Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Materials and Chemicals

2.1.2. Preparation of Delignified Wood Chips

2.1.3. Preparation of Bio-Based Binder

2.1.4. Fabrication of Thermal Insulation Foams

2.2. Methods

2.2.1. Characterization of Natural and Delignified Wood Chips

2.2.2. Characterization of Thermal Insulation Foams

3. Results and Discussion

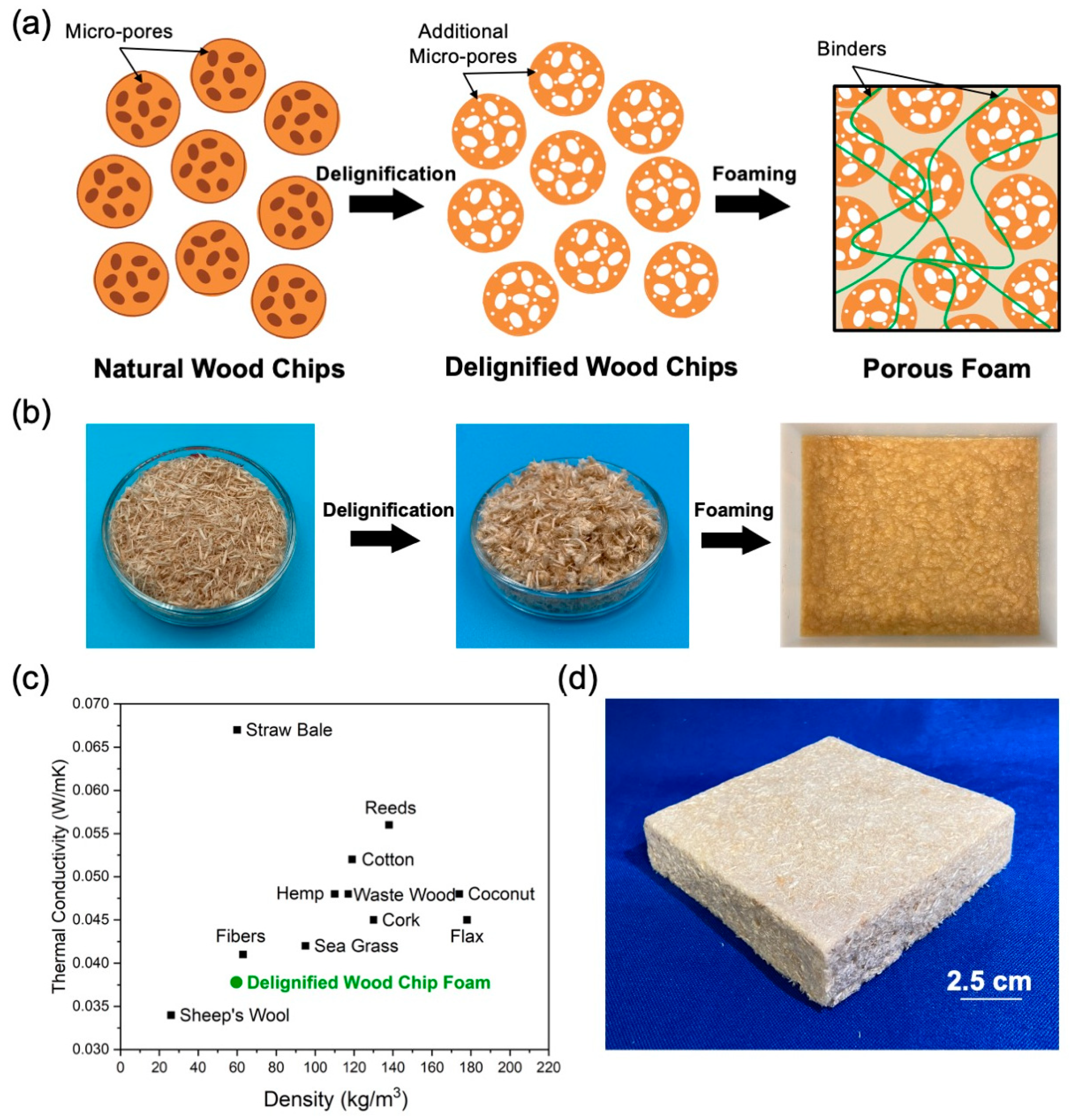

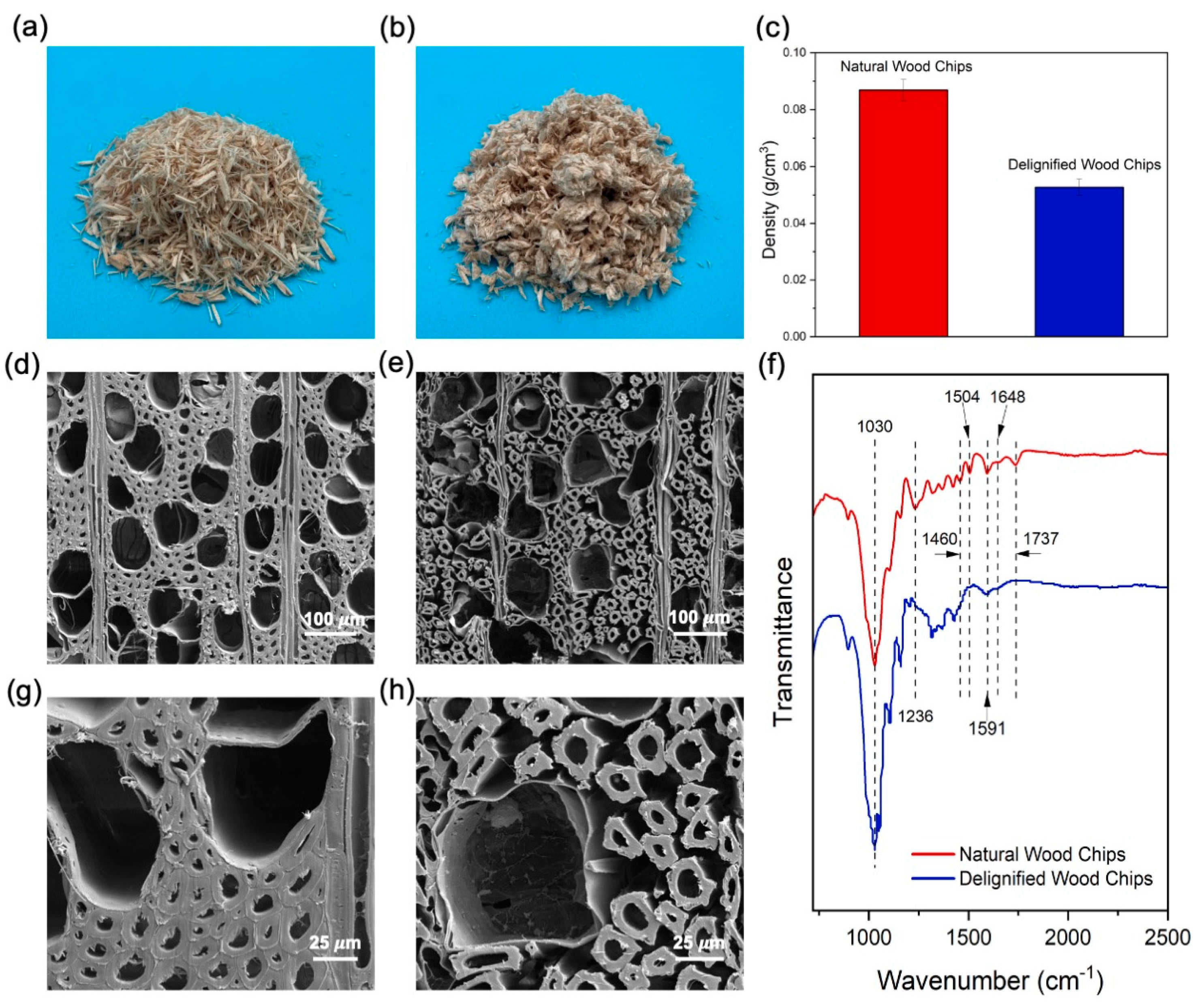

3.1. Fabrication and Characterization of Natural and Delignified Wood Chips

