Long Short-Term Memory Network for Predicting Wind-Induced Vibration Response of Lightning Rod Structures

Abstract

1. Introduction

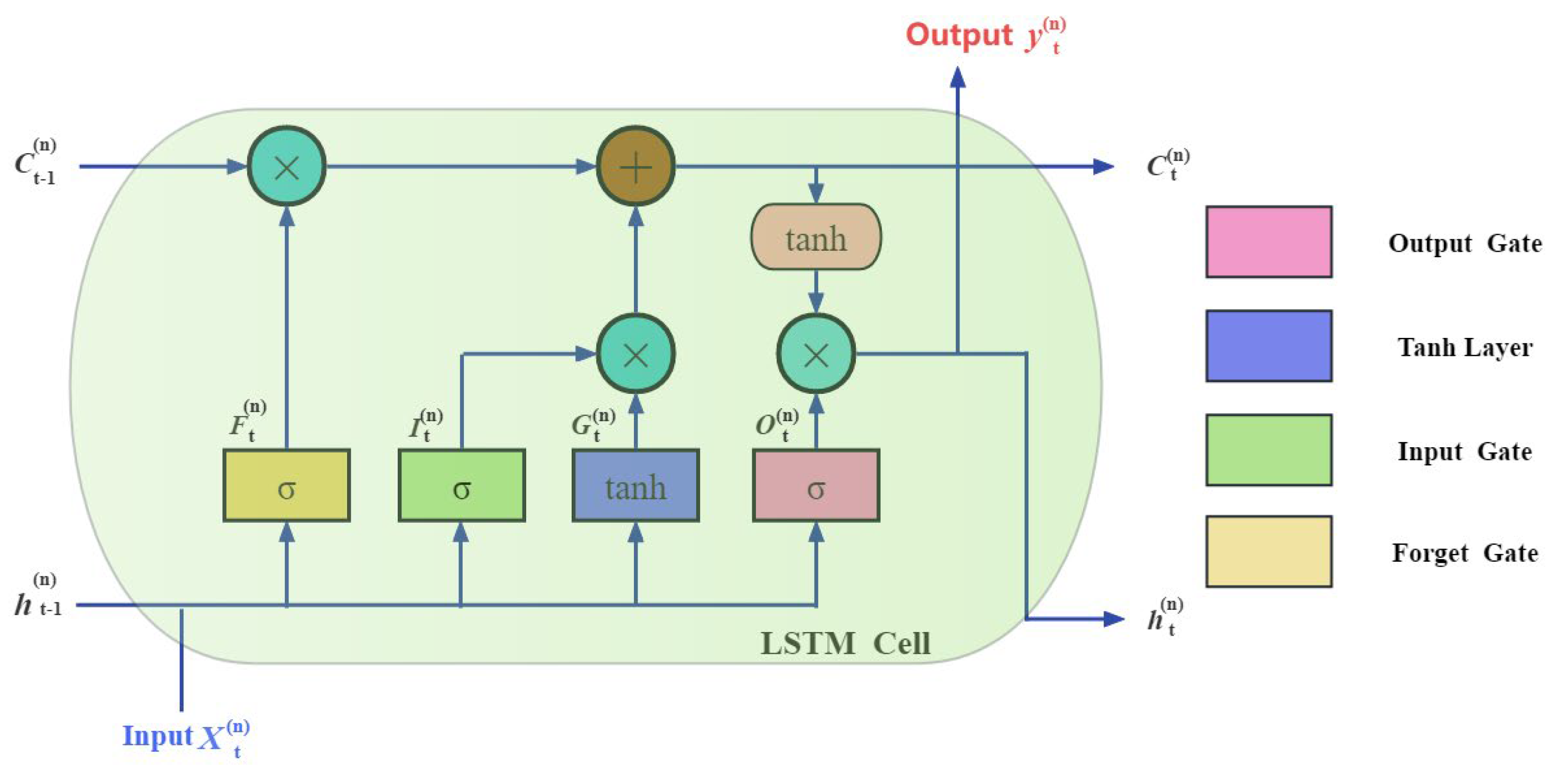

2. Long Short-Term Memory Network

2.1. Forget Gate

2.2. Input Gate

2.3. Output Gate

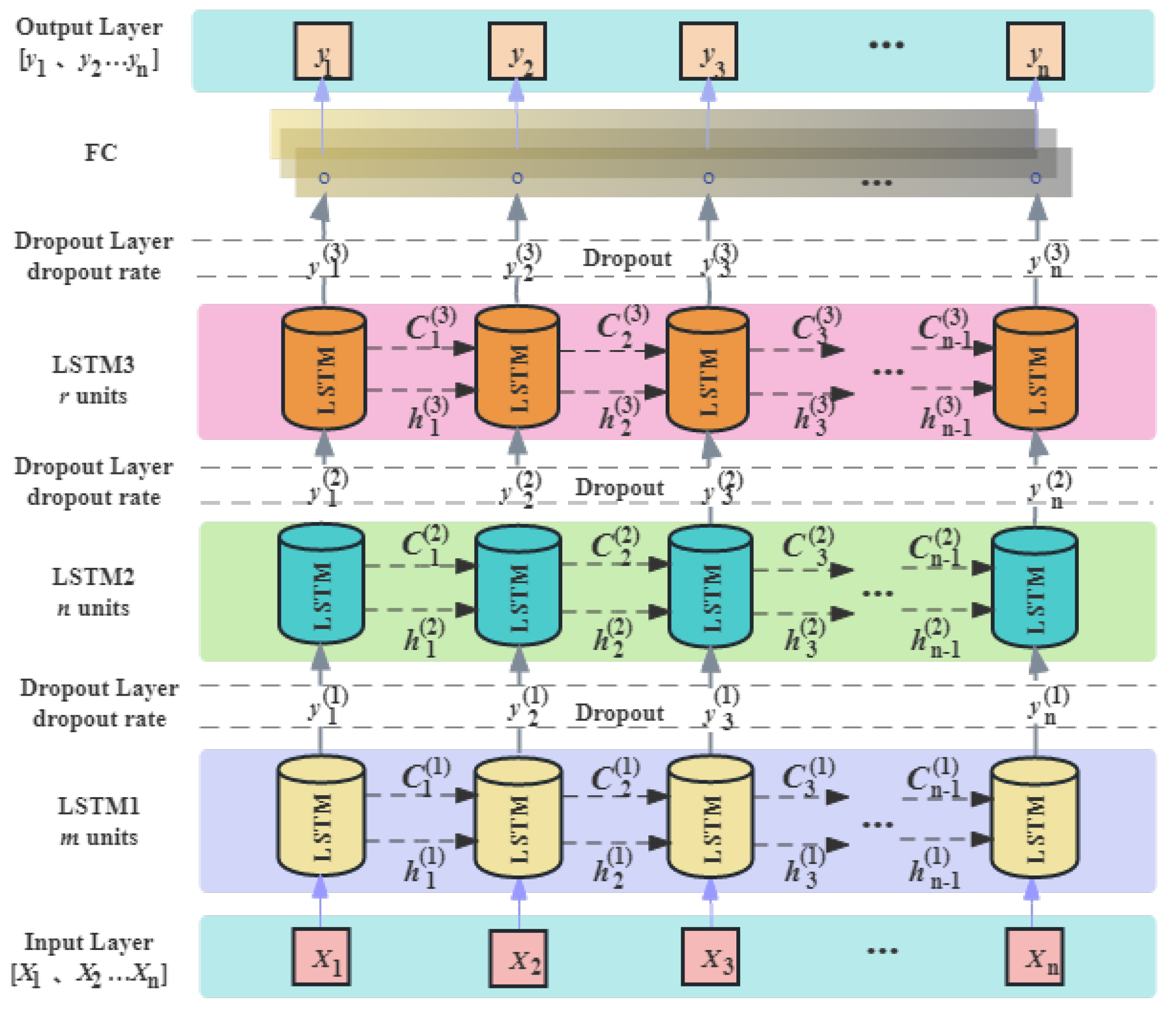

2.4. Multi-Hidden-Layer LSTM Structure

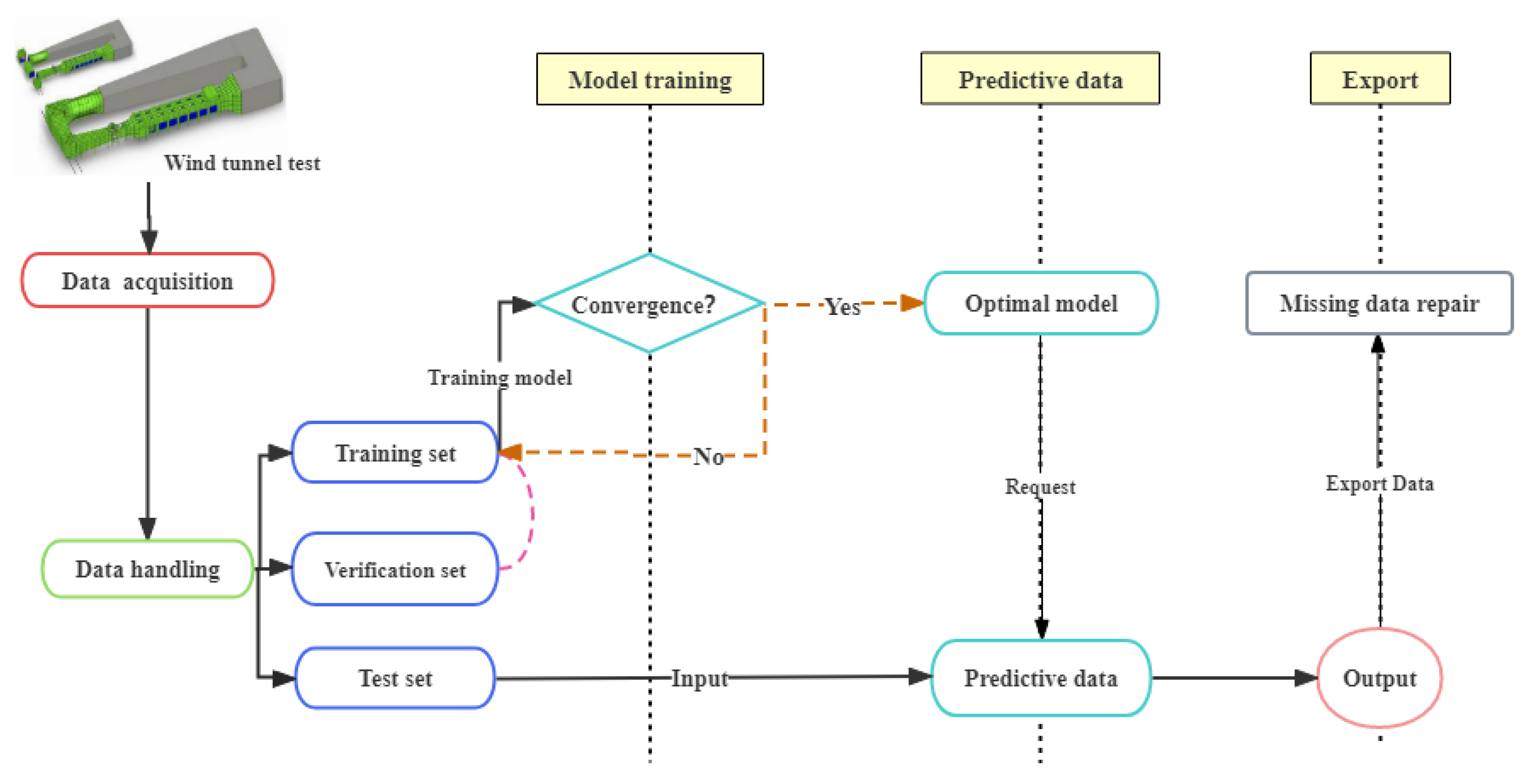

3. Prediction Method of the Wind-Induced Strain Response of Lightning Rod Structures Based on LSTM

