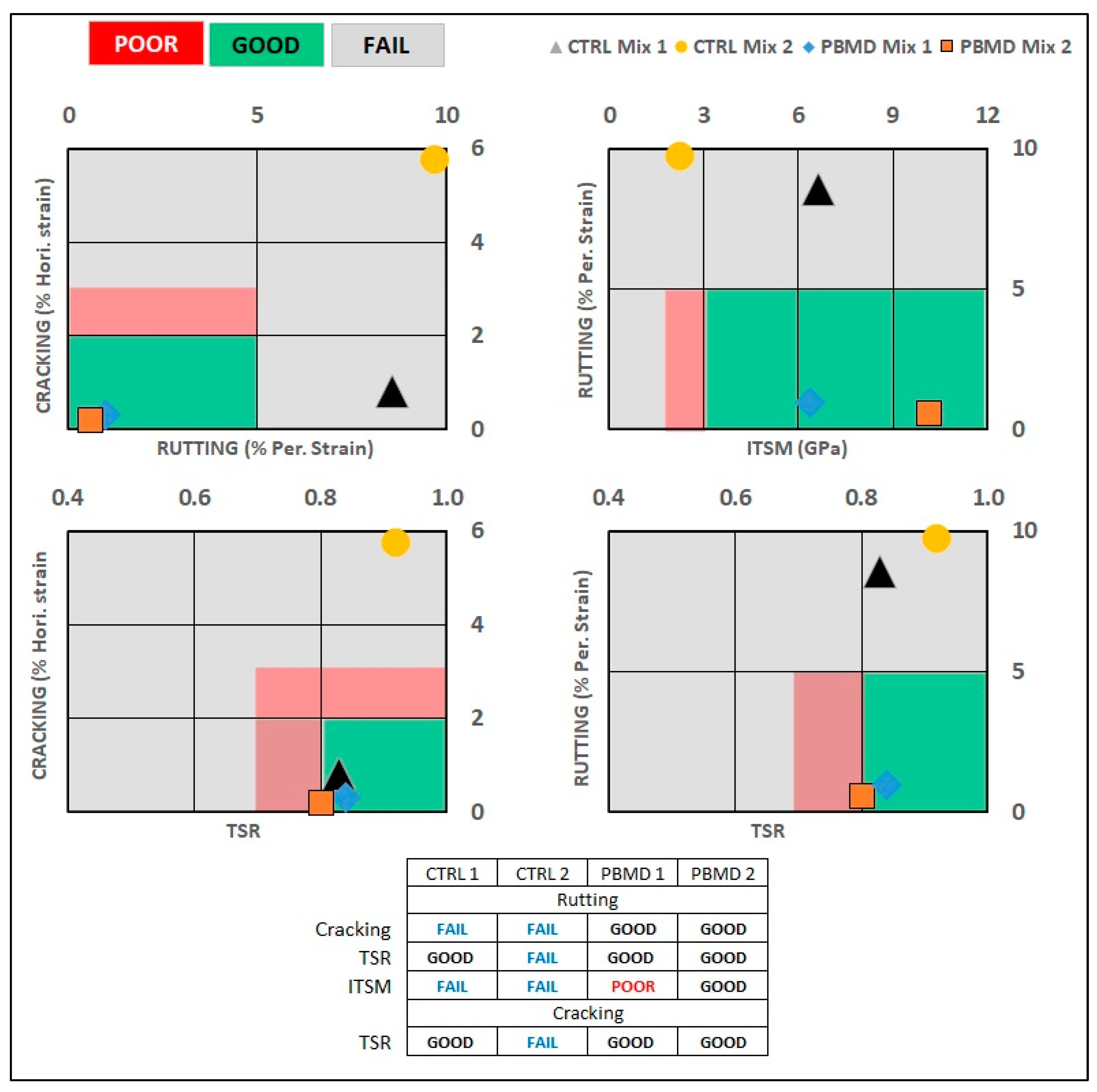

3. Results and Discussion

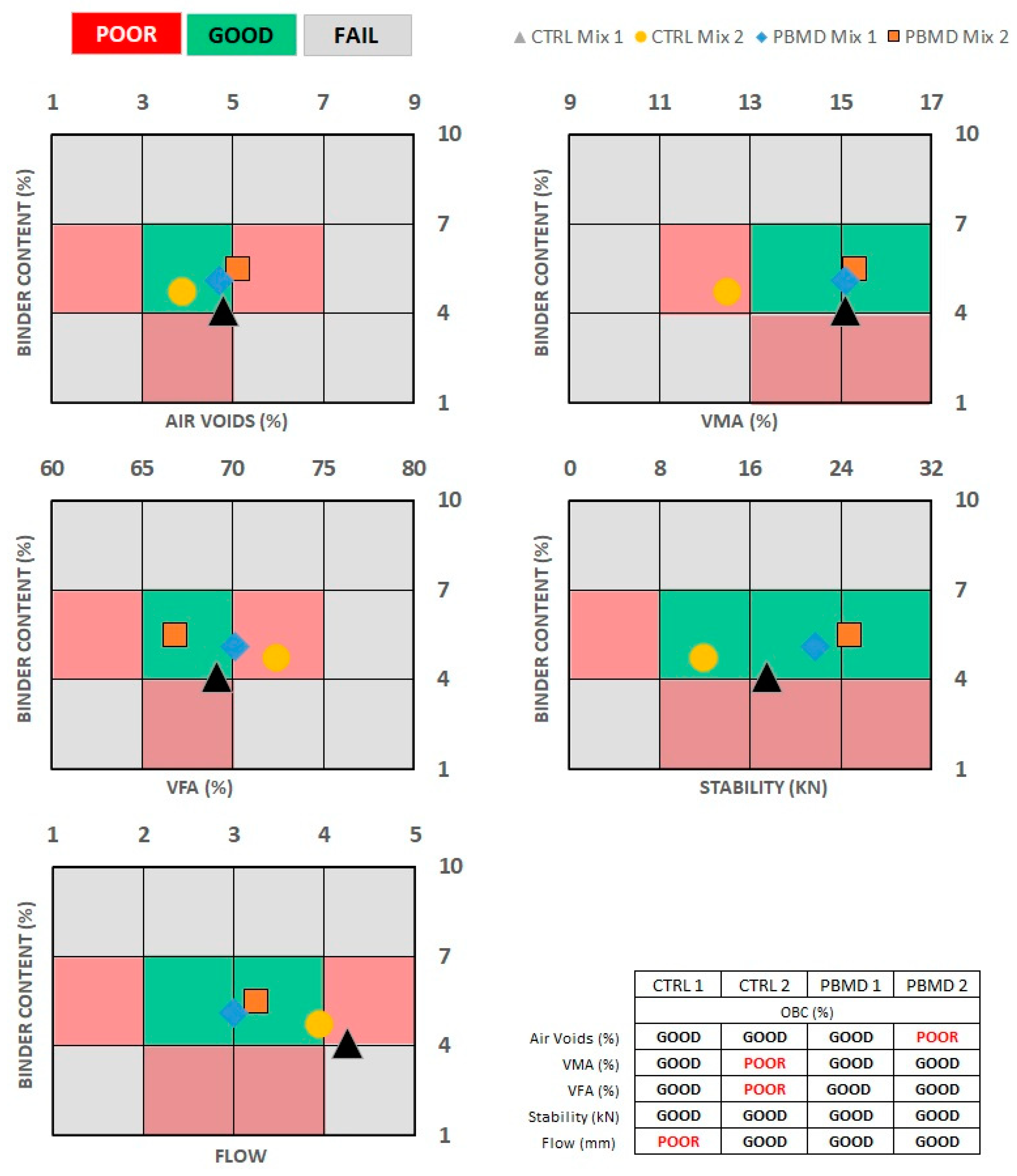

3.1. Volumetric and Performance Check

3.2. Proposed PBMD Framework

3.3. Comparative Analysis with Recent Literature

4. Conclusions

- (1)

- Volumetric Properties of mixture selection of the rejection process were categorized as ‘GOOD’ for achieving the established volumetric criteria, ‘POOR’ for demonstrating marginal results, and as a ‘FAIL’ if they did not satisfy the established criteria specified in both the CTB Schedule 20 Specifications and The Ministry of Works and Transport—Programme for Upgrading Roads Efficiency (MOW—PURE) Specifications and the Asphalt Institute MS-2 Asphalt Mix Design Methods. The control mixes were categorized into the FAIL or POOR groups for 50% of the volumetric criteria within the local specification. However, the PBMD mixtures were classified as POOR for less than 20% of the volumetric requirements.