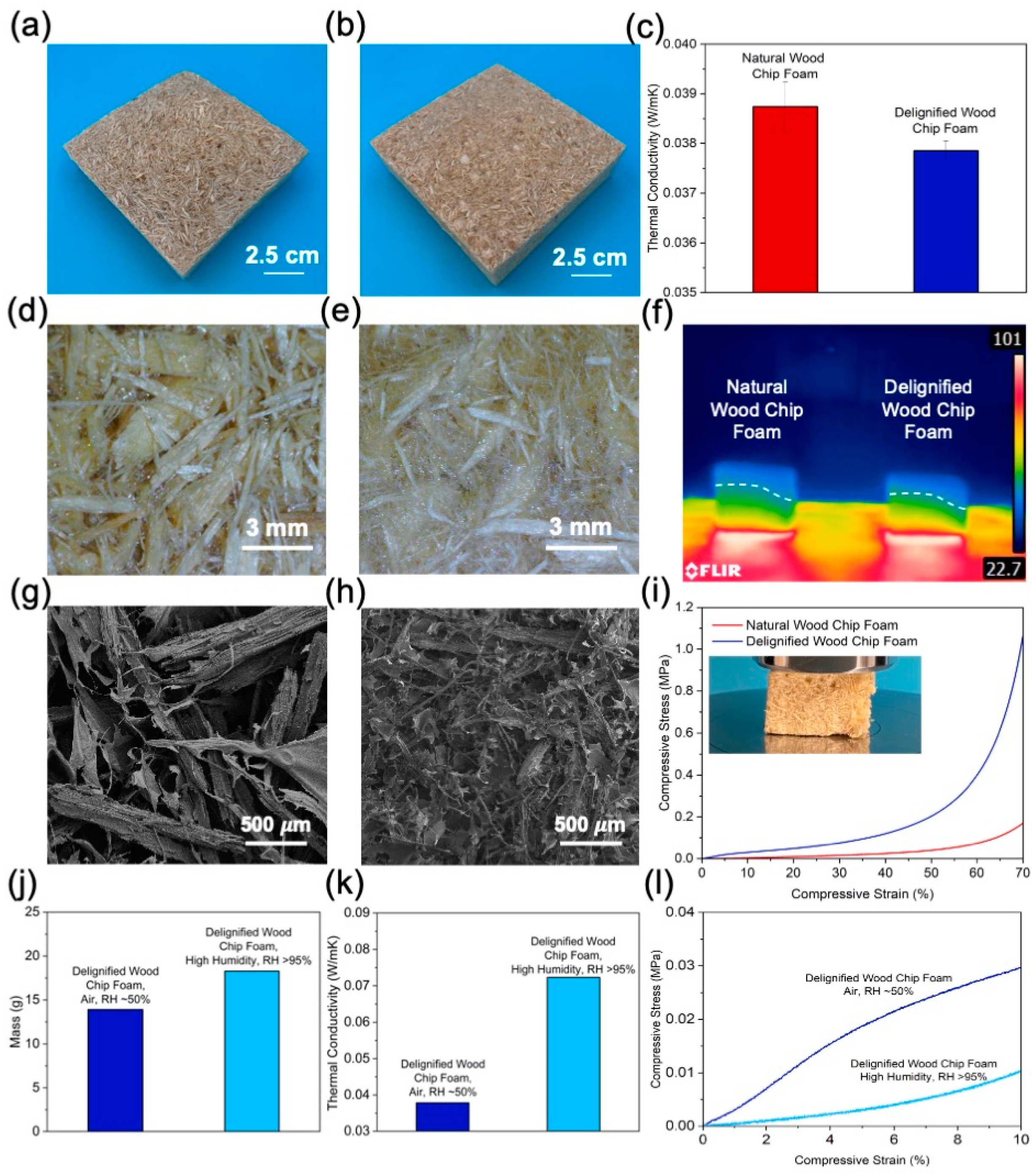

3.2. Fabrication and Characterization of Wood-Chip-Derived Thermal Insulation Foams

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 2022 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 22 November 2022).