4. Example Verification

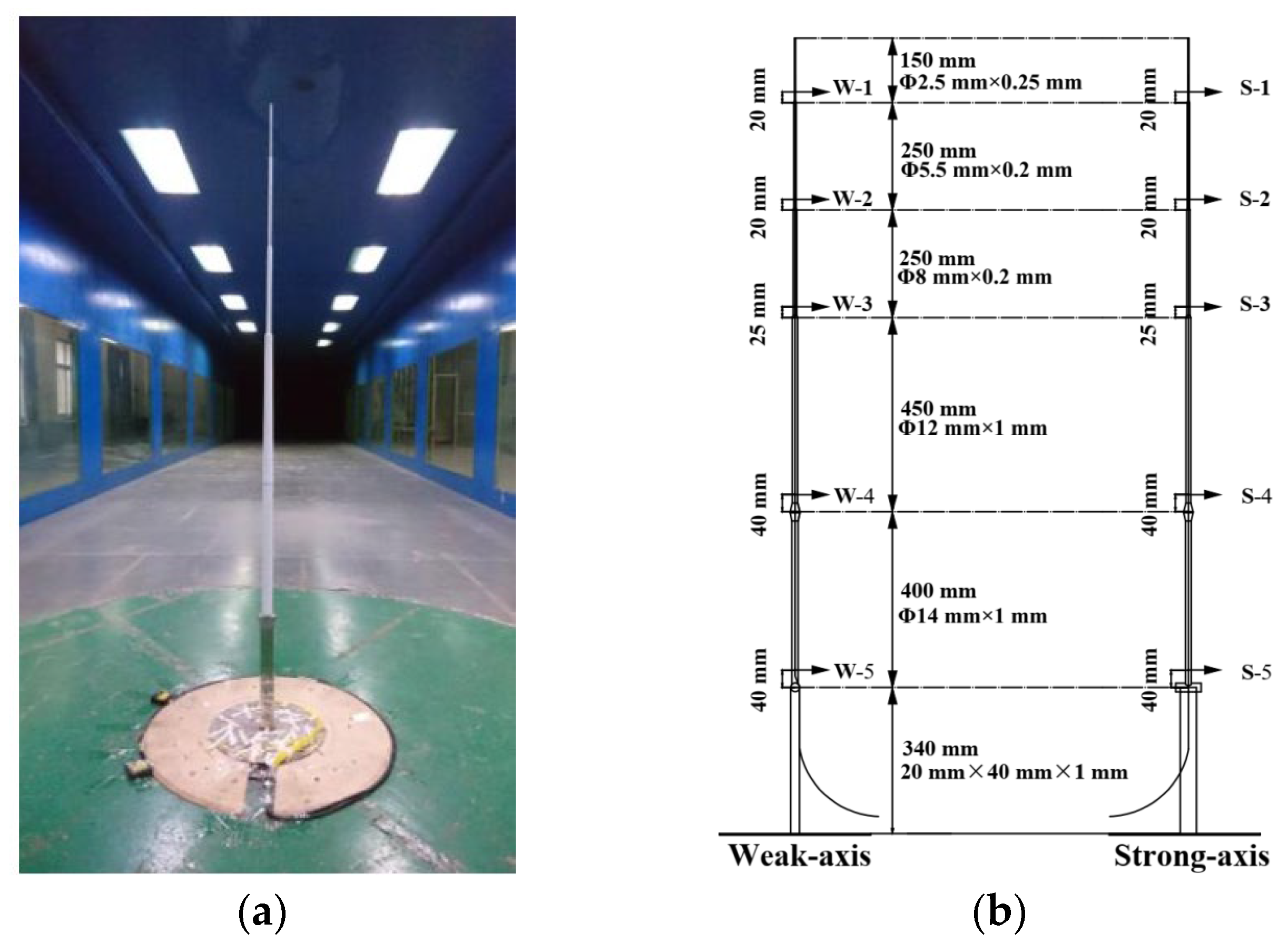

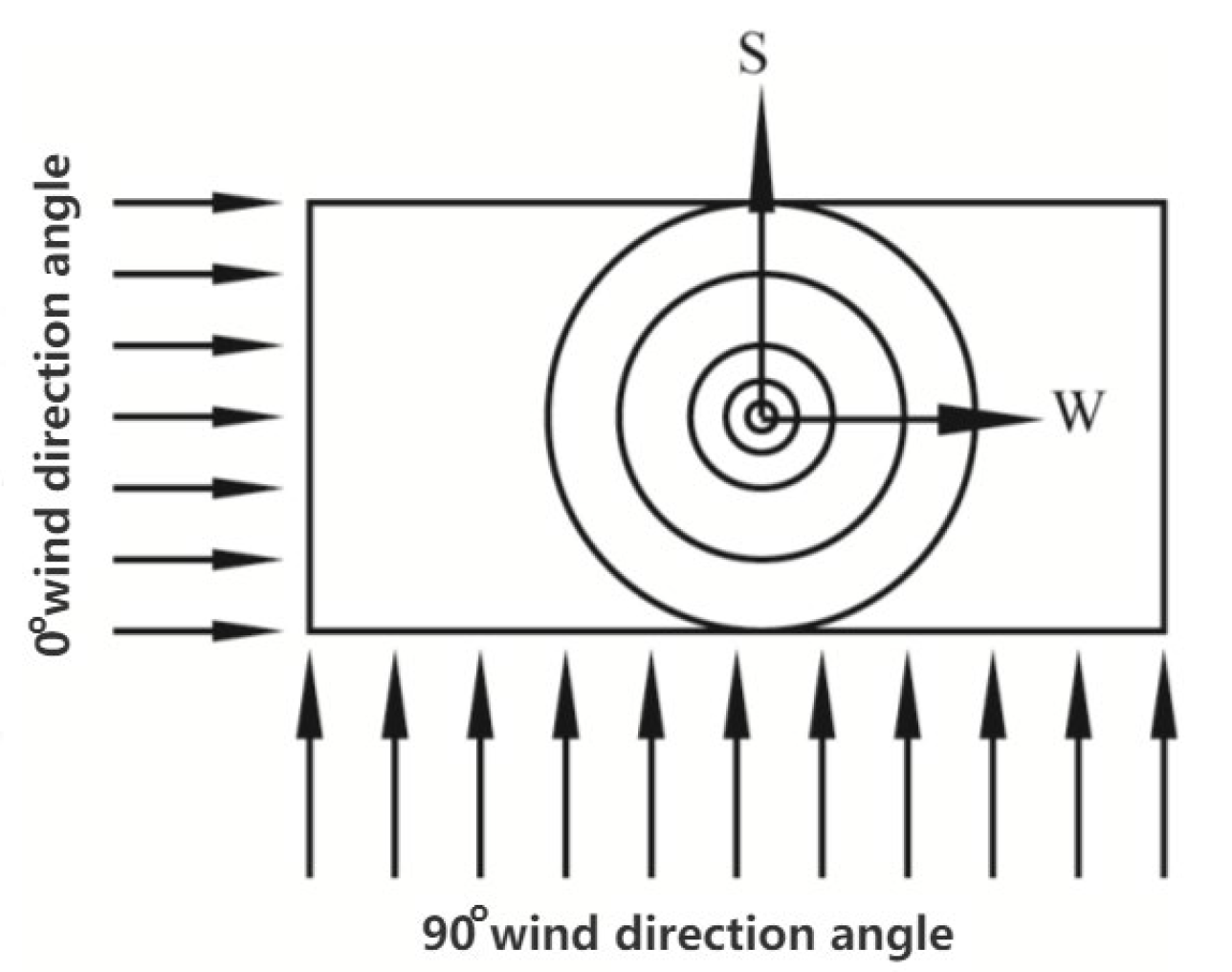

4.1. Wind Tunnel Test of the Lightning Rod Aeroelastic Model

4.2. Selection and Processing of Data Samples

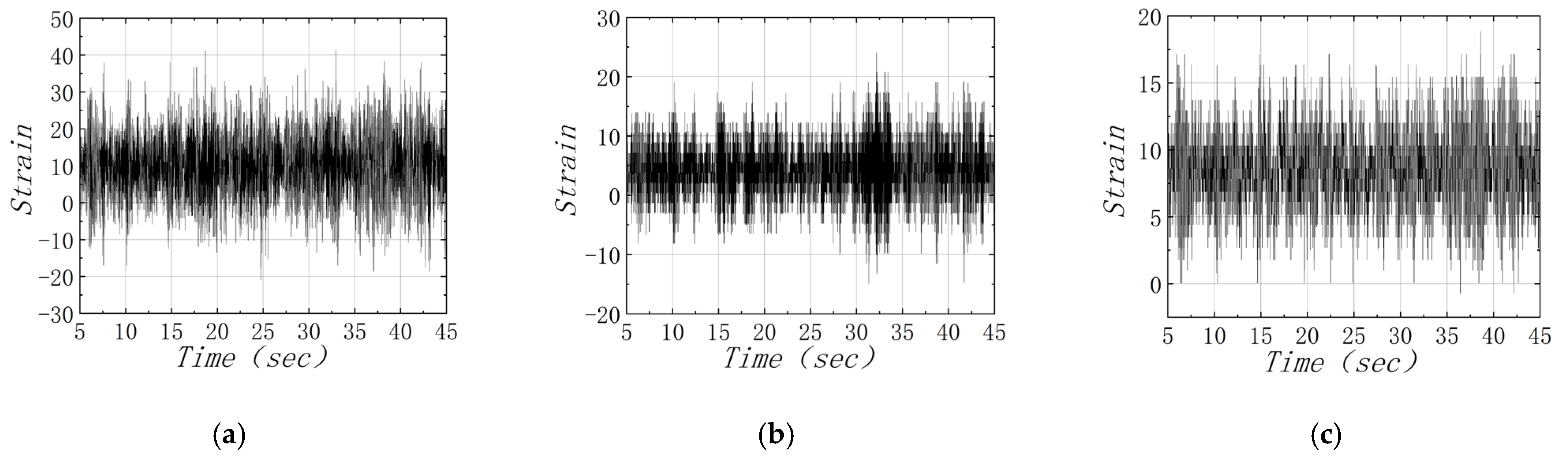

4.3. Determination of Model Structure and Parameters

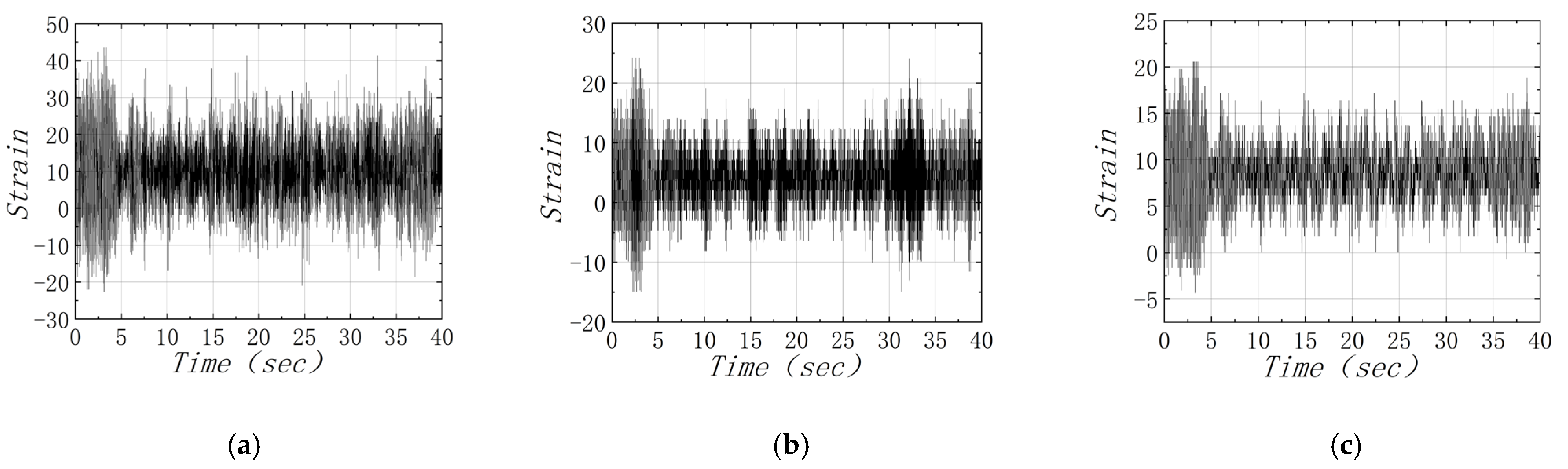

4.4. Analysis of Wind Vibration Response of Lightning Rod Structure under the Action of Wind Speed 25.30 m/s

