Influence of Friction Coefficient between Cable and Membrane on Wind-Induced Response of Air-Supported Membrane Structures with Oblique Cable Net

Abstract

1. Introduction

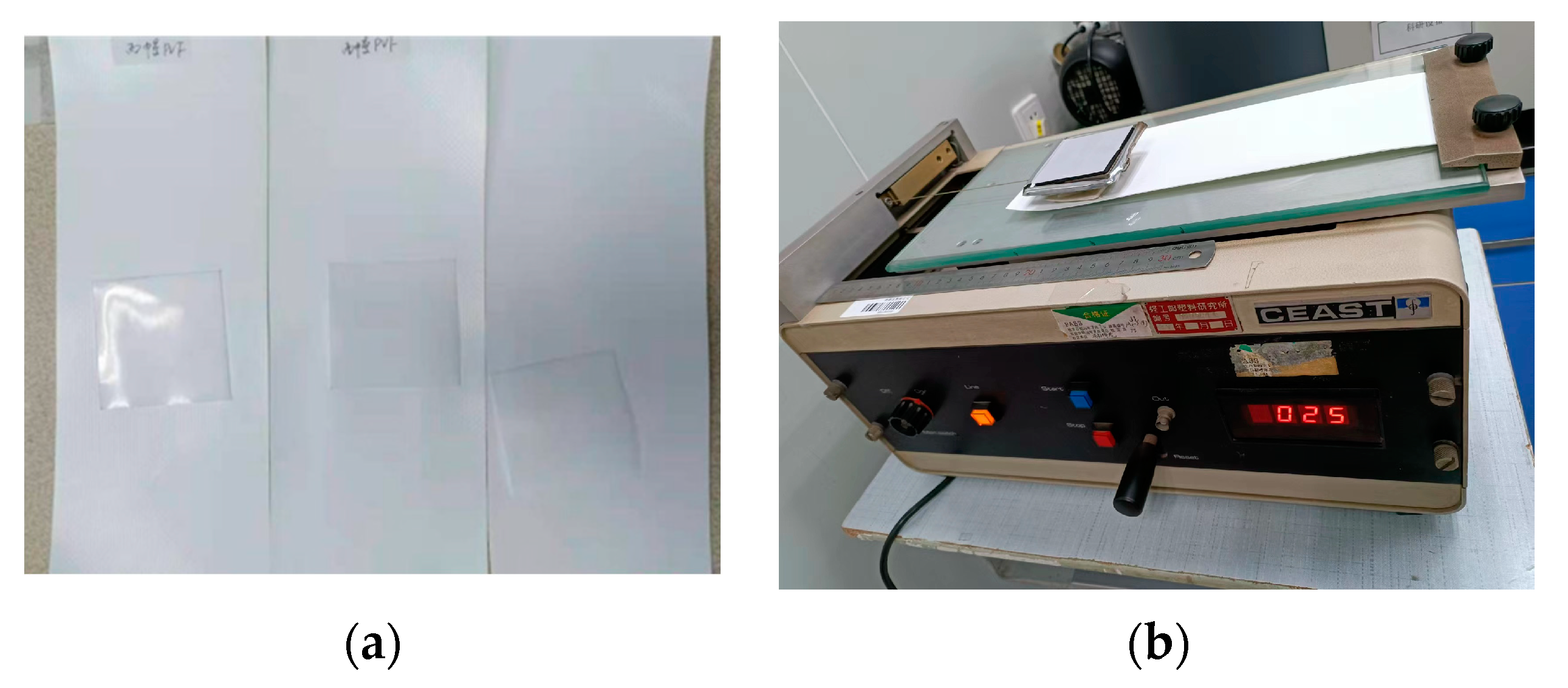

2. Coefficients of Friction Test between Cable and Membrane Materials

3. Model and Methods

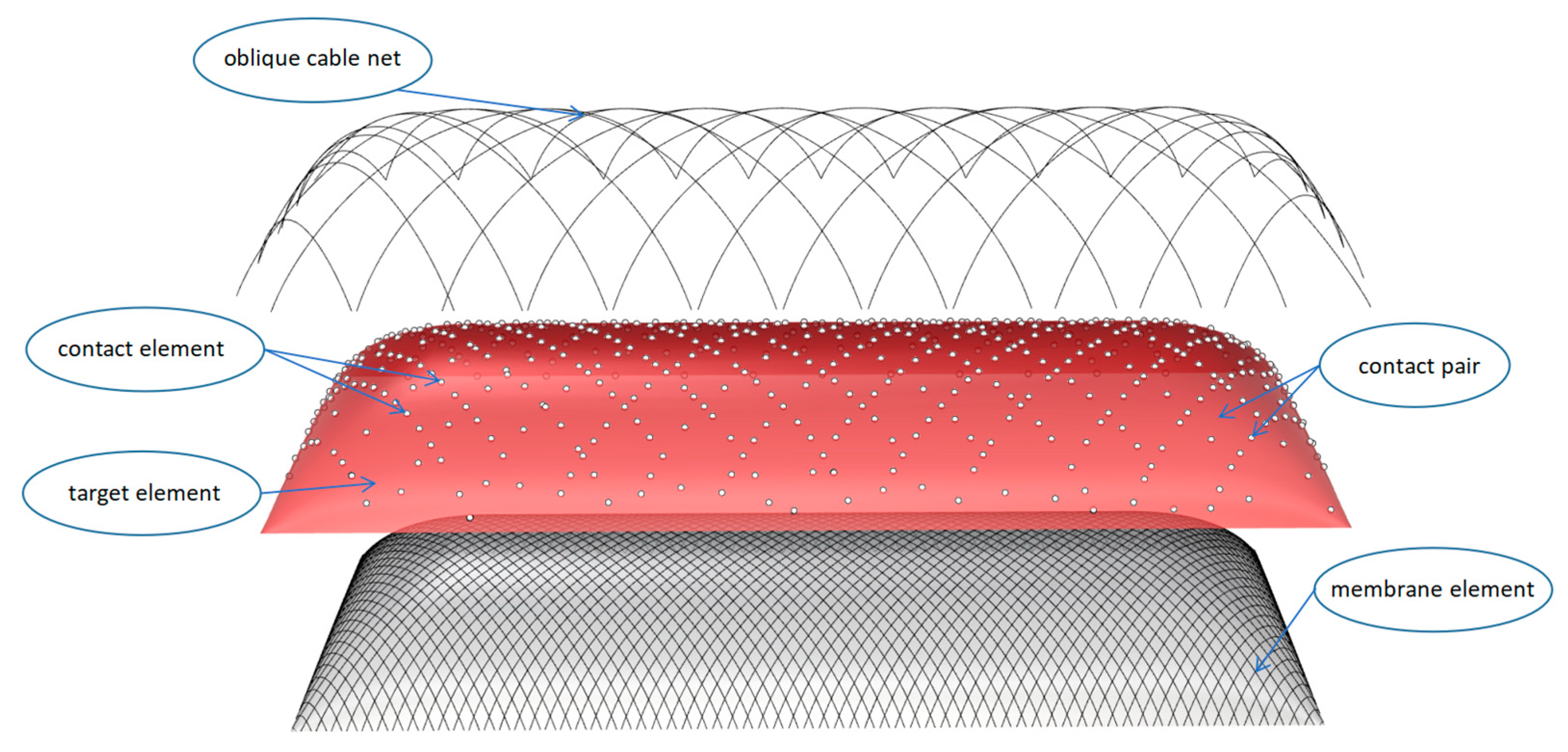

3.1. Model Establishment

3.2. Methods

- The contact surface is smooth and continuous.

- Friction on contact surfaces obeys Coulomb’s law of friction.

- The membrane material is an orthotropic elastic material, and the warp and weft directions of the material are always perpendicular before and after deformation.