- (2)

- Based on performance testing data, the selection process similarly factored in categorization (into GOOD, POOR, and FAIL groups). The control mix designed using the existing local specification failed some of the performance testing grouping used in the study. The control mixes were categorized as poor when examined against the PBMD grouping criteria (Rutting vs. TSR, Rutting vs. ITSM, and cracking vs. Rutting). However, although some of the PBMD mixtures were classified as poor under the volumetric requirements, all recorded a classification of GOOD for the performance evaluation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leon, L.P.; Ellis, L.A.; Martin, H.H.; Fermin, B. Dominating Factors of Road Failures: Perceptions of Key Stakeholders in the Small Island Developing State of Trinidad and Tobago. West Indian J. Eng. 2023, 45, 68–76. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Zeiada, W.; Ismail, M.; Shabib, A.; Tayara, A. Mechanistic-empirical evaluation of specific polymer-modified asphalt binders effect on the rheological performance. Sci. Prog. 2020, 103, 36850420959876. [Google Scholar] [CrossRef]

- Varma, S.; Seebaaly, H.; Maina, J.; Al Ghabani, A. Experimental Investigation of Marshall and Superpave Mix Design Methods for Rutting Criteria. In Proceedings of the Annual Southern African Transport Conference, Pretoria, South Africa, 8–11 July 2019. [Google Scholar]

- Zumrawi, M.; Edrees, S.A.S. Comparison of Marshall and Superpave Asphalt Design Methods for Sudan Pavement Mixes. Int. J. Sci. Tech. Adv. 2016, 2, 29–35. [Google Scholar]

- Buchanan, S. Balanced Asphalt Mixture Design—A Formula for Success; Hartford, CT, USA, 2017; pp. 1–40. Available online: https://nesmea.engr.uconn.edu/wp-content/uploads/sites/2933/2020/01/Buchanan-Balanced-Asphalt-Mix-Desgin.pdf (accessed on 20 June 2023).

- Sholar, G.A.; Gale, P.C.; Musselman, J.A.; Moseley, H.L. Evaluating the Use of Lower VMA Requirements for Superpave Mixtures; Florida Department of Transportation: Tallahassee, FL, USA, 2004.

- Kim, M.; Mohammad, L.N.; Challa, H.; Elseifi, M.A. A simplified performance-based specification for asphalt pavements. Road Mater. Pavement Des. 2015, 16, 168–196. [Google Scholar] [CrossRef]

- Sheng, B. Evaluation of Florida Asphalt Mixes for Crack Resistance Properties using the Laboratory Overlay Test Procedure; Florida Department of Transportation: Tallahassee, FL, USA, 2016.

- Bahia, H.; Teymourpour, P.; Swiertz, D.; Ling, C.; Varma, R.; Mandal, T.; Chaturabong, P.; Lyngdal, E.; Hanz, A. Analysis and Feasibility of Asphalt Pavement Performance-Based Specifications for WisDOT (No. 0092-15-04); Wisconsin Department of Transportation: Madison, WI, USA, 2016.

- Zhang, W.; Shen, S.; Wu, S.; Chen, X.; Xue, J.; Mohammad, L.N. Effects of in-place volumetric properties on field rutting and cracking performance of asphalt pavement. J. Mater. Civ. Eng. 2019, 31, 04019150. [Google Scholar] [CrossRef]

- Al-Khayat, H.; Newcomb, D.E.; Zhou, F.; Van Deusen, D. Evaluation of the Minnesota Asphalt Mixtures Based on Balanced Mix-Design Approach. Transp. Eng. Part B Pavements 2021, 147, 04021045. [Google Scholar] [CrossRef]

- Pujadas, P.; Cavalaro, S.H.P.; Aguado, A. Mives multicriteria assessment of urban-pavement conditions: Application to a case study in Barcelona. Road Mater. Pavement Des. 2018, 20, 1827–1843. [Google Scholar] [CrossRef]

- Elhadidy, A.A.; El-Badawy, S.M.; Elbeltagi, E.E. A simplified pavement condition index regression model for pavement evaluation. Int. J. Pavement Eng. 2021, 22, 643–652. [Google Scholar] [CrossRef]

- ARA Inc. Guide for Mechanistic–Empirical Design of New and Rehabilitated Pavement Structures; NCHRP Project 1-37A; Transportation Research Board of the National Academies: Washington, DC, USA, 2004. [Google Scholar]

- Christensen, D.W., Jr.; Pellinen, T.K.; Bonaquist, R.F. Hirsch Model for Estimating the Modulus of Asphalt Concrete. J. Assoc. Asph. Paving Technol. 2003, 72, 97–121. [Google Scholar]

- Kaloush, K.; Witczak, M.W. Development of Permanent to Elastic Strain Ratio Model for Asphalt Mixtures. In Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structure; University of Maryland: College Park, MD, USA, 1999. [Google Scholar]

