1. Introduction

Spherical reticulated shell structure is one of the important structural forms of large-span space buildings. With the advantages of cheap materials and excellent performance, it has been a great development prospect in recent years [

1]. At present, spherical reticulated shell structures are mainly used for airports, stations, gymnasiums and other densely populated infrastructures. However, as a multi-degree-of-freedom nonlinear structure, the structure members and nodes of the spherical reticulated shell structure may be deformed in three dimensions when an earthquake occurs. For example, Lushan Gymnasium, the largest-span space structure in Lushan County, Ya’an City, Sichuan Province, China, suffered different degrees of damage in its members and nodes during the Lushan earthquake in 2013 [

2]. Therefore, we need to monitor the three-dimensional (3D) dynamic responses and analyze the seismic performance of shell structure before it is used to construct large-span space buildings [

3].

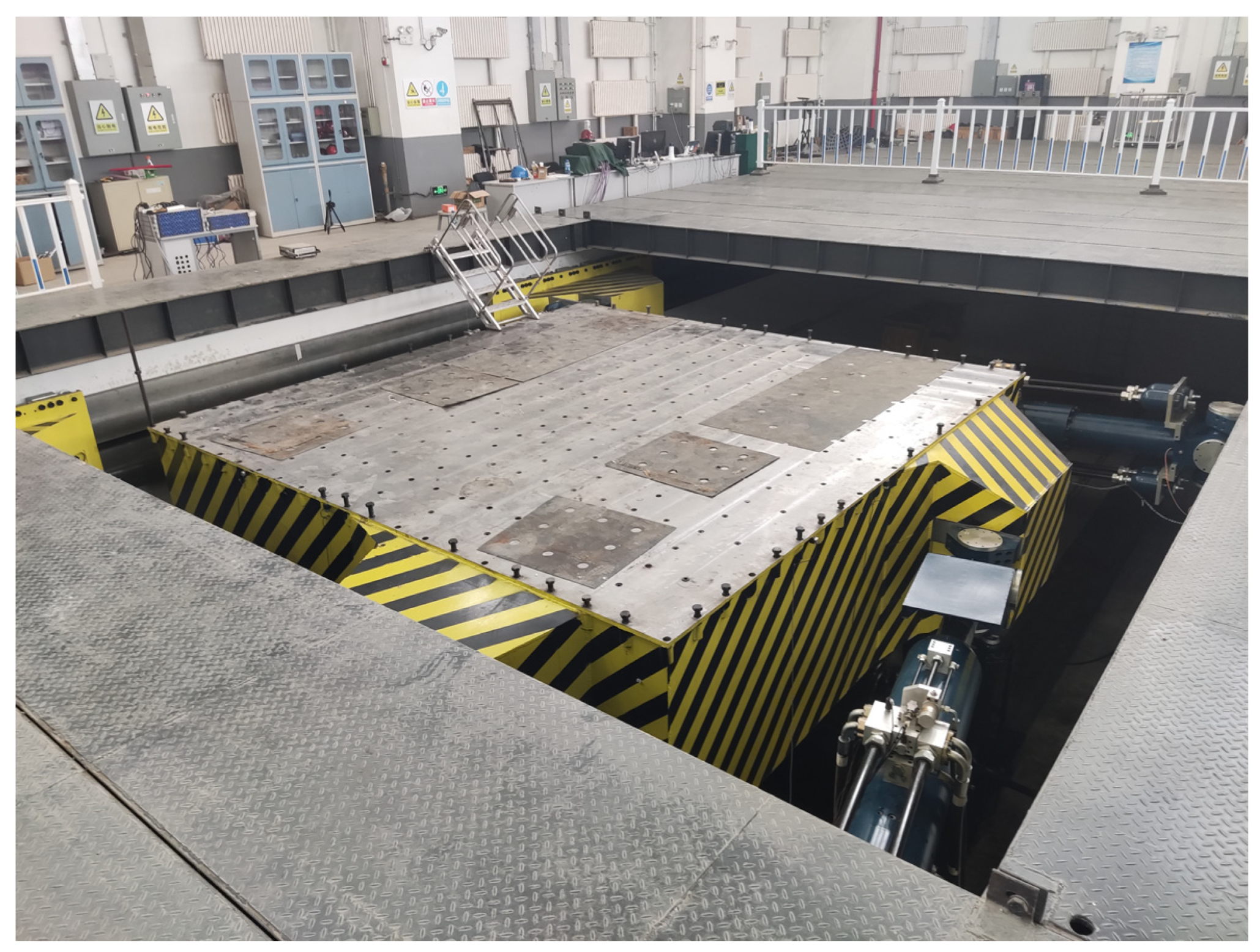

In general, the earthquake shaking table can be used to test the seismic performance of scaled structure models, which is a specific device for shaking structural models by creating simulated seismic waves [

4]. Moreover, displacement and acceleration are the most frequently used response parameters for analyzing the seismic performance of structures [

5,

6]. Contact-based transducers, such as linear variable differential transformers [

7], strain gauges [

8] and accelerometers [

9], are commonly applied to acquire the dynamic responses of monitored structures on the shaking table. However, there are several limitations for contact-based transducers: (1) If a large number of transducers are arranged, it is time-consuming and inconvenient to install contact-based transducers on the monitored structures [

10]. (2) When a structure has been damaged or experienced a large deformation, the transducer may be out of its range, and the correct dynamic results cannot be obtained. In order to solve the defects of contact-based transducers, non-contact-based transducers, such as Global Positioning System (GPS), Laser Doppler Vibrometer (LDV), Terrestrial Laser Scanning (TLS) and Digital Holographic Interferometry (DHI), have been applied to obtain the dynamic responses of structures. However, due to some different disadvantages, such as high cost, low acquisition frequency and small measurement range, it is not suitable to monitor large and complex reticulated shell structures using the above non-contact-based transducers [

11,

12,

13,

14,

15,

16].