- Ahmad, M.W.; Mourshed, M.; Yuce, B.; Rezgui, Y. Computational Intelligence Techniques for HVAC Systems: A Review. Build. Simul. 2016, 9, 359–398. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions—Properties, Requirements and Possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Bio-Based Foam Market Share, Size | 2022–2027. Available online: https://www.marketsandmarkets.com/Market-Reports/bio-based-foam-market-109520048.html (accessed on 22 November 2022).

- Ding, Y.; Pang, Z.; Lan, K.; Yao, Y.; Panzarasa, G.; Xu, L.; Lo Ricco, M.; Rammer, D.R.; Zhu, J.Y.; Hu, M.; et al. Emerging Engineered Wood for Building Applications. Chem. Rev. 2022, 123, 1843–1888. [Google Scholar] [CrossRef]

- Structure–Property–Function Relationships of Natural and Engineered Wood | Nature Reviews Materials. Available online: https://www.nature.com/articles/s41578-020-0195-z (accessed on 22 November 2022).

- Zhao, X.; Liu, Y.; Zhao, L.; Yazdkhasti, A.; Mao, Y.; Siciliano, A.P.; Dai, J.; Jing, S.; Xie, H.; Li, Z.; et al. A Scalable High-Porosity Wood for Sound Absorption and Thermal Insulation. Nat. Sustain. 2023, 1–10. [Google Scholar] [CrossRef]

- Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures: A Methodology Document. Available online: https://www.epa.gov/sites/default/files/2015-12/documents/methodolgy_document_for_selected_municipal_solid_waste_products.pdf (accessed on 22 November 2022).

- Advancing Sustainable Materials Management: 2018 Fact Sheet. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf (accessed on 22 November 2022).

- Ihnát, V.; Lübke, H.; Russ, A.; Borůvka, V. Waste agglomerated wood materials as a secondary raw material for chipboards and fibreboards part i. preparation and characterization of wood chips in terms of their reuse. Wood Res. 2017, 62, 45–56. [Google Scholar]

- Merli, F.; Belloni, E.; Buratti, C. Eco-Sustainable Wood Waste Panels for Building Applications: Influence of Different Species and Assembling Techniques on Thermal, Acoustic, and Environmental Performance. Buildings 2021, 11, 361. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Suleiman, B.M.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal Conductivity and Diffusivity of Wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Zhao, X.; Brozena, A.H.; Hu, L. Critical Roles of Pores and Moisture in Sustainable Nanocellulose-Based Super-Thermal Insulators. Matter 2021, 4, 769–772. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X. Thermal Conductivity Analysis of High Porosity Structures with Open and Closed Pores. Int. J. Heat Mass Transf. 2022, 183, 122089. [Google Scholar] [CrossRef]

- Zhuang, J.; Ghaffar, S.H.; Fan, M.; Corker, J. Restructure of Expanded Cork with Fumed Silica as Novel Core Materials for Vacuum Insulation Panels. Compos. Part B Eng. 2017, 127, 215–221. [Google Scholar] [CrossRef]

- Zach, J.; Novák, V.; Peterková, J.; Bubeník, J. Development of Vacuum Insulation Panels with Utilization of Organic By-Products. Energies 2020, 13, 1165. [Google Scholar] [CrossRef]

- Vaitkus, S.; Karpavičiūtė, R.; Vėjelis, S.; Lekūnaitė, L. Development and Research of Thermal Insulation Materials from Natural Fibres. Key Eng. Mater. 2014, 604, 285–288. [Google Scholar] [CrossRef]

- Page, J. Design and Multi-Physical Properties of a New Hybrid Hemp-Flax Composite Material | Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S0950061816319432?token=13E3B1FEB12A186406DF934FCD1CE4EECCA2548CF6F00644F6E53E1CBD490712E7BECE86D92B5A427B493F63605E0F68&originRegion=us-east-1&originCreation=20221205195505 (accessed on 5 December 2022).