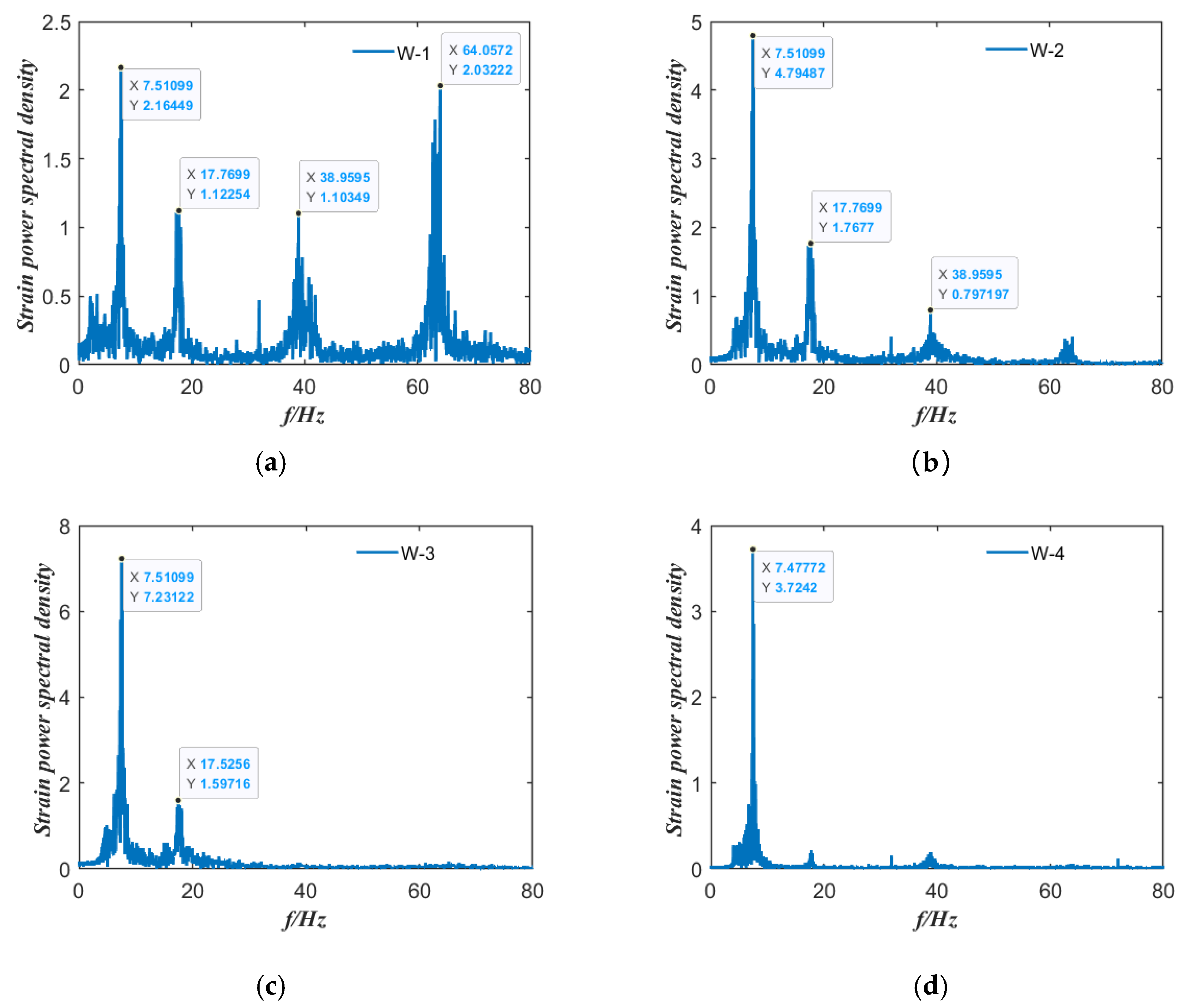

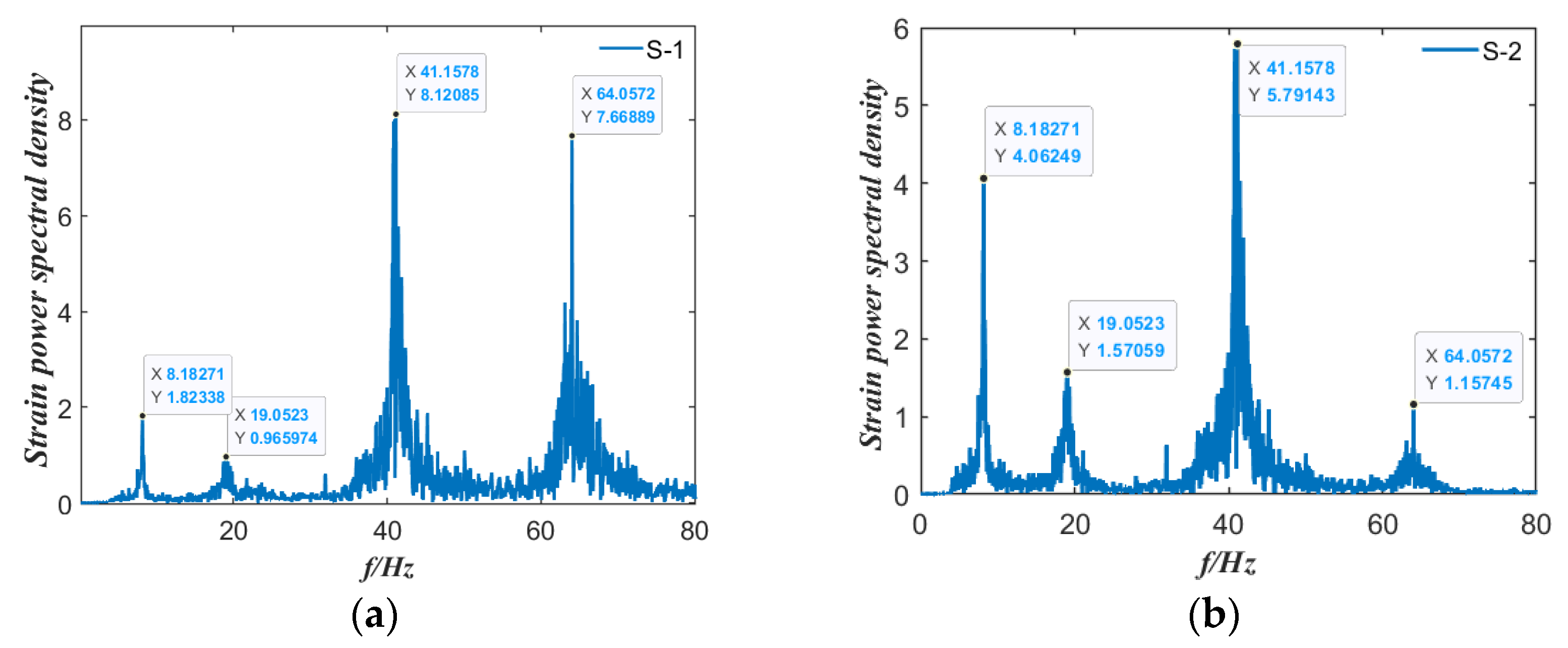

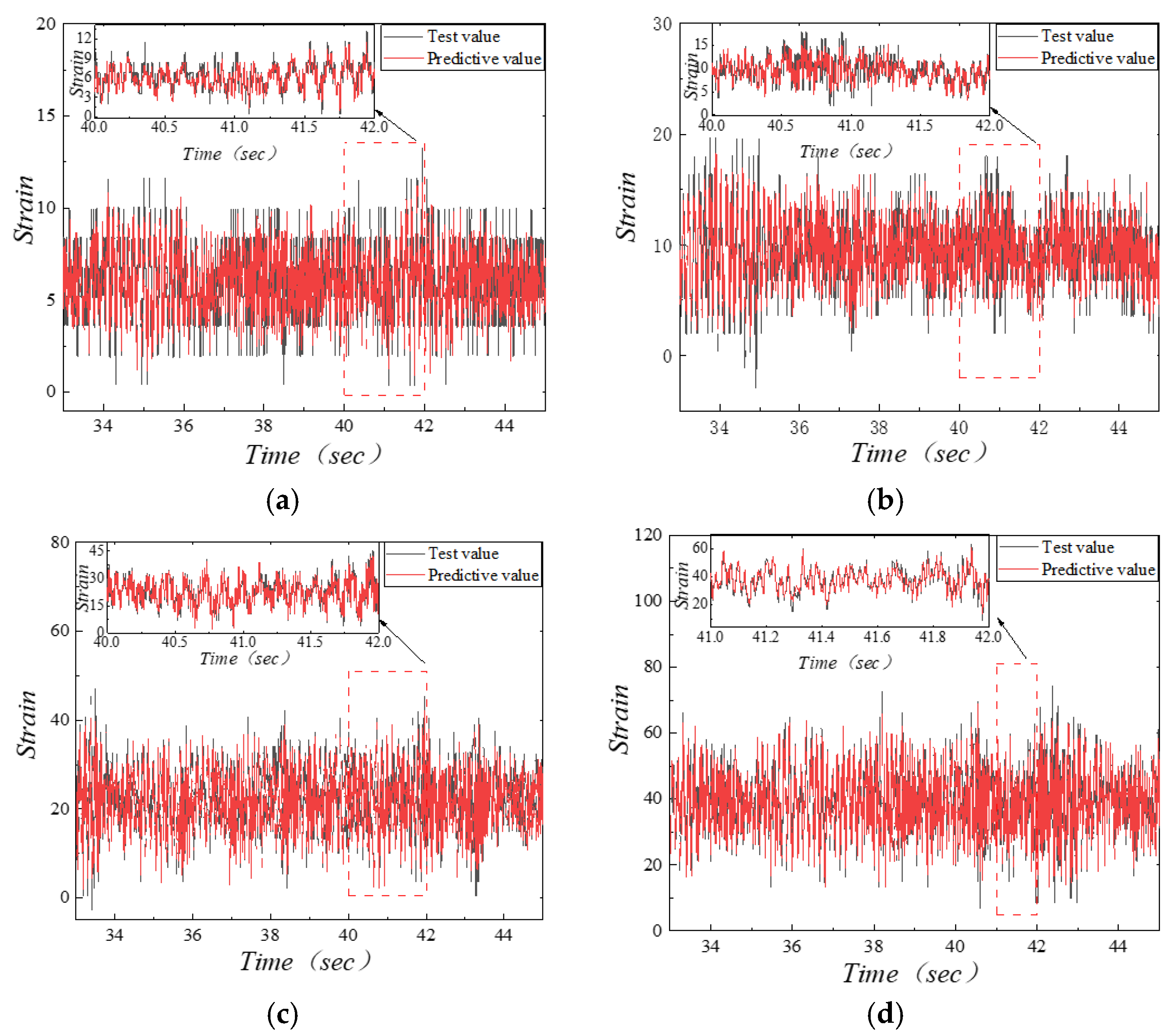

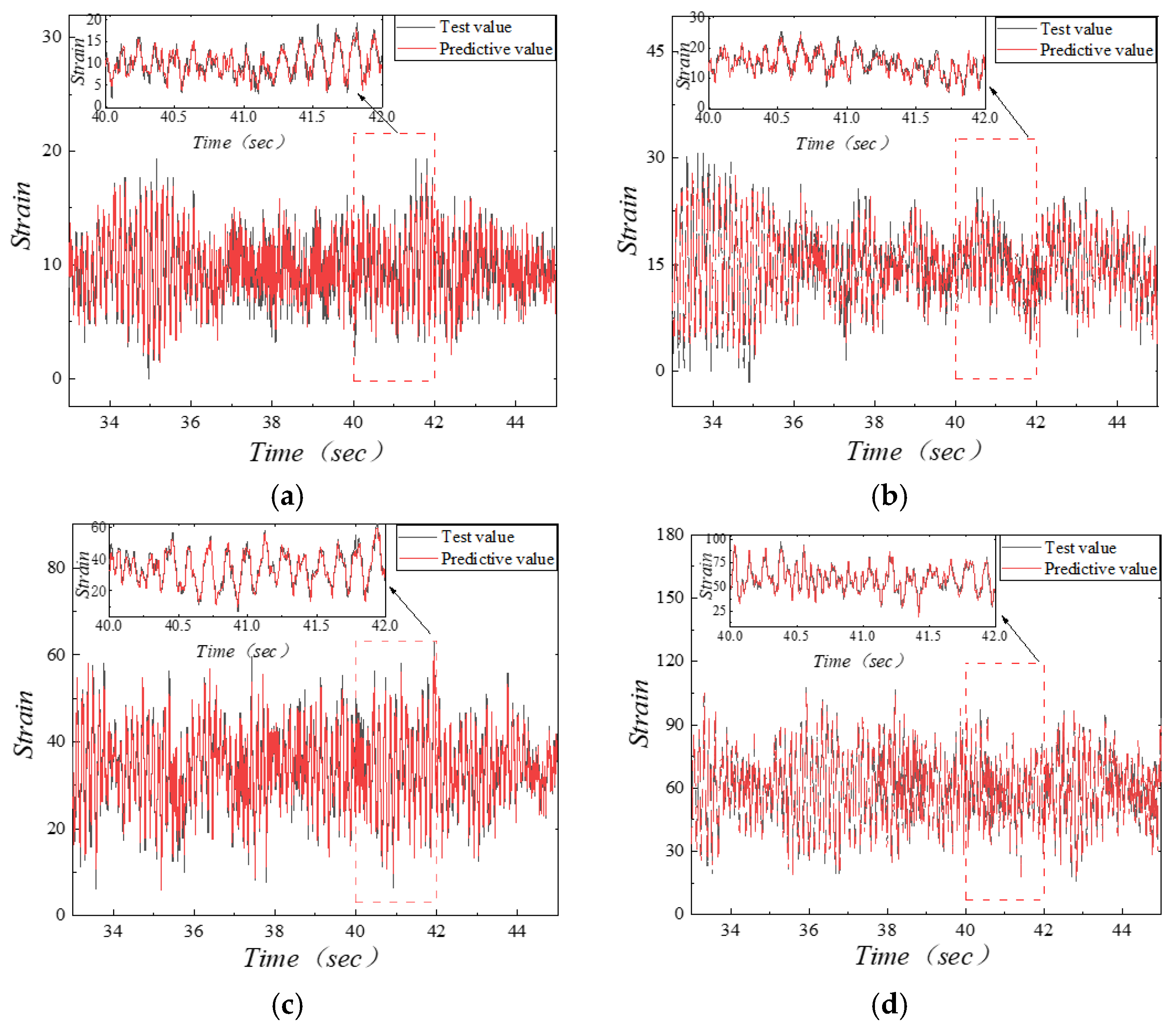

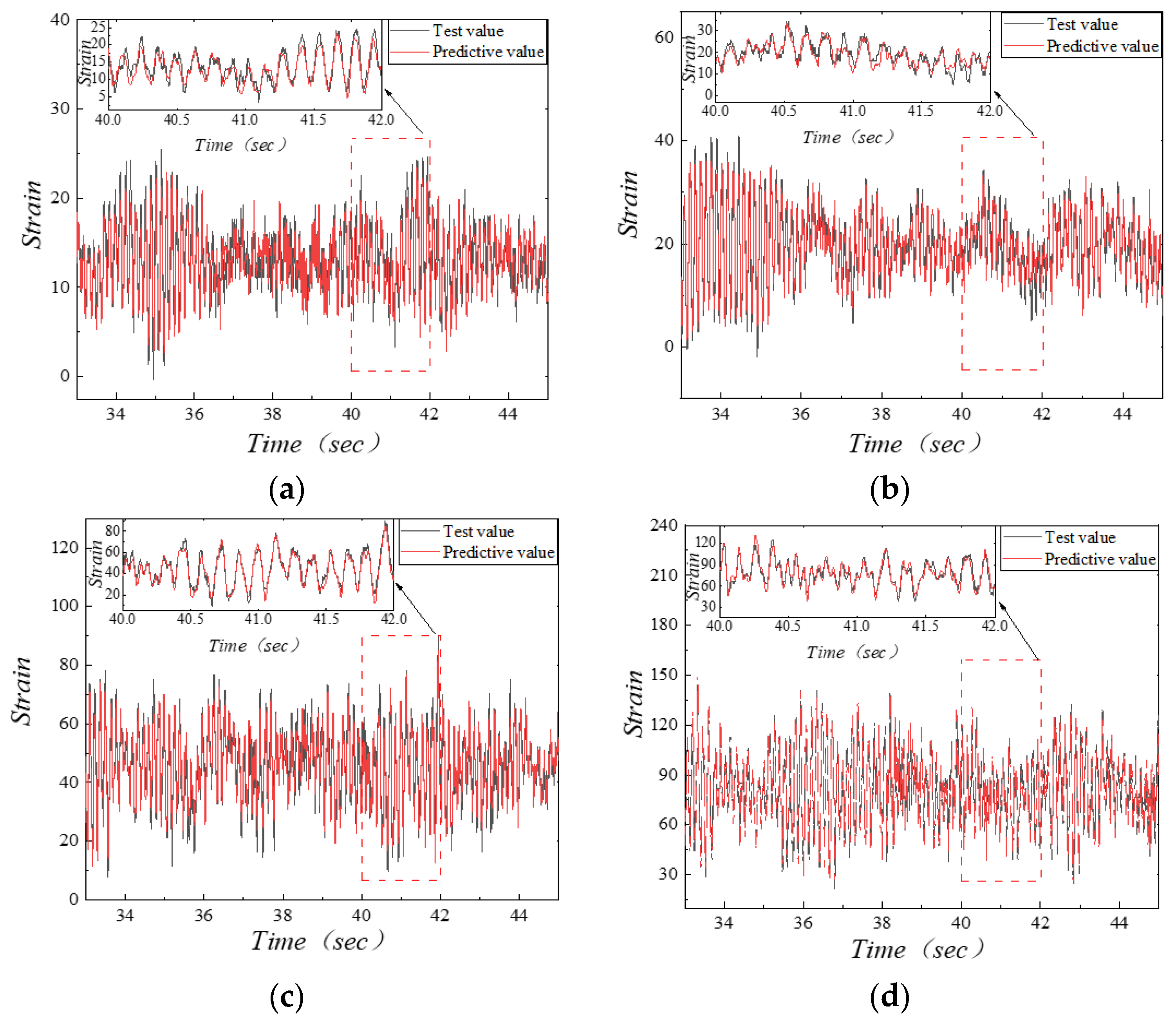

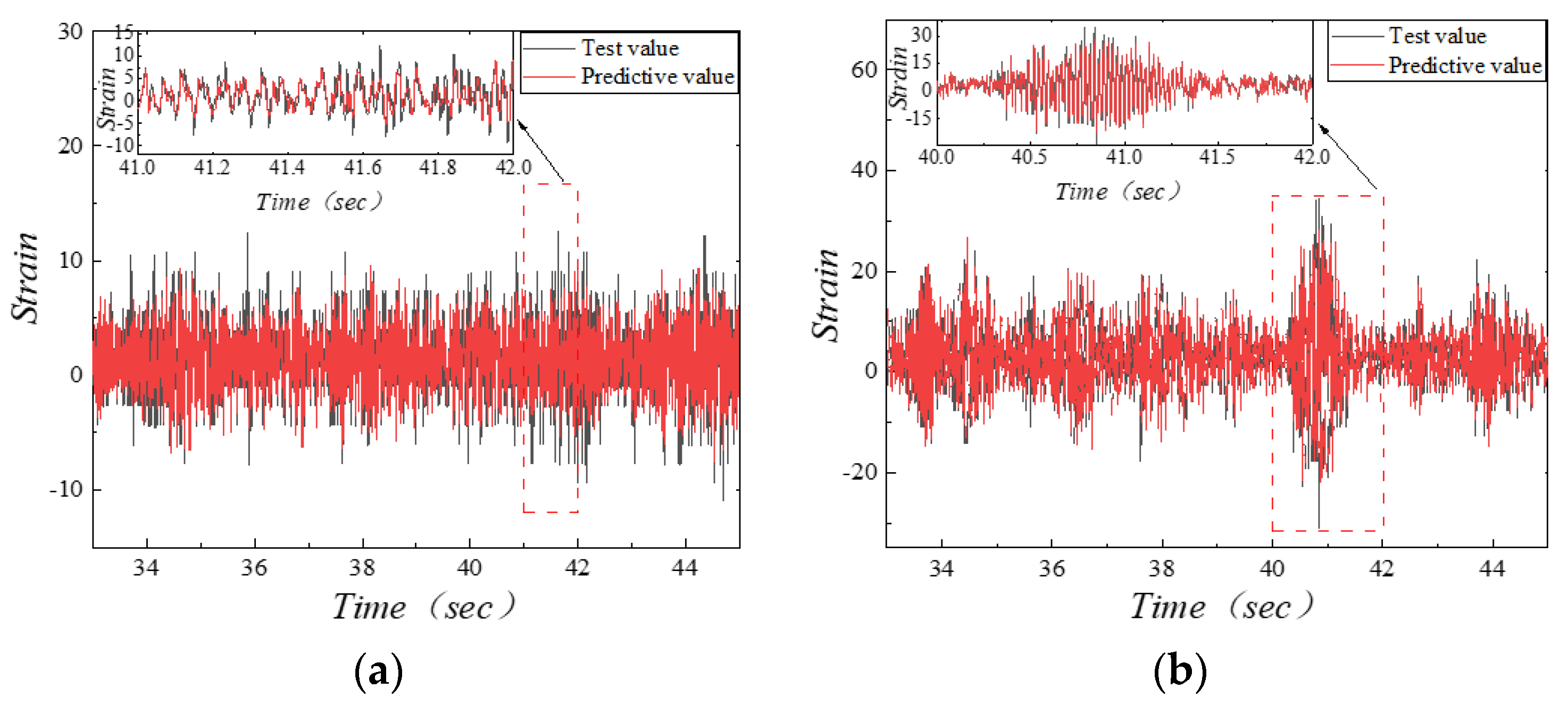

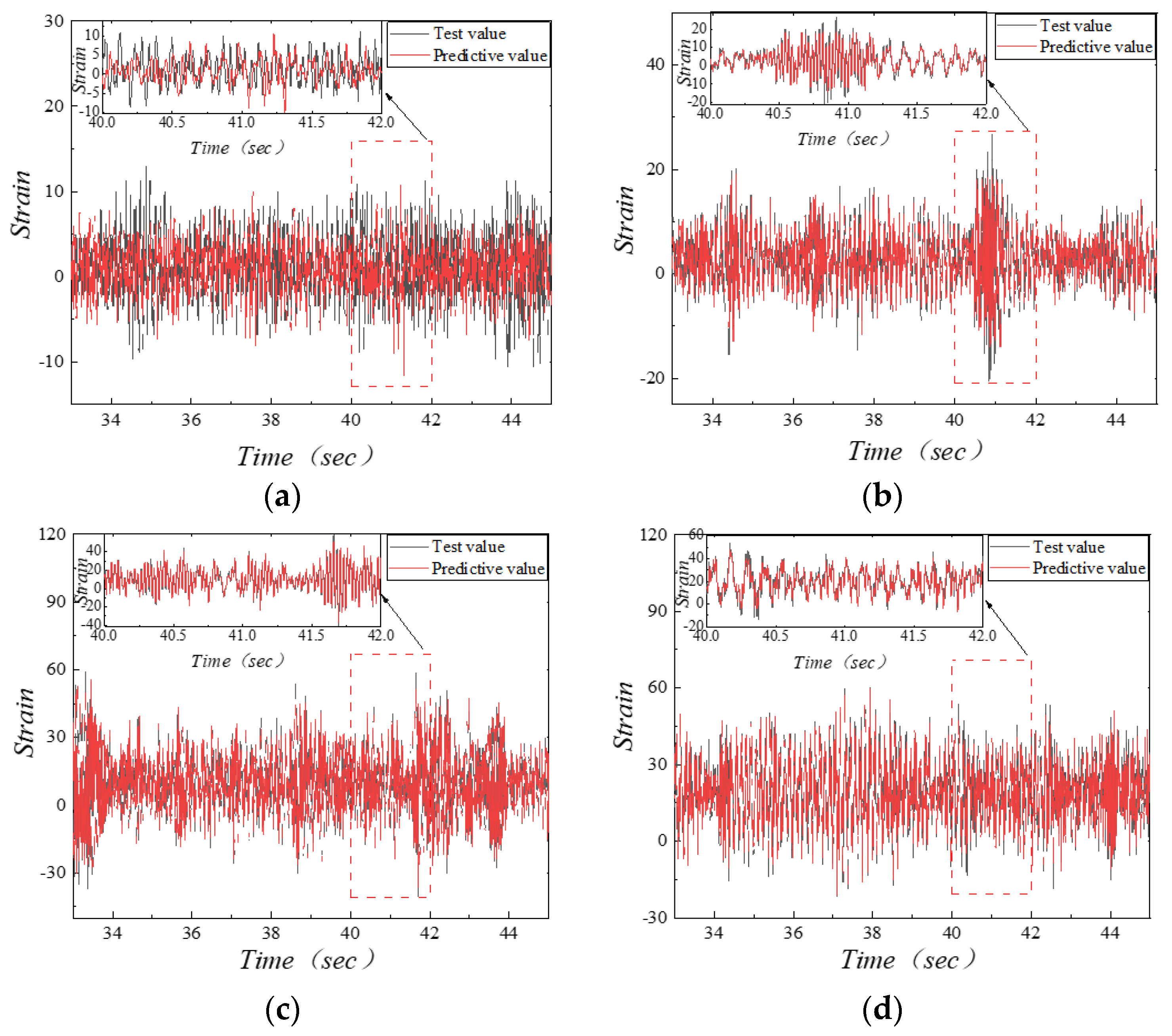

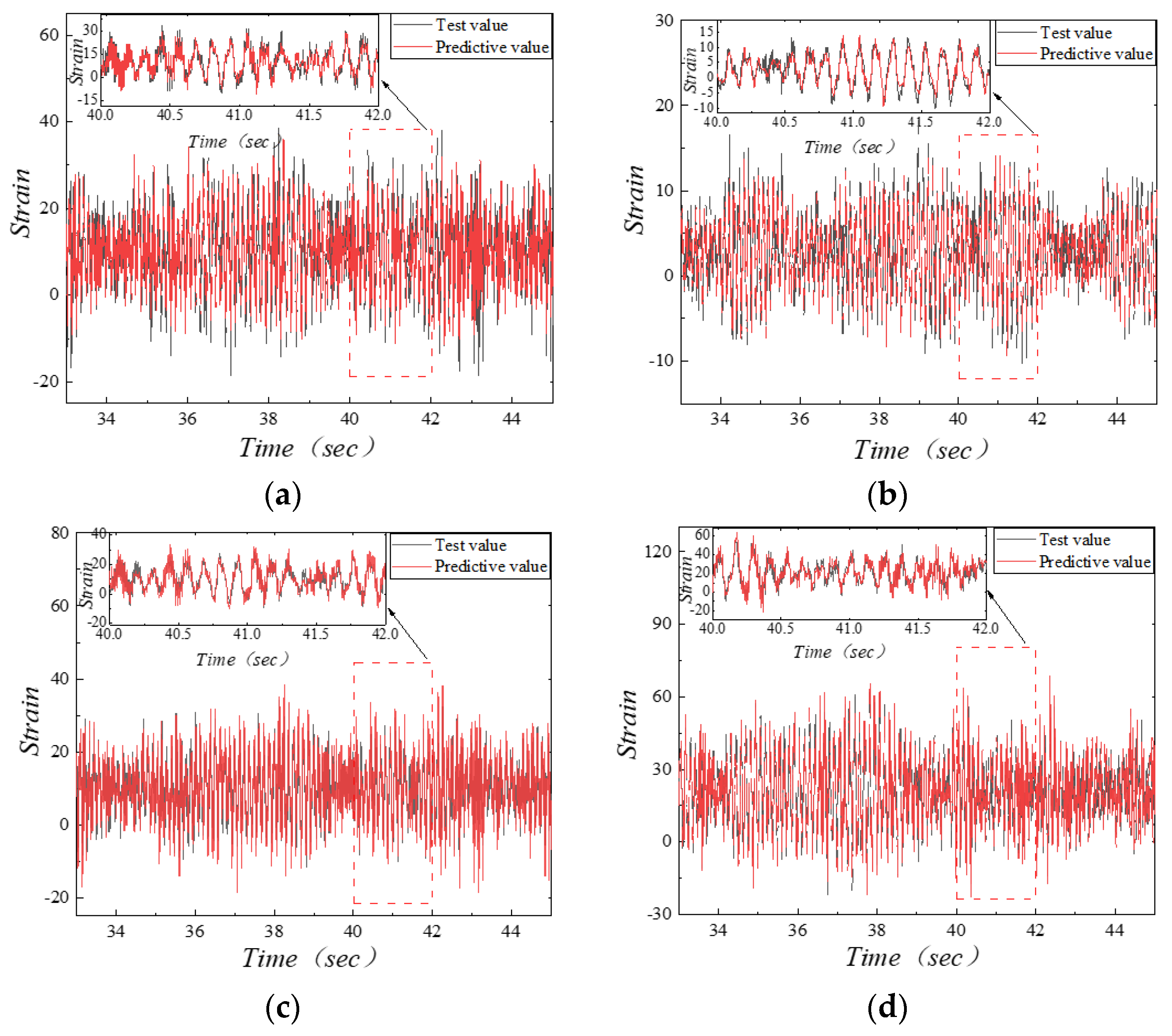

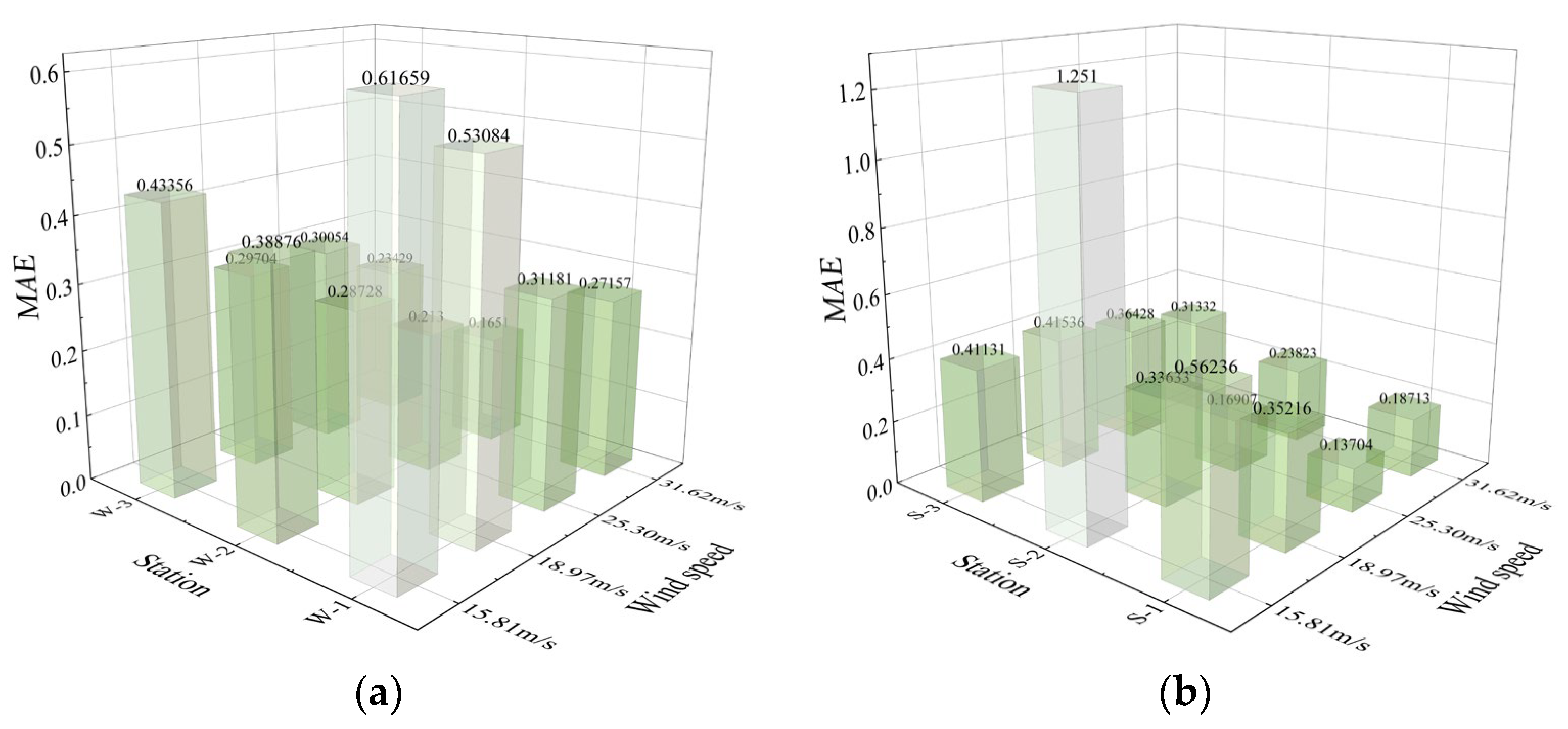

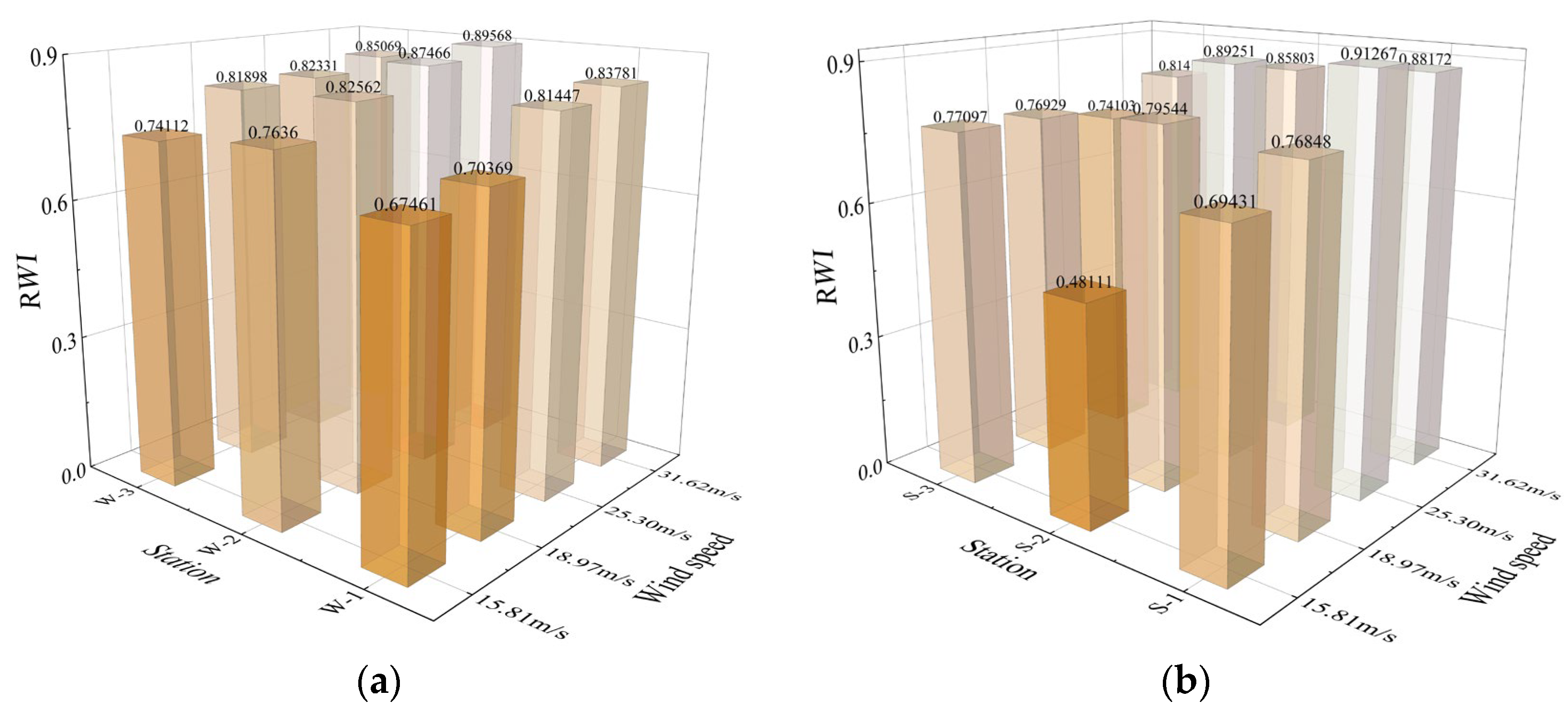

4.5. Prediction Results of the Strain Response Data of the Lightning Rod

