Fabrication-Aware Joint Clustering in Freeform Space-Frames

Abstract

1. Introduction

2. Context

2.1. Clustering Analysis of Space-Frame Joints

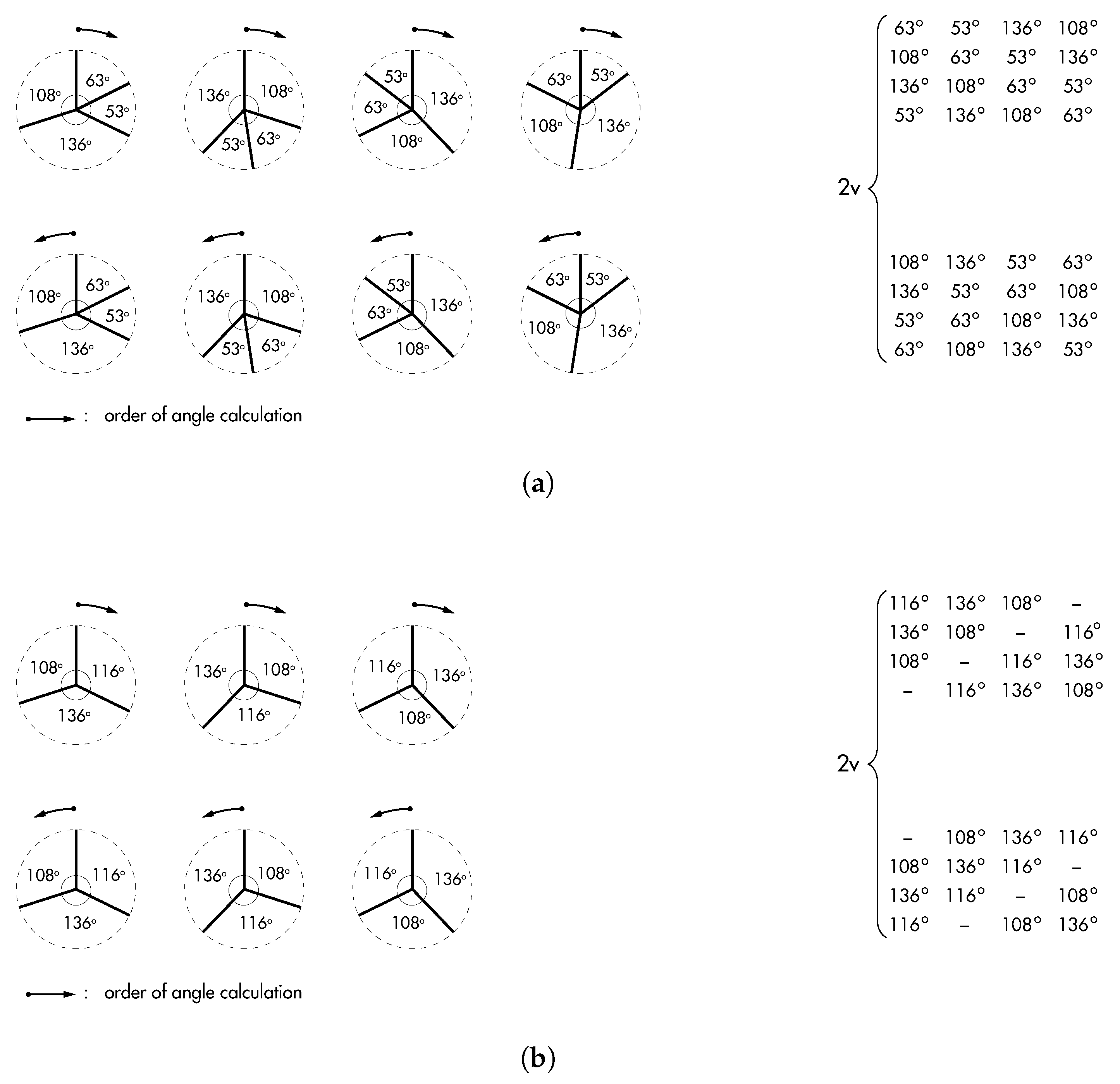

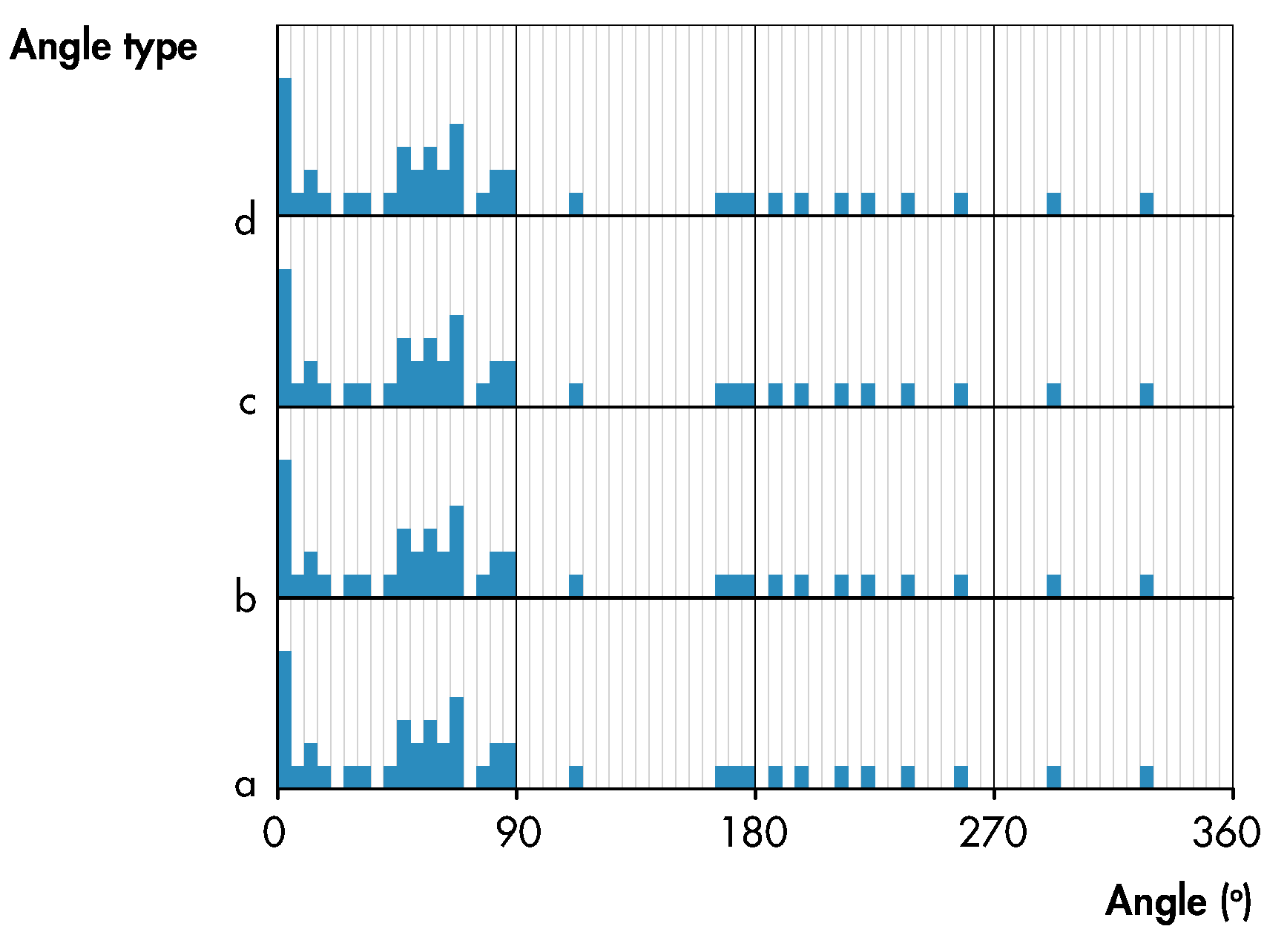

2.1.1. Angles Dataset

2.1.2. Joint Valence

2.1.3. Adaptive Sampling

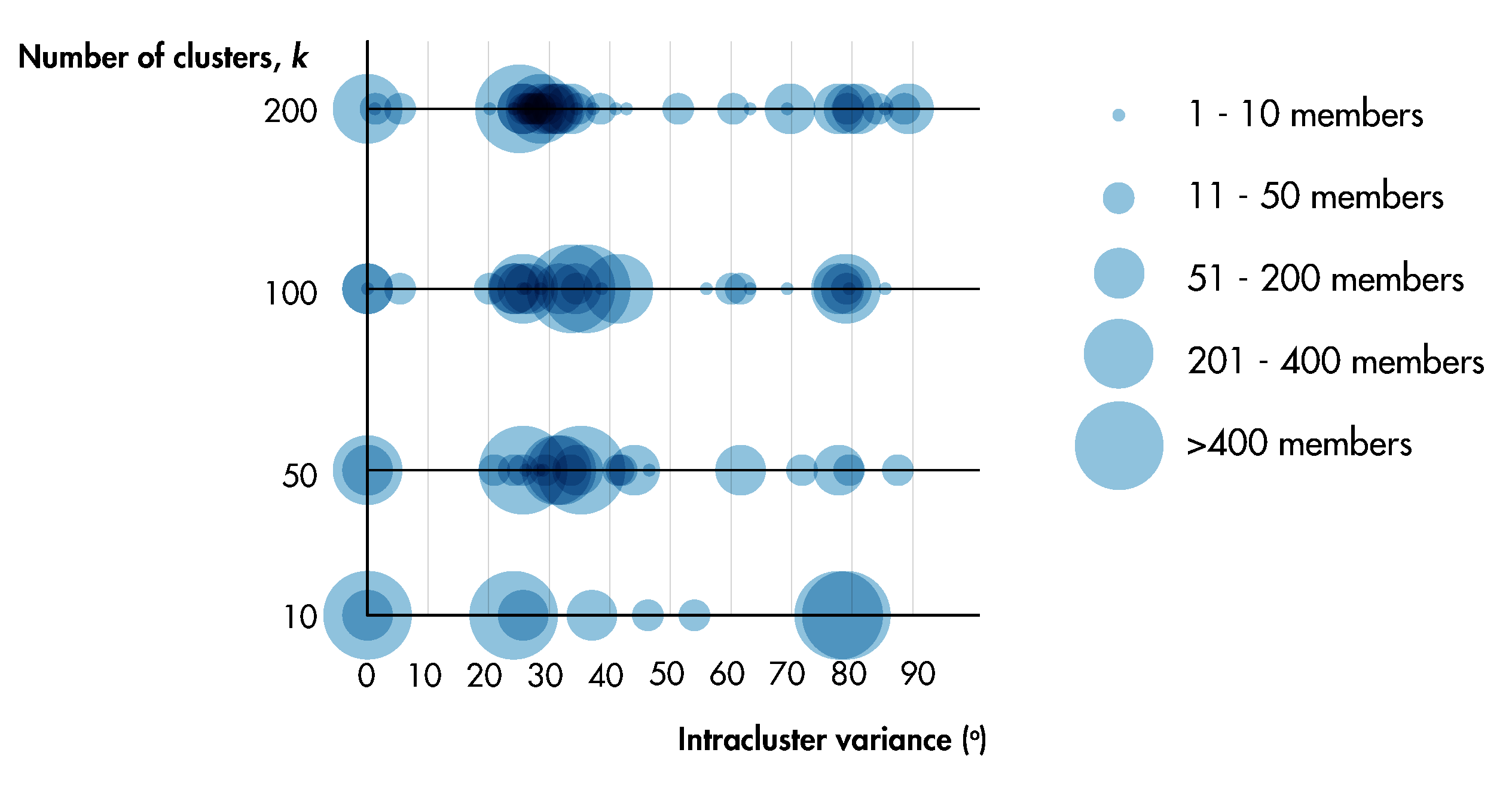

2.1.4. Evaluation of Cluster Compactness

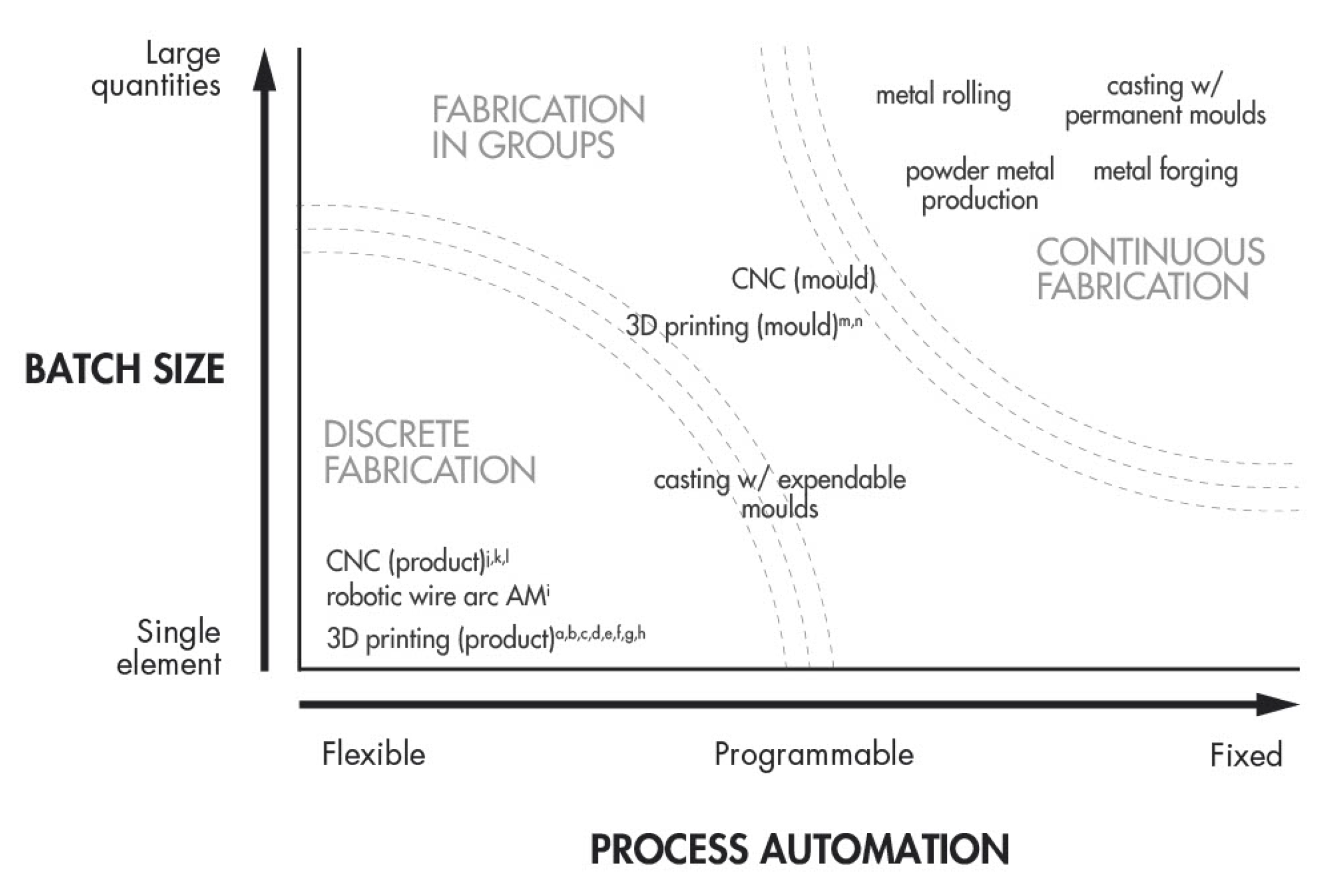

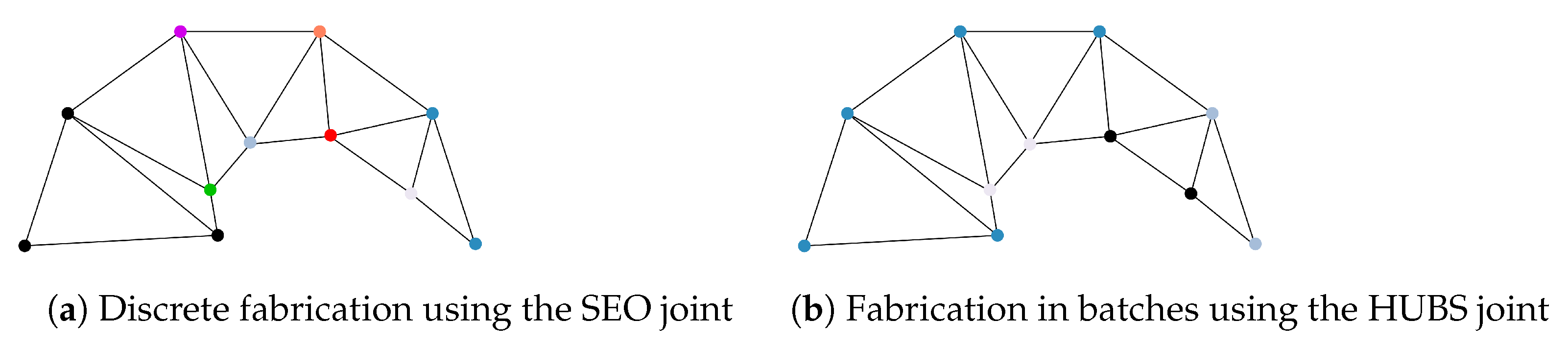

2.2. Classification of Fabrication Processes

2.3. Joint Tolerance

3. Research Methodology

3.1. Clustering Joints of Different Valence

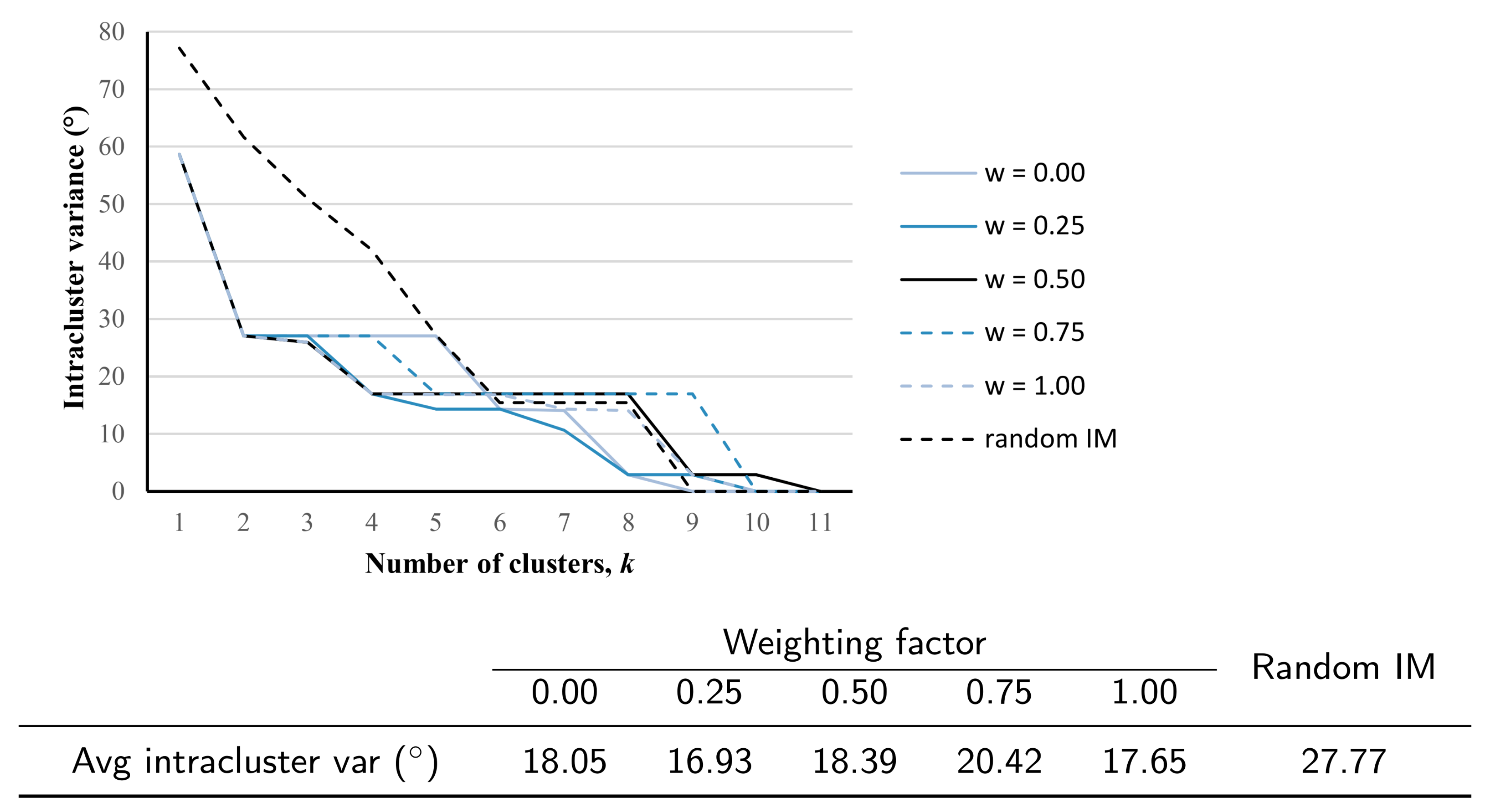

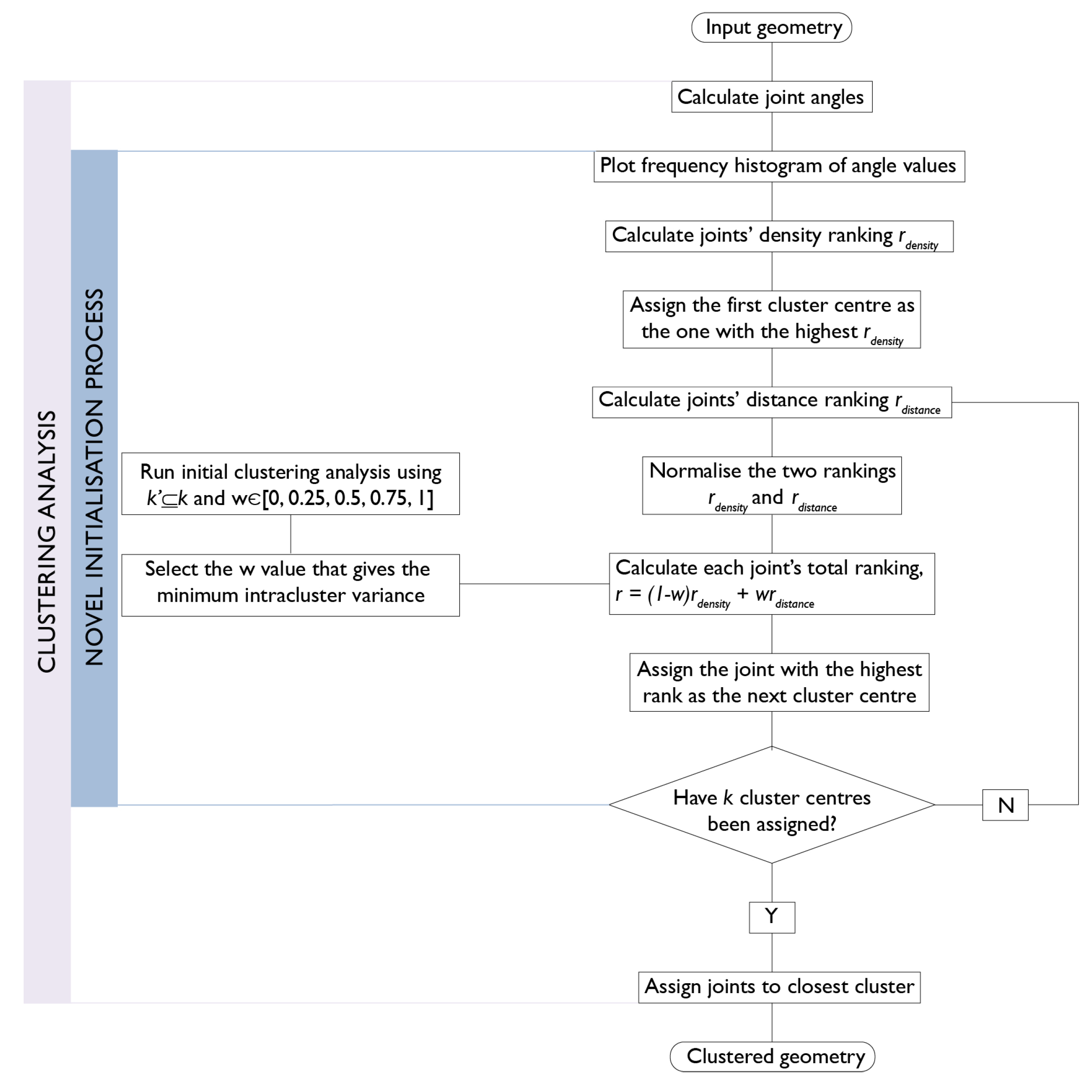

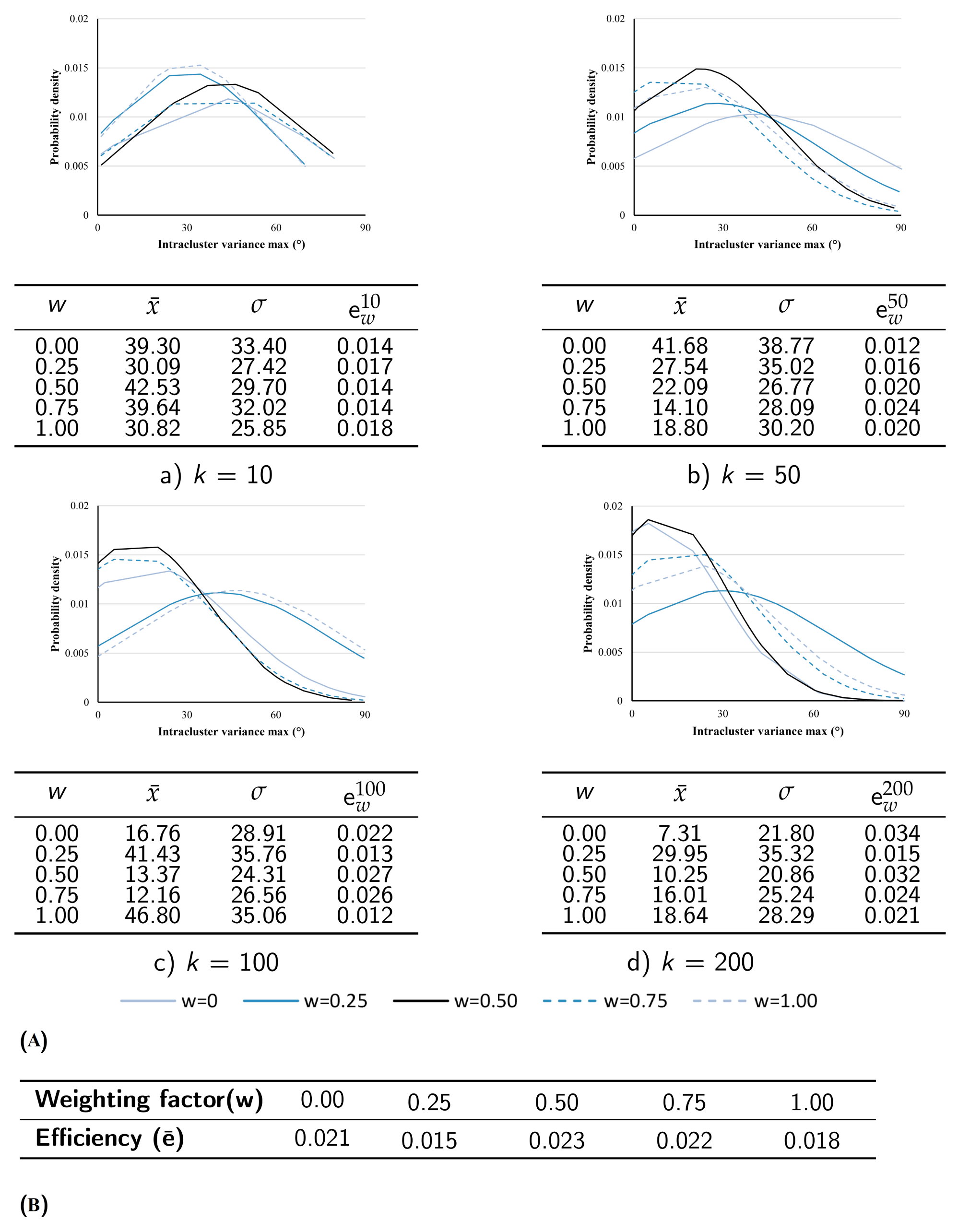

3.2. New Formulation of the k-Means Initialisation Method