- Bonaquist, R.; Paye, B.; Johnson, C. Application of Intermediate Temperature Semi-Circular Bending Test Results to Design Mixtures with Improved Load-Associated Cracking Resistance. Road Mater. Pavement Des. 2017, 18, 2–29. [Google Scholar] [CrossRef]

- West, R.; Rodezno, C.; Leiva, F.; Yin, F. Development of a Framework for Balanced Mix Design; Final report, NCHRP 20-07/Task 406; Transportation Research Board of the National Academies: Washington, DC, USA, 2018; pp. 7–20. [Google Scholar]

- Blab, R.; Eberhardsteiner, J. Methoden der Strukturoptimierung flexibler Straßenbefestigungen (Performance-Based Optimization of Flexible Road Structures), Progress Report of the CD Laboratory at the Institute of Road Construction; Vienna University of Technology: Vienna, Austria, 2009. [Google Scholar]

- Habbouche, J.; Boz, I.; Diefenderfer, S.D. Validation of Performance-Based Specifications for Surface Asphalt Mixtures in Virginia. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 277–296. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Aschenbrener, T.B.; Nener-Plante, D. Case Studies on the Implementation of Balanced Mix Design and Performance Tests for Asphalt Mixtures; Illinois Department of Transportation (IDOT). Report No. WRSC-TR-21-03, Pavement Engineering & Science Program; University of Nevada: Reno, NV, USA, 2021. [Google Scholar]

- Buttlar, W.G.; Urra-Contreras, L.; Jahangiri, B.; Rath, P.; Majidifard, H. Support for Balanced Asphalt Mixture Design Specification Development in Missouri; Missouri Department of Transportation: Jefferson, MO, USA, 2020.

- Coleri, E.; Sreedhar, S.; Obaid, I.A. Development of A Balanced Mix Design Method in Oregon; Oregon Department of Transportation (ODOT): Salem, OR, USA, 2020.

- Diefenderfer, S.D.; Bowers, B.F. Initial Approach to Performance (Balanced) mix design; The Virginia Experience. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 335–345. [Google Scholar] [CrossRef]

- Bennert, T.; Fee, F.; Sheehy, E.; Blight, R.; Sauber, R. Implementation of performance-based HMA specialty mixtures in New Jersey. In Asphalt Paving Technology: Association of Asphalt Paving Technologists-Proceedings of the Technical Sessions; Association of Asphalt Paving Technologist: Tampa, FL, USA, 2011; Volume 80, pp. 719–740. [Google Scholar]

- Central Tenders Board (CTB). Standard Specifications Hot Asphaltic Mixtures for Use in Road Paving; Ministry of Finance, Port of Spain, Republic of Trinidad and Tobago, 2008.

- Asphalt Institute. MS-2 Asphalt Mix Design Methods, 7th ed.; Asphalt Institute: Lexington, KY, USA, 2014. [Google Scholar]

- GmbH, Wirtgen. Cold Recycling Wirtgen Cold Recycling Technology; Wirtgen GmbH: Windhagen, Germany, 2010. [Google Scholar]

- BS EN 12697-24:2018; Bituminous Mixtures. Test Methods Resistance to Fatigue. British Standards Institution—European Standard (BSEN): London, UK, 2018.

- Prowell, B.D. Validating the Fatigue Endurance Limit for Hot Mix Asphalt; NCHRP Report 646; NCHRP: Washington, DC, USA, 2010. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage; AASHTO T283; AASHTO: Washington, DC, USA, 2022. [Google Scholar]

- Zaumanis, M.; Poulikakos, L.D.; Partl, M.N. Performance-based design of asphalt mixtures and review of key parameters. Mater. Des. 2018, 141, 185–201. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, L.; Liu, L. Performance-based design of hard asphalt mixtures based on different compaction effort variable. Constr. Build. Mater. 2020, 254, 119240. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, H.; Sun, L. Performance-based design of recycled hot-mix asphalt (HMA) incorporating compaction effort variable. Constr. Build. Mater. 2021, 303, 124277. [Google Scholar] [CrossRef]

- Sabouri, M. Evaluation of performance-based mix design for asphalt mixtures containing reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2020, 235, 117545. [Google Scholar] [CrossRef]

