Uncovering the Efficiency and Performance of Ground-Source Heat Pumps in Cold Regions: A Case Study of a Public Building in Northern China

Abstract

:1. Introduction

2. System Profile

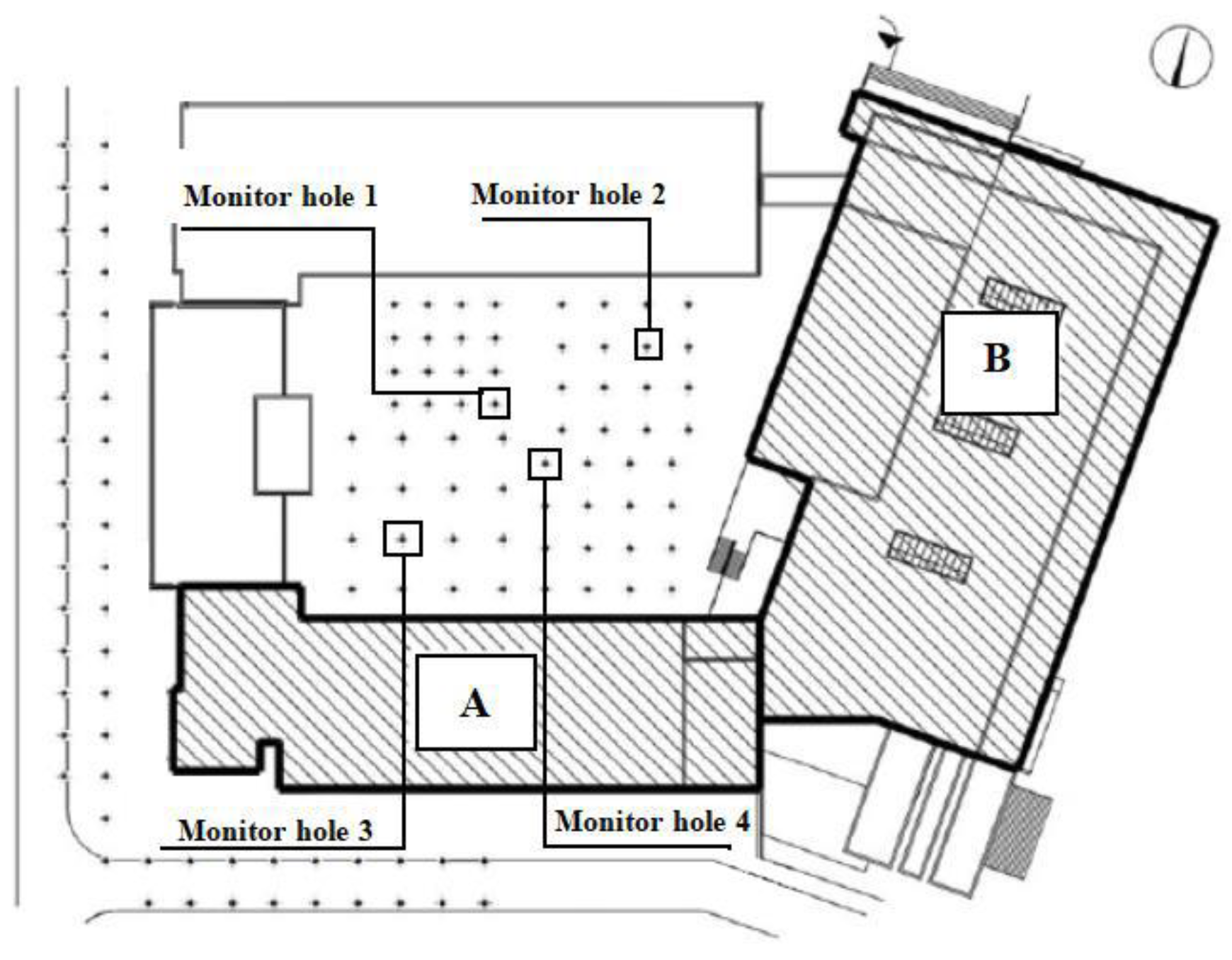

2.1. Project Overview

2.2. Area Thermal Compensation Technology

3. Methods

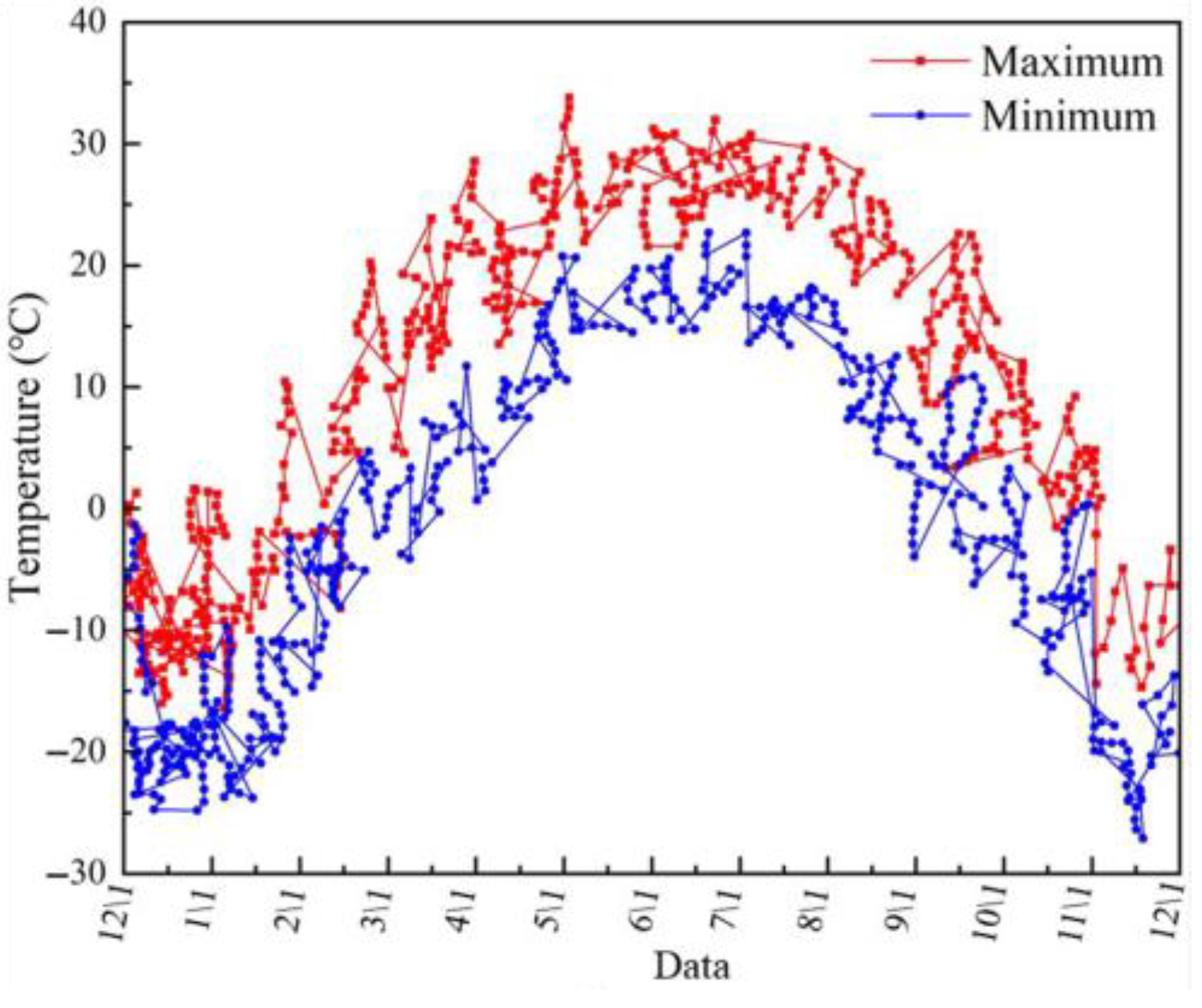

3.1. Operation Data Monitoring of GSHPs