In recent years, with the continuous development of image sensors, the frame rate per second (fps) of high-speed cameras can exceed 10,000 frames, with a one-million level of resolution for image sensors. Therefore, with the advantages of high frame rate, high resolution and low cost, high-speed cameras have been greatly applied and developed in the fields of civil engineering, medicine, military and biology [

17,

18,

19,

20]. For example, Steinbauer et al. used a Y4 high-speed camera with a frame rate of 6000 fps to trace the impact of hailstones on an external thermal insulation composite system [

21]. Bailey et al. used two high-speed cameras with a frame rate of 240 fps to accurately calculate the changes in translational and rotational velocity of a helmet and further analyze American football helmet kinematics [

22]. Ma et al. used two high-speed cameras at 320 × 320 resolution and 2681 fps to obtain the bullet velocity parameter [

23]. However, since high-speed cameras generate massive amounts of image data per second, images will be lost if the acquisition system cannot meet the requirements of high-speed storage. Moreover, the massive image storage integrity can also affect the accuracy of image processing results. Therefore, it is necessary to configurate an adapted hardware system (including high-speed transmission cables, acquisition card and high-speed storage media) and design an efficient writing strategy (buffer pool) to realize high-speed image storage. At present, many scholars have proposed solutions to solve the problem of high-speed image storage in real time. Combining asynchronous First Input First Output (FIFO) and the Double Data Rate 2 (DDR2) caching method, Wang et al. designed a high-speed image acquisition system with a transmission speed of 800 Mb/s [

24]. With the method of memory ping-pong operation and channel arbite, Zhou et al. optimized the DMA dual channel for a high-speed data acquisition system that can receive optical fiber data at the rate of 7.57 Gb/s [

25]. Sanskriti et al. proposed the Reconfigurable First-In First-Out (r-FIFO) method to acquire Complementary Metal Oxide Semiconductor (CMOS) data [

26]. However, these methods only provide the framework for the overall design of the buffer pool and do not mention how to set the size of individual buffers. Therefore, combined with the minimal storage unit size of the storage media, an adaptive optimal buffer pool is designed to cache high-speed images in this paper.

As high-speed videogrammetric network configuration can determine the position of the target in the image, which affects the accuracy of target point tracking and positioning, it is also important to configure the high-speed videogrammetric network after configuring the high-speed videogrammetric acquisition system. High-speed videogrammetric network configuration mainly includes a high-speed camera configuration and control network configuration. High-speed camera configuration includes normal case photography and convergent photography. For high-speed videogrammetry, the convergent photography can obtain higher accuracy than normal case photography [

27]. The control network configuration method, including the relative control method and control points method, can obtain the scale and orientation parameters of the images. For example, Rajaram et al. placed coded markers at different locations on the wall of masonry buildings to obtain the scale parameters in the relative control method [

28]. The relative control method was very effective for measuring targets at the same base plane. Yet, because the nodes in the spherical reticulated shell structures were not at the same base plane, the method was not suitable for spherical reticulated shell structures. The control points method can obtain more accurate scale and orientation parameters of different spatial positions by the 3D coordinates of the control targets [

29,

30]. Therefore, according to the spatial geometric characteristics of the spherical reticulated shell structures, a high-speed videogrammetric network configuration is designed in this study to improve the accuracy of target point tracking and positioning.

