Abstract

Ultra-high-performance concrete (UHPC) is a kind of structural material with ultra-high strength, extremely low porosity, and excellent durability, which has extremely broad application prospects. In order to promote the application of UHPC constrained by carbon fiber-reinforced polymer (CFRP) sheets as strengthening material in practical engineering, a total of nine specimens were designed, and two kinds of UHPC strengthening layer thickness (35 mm and 45 mm, respectively) were designed. By changing the constraint form of the UHPC strengthening layer (longitudinal reinforcements and ordinary stirrups, longitudinal reinforcements and spiral stirrups, and CFRP sheets, respectively), the axial compression performance of the strengthened column was explored. The study shows that compared with the without strengthened column, the uplift of carrying capacity of the strengthened test column is 277–561%. The reinforcement form of the strengthening layer has little influence on the lifting capacity. Among the three different strengthening methods, the wrapped CFRP has the best improvement effect on carrying capacity and ductility, followed by longitudinal reinforcements and spiral stirrups in the strengthening layer. With the increase of CFRP layers from two to five layers, the maximum carrying capacity increases by 21.3%. The carrying capacity of three different types of UHPC-strengthened columns is theoretically calculated, and the accuracy of the theoretical calculation method is verified by comparing the test value with the theoretical value, which provides a theoretical basis for the application of UHPC-strengthened columns in the future.

1. Introduction

Ultra-high-performance concrete (UHPC) is a fiber-reinforced cement-based composite with ultra-high impermeability and mechanical properties, which is based on micro-scale optimization of fine aggregate and ultra-fine aggregate (silica fume and sand), mixed with high-efficiency superplasticizer to reduce the water-cement ratio, and mixed with high-strength steel fiber [1]. As a new type of cement-based structural engineering material, it has ultra-high strength and toughness and can be used to construct new lightweight and high-strength structures. Good durability makes the UHPC structure have a longer life and lower maintenance costs [2].

At present, research on reinforced concrete members strengthened by UHPC has been carried out [3], Tanarslan et al. [4] enhanced the interfacial bonding ability between prefabricated UHPC thin layer and reinforced concrete beams by implanted bars, epoxy resin interfacial agent, and compression. Al-Osta et al. [5] carried out research on UHPC strengthening of reinforced concrete beams, considering the influence of different interface treatment methods and different strengthening positions on the beam strengthening effect. Using UHPC material as the strengthening layer of the ordinary concrete short column can improve the ultimate compressive capacity and ductility of the short column. The test results of Alsomiri and Xie et al. [6,7] show that increasing the thickness of the UHPC strengthening layer can significantly improve the compressive capacity of the cylinder, which provides a theoretical basis and reference for practical strengthening engineering.

UHPC usually exhibits weak ductility under axial compression, which can be improved by fiber-reinforced polymer confinement. Zeng [8,9,10] proposed using fiber-reinforced polymer (FRP) grids as the reinforcement material of UHPC and embedding FRP grids in UHPC to improve its strength and ductility. The experimental results show that the confinement of FRP grids improves the strength and ductility of UHPC. Carbon fiber-reinforced polymer (CFRP) sheets have the advantages of high strength and durability and are lighter than other strengthening materials. Many scholars have studied the mechanical properties, thermal properties, and alkaline resistance of CFRP materials [11,12]. Guo et al. [13] performed accelerated aging experiments on carbon fiber-/glass fiber-reinforced hybrid rods. The water absorption and diffusion behavior of the fiber matrix, the change of interfacial strength, and dynamic thermodynamic properties were investigated. The long-term life evaluation shows that the interface shear strength of the hybrid rod shell has a fast degradation rate and reaches a stable level of 62%. The advantages of CFRP are also reflected in the seismic restoration and reinforcement of existing reinforced concrete structures [14]. Many scholars have studied the compressive properties of FRP-constrained UHPC [15,16,17]; the tests show that the ultimate strength and strain of UHPC columns are significantly improved by increasing the thickness of the FRP constraint layer, showing better ductility. Huang [18] conducted experiments on FRP-constrained UHPC columns under cyclic axial compression and proposed its stress-strain model. Abadel et al. [19] explored the influence of CFRP sheets strengthening on the compressive strength of UHPC at 400 °C. After CFRP sheets material strengthening, the compressive strength has been improved. The model of FRP-constrained concrete column to predict the axial stress-strain and ultimate strength of FRP-constrained UHPC column is not accurate [20,21,22,23,24] due to the limited test results, and a large number of test studies are needed. The study on the strengthening of UHPC with FRP sheets is of great significance to the engineering application of UHPC materials.

Some scholars have studied the axial compression performance of UHPC columns by combining FRP sheets and stirrups. Chang et al. [25,26] used high-strength spiral stirrups constrained UHPC and stirrups and CFRP sheets constrained UHPC to carry out axial compression tests. With the increase of stirrups volume ratio, the ductility of UHPC was improved, and the prediction model of transverse strain and axial strain curves of UHPC constrained by CFRP sheets and stirrups was established. Lu [27] conducted the axial compression test on reinforced concrete columns strengthened with fiber high-performance concrete by using the enlarged section method. The effects of the thickness of the strengthening layer, the stirrups in the strengthening layer, and the stirrup spacing on the axial compression performance of the FRP-strengthened columns were evaluated. Based on the confined concrete theory, a theoretical calculation model was established, and the axial carrying capacity of the column was discussed. The results showed that the carrying capacity and ductility of the column can be improved by adding stirrups in the strengthening layer.

In conclusion, UHPC, as a new type of composite material, has been widely recognized for its superior mechanical properties in the practical application of civil engineering. The performance and durability of reinforced concrete members strengthened UHPC are better than those reinforced concrete members, so it has better engineering application value to strengthen concrete members by UHPC. Due to the limitation of the test equipment and the test site, to avoid the stress concentration phenomenon of the square column, the shortened cylindrical column is used as the research object. Whether the relevant conclusions can be applied to long columns, remain to be studied. In order to further explore the compressive performance of the UHPC strengthening layer, this paper uses CFRP sheets to wrap the UHPC strengthening layer, adds longitudinal reinforcements and ordinary stirrups to the UHPC strengthening layer, and adds longitudinal reinforcements and spiral stirrups to the UHPC strengthening layer. In this paper, a total of nine specimens were designed to study the effects of the thickness of the UHPC strengthening layer, strengthening layer reinforcement form, and confinement form on the axial compression performance of the strengthening column, providing a theoretical basis for the application of UHPC as strengthening material in engineering.

2. Test Program

2.1. Design of Test

Nine reinforced concrete columns were made; the height of the specimen column was 300 mm, the diameter was 150 mm, the concrete strength grade was C35, the longitudinal reinforcement was configured as 6 12 mm, the stirrup was configured as Φ8@60 mm, and the thickness of the concrete cover was 15 mm. The parameters of the specimens are shown in Table 1.

12 mm, the stirrup was configured as Φ8@60 mm, and the thickness of the concrete cover was 15 mm. The parameters of the specimens are shown in Table 1.

12 mm, the stirrup was configured as Φ8@60 mm, and the thickness of the concrete cover was 15 mm. The parameters of the specimens are shown in Table 1.

12 mm, the stirrup was configured as Φ8@60 mm, and the thickness of the concrete cover was 15 mm. The parameters of the specimens are shown in Table 1.

Table 1.

Test column parameters.

For each cylinder, 6 12 steel bars 270 mm in length were first cut and bound for stirrups. After the steel cage was made, the steel cage was put into the prefabricated mold with an inner diameter of 150 mm and a height of 300 mm. Then concrete was poured, and six C35 concrete cube test blocks (150 mm × 150 mm × 150 mm) were reserved, which were naturally cured to maturity with the specimens. After the column was cured, according to the code for the design of strengthening concrete structure, the column was chipped with a chipping machine, and the surface was cleaned. The column, after chipping, was connected with the longitudinal reinforcement of the strengthening layer through the anchor bar, and then it was put into the prefabricated strengthening layer mold. After removing the mold, it can be seen that the interface between the UHPC strengthening layer and the new and old concrete of the strengthening column was well combined, and the appearance of the UHPC strengthening layer was smooth and dense. The UHPC surface was polished after the strengthening column specimens were cured to the age, the impregnating glue was evenly applied to the CFRP sheets by wet adhesive method, and the CFRP sheets were seamlessly wound around the surface of the strengthening column.

12 steel bars 270 mm in length were first cut and bound for stirrups. After the steel cage was made, the steel cage was put into the prefabricated mold with an inner diameter of 150 mm and a height of 300 mm. Then concrete was poured, and six C35 concrete cube test blocks (150 mm × 150 mm × 150 mm) were reserved, which were naturally cured to maturity with the specimens. After the column was cured, according to the code for the design of strengthening concrete structure, the column was chipped with a chipping machine, and the surface was cleaned. The column, after chipping, was connected with the longitudinal reinforcement of the strengthening layer through the anchor bar, and then it was put into the prefabricated strengthening layer mold. After removing the mold, it can be seen that the interface between the UHPC strengthening layer and the new and old concrete of the strengthening column was well combined, and the appearance of the UHPC strengthening layer was smooth and dense. The UHPC surface was polished after the strengthening column specimens were cured to the age, the impregnating glue was evenly applied to the CFRP sheets by wet adhesive method, and the CFRP sheets were seamlessly wound around the surface of the strengthening column.

12 steel bars 270 mm in length were first cut and bound for stirrups. After the steel cage was made, the steel cage was put into the prefabricated mold with an inner diameter of 150 mm and a height of 300 mm. Then concrete was poured, and six C35 concrete cube test blocks (150 mm × 150 mm × 150 mm) were reserved, which were naturally cured to maturity with the specimens. After the column was cured, according to the code for the design of strengthening concrete structure, the column was chipped with a chipping machine, and the surface was cleaned. The column, after chipping, was connected with the longitudinal reinforcement of the strengthening layer through the anchor bar, and then it was put into the prefabricated strengthening layer mold. After removing the mold, it can be seen that the interface between the UHPC strengthening layer and the new and old concrete of the strengthening column was well combined, and the appearance of the UHPC strengthening layer was smooth and dense. The UHPC surface was polished after the strengthening column specimens were cured to the age, the impregnating glue was evenly applied to the CFRP sheets by wet adhesive method, and the CFRP sheets were seamlessly wound around the surface of the strengthening column.

12 steel bars 270 mm in length were first cut and bound for stirrups. After the steel cage was made, the steel cage was put into the prefabricated mold with an inner diameter of 150 mm and a height of 300 mm. Then concrete was poured, and six C35 concrete cube test blocks (150 mm × 150 mm × 150 mm) were reserved, which were naturally cured to maturity with the specimens. After the column was cured, according to the code for the design of strengthening concrete structure, the column was chipped with a chipping machine, and the surface was cleaned. The column, after chipping, was connected with the longitudinal reinforcement of the strengthening layer through the anchor bar, and then it was put into the prefabricated strengthening layer mold. After removing the mold, it can be seen that the interface between the UHPC strengthening layer and the new and old concrete of the strengthening column was well combined, and the appearance of the UHPC strengthening layer was smooth and dense. The UHPC surface was polished after the strengthening column specimens were cured to the age, the impregnating glue was evenly applied to the CFRP sheets by wet adhesive method, and the CFRP sheets were seamlessly wound around the surface of the strengthening column.2.2. Details of Material Mechanical Properties

The concrete design strength grade was C35, and the mix design and preparation are shown in Table 2. Six standard cube test blocks (150 mm × 150 mm × 150 mm) were reserved during concrete pouring, and their compressive strength was measured after 28d of laboratory curing together with the specimens. Their mechanical properties are shown in Table 3. Table 4 shows the UHPC mix design and preparation, and Table 5 shows its mechanical properties. Table 6 shows the mechanical properties of steel bars, HPB300 strength grades stirrup, and HRB400 strength grades longitudinal reinforcement. Table 7 shows the mechanical properties of CFRP sheets. Table 8 shows the mechanical properties of CFRP sheets impregnating glue.

Table 2.

