Carbon Emission Evaluation Method and Comparison Study of Transformer Substations Using Different Data Sources

Abstract

1. Introduction

2. Data Resources and Methods

2.1. Data Resource

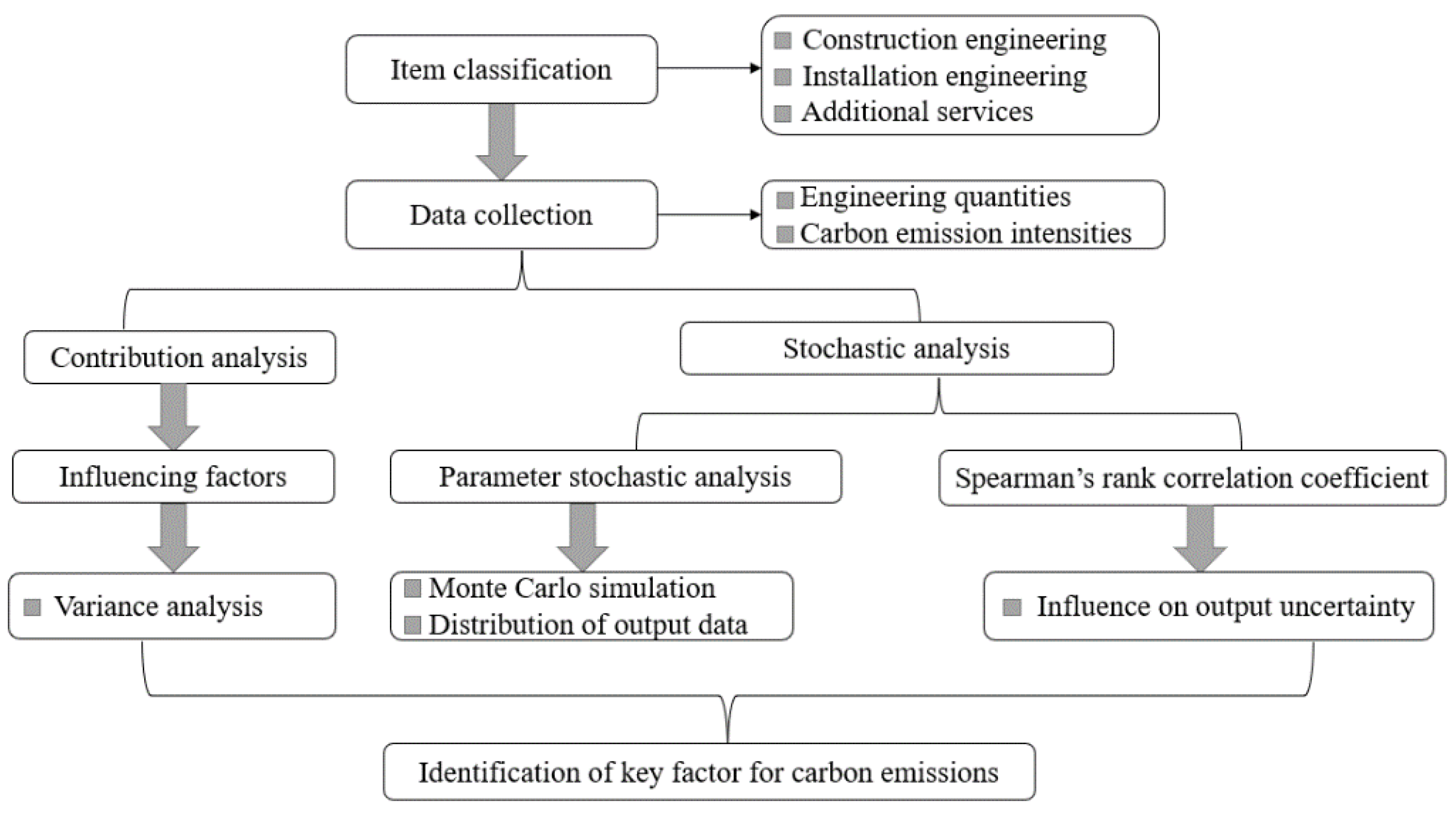

2.2. Proposed Method

2.3. Parameter Stochastic Analysis

3. Results and Discussion

3.1. Transformer Substation Carbon Emission Results

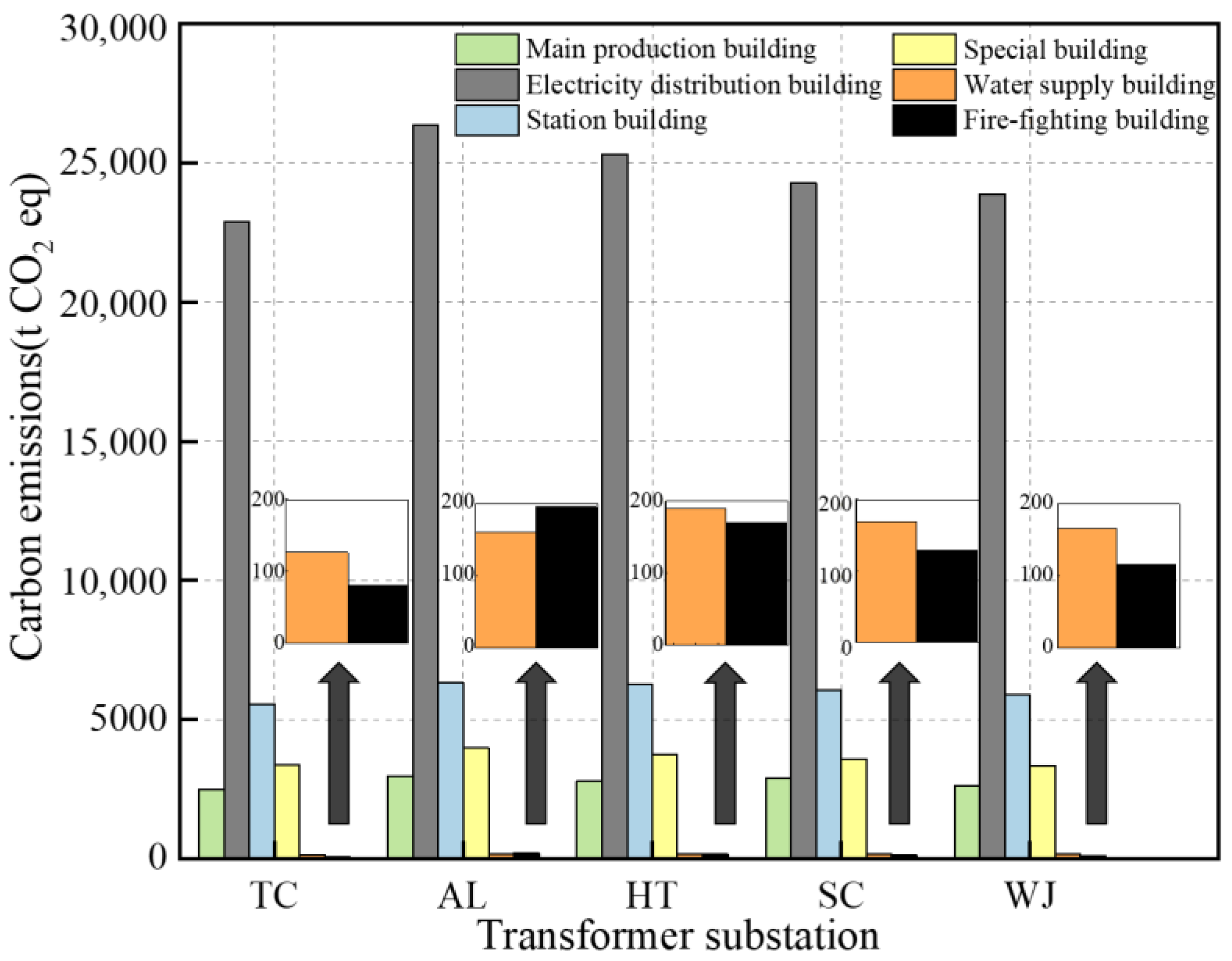

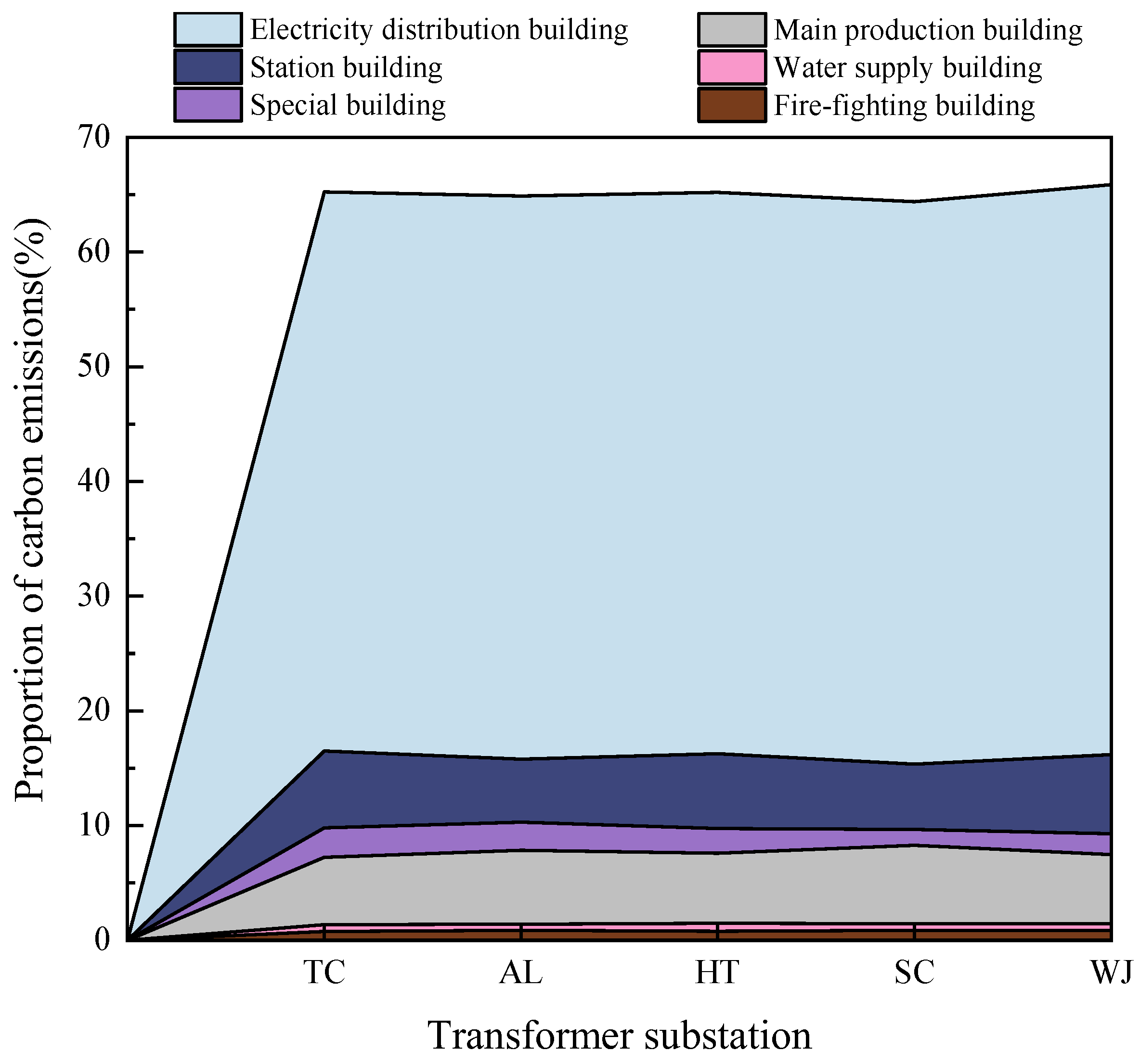

3.1.1. Carbon Emissions from Construction Engineering

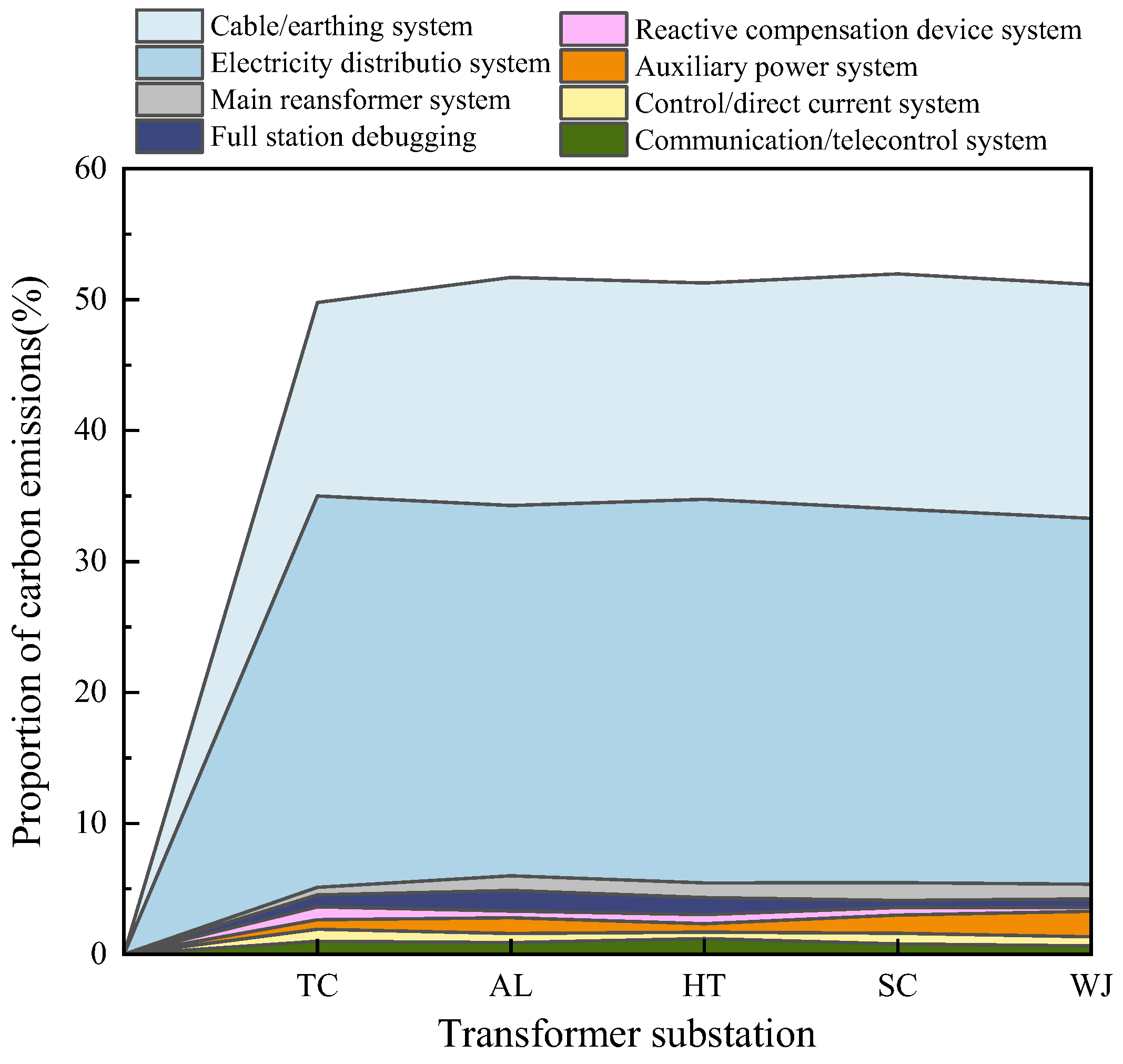

3.1.2. Carbon Emissions from Installation Engineering

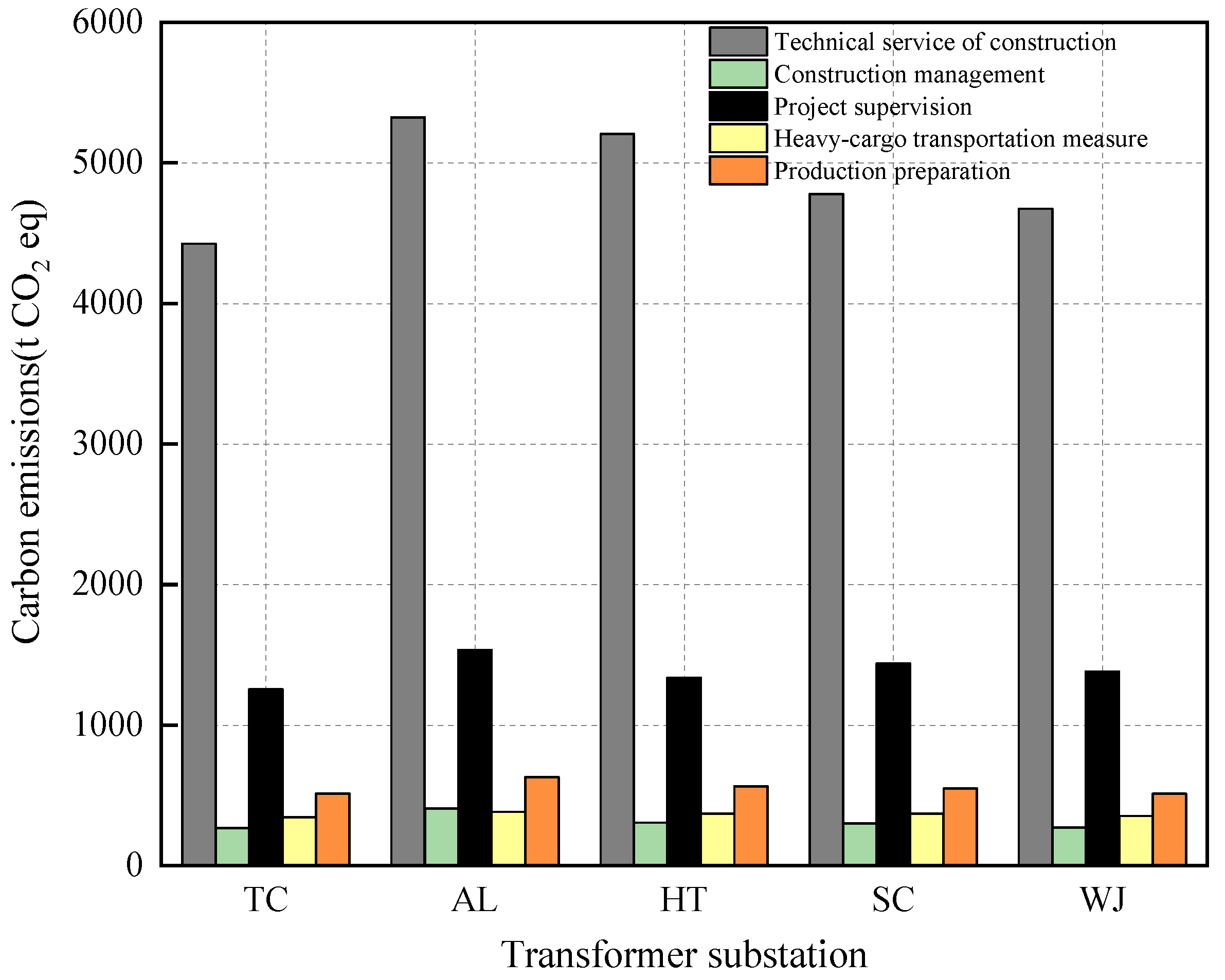

