Photocatalytic Activity and Mechanical Properties of Cement Slurries Containing Titanium Dioxide

Abstract

1. Introduction

2. Context and Scope of This Study

3. Materials and Methods

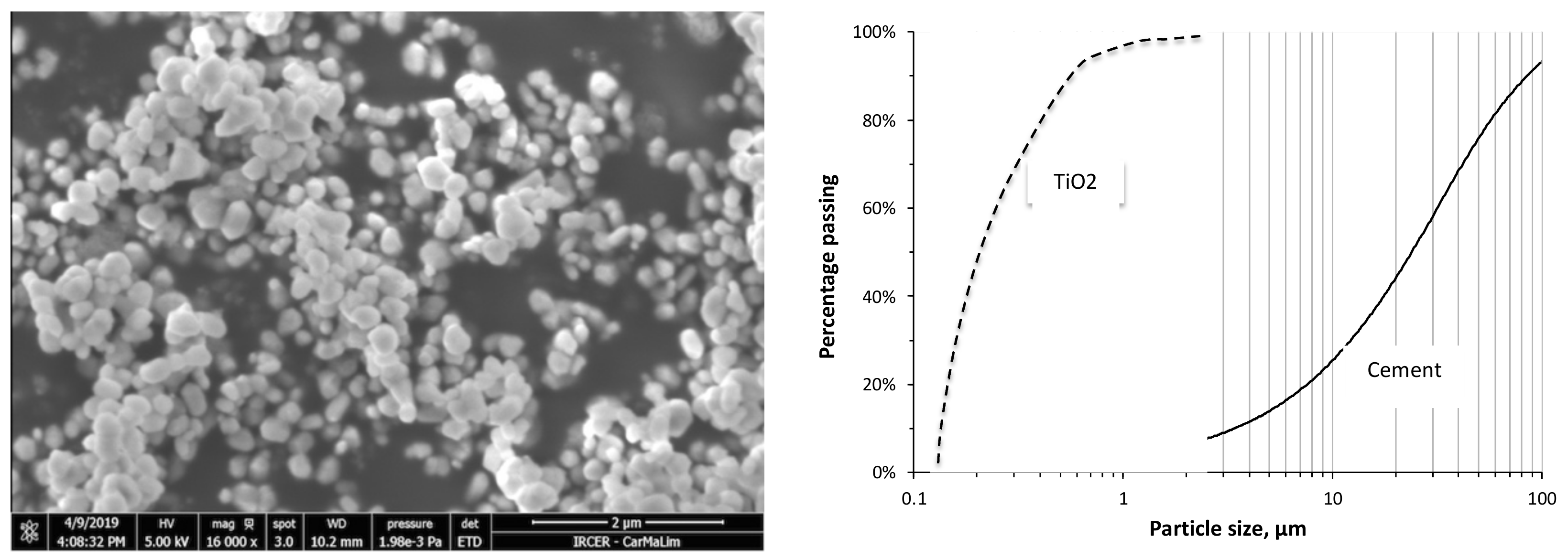

3.1. Materials

3.2. Cement Slurry Proportions

3.3. Testing Procedures

3.3.1. Flowability and Density

3.3.2. Colorimetry

3.3.3. Flexural and Compressive Strengths

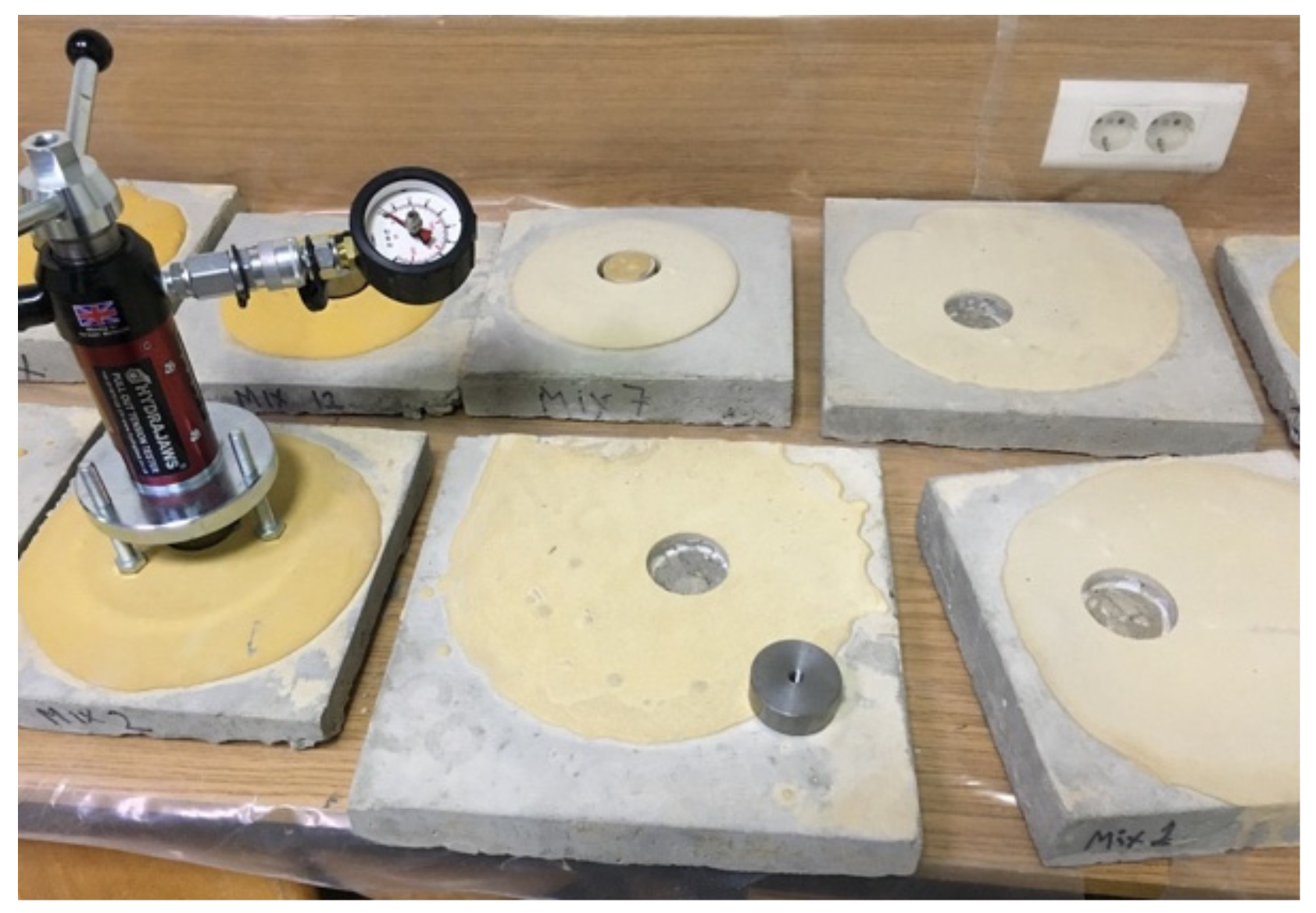

3.3.4. Bond Strength

3.3.5. Water Absorption

3.3.6. UV Reactor and NOx Measurements

4. Results and Discussion

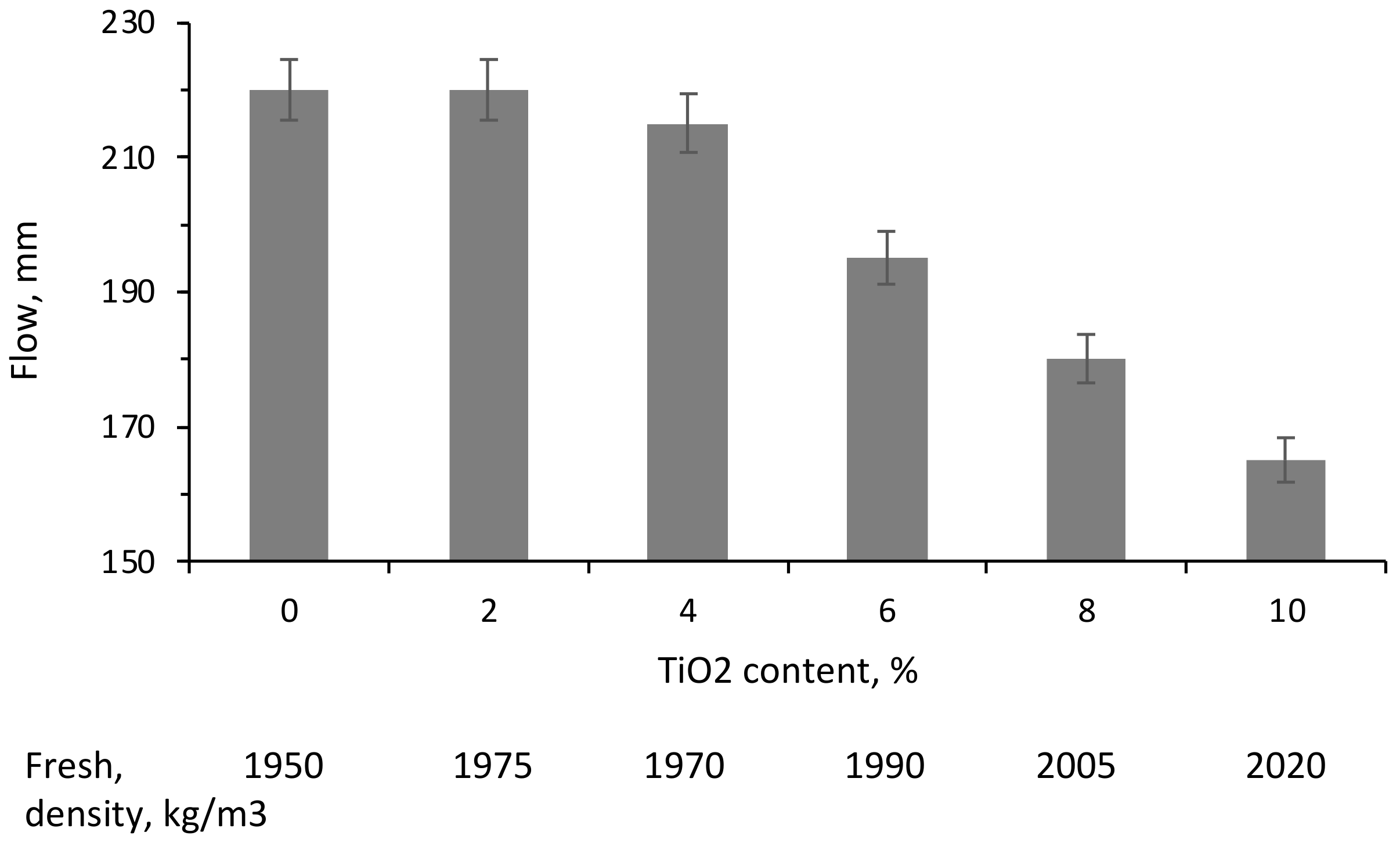

4.1. Effect on Flow and Density

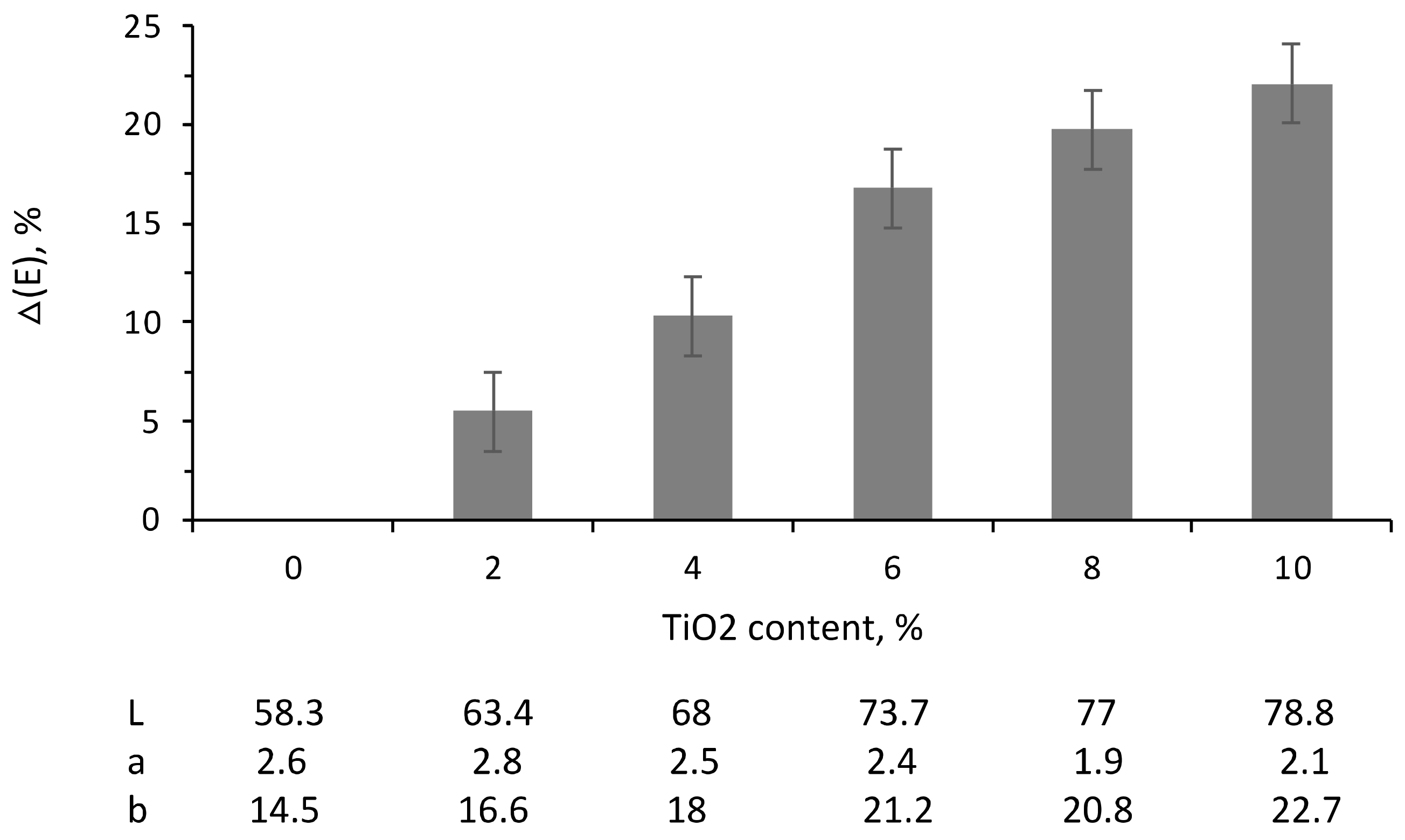

4.2. Effect on Color Characteristics of the Hardened Slurry