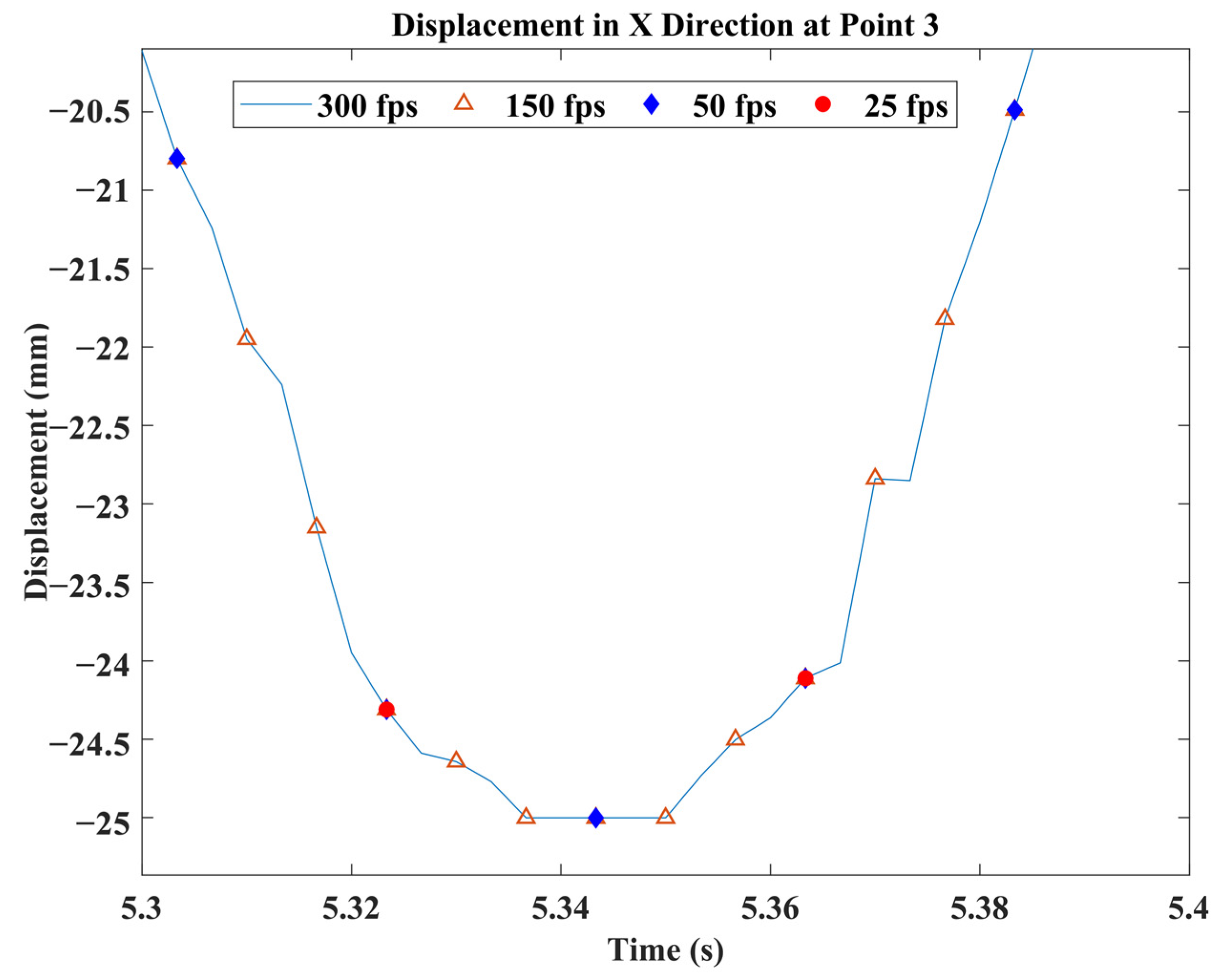

In general, for structure monitoring, the commonly used excitation frequency is about in the range of 0.1 Hz~50 Hz. Therefore, in order to obtain the accurate dynamic response of the structure, the frame rate of the camera is set in the range of 50 fps~1000 fps. For such massive image sequences, it is difficult to track and position the targets, which will affect the accuracy of the 3D reconstruction of targets. Therefore, it is crucial to track and position the targets of image sequences. At present, the target-tracking and positioning algorithms have been relatively mature in videogrammetry. For example, with a camera at 50 fps and a single camera template-matching algorithm, Feng et al. measured the bridge displacement for low-cost video measurement of structural health monitoring [

31]. Wei et al. proposed a multi-camera 3D DIC method to measure the seismic performance of large structures with 4 high-speed cameras at 50 fps and a resolution of 2048 × 2048 pixels [

32]. Using a high-speed camera with a resolution of 512 × 400 and a frame rate of 1000 fps, Goyal et al. obtained the displacement for a single-room full-scale model of an interlinked block masonry system on the shaking table [

33]. With less than 0.5 mm displacement accuracy, Tong et al. successfully conducted a rubber support shaking table experiment to monitor the 3D displacement time curve at key points by using a 3-camera high-speed video measurement system consisting of 3 CMOS high-speed cameras at a speed of 300 fps [

34]. Our team has proposed a videogrammetric image sequence processing technique for tracking target detection [

35]. The method has been successfully applied for 3D, structural, progressive collapse measurement. Thus, in this study, we would like to further apply the proposed method to monitor the seismic response of the more complex spatial spherical reticulated shell structure.

In order to acquire the dynamic response of the spherical reticulated shell structure on the shaking table, this study proposed a high-speed videogrammetric measurement method. The method can obtain the 3D dynamic information of the key locations on the monitored structural model accurately through: (1) proposing a high-speed videogrammetric hardware system and network configuration method to solve the problem of massive image storage and improve the accuracy of target tracking and positioning, and (2) applying the critical technique of image sequence tracking and positioning to obtain the precise 3D coordinates of the targets. The rest of the paper is organized as follows.

Section 2 presents the methodology of the proposed high-speed videogrammetry.

Section 3 presents the experimental setup, experimental results and accuracy analysis. Some conclusions are presented in

Section 4.

