Influence of Water Content and Mixing Conditions on the Properties of Lime-Based Materials

Abstract

1. Introduction

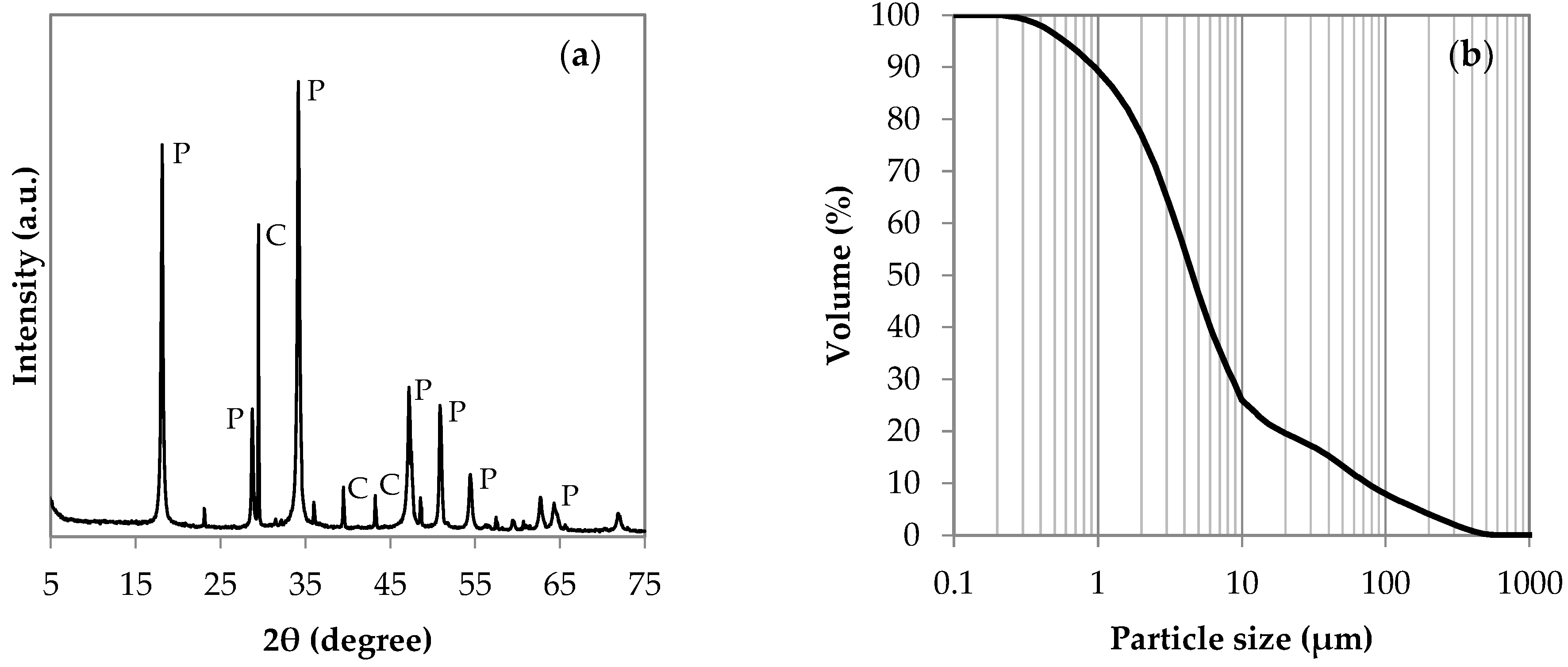

2. Materials and Methods

2.1. Materials and Formulations

2.2. Fresh State Characterisation

2.2.1. Consistency and Fluidity

2.2.2. Particle Size Determination

2.2.3. Rheological Measurements

2.2.4. Hardened State Characterisation

3. Fresh State Properties

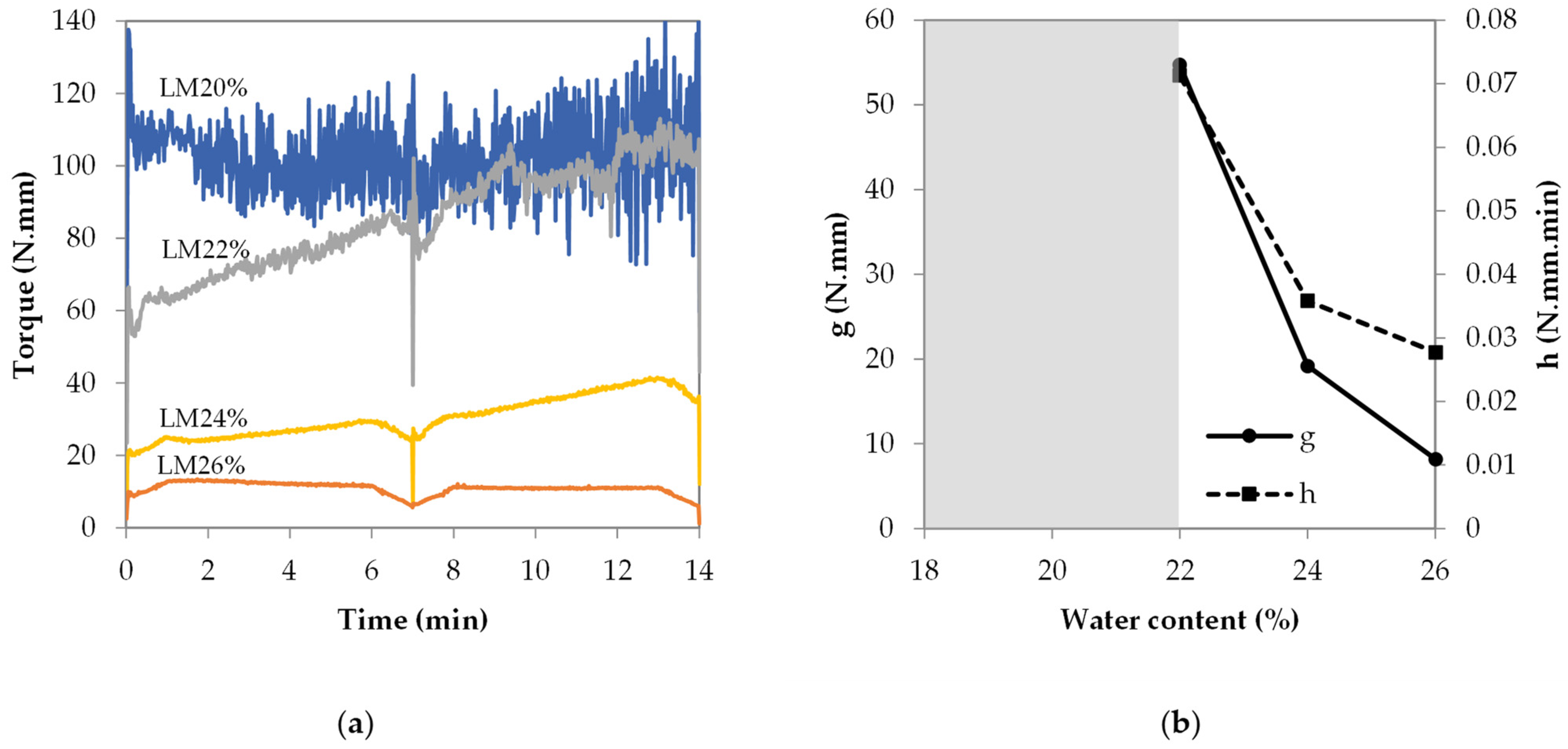

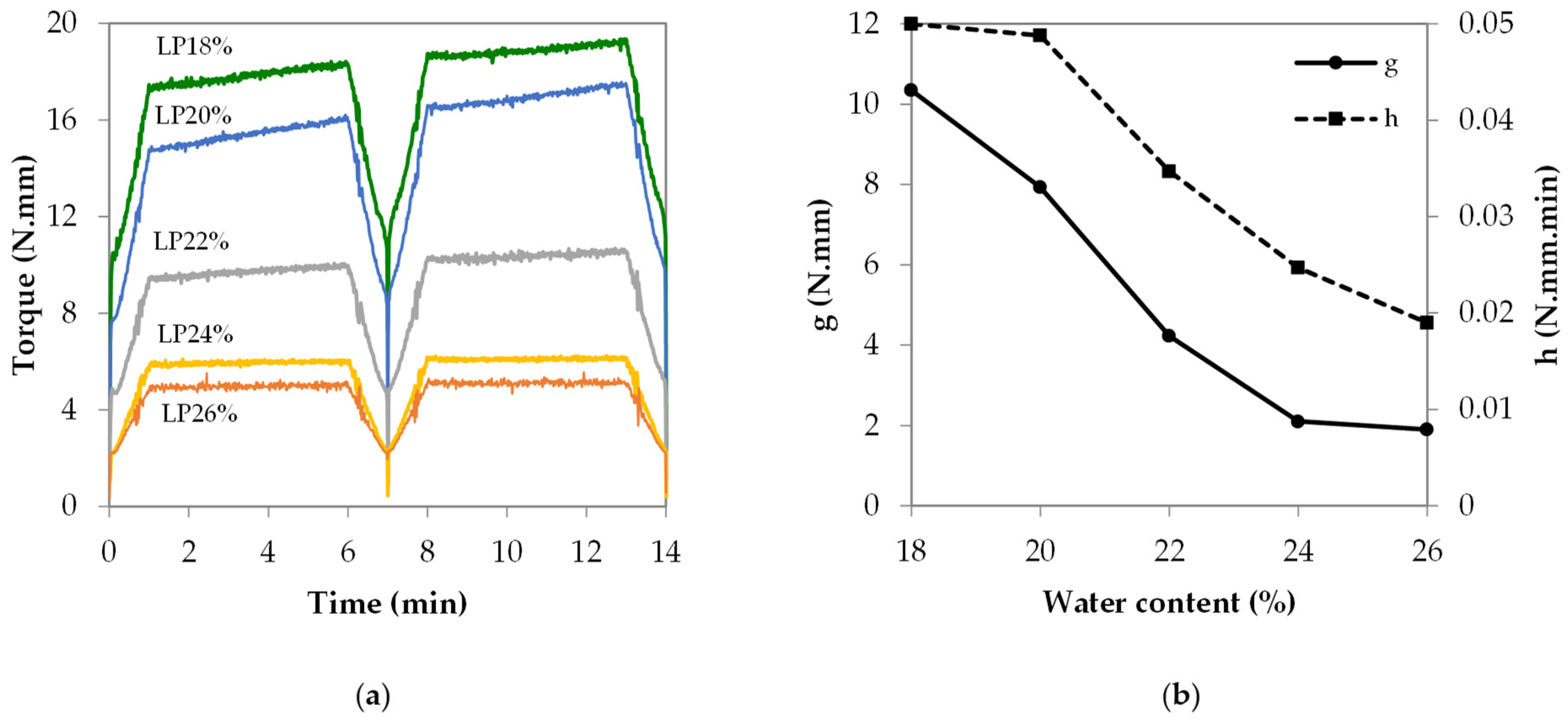

3.1. Influence of Water Content

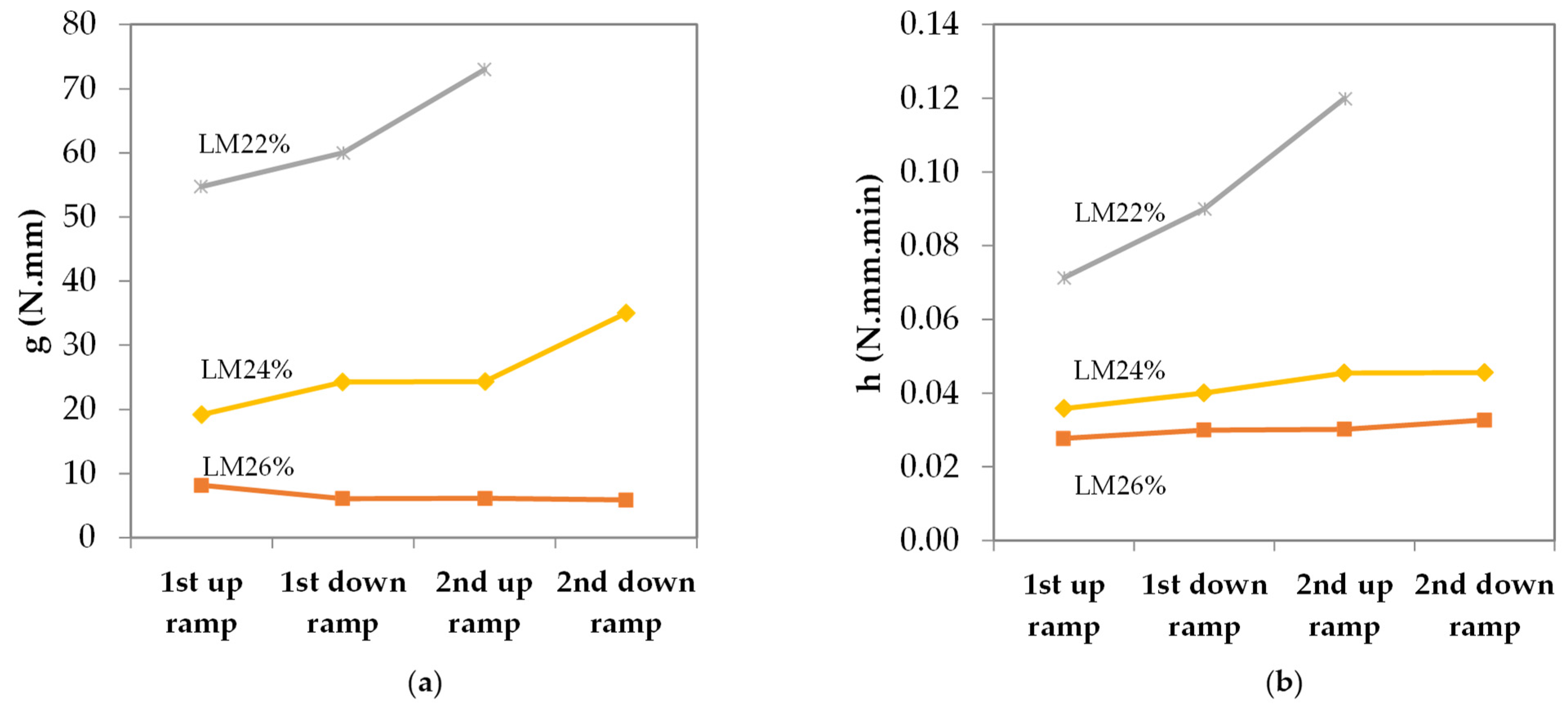

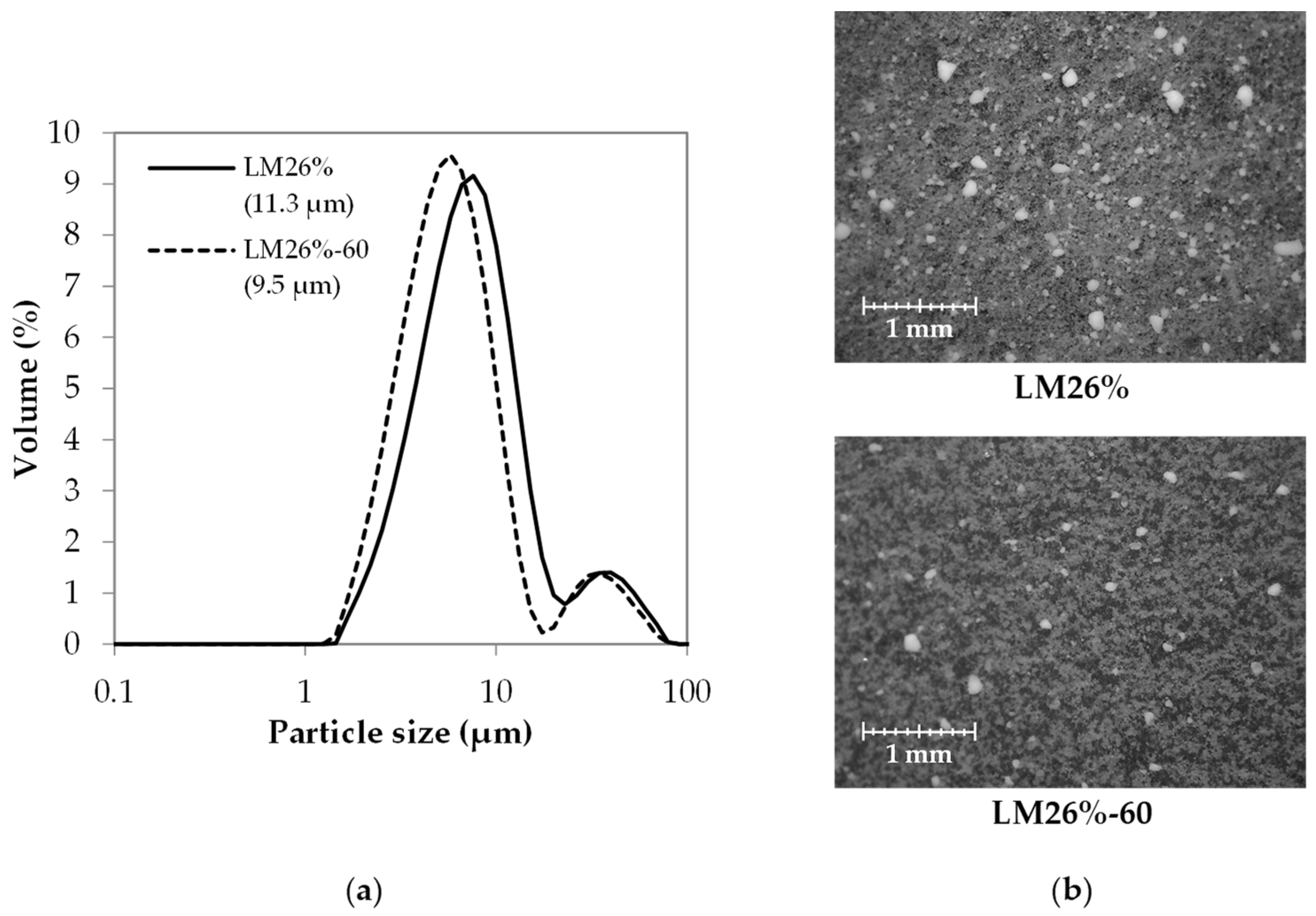