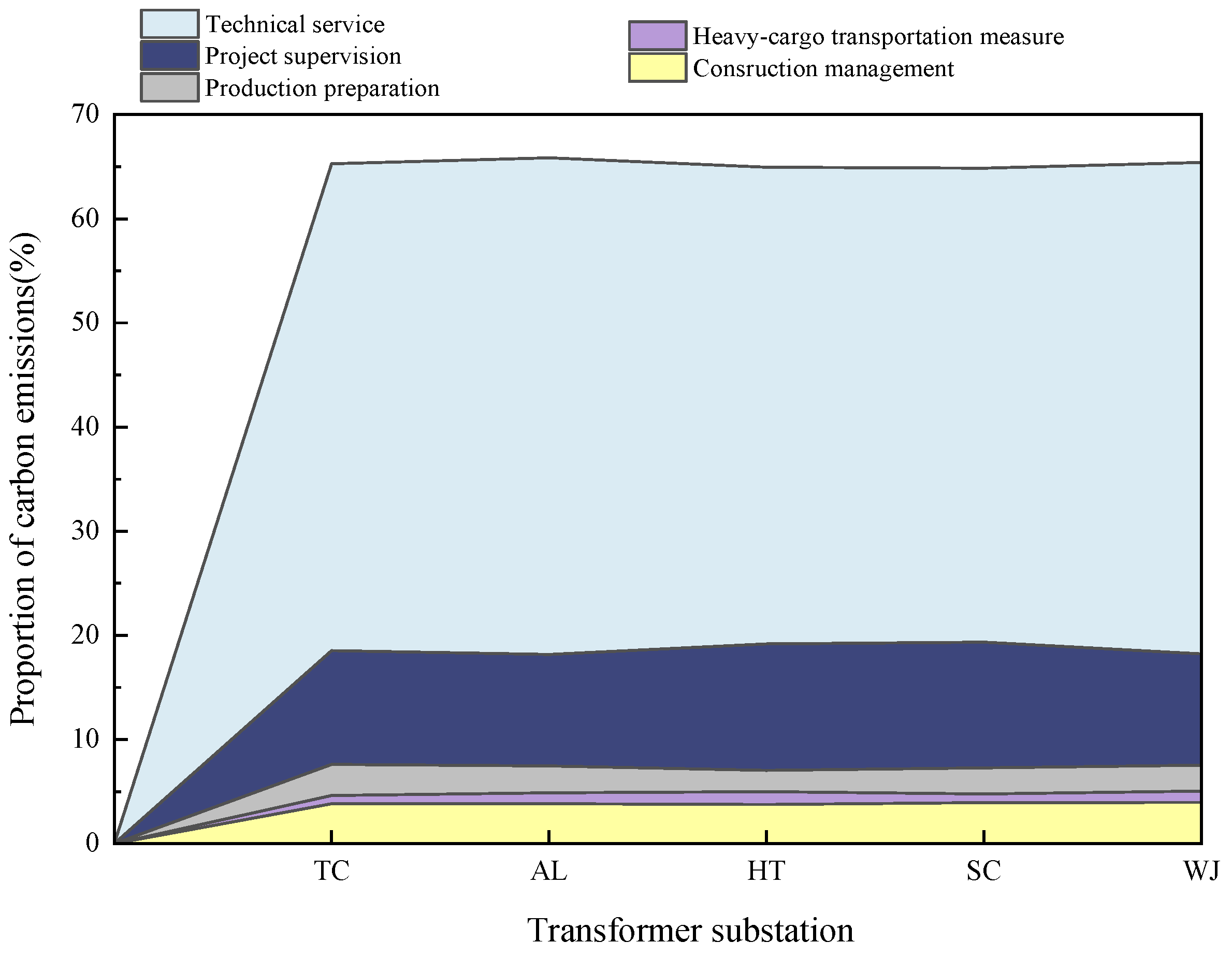

3.1.3. Carbon Emissions of Additional Service

3.1.4. Discussion about the Proposed Method and Carbon Emissions

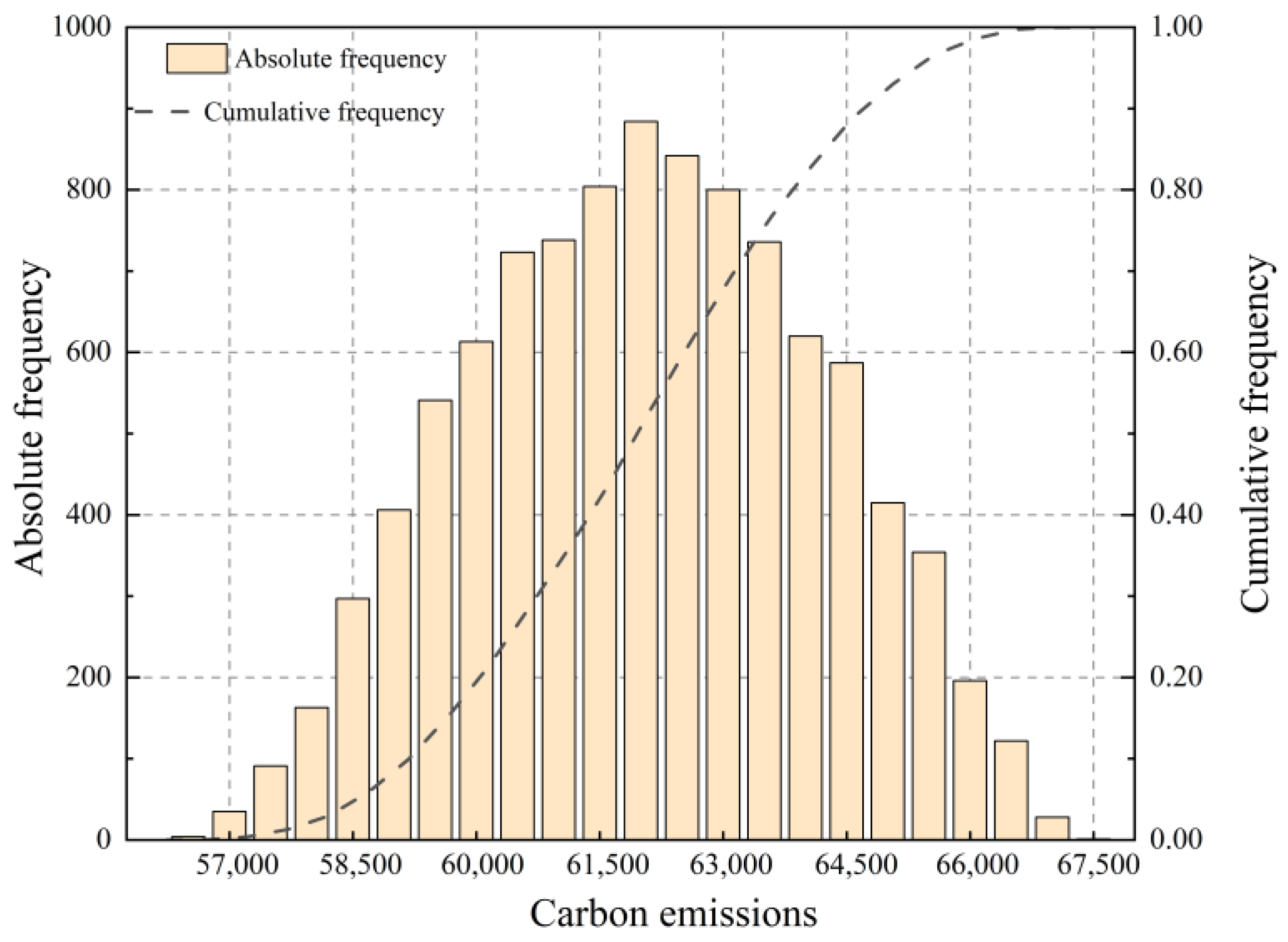

3.2. Parameter Stochastic Analysis

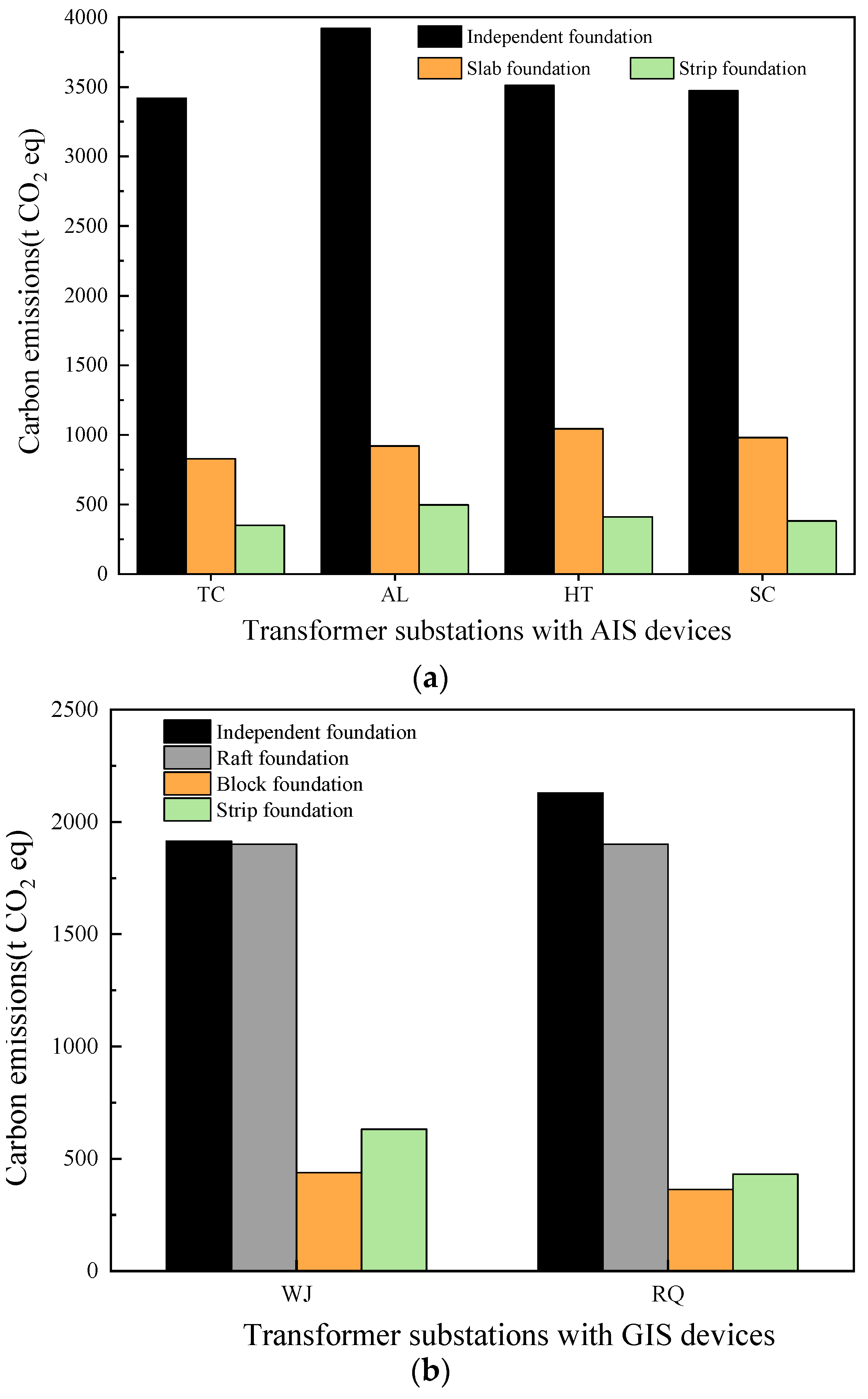

3.3. Influence of Different Types of Foundations on Carbon Emissions

4. Conclusions

- The proposed method is capable of giving a comprehensive and accurate calculation of carbon emissions for transformer substations. The carbon emissions of the selected representative 750 kV substations are between 56,000 and 68,000 t CO2 eq. In terms of item category, construction engineering