4. Results and Discussion

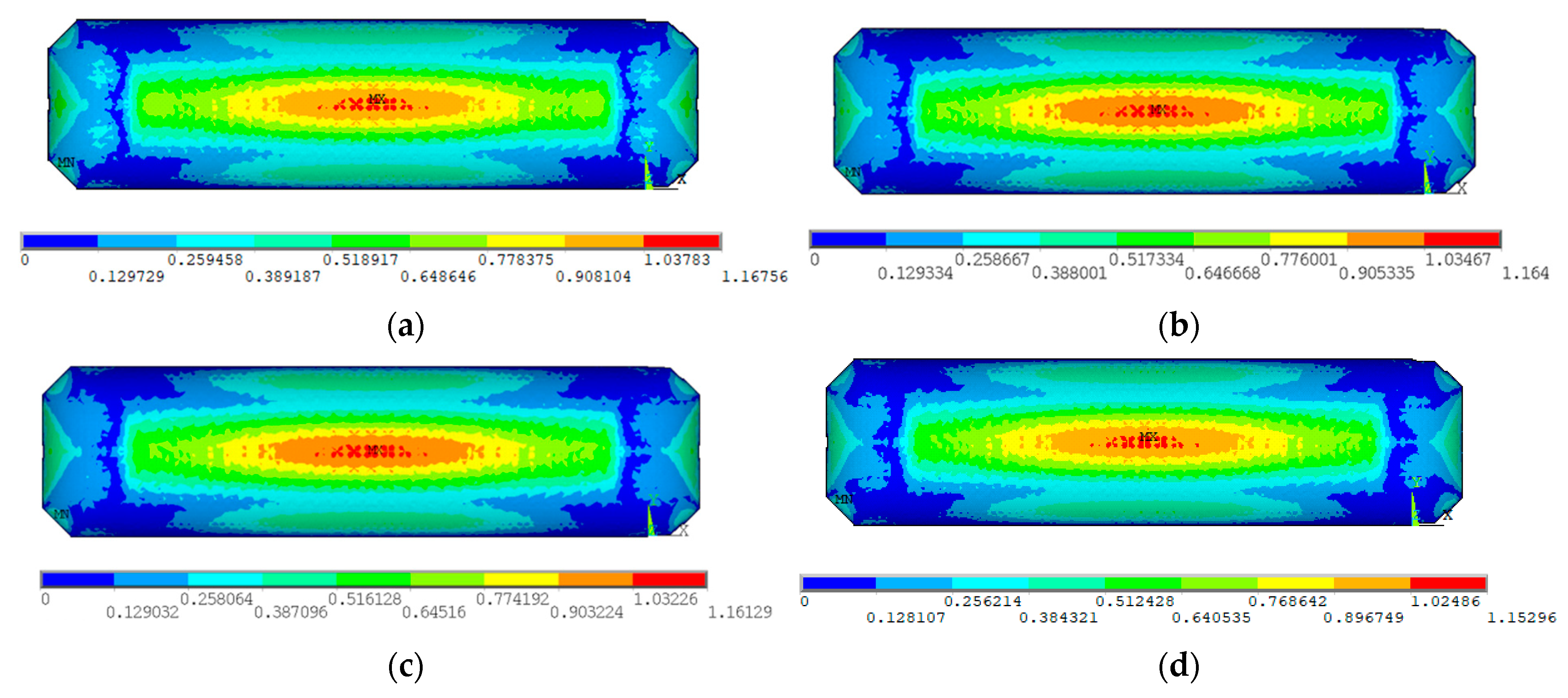

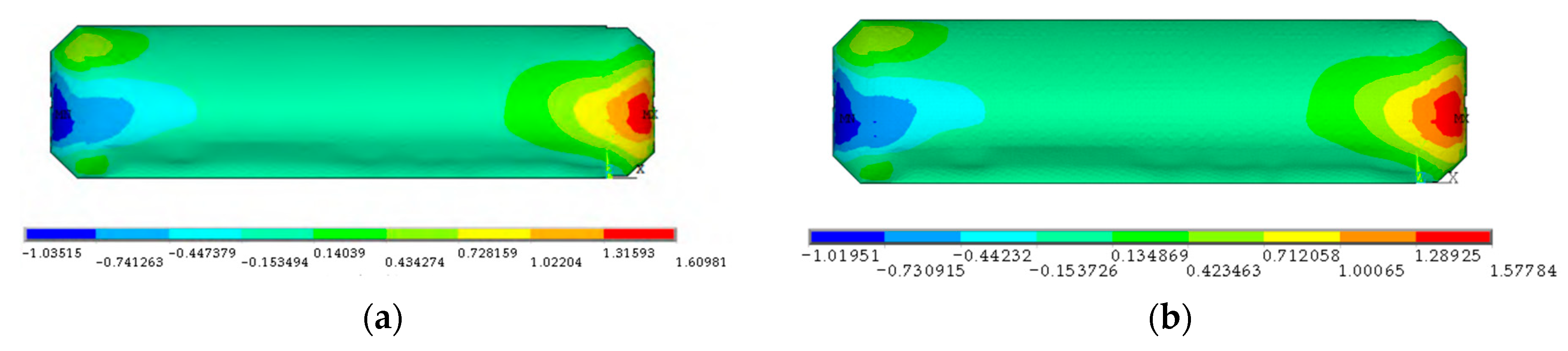

4.1. Initial Form Analysis

4.2. Cable-Membrane Contact under Equivalent Static Wind Load Action

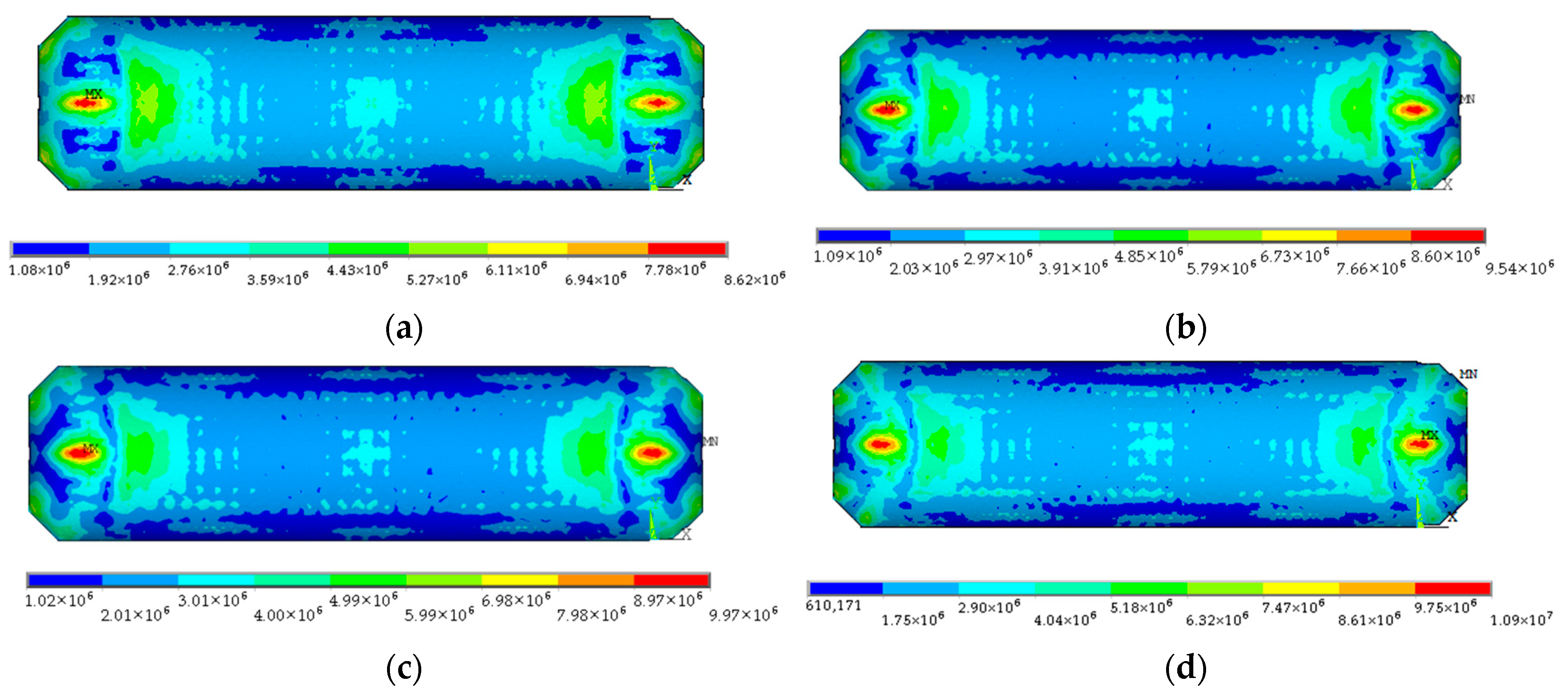

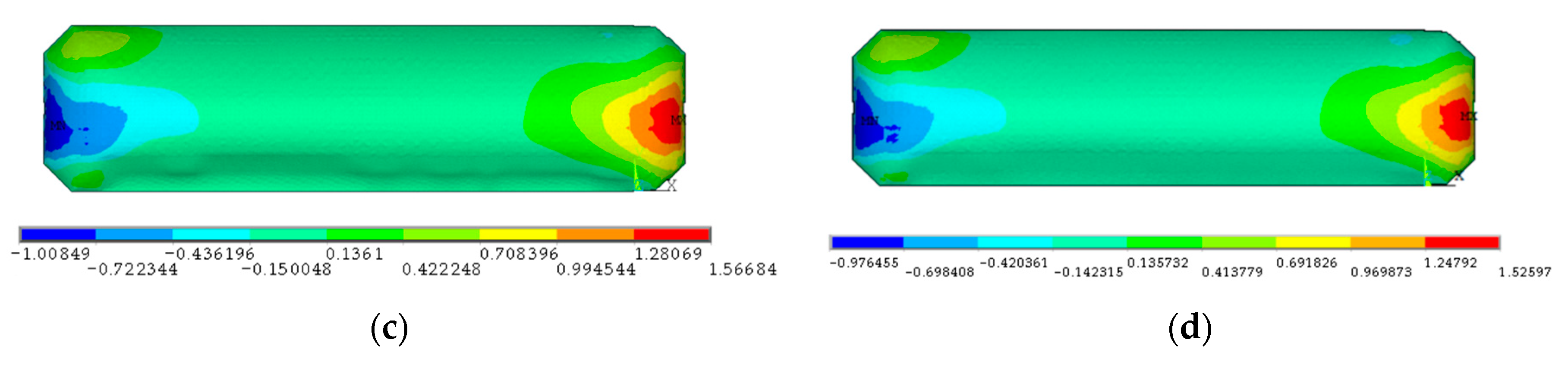

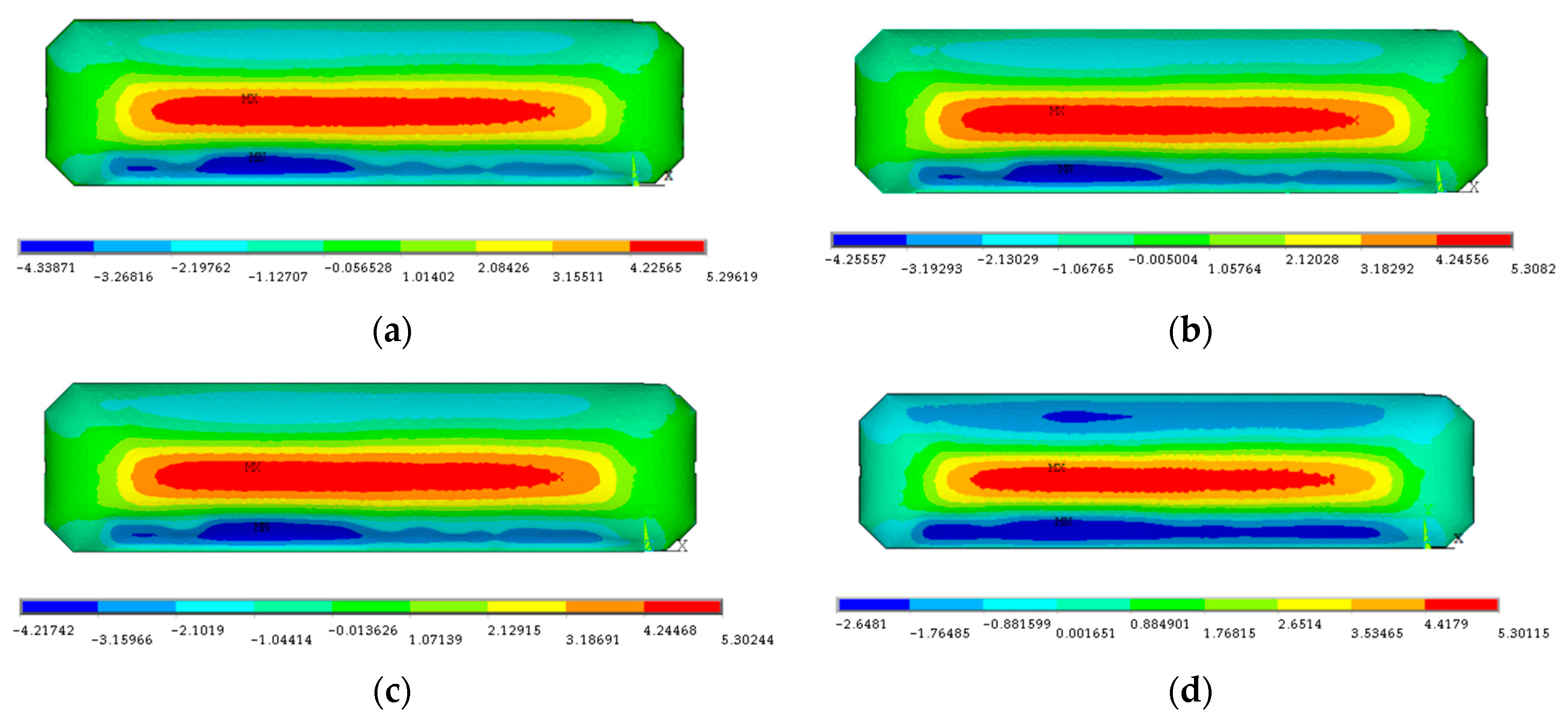

4.2.1. Membrane Surface

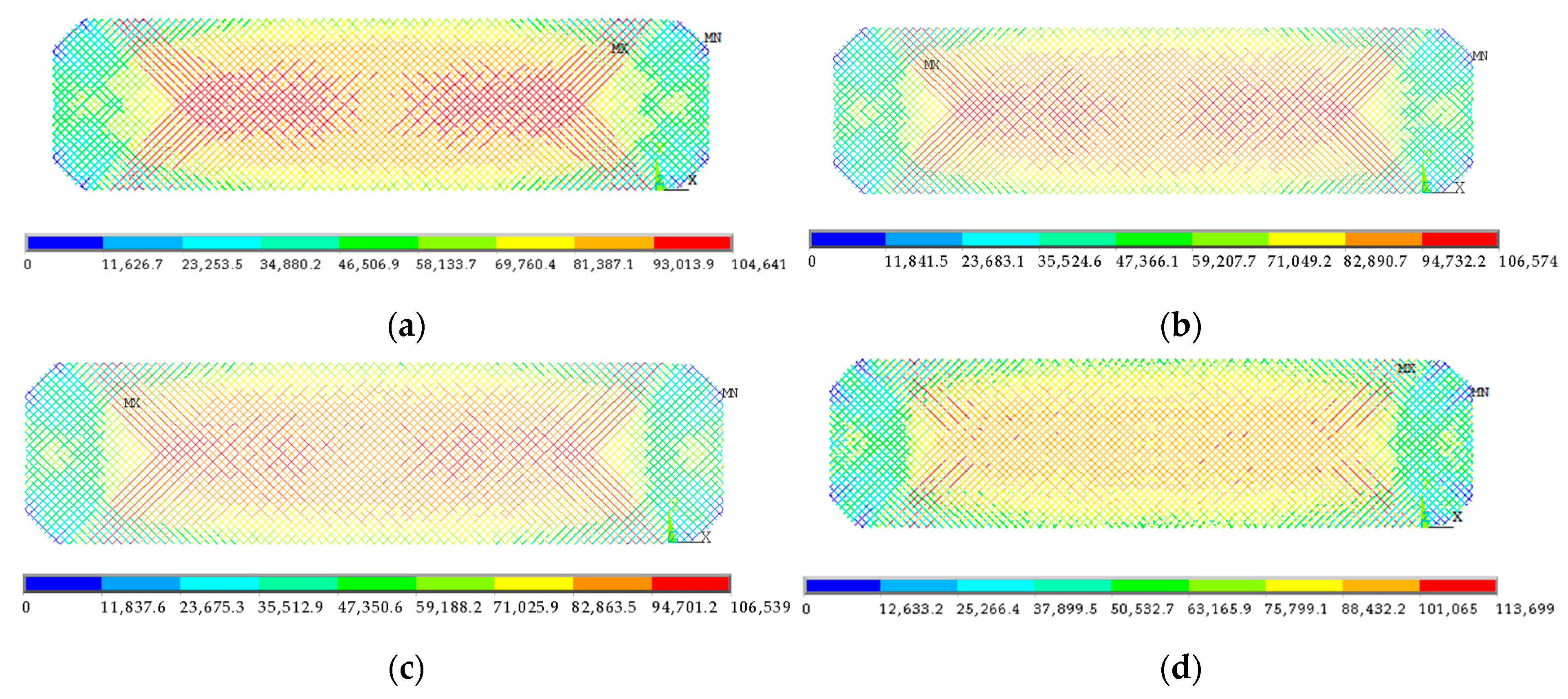

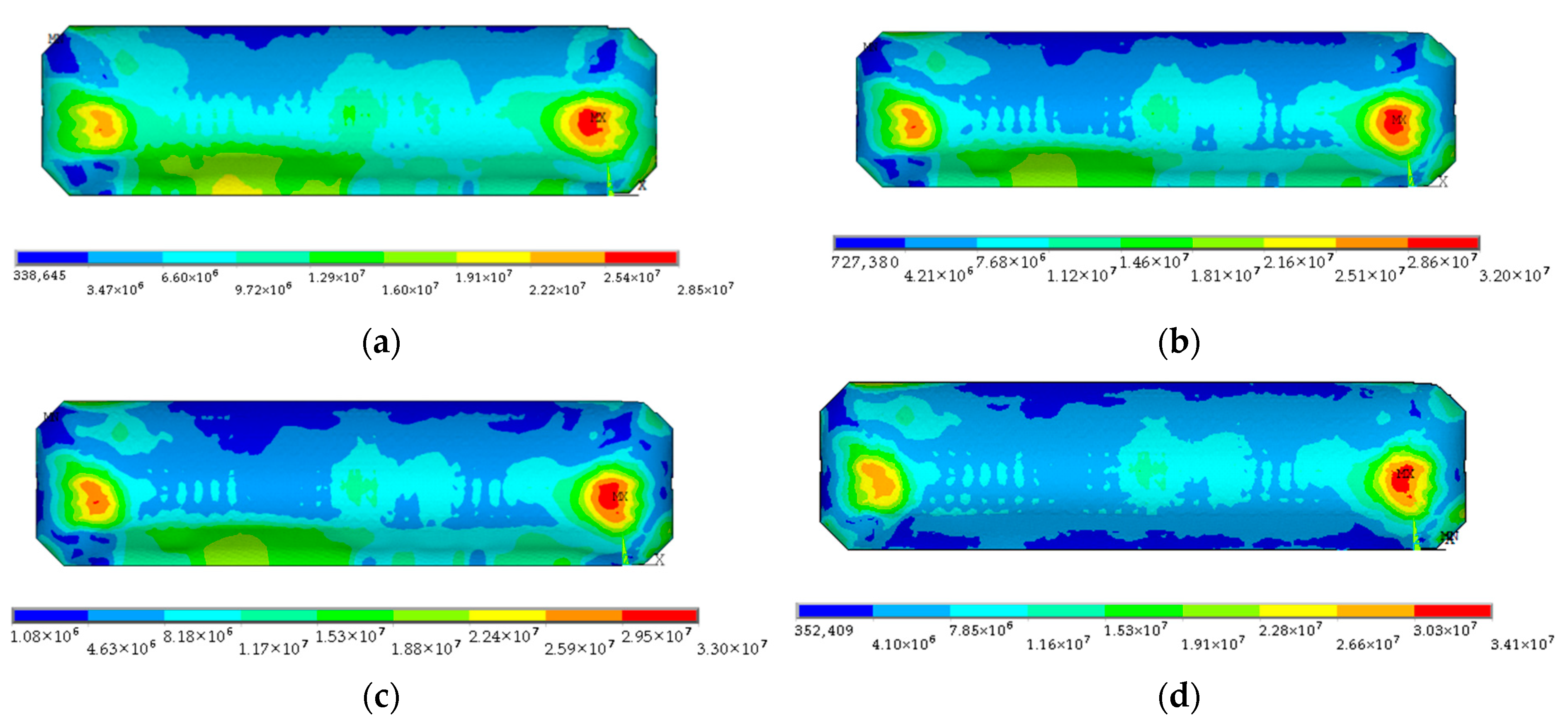

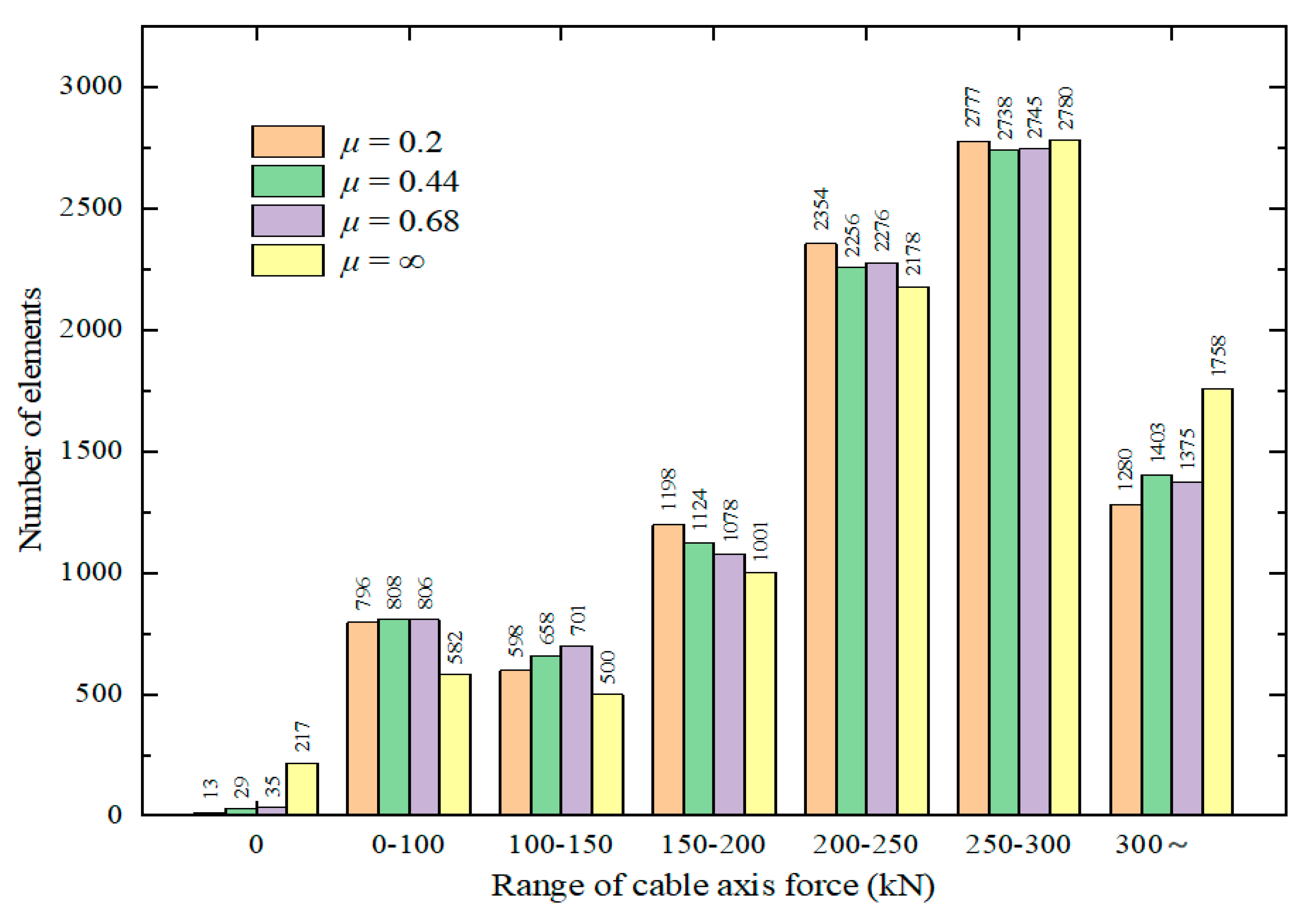

4.2.2. Cable Net

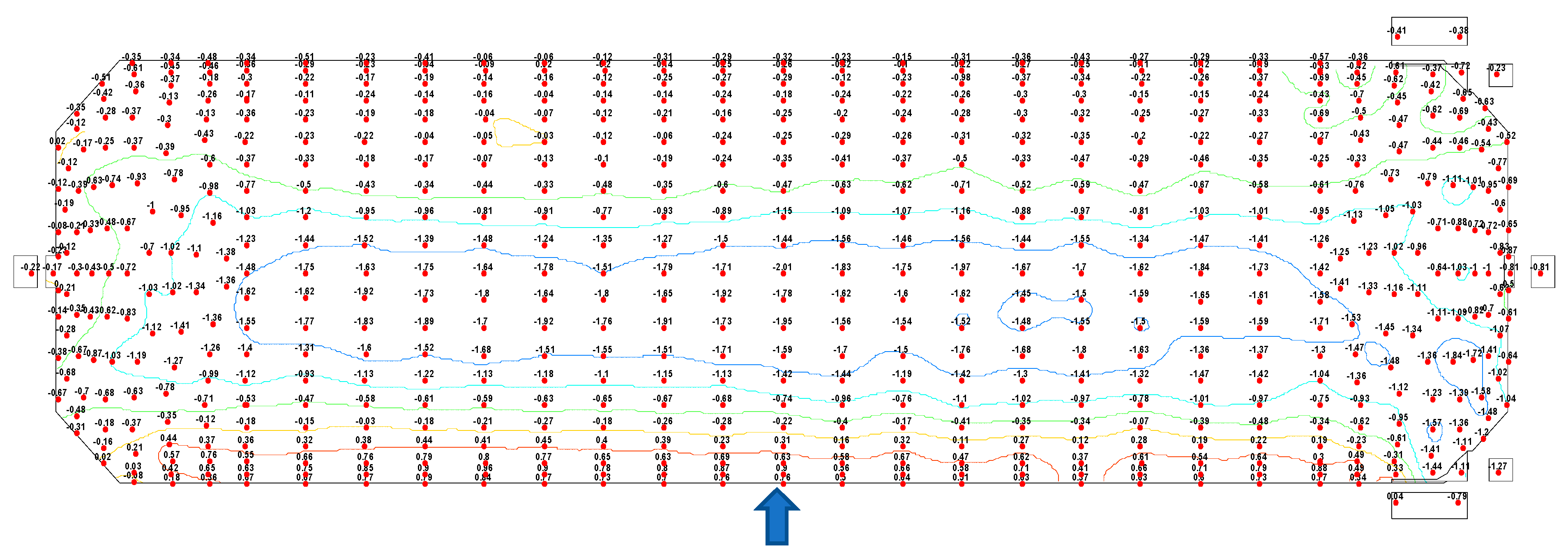