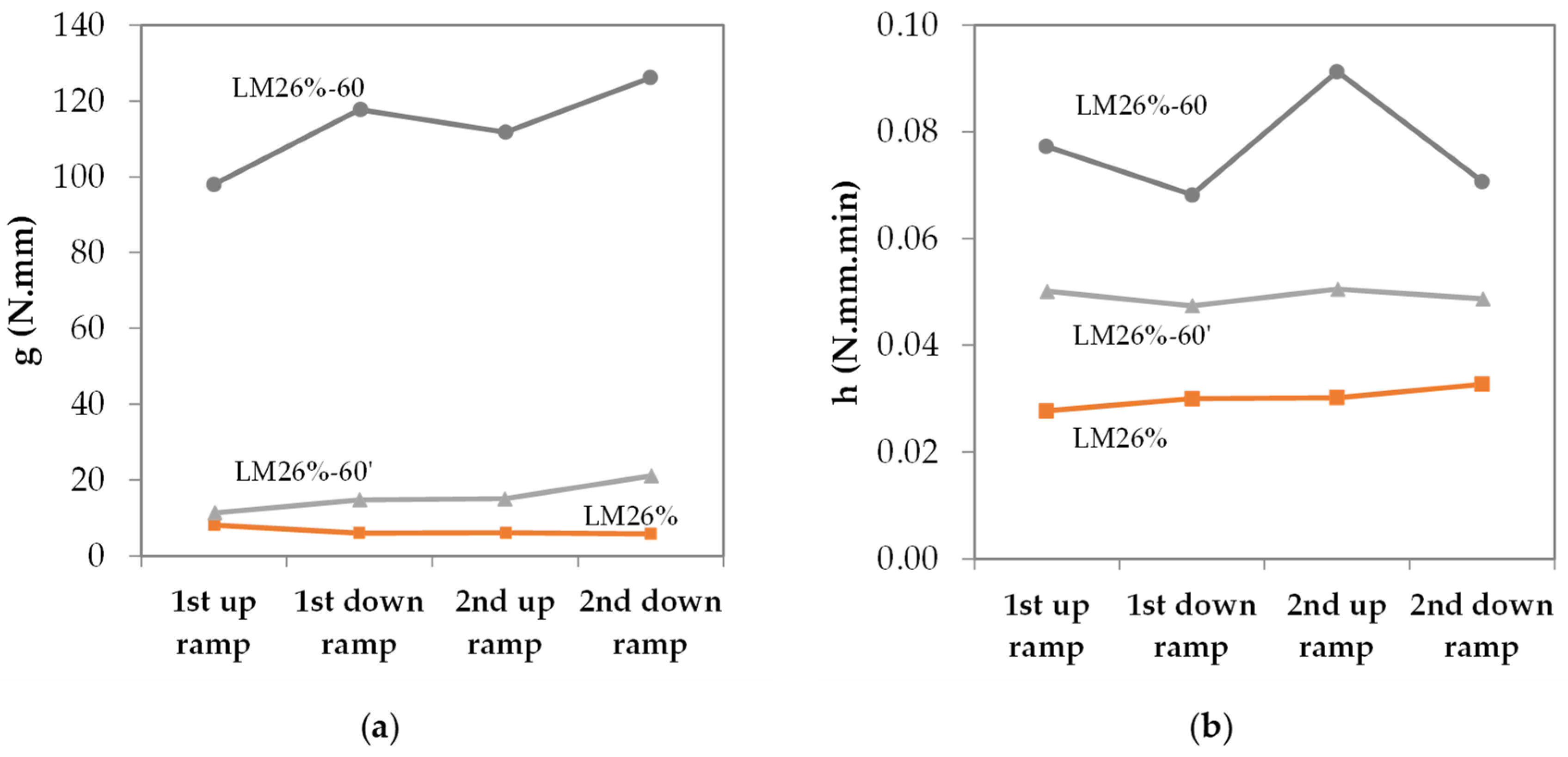

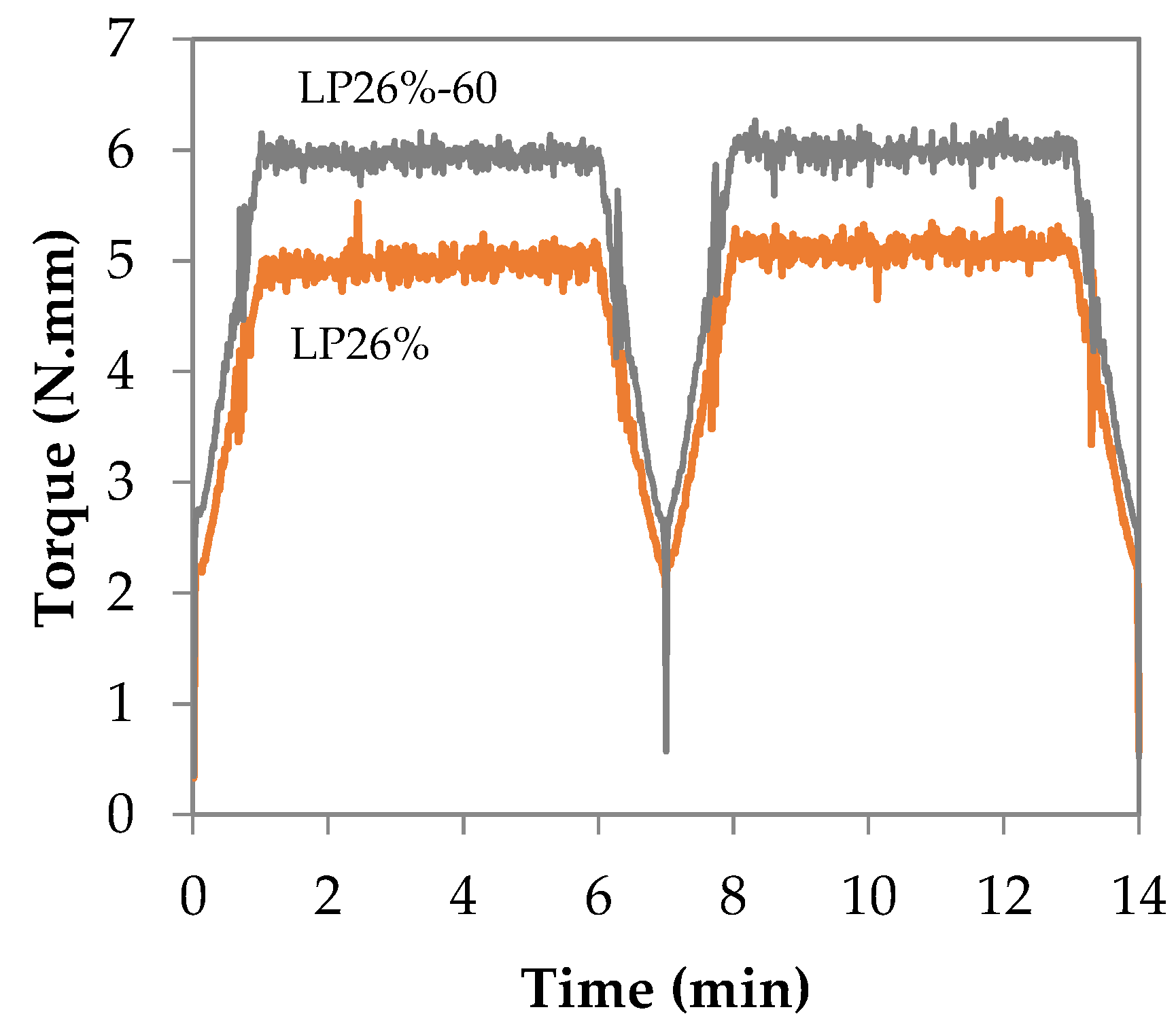

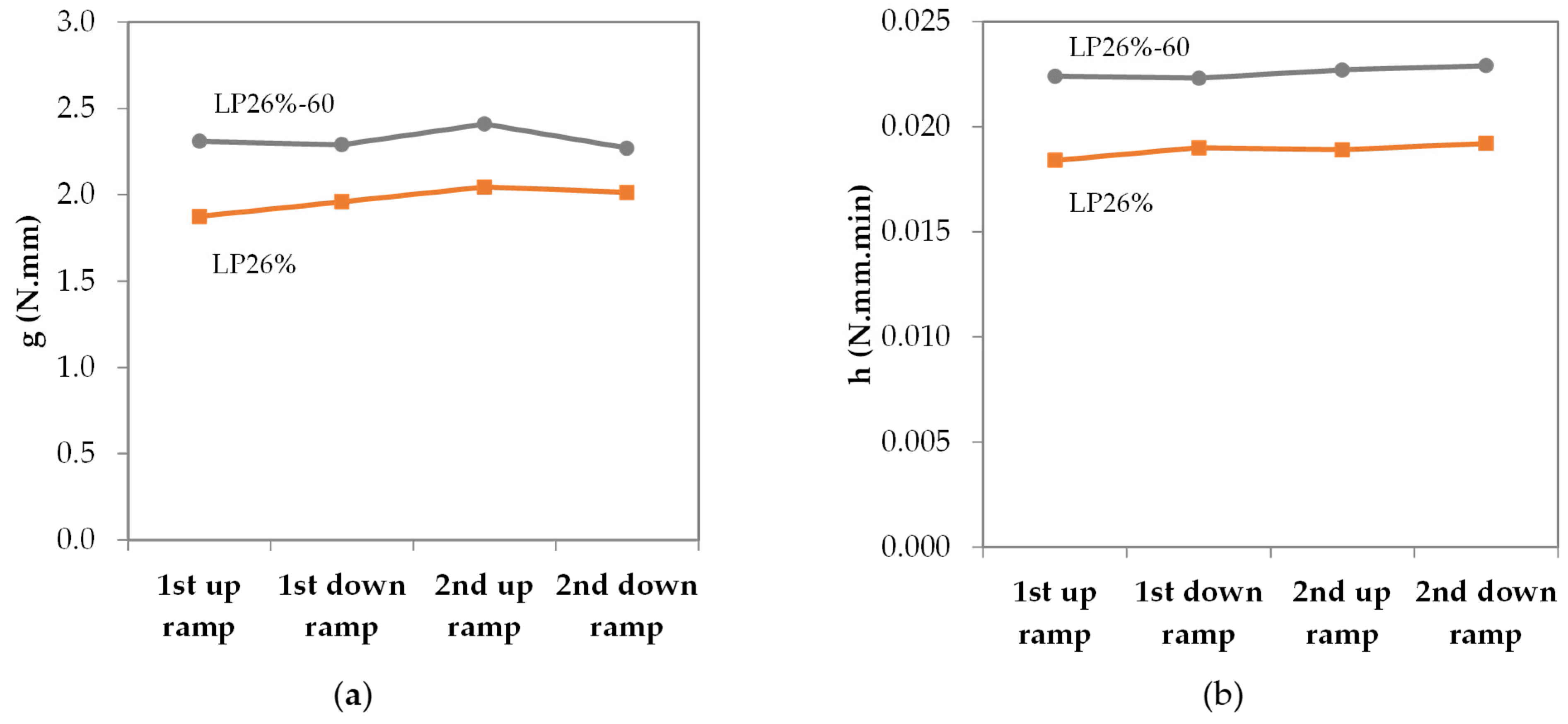

3.2. Influence of Mixing Conditions

4. Hardened State Properties

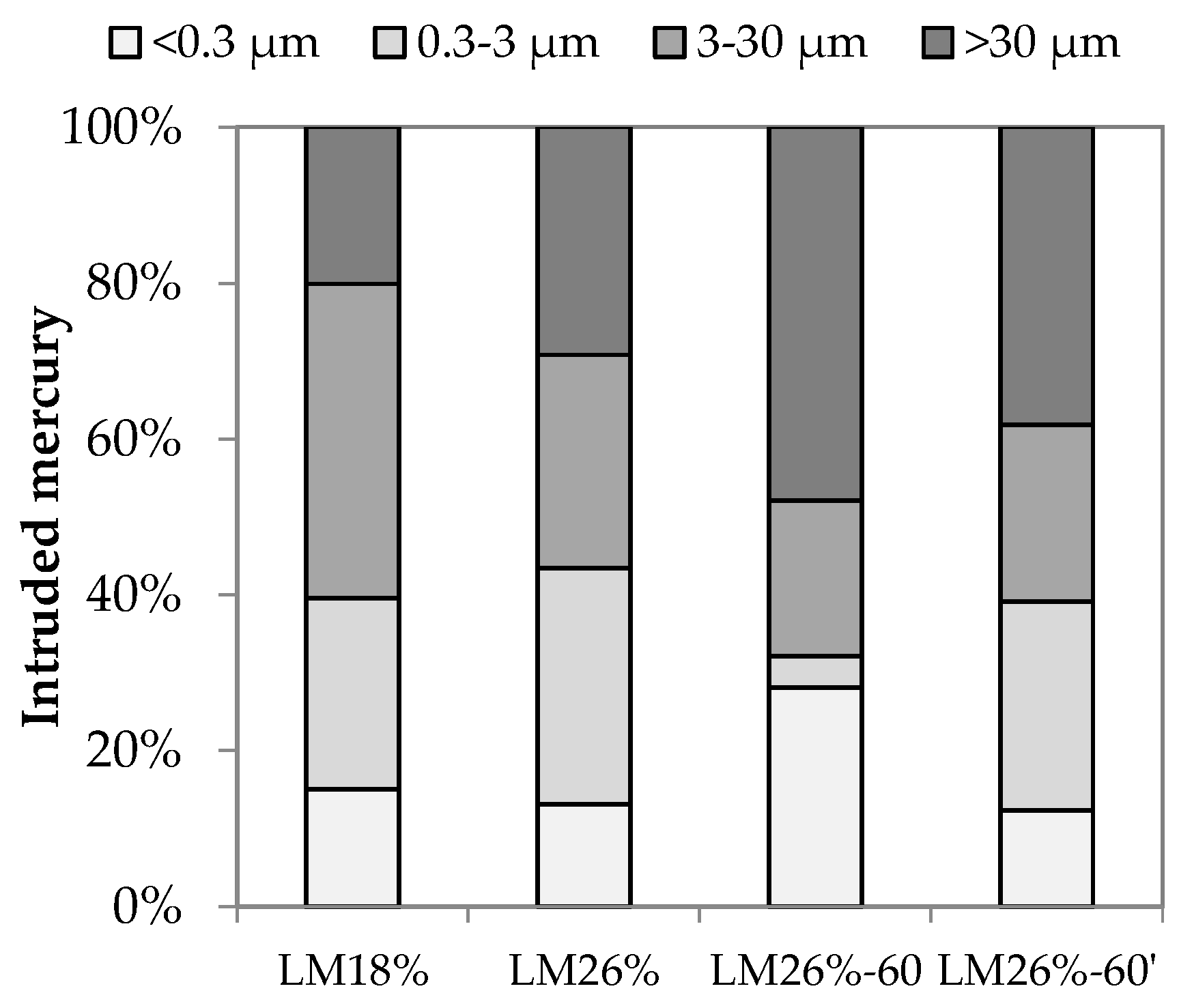

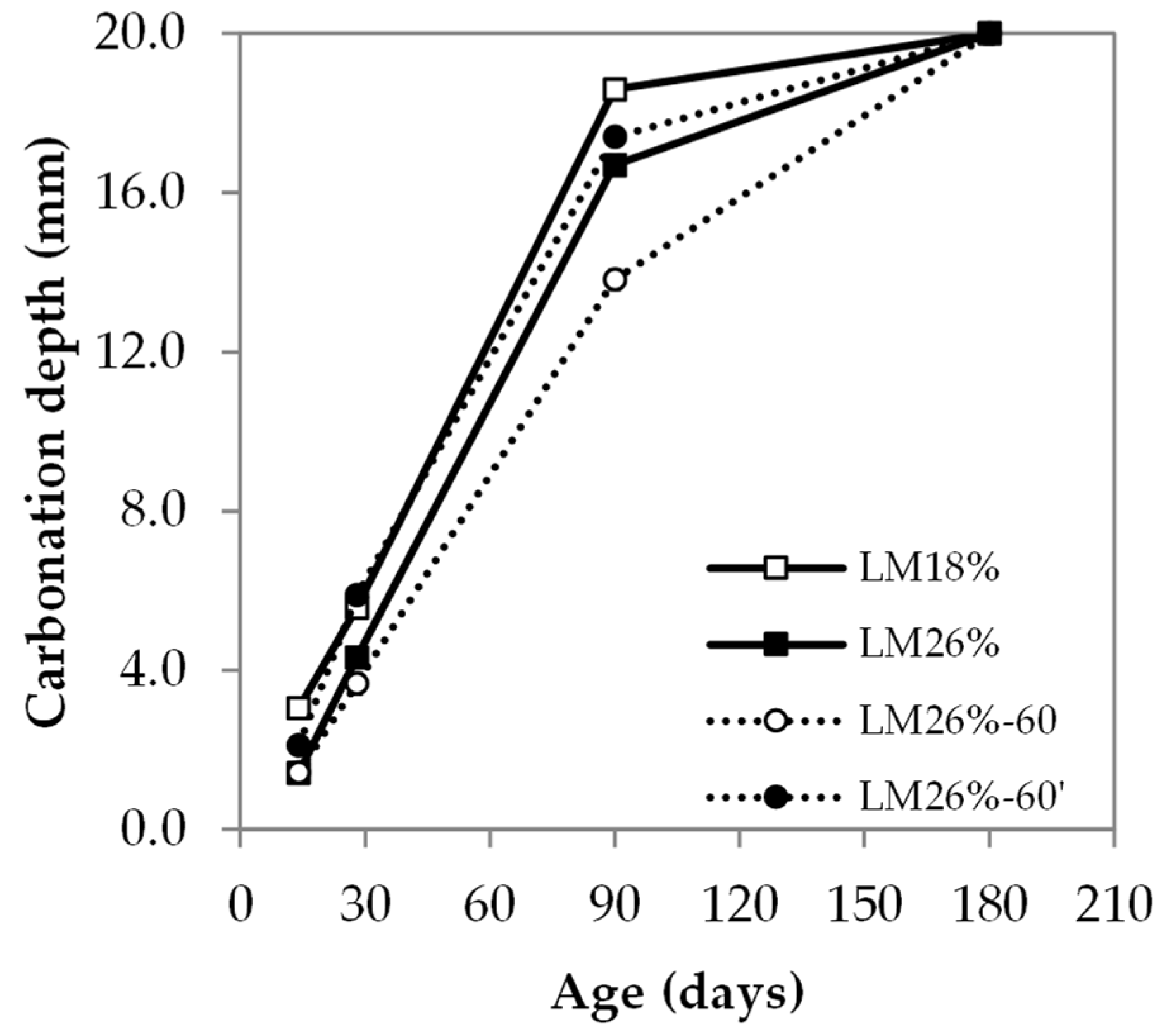

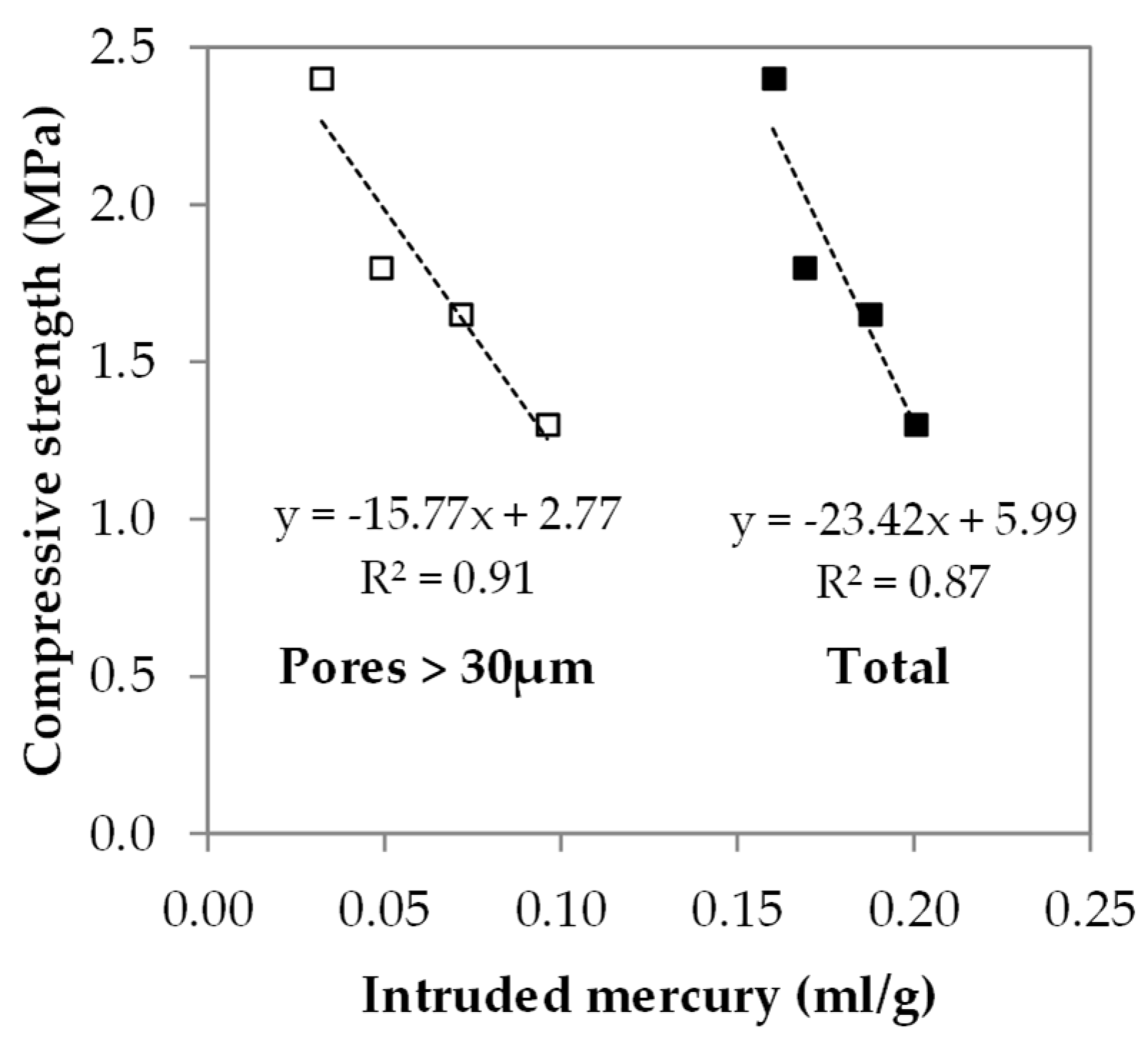

4.1. Influence of Water Content

4.2. Influence of Mixing Conditions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teutonico, J.M.; McCaig, I.; Burns, C.; Ashurst, J. The Smeaton project: Factors affecting the properties of lime-based mortars. APT Bull. 1993, 25, 32–49. [Google Scholar] [CrossRef]