Mixture proportions of concrete (kg/m3).

Table 3.

Mechanical properties of concrete.

Table 4.

Mixture proportions of UHPC (kg/m3).

Table 5.

Mechanical properties of UHPC.

Table 6.

Mechanical properties of steel bars.

Table 7.

CFRP sheet parameters.

Table 8.

Mechanical parameters of adhesive.

2.3. Loading Device and Measuring Point Layout

2.3.1. Test Setup

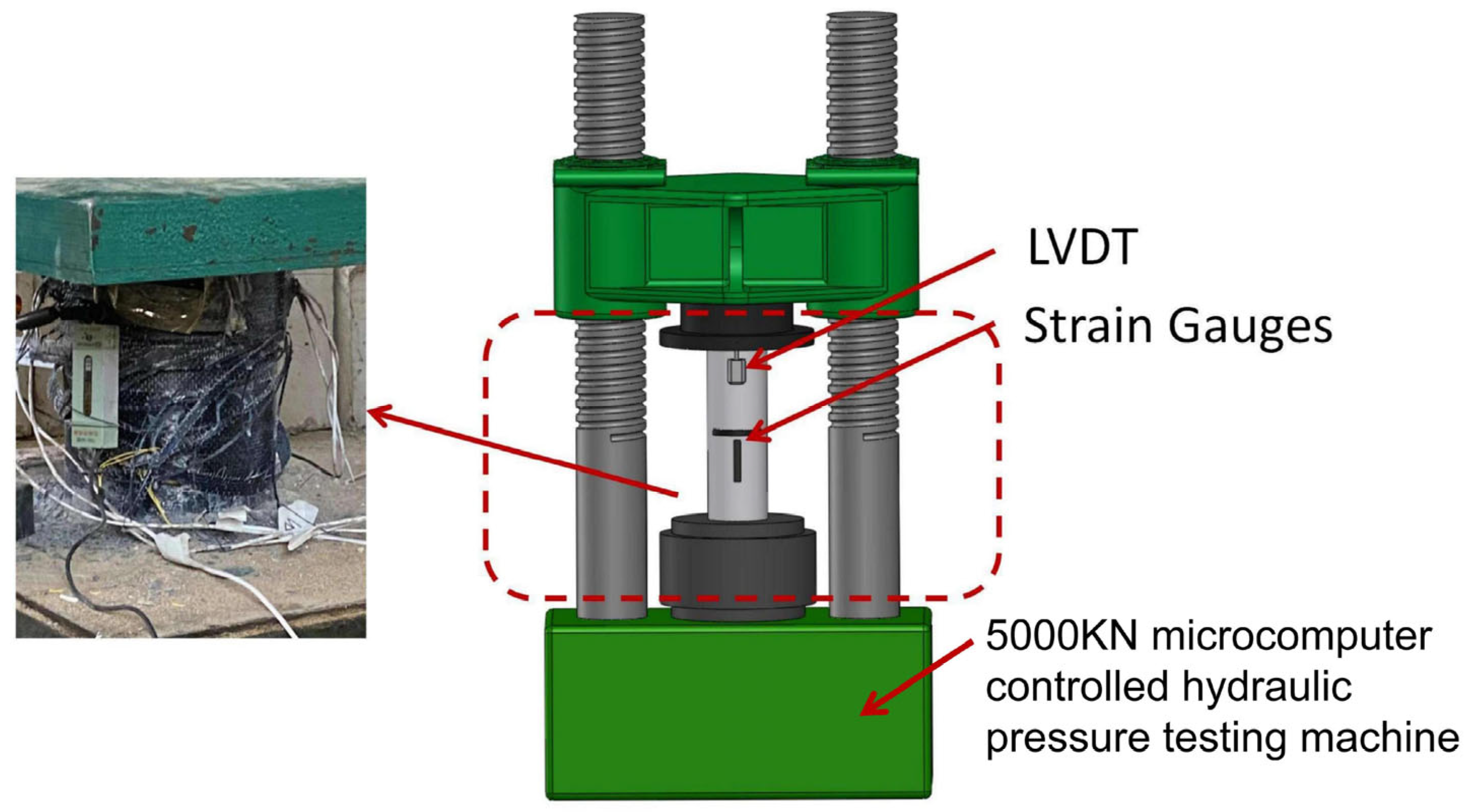

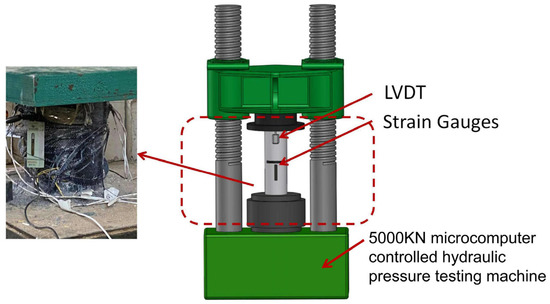

It was loaded monotonically at a rate of 0.3 mm/min. Before loading, the end of the specimen was polished by an angle grinder and made level with fine sand to ensure that the whole section of the specimen was compressed. The specimens were preloaded, and the preloaded load value was 10% of the calculated ultimate carrying capacity. Checked whether the strain box, testing machine, and other equipment were working normally before starting the formal test. Figure 1 shows the test loading device.

Figure 1.

Setup of the test.

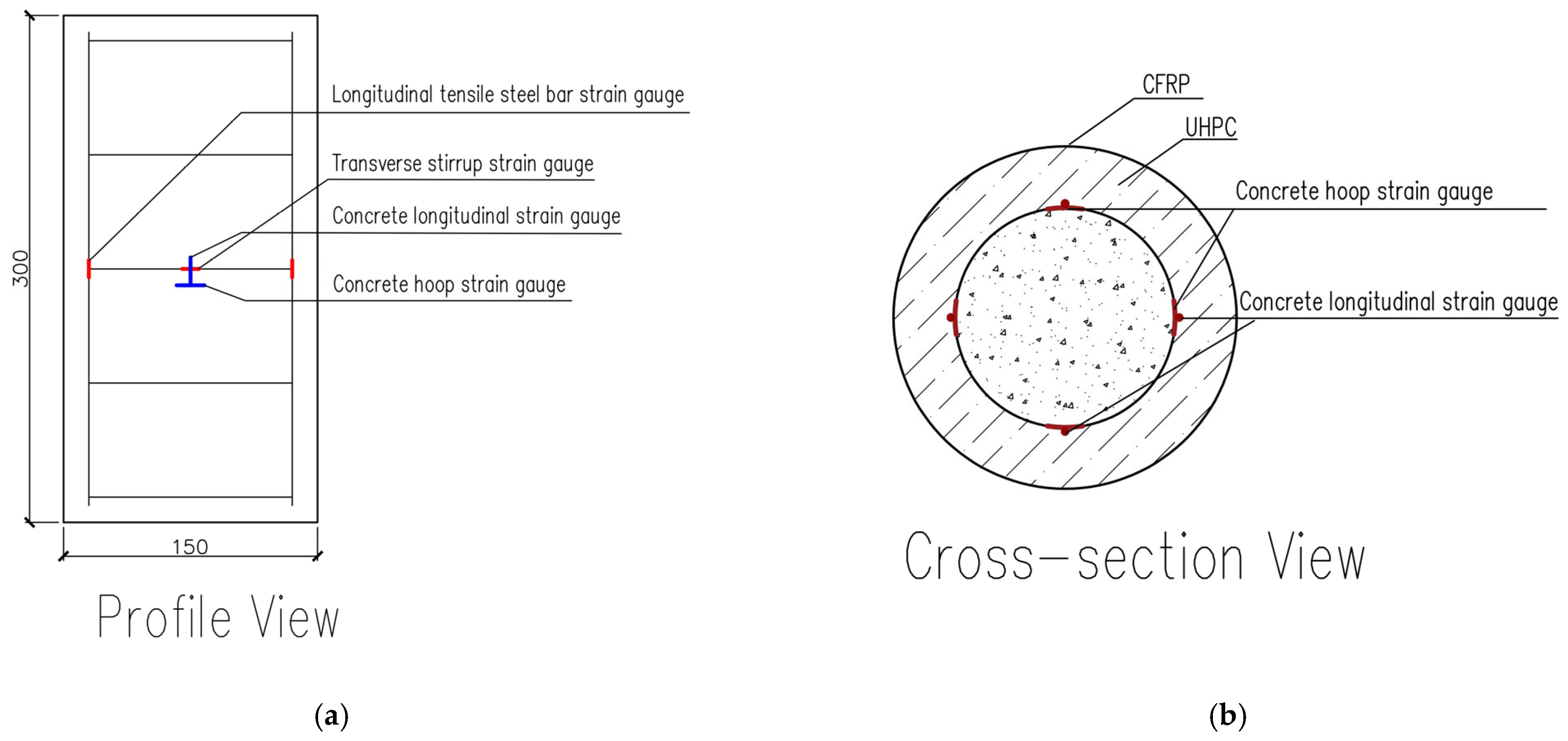

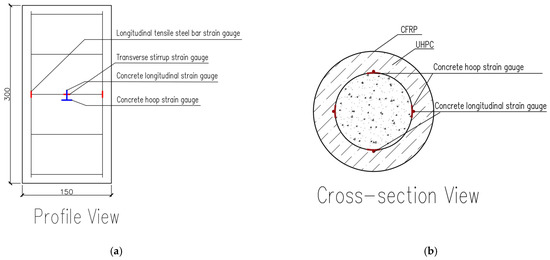

2.3.2. Loading Device and Measuring Point Layout

Longitudinal strain gauges and hoop strain gauges were pasted on two symmetrical sides in the middle of the concrete; longitudinal strain gauges and hoop strain gauges were pasted on two symmetrical sides of the middle part of the strengthening layer of UHPC; three longitudinal reinforcements were spaced apart, and strain gauges were pasted in the middle; two strain gauges were symmetrically pasted on the stirrups. Figure 2 shows the position of strain gauges.

Figure 2.

Location of the strain gauge. (a) Profile view. (b) Cross-section view.