- Kymäläinen, H.-R.; Sjöberg, A.-M. Flax and Hemp Fibres as Raw Materials for Thermal Insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and Performance Evaluation of Natural Thermal-Insulation Materials Composed of Renewable Resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Kuqo, A.; Mai, C. Seagrass Leaves: An Alternative Resource for the Production of Insulation Materials. Materials 2022, 15, 6933. [Google Scholar] [CrossRef]

- Goodhew, S.; Griffiths, R. Sustainable Earth Walls to Meet the Building Regulations. Energy Build. 2005, 37, 451–459. [Google Scholar] [CrossRef]

- Rodríguez, N.J.; Yáñez-Limón, M.; Gutiérrez-Miceli, F.A.; Gomez-Guzman, O.; Matadamas-Ortiz, T.P.; Lagunez-Rivera, L.; Feijoo, J.A.V. Assessment of Coconut Fibre Insulation Characteristics and Its Use to Modulate Temperatures in Concrete Slabs with the Aid of a Finite Element Methodology. Energy Build. 2011, 43, 1264–1272. [Google Scholar] [CrossRef]

- Brzyski, P.; Kosiński, P.; Skoratko, A.; Motacki, W. Thermal Properties of Cellulose Fiber as Insulation Material in a Loose State. In Proceedings of the AIP Conference, Banská Bystrica, Slovakia, 25 July 2019; p. 020006. [Google Scholar]

- Tsapko, Y.V.; Tsapko, A.Y.; Bondarenko, O.P. Modeling of Thermal Conductivity of Reed Products. IOP Conf. Ser. Mater. Sci. Eng. 2020, 907, 012057. [Google Scholar] [CrossRef]

- Ye, Z.; Wells, C.M.; Carrington, C.G.; Hewitt, N.J. Thermal Conductivity of Wool and Wool–Hemp Insulation. Int. J. Energy Res. 2006, 30, 37–49. [Google Scholar] [CrossRef]

- National Research Council Canada; Poplar Council of Canada; Poplar Council of the United States. Poplar Culture in North America; NRC Research Press: Ottawa, ON, Canada, 2001; ISBN 978-0-660-18145-5.

- D 4442; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials. ASTM Standard: West Conshohocken, PA, USA, 2003.

- D4933; Standard Guide for Moisture Conditioning of Wood and Wood-Based Materials. ASTM Standard: West Conshohocken, PA, USA, 2010.

- Ismail, I.; Mardiani, M.; Lismayani, D.; Fauzi, F. Sawdust for Thermal Insulation Building. In Proceedings of the International Conference on Natural and Environmental Science (ICONES), Banda Aceh, Indonesia, 9–11 September 2014; pp. 43–48. [Google Scholar]

- Chithra, A.; Wilson, P.; Vijayan, S.; Rajeev, R.; Prabhakaran, K. Carbon Foams with Low Thermal Conductivity and High EMI Shielding Effectiveness from Sawdust. Ind. Crops Prod. 2020, 145, 112076. [Google Scholar] [CrossRef]

- Carboxymethylcellulose High Viscosity 9004-32-4. Available online: http://www.sigmaaldrich.com/ (accessed on 20 December 2022).

- Anisotropic, Lightweight, Strong, and Super Thermally Insulating Nanowood with Naturally Aligned Nanocellulose | Science Advances. Available online: https://www.science.org/doi/full/10.1126/sciadv.aar3724 (accessed on 20 December 2022).