- Elert, K.; Rodriguez-Navarro, C.; Pardo, E.S.; Hansen, E.; Cazalla, O. Lime mortars for the conservation of historic buildings. Stud. Conserv. 2002, 47, 62–75. [Google Scholar]

- Lanas, J.; Alvarez-Galindo, J.I. Masonry repair lime-based mortars: Factors affecting the mechanical behaviour. Cem. Concr. Res. 2003, 33, 1867–1876. [Google Scholar] [CrossRef]

- Lanas, J.; Bernal, J.P.; Bello, M.A.; Galindo, J.A. Mechanical properties of natural hydraulic lime-based mortars. Cem. Concr. Res. 2004, 34, 2191–2201. [Google Scholar] [CrossRef]

- Stefanidou, M.; Papayianni, I. The role of aggregates on the structure and properties of lime mortars. Cem. Concr. Compos. 2005, 27, 914–919. [Google Scholar] [CrossRef]

- Faria, P.; Henriques, F.; Rato, V. Comparative evaluation of lime mortars for architectural conservation. J. Cult. Herit. 2008, 9, 338–346. [Google Scholar] [CrossRef]

- Paiva, H.; Velosa, A.; Veiga, R.; Ferreira, V.M. Effect of maturation time on the fresh and hardened properties of an air lime mortar. Cem. Concr. Res. 2010, 40, 447–451. [Google Scholar] [CrossRef]

- Silva, B.A.; Pinto, A.F.; Gomes, A. Influence of natural hydraulic lime content on the properties of aerial lime-based mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall: Harlow, UK, 2011. [Google Scholar]

