Abstract

This research aimed at ascertaining the performance of raw dura species of Palm Kernel Shells (PKS) in comparison to a different species of PKS (tenera) as a replacement for known aggregates for pervious lightweight concrete. Using limestones as the known aggregates, control pervious concrete was batched, and relevant tests were conducted. Major tests conducted on the composites concerned compressive, tensile, and flexural strength, as well as permeability, densities, and absorption. Logistic constraints on transporting the dura-PKS limited the quantity needed to ascertain the variety of replacements of the dura-PKS. With a 25% replacement known to be the most suitable ratio for related investigations, we adopted that ratio and compared to the extreme ratio of 100% dura-PKS. The tests revealed that a 100% replacement of known aggregates by the dura-PKS resulted in high porosity and permeability, although the resistances to compression, tension, and flexural loads read low for the same mixture. Instead, pervious concrete 25% of dura-PKS replacement yielded optimum water permeability rate and flexural and compressive stresses. However, the flakiness index recorded for the dura-PKS was almost half that of the tenera species and was not reflected in the mechanical properties as the results gave relatively lower strengths. The results in the case of the dura species do not differ significantly compared to the tenera-PKS in terms of strength and permeability.

1. Introduction

The perspective of urban floods in Ghana requires a practical and local strategy to address the phenomena [1]. By adopting an indicator-based approach, the overall flood vulnerability in the country and sub-Saharan Africa may be determined [2]. Responses gathered on flood perception in Ghana highlighted mainly social and technical aspects as the way forward to improve flood risk management in the Sub-Saharan zone.

Regarding social intervention, Mashi et al. [3] and Mulligan et al. [4] emphasized that citizen participation is significant to flood risk management. In the case of Dhaka, in 1988 for instance, non-structural measures contributed significantly to flood damage reduction [5]. In effect, developing educational programs which aim at nurturing the citizenry on flood awareness is crucial to boosting readiness for societal resilience.

Similarly, for the technical aspect, green or grey mitigation measures are suggested as a substantial and efficient approach to consider [6,7]. These facts stress the need for designing hybrid systems capable of dealing with the increasing drainage demands posed by climate and land cover changes [8]. In adopting a more proactive approach, it is important to develop a comprehensive approach considering both technical and social aspects that do not conflict with environmental sustainability [9].

As a practical engineering novelty is needed to mitigate flooding, attention must be placed on a functional design considering the materials, desired rate of permeability, and minimum resistance to potential loads. In this vein, Sub-Saharan Africa can shift to the application of permeable concrete pavements. Its high-solar reflectance is an effective method to alleviate the Urban Heat Island effect [10], whereas its use for drainage systems is sustainable considering its yield on permeability and strength [11]. It is encouraging for community developers to adopt a similar system to help actualize flood resilience [12].

There is a direct relation between the fractal dimension and the porosity of pervious concrete. The nature of pores in a concrete specimen provides information about the permeability rate of that specimen. Additionally, porosity increases as the tortuosity of the previous concrete decreases. Meanwhile, the aggregate size contributes to the average pore size, which also affects porosity [13]. The cement-to-aggregate ratio is an important parameter for determining the permeability rate when designing pervious concrete mixtures. Thus, an understanding of the hydrodynamics of water flow in pervious concrete is equally relevant to the rationalization of pervious concrete pavement designs [14].

Many research works have examined the performance of pervious concretes considering the materials used and their sizes. For instance, pervious concrete mixtures with varied dolomite aggregate types were analyzed to determine the influence of aggregate type and size on the properties of pervious concrete [15]. The properties of basalt fiber-reinforced pervious concrete (BFRPC) and carbon fiber-reinforced pervious concrete (CFRPC) with two single-sized aggregates were also compared [16]. Similarly, Malaiskiene et al. [17] studied the influence of the percentage of coarse aggregates on the concrete structure with a focus on density, infiltration rate, water absorption, and compressive strength. A review of this literature reveals that all of the investigations tested the performances of different pervious concretes with distinct aggregates such as polypropylene, glass fiber, basalt fiber, carbon fiber, and dolomites.

As reviewed by Alengaram et al. [18], an alternative to these materials can be found in Palm Kernel Shells (PKS), which are a recognized lightweight aggregate in concrete production and have no negative effect when encountering water. It bears no risk of pollution either to land or water bodies. PKS is ideally a multipurpose bioproduct [19] but is insignificantly used (biofuel by individuals and factories). Nevertheless, this product is very common in Sub-Saharan Africa, where it has virtually negligible economical value and becomes a nuisance to the environment.

The high absorptive nature, together with the presence of silica (SiO2), in PKS raises interest in investigating the replacement of natural aggregates by PKS for pervious lightweight concrete [20,21]. As demonstrated, PKS is a suitable composite aggregate for concrete production, considering their respective strengths and densities when replaced with crushed granite [22]. Moreso, composites incorporated with PKS have higher permeability potential since the water permeability of pervious concrete is primarily influenced by porosity [21].

According to Khankhaje et al. [11], a partial replacement of natural coarse aggregate sized 6.30–9.50 mm by Oil PKS from 25 to 75% by mass produced a sustainable lightweight pervious concrete. The size of PKS ranged from 4.75 to 9.50 mm. The PKS-incorporated concrete yielded acceptable physical properties after 28 days of curing. A high-water permeability ranged from 4 to 16 mm/s, and compressive strength ranged from 6 to 12 MPa. Hence, PKS can be concluded to be a suitable aggregate for permeable pavements for light traffic areas.

Additionally, an investigation by Khankhaje et al. [23] justifies the use of both PKS and Cockle Shell (CS) both mechanically and environmentally. After several mixtures were made, 25%, 50%, and 75% of limestone were replaced by mass. Interestingly, after 28 days of curing, the mixture with 75% PKS recorded the maximum void content. Moreover, increased sound absorption was reported with the application of both shells, particularly PKS. Although the experimental mixtures recorded low readings for mechanical properties, the values fell within the acceptable range for pervious concrete.