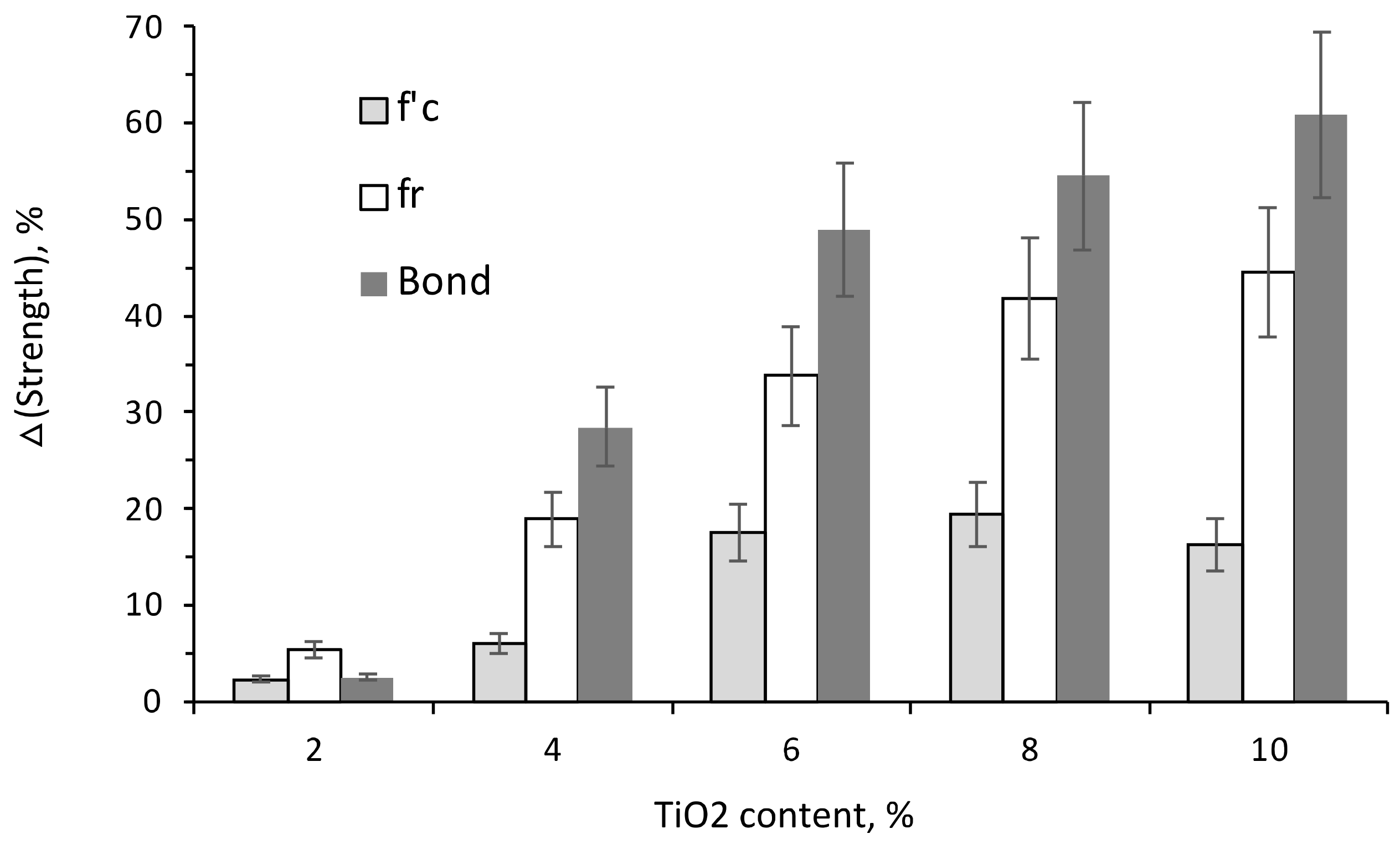

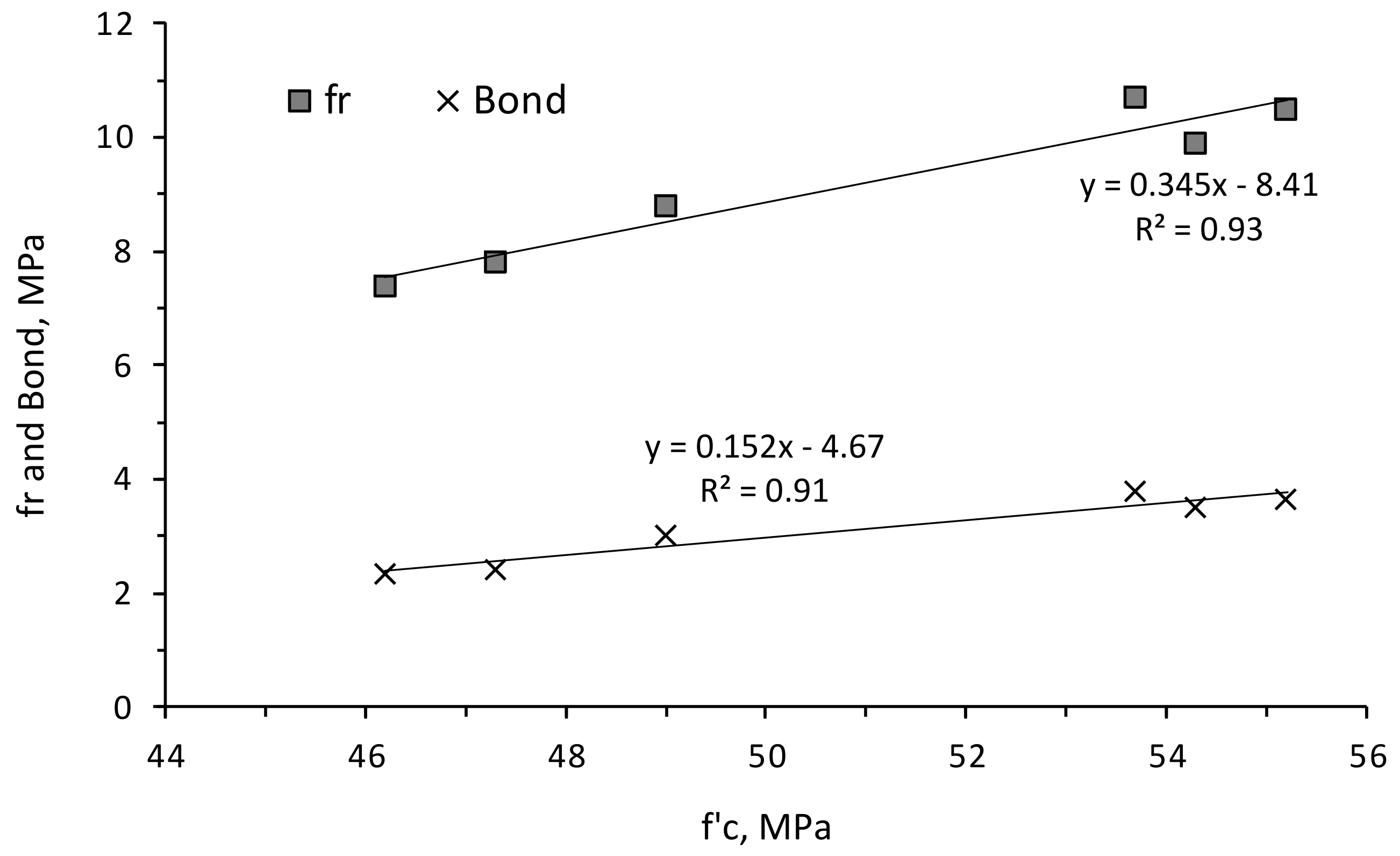

4.3. Effect on Mechanical Properties

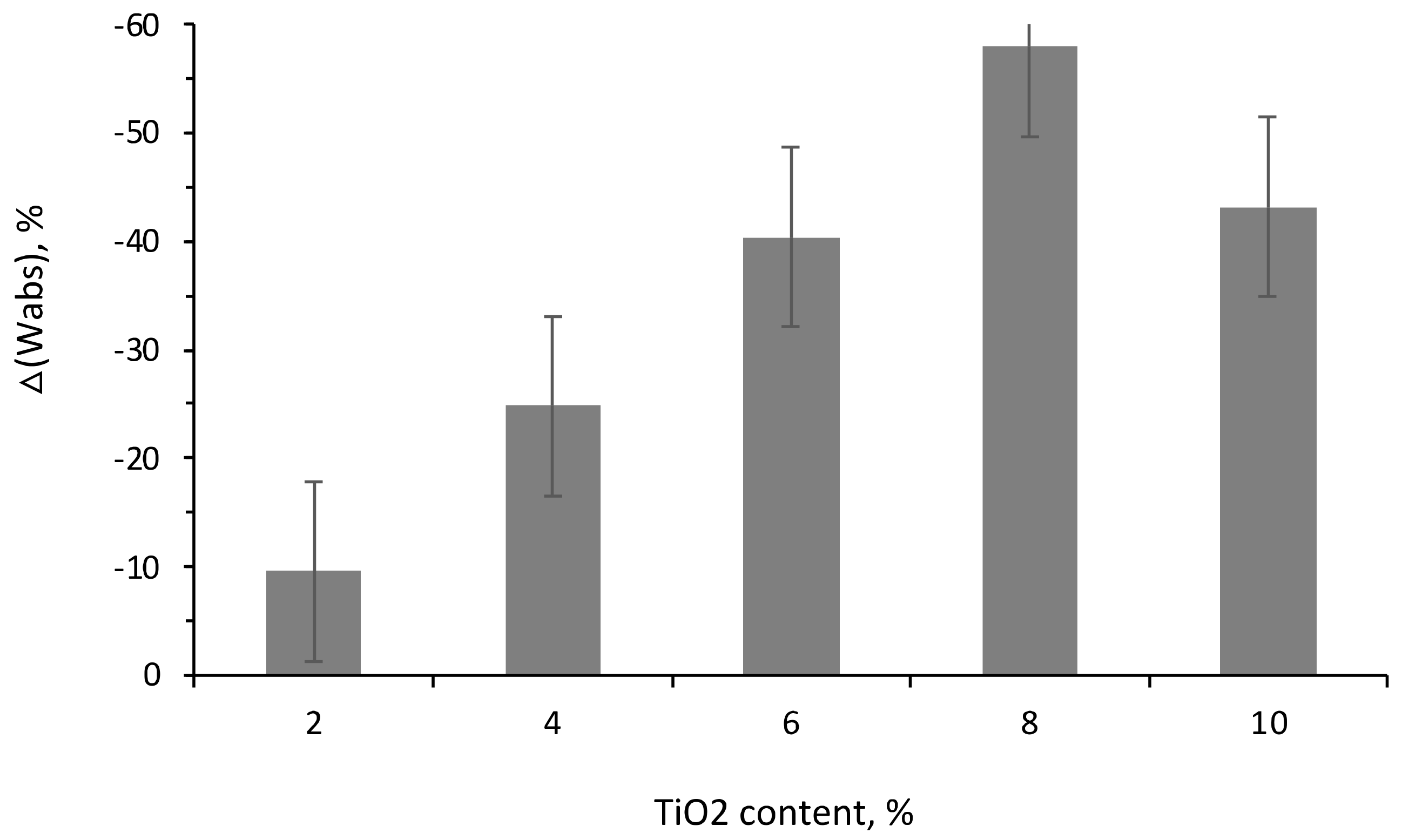

4.4. Effect on Water Absorption

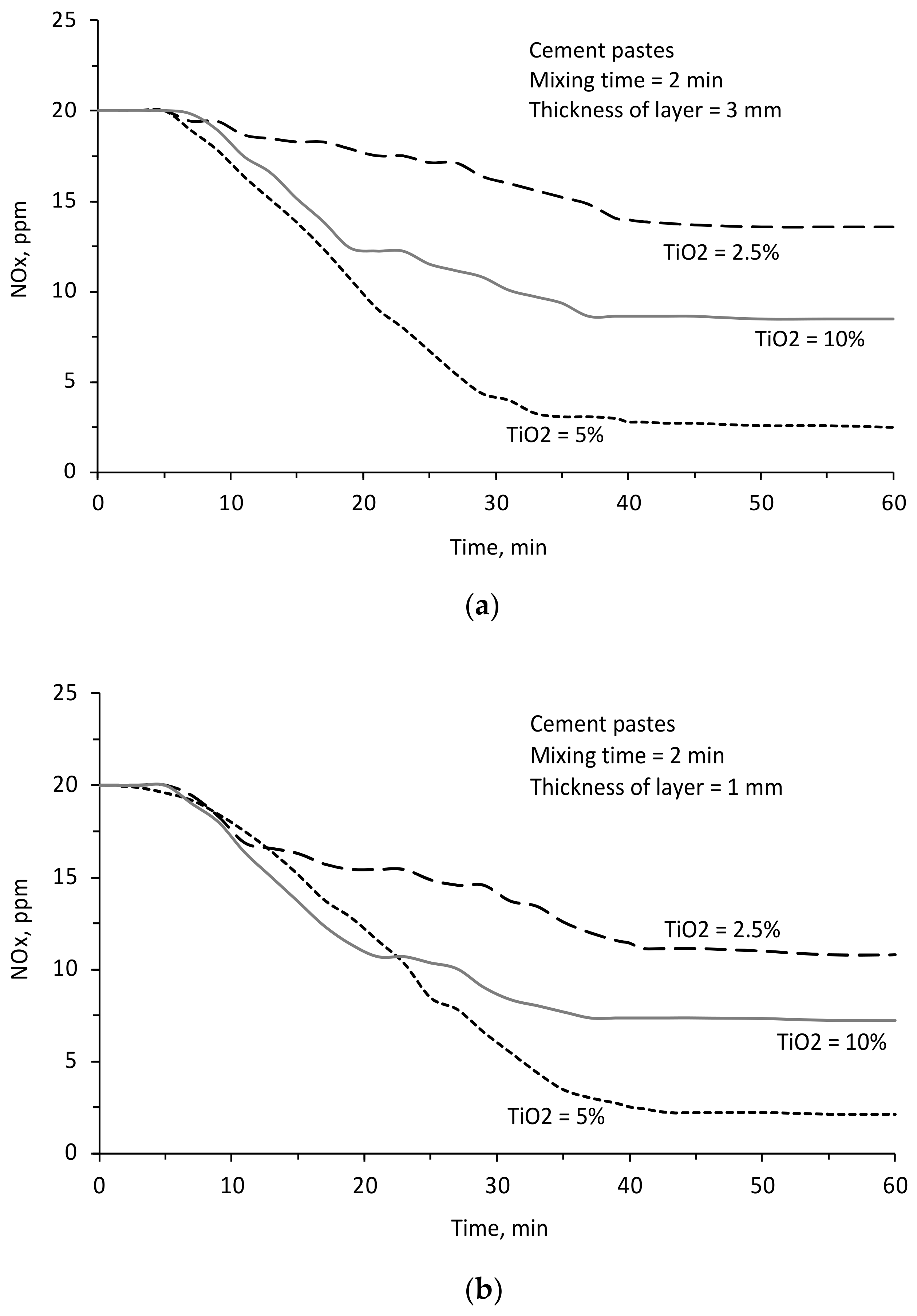

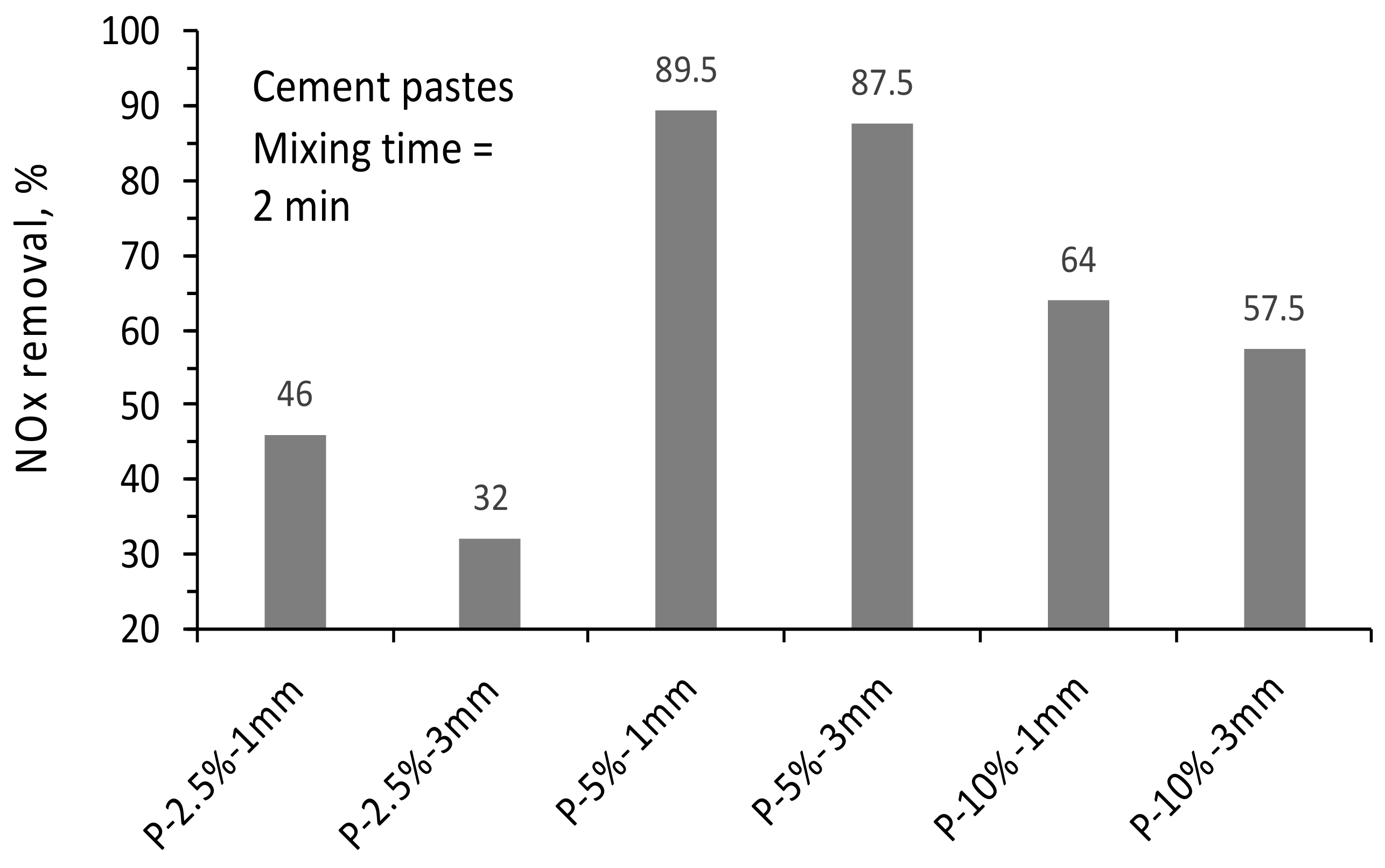

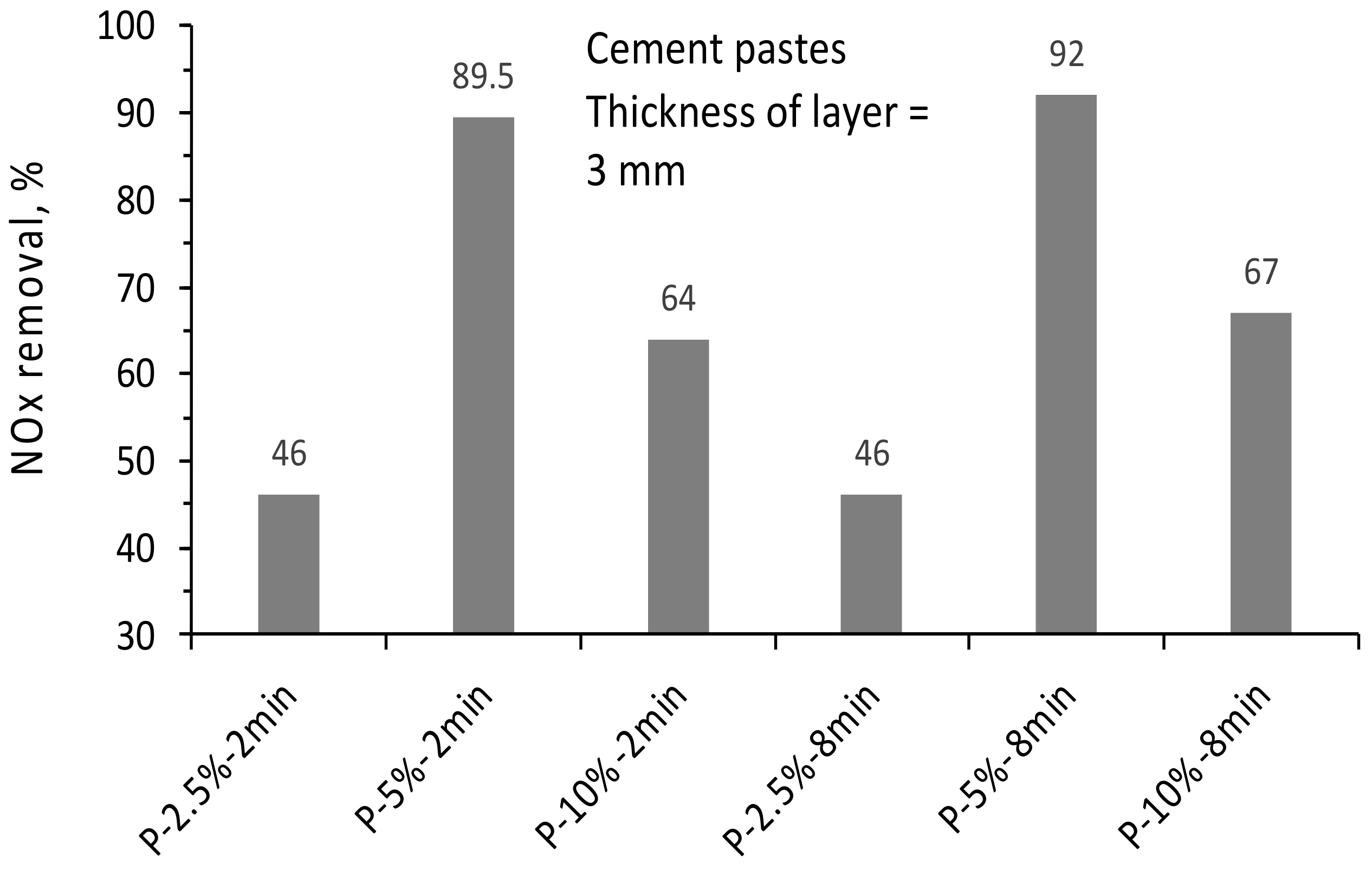

4.5. Effect on NOx Removal

5. Conclusions

- The flow is marginally affected when up to 4% TiO2 is added to the cement slurry, which thereafter gradually curtailed at higher rates. This was attributed to the fine TiO2 particles that are believed to increase the inter-particle links within the suspension.