3.1.1. Energy Efficiency Calculation

3.1.2. Energy Saving Benefit

3.1.3. Monitoring of Underground Soil Temperature Data

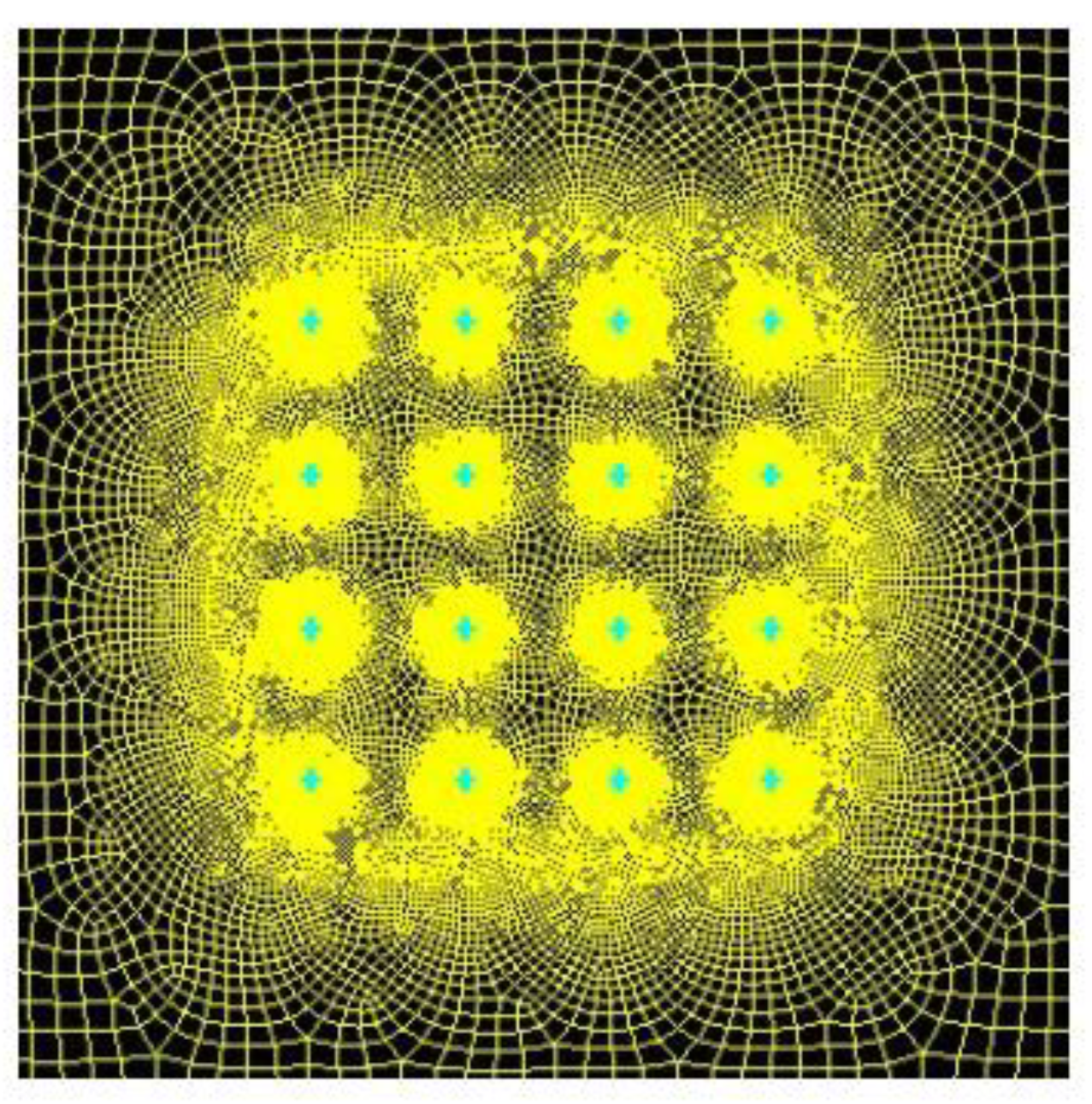

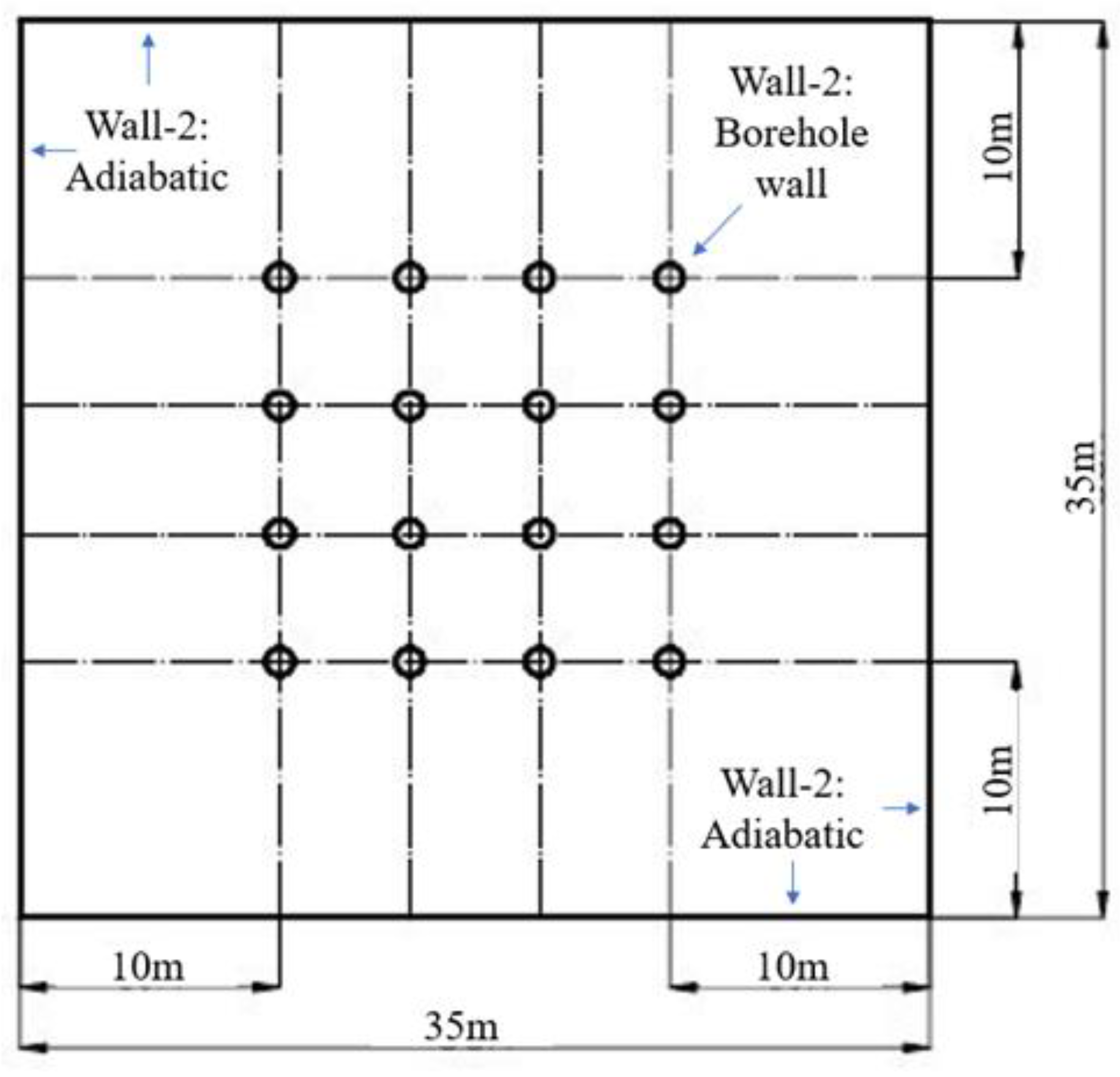

3.2. Soil Temperature Simulation Study

3.2.1. Model Description

3.2.2. Governing Equation

3.2.3. Model Simplification

- (1)

- In the whole heat transfer, the average soil physical property parameters are calculated;

- (2)

- The initial soil temperature is assumed to be uniform;

- (3)

- The soil density, thermal conductivity, specific heat, and other parameters do not change with soil temperature and depth;

- (4)

- The thermal migration caused by water migration in the soil is ignored, i.e., the heat transfer mode between the soil and buried pipe is assumed to be pure heat conduction.