Investigations on PKS as a potential sustainable construction material have predominantly been carried out in Asia. However, PKS depends on the species of the oil palm (dura, pisifera, and tenera species). The tenera variety (common material in Malaysia) is the hybrid of the dura and the pisifera species, whilst the dura is the mother of the tenera with a thicker shell variety [24]. The dura-PKS is a very common material in West Africa and readily available as a local palm oil industrial waste [25]. The difference between the varieties of the shells is dependent on the thickness of the shells.

Considering the effect of size and shape of aggregates on concrete performance, the thickness of PKS is similarly relevant to examine when using a variety as an alternate aggregate for pervious concrete. However, previous research works have not considered the dura species as an aggregate for pervious concrete. Additionally, the insignificant usage of the dura-PKS in the sub-Saharan area despite its availability is of worry to the physical environment. This investigation aims to gain insight into the use of the dura species of PKS by analyzing their mechanical and physical properties when used as a partial replacement of known aggregates in low-traffic permeable concrete pavement. The study also aims at using dura-PKS without any previous treatment and considering higher replacement ratios (100%), which differs from what has been conducted in previous studies. This, in turn, allows a comparison to ascertain if there is any difference or relation between the dura-PKS from Ghana and the tenera species from Malaysia in terms of permeability, strength, and porosity.

Therefore, the novelty of this investigation essentially lies in the uniqueness of the material used and the fact that no literature has examined the use of untreated dura-PKS for pervious concrete. Knowing the properties and performance of the tenera species in pervious concretes and similar composites [11,18,23,26], this study attempts to answer the following research questions:

- What contribution and what performance does the dura-PKS make when replacing known coarse aggregates for pervious concrete pavement?

- Will the granulometry and physical properties of the dura be different compared to the tenera-PKS?

- What influence do the granulometry and physical properties of the dura-PKS have on the composites in terms of permeability, physical, and mechanical properties when known aggregates are partially or fully replaced?

Hence, this paper seeks to fill a research gap regarding the use of dura-PKS as a coarse aggregate in lightweight pervious concrete while also exploring the relationship between the effects of the two species of PKS (dura and tenera) on these composites.

2. Methodology

This section adopts experimental work to prepare lightweight concrete specimens. The aggregates were graded and batched with cement and water to prepare lightweight concrete specimens without using any pre-treatment or additives. The mechanical and physical properties of the specimens were determined via testing after being kept in a curing chamber for 28 days. Samples of the PKS were scanned with a microscope to gain insight into the cellular nature of these materials.

The preliminary nature of this study narrowed the experimental campaign to a series of general mechanical and permeability tests to ascertain the main properties of untreated dura-PKS pervious concrete. Hence, tests to determine other properties of interest due to the purpose of the mixtures, such as the Los Angeles test for abrasion resistance, were not performed. Information on the behavior of concrete made with PKS in this regard can be found in Acheampong et al. [27]; although, the PKS were used as fine aggregates, and the mixtures were not dosed to result in pervious composites.

In general, a minimum of nine specimens (three of each type: control, 100% PKS, and 25% PKS) would have been desirable for each mechanical test to be performed. However, the complexity of the logistics, with the laboratory work being carried out in Spain and the dura-PKS being sourced from Ghana, prevented this minimum.

Due to its relevance as a key mechanical test for concrete and the focus of the study on flood mitigation, a larger number of specimens were tested for compressive strength and permeability. Instead, this figure was reduced for the tensile splitting and flexural strength tests, which also required more material because of the larger dimensions of the specimens.

2.1. Properties of the Aggregates

2.1.1. Particle Size Gradation

The study adopted limestones and PKS (Figure 1a) as aggregates. Their particle size distribution and geometrical properties were determined by adopting EN 933:1&2 for the tests [28,29]. Here, both aggregates were passed through a series of sieves (nominal size of apertures ranging from 0.5 mm to 14 mm) under a minimum vibration in a space of time (Figure 1b). Due to the lack of fine particles, sieve sizes below 0.5 were not useful. Unlike the trend where PKS are pre-treated before being used [26], those used in this study were screened directly without washing, decantation, or fiber removal.

Figure 1.

Aggregates undergoing sieve test: (a) hand sieving; (b) sieving machine.

2.1.2. Flakiness Index and Shape Index

By applying the EN 933-3 test for the geometrical properties of the aggregates, the flakiness index was determined [30]. The standard defines opening sizes for the bar screens to be used, which depend on the mesh screen size where the material has been retained. The relation established between mesh and bar sieves is thereof established.

Going by EN 933-4, the particle shape of aggregates was examined [31]. The samples were prepared according to EN 932-2 [32]. Particles smaller than 4 mm and larger than 63 mm were rejected by using the previous sieving. The test was not carried out on the 0/4 fraction since the large part of its mass corresponded to particle sizes more than 4 mm. By interpolation, the test samples were obtained. The SI for each fraction and material was calculated as the quotient between the mass of non-cubic particles and the total mass of the test sample.