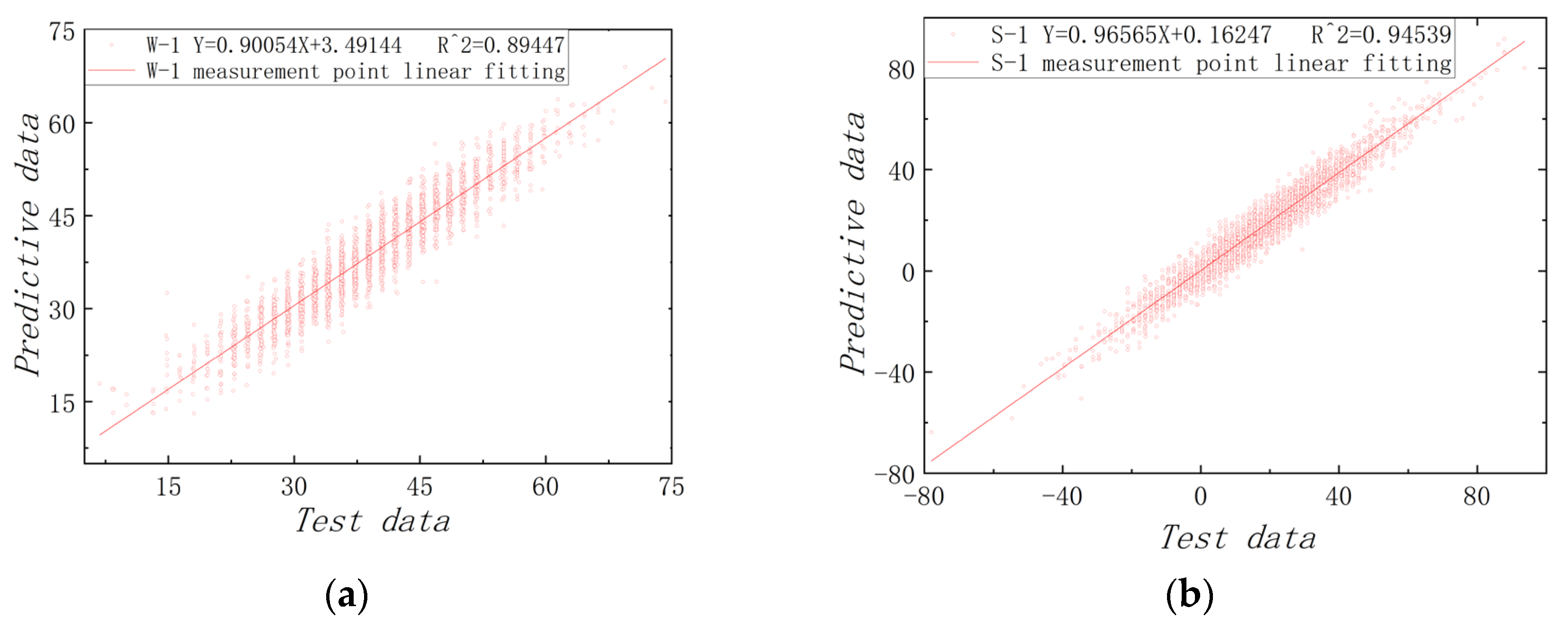

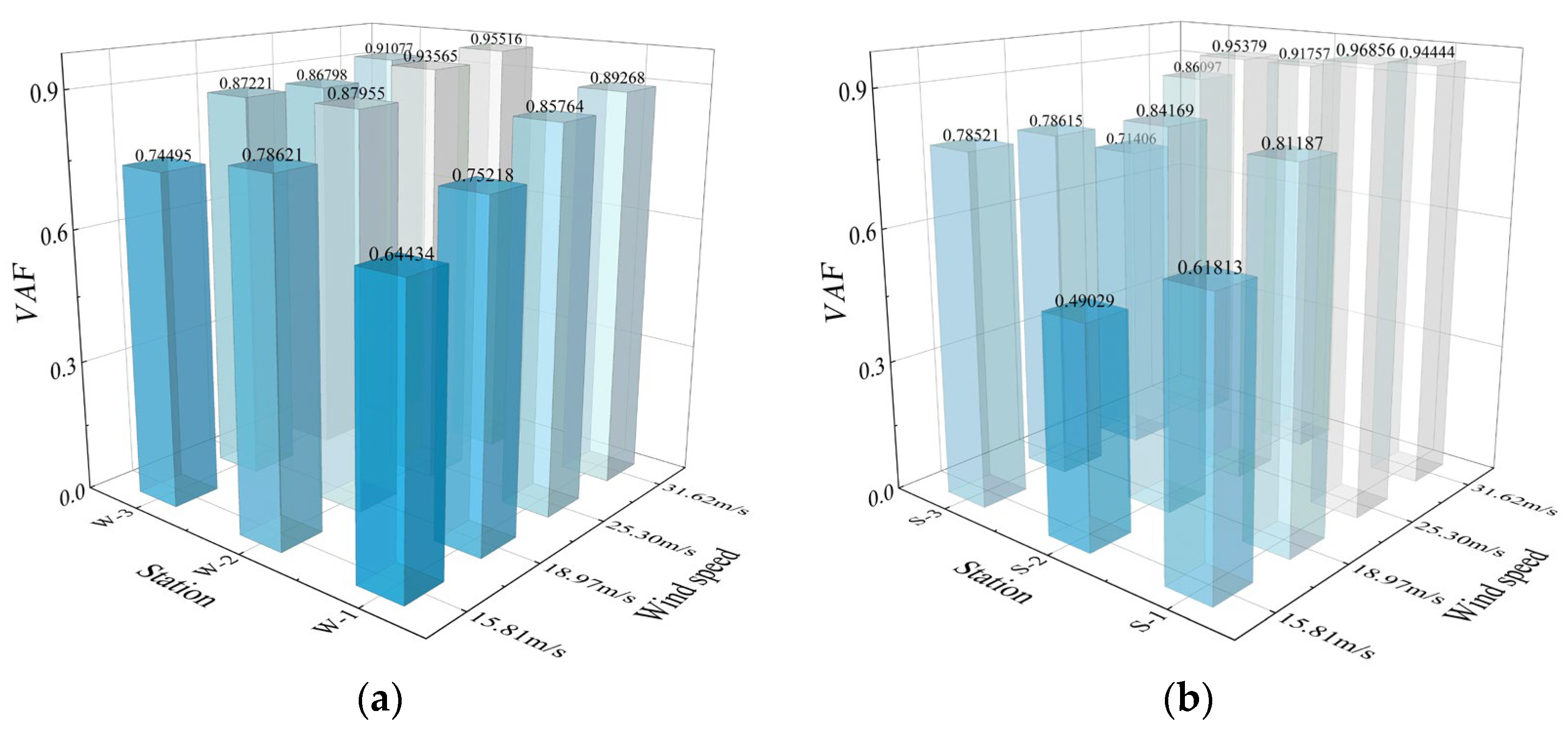

4.6. Correlation Analysis of the Predictive Data under Extreme Wind Speed Conditions

5. Conclusions

- The high-frequency and complex response of the lightning rod structure in the along-wind direction and the crosswind direction mainly occurs near measurement point 1 on the upper part of the structure. Problems such as loss or abnormality of monitoring data are prone to occur. Therefore, it is important to