3.2.1. Density Distribution

3.2.2. Joint Ranking

3.2.3. Weighting Factor w

4. Real-Building Case Study

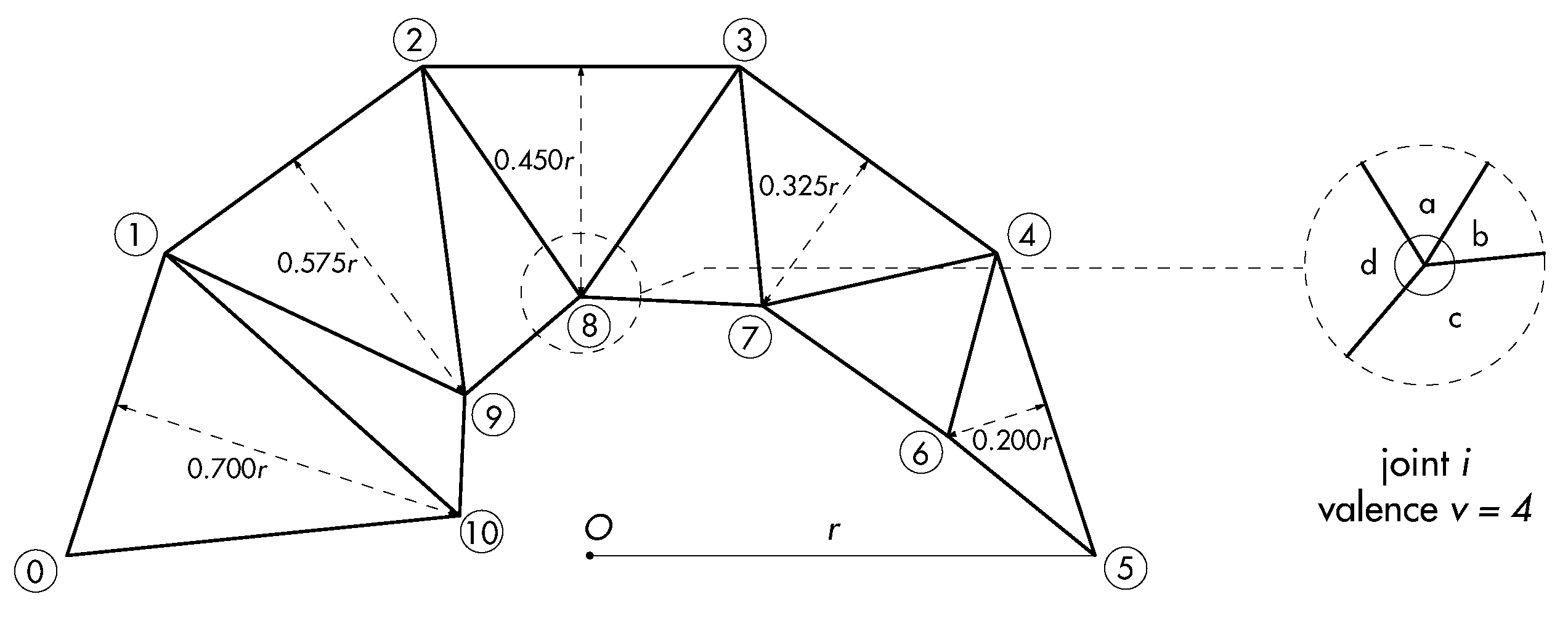

4.1. Description

4.2. Results

4.3. Assessing Fabrication Complexity

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klimke, H.; Sanchez, J.; Vasiliu, M.; Stühler, W.; Kaspar, C. The Envelopes of the Arts Centre in Singapore. In Proceedings of the IABSE Symposium: Towards a Better Built Environment—Innovation, Sustainability, Information Technology, Melbourne, Australia, 11–13 September 2002. [Google Scholar] [CrossRef]

- Sanchez-Alvarez, J. Practical aspects determining the modelling of the space structure for the free-form envelope enclosing Baku’s Heydar Aliyev Cultural Centre. In Proceedings of the Symposium of the