2.1.3. Microscopical Scan of PKS

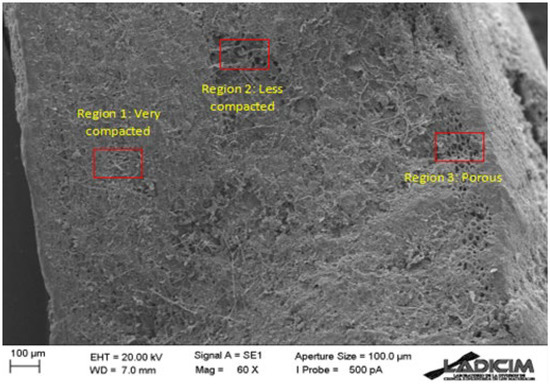

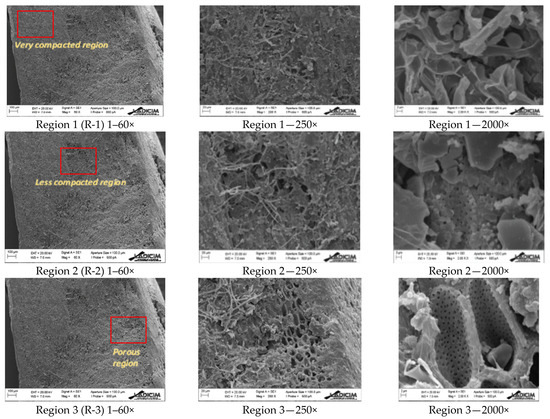

The cellular nature of the PKS was diagnosed using a Zeiss Scanning Electron Microscope (SEM). As it is equipped with Andor—Oxford Instrument (X-ray detector), the model EVO MA15 zoomed out the microstructure of the PKS (Figure 2). Three parts of the PKS were considered for the scanning: regions 1 (very compacted), 2 (less compacted), and 3 (porous).

Figure 2.

Microscopic analysis of the cellular structure of the dura-PKS.

2.1.4. Physical Properties

The physical properties of the aggregates were investigated, taking into consideration their densities (apparent specific density, bulk specific density, saturated surface dry density, and set density), water absorption rate, porosity, and permeability. These properties prevailed via the application of the standards EN 1097-3 & 6 [33,34].

Aggregates were put in an oven at a constant temperature of 100 °C for a day. By EN 932-1 & 2, the materials were dehydrated until a constant weight was ascertained, and the dry weight of the sample was recorded [32,35]. The sample was then conditioned to vacuum for the next 24 h in a compartment such that air was trapped out from both compartments and the accessible pores of aggregates. For the subsequent 24 h, the chamber was filled with water through a water inlet valve without losing the vacuum at a pressure of 5 kPa, whilst the vacuum was constantly retained. At length, after 24 h, the water-saturated sample was released from the compartment.

After the three-stage saturation process, the aggregates were removed and superficially dried with the help of a weak absorbent cloth, eliminating the surface shine of the particles. Subsequently, the saturated weight with the dry surface was recorded. The apparent volume of the sample was then determined from the thrust exerted by the volume of the displaced water according to Archimedes’ Principle.

The accessible pore volume was obtained by differences between saturated dry surface weight and dry weight. Assuming that the density of water in the laboratory was 1 g/cm3 and the same units were used, the bulk and apparent specific densities were obtained. Once the accessible porosity and the dry weight were known, the water absorption rate was deduced. The ratio between the accessible pore volume and the apparent volume of the sample provided the accessible porosity of the material.

Chemical characterization of dura-PKS was not carried out in this study. The existing literature has not been specific on the chemical composition of this species of PKS either. To the best of our knowledge, the main references in this sense are Ikubanni et al. [36], Shehu et al. [37], and Zubair Yahaya et al. [38], where the influence of temperature and particle size on the chemical composition of PKS can be consulted.

2.2. Mix Design and Batching

Upon review of the existing scientific literature on mix design for permeable concrete, the respective quantities for the concrete constituents (cement, aggregates, and water) were established [18,21,39]. A 42.5 grade of ordinary Portland cement was used as the binder for all the mixtures. A mix design for permeable concrete was designed, and three different mixtures were batched, as shown in Table 1.

Table 1.

Mix design for pervious concrete.

Concrete with only limestone as the aggregates were batched and applied as control. Experimental concrete with 100% and 25% replacements of PKS were also batched, respectively. A replacement ratio of 25% PKS has been used in previous studies, yielding the best results in related experimental works. This is the case of Khankhaje et al. [11], who obtained remarkable results for the tenera PKS species, especially from a mechanical point of view. However, to the best of our knowledge, a replacement ratio of 100% has not been used yet for any PKS species. Testing this extreme ratio is of interest to determine if permeability can be increased while maintaining an adequate mechanical response. When concrete specimens were well-set, they were conditioned to a constant temperature of 20 °C in a chamber for 28 days before all tests began.

2.3. Physical Properties of the Concrete

Using an electric cutter with a wet diamond disk saw, standard cylindrical specimens a diameter of 150 mm and height of 300 mm were cut into three. It was ensured that sub-samples of the specimens of the same size (150 mm × 75 mm) had evenly distributed pores devoid of segregation.

By determining the sets of densities following EN 12390-7 [40], accessible porosity and absorption rates were also deduced using standard EN 83980 [41]. Bestowing Archimedes’ Principle, the saturated weight with the dry surface was recorded to determine their apparent volume. The apparent volume of the sample was then determined from the thrust exerted by the volume of the displaced water.

The same samples (150 mm × 75 mm) were exposed to varying climate conditions to ascertain the behavior of the composites in both wet and dry conditions. The specimens were put in a dry oven (100 °C) for 72 h and immediately thereafter placed in a water tank for 6 weeks. Although this test did not follow any specific standard, it was added to the study to aid in examining the properties of the experimental composites.

2.4. Mechanical Properties of the Concrete

2.4.1. Compressive Strength

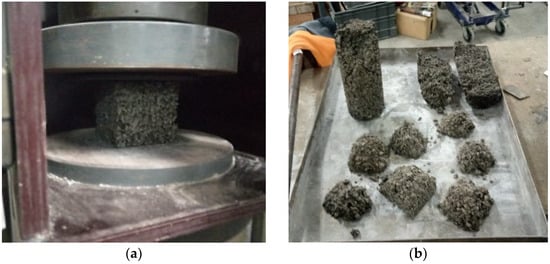

The compressive strength was determined using a 1500 kN capacity of a universal servo-hydraulic press and a load application speed of 0.5 MPa/s. The uniaxial compressive strength of the concrete cubic specimens was determined at 28 days of age (Figure 3). Here, five cubic specimens of 10 cm were made available per mix, and standard EN 12390-3 was followed to ascertain the compressive strength of the hardened concrete [42].