3. Test Result and Analysis

3.1. Test Observations

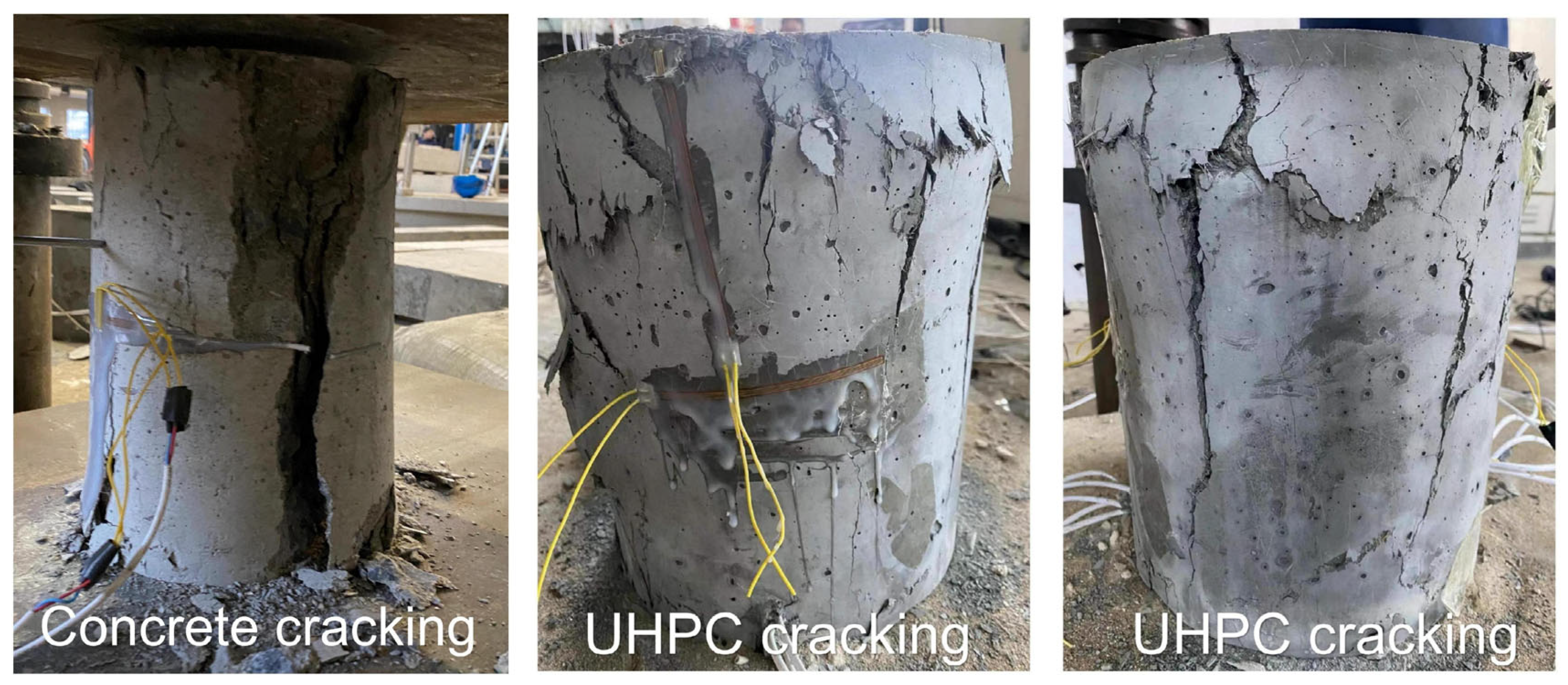

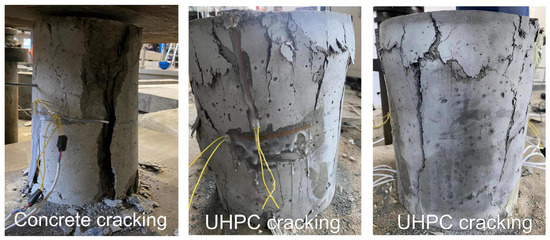

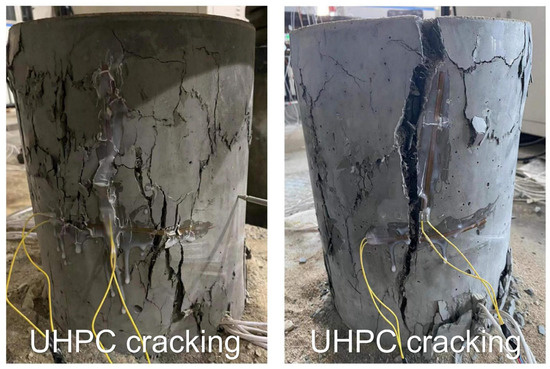

Z1 is the without-strengthening column, and the strain of the whole section was uniformly distributed under the axial load. At the initial stage of loading, the steel bars and concrete were in the elastic stage. In this stage, the compression deformation of the test column increased with the increase of the load, and the load of the steel bars and concrete was proportional to the displacement. When the load continued to increase, the concrete began to appear in small vertical cracks. When approaching the failure load, the cracks gradually extended, and obvious longitudinal penetrating cracks appeared. The concrete fell off, and the longitudinal reinforcements and stirrups were deformed. The failure form is shown in Figure 3.

Figure 3.

Z1, Z2, and Z3 failure forms.

The UHPC-strengthened columns with longitudinal reinforcements and ordinary circular stirrups in the strengthening layers of Z2 and Z3 had the same elastic stage in the initial loading period as Z1, and the load had a linear relationship with the axial deformation. The load continued to increase, and the increased rate of axial deformation exceeded the increased rate of load. When the load was close to the peak, the sound of steel fiber pulling out in UHPC could be heard. When the load reached the peak load, the load did not drop precipitously but showed a slow decline. After the longitudinal crack was connected, it could still bear a large load. Finally, the crack of the UHPC strengthening layer was connected, and the failure form is shown in Figure 3.

Z4–Z5 are UHPC-strengthened columns equipped with longitudinal reinforcements and spiral stirrups in the strengthening layer, and the test phenomenon is similar to that of Z2 and Z3. When the confinement capacity of spiral stirrups completely lost its effect, the load of the test column decreased significantly, and the failure form is shown in Figure 4.

Figure 4.

Z4 and Z5 failure forms.