International Association for Shell and Spatial Structures (50th. 2009. Valencia), Evolution and Trends in Design, Analysis and Construction of Shell and Spatial Structures: Proceedings, Valencia, Spain, 28 September–2 October 2009. [Google Scholar]

- Kalpakjian, S.; Schmid, S. Manufacturing Engineering and Technology, 7th ed.; Pearson: New York, NY, USA, 2013. [Google Scholar]

- Lan, T.T. Space Frame Structures. In Structural Engineering Handbook; Wai-Fah, C., Ed.; Number 1999; CRC Press: Boca Raton, FL, USA, 2005; pp. 1–50. [Google Scholar] [CrossRef]

- Koronaki, A.; Shepherd, P.; Evernden, M. Geometry optimization of space frame structures for joint modularity. In Proceedings of the Creativity in Structural Design, Boston, MA, USA, 16–20 July 2018. [Google Scholar]

- Koronaki, A.; Shepherd, P.; Evernden, M. Rationalization of freeform space-frame structures: Reducing variability in the joints. Int. J. Archit. Comput. 2020, 18, 84–99. [Google Scholar] [CrossRef]

- Asadpoure, A.; Guest, J.K.; Valdevit, L. Incorporating fabrication cost into topology optimization of discrete structures and lattices. Struct. Multidiscip. Optim. 2015, 51, 385–396. [Google Scholar] [CrossRef]

- Paulson, B. Designing to reduce construction cost. J. Constr. Div. 1976, 102, 587–592. [Google Scholar] [CrossRef]

- Ranalli, F.; Flager, F.; Fischer, M. A Ground Structure Method to Minimize the Total Installed Cost of Steel Frame Structures. World Acad. Sci. Eng. Technol. Int. J. Civ. Environ. Eng. 2018, 12, 115–123. [Google Scholar]