- Chen, C.; Li, Z.; Mi, R.; Dai, J.; Xie, H.; Pei, Y.; Li, J.; Qiao, H.; Tang, H.; Yang, B.; et al. Rapid Processing of Whole Bamboo with Exposed, Aligned Nanofibrils toward a High-Performance Structural Material. ACS Nano 2020, 14, 5194–5202. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In Situ Wood Delignification toward Sustainable Applications. Acc. Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Strong and Optically Transparent Films Prepared Using Cellulosic Solid Residue Recovered from Cellulose Nanocrystals Production Waste Stream | ACS Applied Materials & Interfaces. Available online: https://pubs.acs.org/doi/full/10.1021/am302967m (accessed on 19 December 2022).

- Lazzari, L.K.; Perondi, D.; Zampieri, V.B.; Zattera, A.J.; Santana, R.M.C. Cellulose/Biochar Aerogels with Excellent Mechanical and Thermal Insulation Properties. Cellulose 2019, 26, 9071–9083. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, W.; Zhang, Z.; Gao, H.; Zeng, Q.; Du, G.; Fan, M. Development and Performance Evaluation of Wood-Pulp/Glass Fibre Hybrid Composites as Core Materials for Vacuum Insulation Panels. J. Clean. Prod. 2022, 357, 131957. [Google Scholar] [CrossRef]

- Li, L.; Yu, L.; Wu, Z.; Hu, Y. Delignification of poplar wood with lactic acid-based deep eutectic solvents. Wood Res. 2019, 64, 499–514. [Google Scholar]

- Wang, J.; Liu, J.; Li, J.; Zhu, J.Y. Characterization of Microstructure, Chemical, and Physical Properties of Delignified and Densified Poplar Wood. Materials 2021, 14, 5709. [Google Scholar] [CrossRef]

- Best Price Naoh Alkali Industrial Grade Soild 99% Soda Flakes—Buy Soda 20 kg, Soda Bags 25 kg Plastic Bags, Soda. Caustic Manufacturers Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Best-Price-Naoh-Alkali-Industrial-Grade_1600754344988.html?spm=a2700.galleryofferlist.normal_offer.d_image.504e706ebjxuiT (accessed on 6 March 2023).

- Culbertson, G. Northwest Wood Chip Prices Level Off. Available online: https://www.forest2market.com/blog/northwest-wood-chip-prices-level-off (accessed on 6 March 2023).

- China Supplier Construction Grade Sodium Carboxymethyl Cellulose Cmc Powder For Liquid Soap Additive—Buy Carbon Methyl Cellulose Cmc,Adhesive Cmc Powder,Sodium Carboxymethyl Cellulose Cmc For Thickener Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/China-Supplier-Construction-Grade-Sodium-Carboxymethyl_1600647318658.html?spm=a2700.galleryofferlist.normal_offer.d_image.4adc2cc1RYSOyI&s=p (accessed on 6 March 2023).

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siciliano, A.P.; Zhao, X.; Fedderwitz, R.; Ramakrishnan, K.; Dai, J.; Gong, A.; Zhu, J.Y.; Kośny, J.; Hu, L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings 2023, 13, 840. https://doi.org/10.3390/buildings13040840

Siciliano AP, Zhao X, Fedderwitz R, Ramakrishnan K, Dai J, Gong A, Zhu JY, Kośny J, Hu L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings. 2023; 13(4):840. https://doi.org/10.3390/buildings13040840

Chicago/Turabian StyleSiciliano, Amanda P., Xinpeng Zhao, Rebecca Fedderwitz, Kishore Ramakrishnan, Jiaqi Dai, Amy Gong, J. Y. Zhu, Jan Kośny, and Liangbing Hu. 2023. "Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency" Buildings 13, no. 4: 840. https://doi.org/10.3390/buildings13040840

APA StyleSiciliano, A. P., Zhao, X., Fedderwitz, R., Ramakrishnan, K., Dai, J., Gong, A., Zhu, J. Y., Kośny, J., & Hu, L. (2023). Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings, 13(4), 840. https://doi.org/10.3390/buildings13040840