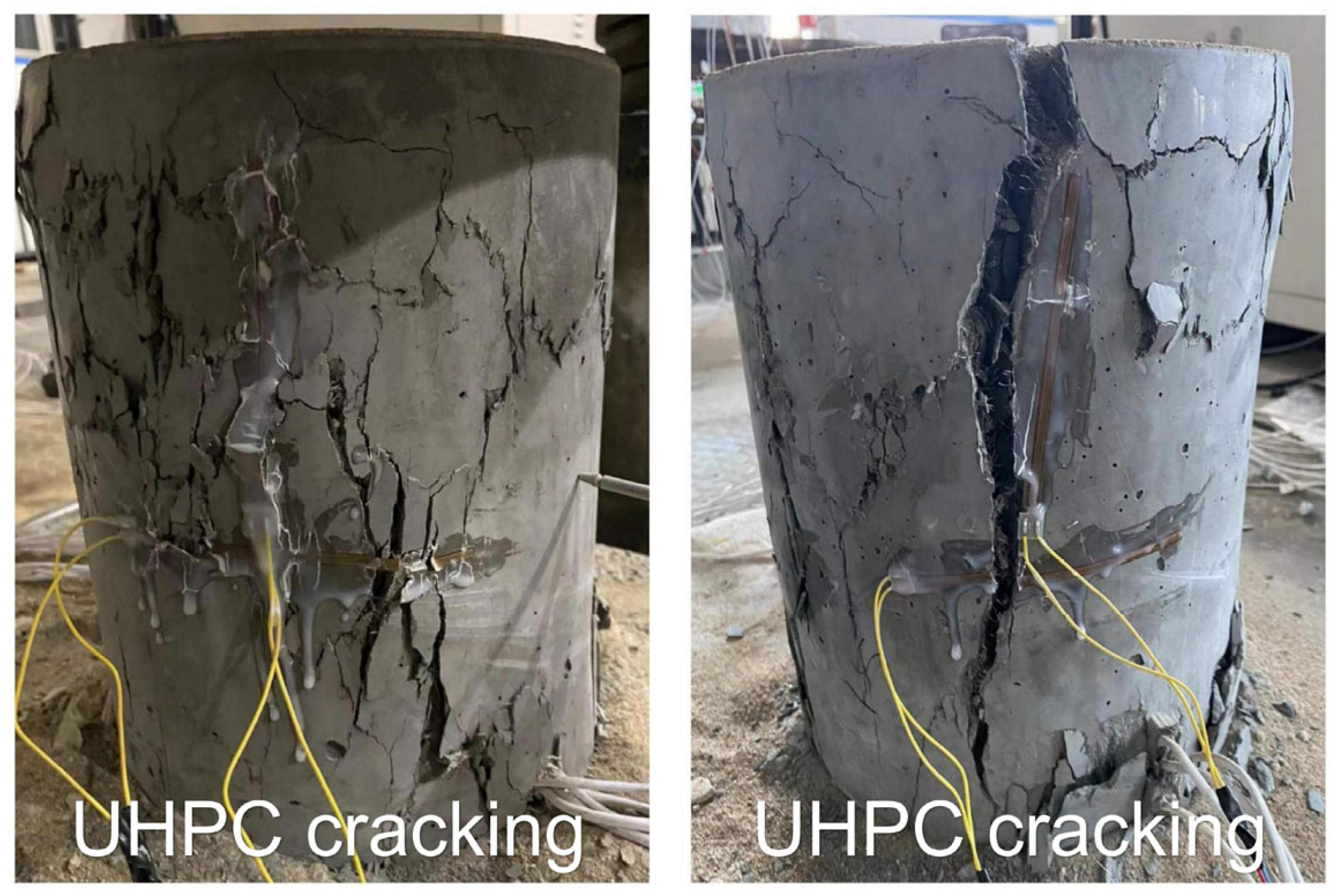

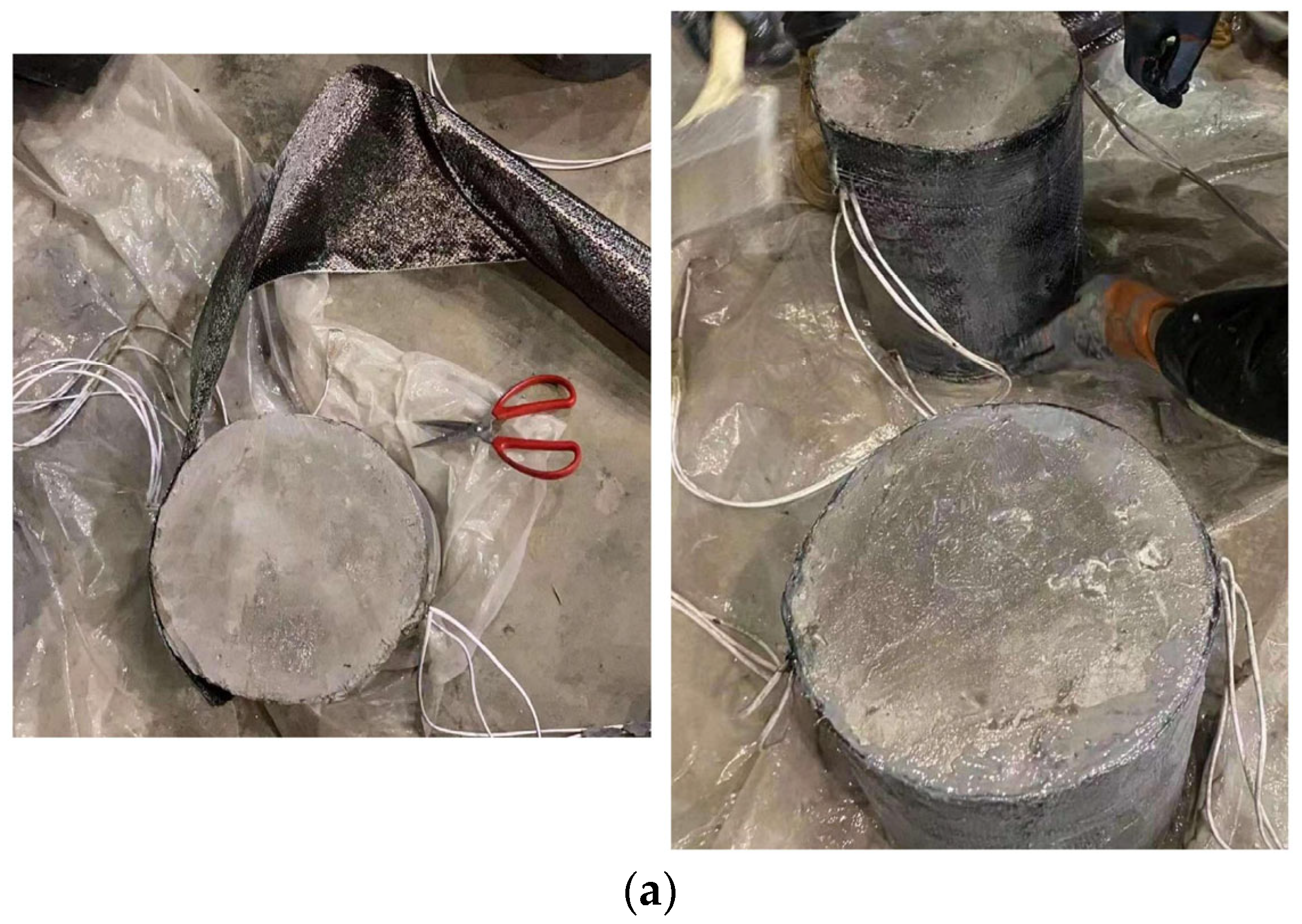

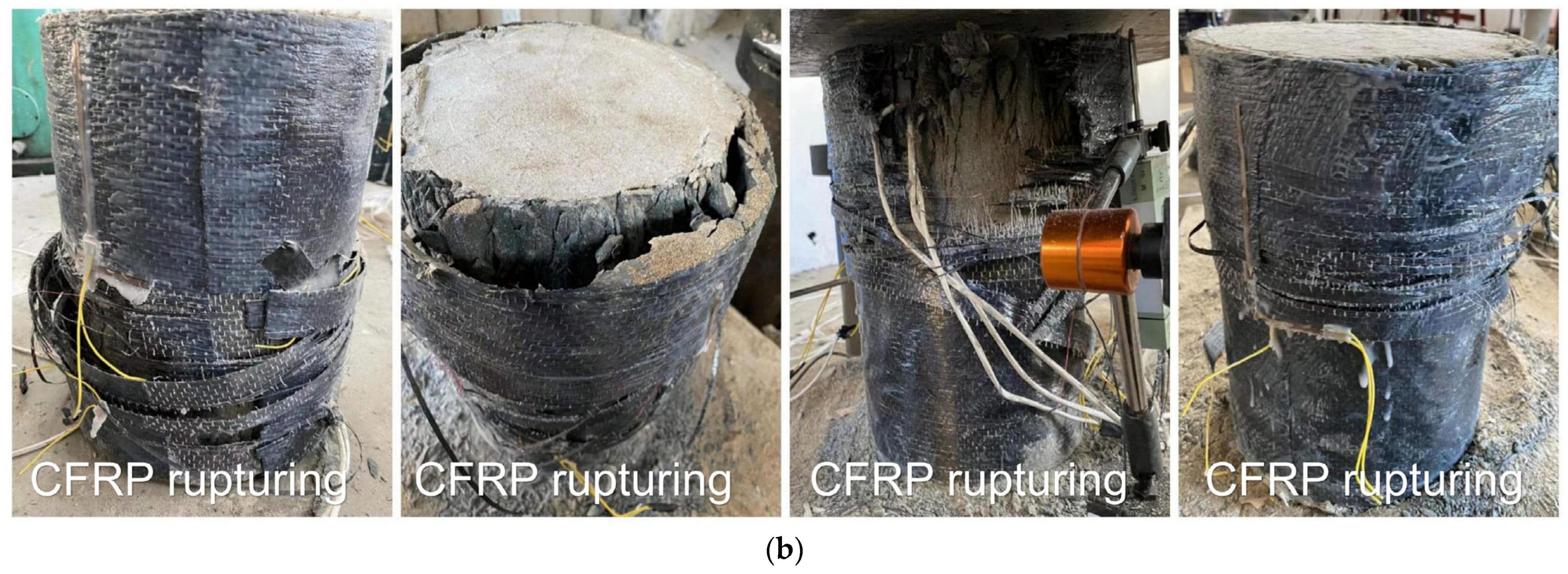

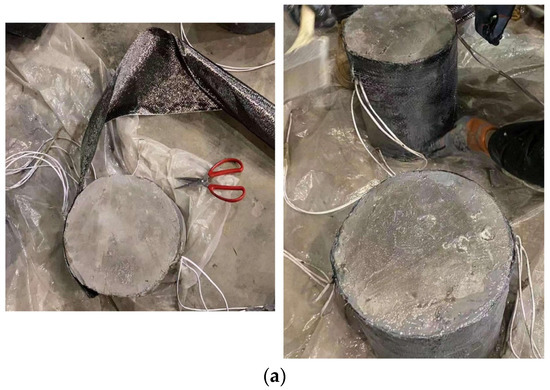

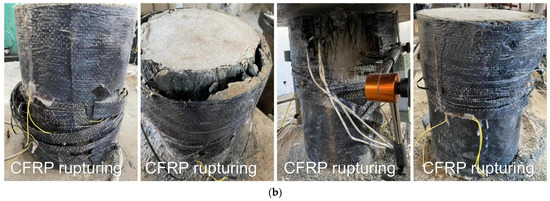

Z6–Z9 are UHPC-strengthened columns with CFRP sheets, which are in the elastic stage in the early stage of the test. With the gradual increase of load, the surface of CFRP sheets did not change, and the sound of concrete cracking was heard, and the sound of steel fiber pulling out was always heard. The crack of the UHPC strengthening layer made a sound, and the slope of the load-displacement curve decreased, which was still linear. The original pictures and failure forms of CFRP-constrained strengthening columns are shown in Figure 5.

Figure 5.

Z6–Z9 original pictures and failure forms. (a) Original pictures. (b) Failure forms.

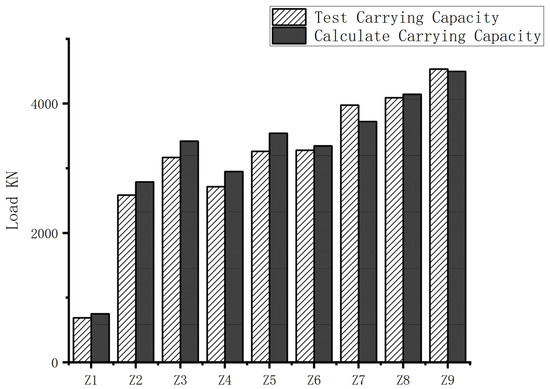

3.2. Ultimate Carrying Capacity

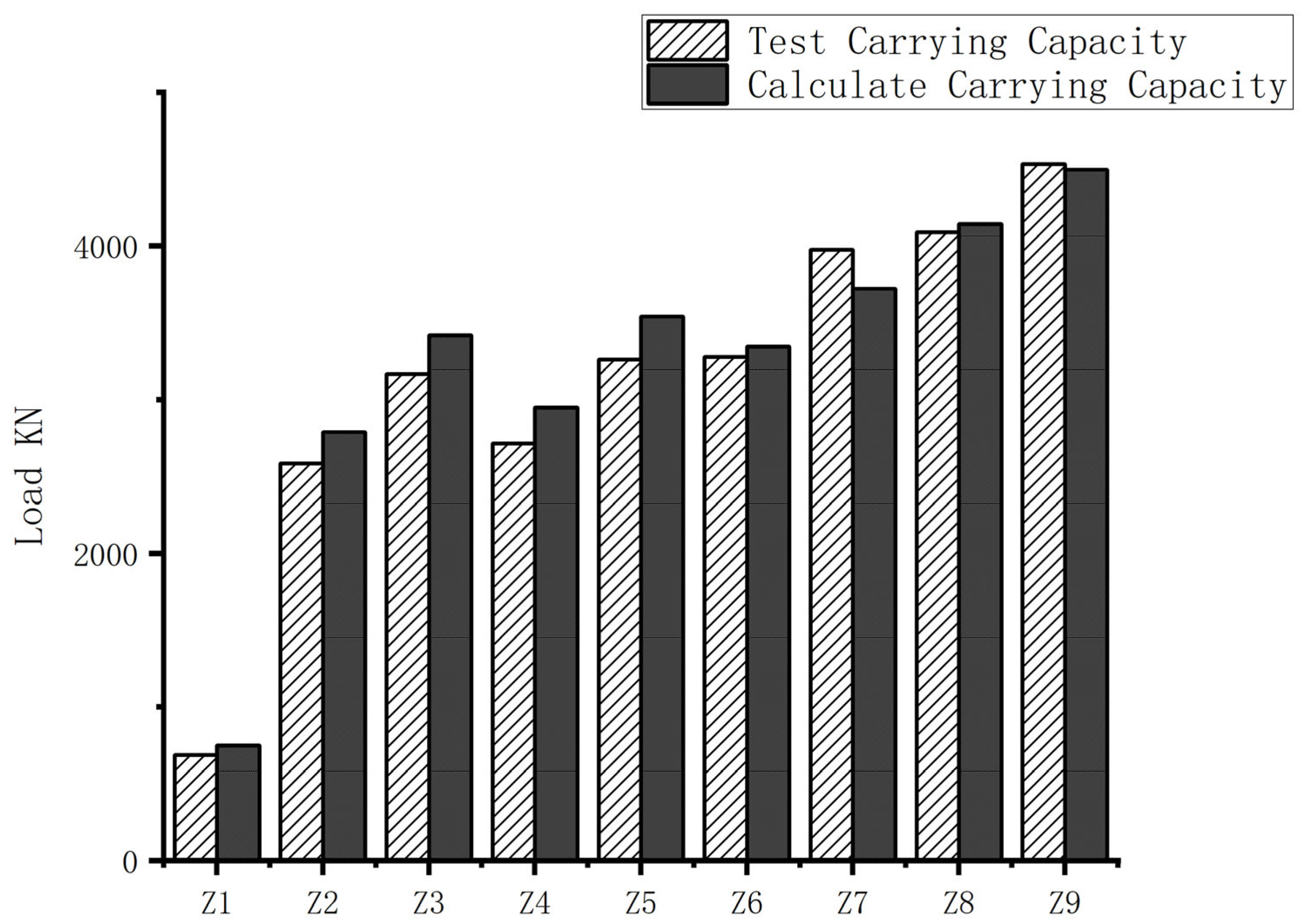

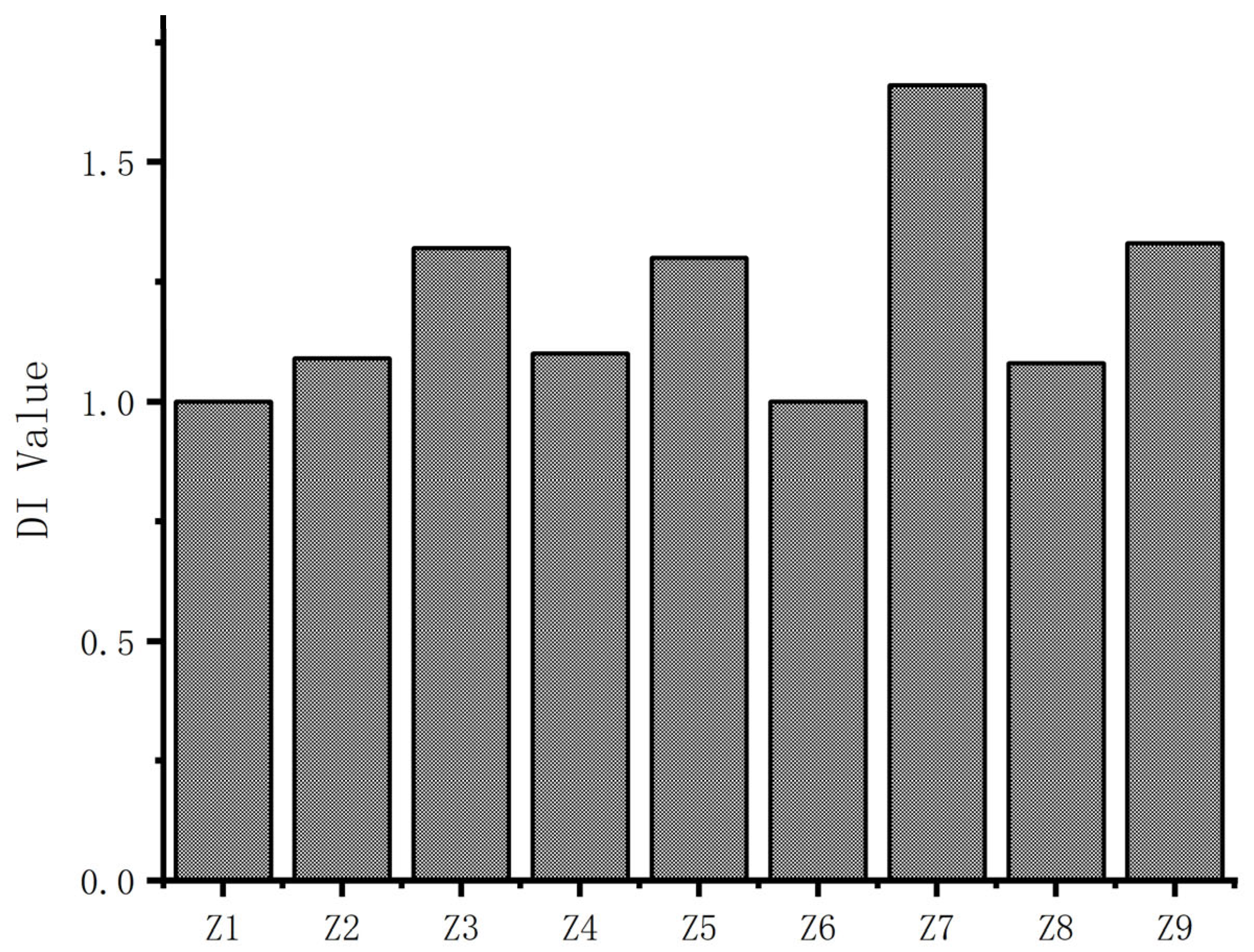

The carrying capacity of the test columns with the three strengthening methods was greatly improved compared with that of the without strengthening column. Table 9 and Figure 6 show the ultimate carrying capacity of each test column. According to the different strengthened methods, the three strengthened columns were compared with the without strengthened columns, and the three different strengthening methods were compared.