2. Methods

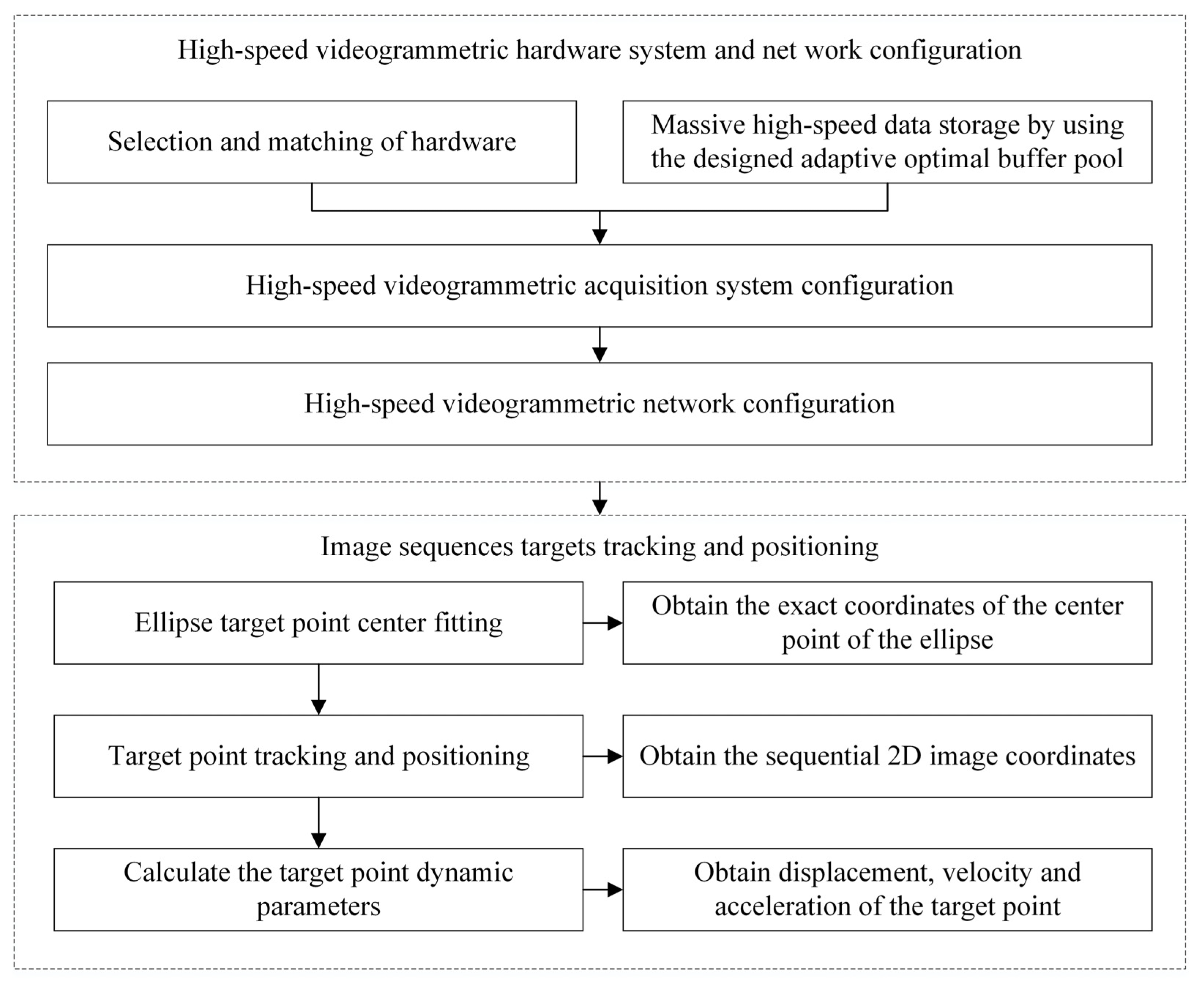

Figure 1 shows the entire framework of the proposed high-speed videogrammetric-based methodology, which includes the following two key components: (1) high-speed videogrammetric acquisition system and network configuration, and (2) targets tracking and positioning in the obtained image sequences.

2.1. High-Speed Videogrammetric Acquisition System and Network Configuration

2.1.1. High-Speed Videogrammetric Acquisition System Configuration

In general, the higher accuracy of the 3D spatial coordinates of critical points can be guaranteed by the used high-speed cameras with a higher resolution and a higher frame rate. It is important to acquire and store massive images in real time to further calculate the 3D coordinates of targeting points. A high-speed videogrammetric hardware system and massive image sequence transmission are the two critical issues in the high-speed videogrammetric acquisition system.

(1) High-speed videogrammetric hardware system construction is necessary to achieve the acquisition of massive images in real time. In this study, two high-speed CMOS cameras (OPTRONIS CP80-4-M500; parameters shown in

Table 1), two high-speed acquisition cards, one high-speed synchronous controller, two Industrial Personal Computers (IPC, one of which was used as the host computer) and eight CoaXPress (CXP) cables were integrated to construct the high-speed videogrammetric hardware system. In the high-speed videogrammetric hardware system, as shown in

Figure 2, two high-speed acquisition cards were plugged into two IPCs. The high-speed CMOS cameras were connected to the high-speed acquisition card via four CXP cables. The synchronous controller was connected to the host computer and the two high-speed cameras through the cables. The host computer would send synchronous signals to the two cameras through the synchronous controller, and then two high-speed cameras would capture images simultaneously and store the image sequences in the high-speed Solid-State Drive (SSD) of the IPC through the high-speed acquisition cards. The above high-speed videogrammetric hardware system can ensure the stability of the acquisition system.