- Hewlett, P. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2004. [Google Scholar]

- Seabra, M.P.; Paiva, H.; Labrincha, J.A.; Ferreira, V.M. Admixtures effect on fresh state properties of aerial lime based mortars. Constr. Build. Mater. 2009, 23, 1147–1153. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheological methods for assessing the flow properties of mortar and related materials. Constr. Build. Mater. 1994, 8, 43–50. [Google Scholar] [CrossRef]

- Roussel, N. (Ed.) Understanding the Rheology of Concrete, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Aïtcin, P.; Flatt, R.J. (Eds.) Science and Technology of Concrete Admixtures, 1st ed.; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Gołaszewski, J.; Szwabowski, J. Influence of superplasticizers on rheological behaviour of fresh cement mortars. Cem. Concr. Res. 2004, 34, 235–248. [Google Scholar] [CrossRef]

- Papo, A.; Piani, L. Effect of various superplasticizers on the rheological properties of Portland cement pastes. Cem. Concr. Res. 2004, 34, 2097–2101. [Google Scholar] [CrossRef]

- Williams, D.A.; Saak, A.W.; Jennings, H.M. The influence of mixing on the rheology of fresh cement paste. Cem. Concr. Res. 1999, 29, 1491–1496. [Google Scholar] [CrossRef]