- The Δ(E) values gradually increased with the TiO2 additions, reflecting their beneficial effects on magnifying the white color of the hardened material. This aesthetically can be attractive in urban cities, besides the associated benefits on maintaining better air quality.

- The mechanical properties improved with the TiO2 additions due to two concurrent phenomena including the micro-filler effect and formation of nucleation sites that promote the cement hydration reactions. The improvement in strength was particularly noticed in the flexural and pull-off bond strengths.

- The incorporation of TiO2 reduced the tendency towards water absorption, which is consistent with the improvement in the mechanical properties. The reduced rate of water absorption can be relevant to protect the external facades and surfaces for moisture-related problems.

- The NOx concentration at the reactor outlet dropped from 20 ppm for the control mix to 12 and 2 ppm with the incorporation of 2.5% and 5% TiO2, respectively, reflecting the efficiency of TiO2 additions. Nevertheless, the increase in TiO2 to 10% appears to reduce the photocatalytic efficiency due to a densification process of the slurry microstructure.

- The NOx removal is marginally affected by the dispersion time used for preparing the TiO2-modified slurry mixture, and also by the thickness of the slurry that is applied on the substrate surface. This can be economically advantageous in new construction or renovation applications.

- The cement slurry containing 5% TiO2, mixed for 2 min, and applied at a 1 mm thickness exhibited the highest photocatalytic efficiency. This can be recommended for cement slurries used in the construction industry, either in new structures or for the renovation of existing facades.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Poon, C.-S. Photocatalytic Cementitious Materials: Influence of the Microstructure of Cement Paste on Photocatalytic Pollution Degradation. Environ. Sci. Technol. 2009, 43, 8948–8952. [Google Scholar] [CrossRef]

- Duncan, B.N.; Lamsal, L.N.; Thompson, A.M.; Yoshida, Y.; Lu, Z.; Streets, D.G.; Hurwitz, M.M.; Pickering, K.E. A space-based, high-resolution view of notable changes in urban NOx pollution around the world (2005–2014). J. Geophys. Res. Atmos. 2016, 121, 976–996. [Google Scholar] [CrossRef]

- Anderegg, W.R.L.; Prall, J.W.; Harold, J.; Schneider, S.H. Expert credibility in climate change. Proc. Natl. Acad. Sci. USA 2010, 107, 12107–12109. [Google Scholar] [CrossRef] [PubMed]

- Sikkema, J.; Ong, S.; Alleman, J. Photocatalytic concrete pavements: Laboratory investigation of NO oxidation rate under varied environmental conditions. Constr. Build. Mater. 2015, 100, 305–314. [Google Scholar] [CrossRef]

- WHO. Air Quality Guidelines—Global Update. 2005. Available online: https://www.who.int/phe/health_topics/outdoorair/outdoorair_aqg/en/ (accessed on 11 October 2011).