Figure 3.

Setup demonstrating the compressive test: (a) before crushing; (b) after crushing.

2.4.2. Tensile Splitting Strength

Following EN 12390-6 [43], a pair of cylindrical specimens (15 × 30 cm) were tested for tensile splitting strength at 28 days of age. A 2500 kN capacity of a universal servo-hydraulic press was exerted on the specimens until failure (Figure 4). The load application speed was 0.5 MPa/s, and the tensile strength (, MPa) was calculated using Equation (1).

where is the maximum load (N) resisted by the specimen, is the length of the load application line (mm), and is the diameter of the specimen (mm).

Figure 4.

Setup demonstrating the tensile splitting test: (a) before split; (b) after split.

2.4.3. Flexural Strength

The flexural strength was determined using a 250 kN capacity of a universal servo-hydraulic press. Six prismatic specimens of sizes 10 × 10 × 40 cm each were sampled for testing on flexural strength after 28 days of curing. There were three cylindrical supports 10 cm in length, two at the bottom and one at the top of the specimens. Amongst the six specimens, two represented the control, 100%, and 25% PKS replacement, respectively. As depicted in Figure 5, a single load roller (60 mm long metallic hook) was placed at the midpoint of each specimen and laid laterally until the limit of distortion was reached, and the flexural strength was recorded.

Figure 5.

Setup demonstrating a specimen subject to the flexural test.

The flexural strength of hardened concrete was tested by following EN 12390-5 [35]. The load application speed (, N/s) is defined in the standard and was calculated using Equation (2):

where is the increase in stress (MPa), is dimension corresponding to the depth of the specimen (mm), is the height of the specimen (mm), and is the distance between the centers of the rollers (mm). Each specimen collapsed within a certain period (in seconds), and the cracking stress (, MPa) was determined by Equation (3).

2.5. Permeability Test

The permeability test followed the standard EN 12697-19 [44] and was conducted using the falling head permeameter at an environmental temperature in well-sealed and compacted cylindrical pipes (Figure 6). Three specimens were used for the test, which was repeated twice for each specimen. Samples of each type of mixture were evaluated for permeability repetitively, and the average values were recorded.

Figure 6.

Setup demonstrating the permeability test.

Permeability () was measured as the time that takes a specific volume of water to pass through the specimen. More specifically, the time until the water level was high between two fixed points and was recorded with a hydraulic head gap of 200 mm inside the permeameter tube. Following Darcy’s law, was determined as shown in Equation (4):

where is the inside cross-section area of the inlet standpipe, is the thickness of the specimen, is the specimen cross-section area, and and are initial and final hydraulic heads measured at a time in seconds (), respectively.

3. Results and Discussion

3.1. Properties of the Aggregates

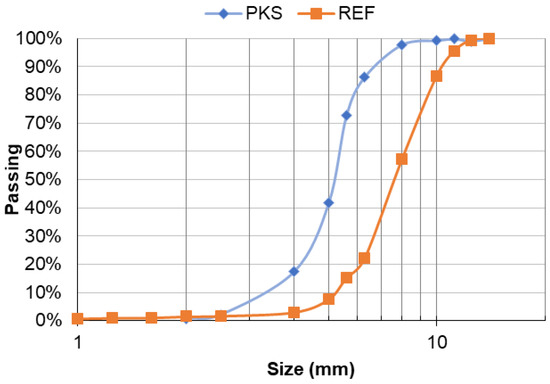

The particle size distribution was ascertained after the sieving test was complete. It was observed that a small quantity of PKS passed through the 1 mm to 2 mm sieves, which contrasts with the case of the reference aggregates (Figure 7). Inversely, between sieve sizes 2.5 mm to 10 mm, the volume of PKS particles was more than that of limestones. This means that though both aggregate sizes fell within the limits of 1 mm and 14 mm, the PKS particles were coarser but flaky, whilst the limestone particles were slightly finer with a lower flakiness index.

Figure 7.

Particle distribution curve for reference aggregates (limestone) and dura-PKS.

The test results regarding the physical properties of the aggregates revealed that the densities of limestones were higher than that of PKS; however, the trend reverted in the case of flakiness, humidity, porosity, and absorption (Table 2). The flakiness index of the dura-PKS determined by this investigation was 33.4%, which differs significantly from that of 65 derived in related literature [18]. According to Yilmaz and Tugrul [45], the strengths of hardened concretes decrease with increasing FI. In this case, this variation highlights the hypothesis by exposing the distinction between the origins of the PKS (Ghana and Malaysia) and the species (dura, pisifera, or tenera) of the palm that produced it.

Table 2.

Physical properties of the aggregates.

International references such as the South African National Standard 1083:2006 [46] and the British Standard 12620:A1:2008 [47] limit the FI of coarse aggregates to 35% and 50%, respectively. Additionally, according to Tam and Tam [48], the combined FI for their 11 samples was lower than 40%. Moreso, the FI of 33.4 % is less compared to the values reached in similar investigations [18,49].

The recorded densities for the control concrete conform with the literature [50]. Similarly, the composites with both 100% and 25% as aggregates fall in the range of 1600–1900 kg/m3, as already established by Alengaram et al. [18]. The lower recorded densities of 1460 kg/m3, 2150 kg/m3, and 1780 kg/m3 for apparent, relative, and saturated densities, respectively, for the experimental composites are due to the presence of the PKS. In the same vein, the recorded water absorption rate within 24 h of 22% falls within the range of 14–33%, as suggested in the literature [18].