Table 9.

Carrying capacity of test columns.

Figure 6.

Ultimate carrying capacity of test columns.

Compared with the without-strengthening column, the carrying capacity of the test column was greatly improved by using UHPC strengthening, and the carrying capacity increased more with the increase of the thickness of the strengthening layer. The strengthening method of Z2 and Z3 is the UHPC column with longitudinal reinforcements and ordinary circular stirrups in the strengthening layer. With the increase of the thickness of the strengthening layer, the lifting range of the carrying capacity of the strengthening column also increased. Compared with Z1, the carrying capacity increased by 277% and 362%, respectively. For UHPC columns in Z4 and Z5 with longitudinal reinforcements and spiral stirrups in the strengthening layer, when the thickness of the strengthening layer increased, the carrying capacity of the strengthened column also increased. Compared with Z1, the carrying capacity of Z4 and Z5 increased by 296% and 375%, respectively.

The longitudinal reinforcements and circular stirrups were used in the strengthening layer, and the carrying capacity of Z3 with a thickness of 45 mm increased by 22.6% compared with that of Z2 with a thickness of 35 mm. The carrying capacity of Z5 with a thickness of 45 mm strengthened by longitudinal reinforcements and spiral stirrups was 20.1% higher than that of Z4 with a thickness of 35 mm strengthening layer. When the strengthening layer is thick, the strengthening efficiency can be improved by changing the reinforcement form of the strengthening layer. Under the condition that the thickness of the strengthening layer was the same and the stirrup spacing of the strengthening layer was the same, when the thickness of the strengthening layer was 35 mm, the carrying capacity of Z4 of the strengthening layer with longitudinal reinforcements and spiral stirrups was 5% higher than Z2 of the strengthening layer with longitudinal reinforcements and circular stirrups. When the thickness of the strengthening layer was 45 mm, the carrying capacity of Z5 with longitudinal reinforcements and spiral stirrups in the strengthening layer was 2.9% higher than that of Z3 with longitudinal reinforcements and circular stirrups in the strengthening layer.

By comparing the carrying capacity of three different strengthened column confinement forms, when the thickness of the strengthening layer was 35 mm, the Z6 carrying capacity of the strengthening layer with two layers of CFRP sheets was 26.9% higher than the Z2 of the strengthening layer with longitudinal reinforcements and circular stirrups, and the Z7 carrying capacity of the strengthening layer with five layers of CFRP sheets was 53.9% higher than Z2 of the strengthening layer with longitudinal reinforcements and circular stirrups. When the thickness of the strengthening layer was 45 mm, the Z8 of the strengthening layer with two layers of CFRP sheets was 29.1% higher than the Z3 carrying capacity of the strengthening layer with longitudinal reinforcements and circular stirrups, and the Z9 of the strengthening layer with five layers of CFRP sheets was 43.1% higher than the Z3 carrying capacity of the strengthening layer with longitudinal reinforcements and circular stirrups. When the thickness of the strengthening layer was the same, the maximum increase in the carrying capacity of the wrapped CFRP sheets was 53.9% among the three strengthening methods.

For the CFRP-constrained UHPC strengthening column, Z6 and Z7 were strengthened with CFRP sheets on the basis of 35 mm UHPC strengthening layers. Z8 and Z9 were strengthened with CFRP sheets based on a 45 mm UHPC strengthening layer. Compared with the without strengthened column Z1, the carrying capacity of Z6, Z7, Z8 and Z9 increased by 378%, 480%, 496% and 561%, respectively. The thickness of the strengthening layer of Z6 and Z7, Z8 and Z9 were 35 mm and 45 mm, respectively. With the increase of the thickness of the strengthening layer, the carrying capacity of Z8 with the thickness of the strengthening layer of 45 mm was 24.8% higher than that of Z6 with the thickness of the strengthening layer of 35 mm. Using five layers of CFRP sheets to reinforce the specimen, the carrying capacity of Z9 with a thickness of 45 mm was 14.0% higher than that of Z7 with a thickness of 35 mm. The maximum carrying capacity increased by 24.8% with the increase in strengthening layer thickness. The carrying capacity can be greatly improved by using CFRP constraints. With the increase of CFRP layers from two to five layers, the carrying capacity of Z7 was 21.3% higher than that of Z6, and that of Z9 was 10.8% higher than that of Z8.

All three strengthening methods can greatly improve the carrying capacity of the column. The optimal carrying capacity of the column is strengthened by UHPC constrained by wrapped CFRP. The carrying capacity of the column strengthened by longitudinal reinforcements and spiral stirrups in the UHPC strengthening layer is the second, and the carrying capacity of the column strengthened by longitudinal reinforcements and ordinary circular stirrups in the UHPC strengthening layer is the worst.

The axial force of ordinary reinforced concrete columns is borne by both steel bars and concrete, as shown in Equation (1).

fco is the axial compression strength of concrete; Aco is the section area of concrete; fy is the compression strength of longitudinal reinforcement; As is the cross-section area of longitudinal reinforcement.

According to the literature [30], the axial compressive carrying capacity of UHPC strengthened column with longitudinal reinforcements and ordinary stirrups are shown in Equation (2).

αcs is the correction coefficient considering the degree of strength utilization of newly added concrete and steel bars; fc is the axial compression strength of UHPC; Ac is the section area of UHPC; f′y is the compression strength of the longitudinal reinforcement in the strengthening layer; A′s is the cross-section area of longitudinal reinforcement in the strengthening layer.

According to the literature [31], the calculation formula of carrying capacity of UHPC strengthened column with longitudinal reinforcements and spiral stirrup are shown in Equations (3) and (4).

α is the reduction coefficient of the constraint of a spiral stirrup on concrete; Ass0 is the conversion area of spiral stirrups; dcor is the diameter of the core area, determined according to the inner surface of the spiral stirrup; Ass1 is the section area of a single screw stirrup; s is the spacing of spiral stirrups; fy,s is the compression strength of spiral stirrups.

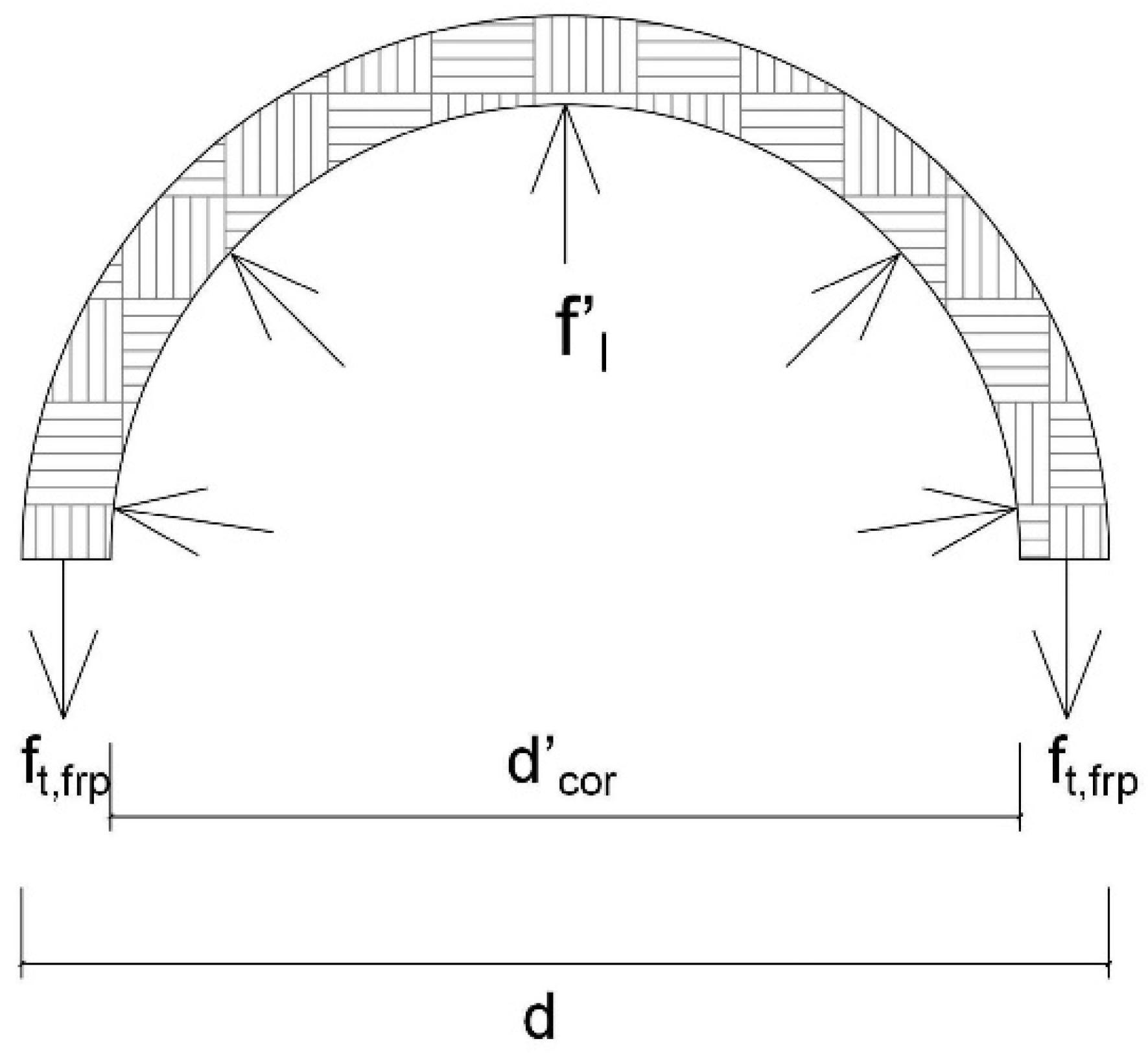

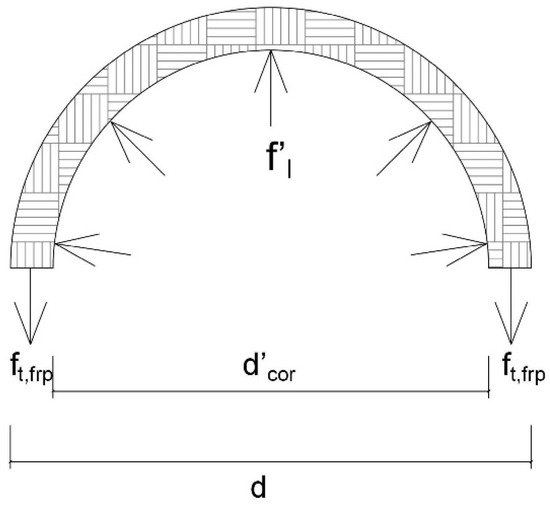

There are few research results on the axial compression test of CFRP-constrained UHPC concrete columns. Due to the strain difference between UHPC and concrete being very small, the confining pressure effect of UHPC on concrete is not considered in the calculation of the carrying capacity, but only the confining effect of CFRP sheets on UHPC and concrete is considered. The calculation of the carrying capacity of the CFRP-constrained UHPC column is given in reference [32], and CFRP constrained concrete column is given in reference [33]. Equations (5) and (6) are used to calculate the confinement stress of the CFRP sheets. The calculation formula of confinement stress f′l is shown in Figure 7 and Equation (7).