generates the most carbon emissions, followed by installation engineering and additional services. From the economic sector, the manufacture of equipment for power transmission (code 78) and construction (code 95) have the most significant impact on carbon emissions.

- Through Monte Carlo simulation, the mean value and the standard deviation of carbon emissions for a newly built 750 kV transformer substation in Xinjiang are 62,317.59 t CO2 eq and 2096.59 t CO2 eq, respectively. The 90% confidence interval is [58,871.04, 65,759.34] t CO2 eq. The simulation results can be used to describe the distribution of carbon emissions from 750 kV substations in Xinjiang or similar terrain, and the influence of output data on the uncertainty is determined by studying the key factors of carbon emissions.

- Due to the differences between AIS and GIS equipment, different types of foundations will be built. When arranged with AIS, the equipment foundation is mostly a slab foundation. While arranging with GIS, mostly use the raft foundation for electricity distribution equipment and the block foundation for the HV reactor, LV capacitor, and main transformer. Through the calculation, AIS has no obvious advantage on carbon emissions, while GIS covers a small area and has high reliability in operation, which is more in accord with the development direction of smart grids and low-carbon economies.

- The expansion or renovation of substations will cause a change in carbon emissions, so the accuracy and timeliness of construction lists and investments are significant. Due to the differences in different voltage levels of substations, further research will focus on the establishment of construction lists and a comparison of carbon emissions at different voltage levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Item Component | Sector Code | Monetary Cost (1 × 104 CNY) | Carbon Intensity (t CO2/1 × 104 CNY) | Carbon Emission (t CO2 eq) |