- Pérez-Nicolás, M.; Plank, J.; Ruiz-Izuriaga, D.; Navarro-Blasco, I.; Fernández, J.; Alvarez, J. Photocatalytically active coatings for cement and air lime mortars: Enhancement of the activity by incorporation of superplasticizers. Constr. Build. Mater. 2018, 162, 628–648. [Google Scholar] [CrossRef]

- Hassan, M.M.; Dylla, H.; Mohammad, L.N.; Rupnow, T. Evaluation of the durability of titanium dioxide photocatalyst coating for concrete pavement. Constr. Build. Mater. 2010, 24, 1456–1461. [Google Scholar] [CrossRef]

- Wu, X. Applications of titanium dioxide materials. In Titanium Dioxide—Advances and Applications; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Cárdenas, C.; Tobón, J.I.; García, C.; Vila, J. Functionalized building materials: Photocatalytic abatement of NOx by cement pastes blended with TiO2 nanoparticles. Constr. Build. Mater. 2012, 36, 820–825. [Google Scholar] [CrossRef]

- Lee, B.Y.; Jayapalan, A.R.; Bergin, M.H.; Kurtis, K.E. Photocatalytic cement exposed to nitrogen oxides: Effect of oxidation and binding. Cem. Concr. Res. 2014, 60, 30–36. [Google Scholar] [CrossRef]

- Saleh, H.M.; El-Sheikh, S.M.; Elshereafy, E.E.; Essa, A.K. Mechanical and physical characterization of cement reinforced by iron slag and titanate nanofibers to produce advanced containment for radioactive waste. Constr. Build. Mater. 2019, 200, 135–145. [Google Scholar] [CrossRef]

- Saleh, H.M.; Salman, A.A.; Faheim, A.A.; El-Sayed, A.M. Influence of aggressive environmental impacts on clean, lightweight bricks made from cement kiln dust and grated polystyrene. Case Stud. Constr. Mater. 2021, 15, e00759. [Google Scholar] [CrossRef]

- Ramirez, A.M.; Demeestere, K.; Belie, N.D.; Mäntylä, T.; Levänen, E. Titanium dioxide coated cementitious materials for air purifying purposes: Preparation, characterization and toluene removal potential. Build. Environ. 2010, 45, 832–838. [Google Scholar] [CrossRef]

- Delnavaz, M.; Ayati, B.; Ganjidoust, H.; Sanjabi, S. Application of concrete surfaces as novel substrate for immobilization of TiO2 nano powder in photocatalytic treatment of phenolic water. J. Environ. Health Sci. Eng. 2015, 13, 58. [Google Scholar] [CrossRef]

- Yang, J.; Wang, G.; Wang, D.; Liu, C.; Zhang, Z. A self-cleaning coating material of TiO2 porous microspheres/cement composite with high-efficient photocatalytic depollution performance. Mater. Lett. 2017, 200, 1–5. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Q.; Peng, B.; Chai, L.; Liu, H. Self-cleaning performance of TiO2 -coating cement materials prepared based on solidification/stabilization of electrolytic manganese residue. Constr. Build. Mater. 2016, 106, 236–242. [Google Scholar] [CrossRef]

- ISO 22197-1:2007; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics). Test Method for Air-Purification Performance of Semiconducting Photocatalytic Materials. ISO: London, UK, 2007. [CrossRef]

- JSA-JIS R1701-1; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Air Purification Performance of Photocatalytic Materials—Part 1: Removal of Nitric Oxide. Japanese Standards Association: Tokyo, Japan, 2016.

- Jimenez-Relinque, E.; Rodriguez-Garcia, J.; Castillo, A.; Castellote, M. Characteristics and efficiency of photocatalytic cementitious materials: Type of binder, roughness and microstructure. Cem. Concr. Res. 2015, 71, 124–131. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Yu, X.; Han, B.; Ou, J. Multifunctional cementitious composites modified with nano titanium dioxide: A review. Compos. Part A Appl. Sci. Manuf. 2018, 111, 115–137. [Google Scholar] [CrossRef]

- Binas, V.; Papadaki, D.; Maggos, T.; Katsanaki, A.; Kiriakidis, G. Study of innovative photocatalytic cement based coatings: The effect of supporting materials. Constr. Build. Mater. 2018, 168, 923–930. [Google Scholar] [CrossRef]

- Witkowski, H.; Jackiewicz-Rek, W.; Chilmon, K.; Jarosławski, J.; Tryfon-Bojarska, A.; Gąsiński, A. Air Purification Performance of Photocatalytic Concrete Paving Blocks after Seven Years of Service. Appl. Sci. 2019, 9, 1735. [Google Scholar] [CrossRef]

- Martinez, T.; Bertron, A.; Ringot, E.; Escadeillas, G. Degradation of NO using photocatalytic coatings applied to different substrates. Build. Environ. 2011, 46, 1808–1816. [Google Scholar] [CrossRef]

- Daniyal, M.; Akhtar, S.; Azam, A. Effect of nano-TiO2 on the properties of cementitious composites under different exposure environments. J. Mater. Res. Technol. 2019, 8, 6158–6172. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, S.H.; Jang, Y.I.; Park, H.M. Evaluation of reducing no and SO2 concentration in nano SiO2-TiO2 photocatalytic concrete blocks. Materials 2021, 14, 7182. [Google Scholar] [CrossRef] [PubMed]

- Lapidus, A.; Korolev, E.; Topchiy, D.; Kuzmina, T.; Shekhovtsova, S.; Shestakov, N. Self-cleaning cement-based building materials. Buildings 2022, 12, 606. [Google Scholar] [CrossRef]

- Diamanti, M.V.; Luongo, N.; Massari, S.; Lupica Spagnolo, S.; Daniotti, B.; Pedeferri, M.P. Durability of self-cleaning cement-based materials. Constr. Build. Mater. 2021, 280, 122442. [Google Scholar] [CrossRef]

- Jimenez-Relinque, E.; Castellote, M. Quick assessment of the photocatalytic activity of TiO2 construction materials by nitroblue tetrazolium (NBT) ink. Constr. Build. Mater. 2019, 214, 1–8. [Google Scholar] [CrossRef]

- Folli, A.; Pade, C.; Hansen, T.B.; De Marco, T.; Macphee, D.E. TiO2 photocatalysis in cementitious systems: Insights into self-cleaning and depollution chemistry. Cem. Concr. Res. 2012, 42, 539–548. [Google Scholar] [CrossRef]

- Assaad, J.J. Disposing waste latex paints in cement based materials—Effect on flow and rheological properties. J. Build. Eng. 2016, 6, 75–85. [Google Scholar] [CrossRef]

- Assaad, J.J.; Nasr, D.; Chwaifaty, S.; Tawk, T. Parametric study on polymer-modified pigmented cementitious overlays for colored applications. J. Build. Eng. 2020, 27, 101009. [Google Scholar] [CrossRef]

- Bartos, P. Fresh Concrete Properties and Test; Elsevier: Amsterdam, The Netherlands, 1992; ISBN 0444881417. [Google Scholar]

- Yildizel, S.A.; Kaplan, G.; Ozturk, A.U. Cost optimization of mortars containing different pigments and their freeze-thaw resistance properties. Adv. Mater. Sci. Eng. 2016, 2016, 5346213. [Google Scholar] [CrossRef]

- Hospodarova, V.; Junak, J.; Stevulova, N. Color pigments in concrete and their properties. Pollack Period. 2015, 10, 143–151. [Google Scholar] [CrossRef]

- Assaad, J.J. Effect of Waste Latex Paint on Rheological Properties of Cement Pastes—Compatibility with Water Reducers. Jr. Mater. Civ. Eng. 2015, 27, 12. [Google Scholar] [CrossRef]

- Buxbaum, G. Industrial Inorganic Pigments, 2nd ed.; WILEY-VCH: Weinheim, Germany, 1998. [Google Scholar]

- Teichmann, G. The use of colorimetric methods in the concrete industry. Betonw. Fertigtl. 1990, 11, 58–73. [Google Scholar]

- BS EN 196/1; Methods of Testing Cement. Determination of Strength. British Standard Institution: London, UK, 2016; p. 38.