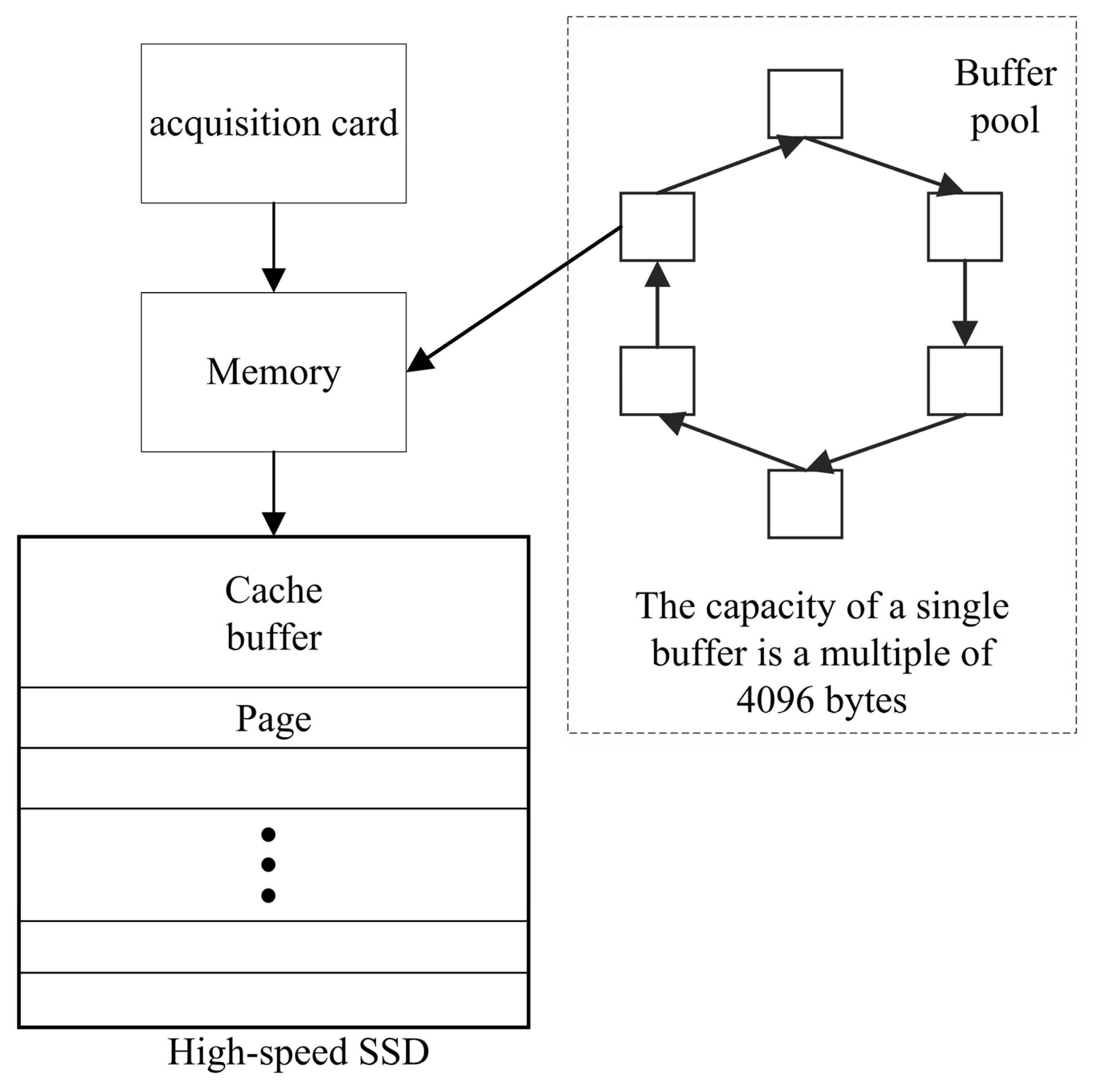

(2) High efficiency of massive image sequence transmission is an essential part to ensure the storage efficiency of massive images in real time. As shown in

Figure 3, high-speed image sequences are outputted from the acquisition card and are stored from memory to a high-speed SSD. The read and write performance of the high-speed SSD cannot be fully released due to the impact of the operating system (OS). Therefore, it is important to release the hardware performance from the software layer. Thus, in this study, firstly, according to the principle of file writing, an adaptive optimal buffer pool was designed to cache high-speed image sequences from the acquisition card. With the purpose of changing the size of a single buffer into a multiple of the minimum storage unit (4 k bytes) of a high-speed SSD, the capacity of a single buffer was expanded to a multiple of 4096 (4 k) bytes, which could improve storage efficiency. Secondly, a storage strategy of the cache buffer of the high-speed SSD was applied to the high-speed image sequences. Due to the limitation of Input/Output (I/O) per second for the high-speed SSD, the proposed storage strategy could reduce the number of I/O to improve the storage efficiency.

2.1.2. High-Speed Videogrammetric Network Configuration

The position of the target in the image is determined by the network configuration. Therefore, the network configuration affects the accuracy of target tracking and positioning. There are three issues that need to be addressed for an optimal high-speed videogrammetric network configuration: (1) the location of cameras, (2) the design of artificial targets and (3) the location of artificial targets.