The humidity of PKS was found to vary depending on temperature. Nonetheless, the structure of PKS did not break or distort when exposed to both extreme cold (deep freezer) and hot (oven) conditions. Drying it in the sun for three consecutive days and soaking it in water for the same period continuously did not change its strength as it did for natural rocks and aggregates [51]. Following the report by Powers [52], the high porosity and absorption rates reached for the PKS confirmed the drainage potential of these materials and the interest in incorporating them into permeable concrete mixtures.

Upon scanning a sample of the PKS, it was observed that the pore distribution varied depending on the region analyzed. The level of compactness or porosity depended on the region of the PKS. Moreso, the pore openings in the interior parts of the PKS were different from those in the exterior parts. Accordingly, as illustrated in Figure 8, the R-1 region represented the part that had negligible pores. R-2 represented those parts of the PKS having fewer pores, whilst the R-3 was the porous parts carrying many pores. Mostly, the structural nature of a typical pore of the PKS is conical or funnel-like. It widens at one end and narrows at the other end, as depicted in Figure 8. This revelation by the microscopic test and analysis indicates the need for further investigation in the future that focuses on the placement of the aggregates in the concrete when used for lightweight pervious concrete.

Figure 8.

Microscopic analysis of the cellular nature of Palm Kernel Shells (PKS) with zooms of 250× and 2000× for Region 1 (R-1), Region 2 (R-2), and Region 3 (R-3).

3.2. Physical Properties of the Concrete

As depicted in Table 3, the densities were reduced because of replacing PKS in a block of ordinary concrete. This was due to the less dense nature of the PKS (Figure 8). In the same vein, the porosity of concrete increased when a portion of the aggregate was replaced by PKS. PKS are highly porous and absorptive; thus, they tend to induce ordinary concrete to increase its porosity and absorption rates when partially replaced.

Table 3.

Physical properties of permeable concrete mixes under study.

The behavior of PKS in the presence of water was uneven for the two experimental mixtures. With minimal manual compression, the 100% dura-PKS composites failed after 72 h of cycling in a drying oven (100 °C) followed by 6 weeks of conditioning in water. Instead, the composites with 25% dura-PKS remained physically stable when the same test was applied. This confirms that the durability of mixtures with very high contents of dura-PKS is unreliable when exposed to intensive dry–humid environments.

3.3. Mechanical Properties and Permeability of the Concrete

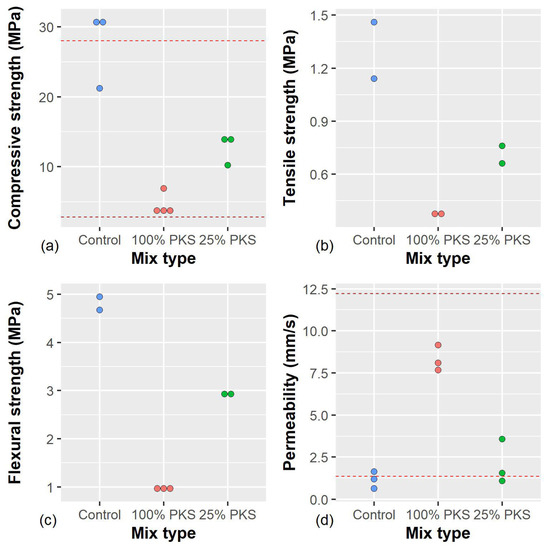

Generally, the compressive strengths recorded in this investigation (Figure 9a) fall within the range of values obtained in related works [11,53]. Moreso, the assertion by Aoki [54] that pervious concrete with a density of around 1800 kg/m3 yields a compressive strength between 5.7 MPa and 10.1 MPa validates the outcome of these results. Though strength was reduced by the increasing contents of the dura-PKS, the minimum compressive strength of 4.6 MPa is higher than the average compressive strength obtained in related works where mixtures are devoid of fines [55]. The strength at 28 days of the mixtures with 25% and 100% of dura-PKS were reduced by 59% and 83%, respectively, compared to the control.

Figure 9.

Tests conducted on the permeable concrete specimens: (a) compressive strength; (b) tensile splitting strength; (c) flexural strength; (d) permeability. The red dashed lines in (a,d) indicate the lower and upper bounds suggested for permeable concrete mixes in the American Concrete Institute (ACI, 2021).

Additionally, the American Concrete Institute (ACI) reports that the minimum stress when pervious concrete is under compression is 2.8 MPa [56]. This implies that all three concrete mixtures satisfied the condition for compression (Figure 9a). The compressive stresses obtained for the control and experimental composites with PKS replacement are not out of range [11,26,57]. However, the values decreased as the PKS content increased [58]. This trend is influenced by the weaker bonding, and the lower rigidity of the dura-PKS is lower than that of the limestones. Additionally, the flaky and curvy nature of the dura-PKS and higher voids of the composite have an impact.

The strengths produced when concrete samples were subjected to tension were low for all three mixtures. Considering that the values of tensile strength in pervious concrete mixtures range from 0.79 MPa to 2.47 MPa according to Khankhaje et al. [11], both composites with dura-PKS incorporated recorded lower strengths. The mixture with 25% replacement was 11% closer to the minimum threshold. Moreso, the tensile strengths of the 25% and 100% dura-PKS composites recorded 45% to 71% reduced strengths from that achieved by the control mixtures (Figure 9b).