- Batta, M. Machine Learning Algorithms—A Review. Int. J. Sci. Res. 2020, 9, 381–386. [Google Scholar] [CrossRef]

- Carleo, G.; Cirac, I.; Cranmer, K.; Daudet, L.; Schuld, M.; Tishby, N.; Vogt-Maranto, L.; Zdeborová, L. Machine learning and the physical sciences. Rev. Mod. Phys. 2019, 91, 45002. [Google Scholar] [CrossRef]

- Wierzchoń, S.T.; Kłopotek, M.A. Modern Algorithms of Cluster Analysis; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Celebi, M.E. Partitional Clustering Algorithms; Springer International Publishing: Cham, Switzerland, 2015; pp. 1–415. [Google Scholar] [CrossRef]

- Xu, D.; Tian, Y. A Comprehensive Survey of Clustering Algorithms. Ann. Data Sci. 2015, 2, 165–193. [Google Scholar] [CrossRef]

- Lloyd, S.P. Least squares quantization in PCM. IEEE Trans. Inf. Theory 1982, 28, 129–137. [Google Scholar] [CrossRef]

- Ghazal, T.M.; Hussain, M.Z.; Said, R.A.; Nadeem, A.; Hasan, M.K.; Ahmad, M.; Khan, M.A.; Naseem, M.T. Performances of k-means clustering algorithm with different distance metrics. Intell. Autom. Soft Comput. 2021, 30, 735–742. [Google Scholar] [CrossRef]

- Jain, A.K. Data clustering: 50 years beyond K-means. Pattern Recognit. Lett. 2010, 31, 651–666. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, G.; Du, J.; Sui, Y. Initialization of K-modes clustering using outlier detection techniques. Inf. Sci. 2016, 332, 167–183. [Google Scholar] [CrossRef]

- Celebi, M.E.; Kingravi, H.A.; Vela, P.A. A comparative study of efficient initialization methods for the k-means clustering algorithm. Expert Syst. Appl. 2013, 40, 200–210. [Google Scholar] [CrossRef]