(1) The location of the cameras will determine the optimal convergent angle and the similarity between the circular targets and imaged elliptical targets. These two factors will influence the accuracy of the reticulated shell structures, 3D, dynamic monitoring using videogrammetry [

36]. In order to improve the monitoring accuracy, in this study, the photographic baseline was set at 9 m and the object distance at 8 m, which could ensure the convergent angle was about 60° between the two cameras; the similarity was better than 0.9 between the circular targets and imaged elliptical targets, as shown in

Figure 4. Moreover, two OPTRONIS CP80-4-M500 CMOS cameras with two AF Nikkor 35 mm f/2 d lenses were used to satisfy the depth-of-field requirements of the shaking table experiment. The actual size of the camera’s field of view was 4.02 m × 3.00 m, which could ensure to fully cover the structure model. The resulting actual size of each pixel was 1.7 mm.

(2) The circular target is an elliptical form with five degrees of freedom in the image. Thus, compared with the point or line target with only two degrees of freedom, the circular target is more stable. In this study, the side length of the artificial targets and the diameter of the inner circle were designed to be 16 cm and 10 cm, respectively. To obtain accurate videogrammetric results, two types of target points, control points and tracking points were designed in this study [

37]. The control points were used to determine the exterior orientation parameters of the two cameras. The tracking points were used to obtain the dynamic 3D coordinates of the key locations on the structure model. As shown in

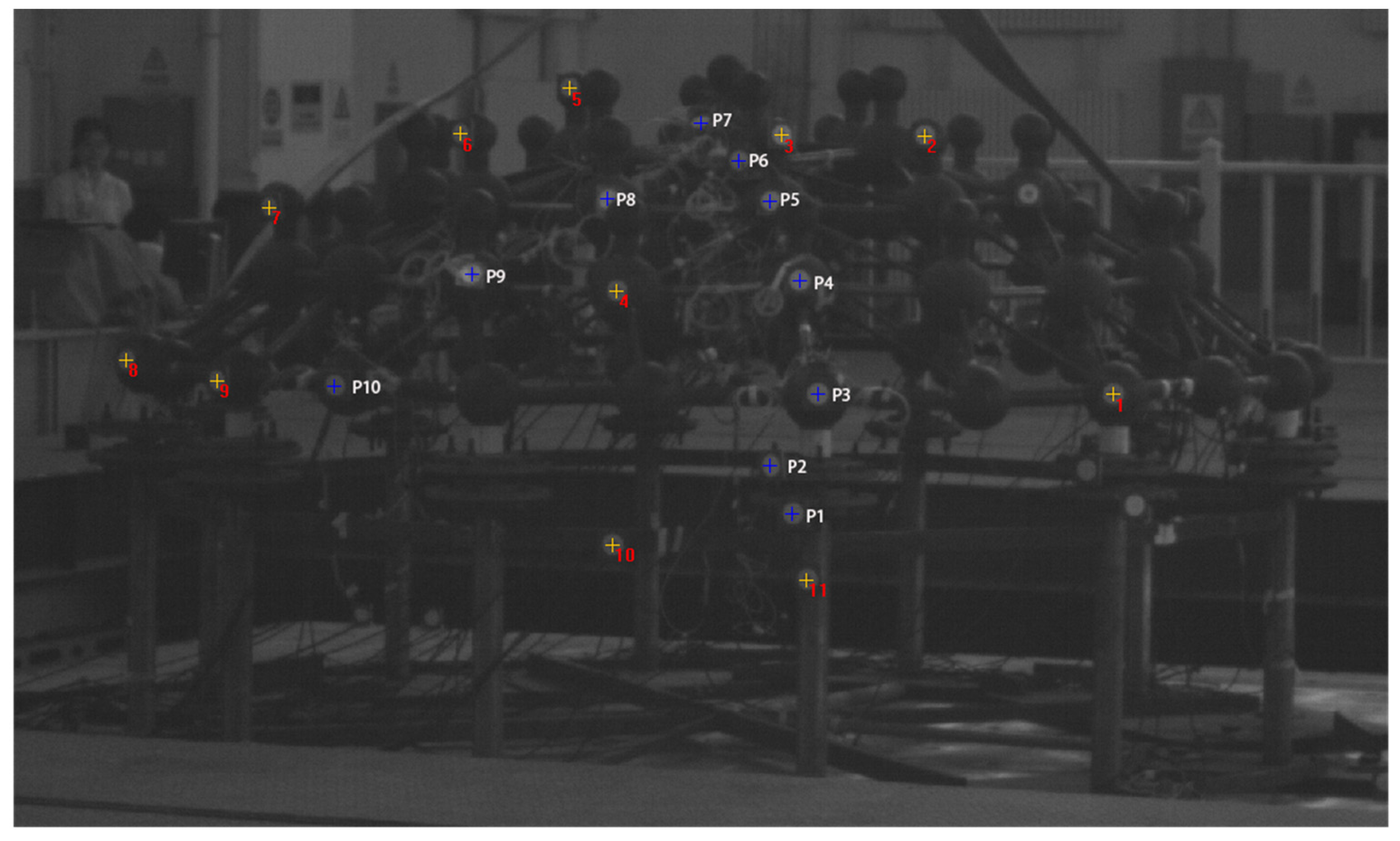

Figure 5, the black crosswire of the artificial targets was designed to determine the coordinates of the center circle. The control points were affixed with a reflective sheet, of which 3D coordinates were acquired by a total station.