Figure 7.

Distribution of confinement stress of UHPC-concrete column by CFRP sheets.

EFRP is the elastic modulus of CFRP sheets; εh,rup is the measured hoop rupture strain of CFRP sheets, and the calculation method is shown in Equation (8); εfrp is the CFRP sheets’ ultimate tensile strain; d′cor is the diameter of the confinement members; tfrp is the thickness of CFRP sheets; fcc is the confinement stress of CFRP on concrete; fco is the axial compression strength of concrete; f′cc is the confinement stress of CFRP on UHPC; f′co is the axial compression strength of UHPC; Acc is the cross-section area of concrete; A′cc is the cross-section area of UHPC; fy is the compression strength of longitudinal reinforcement; As is the cross-section area of longitudinal reinforcement. The carrying capacity calculation formula is shown in (9) and (10). The calculation results are shown in Table 10.

Table 10.

Results of calculation.

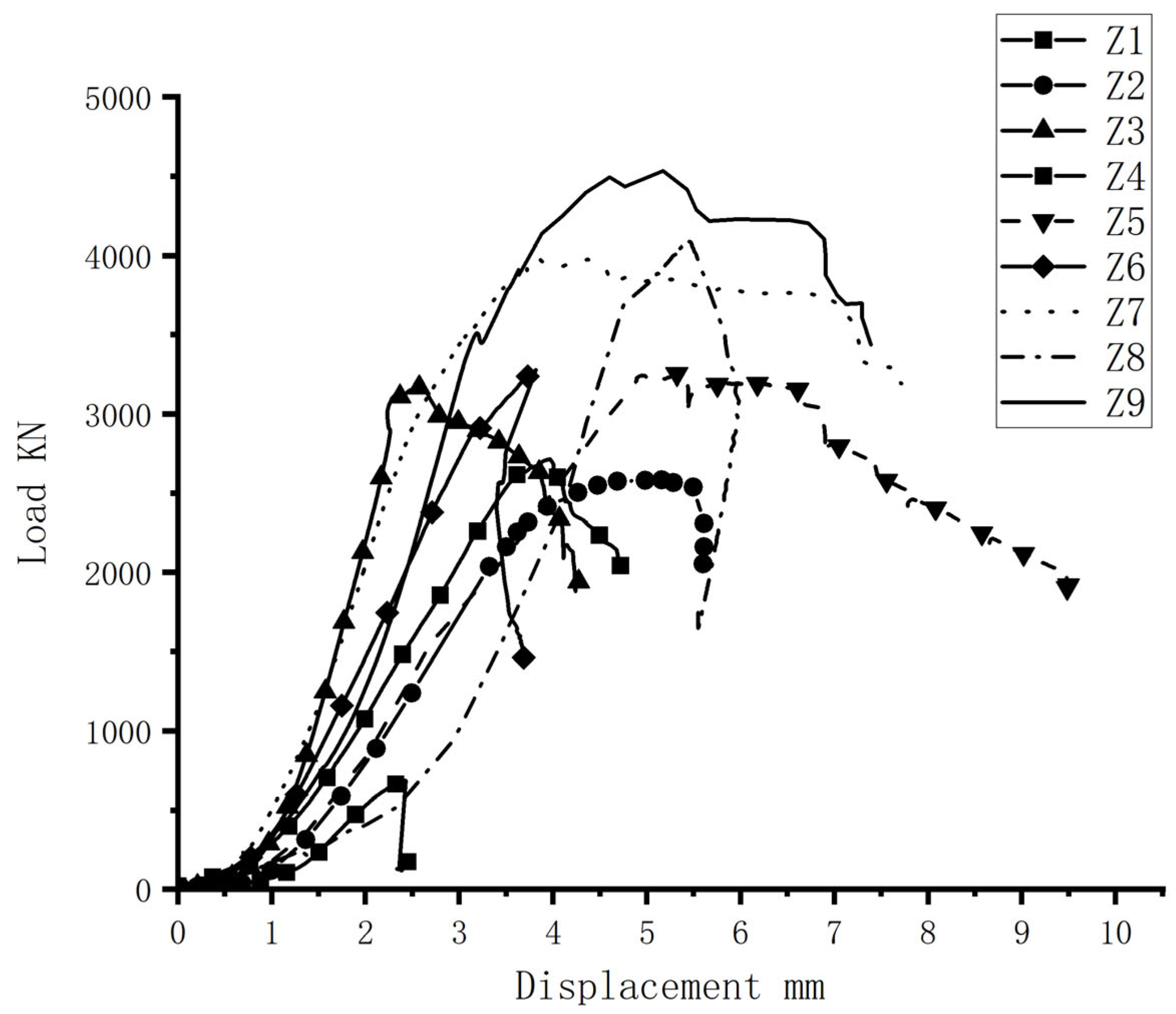

3.3. Load-Displacement Curve

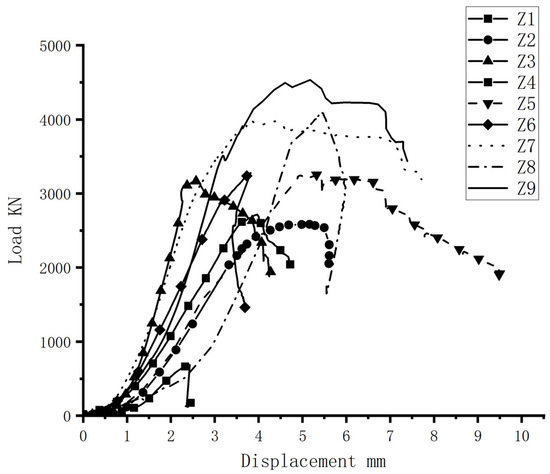

Z2 and Z3 are UHPC-strengthened columns equipped with longitudinal reinforcements and ordinary circular stirrups in the strengthening layer; Z4 and Z5 are UHPC-strengthened columns equipped with longitudinal reinforcements and spiral stirrups in the strengthening layer; Z6–Z9 are UHPC-strengthened columns constrained by CFRP sheets. The carrying capacity of strengthened columns Z2–Z9 was greatly improved compared with that of without strengthened Z1. Compared with Z1, the carrying capacity of the columns strengthened with wrapped with CFRP sheets could be improved by up to 561%. When the wrapped two layers of CFRP sheets Z6 and Z8 (the thickness of the strengthening layer is 35 mm and 45 mm, respectively) reached the peak load, the carrying capacity decreased rapidly. When wrapped in five layers of CFRP sheets, compared with Z6 and Z8, the curve trend of Z7 and Z9 was relatively smooth after the load approached the peak load, and the strengthening effect was better. The displacement corresponding to the peak load of each strengthened column was larger than the displacement corresponding to the ultimate load of the without-strengthened column Z1 because the peak strain of UHPC was larger than that of ordinary concrete. For the strengthened column with steel bars or CFRP sheets, when the peak load was reached except for Z6 and Z8 with fewer CFRP sheets, other strengthened columns had greater deformation capacity.

Figure 8 shows the load-displacement curve of Z1–Z9. The curve of Z2–Z5 shows a straight line at the initial stage of loading, and when it is close to the peak load, the curve shows an inflection point. At this time, large cracks appeared in the UHPC strengthening layer, and then the peak load was reached. Compared with the brittle failure of Z1, Z2–Z5 still has greater deformation ability and better ductility after passing the inflection point. At the initial stage of loading, columns Z6–Z9 constrained by CFRP sheets presented a straight line, which rose to about the peak load of columns Z2–Z5 constrained by longitudinal reinforcement and stirrups. At this stage, there was no large crack in UHPC. When the load exceeded the peak load of Z2–Z5, the strengthening layer of UHPC cracked and generated transverse deformation. At this time, the CFRP sheets began to play a restraint role, and the strengthening layer wrapped by the CFRP sheets was in a state of three-dimensional compression, which could continue to bear the load. After Z6 and Z8 reached the peak load, the curve had an inflection point, and then the specimen had a brittle failure. The brittle failure of Z6 and Z8 columns occurred due to the small number of CFRP sheets. It can be seen from the curve of Z7 and Z9 that with the increase of load, the transverse deformation of the strengthening layer increased, and the restraint effect of CFRP sheets was fully exerted. Due to the large thickness of CFRP sheets, the failure mode was in which CFRP sheets gradually ruptured from the inside out. There is no obvious inflection point in Z7 and Z9 curves, and the load-displacement curve fluctuates until the end of loading. After the test, it was observed that the failure form of Z6–Z9 was that the concrete in the strengthening layer was crushed, and the CFRP sheets were ruptured. Due to the wrapping of the CFRP sheets, it was difficult to monitor the compression state of the internal UHPC and concrete at any time during the test. Therefore, the maximum load generated by the press was recorded as the ultimate carrying capacity of the test column.

Figure 8.

Load-displacement curve of test columns.