|---|---|---|---|---|

| 1 Construction engineering | ||||

| 1.1 Main production building | ||||

| 1.1.1 Main control communication building | ||||

| Construction engineering cost | 95 | 189.95 | 4.88 | 926.96 |

| Installation materials cost | 95 | 33.81 | 4.88 | 164.99 |

| 1.1.2 750 kV relay chamber | ||||

| Construction engineering cost | 95 | 96.41 | 4.88 | 470.48 |

| Installation materials cost | 95 | 18.41 | 4.88 | 89.84 |

| 1.1.3 Main transformer and 220 kV, 66 kV relay chamber No. 1 | ||||

| Construction engineering cost | 95 | 43.90 | 4.88 | 214.23 |

| Installation materials cost | 95 | 7.89 | 4.88 | 38.50 |

| 1.1.4 Main transformer and 220 kV, 66 kV relay chamber No. 2 | ||||

| Construction engineering cost | 95 | 43.91 | 4.88 | 214.28 |

| Installation materials cost | 95 | 7.88 | 4.88 | 38.45 |

| 1.1.5 Substation power chamber | ||||

| Construction engineering cost | 95 | 68.91 | 4.88 | 336.28 |

| Installation materials cost | 95 | 12.25 | 4.88 | 59.78 |

| 1.1.6 Security equipment room | ||||

| Construction engineering cost | 95 | 30.02 | 4.88 | 146.50 |

| Installation materials cost | 95 | 5.97 | 4.88 | 29.13 |

| 1.1.7 Guardhouse | ||||

| Construction engineering cost | 95 | 28.71 | 4.88 | 140.10 |

| Installation materials cost | 95 | 5.26 | 4.88 | 25.67 |

| 1.2 Electricity distribution building | ||||

| 1.2.1 Frames and foundation | ||||

| Construction engineering cost | 95 | 111.32 | 4.88 | 543.24 |

| 1.2.2 Foundation of main transformer | ||||

| Construction engineering cost | 95 | 29.77 | 4.88 | 145.27 |

| 1.2.3 Main transformer oil pit and pebbles | ||||

| Construction engineering cost | 95 | 66.80 | 4.88 | 325.98 |

| 1.2.4 Main transformer system firewall | ||||

| Construction engineering cost | 95 | 57.57 | 4.88 | 280.92 |

| 1.2.5 Emergency oil pond | ||||

| Construction engineering cost | 95 | 25.92 | 4.88 | 126.51 |

| 1.2.6 750 kV frames and foundation | ||||

| Construction engineering cost | 95 | 2464.56 | 4.88 | 12,027.04 |

| 1.2.7 750 kV equipment support and foundation | ||||

| Construction engineering cost | 95 | 401.92 | 4.88 | 1961.39 |

| 1.2.8 220 kV frames and foundation | ||||

| Construction engineering cost | 95 | 652.86 | 4.88 | 3185.95 |

| 1.2.9 220 kV equipment support and foundation | ||||

| Construction engineering cost | 95 | 181.32 | 4.88 | 884.86 |

| 1.2.10 66 kV frames and foundation | ||||

| Construction engineering cost | 95 | 49.88 | 4.88 | 243.41 |

| 1.2.11 66 kV equipment support and foundation | ||||

| Construction engineering cost | 95 | 28.68 | 4.88 | 139.96 |

| 1.2.12 HV shunt reactor foundation | ||||

| Construction engineering cost | 95 | 76.41 | 4.88 | 372.87 |

| 1.2.13 HV shunt reactor oil pit and pebbles | ||||

| Construction engineering cost | 95 | 99.08 | 4.88 | 483.51 |

| 1.2.14 HV shunt reactor firewall | ||||

| Construction engineering cost | 95 | 148.56 | 4.88 | 724.97 |

| 1.2.15 Substation transformer | ||||

| Construction engineering cost | 95 | 54.56 | 4.88 | 266.23 |

| 1.2.16 LV capacitor | ||||

| Construction engineering cost | 95 | 7.88 | 4.88 | 38.45 |

| 1.2.17 LV reactor | ||||

| Construction engineering cost | 95 | 24.67 | 4.88 | 120.39 |

| 1.2.18 Independent lighting rod tower | ||||

| Construction engineering cost | 95 | 49.61 | 4.88 | 242.11 |

| 1.2.19 Conduit line | ||||

| Construction engineering cost | 95 | 344.07 | 4.88 | 1679.05 |

| 1.2.20 Barrier and floor | ||||

| Construction engineering cost | 95 | 102.35 | 4.88 | 499.45 |

| 1.3 Water supply building | ||||

| 1.3.1 Substation water pipe | ||||

| Construction engineering cost | 95 | 0.26 | 4.88 | 1.27 |

| 1.3.2 Integrated pumped house | ||||

| Construction engineering cost | 95 | 18.58 | 4.88 | 90.67 |

| Installation materials cost | 95 | 15.52 | 4.88 | 76.74 |

| 1.4 Fire-fighting building | ||||

| 1.4.1 Foam equipment chamber | ||||

| Construction engineering cost | 95 | 24.30 | 4.88 | 118.58 |

| 1.4.2 Fire protection, alarm and detection | ||||

| Equipment purchasing | 72 | 1.79 | 3.79 | 6.78 |

| 1.4.3 Special fire protection system | ||||

| Equipment purchasing | 84 | 1.08 | 2.72 | 2.93 |

| 1.5 Station building | ||||

| 1.5.1 Site formation | ||||

| Construction engineering cost | 95 | 275.93 | 4.88 | 1346.54 |

| 1.5.2 Station road and square | ||||

| Construction engineering cost | 95 | 500.37 | 4.88 | 2441.81 |

| 1.5.3 Drainage pipeline | ||||

| Construction engineering cost | 95 | 188.88 | 4.88 | 921.73 |

| 1.5.4 Walls and gate | ||||

| Construction engineering cost | 95 | 271.75 | 4.88 | 1326.14 |

| 1.5.5 Sewage pool | ||||

| Construction engineering cost | 95 | 8.03 | 4.88 | 39.19 |

| 1.6 Special building | ||||

| 1.6.1 Foundation treatment | ||||

| Construction engineering cost | 95 | 129.01 | 4.88 | 629.57 |

| 1.6.2 Offsite roadway | ||||

| Construction engineering cost | 95 | 247.61 | 4.88 | 1208.34 |

| 1.6.4 Offsite water supply and drainage | ||||

| Construction engineering cost | 95 | 76.38 | 4.88 | 372.73 |

| 1.6.5 Retaining wall | ||||

| Construction engineering cost | 95 | 282.57 | 4.88 | 1378.94 |

| Subtotal | 37,148.71 | |||

| 2 Installation engineering | ||||

| 2.1 Main transformer system | ||||

| 2.1.1 Main transformer | ||||

| Installation materials cost | 79 | 88.45 | 3.84 | 339.65 |

| Installation engineering cost | 95 | 91.32 | 4.88 | 445.64 |

| 2.2 Electricity distribution equipment | ||||

| 2.2.1 750 kV distribution device | ||||

| Installation materials cost | 79 | 538.61 | 3.84 | 2068.26 |

| Installation engineering cost | 95 | 314.77 | 4.88 | 1536.08 |

| 2.2.2 220 kV distribution equipment | ||||

| Installation materials cost | 79 | 485.75 | 3.84 | 1865.27 |

| Installation engineering cost | 95 | 82.14 | 4.88 | 400.84 |

| 2.2.3 66 kV distribution equipment | ||||

| Installation materials cost | 79 | 38.78 | 3.84 | 148.91 |

| Installation engineering cost | 95 | 12.14 | 4.88 | 59.24 |

| 2.3 Reactive compensation device system | ||||

| 2.3.1 750 kV HV shunt reactor | ||||

| Installation materials cost | 79 | 21.28 | 3.84 | 81.71 |

| Installation engineering cost | 95 | 32.94 | 4.88 | 160.75 |

| 2.3.2 66 kV capacitor | ||||

| Installation materials cost | 79 | 0.93 | 3.84 | 3.57 |

| Installation engineering cost | 95 | 4.39 | 4.88 | 21.42 |

| 2.3.3 66 kV reactor | ||||

| Installation materials cost | 79 | 6.03 | 3.84 | 23.15 |

| Installation engineering cost | 95 | 20.71 | 4.88 | 101.06 |

| 2.4 Control/direct current system | ||||

| 2.4.1 Control system | ||||

| Installation engineering cost | 95 | 19.67 | 4.88 | 95.99 |