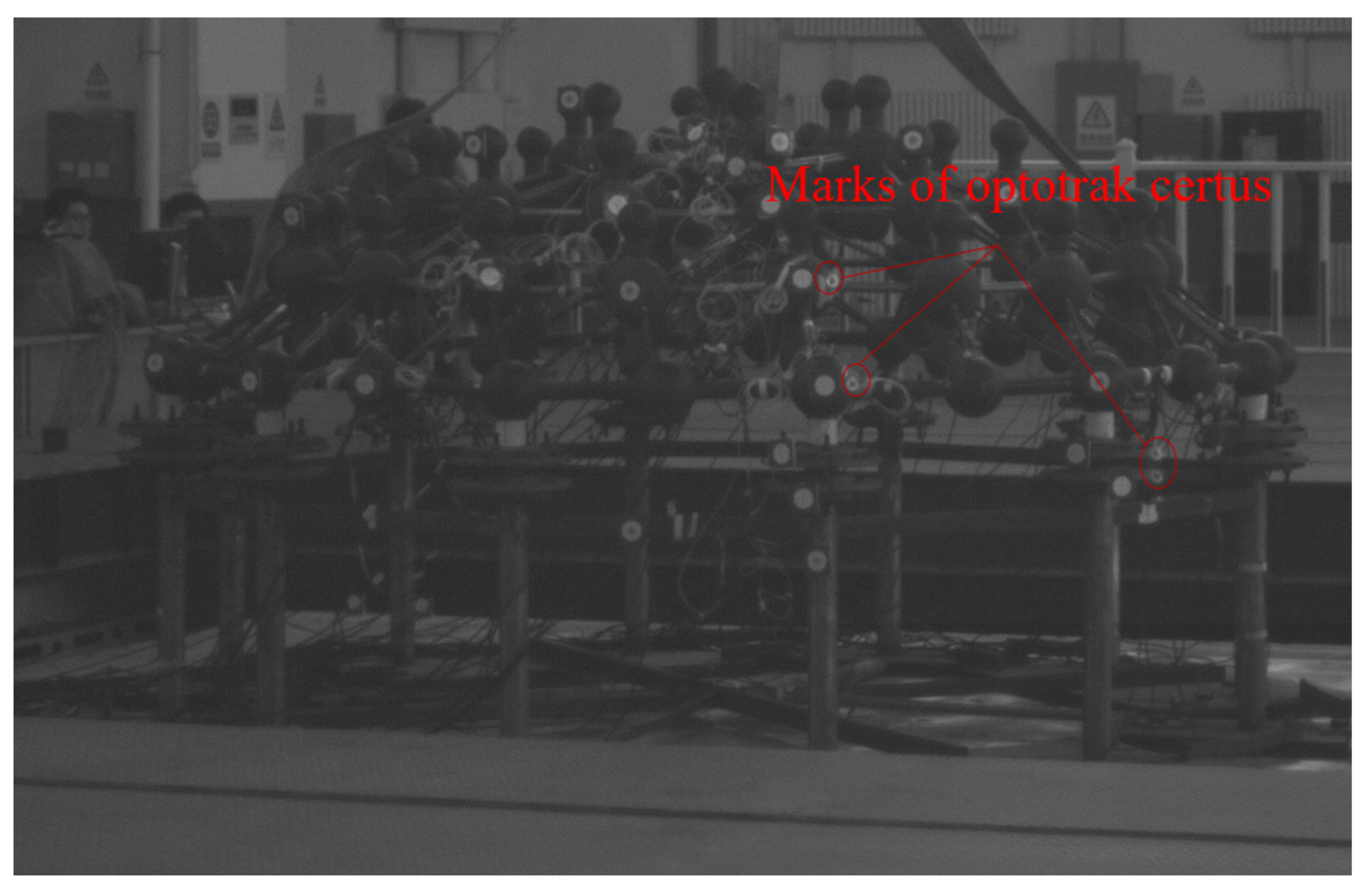

(3) If the locations of the artificial target points (especially the control points) are not placed in the correct position, it will affect the calculation accuracy of the tracking target 3D coordinates. Thus, in this study, 11 control points were placed on the spherical reticulated shell structure with different depths, under the principle that control points should be evenly placed near the tracking targets. Control point 1 and control point 6 would be used to check the accuracy of the results of the proposed method. Moreover, due to the symmetry of the spherical reticulated shell structure, 10 tracking points were deployed at the representative locations of the spherical reticulated shell structure. As shown in

Figure 6, control points are red and tracking points are white. Among these tracking points, points 1–2 were deployed on the bottom and top plates of the Friction Pendulum Bearing (FPB), and points 3–10 were deployed on the corresponding nodes of the spherical reticulated shell structure. To improve the contrast of the obtained images, a flicker-free 500-watt illumination source was placed in front of the structural model. Besides the above configuration of the high-speed videogrammetric network, the cameras were calibrated with the Zhang model [

38] to obtain accurate internal orientation parameters and lens distortion parameters.

2.2. Image Sequences Targets Tracking and Positioning

Among all the massive image sequences, it is crucial to track and position target points with an efficiency algorithm. There are three critical techniques for tracking and positioning targets in image sequences: (1) elliptical target point center fitting; (2) target point tracking and positioning and (3) target point dynamic response parameters calculation.

(1) Elliptical target point center fitting combines the feature-based elliptic contour extraction and optimal least squares fitting methods.