- Toumbakari, E.E.; Van Gemert, D.; Tassios, T.P.; Tenoutasse, N. Effect of mixing procedure on injectability of cementitious grouts. Cem. Concr. Res. 1999, 29, 867–872. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Obla, K.H.; Hill, R. The influence of mineral admixtures on the rheology of cement paste and concrete. Cem. Concr. Res. 2001, 31, 245–255. [Google Scholar] [CrossRef]

- Chandra, S.; Björnström, J. Influence of cement and superplasticizers type and dosage on the fluidity of cement mortars—Part I. Cem. Concr. Res. 2002, 32, 1605–1611. [Google Scholar] [CrossRef]

- Puertas, F.; Santos, H.; Palacios, M.; Martínez-Ramírez, S. Polycarboxylate superplasticiser admixtures: Effect on hydration, microstructure and rheological behaviour in cement pastes. Adv. Cem. Res. 2005, 17, 77–89. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheology of fresh cement and concrete. In Proceedings of the 11th International Cement Chemistry Congress, Durban, South Africa, 11–16 May 2003; Volume 1, pp. 50–62. [Google Scholar]

- Fernàndez-Altable, V.; Casanova, I. Influence of mixing sequence and superplasticiser dosage on the rheological response of cement pastes at different temperatures. Cem. Concr. Res. 2006, 36, 1222–1230. [Google Scholar] [CrossRef]

- Dils, J.; De Schutter, G.; Boel, V. Influence of mixing procedure and mixer type on fresh and hardened properties of concrete: A review. Mater. Struct. 2012, 45, 1673–1683. [Google Scholar] [CrossRef]

- Trejo, D.; Prasittisopin, L. Effects of mixing variables on early-age characteristics of portland cement systems. J. Mater. Civ. Eng. 2016, 28, 04016094. [Google Scholar] [CrossRef]

- Nowoświat, A.; Gołaszewski, J. Influence of the variability of calcareous fly ash properties on rheological properties of fresh mortar with its addition. Materials 2019, 12, 1942. [Google Scholar] [CrossRef] [PubMed]

- Sonebi, M.; Perrot, A. Effect of mix proportions on rheology and permeability of cement grouts containing viscosity modifying admixture. Constr. Build. Mater. 2019, 212, 687–697. [Google Scholar] [CrossRef]

- De França, M.S.; Cazacliu, B.; Cardoso, F.A.; Pileggi, R.G. Influence of mixing process on mortars rheological behavior through rotational rheometry. Constr. Build. Mater. 2019, 223, 81–90. [Google Scholar] [CrossRef]

- Seabra, M.P.; Labrincha, J.A.; Ferreira, V.M. Rheological behaviour of hydraulic lime-based mortars. J. Eur. Ceram. Soc. 2007, 27, 1735–1741. [Google Scholar] [CrossRef]

- Brás, A.; Henriques, F.M. The influence of the mixing procedures on the optimization of fresh grout properties. Mater. Struct. 2009, 42, 1423–1432. [Google Scholar] [CrossRef]

- Brás, A.; Henriques, F.M.A. Natural hydraulic lime-based grouts—The selection of grout injection parameters for masonry consolidation. Constr. Build. Mater. 2012, 26, 135–144. [Google Scholar] [CrossRef]

- Jorne, F.; Henriques, F.M.; Baltazar, L.G. Influence of superplasticizer, temperature, resting time and injection pressure on hydraulic lime grout injectability. Correlation analysis between fresh grout parameters and grout injectability. J. Build. Eng. 2015, 4, 140–151. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.; Cidade, M.T. Rheology of natural hydraulic lime grouts for conservation of stone masonry—Influence of compositional and processing parameters. Fluids 2019, 4, 13. [Google Scholar] [CrossRef]

- Banfill, P.F.G.; Shimizu, L. Rheology of natural hydraulic limes for masonry repair. In Proceedings of the 4th Historic Mortars Conference, Thessaloniki, Greece, 10–12 October 2016; pp. 606–613. [Google Scholar]

- Arizzi, A.; Banfill, P.F.G. Rheology of lime pastes with biopolymer-based additives. Mater. Struct. 2019, 52, 8–25. [Google Scholar] [CrossRef]

- Atzeni, C.; Farci, A.; Floris, D.; Meloni, P. Effect of aging on rheological properties of lime putty. J. Am. Ceram. Soc. 2004, 87, 1764–1766. [Google Scholar] [CrossRef]

- Ruiz-Agudo, E.; Rodriguez-Navarro, C. Microstructure and rheology of lime putty. Langmuir 2009, 26, 3868–3877. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Navarro, C.; Hansen, E.; Ginell, W.S. Calcium hydroxide crystal evolution upon aging of lime putty. J. Am. Ceram. Soc. 1998, 81, 3032–3034. [Google Scholar] [CrossRef]

- Arizzi, A.; Hendrickx, R.; Cultrone, G.; Van Balen, K. Differences in the rheological properties of calcitic and dolomitic lime slurries: Influence of particle characteristics and practical implications in lime-based mortar manufacturing. Mater. Construcc. 2012, 62, 231–250. [Google Scholar] [CrossRef]

- Boháč, M.; Nečas, R. The role of aging on rheological properties of lime putty. Procedia Eng. 2016, 151, 34–41. [Google Scholar] [CrossRef]

- Rago, F. Características Reológicas de Pastas de Cales Hidratadas Normalizadas e de Cimento. Master’s Thesis, University of São Paulo, São Paulo, Brasil, 1999. (In Portuguese). [Google Scholar]

- Fourmentin, M.; Ovarlez, G.; Faure, P.; Peter, U.; Lesueur, D.; Daviller, D.; Coussot, P. Rheology of lime paste—A comparison with cement paste. Rheol. Acta 2015, 54, 647–656. [Google Scholar] [CrossRef]

- Izaguirre, A.; Lanas, J.; Alvarez, J.I. Characterization of aerial lime-based mortars modified by the addition of two different water-retaining agents. Cem. Concr. Compos. 2011, 33, 309–318. [Google Scholar] [CrossRef]

- Fernández, J.M.; Duran, A.; Navarro-Blasco, I.; Lanas, J.; Sirera, R.; Alvarez, J.I. Influence of nanosilica and a polycarboxylate ether superplasticizer on the performance of lime mortars. Cem. Concr. Res. 2013, 43, 12–24. [Google Scholar] [CrossRef]

- Azeiteiro, L.C.; Velosa, A.; Paiva, H.; Mantas, P.Q.; Ferreira, V.M.; Veiga, R. Development of grouts for consolidation of old renders. Constr. Build. Mater. 2014, 50, 352–360. [Google Scholar] [CrossRef]

- Seabra, M.P.; Labrincha, J.A.; Ferreira, V.M. Ageing effect on aerial lime mortars rheology. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2008; Volume 587, pp. 872–876. [Google Scholar]

- Silva, B.; Ferreira Pinto, A.P.; Gomes, A.; Candeias, A. Fresh and hardened state behaviour of aerial lime mortars with superplasticizer. Constr. Build. Mater. 2019, 225, 1127–1139. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A.; Candeias, A. Impact of a viscosity-modifying admixture on the properties of lime mortars. J. Build. Eng. 2020, 31, 101132. [Google Scholar] [CrossRef]

- Cardoso, F.A.; John, V.M.; Pileggi, R.G.; Banfill, P.F.G. Characterisation of rendering mortars by squeeze-flow and rotational rheometry. Cem. Concr. Res. 2014, 57, 79–87. [Google Scholar] [CrossRef]

- Hendrickx, R. The Adequate Measurement of the Workability of Masonry Mortar. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2009. [Google Scholar]

- EN 459-1; Building Lime. Definitions, Specifications and Conformity Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Rodriguez-Navarro, C.; Ruiz-Agudo, E.; Ortega-Huertas, M.; Hansen, E. Nanostructure and irreversible colloidal behavior of Ca(OH)2: Implications in cultural heritage conservation. Langmuir 2005, 21, 10948–10957. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Physical properties and reactivity of pozzolans, and their influence on the properties of lime-pozzolan pastes. Mater. Struct. 2011, 44, 1139–1150. [Google Scholar] [CrossRef]

- EN 13139; Aggregates for Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- EN 1015-2; Methods of Test for Mortar for Masonry. Bulk Sampling of Mortars and Preparation of Test Mortars. European Committee for Standardization (CEN): Brussels, Belgium, 1998.