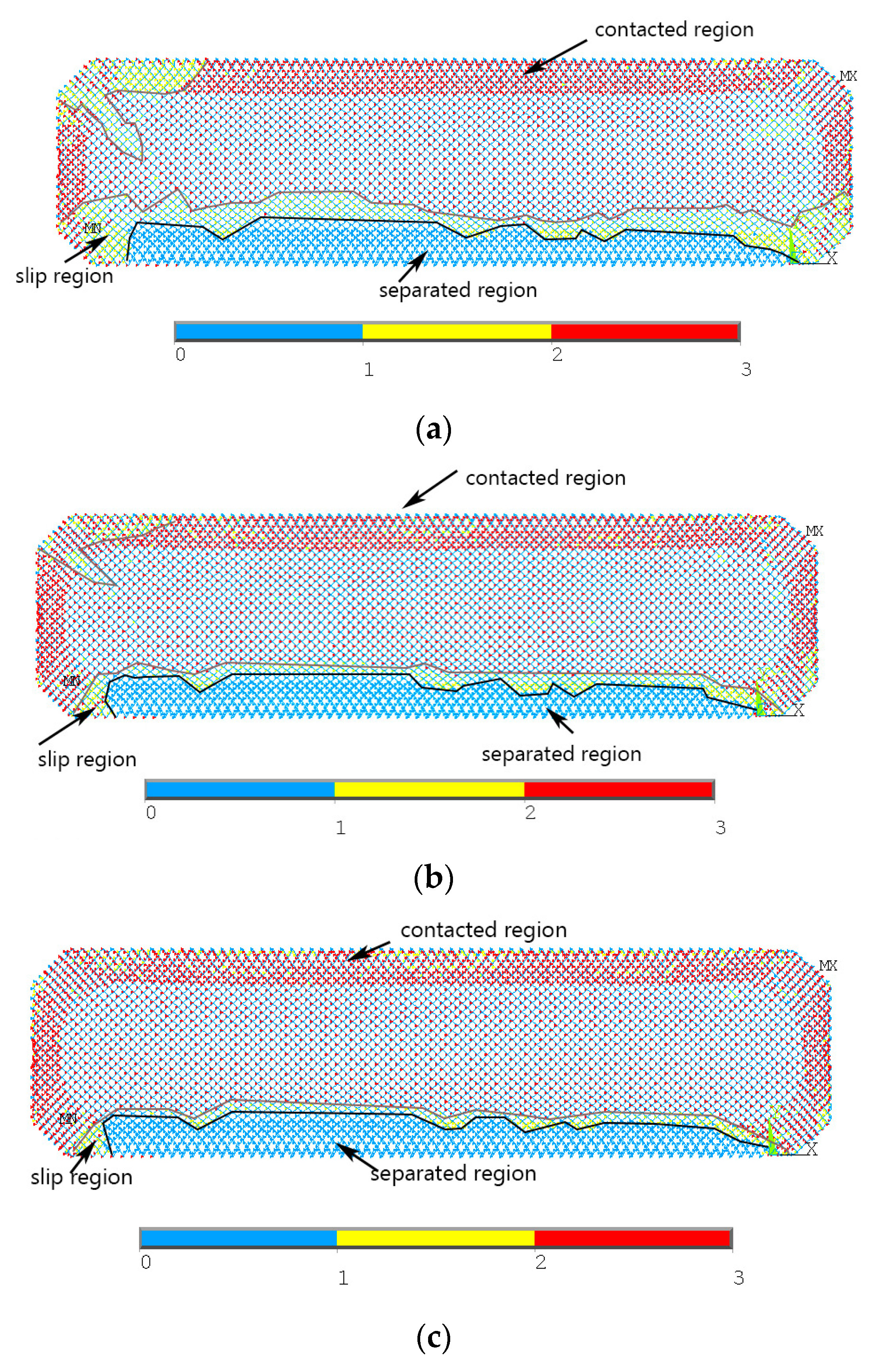

4.2.3. Separated Region, Slip Region, and Contacted Region between Cables and Membranes

5. Conclusions

- The test method adopted in this paper can effectively measure the friction coefficient between the cable and the membrane. The static friction coefficient between the cable and the membrane observed in this study ranges from 0.27 to 0.73, while the dynamic friction coefficient ranges from 0.24 to 0.71. Static friction coefficients are greater than dynamic friction coefficients.