4. Results and Discussion

4.1. Performance Analysis

4.2. Analysis of Energy Saving Benefits

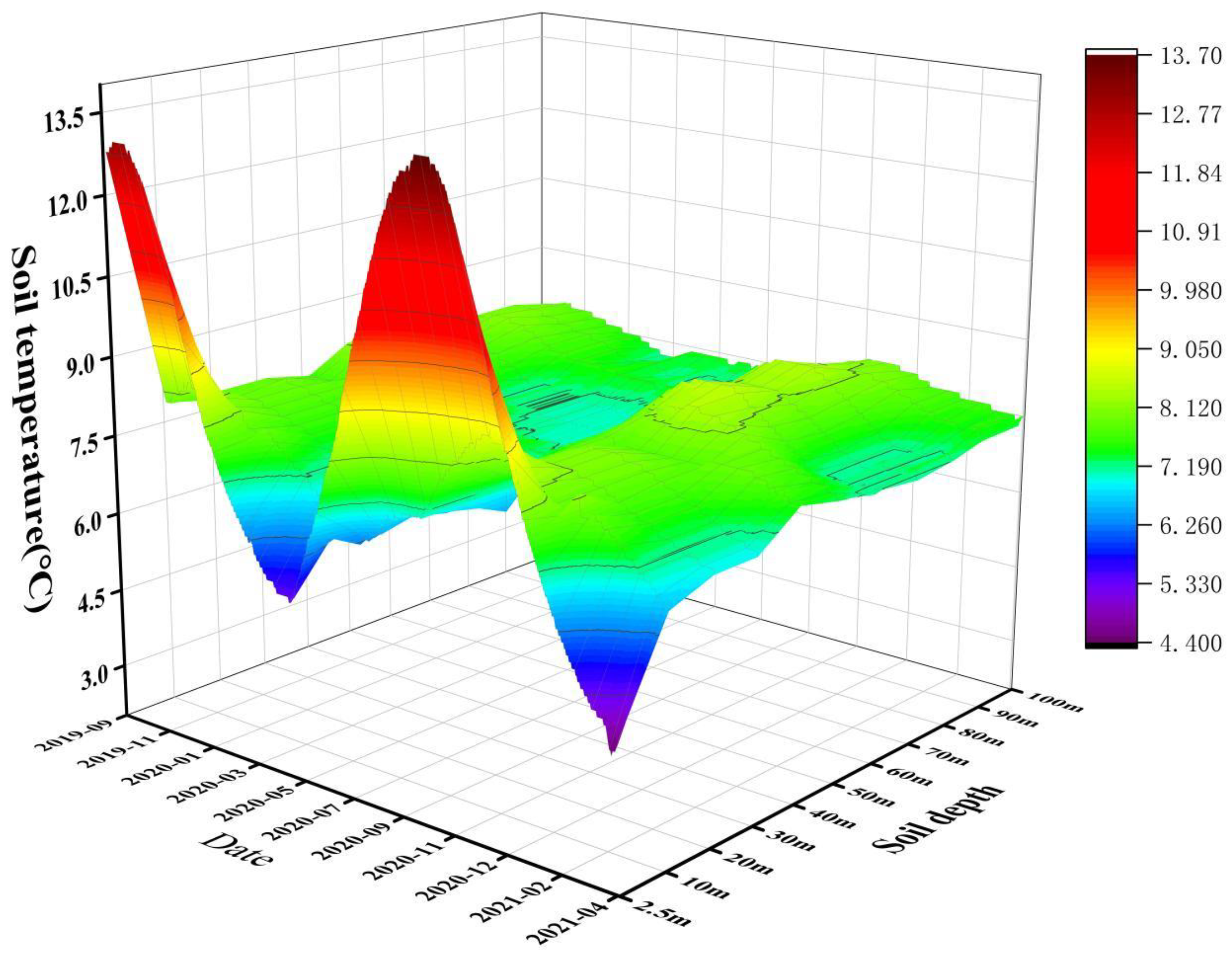

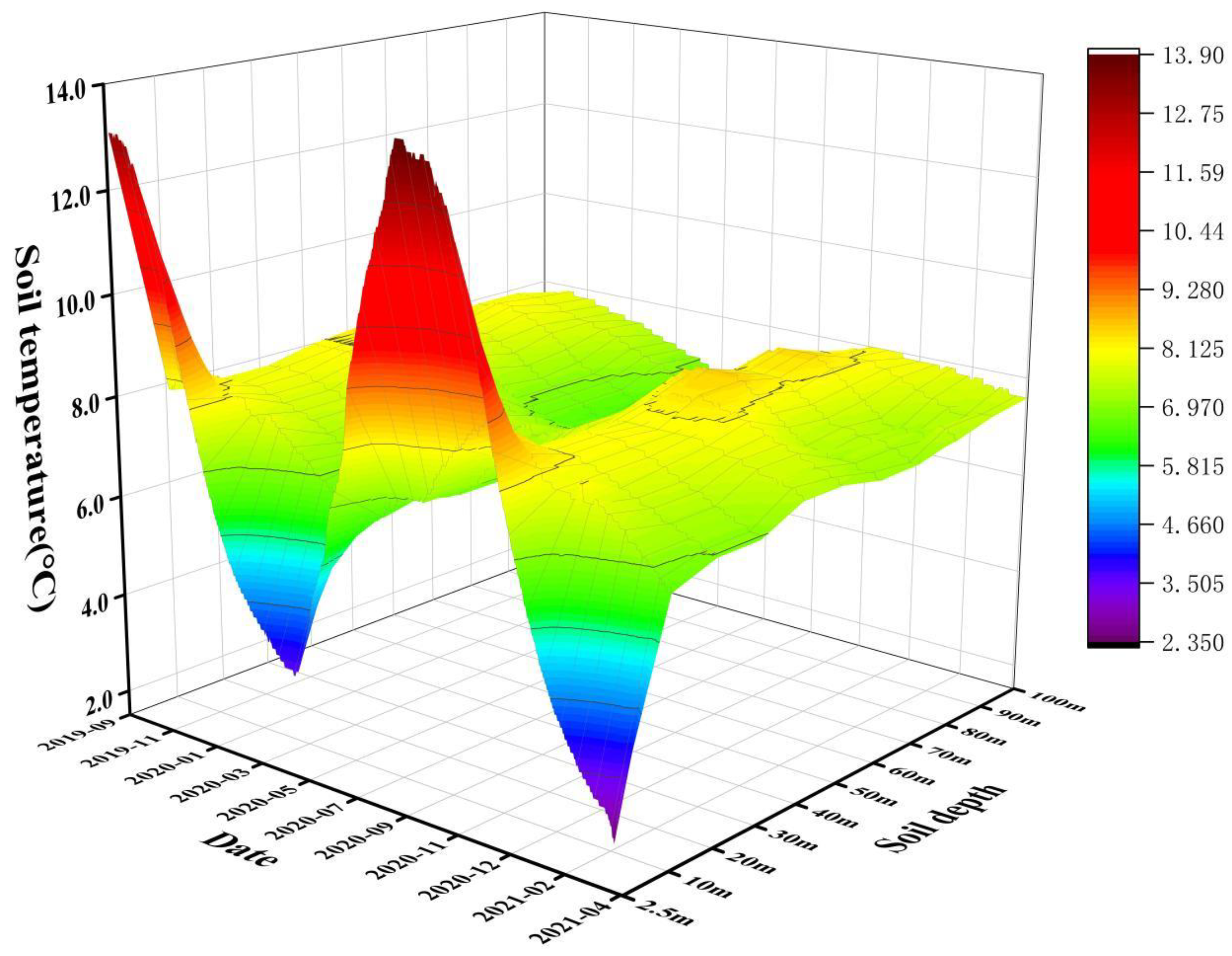

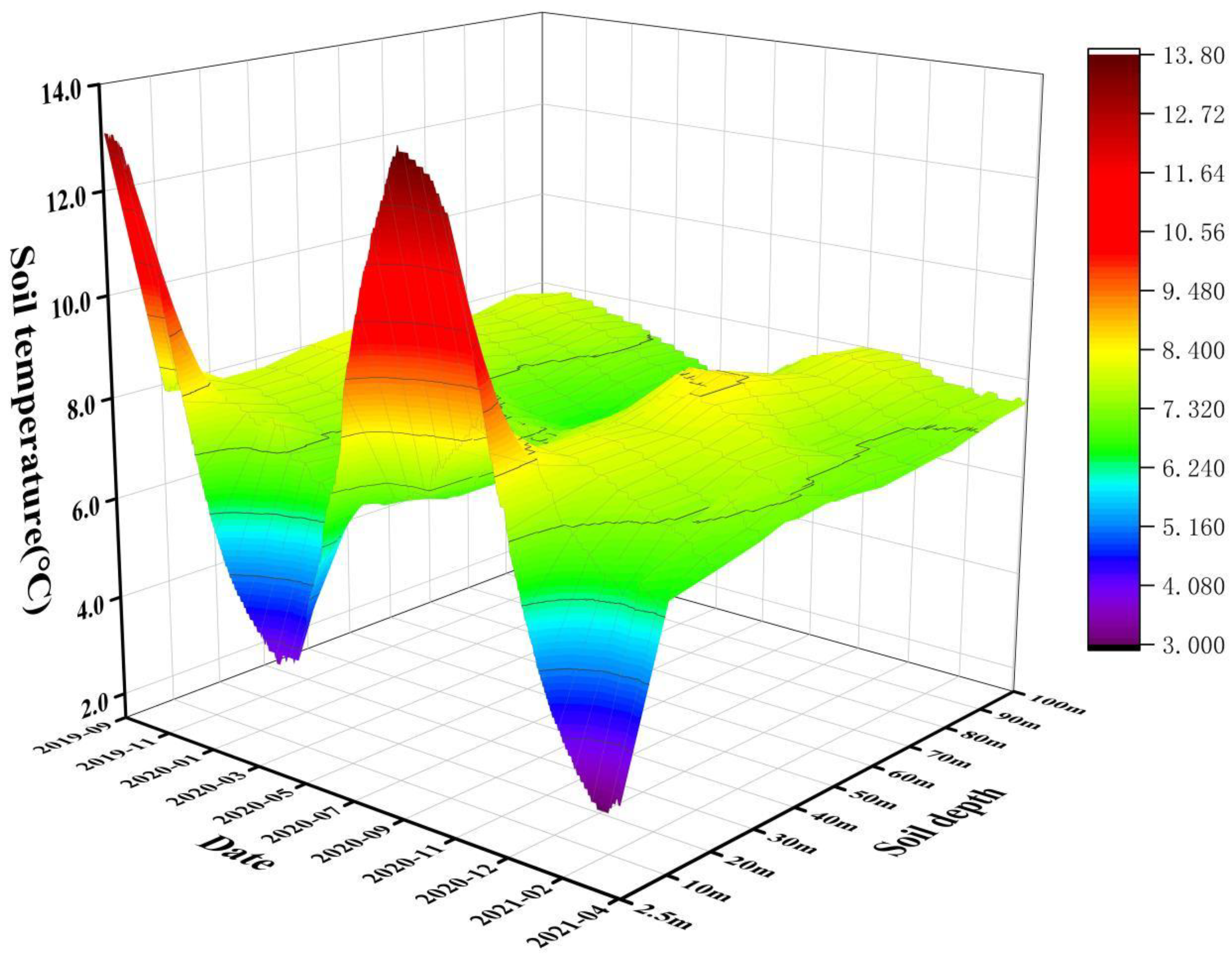

4.3. Analysis of Soil Temperature Monitoring Data

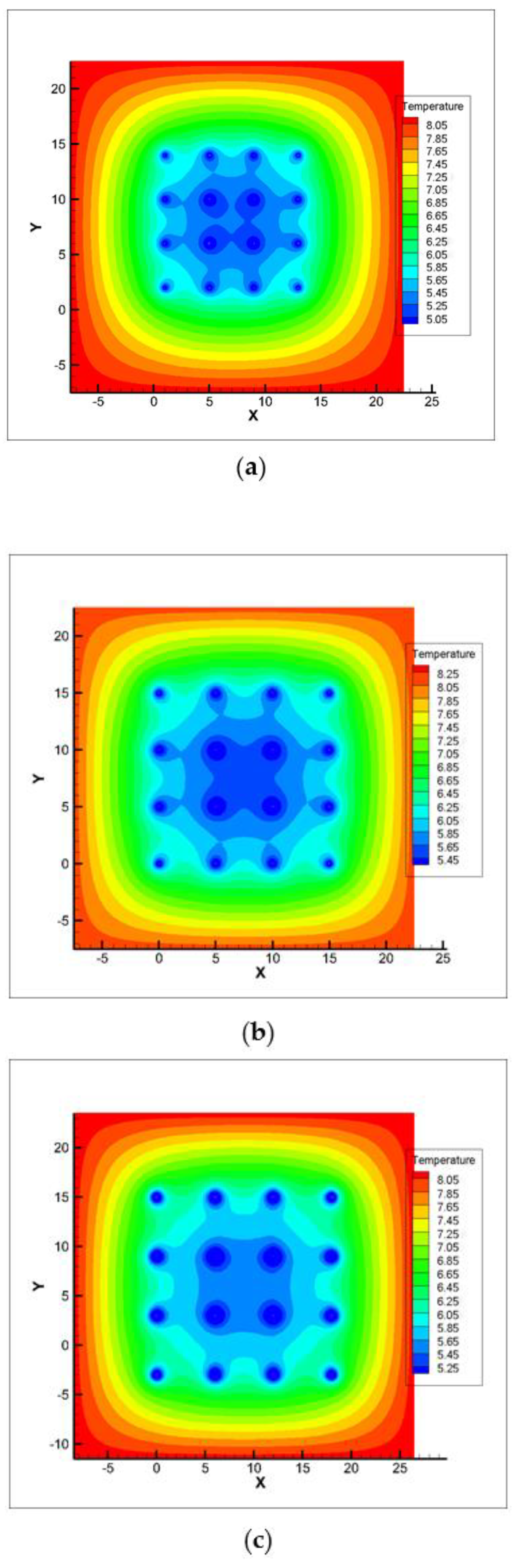

4.4. Simulation Results and Analysis

Verification of Simulation Results

4.5. Optimization Scheme of Heat Exchange Hole Spacing

5. Conclusions

- (1)

- After the long-term operation of GSHPs over 8 years, the soil temperature difference varied between 0.13 °C and 0.51 °C, and the maximum reduction rate was 2.78%. Because the system uses the area compensation technology, by changing the heating and cooling area, the cold and hot load balance was maintained, and the soil temperature field changes tended to be stable after the long-term operation of the system. The results show that the area compensation technology can effectively alleviate the soil heat imbalance in the cold region.

- (2)

- In the long-term operation of GSHPs over 8 years, the average COP of the unit in the winter working condition was 4.42, and the compliance rate ranged between 89.33% and 95.27%. The highest COP was 4.52, the lowest COP was 4.33, and the change rate was 4.2%. In summer, the average COP was 4.84, and the compliance rate ranged between 94.98% and 96.75%. The highest COP was 4.91, the lowest COP was 4.79, and the change rate was 2.4%. The results show that the system can maintain the stability of the soil temperature field using area compensation technology, which can effectively guarantee the stable and efficient operation of the system in long-term operation.