| 2.4.2 Relay protection | ||||

| Installation engineering cost | 95 | 15.97 | 4.88 | 77.93 |

| 2.4.3 Direct current system | ||||

| Installation engineering cost | 95 | 22.85 | 4.88 | 111.51 |

| 2.5 Auxiliary power system | ||||

| 2.5.1 Station transformer substation | ||||

| Installation engineering cost | 95 | 11.51 | 4.88 | 56.17 |

| 2.5.2 Substation power distribution | ||||

| Installation engineering cost | 95 | 0.92 | 4.88 | 4.49 |

| 2.5.3 Substation lighting | ||||

| Installation materials cost | 81 | 52.90 | 3.70 | 195.73 |

| Installation engineering cost | 95 | 5.57 | 4.88 | 27.18 |

| 2.6 Cable/earthing system | ||||

| 2.6.1 Power cable | ||||

| Installation materials cost | 79 | 443.72 | 3.84 | 1703.88 |

| Installation engineering cost | 95 | 15.66 | 4.88 | 76.42 |

| 2.6.2 Control cable | ||||

| Installation materials cost | 79 | 359.29 | 3.84 | 1379.67 |

| Installation engineering cost | 95 | 179.27 | 4.88 | 874.84 |

| 2.6.3 Cable auxiliary device | ||||

| Installation materials cost | 78 | 365.21 | 3.57 | 1303.80 |

| Installation engineering cost | 95 | 72.72 | 4.88 | 354.87 |

| 2.6.4 Cable fire protection | ||||

| Installation materials cost | 72 | 153.12 | 3.79 | 580.32 |

| Installation engineering cost | 95 | 27.23 | 4.88 | 132.88 |

| 2.6.5 Substation earthing | ||||

| Installation materials cost | 79 | 533.87 | 3.84 | 2050.06 |

| Installation engineering cost | 95 | 115.34 | 4.88 | 562.86 |

| 2.7 Communication and motor system | ||||

| Installation materials cost | 79 | 20.43 | 3.84 | 78.45 |

| Installation engineering cost | 95 | 16.29 | 4.88 | 79.49 |

| 2.8 Full station debugging | ||||

| Debugging | 118 | 441.88 | 1.33 | 587.70 |

| Subtotal | 17,589.79 | |||

| 3 Additional service | ||||

| 3.1 Technical service of construction | ||||

| 3.1.1 Survey expenses | 118 | 725.00 | 1.33 | 964.25 |

| 3.1.2 Design fees | 118 | 1891.00 | 1.33 | 2515.03 |

| 3.1.3 Feasibility study and design | 118 | 30.00 | 1.33 | 39.90 |

| 3.1.4 Inspection of the electric power device | 118 | 124.00 | 1.33 | 164.92 |

| 3.1.5 Environmental monitor and inspection | 118 | 330.00 | 1.33 | 438.90 |

| 3.1.6 Pile test, inspection and settlement | 118 | 255.00 | 1.33 | 339.15 |

| 3.1.7 Inspection of soil and water conservation | 122 | 20.00 | 2.55 | 51.00 |

| 3.1.8 Supervision of special equipment safety | 118 | 200.00 | 1.33 | 266.00 |

| 3.2 Construction management | ||||

| 3.2.1 Construction management fees | 118 | 226.71 | 1.33 | 301.52 |

| 3.3 Project supervision | ||||

| 3.3.1 Project supervision fee | 118 | 1082.16 | 1.33 | 1439.27 |

| 3.4 Heavy-cargo transportation measure | ||||

| 3.4.1Heavy-cargo transportation fees | 97 | 150.70 | 2.45 | 369.21 |

| 3.5 Production preparation | ||||

| 3.5.1 Vehicle purchase fees | 74 | 102.30 | 3.26 | 333.50 |

| 3.5.2 Staff training and advance fees | 126 | 128.38 | 1.68 | 215.68 |

| Subtotal | 7438.33 | |||

| Total | 62,176.83 | |||

References

- National Bureau of Statistics of China (NBSC). 2015 China Statistical Yearbook; China Statistics Press: Beijing, China, 2015; pp. 251–252. ISBN 9787503776380. (In Chinese) [Google Scholar]

- NEA. Power Grid Construction Budget and Calculation Rules; China Electric Power Press: Beijing, China, 2013; ISBN 978-7-5123-8866-6. [Google Scholar]

- Yuan, J.; Shen, J.; Pan, L.; Zhao, C.; Kang, J. Smart grids in China. Renew. Sustain. Energy Rev. 2014, 37, 896–906. [Google Scholar] [CrossRef]

- Wei, W.; Wu, X.; Wu, X.; Xi, Q.; Ji, X.; Li, G. Regional study on investment for transmission infrastructure in China based on the State Grid data. Front. Earth Sci. 2017, 11, 162–183. [Google Scholar] [CrossRef]

- Liu, X.L.; Cui, L.L.; Ge, Q.; Jiang, L.L. New ideas for the energy development strategy of central and eastern China. China Popul. Resour. Environ. 2019, 29, 1–9. [Google Scholar]

- Wang, Z.; Zhou, Y.; Zhao, N.; Wang, T.; Zhang, Z. Spatial Correlation Network and Driving Effect of Carbon Emission Intensity in China’s Construction Industry. Buildings 2022, 12, 201. [Google Scholar] [CrossRef]

- Yuan, D.; Jiang, W.; Sha, A.; Xiao, J.; Wu, W.; Wang, T. Technology method and functional characteristics of road thermoelectric generator system based on Seebeck effect. Appl. Energy 2023, 331, 120459. [Google Scholar] [CrossRef]

- Liu, H.; Yang, C.; Chen, Z. Differentiated Improvement Path of Carbon Emission Efficiency of China’s Provincial Construction Industry: A Fuzzy-Set Qualitative Comparative Analysis Approach. Buildings 2023, 13, 543. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, T.; Ren, G.; Zhu, Z.; Gao, Y.; Shi, M.; Ding, S.; Fan, H. Reusing waste coal gangue to improve the dispersivity and mechanical properties of dispersive soil. J. Clean. Prod. 2023, 404, 136993. [Google Scholar] [CrossRef]

- Salama, A.; Farag, A.A.; Eraky, A.; El-Sisi, A.A.; Samir, R. Embodied Carbon Minimization for Single-Story Steel Gable Frames. Buildings 2023, 13, 739. [Google Scholar] [CrossRef]

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 emissions reduction in high-rise concrete office buildings using different material use options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Yamagata, Y.; Ono, M.; Sasamori, K.; Uehara, K. Important technologies applied for UHV AC substations in Japan. Eur. Trans. Electr. Power 2011, 22, 33–48. [Google Scholar] [CrossRef]

- Tan, Z.F. An Optimization-Based Study to Analyze the Impacts of Clean Energy and Carbon Emission Mechanisms on Inter-Regional Energy Exchange. J. Environ. Inform. 2013, 22, 123–130. [Google Scholar] [CrossRef]

- Daniels, L.; Coker, P.; Gunn, A.; Potter, B. Using proxies to calculate the carbon impact of investment into electricity network assets. Appl. Energy 2016, 162, 551–560. [Google Scholar] [CrossRef]

- Garcia, R.; Marques, P.; Freire, F. Life-cycle assessment of electricity in Portugal. Appl. Energy 2014, 134, 563–572. [Google Scholar] [CrossRef]

- Arvesen, A.; Hauan, I.B.; Bolsøy, B.M.; Hertwich, E.G. Life cycle assessment of transport of electricity via different voltage levels: A case study for Nord-Trøndelag county in Norway. Appl. Energy 2015, 157, 144–151. [Google Scholar] [CrossRef]

- Jorge, R.S.; Hertwich, E.G. Grid infrastructure for renewable power in Europe: The environmental cost. Energy 2014, 69, 760–768. [Google Scholar] [CrossRef]

- Wei, W.; Wu, X.; Li, J.; Jiang, X.; Zhang, P.; Zhou, S.; Zhu, H.; Liu, H.; Chen, H.; Guo, J.; et al. Ultra-high voltage network induced energy cost and carbon emissions. J. Clean. Prod. 2018, 178, 276–292. [Google Scholar] [CrossRef]