- The contact relationship between the membrane and the cable net is established by utilizing contact pairs and adopting the ANSYS software; the calculation results indicate that this contact model can accurately simulate the sliding and separation between the membrane and the cable net of air-supported membrane structures with an oblique cable net.

- The conventional binding model is incapable of accurately simulating the actual connection state between the cable net and the membrane. For an air-supported membrane structure with an oblique cable net, when employing the binding model, the axial force of the restrained cable elements is overestimated by approximately 26%. Furthermore, the displacement and von Mises stress on the membrane’s windward region are underestimated by approximately 26.9% and 19.6%, respectively, when the binding model is considered.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Luo, J.; Jiang, B.; He, Y. Optimization analysis of cable membrane contact under wind-induced vibration response of air-supported membrane structure. Shanxi Archit. 2022, 48, 5. [Google Scholar]

- Zhao, Y. Analysis of Air-Supported Membrane Structure Based on Cable Membrane Contact Cooperative Work. Master’s Thesis, Beijing University of Technology, Beijing, China, 2021. [Google Scholar]

- Wood, J.; Breuer, M.; De Nayer, G. Experimental studies on the instantaneous fluid–structure interaction of an air-inflated flexible membrane in turbulent flow. J. Fluids Struct. 2018, 80, 405–440. [Google Scholar] [CrossRef]

- Shen, S.; Wu, Y. Research progress on fluid-solid interaction effect of wind induced vibration response of membrane strcture. J. Archit. Civ. Eng. 2006, 23, 1–9. [Google Scholar]

- Yokosuka, Y.; Honma, T. Form-finding of cable-reinforced membrane structures formalized by discrete differential form. J. Struct. Constr. Eng. 2018, 83, 1801–1809. [Google Scholar] [CrossRef]

- Luo, J.; Han, D. 3D wind-induced response analysis of a cable-membrane structure. J. Zhejiang Univ. Sci. A 2009, 10, 337–344. [Google Scholar] [CrossRef]