focus on this measurement point and prepare for missing data prediction during testing and monitoring.

- Under the normal working wind speed range of the lightning rod structure, regardless of whether frequently encountered wind speed or extreme wind speed, the strain responses of the measurement point predicted by the LSTM model are in good agreement with the measured values of the wind tunnel test. Even under the case of an extreme wind speed of 31.62 m/s, the values of RMSE, MAE, R2, RWI and VAF are 0.24053, 0.18213, 0.94539, 0.88172 and 0.94444, respectively, which are within the acceptable range, indicating that the LSTM method can better capture the nonlinear mapping relationship between the strains of each measurement point and has high reliability and stability.

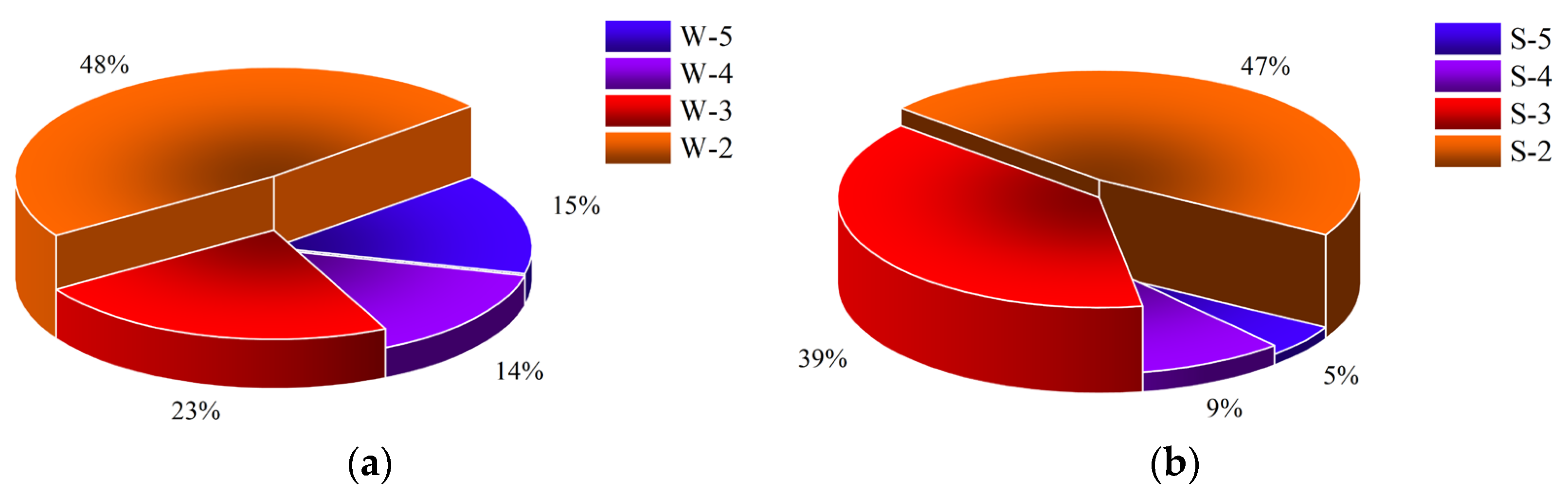

- In the structural vibration response prediction, measurement point 2 plays a decisive role in the prediction result at measurement point 1, while the influence of measurement points 5 and 4 on the prediction results is almost negligible. In general, the measured response data of the monitoring points that are closer to the predicted measurement point have a greater impact on the response of the predicted measurement point, while the measured response data of monitoring points that are far from the predicted measurement point have less impact on the response of the predicted measurement point and are considered ignorable.