- Blömer, J.; Lammersen, C.; Schmidt, M.; Sohler, C. Theoretical analysis of the k-means algorithm—A survey. In Algorithm Engineering; Lecture Notes in Computer Science—LNCS; Springer: Cham, Switzerland, 2016; Volume 9220, pp. 81–116. [Google Scholar] [CrossRef]

- Hussain, S.F.; Haris, M. A k-means based co-clustering (kCC) algorithm for sparse, high dimensional data. Expert Syst. Appl. 2019, 118, 20–34. [Google Scholar] [CrossRef]

- Ayech, M.W.; Ziou, D. Segmentation of Terahertz imaging using k-means clustering based on ranked set sampling. Expert Syst. Appl. 2015, 42, 2959–2974. [Google Scholar] [CrossRef]

- Mac Queen, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the 5th Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 21 June–18 July 1965; University of California Press: Berkeley, CA, USA, 1967; Volume 1, pp. 281–297. [Google Scholar]

- Forgy, E. Cluster analysis of multivariate data: Efficiency versus interpretability of classifications. Biometrics 1965, 21, 768–769. [Google Scholar]

- Li, Z.; Berger, V.W. Adaptive Sampling. In Encyclopedia of Statistics in Behavioral Science; Everitt, B.S., Howell, D.C., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2005; Volume 1, pp. 13–16. [Google Scholar]

- Aggarwal, A.; Deshpande, A.; Kannan, R. Adaptive sampling for k-means clustering. In Proceedings of the 12th International Workshop, APPROX 2009, and 13th International Workshop, RANDOM 2009, Berkeley, CA, USA, 21–23 August 2009; Volume 5687, pp. 15–28. [Google Scholar] [CrossRef]

- Katsavounidis, I.; Kuo, C.C.; Zhang, Z. A New Initialization Technique for Generalized Lloyd Iteration. IEEE Signal Process. Lett. 1994, 1, 144–146. [Google Scholar] [CrossRef]

- Arthur, D.; Vassilvitskii, S. k-means++: The advantages of careful seeding. In Proceedings of the SODA’07: Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms, Society for Industrial and Applied Mathematics. Philadelphia, PA, USA, 7–9 January 2007; pp. 1027–1035. [Google Scholar]

- Khan, S.S.; Ahmad, A. Cluster center initialization algorithm for K-modes clustering. Expert Syst. Appl. 2013, 40, 7444–7456. [Google Scholar] [CrossRef]

- Gourgaris, P.; Makris, C. A Density Based k-Means Initialization Scheme. In Proceedings of the EANN ’15: 16th International Conference on Engineering Applications of Neural Networks (INNs), Rhodes Island, Greece, 25–28 September 2015; pp. 1–9. [Google Scholar] [CrossRef]

- El Alaoui, M.; Ben-azza, H. New initialization for clustering algorithms combining distance and density. In Proceedings of the BDCA 2017: 2nd International Conference on Big Data, Cloud and Applications, Tetouan, Morocco, 29–30 March 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Kumar, K.M.; Reddy, A.R.M. An efficient k-means clustering filtering algorithm using density based initial cluster centers. Inf. Sci. 2017, 418–419, 286–301. [Google Scholar] [CrossRef]

- Yang, W.; Long, H.; Ma, L.; Sun, H. Research on clustering method based on weighted distance density and k-means. Procedia Comput. Sci. 2020, 166, 507–511. [Google Scholar] [CrossRef]

- Oti, E.U.; Unyeagu, S.I.; Nwankwo, C.H.; Alvan, W.K.; Osuji, G.A. New K-means clustering methods that minimize the total intra-cluster variance. Afr. J. Math. Stat. Stud. 2020, 3, 42–54. [Google Scholar]

- Niehe, P. Sand Printing Makes Complex Casted Structural Parts Affordable; European Press Office: Amsterdam, The Netherlands, 2017; Available online: https://www.arup.com/news-and-events/sand-printing-makes-complex-casted-structural-parts-affordable/ (accessed on 20 September 2022).

- Hubs. Geodesic Domes Made Simple. 2017. Available online: https://buildwithhubs.co.uk/ (accessed on 20 September 2022).

- Chun, J.; Lee, J.; Park, D. Topo-joint: Topology Optimization Framework for 3D-Printed Building Joints. In Proceedings of the 23rd International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA): Learning, Adapting and Prototyping, Beijing, China, 17–19 May 2018; Volume 1, pp. 205–214. [Google Scholar]

- Dritsas, S.; Chen, L.; Sass, L. Small 3D printers/large scale artifacts: Computation for Automated Spatial Lattice Design-to-Fabrication with Low Cost Linear Elements and 3D-Printed Nodes. In Proceedings of the CAADRIA 2017—22nd International Conference on Computer-Aided Architectural Design Research in Asia: Protocols, Flows and Glitches, Hong Kong, China, 5–8 April 2017; pp. 821–830. [Google Scholar]

- Sousa, J.P.; Varela, P.d.A.; Carvalho, J.; Santos, R.; Oliveira, M. Mass-customization of Joints for Non-Standard Structures through Additive Manufacturing: The Trefoil and the TriArch projects. In Proceedings of the eCAADe36: Applications in Construction & Optimization, Lodz, Poland, 19–21 September 2018; Volume 1, pp. 197–204. [Google Scholar]

- Tanadini, D.; Ohlbrock, P.O.; Kladeftira, M.; Leschok, M.; Skevaki, E.; Dillenburger, B.; D’Acunto, P. Exploring the potential of equilibrium-based methods in additive manufacturing: The Digital Bambloo pavilioin. In Proceedings of the IASS 2022 Symposium Affiliated with APCS 2022 Conference—Innovation-Sustainability-Legacy, Beijing, China, 19–22 September 2022. [Google Scholar]

- Kladeftira, M.; Leschok, M.; Skevaki, E.; Dillenburger, B. Redefining Polyhedral Space Through 3D Printing. In Proceedings of the AAG Advances in Architectural Geometry, Online, 26–29 April 2021. [Google Scholar]