- Zhou, X.; Han, Z.; Gu, M.; Zhang, A.-A.; Zhang, W.; Fang, W. Research on wind-induced responses of a large-scale membrane structure. Earthq. Eng. Eng. Vib. 2013, 12, 297–305. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, W.; Dong, S. Natural vibration and wind-induced response analysis of the non-fully symmetric Geiger cable dome. J. Vibroeng. 2014, 16, 31–41. [Google Scholar]

- Sun, G.; Wu, M.; He, Y.; Xue, S.; Zhan, P. Influence of a stiffening cable net on performance of large-span air-supported membrane Structure. J. Tianjin Univ. Sci. Technol. 2019, 52, 54–59. [Google Scholar]

- Tsuchiya, M.; Oda, K.; Tachibana, E. Finite element analysis of cable reinforced membrane structures with the use of bendable-element. Shell and Spatial Structures from Models to Realization. In Proceedings of the IASS Annual Symposium 1997, Singapore, 10–13 November 1997. [Google Scholar]

- Lshii, K. Form finding analysis in consideration of cutting patterns of membrane structures. Int. J. Space Struct. 1999, 14, 105–119. [Google Scholar]

- Song, C. Analysis of tensioned membrane structures considering cable sliding. J. Zhejiang Univ. Sci. 2003, 4, 672–682. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhou, H.; Wang, C. Cable-membrane contact analysis of air-supported membrane structures in the initial form. Spat. Struct. 2014, 20, 48–55+74. [Google Scholar]

- Wang, C.; Zhou, H.; Li, X. Cable-membrane contact analysis of air-supported membrane structure under wind loads. Spec. Struct. 2014, 31, 38–43. [Google Scholar]

- Wang, Z. Deformation Control and Load Analysis of Cable-Membrane Inflatable Tube. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Liu, C.; Tian, Q.; Yan, D.; Hu, H. Dynamic analysis of membrane systems undergoing overall motions, large deformations and wrinkles via thin shell elements of ANCF. Comput. Methods Appl. Mech. Eng. 2013, 258, 81–95. [Google Scholar] [CrossRef]

- Sautter, K.; Hofmann, H.; Wendeler, C.; Angel, M. Finite element models to simulate lightweight Rockfall protection structures. In Proceedings of the Structural Membranes 2021—10th International Conference on Textile Composites and Inflatable Structures, Online, 13–15 September 2021. [Google Scholar]

- Zhao, Y.; He, Y. Influence of cable and membrane contact on wind-induced response of air-supported membrane structures. J. Build. Struct. 2021, 43, 31–40. [Google Scholar]

- He, Y.; Zhu, M.; Zhao, Y.; Li, Y. Influence of different cable-membrane connection models on wind-induced responses of an air supported membrane structure with orthogonal cable net. Thin Walled Struct. 2022, 180, 109840. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Zhang, Y.; Xiang, Y. Experimental study on friction coefficients between membranes and cables. Build. Struct. 2010, 40, 107–110. [Google Scholar]

- GB/T 10006-2021; Plastics—Film and Sheeting—Determination of the Coefficients of Friction. State Administration for Market Regulation, Standardization Administration of the R.P.C.: Beijing, China, 2021.

- Wang, J. Research on Contact and Friction in Space Structure. Ph.D. Thesis, Tongji University, Shanghai, China, 2003. [Google Scholar]

- Zhou, Z.; Xu, G.; Huang, G. Analysis of contact problems in cable supported structures. In Proceedings of the 9th National Conference on Spatial Structures OCT, Hangzhou, China, 13 September 2000. [Google Scholar]

- Quan, Y. Engineering Tribology; Zhejiang University Press: Zhejiang, China, 1994. [Google Scholar]

- Wen, S. Principles of Tribology; Tsinghua University Press: Beijing, China, 1990. [Google Scholar]

- Wang, X.; Li, Y.; Xu, H. ANSYS Structural Analysis Unit and Its Application; People’s Communications Press: Beijing, China, 2011. [Google Scholar]

- Wang, X. Structural Dynamicanalysis and Application with ANSYS.; People’s Communications Press: Beijing, China, 2014. [Google Scholar]

- GB 50009; Load Code for the Design of Building Structures. China Association for Engineering Construction Standardization: Beijing, China; China Architecture & Building Press: Beijing, China, 2012.

- CECS 158; Technical Specification for Membrane Structures—2015. Association for Spatial Structures, China Steel Construction Society: Beijing, China; China Planning Press: Beijing, China, 2016.

| Membrane Materials | Static Friction Coefficient | Dynamic Friction Coefficient |

|---|---|---|

| America Seaman BRITE membrane material Tedlar® PVF | 0.27 | 0.24 |

| Duraskin PVDF6915 | 0.36 | 0.28 |

| Kebao PVDF | 0.48 | 0.36 |

| Huifeng 250PVDF | 0.60 | 0.44 |

| Huifeng 450PVDF | 0.53 | 0.44 |

| Xingyida PVDF | 0.53 | 0.44 |

| Hongtai PVDF | 0.73 | 0.65 |

| Tianjinlong PVDF | 0.73 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, G.; He, Y.; Zhao, Y.; Zhang, L. Influence of Friction Coefficient between Cable and Membrane on Wind-Induced Response of Air-Supported Membrane Structures with Oblique Cable Net. Buildings 2023, 13, 649. https://doi.org/10.3390/buildings13030649

Lai G, He Y, Zhao Y, Zhang L. Influence of Friction Coefficient between Cable and Membrane on Wind-Induced Response of Air-Supported Membrane Structures with Oblique Cable Net. Buildings. 2023; 13(3):649. https://doi.org/10.3390/buildings13030649

Chicago/Turabian StyleLai, Guangxin, Yanli He, Yanguo Zhao, and Limei Zhang. 2023. "Influence of Friction Coefficient between Cable and Membrane on Wind-Induced Response of Air-Supported Membrane Structures with Oblique Cable Net" Buildings 13, no. 3: 649. https://doi.org/10.3390/buildings13030649

APA StyleLai, G., He, Y., Zhao, Y., & Zhang, L. (2023). Influence of Friction Coefficient between Cable and Membrane on Wind-Induced Response of Air-Supported Membrane Structures with Oblique Cable Net. Buildings, 13(3), 649. https://doi.org/10.3390/buildings13030649