- (3)

- After the area compensation technology was used in the soil source heat pump system, the maximum decrease rates of the soil temperature were 2.78%, 2.28%, and 2.02% after the long-term operation of heat exchange hole groups with different spacings of 4 m, 5 m, and 6 m. After 30 years of the long-term operation of the simulation system, the temperature drop rates of the soil temperature of 100 m with spacings of 4 m, 5 m, and 6 m were 26.82%, 24.39%, and 21.95%. The measured and simulated results show that the three different spaces of the heat transfer hole groups exhibited little differences in the soil temperature change. The results show that in severe cold areas, when the project area of the GSHP is limited, it is not necessary to excessively attempt to increase the heat exchange hole spacing to maintain the heat balance of the soil temperature field. If the heat exchange hole spacing is 4 m, it can still run stably and efficiently when the cold and heat load is balanced using appropriate methods. Taking the actual number of heat exchange holes in the project as an example, the minimum floor area with 4 m heat exchange hole spacing was reduced by 36% and 55.5%, respectively, compared with that of 5 m and 6 m heat exchange hole spacings. This further shows that, by applying soil source heat pump systems in densely populated cities in cold areas and arranging boreholes at 4 m spacings, more boreholes can be accommodated in the same footprint, reducing the total footprint required for the system, which in turn reduces the cost of land occupation and construction costs, as well as horizontal pipe connection costs. Moreover, the smaller footprint reduces disturbance to underground utilities and buildings, which can reduce the additional work and costs associated with underground work. This also facilitates the use and promotion of GSHPs in colder regions.

- (4)

- After 8 years of the long-term operation of GSHPs, compared with traditional coal-fired boilers and traditional air conditioning methods, the cumulative coal saving amount was 639.58 t, the cumulative CO2 emission reduction was 1579.75 t, the SO2 emission reduction was 12.79 t, and the soot emission reduction was 6.39 t. The results show that the use of GSHPs in severe cold regions can effectively reduce the use of coal energy and reduce CO2 and pollutant emissions, which is of great significance for China to speed up adjustments in its traditional energy structure and promote carbon peak carbon neutralization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Q | average heat production (cooling capacity) of unit [kW] |

| Ni | unit average input power [kW] |

| V | user side average flow [m3/h] |

| ρ | density [kg/m3] |

| C | specific heat capacity at constant pressure [kJ/(kg·°C)] |

| ∆t | temperature difference between supply and return water at user side [°C] |

| Qs | total heat production (cooling capacity) of the heat pump system [kW·h] |

| P | total power consumed by the system [kW·h] |

| CS | heat pump heating consumption converted standard coal amount [t] |

| EH | annual energy consumption of the heat pump system [kW·h] |

| η | electrical energy conversion rate [%] |

| c | standard coal heat [kJ/kg] |

| Cbs | converted into standard coal consumption in boiler heating form [t] |

| QH | building annual cumulative heat load [kW·h] |

| ηb | electrical energy conversion rate [%] |

| κ | energy consumption ratio of end-circulating pump to system |

| CL | converted into the standard coal consumption of heat pump cooling [t] |

| EL | annual cooling power consumption of heat pump system [kW·h] |

| CCL | converted into the standard coal consumption of water chiller [t] |

| QL | building annual cumulative cooling load [kW·h] |

| QCO2 | carbon dioxide emission reduction [t/a] |

| QSO2 | sulfur dioxide emission reduction [t/a] |

| QSoot | soot emission reduction [t/a] |

| Qbm | standard coal saving [t/a] |

| 2.47 | carbon dioxide emission factor of standard coal |

| 0.02 | sulfur dioxide emission factor of standard coal |

| 0.01 | standard coal soot emission factor, dimensionless |

| x, y, z | right-angle coordinate system in three coordinate directions [m] |

| u, v, w | flow velocity in three right-angle coordinate directions [s] |

| ν | dynamic viscosity [Pa·s] |

| P | pressure on the fluid micro-element [Pa] |

| T | temperature [k] |

| a | thermal diffusivity [m2/s] |

| Acronyms | |

| GSHP | soil source heat pump system |

| COP | coefficient of performance |

| SPF | seasonal performance factor |

| GHE | ground heat exchanger |

| CFD | computational fluid dynamics |

| HVAC | heating, ventilation, air conditioning, and cooling |

References

- Wang, W.; Huo, J.-H.; Tao, Y.-T.; Lei, B.; Wu, Y.-T.; Ma, C.-F. Semi-empirical modelling and analysis of single screw expanders considering inlet and exhaust pressure losses. Energy 2023, 266, 126356. [Google Scholar] [CrossRef]

- Xi, C.; Lin, L.; Hongxing, Y. Long term operation of a solar assisted ground coupled heat pump system for space heating and domestic hot water. Energy Build. 2011, 43, 1835–1844. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, J.; Xu, W.; Zhang, G. Current status of ground-source heat pumps in China. Energy Policy 2010, 38, 323–332. [Google Scholar] [CrossRef]

- Hepbasli, A.; Akdemir, O.; Hancioglu, E. Experimental study of a closed loop vertical ground source heat pump system. Energy Convers. Manag. 2003, 44, 527–548. [Google Scholar] [CrossRef]

- Mousa, M.M.; Bayomy, A.M.; Saghir, M.Z. Long-term performance investigation of a GSHP with actual size energy pile with PCM. Appl. Therm. Eng. 2022, 210, 118381. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, Z.; Fang, J.; Cao, S.-J. Impact of ventilation rates on indoor thermal comfort and energy efficiency of ground-source heat pump system. Sustain. Cities Soc. 2018, 37, 154–163. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. Examination of thermal interaction of multiple vertical ground heat exchangers. Appl. Energy 2012, 97, 962–969. [Google Scholar] [CrossRef]

- Yuan, Y.; Cao, X.; Wang, J.; Sun, L. Thermal interaction of multiple ground heat exchangers under different intermittent ratio and separation distance. Appl. Therm. Eng. 2016, 108, 277–286. [Google Scholar] [CrossRef]

- İnallı, M.; Esen, H. Experimental thermal performance evaluation of a horizontal ground-source heat pump system. Appl. Therm. Eng. 2004, 24, 2219–2232. [Google Scholar] [CrossRef]