- Wei, W.; Wang, M.; Zhang, P.; Chen, B.; Guan, D.; Shao, S.; Li, J. A 2015 inventory of embodied carbon emissions for Chinese power transmission infrastructure projects. Sci. Data 2020, 7, 318. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, F. Stochastic analysis of embodied emissions of building construction: A comparative case study in China. Energy Build. 2017, 151, 574–584. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Feng, Y.; Mao, C. Uncertainty analysis for measuring greenhouse gas emissions in the building construction phase: A case study in China. J. Clean. Prod. 2016, 129, 183–195. [Google Scholar] [CrossRef]

- Kong, G.; Hu, S.; Yang, Q. Uncertainty method and sensitivity analysis for assessment of energy consumption of underground metro station. Sustain. Cities Soc. 2023, 92, 104504. [Google Scholar] [CrossRef]

- Shao, W.; Sun, Q.; Xu, X.; Yue, W.; Shi, D. Durability life prediction and horizontal bearing characteristics of CFRP composite piles in marine environments. Constr. Build. Mater. 2023, 367, 130116. [Google Scholar] [CrossRef]

- Kang, G.; Kim, T.; Kim, Y.-W.; Cho, H.; Kang, K.-I. Statistical analysis of embodied carbon emission for building construction. Energy Build. 2015, 105, 326–333. [Google Scholar] [CrossRef]

- Wang, E.; Shen, Z. A hybrid Data Quality Indicator and statistical method for improving uncertainty analysis in LCA of complex system—Application to the whole-building embodied energy analysis. J. Clean. Prod. 2013, 43, 166–173. [Google Scholar] [CrossRef]

- Chou, J.S.; Yeh, K.C. Life cycle carbon dioxide emissions simulation and environmental cost analysis for building construction. J. Clean. Prod. 2015, 101, 137–147. [Google Scholar] [CrossRef]

- Schwartz, Y.; Raslan, R.; Mumovic, D. The life cycle carbon footprint of refurbished and new buildings—A systematic review of case studies. Renew. Sustain. Energy Rev. 2018, 81, 231–241. [Google Scholar] [CrossRef]

- Jones, C.I.; McManus, M.C. Life-cycle assessment of 11kV electrical overhead lines and underground cables. J. Clean. Prod. 2010, 18, 1464–1477. [Google Scholar] [CrossRef]

- Harrison, G.P.; Maclean, E.J.; Karamanlis, S.; Ochoa, L.F. Life cycle assessment of the transmission network in Great Britain. Energy Policy 2010, 38, 3622–3631. [Google Scholar] [CrossRef]

- Acquaye, A.; Duffy, A.; Basu, B. Embodied emissions abatement—A policy assessment using stochastic analysis. Energy Policy 2011, 39, 429–441. [Google Scholar] [CrossRef]

- Bullard, C.W.; Penner, P.S.; Pilati, D.A. Net energy analysis: Handbook for combining process and input-output analysis. Resour. Energy 1978, 1, 267–313. [Google Scholar] [CrossRef]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Liu, S.; Han, M.; Wu, X.; Wu, X.; Li, Z.; Xia, X.; Ji, X. Embodied water analysis for Hebei Province, China by input-output modelling. Front. Earth Sci. 2016, 12, 72–85. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Z. Carbon emissions and resources use by Chinese economy 2007: A 135-sector inventory and input–output embodiment. Commun. Nonlinear Sci. Numer. Simul. 2010, 15, 3647–3732. [Google Scholar] [CrossRef]

- Wu, X.; Xia, X.; Chen, G.; Chen, B. Embodied energy analysis for coal-based power generation system-highlighting the role of indirect energy cost. Appl. Energy 2016, 184, 936–950. [Google Scholar] [CrossRef]

- Wu, X.; Yang, Q.; Chen, G.; Hayat, T.; Alsaedi, A. Progress and prospect of CCS in China: Using learning curve to assess the cost-viability of a 2 × 600 MW retrofitted oxyfuel power plant as a case study. Renew. Sustain. Energy Rev. 2016, 60, 1274–1285. [Google Scholar] [CrossRef]

- Wei, W.; Wang, X.; Zhu, H.; Li, J.; Zhou, S.; Zou, Z. Carbon emissions of urban power grid in Jing-Jin-Ji region: Characteristics and influential factors. J. Clean. Prod. 2017, 168, 428–440. [Google Scholar] [CrossRef]

- Chen, G.; Guo, S.; Shao, L.; Li, J.; Chen, Z.-M. Three-scale input–output modeling for urban economy: Carbon emission by Beijing 2007. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 2493–2506. [Google Scholar] [CrossRef]

- Cellura, M.; Longo, S.; Mistretta, M. Sensitivity analysis to quantify uncertainty in Life Cycle Assessment: The case study of an Italian tile. Renew. Sustain. Energy Rev. 2011, 15, 4697–4705. [Google Scholar] [CrossRef]

- May, J.R.; Brennan, D.J. Application of data quality assessment methods to an LCA of electricity generation. Int. J. Life Cycle Assess. 2003, 8, 215–225. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. Social life cycle assessment of concrete bridge decks exposed to aggressive environments. Environ. Impact Assess. Rev. 2018, 72, 50–63. [Google Scholar] [CrossRef]

- van Dorp, J.R. A dependent project evaluation and review technique: A Bayesian network approach. Eur. J. Oper. Res. 2020, 280, 689–706. [Google Scholar] [CrossRef]

- Ge, Z.; Geng, Y.; Wei, W.; Jiang, M.; Chen, B.; Li, J. Embodied carbon emissions induced by the construction of hydropower infrastructure in China. Energy Policy 2023, 173, 113404. [Google Scholar] [CrossRef]

- Nagarsheth, R.; Singh, S. Study of gas insulated substation and its comparison with air insulated substation. Int. J. Electr. Power Energy Syst. 2014, 55, 481–485. [Google Scholar] [CrossRef]

| Form of Switchgear | Transformer Substation |

|---|---|

| AIS | TC, AL, SC, HT |

| GIS | WJ, RQ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, J.; Hu, Y.; Liu, J.; Ding, S.; Zhao, G.; Zhang, Y.; Li, J.; Nie, Z. Carbon Emission Evaluation Method and Comparison Study of Transformer Substations Using Different Data Sources. Buildings 2023, 13, 1106. https://doi.org/10.3390/buildings13041106

Liu X, Zhang J, Hu Y, Liu J, Ding S, Zhao G, Zhang Y, Li J, Nie Z. Carbon Emission Evaluation Method and Comparison Study of Transformer Substations Using Different Data Sources. Buildings. 2023; 13(4):1106. https://doi.org/10.3390/buildings13041106

Chicago/Turabian StyleLiu, Xigang, Jian Zhang, Yiqi Hu, Jiao Liu, Shijun Ding, Gaowen Zhao, Yang Zhang, Jiawei Li, and Zhibao Nie. 2023. "Carbon Emission Evaluation Method and Comparison Study of Transformer Substations Using Different Data Sources" Buildings 13, no. 4: 1106. https://doi.org/10.3390/buildings13041106

APA StyleLiu, X., Zhang, J., Hu, Y., Liu, J., Ding, S., Zhao, G., Zhang, Y., Li, J., & Nie, Z. (2023). Carbon Emission Evaluation Method and Comparison Study of Transformer Substations Using Different Data Sources. Buildings, 13(4), 1106. https://doi.org/10.3390/buildings13041106