- Finally, it should be noted that it is necessary to perform more complex processing on the noise data to make the prediction results more accurate and meet engineering requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, G.; Li, J.; Zhang, M.; Yi, Y. Experimental study on the bearing capacity and fatigue life of lightning rod structure joints in high-voltage substation structures. Thin-Walled Struct. 2022, 175, 109282. [Google Scholar] [CrossRef]

- Guojun, D.; Lei, G.; Manling, D. Break Fault Analysis and Countermeasure of Frame Lighting Rod. Henan Electr. Power 2015, 4, 6–9. [Google Scholar]

- Tao, S. A Cause Analysis of Fracture Failure with Architecture Type Lightning Rod. Insul. Surge Arresters 2017, 2, 49–52. [Google Scholar]

- Jian, W.; Heming, D. The Deformation Analysis and Countermeasures on the Frame Lightning Rod of 750 kV Substation in the Wind Damage Areas. Insul. Surge Arresters 2017, 2, 14–18. [Google Scholar]

- Gomez-Cabrera, A.; Escamilla-Ambrosio, P.J. Review of Machine-Learning Techniques Applied to Structural Health Monitoring Systems for Building and Bridge Structures. Appl. Sci. 2022, 12, 10754. [Google Scholar] [CrossRef]

- Ye, X.W.; Jin, T.; Yun, C.B. A review on deep learning-based structural health monitoring of civil infrastructures. Smart Struct. Syst. 2019, 24, 567–585. [Google Scholar]

- Rucevskis, S.; Kovalovs, A.; Chate, A. Optimal Sensor Placement in Composite Circular Cylindrical Shells for Structural Health Monitoring. J. Phys. Conf. Ser. 2023, 2423, 12021. [Google Scholar] [CrossRef]

- Luo, Y.; Mei, Y.; Shen, Y.; Yang, P.; Jin, L.; Zhang, P. Field measurement of temperature and stress on steel structure of the National Stadium and analysis of temperature action. J. Build. Struct. 2013, 34, 24–32. [Google Scholar]

- Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Adeli, H. Wireless smart sensors for monitoring the health condition of civil infrastructure. Sci. Iran. 2018, 25, 2913–2925. [Google Scholar]

- Sabato, A.; Niezrecki, C.; Fortino, G. Wireless MEMS-based accelerometer sensor boards for structural vibration monitoring: A review. IEEE Sens. J. 2016, 17, 226–235. [Google Scholar] [CrossRef]

- Sarkar, S.; Reddy, K.K.; Giering, M. Deep learning for structural health monitoring: A damage characterization application. In Proceedings of the Annual Conference of the PHM Society, Denver, CO, USA, 3–6 October 2016; Volume 8. [Google Scholar]

- Oh, B.K.; Glisic, B.; Kim, Y.; Park, H.S. Convolutional neural network-based data recovery method for structural health monitoring. Struct. Health Monit. 2020, 19, 1821–1838. [Google Scholar] [CrossRef]

- Muin, S.; Mosalam, K.M. Structural health monitoring using machine learning and cumulative absolute velocity features. Appl. Sci. 2021, 11, 5727. [Google Scholar] [CrossRef]

- Yuen, K.V.; Kuok, S.C. Ambient interference in long-term monitoring of buildings. Eng. Struct. 2010, 32, 2379–2386. [Google Scholar] [CrossRef]

- Cross, E.J.; Manson, G.; Worden, K.; Pierce, S.G. Features for damage detection with insensitivity to environmental and operational variations. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 4098–4122. [Google Scholar] [CrossRef]

- Sarmadi, H.; Karamodin, A. A novel anomaly detection method based on adaptive Mahalanobis-squared distance and one-class kNN rule for structural health monitoring under environmental effects. Mech. Syst. Signal Process. 2020, 140, 106495. [Google Scholar] [CrossRef]

- Padil, K.H.; Bakhary, N.; Abdulkareem, M.; Li, J.; Hao, H. Nonprobabilistic method to consider uncertainties in frequency response function for vibration-based damage detection using artificial neural network. J. Sound Vib. 2020, 467, 115069. [Google Scholar] [CrossRef]

- Bao, Y.; Tang, Z.; Li, H.; Zhang, Y. Computer vision and deep learning–based data anomaly detection method for structural health monitoring. Struct. Health Monit. 2019, 18, 401–421. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, Z.; Bao, Y.; Li, H. Convolutional neural network-based data anomaly detection method using multiple information for structural health monitoring. Struct. Control Health Monit. 2019, 26, e2296. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Inman, D.J. Wireless and real-time structural damage detection: A novel decentralized method for wireless sensor networks. J. Sound Vib. 2018, 424, 158–172. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Li, S.; Li, S.; Laima, S.; Li, H. Data-driven modeling of bridge buffeting in the time domain using long short-term memory network based on structural health monitoring. Struct. Control Health Monit. 2021, 28, e2772. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Iparraguirre-Villanueva, O.; Alvarez-Risco, A.; Salazar, J.L.H.; Beltozar-Clemente, S.; Zapata-Paulini, J.; Yáñez, J.A.; Cabanillas-Carbonell, M. The Public Health Contribution of Sentiment Analysis of Monkeypox Tweets to Detect Polarities Using the CNN-LSTM Model. Vaccines 2023, 11, 312. [Google Scholar] [CrossRef] [PubMed]

- Smagulova, K.; James, A.P. A survey on LSTM memristive neural network architectures and applications. Eur. Phys. J. Spec. Top. 2019, 228, 2313–2324. [Google Scholar] [CrossRef]

- Bakhshi Ostadkalayeh, F.; Moradi, S.; Asadi, A.; Nia, A.M.; Taheri, S. Performance Improvement of LSTM-based Deep Learning Model for Streamflow Forecasting Using Kalman Filtering. Water Resour. Manag. 2023, 1–17. [Google Scholar] [CrossRef]

- Chen, X.; Chen, W.; Dinavahi, V.; Liu, Y.; Feng, J. Short-Term Load Forecasting and Associated Weather Variables Prediction Using ResNet-LSTM Based Deep Learning. IEEE Access 2023, 11, 5393–5405. [Google Scholar] [CrossRef]

- Graves, A.; Schmidhuber, J. Framewise phoneme classification with bidirectional LSTM and other neural network architectures. Neural Netw. 2005, 18, 602–610. [Google Scholar] [CrossRef]

- Liu, H.-J.; Shan, W.-F.; Geng, G.-Z. Earthquake Prediction Using Dissolved Radon Data in Long and Short Term Memory Network. Sci. Technol. Eng. 2020, 20, 4029–4035. [Google Scholar]

- Gers, F.A.; Schmidhuber, J.; Cummins, F. Learning to forget: Continual prediction with LSTM. Neural Comput. 2000, 12, 2451–2471. [Google Scholar] [CrossRef]

- Nasir, J.; Aamir, M.; Haq, Z.U.; Khan, S.; Amin, M.Y.; Naeem, M. A new approach for forecasting crude oil prices based on stochastic and deterministic influences of LMD Using ARIMA and LSTM Models. IEEE Access 2023, 11, 14322–14339. [Google Scholar] [CrossRef]

- De Pater, I.; Mitici, M. Developing health indicators and RUL prognostics for systems with few failure instances and varying operating conditions using a LSTM autoencoder. Eng. Appl. Artif. Intell. 2023, 117, 105582. [Google Scholar] [CrossRef]

- Roux, A.; Changey, S.; Weber, J.; Lauffenburger, J.-P. LSTM-Based Projectile Trajectory Estimation in a GNSS-Denied Environment. Sensors 2023, 23, 3025. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Chen, Z.; Chen, S.; Zheng, J.; Büyüköztürk, O.; Sun, H. Deep long short-term memory networks for nonlinear structural seismic response prediction. Comput. Struct. 2019, 220, 55–68. [Google Scholar] [CrossRef]

- Byeon, W.; Breuel, T.M.; Raue, F.; Liwicki, M. Scene labeling with lstm recurrent neural networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 3547–3555. [Google Scholar]

- Long, X.; Ding, X.; Li, J.; Dong, R.; Su, Y.; Chang, C. Indentation Reverse Algorithm of Mechanical Response for Elastoplastic Coatings Based on LSTM Deep Learning. Materials 2023, 16, 2617. [Google Scholar] [CrossRef]

- Long, B.; Tan, F.; Newman, M. Forecasting the Monkeypox Outbreak Using ARIMA, Prophet, NeuralProphet, and LSTM Models in the United States. Forecasting 2023, 5, 127–137. [Google Scholar] [CrossRef]

- Xie, X.; Luo, Y.; Zhang, N. Miss data reconstruction in stress monitoring of steel spatial structures using neural network techniques. Spat. Struct. 2019, 25, 38–44. [Google Scholar]

- Han, J.; Pak, W. Hierarchical LSTM-Based Network Intrusion Detection System Using Hybrid Classification. Appl. Sci. 2023, 13, 3089. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, J.; Shen, J.; Xiang, M. Recursive long short-term memory network for predicting nonlinear structural seismic response. Eng. Struct. 2022, 250, 113406. [Google Scholar] [CrossRef]

- Raja, M.N.A.; Shukla, S.K. Predicting the settlement of geosynthetic-reinforced soil foundations using evolutionary artificial intelligence technique. Geotext. Geomembr. 2021, 49, 1280–1293. [Google Scholar] [CrossRef]

- Demirbay, B.; Bayram, D.; Uur, A. A bayesian regularized feed-forward neural network model for conductivity prediction of ps/mwcnt nanocomposite film coatings. Appl. Soft Comput. 2020, 96, 106632. [Google Scholar] [CrossRef]

| Similarity Parameter | Geometric Ratio λL | Mass Ratio λM | Wind Speed Ratio λU | Flexural Rigidity Ratio λEI | Frequency Ratio λf | Damping Ratio λζ |

|---|---|---|---|---|---|---|

| Similitude ratio | n | n3 | n0.5 | n5 | n−0.5 | 1 |

| Values | 1:10 | 1:1000 | 1:3.16 | 1:100,000 | 3.16:1 | 1 |

| Layer | Type | Activation Function | Output Shape |

|---|---|---|---|

| Input | InputLayer | - | (none, n, f + 1) |

| LSTM1 | LSTM | tanh | (none, n, 250) |

| Dropout1 | dropout | - | 0.2 |

| LSTM2 | LSTM | tanh | (none, n, 250) |

| Dropout2 | dropout | - | 0.2 |

| LSTM3 | LSTM | tanh | (none, n, 250) |

| Dropout3 | dropout | - | 0.2 |

| FC | Dense | Linear | (none, s × f) |

| Modal Number | Aeroelastic Model Natural Frequency (Hz) | |

|---|---|---|

| W-Axis | S-Axis | |

| 1st order | 7.95 | 8.97 |

| 2nd order | 17.48 | 19.23 |

| 3rd order | 43.41 | 47.49 |

| 4th order | 64.02 | 71.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Xing, K.; Wang, Y.; Qian, H.; Zhang, M. Long Short-Term Memory Network for Predicting Wind-Induced Vibration Response of Lightning Rod Structures. Buildings 2023, 13, 1256. https://doi.org/10.3390/buildings13051256

Zhao G, Xing K, Wang Y, Qian H, Zhang M. Long Short-Term Memory Network for Predicting Wind-Induced Vibration Response of Lightning Rod Structures. Buildings. 2023; 13(5):1256. https://doi.org/10.3390/buildings13051256

Chicago/Turabian StyleZhao, Guifeng, Kaifeng Xing, Yang Wang, Hui Qian, and Meng Zhang. 2023. "Long Short-Term Memory Network for Predicting Wind-Induced Vibration Response of Lightning Rod Structures" Buildings 13, no. 5: 1256. https://doi.org/10.3390/buildings13051256

APA StyleZhao, G., Xing, K., Wang, Y., Qian, H., & Zhang, M. (2023). Long Short-Term Memory Network for Predicting Wind-Induced Vibration Response of Lightning Rod Structures. Buildings, 13(5), 1256. https://doi.org/10.3390/buildings13051256

_Mei.png)