- Kladeftira, M.; Leschok, M.; Skevaki, E.; Tanadini, D.; Ohlbrock, P.O.; D’Acunto, P.; Dillenburger, B. Digital Bamboo: A study on bamboo, 3D printed joints, and digitally fabricated building components for ultralight structures. In Proceedings of the ACADIA 2022: Hybrids & Haecceities, Philadelphia, PA, USA, 27–29 October 2022. [Google Scholar]

- Bach, P.; Giacomini, I.; Kladeftira, M. Self-interlocking 3D Printed Joints for Modular Assembly of Space Frame Structures. In Proceedings of the 8th Design Modelling Symposium (DMS 2022): Towards Radical Regeneration, Berlin, Germany, 26–28 September 2022. [Google Scholar]

- Ariza, I.; Mirjan, A.; Gandia, A.; Casas, G.; Cros, S.; Gramazio, F.; Kohler, M. In place detailing: Combining 3D printing and robotic assembly. In Proceedings of the ACADIA, Mexico City, Mexico, 18–20 October 2018; pp. 312–321. [Google Scholar] [CrossRef]

- LANIK. Lanik Ingenieros | Hacemos su Proyecto Realidad. 2018. Available online: http://www.lanik.com/ (accessed on 8 September 2022).

- MERO. Home—MERO. 2018. Available online: https://www.mero.de/ (accessed on 8 September 2022).

- Octatube. Octatube | Realizing Challenging Architecture. 2018. Available online: https://www.octatube.nl/ (accessed on 8 September 2022).

- Aghaei Meibodi, M.; Giesecke, R.; Dillenburger, B. 3D Printing sand mold for casting bespoke-Digital Metal: Additive Manufacturing for Casting Metal Parts in Architecture. In Proceedings of the Intelligent and Informed—Proceedings of the 24th International Conference on Computer-Aided Architectural Design Research in Asia, CAADRIA, Wellington, New Zealand, 15–18 April 2019; Volume 1, pp. 133–142. [Google Scholar]

- Bhattacharya, A.; Eube, J.; Röglin, H.; Schmidt, M. Noisy, Greedy and Not So Greedy k-means++. In Proceedings of the 28th Annual European Symposium on Algorithms, ESA 2020, Pisa, Italy, 7–9 September 2020; Volume 1, pp. 1–21. [Google Scholar]

- Dagli, M. Singapore Arts Centre, Singapore. 2019. Available online: https://unsplash.com/photos/Uii70ORiFPE (accessed on 26 May 2020).

- Martí, R. Exact and Heuristic Methods in Combinatorial Optimization; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

| Dataset | Valence | Adaptive Sampling | Distance Metric | |

|---|---|---|---|---|

| Literature | static | constant | random, density, distance | SSE |

| Space-frames | dynamic | varying | density and distance | intracluster var. |

| Joint ID | a () | b () | c () | d () |

|---|---|---|---|---|

| 0 | - | 68.88 | 291.12 | - |

| 1 | 10.55 | 68.88 | 216.00 | 64.57 |

| 2 | 21.14 | 64.57 | 216.00 | 58.28 |

| 3 | 37.16 | 58.28 | 216.00 | 48.56 |

| 4 | 62.53 | 48.56 | 216.00 | 32.91 |

| 5 | 32.91 | - | - | 327.09 |

| 6 | 69.76 | 114.18 | 176.06 | - |

| 7 | 47.71 | 139.16 | 90.25 | 82.88 |

| 8 | 52.59 | 136.15 | 107.82 | 63.43 |

| 9 | 51.03 | 129.94 | 128.17 | 50.85 |

| 10 | 41.28 | 42.24 | 276.48 | - |

| (a) Option 1: Joint 1, valence = 4 | Joint 2, valence = 4 | |||

| Joint 1 | Joint 2 | Distance/Angle | Total Distance d |

| a = 10.55 | a = 21.14 | d = | a − a | = 10.59 | d = |

| b = 68.88 | b = 64.57 | d = | b − b | = 4.31 | |

| c = 216.00 | c = 216.00 | d = | c − c | = 0 | |

| d = 64.57 | d = 58.28 | d = | d − d | = 6.29 | d = 21.19 |

| (b) Option 2: Joint 1, valence = 4 | Joint 6, valence = 3 | |||

| Joint 1 | Joint 6 | Distance/Angle | Total Distance d |

| a = 10.55 | a = 69.76 | d = | a − a | = 59.21 | d = |

| b = 68.88 | b = 114.18 | d = | b − b | = 45.30 | |

| c = 216.00 | c = 176.06 | d = | c − c | = 39.94 | |

| d = 64.57 | - | n/a | d = 144.45 |

| (c) Option 3: Joint 0, valence = 2 | Joint 5, valence = 2 | |||

| Joint 0 | Joint 5 | Distance/Angle | Total Distance d |

| - | a = 32.91 | n/a | n/a→penalty |

| b = 68.88 | - | n/a | |

| c = 291.12 | - | n/a | |

| - | d = 327.09 | n/a | |

| Scenarios | Joint Design | Fabrication Process | Clusters |

|---|---|---|---|

| 1 | High tolerance | Continuous | 10 |

| 2 | Low tolerance | Discrete (148 cl.) | 200 |

| Continuous (52 cl.) | |||

| 3 | High tolerance | Continuous | 200 |

| 4 | Low tolerance (148 cl.) | Continuous | 200 |

| High Tolerance (52 cl.) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koronaki, A.; Shepherd, P.; Evernden, M. Fabrication-Aware Joint Clustering in Freeform Space-Frames. Buildings 2023, 13, 962. https://doi.org/10.3390/buildings13040962

Koronaki A, Shepherd P, Evernden M. Fabrication-Aware Joint Clustering in Freeform Space-Frames. Buildings. 2023; 13(4):962. https://doi.org/10.3390/buildings13040962

Chicago/Turabian StyleKoronaki, Antiopi, Paul Shepherd, and Mark Evernden. 2023. "Fabrication-Aware Joint Clustering in Freeform Space-Frames" Buildings 13, no. 4: 962. https://doi.org/10.3390/buildings13040962

APA StyleKoronaki, A., Shepherd, P., & Evernden, M. (2023). Fabrication-Aware Joint Clustering in Freeform Space-Frames. Buildings, 13(4), 962. https://doi.org/10.3390/buildings13040962