- EN 196-1; Methods of Testing Cement. Determination of Strength. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- EN 1015-3; Methods of Test for Mortar for Masonry. Determination of Consistency of Fresh Mortar by Flow Table. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1015-4; Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Plunger Penetration). European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 445; Grout for Pre-Stressing Tendons. Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2008.

- Coussot, P. Rheophysics—The Matter in All Its States, 1st ed.; Springer: Berlin, Germany, 2014. [Google Scholar]

- Teubert u. Greim GmbH. Schleibinger Viskomat NT and Viskomat XL Manual, Schleibinger Testing Systems; Teubert u. Greim GmbH: Buchbach, Germany, 2016. [Google Scholar]

- EN 1015-11; Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- RILEM Test, I. 1—Porosity Accessible to Water. RILEM TC 25-PEM—Recommended tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. Mater. Struct. 1980, 13, 177–179. [Google Scholar]

- Banfill, P.F.G. (Ed.) Rheology of Fresh Cement and Concrete. In Proceedings of an International Conference; CRC Press: Liverpool, UK, 1990. [Google Scholar]

- Vávrová, P.; Kotlík, P. Rheological properties of lime putty. Meterialy Pro Stavbu 2003, 3, 6. [Google Scholar]

- Banfill, P.F.G. The rheology of fresh mortar. Mag. Concr. Res. 1991, 43, 13–21. [Google Scholar] [CrossRef]

- Arandigoyen, M.; Bernal, J.P.; López, M.B.; Alvarez, J.I. Lime-pastes with different kneading water: Pore structure and capillary porosity. Appl. Surf. Sci. 2005, 252, 1449–1459. [Google Scholar] [CrossRef]

- Hanley, R.; Pavía, S. A study of the workability of natural hydraulic lime mortars and its influence on strength. Mater. Struct. 2008, 41, 373–381. [Google Scholar] [CrossRef]

- Cazalla, O.; Rodriguez-Navarro, C.; Sebastian, E.; Cultrone, G.; De la Torre, M.J. Aging of lime putty: Effects on traditional lime mortar carbonation. J. Am. Ceram. Soc. 2000, 83, 1070–1076. [Google Scholar] [CrossRef]

- Cultrone, G.; Sebastián, E.; Huertas, M.O. Forced and natural carbonation of lime-based mortars with and without additives: Mineralogical and textural changes. Cem. Concr. Res. 2005, 35, 2278–2289. [Google Scholar] [CrossRef]

- Van Balen, K.; Van Gemert, D. Modelling lime mortar carbonation. Mater. Struct. 1994, 27, 393–398. [Google Scholar] [CrossRef]

- Strottman, R. Dispersed Hydrated Lime: Development and Production, Techniques and Applications. In Proceedings of the International RILEM Workshop on Historic Mortars: Characteristics and Tests, Paisley, Scotland, 12–14 May 1999; RILEM Publications SARL: Champs-sur-Marne, France; pp. 407–411. [Google Scholar]

- Lawrence, R.M.H. A Study of Carbonation in Non-Hydraulic Lime Mortars. Ph.D. Thesis, University of Bath, Bath, UK, 2006. [Google Scholar]

| Mortars | LM18% | LM20% | LM22% | LM24% | LM26% |

| Water content (%) 1 | 18 | 20 | 22 | 24 | 26 |

| Water/binder ratio | 1.13 | 1.20 | 1.32 | 1.44 | 1.56 |

| Flow value (mm) | 161 | 197 | 215 | 261 | 284 |

| Plunger pen. (mm) | 11 | 20 | 39 | 51 | 68 |

| Pastes | LP18% | LP20% | LP22% | LP24% | LP26% |

| Water/binder ratio | 1.13 | 1.20 | 1.32 | 1.44 | 1.56 |

| Flow time (s) | 11.0 | 10.0 | 8.5 | 8.0 | 7.5 |

| Mortars and Pastes | Mixing Time (min), Speed (rpm) and Sequence of Addition of the Constituents | ||||||

|---|---|---|---|---|---|---|---|

| Lime + Water | Aggregate | Total Mixing Time | |||||

| LM26% | 1 min 1 (140 ± 5 rpm) | 3 min 2 (285 ± 5 rpm) | 4 min | ||||

| LM26%-60 | 3 min 2 (285 ± 5 rpm) | 60 min (140 ± 5 rpm) | 64 min | ||||

| LM26%-60′ | 1 min 1 (140 ± 5 rpm) | 60 min (140 ± 5 rpm) | 3 min 2 (285 ± 5 rpm) | 64 min | |||

| LP26% | 1 min (140 ± 5 rpm) | 3 min (285 ± 5 rpm) | - | 4 min | |||

| LP26%-60 | 1 min (140 ± 5 rpm) | 3 min (285 ± 5 rpm) | 60 min (140 ± 5 rpm) | - | 64 min | ||

| Mortars | LM26% | LM26%-60 | LM26%-60′ |

| Water/binder ratio | 1.56 | 1.56 | 1.56 |

| Flow value (mm) | 284 | 165 | 275 |

| Plunger pen. (mm) | 68 | 13 | 67 |

| Pastes | LP26% | LP26%-60 | - |

| Water/binder ratio | 1.56 | 1.56 | - |

| Flow time (s) | 7.5 | 8.0 | - |

| Mortar | LM18% | LM26% | LM26%-60 | LM26%-60′ |

|---|---|---|---|---|

| Water content (%) | 18 | 26 | 26 | 26 |

| Water/binder ratio | 1.08 | 1.56 | 1.56 | 1.56 |

| Mixing time (min) | 4 | 4 | 64 | 64 |

| Flow value (mm) | 161 | 284 | 165 | 275 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A.; Candeias, A. Influence of Water Content and Mixing Conditions on the Properties of Lime-Based Materials. Buildings 2023, 13, 1530. https://doi.org/10.3390/buildings13061530

Silva BA, Ferreira Pinto AP, Gomes A, Candeias A. Influence of Water Content and Mixing Conditions on the Properties of Lime-Based Materials. Buildings. 2023; 13(6):1530. https://doi.org/10.3390/buildings13061530

Chicago/Turabian StyleSilva, Bruna A., Ana Paula Ferreira Pinto, Augusto Gomes, and António Candeias. 2023. "Influence of Water Content and Mixing Conditions on the Properties of Lime-Based Materials" Buildings 13, no. 6: 1530. https://doi.org/10.3390/buildings13061530

APA StyleSilva, B. A., Ferreira Pinto, A. P., Gomes, A., & Candeias, A. (2023). Influence of Water Content and Mixing Conditions on the Properties of Lime-Based Materials. Buildings, 13(6), 1530. https://doi.org/10.3390/buildings13061530