For the essence of this investigation where the aim is to ascertain a permeable pavement for lightweight vehicles, flexural strength is a particularly important measure to consider [59]. As depicted in Figure 9c, the results ranged from 10 to 20 percent of their corresponding compressive strengths, which is in line with the trends found in the literature [53]. The 100% and 25% dura-PKS composites recorded a reduction of 80% and 39% in flexural strength when compared to that of the control. Though the flexural strength obtained by the experimental composites was lower, the 2.93 MPa value obtained by the mixture with 25% dura-PKS is upgraded when compared to the maximum stress of 1.32 MPa reported by Ibrahim et al. [55]. Moreso, the result obtained in this investigation is even more validated and satisfactory considering the flexural strength range of 1.5–3.2 MPa established by Chandrappa and Biligiri [14]. This, therefore, points out to the mixture with 25% of dura-PKS as a potential alternative for lightweight pavement [60].

As for the permeability results in Figure 9d, the pores on the PKS influenced the high permeability rates of the experimental composites compared to that of the control [61,62,63]. The permeability of the mixtures with 25% and 100% dura-PKS was 78.4% and 61.5% higher than that of the control, respectively. The values obtained for the 100% dura-PKS samples demonstrated a remarkable increase in permeability compared with previous works using lower replacement ratios [11]. The porous and absorptive nature of the dura-PKS influenced the high permeability rates of the composites with an increasing amount of PKS introduced in the mixes [23,26,61,63]. Considering the minimum water permeability rate required according to previous research [50,63,64], the results obtained in this regard show that the values obtained by the falling head test for all mixtures were enough (Figure 9d).

4. Conclusions

It is confirmed by this experiment that the dura-PKS from Ghana can be used without any treatment as an aggregate for concrete considering its physical, mechanical, and hydraulic properties. Furthermore, the results achieved revealed that the dura-PKS does not differ significantly compared to the tenera-PKS in terms of strength and permeability. The following are the main conclusions drawn from the investigation:

- By replacing natural aggregates with untreated dura-PKS for pervious concrete, the percentage of replacement matters. The more content of the dura-PKS, the higher the hydraulic properties but the lower the strength to resist loads.

- The results show that the dura-PKS is a suitable replacement for known aggregates for lightweight concrete, especially for mixtures with a replacement ratio of 25%. Though the replacement ratios were wide, 25% has been determined to be the most suitable ratio for related investigations whilst compared to the extreme ratio of 100% dura-PKS.

- For flood control purposes, partially replacing known aggregates with dura-PKS can produce useful permeable lightweight concrete. In effect, composites with 25% dura-PKS demonstrated higher durability under the effect of wet–dry cycles but were fair in the case of load resistance. The composite with 100% PKS exhibited poor performance when exposed to alternating dry–humid environments.

- The higher flakiness index of the dura-PKS compared to a lower index of other species did not necessarily affect the results of the composites.

The use of the PKS in its raw state without any pre-treatment for such green concrete is ecologically useful, especially for locations where the PKS is excessively available and regarded as waste. Additionally, by the affirmation and implementation of the outcome of the investigation, the economic value of dura-PKS will be on the rise.

Notwithstanding the results achieved, there are some limitations that future research should pay attention to. One of them is the reduced number of samples tested and limited percentage replacements for the dura-PKS-incorporated mixtures. The other main limitation lies in the incomplete characterization of the materials, whereby the study would benefit from a chemical investigation of the PKS and testing of the abrasion resistance of the composites with PKS. These limitations may have constrained potential results that could lead to relevant information. Future investigations should focus on evaluating the implementation of these permeable pavements in Ghana through a spatial multi-criteria decision-making methodology. Moreso, future research may also consider using ashes of dura-PKS to replace cement in a mixture with clay for brick-and-mortar production for local construction works.

Author Contributions

Conceptualization, E.Y., P.T., D.J.-E. and C.T.; methodology, E.Y., P.T., D.J.-E., G.G.D.A. and C.T.; formal analysis, E.Y., P.T., D.J.-E. and C.T.; investigation, E.Y. and G.G.D.A.; resources, D.J.-E. and C.T.; data curation, E.Y.; writing—original draft, E.Y.; writing—review & editing, P.T., D.J.-E. and C.T.; visualization, E.Y.; supervision, P.T., D.J.-E. and C.T.; project administration, D.J.-E. and C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qi, W.; Ma, C.; Xu, H.; Chen, Z.; Zhao, K.; Han, H. A Review on Applications of Urban Flood Models in Flood Mitigation Strategies. Nat. Hazards 2021, 108, 31–62. [Google Scholar] [CrossRef]

- Nasiri, H.; Mohd Yusof, M.J.; Mohammad Ali, T.A. An Overview to Flood Vulnerability Assessment Methods. Sustain. Water Resour. Manag. 2016, 2, 331–336. [Google Scholar] [CrossRef]

- Mashi, S.A.; Inkani, A.I.; Obaro, O.; Asanarimam, A.S. Community Perception, Response and Adaptation Strategies towards Flood Risk in a Traditional African City. Nat. Hazards 2020, 103, 1727–1759. [Google Scholar] [CrossRef]

- Mulligan, J.; Harper, J.; Kipkemboi, P.; Ngobi, B.; Collins, A. Community-Responsive Adaptation to Flooding in Kibera, Kenya. Proc. Inst. Civ. Eng. Eng. Sustain. 2017, 170, 268–280. [Google Scholar] [CrossRef]

- Faisal, I.M.; Kabir, M.R.; Nishat, A. Non-Structural Flood Mitigation Measures for Dhaka City. Urban Water 1999, 1, 145–153. [Google Scholar] [CrossRef]

- Schubert, J.E.; Burns, M.J.; Fletcher, T.D.; Sanders, B.F. A Framework for the Case-Specific Assessment of Green Infrastructure in Mitigating Urban Flood Hazards. Adv. Water Resour. 2017, 108, 55–68. [Google Scholar] [CrossRef]