- Norouzi, Y.; Ghasemi, S.H.; Nowak, A.S.; Jalayer, M.; Mehta, Y.; Chmielewski, J. Performance-based design of Asphalt Pavements concerning the reliability analysis. Build. Mater. 2022, 332, 127393. [Google Scholar] [CrossRef]

| Property | Oregon | Nevada | Missouri | Trinidad | Jamaica | St. Lucia | Test Method |

|---|---|---|---|---|---|---|---|

| Marshal Stability—kN | - | >8 | - | >8 | >8 | >8 | ASTM D6927 |

| Marshall Flow (mm) | - | 2–5 | - | 2–4 | 2–4 | 2–3.5 | ASTM D6927 |

| Tensile Strength Ratio | - | >0.7 | - | >0.7 | - | - | |

| Flexibility Index | 6–8 | - | - | - | - | - | |

| HWTT Rutting—mm | 2.5–3 | <12.5 | <12.5 | - | - | - | AASHTO T 324 |

| Flow Number | 500–1000 | - | - | - | - | - | AASHTO T 378 |

| Ideal CT | - | >54 | - | - | - | - | ASTM D8225 |

| Fracture Energy—J/m2 | - | - | >200 | - | - | - | |

| IFIT | - | - | 0.8–2.5 | - | - | - | AASHTO T 393 |

| Compaction Method | gyratory | gyratory | gyratory | Marshall | Marshall | Marshall |

| Property | Trinidad | Asphalt Institute | St. Lucia | Jamaica |

|---|---|---|---|---|

| Optimum binder content (OBC), % | 4–7 | 4–7 | 4.5–7 | 4–7 |

| Marshall stability, kN | >8 | >8 | >8 | >8 |

| Marshall flow (mm) | 2–4 | 2–3.5 | 2–3.5 | 2–4 |

| Air voids content, % | 3–5 | 3–5 | 3–5 | 3–5 |

| Voids in mineral aggregate (VMA), min% | >15 | >13 | >14 | >14 |

| Voids filled with asphalt (VFA), % | 70–80 | 65–75 | 65–75 | 75–85 |

| Dust/asphalt ratio | 0.6–1.3 | - | 1.5–1 | - |

| No. of blows per specimen face | 75 | 75 | 75 | 75 |

| Property | 60/75 Pure TLA | 40/55 Pure TLA | 60/70 Polymer Modified |

|---|---|---|---|

| Specific gravity @ 25 °C (g/cm3) | 1.022 | 1.2 | 1.1 |

| Penetration @ 25 °C (mm) | 7.2 | 5.1 | 6.7 |

| Flash point °C | 135 | 150 | 165 |

| Kinematic Viscosity @ 135 °C (Pa.s) | 414 | 677 | 409 |

| Test | Test Temperature (°C) | Loading Cycles | Selection Criteria |

|---|---|---|---|

| Repeated Load Axial test (RLAT)—% strain (deformation/rutting) | 60 | 3600 s | <5 (Good) >5 (Fail) |

| Indirect Tensile Stiffness Modulus Test (ITSM)—MPa | 25 | NA | >3000 (Good) <1500 (Fail) |

| Indirect Tensile Fatigue Test (ITFT)—% strain (cracking) | 25 | NA | <2 (Good) >2 (Fail) |

| Tensile Strength Ratio test (TSR) | 25 | NA | >0.70 (Good) |

| <0.70 (Fail) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon, L.P.; Roopnarine, K.; Azamathulla, H.M.; Chadee, A.A.; Rathnayake, U. A Performance-Based Design Framework for Enhanced Asphalt Concrete in the Caribbean Region. Buildings 2023, 13, 1661. https://doi.org/10.3390/buildings13071661

Leon LP, Roopnarine K, Azamathulla HM, Chadee AA, Rathnayake U. A Performance-Based Design Framework for Enhanced Asphalt Concrete in the Caribbean Region. Buildings. 2023; 13(7):1661. https://doi.org/10.3390/buildings13071661

Chicago/Turabian StyleLeon, Lee P., Karishma Roopnarine, Hazi Mohammad Azamathulla, Aaron Anil Chadee, and Upaka Rathnayake. 2023. "A Performance-Based Design Framework for Enhanced Asphalt Concrete in the Caribbean Region" Buildings 13, no. 7: 1661. https://doi.org/10.3390/buildings13071661

APA StyleLeon, L. P., Roopnarine, K., Azamathulla, H. M., Chadee, A. A., & Rathnayake, U. (2023). A Performance-Based Design Framework for Enhanced Asphalt Concrete in the Caribbean Region. Buildings, 13(7), 1661. https://doi.org/10.3390/buildings13071661