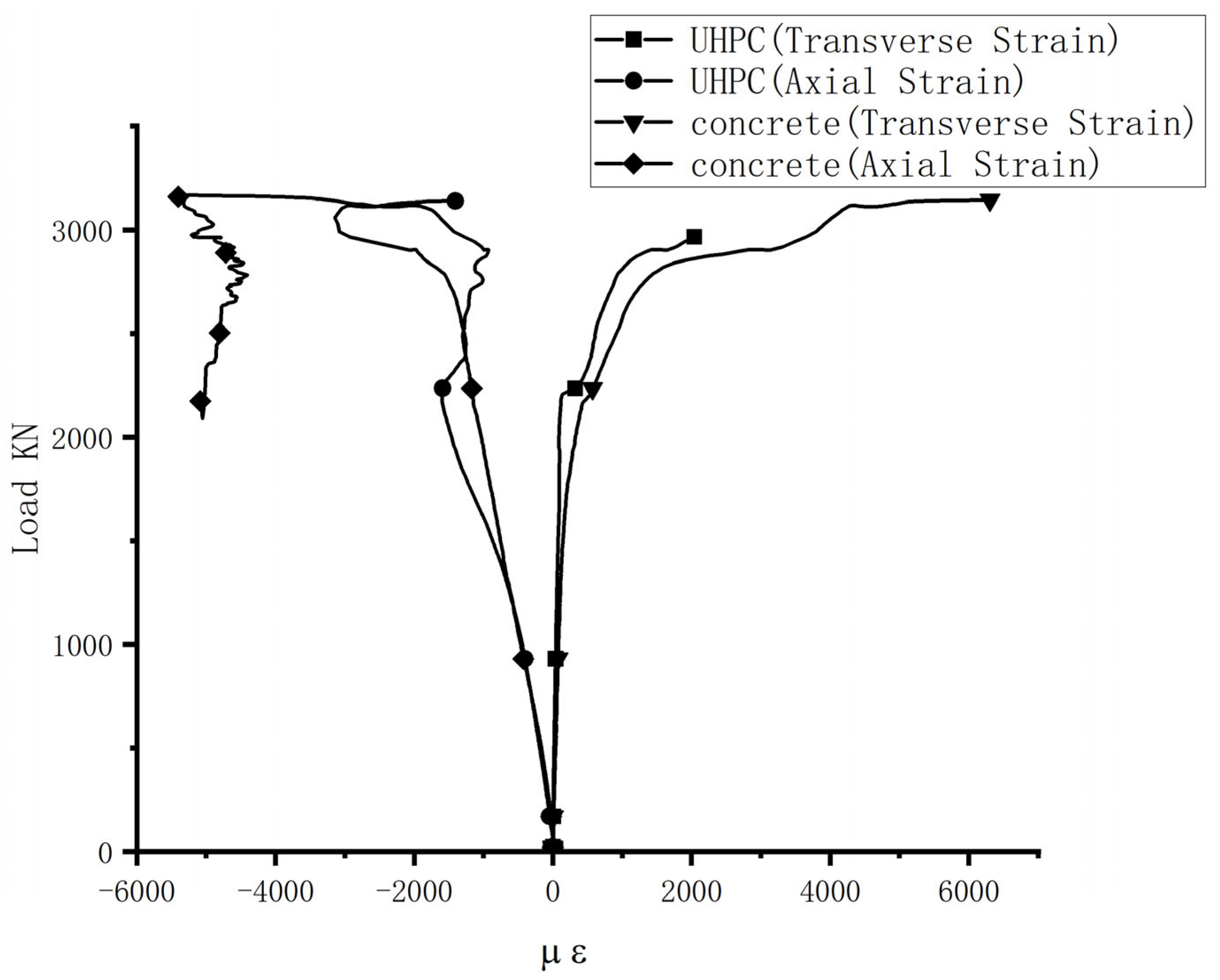

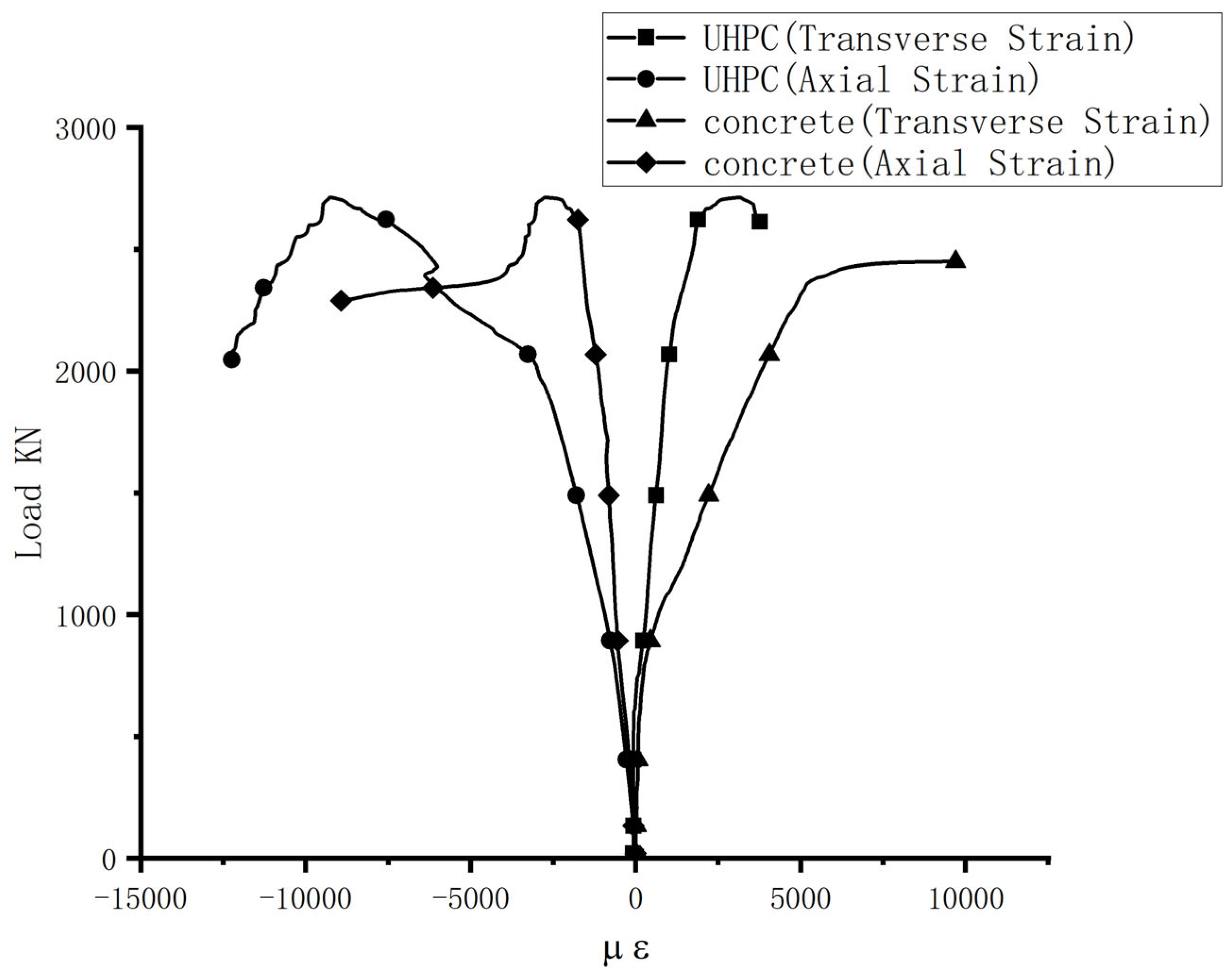

3.4. Strain Analysis

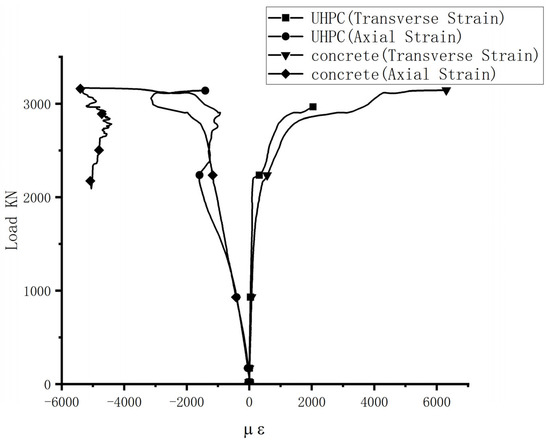

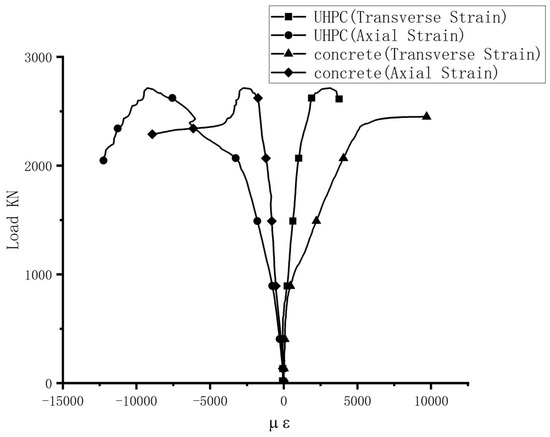

Figure 9 and Figure 10 show the load-strain curves of the columns with longitudinal reinforcements and circular stirrups in the strengthening layer and longitudinal reinforcements and spiral stirrups in the strengthening layer. At the initial stage of load application, the load-strain curve of concrete was close to the slope of UHPC. In this case, the difference between the axial strain of UHPC and concrete was small, indicating that there was no relative slip between UHPC and concrete with the increase of load. When the load approached the peak load, the strengthening layer was the strengthening column with longitudinal reinforcements and stirrups, and the concrete reached the axial and transverse limit strain before the UHPC, then the load decreased after the UHPC reached the limit strain. In Figure 9 and Figure 10, the load-strain curves of UHPC and concrete gradually decreased with the increasing load, indicating that the growth rate of axial strain and transverse strain of UHPC and concrete exceeded the increase rate of load when the load approached the peak load.

Figure 9.

The strengthening layer is the load-strain curve of UHPC and concrete longitudinal reinforcement and ordinary stirrup.

Figure 10.

The strengthening layer is the load-strain curve of UHPC and concrete longitudinal reinforcement and spiral stirrup.

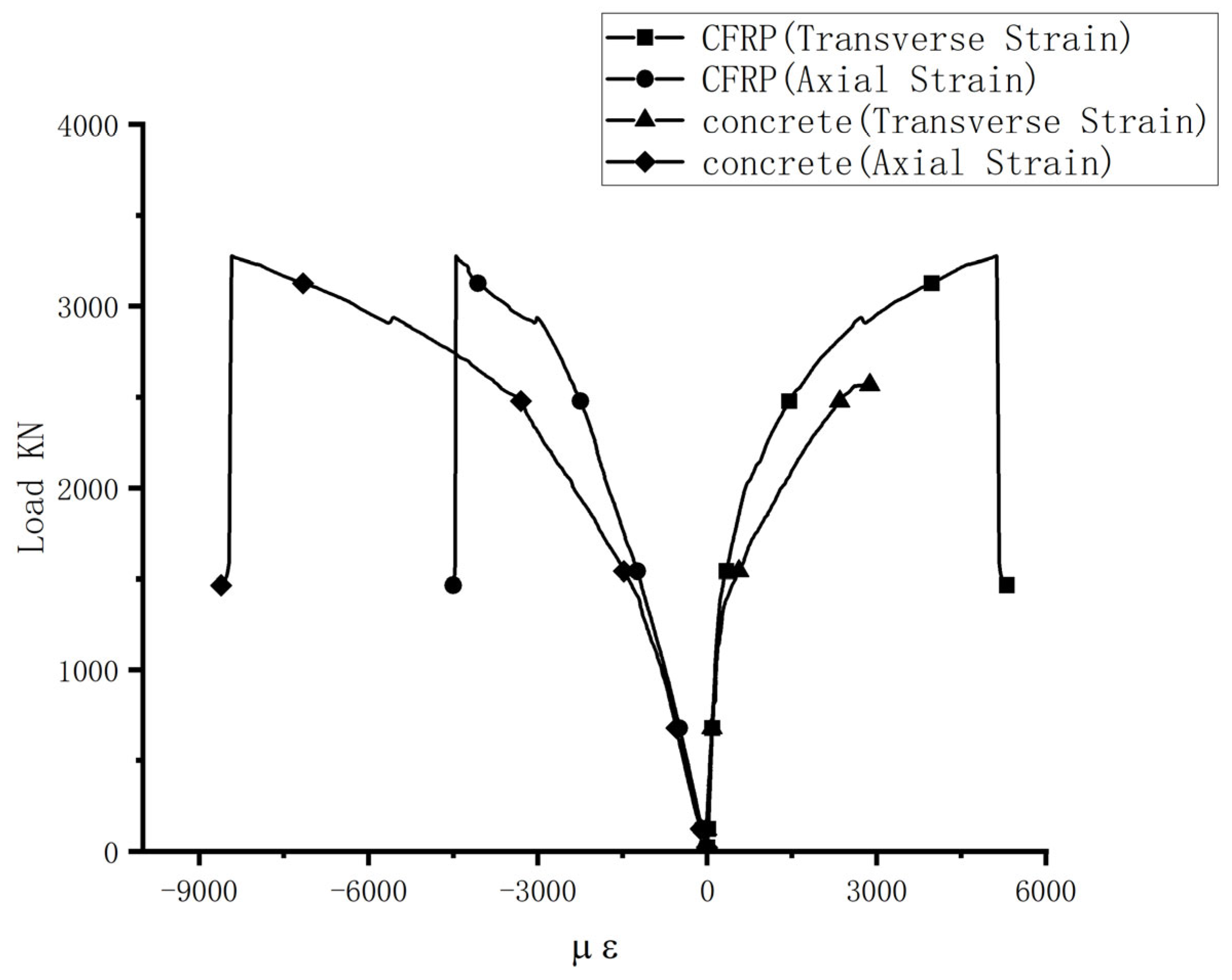

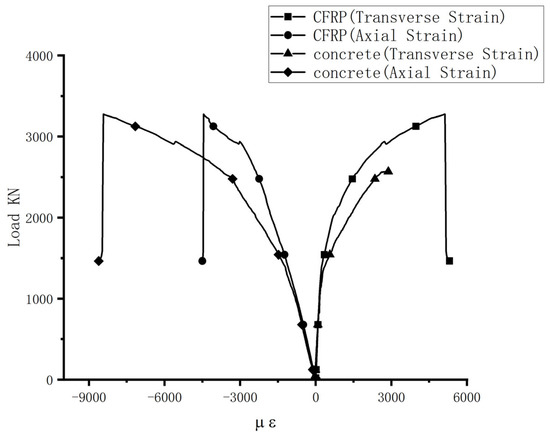

Figure 11 shows the load-strain curves of CFRP and concrete of UHPC strengthened column constrained by CFRP. At the initial stage of loading, the slope of the two was close, showing a linear relationship. The strain change was relatively small, indicating that CFRP and concrete had good cooperation. No slip phenomenon occurred, and the overall performance of the strengthened column was good. As the load increased, the concrete reached the ultimate transverse strain before CFRP. The slope of the load-strain curve of CFRP and concrete decreased gradually with the continuous increase of load, indicating that the growth rate of axial strain and transverse strain of CFRP and concrete exceeded the increase rate of load when the load approached the peak load.