- Lennon, M.; Scott, M.; O’Neill, E. Urban Design and Adapting to Flood Risk: The Role of Green Infrastructure. J. Urban Des. 2014, 19, 745–758. [Google Scholar] [CrossRef]

- Yiwo, E.; Jato-Espino, D.; Carracedo, P.; De Brito, M.M. Multi-Stakeholder Perception on Flood Management in Ghana: Analysis of Drivers and Potential Solutions, with a Focus on Surface Permeability. Int. J. Disaster Risk Reduct. 2022, 76, 102990. [Google Scholar] [CrossRef]

- Zeleňáková, M.; Zvijáková, L. Environmental Impact Assessment of Structural Flood Mitigation Measures: A Case Study in Šiba, Slovakia. Environ. Earth Sci. 2016, 75, 795. [Google Scholar] [CrossRef]

- Kim, Y.J.; Gaddafi, A.; Yoshitake, I. Permeable Concrete Mixed with Various Admixtures. Mater. Des. 2016, 100, 110–119. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Hussin, M.W.; Rafieizonooz, M. Properties of Sustainable Lightweight Pervious Concrete Containing Oil Palm Kernel Shell as Coarse Aggregate. Constr. Build. Mater. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Fanijo, E.; Babafemi, A.J.; Arowojolu, O. Performance of Laterized Concrete Made with Palm Kernel Shell as Replacement for Coarse Aggregate. Constr. Build. Mater. 2020, 250, 118829. [Google Scholar] [CrossRef]

- Shan, J.; Zhang, Y.; Wu, S.; Lin, Z.; Li, L.; Wu, Q. Pore Characteristics of Pervious Concrete and Their Influence on Permeability Attributes. Constr. Build. Mater. 2022, 327, 126874. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Comprehensive Investigation of Permeability Characteristics of Pervious Concrete: A Hydrodynamic Approach. Constr. Build. Mater. 2016, 123, 627–637. [Google Scholar] [CrossRef]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of Aggregate Type and Size on Properties of Pervious Concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Bright Singh, S.; Madasamy, M. Investigation of Aggregate Size Effects on Properties of Basalt and Carbon Fibre-Reinforced Pervious Concrete. Road Mater. Pavement Des. 2022, 23, 1305–1328. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Kizinievic, O.; Sarkauskas, A. The Impact of Coarse Aggregate Content on Infiltration Rate, Structure and Other Physical & Mechanical Properties of Pervious Concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 569–582. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Muhit, B.A.A.; Jumaat, M.Z.B. Utilization of Oil Palm Kernel Shell as Lightweight Aggregate in Concrete—A Review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Ikumapa, O.M.; Akinlab, E.T. Composition, Characteristics and Socioeconomic Benefits of Palm Kernel Shell Exploitation-An Overview. J. Environ. Sci. Technol. 2018, 11, 220–232. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Ukoba, K.O.; Jen, T.-C. Synthesis and Characterization of Amorphous Mesoporous Silica from Palm Kernel Shell Ash. Boletín Soc. Española Cerámica Vidr. 2020, 59, 159–164. [Google Scholar] [CrossRef]

- Sriravindrarajah, R.; Wang, N.D.H.; Ervin, L.J.W. Mix Design for Pervious Recycled Aggregate Concrete. Int. J. Concr. Struct. Mater. 2012, 6, 239–246. [Google Scholar] [CrossRef]

- Oti, O.P.; Nwaigwe, K.N.; Okereke, N.A.A. Assessment of Palm Kernel Shell as a Composite Aggregate in Concrete. Agric. Eng. Int. CIGR J. 2017, 19, 34–41. [Google Scholar]

- Khankhaje, E.; Rafieizonooz, M.; Salim, M.R.; Mirza, J.; Salmiati; Hussin, M.W. Comparing the Effects of Oil Palm Kernel Shell and Cockle Shell on Properties of Pervious Concrete Pavement. Int. J. Pavement Res. Technol. 2017, 10, 383–392. [Google Scholar] [CrossRef]

- Sathish, D.; Mohankumar, C. RAPD Markers for Identifying Oil Palm (Elaeis Guineensis Jacq.) Parental Varieties (Dura & Pisifera) and the Hybrid Tenera. Indian J. Biotechnol. 2007, 6, 354–358. [Google Scholar]

- Babu, B.K.; Mathur, R.K.; Kumar, P.N.; Ramajayam, D.; Ravichandran, G.; Venu, M.V.B.; Babu, S.S. Development, Identification and Validation of CAPS Marker for SHELL Trait Which Governs Dura, Pisifera and Tenera Fruit Forms in Oil Palm (Elaeis Guineensis Jacq.). PLoS ONE 2017, 12, e0171933. [Google Scholar] [CrossRef]

- Khankhaje, E.; Salim, M.R.; Mirza, J.; Salmiati; Hussin, M.W.; Khan, R.; Rafieizonooz, M. Properties of Quiet Pervious Concrete Containing Oil Palm Kernel Shell and Cockleshell. Appl. Acoust. 2017, 122, 113–120. [Google Scholar] [CrossRef]

- Acheampong, A.; Adom-Asamoah, M.; Ayarkwa, J.; Afrifa, R. Comparative Study of the Physical Properties of Palm Kernel Shell Concrete and Normal Concrete in Ghana. J. Sci. Multidiscip. Res. 2013, 5, 129–146. [Google Scholar]

- CEN EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee For Standardisation: London, UK, 2012.

- CEN EN 933-2:2020; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. European Committee For Standardisation: London, UK, 2020.

- CEN EN 933-3:2012; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. European Committee For Standardisation: London, UK, 2012.

- CEN EN 933-4:2008; Tests for Geometrical Properties of Aggregates—Part 4: Determination of Particle Shape—Shape Index. European Committee For Standardisation: London, UK, 2008.