- Blum, P.; Campillo, G.; Münch, W.; Kölbel, T. CO2 savings of ground source heat pump systems–A regional analysis. Renew. Energy 2010, 35, 122–127. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, W.; Qian, C.; Chen, X.; Jin, G. Investigation on the feasibility and performance of ground source heat pump (GSHP) in three cities in cold climate zone, China. Renew. Energy 2015, 84, 89–96. [Google Scholar] [CrossRef]

- You, T.; Wu, W.; Shi, W.; Wang, B.; Li, X. An overview of the problems and solutions of soil thermal imbalance of ground-coupled heat pumps in cold regions. Appl. Energy 2016, 177, 515–536. [Google Scholar] [CrossRef]

- Qian, H.; Wang, Y. Modeling the interactions between the performance of ground source heat pumps and soil temperature variations. Energy Sustain. Dev. 2014, 23, 115–121. [Google Scholar] [CrossRef]

- Yu, T.; Liu, Z.; Chu, G.; Qu, Y. Influence of Intermittent Operation on Soil Temperature and Energy Storage Duration of Ground-Source Heat Pump System for Residential Building. In Proceedings of the 8th International Symposium on Heating, Ventilation and Air Conditioning; Springer: Berlin/Heidelberg, Germany, 2014; pp. 203–213. [Google Scholar]

- You, T.; Wang, B.; Wu, W.; Shi, W.; Li, X. Performance analysis of hybrid ground-coupled heat pump system with multi-functions. Energy Convers. Manag. 2015, 92, 47–59. [Google Scholar] [CrossRef]

- Shang, Y.; Dong, M.; Li, S. Intermittent experimental study of a vertical ground source heat pump system. Appl. Energy 2014, 136, 628–635. [Google Scholar] [CrossRef]

- Retkowski, W.; Ziefle, G.; Thöming, J. Evaluation of different heat extraction strategies for shallow vertical ground-source heat pump systems. Appl. Energy 2015, 149, 259–271. [Google Scholar] [CrossRef]

- Kurevija, T.; Vulin, D.; Krapec, V. Effect of borehole array geometry and thermal interferences on geothermal heat pump system. Energy Convers. Manag. 2012, 60, 134–142. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, W.; Sun, J.; Xu, X.; Wang, R.; Lu, Y.; Zhang, S.; Zhou, W. Assessing the effects of 2D/3D urban morphology on the 3D urban thermal environment by using multi-source remote sensing data and UAV measurements: A case study of the snow-climate city of Changchun, China. J. Clean. Prod. 2021, 321, 128956. [Google Scholar] [CrossRef]

- Daemi, N.; Krol, M.M. Impact of building thermal load on the developed thermal plumes of a multi-borehole GSHP system in different canadian climates. Renew. Energy 2019, 134, 550–557. [Google Scholar] [CrossRef]

- Liu, X.; Ren, H.; Wu, Y.; Kong, D. An analysis of the demonstration projects for renewable energy application buildings in China. Energy Policy 2013, 63, 382–397. [Google Scholar] [CrossRef]

- Sang, J.; Liu, X.; Liang, C.; Feng, G.; Li, Z.; Wu, X.; Song, M. Differences between design expectations and actual operation of ground source heat pumps for green buildings in the cold region of northern China. Energy 2022, 252, 124077. [Google Scholar] [CrossRef]

- Nouri, G.; Noorollahi, Y.; Yousefi, H. Designing and optimization of solar assisted ground source heat pump system to supply heating, cooling and hot water demands. Geothermics 2019, 82, 212–231. [Google Scholar] [CrossRef]

- Ma, G.; Gu, F.; Gu, J.; Li, X. Numerical Simulation on Soil Temperature Field around Underground Hot Oil Pipelines and Medium Temperature-Drop in the Process of Staring. In ICPTT 2009; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 373–380. [Google Scholar]

- Gao, Z.; Hu, Z.; Chen, T.; Xu, X.; Feng, J.; Zhang, Y.; Su, Q.; Ji, D. Numerical study on heat transfer efficiency for borehole heat exchangers in Linqu County, Shandong Province, China. Energy Rep. 2022, 8, 5570–5579. [Google Scholar] [CrossRef]

- Michopoulos, A.; Zachariadis, T.; Kyriakis, N. Operation characteristics and experience of a ground source heat pump system with a vertical ground heat exchanger. Energy 2013, 51, 349–357. [Google Scholar] [CrossRef]

- Yao, X.P. Study and Numerical Analysis of Soil Temperature Field of Soil Source Heat Pump Heat Exchanger in Cold Regio. Master’s Thesis, Harbin University of Commerce, Harbin, China, 2020. [Google Scholar]

| Heating Days Z (d) | Heating Degree-Days (°C d) | Mean Temperature (°C) | Outdoor Dry Bulb Temperature for Heating (°C) | Outdoor Relative Humidity for Heating (%) | Minimum Temperature (°C) |

|---|---|---|---|---|---|

| 168 | 4471 | 4.8 | −23 | 69 | −39.8 |

| Device | Model | Quantity | Heating Condition /Cooling Condition (kW) | Pump Head (m) | Flow (m3/h) |

|---|---|---|---|---|---|

| GSHP | AQSW0612 | 2 | 184.1/216.6 | - | - |

| Circulating pump | QPG80-160 | 3 | - | 28 | 46.7 |

| Circulating pump | QPG80-160 | 3 | - | 24 | 43.3 |

| Original Soil Temperature (°C) | Soil Heat Transfer Coefficient (W/(m·°C)) | Soil Density (kg/m³) | Specific Heat Capacity of Soil J/(kg·°C) | Ethylene Glycol Thermal Conductivity W/(m·°C) | Ethylene Glycol Density (kg/m3) | Specific Heat Capacity of Ethylene Glycol J/(kg·°C) | Heat Transfer (w/m) | Thermal Conductivity of Wells W/(m·°C) | Thermal Resistance of Wells (m·°C)/W |

|---|---|---|---|---|---|---|---|---|---|

| 8.31 | 2.573 | 2200 | 950 | 0.442 | 1050.33 | 3603 | 25 | 2.24 | 0.227 |

| Cum | C1-Epsilon | C2-Epsilon | TKE Prandtl Number | TDR Prandtl Number |

|---|---|---|---|---|

| 0.09 | 1.44 | 1.92 | 1 | 1.3 |

| Running Time (Winter) | Heating Capacity (kW·h) | COP Variation Range | Average COP | Rate of Compliance (%) | Running Time (Summer) | Cooling Capacity (kW·h) | COP Variation Range | Average COP | Rate of Compliance (%) | Electricity Consumption (kW·h) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2013 | 526,505.98 | 3.06–5.15 | 4.37 | 93.56 | 2013 | - | - | - | - | 101,705 |