Figure 11.

The strengthening columns with CFRP sheets and load-strain curves of CFRP and concrete.

3.5. Ductility Analysis

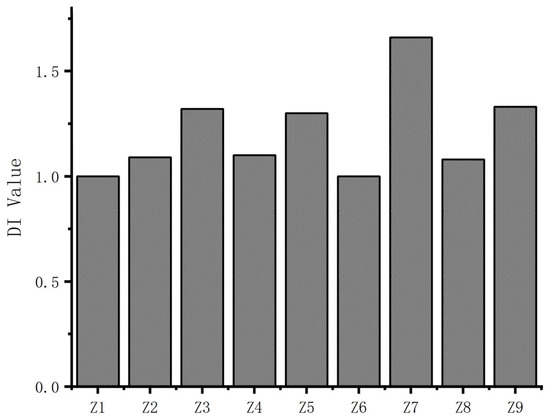

Ductility is the deformation capacity during which the carrying capacity does not decrease significantly after reaching the ultimate carrying capacity. The ratio DI of displacement δ0.85 when the reinforced column reaches 85% of the residual bearing capacity after the peak load and displacement δu when the peak load is adopted as the ductility index. The greater the DI value, the better the ductility. Table 9 shows the DI values of each column. Brittle failure occurs when column Z1 reaches the peak load and the DI value is 1. The DI values of strengthened columns Z2 and Z3 are 1.09 and 1.32, respectively. When the strengthening layer is equipped with longitudinal and stirrups, the ductility can be increased by increasing the thickness of the strengthening layer. The DI values of the strengthened columns Z4 and Z5 are 1.10 and 1.30, respectively. For Z6 and Z8, brittle fracture occurs due to the small number of wrapped CFRP layers, the DI values are 1.00 and 1.08, and the ductility is low. Compared with Z6 and Z8, when the number of CFRP layers is five, the DI values of Z7 and Z9 are 1.66 and 1.33. With the increase of CFRP layers, the ductility of columns will be improved.

According to the load-displacement curves of the three strengthening methods in Figure 8 and Figure 12, it can be seen that the DI value of the column strengthened by longitudinal reinforcement and circular stirrup is higher. Compared with the load-displacement curve of the column strengthened with spiral stirrup and CFRP sheets, the curve of the column strengthened with longitudinal reinforcement and circular stirrup decreases faster and is steeper after reaching the ultimate carrying capacity, indicating that the column strengthened with spiral stirrup and CFRP confinement has better ductility. In the strengthening layer, the longitudinal reinforcements and stirrups have the same influence factors on the ductility of the strengthening column; that is, the thicker the strengthening layer is, the better the ductility is. The ductility of CFRP sheets confined strengthened column is influenced as the more CFRP sheets layers, the better ductility. CFRP sheets confined strengthened column should pay attention to the CFRP sheets; when the number of wrapped CFRP sheets layer is small, brittle fracture is easy to occur.

Figure 12.

DI values of ductility of test columns.

4. Conclusions

In this paper, the axial compressive properties of three UHPC-strengthened columns were studied which are strengthened columns with longitudinal reinforcements and ordinary circular stirrups in the strengthening layer, strengthened columns with longitudinal reinforcements and spiral stirrups in the strengthening layer, and strengthened columns with CFRP sheets. The failure form and carrying capacity of strengthened columns were studied, and the following conclusions were obtained:

- (1)

- The thicker the UHPC strengthening layer is, the greater the uplift of carrying capacity is. Compared with the without strengthened column Z1, the uplift of carrying capacity of the strengthened test column Z2–Z9 is 277–561%.

- (2)

- For the three different strengthening methods, the wrapped CFRP sheets have the best effect on improving the carrying capacity and ductility, followed by longitudinal reinforcements and spiral stirrups. Compared with the strengthening form in the strengthening layer, the carrying capacity of the wrapped CFRP sheets increases by 53.9% at most, and the reinforcement form of the strengthening layer has little influence on the increase of the carrying capacity. The carrying capacity of the strengthening column with the strengthening form of longitudinal reinforcements and spiral stirrups increases by 2.9% to 5% compared with the strengthening form of longitudinal reinforcements and circular stirrups.

- (3)

- Due to the confinement effect of UHPC and CFRP, the internal core concrete and UHPC strengthening layer are in a state of three-dimensional compression, which greatly improves the strength of concrete and UHPC, and the ultimate carrying capacity of UHPC strengthened concrete column with CFRP confinement is greatly improved.

- (4)

- Calculate the carrying capacity of three different strengthening methods, and the calculated value is similar to the test value, which provides a reference for the calculation of the carrying capacity of columns strengthened with UHPC.

Author Contributions

Conceptualization, B.W.; Resources, B.W.; Writing—review and editing, B.W.; Supervision, B.W.; Funding acquisition, B.W.; Validation, G.L.; Writing—original draft, G.L.; Writing—review and editing, G.L.; Visualization, G.L.; Investigation, J.Z.; Visualization, J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Jilin Province Innovation and Entrepreneurship Talent Funding Project; the National Key Research and Development Program, grant number 2017YFC0806100; National Natural Science Foundation of China, grant number 51178206.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bajaber, M.A.; Hakeem, I.Y. UHPC evolution, development, and utilization in construction: A review. J. Mater. Res. Technol. 2021, 10, 1058–1074. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.P.; Zhang, Y.; Hussein, H.H.; Chen, G.D. Flexural strengthening of reinforced concrete beams or slabs using ultra-high performance concrete (UHPC): A state of the art review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Tanarslan, H.M. Flexural strengthening of RC beams with prefabricated ultra high performance fibre reinforced concrete laminates. Eng. Struct. 2017, 151, 337–348. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Alsomiri, M.; Jiang, X.F.; Liu, Z. Elastic Confinement Effect of Concrete Circular Columns with Ultrahigh-Performance Concrete Jackets: An Analytical and Experimental Study. Materials 2021, 14, 3278. [Google Scholar] [CrossRef]

- Xie, J.; Fu, Q.H.; Yan, J.B. Compressive behaviour of stub concrete column strengthened with ultra-high performance concrete jacket. Constr. Build. Mater. 2019, 204, 643–658. [Google Scholar] [CrossRef]

- Zeng, J.J.; Long, T.W. Compressive Behavior of FRP Grid-Reinforced UHPC Tubular Columns. Polymers 2022, 14, 125. [Google Scholar] [CrossRef]

- Zeng, J.J.; Pan, B.Z.; Fan, T.H.; Zhuge, Y.; Liu, F.; Li, L.J. Shear behavior of FRP-UHPC tubular beams. Compos. Struct. 2023, 307, 116576. [Google Scholar] [CrossRef]

- Zeng, J.J.; Zeng, W.B.; Ye, Y.Y.; Liao, J.J.; Zhuge, Y.; Fan, T.H. Flexural behavior of FRP grid reinforced ultra-high-performance concrete composite plates with different types of fibers. Eng. Struct. 2022, 272, 115020. [Google Scholar] [CrossRef]

- Xian, G.J.; Guo, R.; Li, C.G.; Wang, Y.J. Mechanical performance evolution and life prediction of prestressed CFRP plate exposed to hygrothermal and freeze-thaw environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Pan, Y.F.; Yan, D.M. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.G.; Xian, G.J. Water absorption and long-term thermal and mechanical properties of carbon/glass hybrid rod for bridge cable. Eng. Struct. 2023, 274, 115176. [Google Scholar] [CrossRef]

- Kobatake, Y. A seismic retrofitting method for existing reinforced concrete structures using CFRP. Adv. Compos. Mater. 1998, 7, 1–22. [Google Scholar] [CrossRef]

- Wang, W.Q.; Wu, C.Q.; Liu, Z.X.; Si, H.L. Compressive behavior of ultra-high performance fiber-reinforced concrete (UHPFRC) confined with FRP. Compos. Struct. 2018, 204, 419–437. [Google Scholar] [CrossRef]

- Liao, J.J.; Zeng, J.J.; Gong, Q.M.; Quach, W.M.; Gao, W.Y.; Zhang, L.H. Design-oriented stress-strain model for FRP-confined ultra-high performance concrete (UHPC). Constr. Build. Mater. 2022, 318, 126200. [Google Scholar] [CrossRef]

- Liao, J.J.; Yang, R.T.; Zeng, J.J.; Quach, W.M.; Ye, Y.Y.; Zhang, L.H. Compressive behavior of FRP-confined ultra-high performance concrete (UHPC) in circular columns. Eng. Struct. 2021, 249, 113246. [Google Scholar] [CrossRef]

- Huang, L.; Xie, J.H.; Li, L.M.; Xu, B.Q.; Huang, P.Y.; Lu, Z.Y. Compressive behaviour and modelling of CFRP-confined ultra-high performance concrete under cyclic loads. Constr. Build. Mater. 2021, 310, 124949. [Google Scholar] [CrossRef]

- Abadel, A.A.; Alharbi, Y.R. Confinement effectiveness of CFRP strengthened ultra-high performance concrete cylinders exposed to elevated temperatures. Mater. Sci. -Pol. 2021, 39, 478–490. [Google Scholar] [CrossRef]

- Zohrevand, P.; Mirmiran, A. Stress-Strain Model of Ultrahigh Performance Concrete Confined by Fiber-Reinforced Polymers. J. Mater. Civ. Eng. 2013, 25, 1822–1829. [Google Scholar] [CrossRef]

- Zohrevand, P.; Mirmiran, A. Behavior of Ultrahigh-Performance Concrete Confined by Fiber-Reinforced Polymers. J. Mater. Civ. Eng. 2011, 23, 1727–1734. [Google Scholar] [CrossRef]

- Guler, S.; Copur, A.; Aydogan, M. Nonlinear finite element modeling of FRP-wrapped UHPC columns. Comput. Concr. 2013, 12, 243–259. [Google Scholar] [CrossRef]

- Guler, S. Axial behavior of FRP-wrapped circular ultra-high performance concrete specimens. Struct. Eng. Mech. 2014, 50, 709–722. [Google Scholar] [CrossRef]

- Lam, L.; Huang, L.; Xie, J.H.; Chen, J.F. Compressive behavior of ultra-high performance concrete confined with FRP. Compos. Struct. 2021, 274, 114321. [Google Scholar] [CrossRef]

- Chang, W.; Hao, M.J.; Zheng, W.Z. Compressive behavior of UHPC confined by both spiral stirrups and carbon fiber-reinforced polymer (CFRP). Constr. Build. Mater. 2020, 230, 117007. [Google Scholar] [CrossRef]

- Chang, W.; Zheng, W.Z. Lateral response of HPC confined by both spiral stirrups and CFRP under axial compression. Mater. Struct. 2021, 54, 81. [Google Scholar] [CrossRef]

- Lu, C.L.; Ouyang, K.; Wang, Q.; Zhu, W.X.; Chen, H.Q.; Lei, Z.X.; Qin, Z.J. Axial behavior of RC column strengthened with laterally reinforced FRHPC jacket. Struct. Concr. 2022, 23, 1718–1734. [Google Scholar] [CrossRef]

- GB/T50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2003. (In Chinese)

- Qu, W.J.; Wu, S.J.; Qin, Y.H. Mechanical Property Tests of Reactive Powder Concrete. J. Archit. Civ. Eng. 2008, 25, 13–18. (In Chinese) [Google Scholar]

- GB 50367-2013; Code for Design of Strengthening Concrete Structure. China Architecture & Building Press: Beijing, China, 2014. (In Chinese)

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- Deng, Z.C. Effects of thicknesses and types of fiber reinforced polymer tubes on the uniaxial compressive behaviors of confined UHPC specimen. J. Harbin Eng. Univ. 2016, 37, 218–222. (In Chinese) [Google Scholar]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).