- EN 1542; Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Measurement of Bond Strength by Pull-Off. BSI: London, UK, 1999.

- Issa, C.; Assaad, J. Stability and Bond Properties of Polymer-Modified Self-Consolidating Concrete for Repair Applications. Mater. Struct. 2017, 50, 28. [Google Scholar] [CrossRef]

- Assaad, J.J. Development of Polymer-Modified Cement for Adhesive and Repair Applications. Constr. Build. Mater. 2018, 163, 139–148. [Google Scholar] [CrossRef]

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013.

- Assaad, J.; Issa, C. Use of Locked-Cycle Protocol to Assess Cement Fineness and Properties in Laboratory-Grinding Mills. ACI Mater. J. 2016, 113, 429–438. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effect of TiO2 nanoparticles on water permeability and thermal and mechanical properties of high strength self-compacting concrete. Mater. Sci. Eng. A 2010, 528, 756–763. [Google Scholar] [CrossRef]

- Beushausen, H.; Gillmer, M. The use of superabsorbent polymers to reduce cracking of bonded mortar overlays. Cement Concr. Compos. 2014, 52, 1–8. [Google Scholar] [CrossRef]

- El Sakka, F.; Assaad, J.J.; Hamzeh, F.; Nakhoul, C. Thixotropy and interfacial bond strengths of polymer-modified printed mortars. Mater. Struct. 2019, 52, 79. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; Deng, X. NOx removal ability of photocatalytic cement-based materials with porous structure. J. Clean. Prod. 2022, 377, 134396. [Google Scholar] [CrossRef]

- Jiang, J.; Dong, X.; Wang, H.; Wang, F.; Li, Y.; Lu, Z. Enhanced mechanical and photocatalytic performance of cement mortar reinforced by nano-TiO2 hydrosol-coated sand. Cem. Concr. Compos. 2023, 137, 104906. [Google Scholar] [CrossRef]

- Saade, J.; Assaad, J.J. Effect of Pigments on Structural Properties of Colored Reinforced Concrete Beams. Adv. Civ. Eng. Mater. 2022, 11, 17–32. [Google Scholar] [CrossRef]

- Assaad, J.J.; Mattew, M.; Saade, J. Effect of Pigments on Bond Strength Between Coloured Concrete and Steel Reinforcement. Acta Polytech. 2022, 62, 248–261. [Google Scholar] [CrossRef]

| TiO2, % | Flow, mm | Density (Fresh), kg/m3 | Density (Hardened), kg/m3 | f’c, MPa | fr, MPa | Pull-Off Bond, MPa | Wabs, mm/min0.5 |

|---|---|---|---|---|---|---|---|

| 0 | 220 | 1950 | 1920 | 46.2 | 7.4 | 2.35 | 0.414 |

| 2 | 220 | 1975 | 1935 | 47.3 | 7.8 | 2.41 | 0.374 |

| 4 | 215 | 1970 | 1960 | 49 | 8.8 | 3.02 | 0.311 |

| 6 | 195 | 1990 | 2005 | 54.3 | 9.9 | 3.5 | 0.247 |

| 8 | 180 | 2005 | 2000 | 55.2 | 10.5 | 3.63 | 0.174 |

| 10 | 165 | 2020 | 2015 | 53.7 | 10.7 | 3.78 | 0.235 |

| TiO2 Content, % | L-Value | a-Value | b-Value | Δ(E) |

|---|---|---|---|---|

| 0 | 58.3 | 2.6 | 14.5 | - |

| 2 | 63.4 | 2.8 | 16.6 | 5.5 |

| 4 | 68 | 2.5 | 18 | 10.3 |

| 6 | 73.7 | 2.4 | 21.2 | 16.8 |

| 8 | 77 | 1.9 | 20.8 | 19.8 |

| 10 | 78.8 | 2.1 | 22.7 | 22.1 |

| TiO2, % of Cement | Mixing time, min | Thickness, mm | NOx after Stabilization, ppm | NOx Removal, % | |

|---|---|---|---|---|---|

| 2.5%TiO2-2 min-1 mm | 2.5 | 2 | 1 | 10.8 | 46.0 |

| 2.5%TiO2-2 min-3 mm | 2.5 | 2 | 3 | 13.6 | 32.0 |

| 2.5%TiO2-8 min-1 mm | 2.5 | 8 | 1 | 10.8 | 46.0 |

| 2.5%TiO2-8 min-3 mm | 2.5 | 8 | 3 | 12.0 | 40.0 |

| 5%TiO2-2 min-1 mm | 5 | 2 | 1 | 2.1 | 89.5 |

| 5%TiO2-2 min-3 mm | 5 | 2 | 3 | 2.5 | 87.5 |

| 5%TiO2-8 min-1 mm | 5 | 8 | 1 | 1.6 | 92.0 |

| 5%TiO2-8 min-3 mm | 5 | 8 | 3 | 2.2 | 89.0 |

| 10%TiO2-2 min-1 mm | 10 | 2 | 1 | 7.2 | 64.0 |

| 10%TiO2-2 min-3 mm | 10 | 2 | 3 | 8.5 | 57.5 |

| 10%TiO2-8 min-1 mm | 10 | 8 | 1 | 6.6 | 67.0 |

| 10%TiO2-8 min-3 mm | 10 | 8 | 3 | 8.1 | 59.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabali, Y.; Assaad, J.; Aouad, G. Photocatalytic Activity and Mechanical Properties of Cement Slurries Containing Titanium Dioxide. Buildings 2023, 13, 1046. https://doi.org/10.3390/buildings13041046

Jabali Y, Assaad J, Aouad G. Photocatalytic Activity and Mechanical Properties of Cement Slurries Containing Titanium Dioxide. Buildings. 2023; 13(4):1046. https://doi.org/10.3390/buildings13041046

Chicago/Turabian StyleJabali, Yasmine, Joseph Assaad, and Georges Aouad. 2023. "Photocatalytic Activity and Mechanical Properties of Cement Slurries Containing Titanium Dioxide" Buildings 13, no. 4: 1046. https://doi.org/10.3390/buildings13041046

APA StyleJabali, Y., Assaad, J., & Aouad, G. (2023). Photocatalytic Activity and Mechanical Properties of Cement Slurries Containing Titanium Dioxide. Buildings, 13(4), 1046. https://doi.org/10.3390/buildings13041046