| 2014 | 531,574.05 | 3.51–5.38 | 4.52 | 95.27 | 2014 | 525,873.65 | 4.22–5.89 | 4.91 | 96.75 | 154,897 |

| 2015 | 437,091.95 | 3.78–5.22 | 4.43 | 93.68 | 2015 | 427,107.59 | 3.74–5.84 | 4.86 | 96.52 | 138,580 |

| 2016 | 527,108.87 | 3.42–5.15 | 4.51 | 92.71 | 2016 | 525,365.71 | 3.76–5.92 | 4.81 | 96.34 | 149,876 |

| 2017 | 530,755.05 | 3.39–5.16 | 4.49 | 91.26 | 2017 | 528,973.06 | 3.95–5.88 | 4.79 | 95.48 | 153,478 |

| 2018 | 527,786.72 | 3.48–5.01 | 4.38 | 91.18 | 2018 | 519,234.18 | 4.05–5.93 | 4.83 | 96.02 | 150,254 |

| 2019 | 531,244.58 | 3.56–4.95 | 4.33 | 89.97 | 2019 | 529,723.19 | 4.08–5.98 | 4.84 | 95.23 | 149,537 |

| 2020 | 426,588.72 | 3.65–4.84 | 4.34 | 89.33 | 2020 | 424,518.62 | 3.72–5.87 | 4.88 | 94.98 | 137,584 |

| Running Time (Winter) | SPF Variation Range | Average SPF | Rate of Compliance (%) | Running Time (Summer) | SPF Variation Range | Average SPF | Rate of Compliance (%) |

|---|---|---|---|---|---|---|---|

| 2013 | 2.07–3.76 | 3.08 | 97.32 | 2013 | - | - | - |

| 2014 | 2.09–3.59 | 3.02 | 97.46 | 2014 | 2.86–3.68 | 2.95 | 98.36 |

| 2015 | 2.58–4.07 | 3.11 | 98.57 | 2015 | 2.51–3.49 | 2.82 | 97.78 |

| 2016 | 2.47–3.56 | 2.95 | 96.73 | 2016 | 2.66–3.74 | 2.95 | 97.86 |

| 2017 | 2.12–3.67 | 2.97 | 96.62 | 2017 | 2.95–3.89 | 3.18 | 98.55 |

| 2018 | 2.38–3.71 | 2.86 | 95.89 | 2018 | 2.78–3.88 | 2.98 | 97.72 |

| 2019 | 2.45–3.68 | 2.92 | 96.97 | 2019 | 2.61–3.79 | 2.93 | 96.89 |

| 2020 | 2.23–3.66 | 2.89 | 96.88 | 2020 | 2.57–3.85 | 2.95 | 97.91 |

| Running Time (Year) | Winter Energy Saving (Tons of Standard Coal) | Summer Energy Saving (Tons of Standard Coal) | Annual Energy Saving (Tons of Standard Coal) | Annual CO2 Reduction (t) | Annual SO2 Reduction (t) | Annual Soot Reduction (t) |

|---|---|---|---|---|---|---|

| 2013 | 50.96 | 0 | 50.96 | 125.87 | 1.0192 | 0.5096 |

| 2014 | 50.22 | 35.13 | 85.35 | 210.81 | 1.707 | 0.8535 |

| 2015 | 45.45 | 36.54 | 81.99 | 202.51 | 1.6398 | 0.8199 |

| 2016 | 48.54 | 35.85 | 84.39 | 208.44 | 1.6878 | 0.8439 |

| 2017 | 50.65 | 36.72 | 87.37 | 215.81 | 1.7474 | 0.8737 |

| 2018 | 47.88 | 34.98 | 82.86 | 204.66 | 1.6572 | 0.8286 |

| 2019 | 48.36 | 35.47 | 83.83 | 207.06 | 1.6766 | 0.8383 |

| 2020 | 46.72 | 36.11 | 82.83 | 204.59 | 1.6566 | 0.8283 |

| Running Time (Winter) | Average Thermal Coal Price (CNY/t) | Total Amount (CNY) | Running Time (Summer) | Average Thermal Coal Price (CNY/t) | Total Amount (CNY) |

|---|---|---|---|---|---|

| 2013 | 554 | 28,232 | 2013 | — | — |

| 2014 | 489 | 24,558 | 2014 | 482 | 16,933 |

| 2015 | 375 | 17,044 | 2015 | 401 | 14,653 |

| 2016 | 638 | 30,969 | 2016 | 462 | 16,563 |

| 2017 | 611 | 30,947 | 2017 | 589 | 21,628 |

| 2018 | 578 | 27,675 | 2018 | 578 | 20,218 |

| 2019 | 552 | 26,695 | 2019 | 577 | 20,466 |

| 2020 | 626 | 29,247 | 2020 | 556 | 20,077 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Wang, Y.; Gao, W.; Xu, T.; Wei, X.; Shi, C.; Qi, Z.; Bai, L. Uncovering the Efficiency and Performance of Ground-Source Heat Pumps in Cold Regions: A Case Study of a Public Building in Northern China. Buildings 2023, 13, 1564. https://doi.org/10.3390/buildings13061564

Wang P, Wang Y, Gao W, Xu T, Wei X, Shi C, Qi Z, Bai L. Uncovering the Efficiency and Performance of Ground-Source Heat Pumps in Cold Regions: A Case Study of a Public Building in Northern China. Buildings. 2023; 13(6):1564. https://doi.org/10.3390/buildings13061564

Chicago/Turabian StyleWang, Pengxuan, Yixi Wang, Weijun Gao, Tongyu Xu, Xindong Wei, Chunyan Shi, Zishu Qi, and Li Bai. 2023. "Uncovering the Efficiency and Performance of Ground-Source Heat Pumps in Cold Regions: A Case Study of a Public Building in Northern China" Buildings 13, no. 6: 1564. https://doi.org/10.3390/buildings13061564

APA StyleWang, P., Wang, Y., Gao, W., Xu, T., Wei, X., Shi, C., Qi, Z., & Bai, L. (2023). Uncovering the Efficiency and Performance of Ground-Source Heat Pumps in Cold Regions: A Case Study of a Public Building in Northern China. Buildings, 13(6), 1564. https://doi.org/10.3390/buildings13061564