- CEN EN 932-2:1999; Tests for General Properties of Aggregates—Part 2: Methods for Reducing Laboratory Samples. European Committee For Standardisation: London, UK, 1999.

- CEN EN 1097-3:1998; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. European Committee For Standardisation: London, UK, 1998.

- CEN EN 1097-6:2022; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee For Standardisation: London, UK, 2022.

- CEN EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. European Committee For Standardisation: London, UK, 2019.

- Ikubanni, P.P.; Oki, M.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S. Influence of Temperature on the Chemical Compositions and Microstructural Changes of Ash Formed from Palm Kernel Shell. Results Eng. 2020, 8, 100173. [Google Scholar] [CrossRef]

- Shehu, U.; Aponbiede, O.; Ause, T. Effect of Particle Size on the Properties of Polyester/Palm Kernel Shell (PKS) Particulate Composites. J. Mater. Environ. Sci. 2014, 5, 366–373. [Google Scholar]

- Zubair Yahaya, A.; Rao Somalu, M.; Muchtar, A.; Anwar Sulaiman, S.; Ramli Wan Daud, W. Effects of Temperature on the Chemical Composition of Tars Produced from the Gasification of Coconut and Palm Kernel Shells Using Downdraft Fixed-Bed Reactor. Fuel 2020, 265, 116910. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.; Yahia, A. Pervious Concrete: Mix Design, Properties and Applications. RILEM Tech. Lett. 2016, 1, 109–115. [Google Scholar] [CrossRef]

- CEN EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. European Committee For Standardisation: London, UK, 2019.

- UNE UNE 83980:2014; Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete. European Committee For Standardisation: London, UK, 2014.

- CEN EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee For Standardisation: London, UK, 2019.

- CEN EN 12390-6:2009; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. European Committee For Standardisation: London, UK, 2009.

- CEN EN 12697-19:2020; Bituminous Mixtures—Test Methods—Part 19: Permeability of Specimen. European Committee For Standardisation: London, UK, 2020.

- Yilmaz, D.; Sabre, M.; Lassabatère, L.; Dal, M.; Rodriguez, F. Storm Water Retention and Actual Evapotranspiration Performances of Experimental Green Roofs in French Oceanic Climate. Eur. J. Environ. Civ. Eng. 2016, 20, 344–362. [Google Scholar] [CrossRef]

- SANS 1083:2006; Aggregates from Natural Sources: Aggregates for Concrete. Ed. 2.2. South African Bureau of Standards (SABS): Pretoria, South Africa, 2006.

- CEN EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee For Standardisation: London, UK, 2008.

- Tam, V.W.Y.; Tam, C.M. Parameters for Assessing Recycled Aggregate and Their Correlation. Waste Manag Res 2009, 27, 52–58. [Google Scholar] [CrossRef]

- Akbulut, H.; Gürer, C. Use of Aggregates Produced from Marble Quarry Waste in Asphalt Pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Yahia, A.; Kabagire, K.D. New Approach to Proportion Pervious Concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

- Gillott, J.E. Properties of Aggregates Affecting Concrete in North America. QJEGH 1980, 13, 289–303. [Google Scholar] [CrossRef]

- Powers, T.C. The Physical Structure and Engineering Properties of Concrete; Research Department Bulletin; Portland Cement Association: Washington, DC, USA, 1958; Volume 90. [Google Scholar]

- Yang, J.; Jiang, G. Experimental Study on Properties of Pervious Concrete Pavement Materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Aoki, Y. Development of Pervious Concrete; University of Technology Sydney (UTS): Sydney, Australia, 2009. [Google Scholar]

- Ibrahim, R.; Rashidi, A.; Said, N.S.; Othman, M.S. Engaging Capability Training in Serious Game Technology for Delivering Industrialized Construction. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 2095–2102. [Google Scholar]

- ACI SPEC-522.1-20; Specification for Construction of Pervious Concrete Pavement. ACI Committee: Farmington Hills, MI, USA.

- Güneyisi, E.; Gesoğlu, M.; Booya, E.; Mermerdaş, K. Strength and Permeability Properties of Self-Compacting Concrete with Cold Bonded Fly Ash Lightweight Aggregate. Constr. Build. Mater. 2015, 74, 17–24. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A Comparative Study of Concrete Properties Using Coconut Shell and Palm Kernel Shell as Coarse Aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious Concrete Mixture Optimization, Physical, and Mechanical Properties and Pavement Design: A Review. J. Clean. Prod. 2021, 288, 125095. [Google Scholar] [CrossRef]

- Titiksh, A.; Wanjari, S.P. Hyper-Plasticizer Dosed Concrete Pavers Containing Fly Ash in Lieu of Fine Aggregates—A Step towards Sustainable Construction. Case Stud. Constr. Mater. 2022, 17, e01338. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.-J.; Liang, D. Mechanical Properties of Pervious Cement Concrete. J. Cent. South Univ. 2012, 19, 3329–3334. [Google Scholar] [CrossRef]

- Malami, S.I.; Musa, A.A.; Haruna, S.I.; Aliyu, U.U.; Usman, A.G.; Abdurrahman, M.I.; Bashir, A.; Abba, S.I. Implementation of Soft-Computing Models for Prediction of Flexural Strength of Pervious Concrete Hybridized with Rice Husk Ash and Calcium Carbide Waste. Model. Earth Syst. Environ. 2022, 8, 1933–1947. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, H.; Deng, Z.; He, J. Water Permeability of Pervious Concrete Is Dependent on the Applied Pressure and Testing Methods. Adv. Mater. Sci. Eng. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Martin, W.D.; Kaye, N.B.; Putman, B.J. Impact of Vertical Porosity Distribution on the Permeability of Pervious Concrete. Constr. Build. Mater. 2014, 59, 78–84. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).