Due to the obvious difference between the artificial targets and the background, the elliptical targets can be quickly identified and extracted based on the characteristics of perimeter, area and circularity. After obtaining the ellipse contour, the exact coordinate of the ellipse center can be calculated using the optimal least square algorithm combined with the nonlinear optimization Levenberg–Marquardt method.

(2) Target point tracking and positioning with a coarse-to-fine matching strategy.

Firstly, coarse matching was used to obtain initial point locations in the search area with the algorithm of normalized correlation coefficient. Secondly, fine matching was used to obtain sub-pixel accurate locations of the target points with the least squares matching method. For homonymous point matching, the positions of the tracking target points were obtained by manual matching in the initial image. Therefore, the initial image would be used as the reference image, and the subsequent images were matched with the reference image, which can effectively avoid the accumulation of errors.

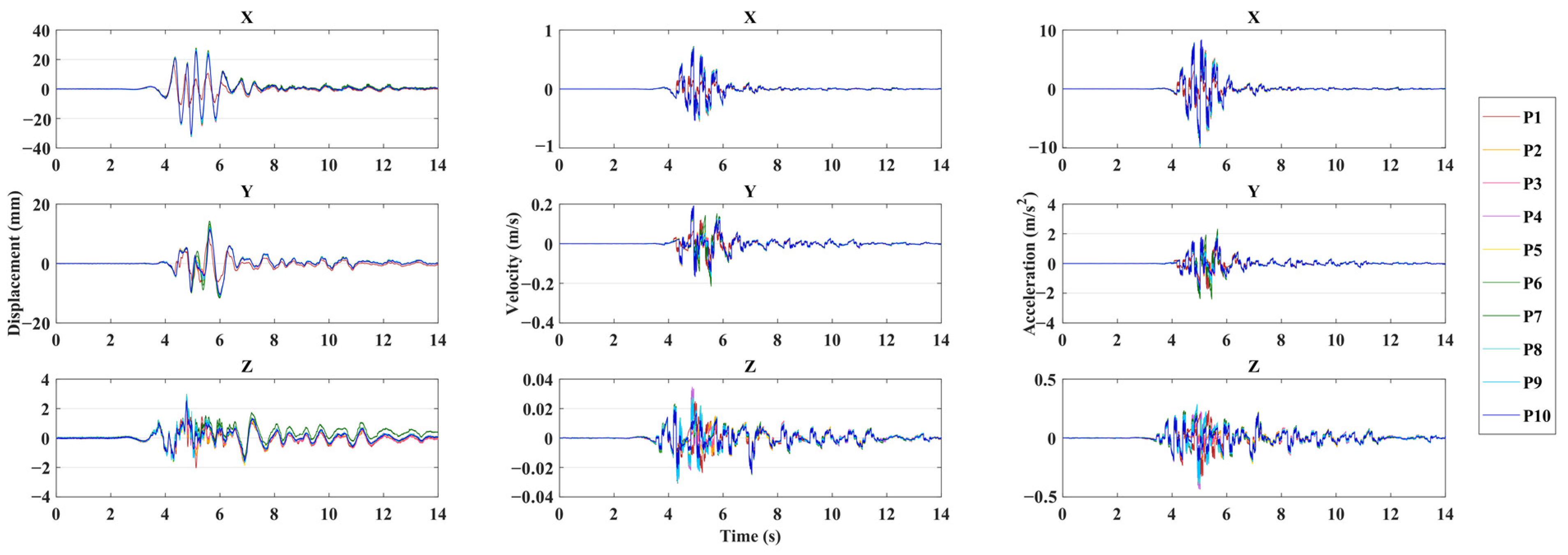

Target point dynamic response parameters can be calculated from the 3D spatial coordinates of the tracking points. The accuracy of the 3D spatial coordinates of the tracking target points directly determines the accuracy of the dynamic analysis of the spherical reticulated shell structure. Therefore, the bundle adjustment algorithm was adopted to calculate the 3D spatial coordinates of the tracking target points. The dynamic parameters of the tracking target point mainly include displacement, velocity and acceleration. The displacement of the tracking point is the distance difference between the initial coordinate and current spatial coordinate of the tracking target points. The velocity and acceleration values were obtained by the displacement differential, and the wavelet domain denoising algorithm was adopted to reduce the effects of the noise caused by the displacement differential.

4. Conclusions

In this paper, to compensate for the limitations of traditional contacted transducers, a non-contacted, high-speed, videogrammetric-based measurement method was proposed to monitor the seismic performance of the spherical reticulated shell structure. An experiment to monitor the seismic responses of the seismically isolated, spherical, reticulated shell structural model was conducted at Beijing University of Civil Engineering and Architecture. In the experiment, the high-speed videogrammetric hardware system consisted of a hardware system and software system. The high-speed videogrammetric hardware system consisted of two CMOS high-speed cameras, two high-speed capture cards, one high-speed synchronous controller, two IPCs and eight CXP cables. The software system used the technology of the adaptive optimal buffer pool. Based on the geometric characteristics of the spherical reticulated shell structure, 10 tracking points were selected, and 11 control points (among which, control point 1 and control point 6 were used to check the measurement accuracy) were set up on other nodes of the mesh shell structure. The frame rate of the two high-speed CMOS cameras was set at 300 fps, and the consumed time of the experiments was 14 s. With three techniques (circular target point center fitting, target point tracking and positioning, and target point dynamic response results calculation), the problem of image sequences tracking and positioning can be solved.

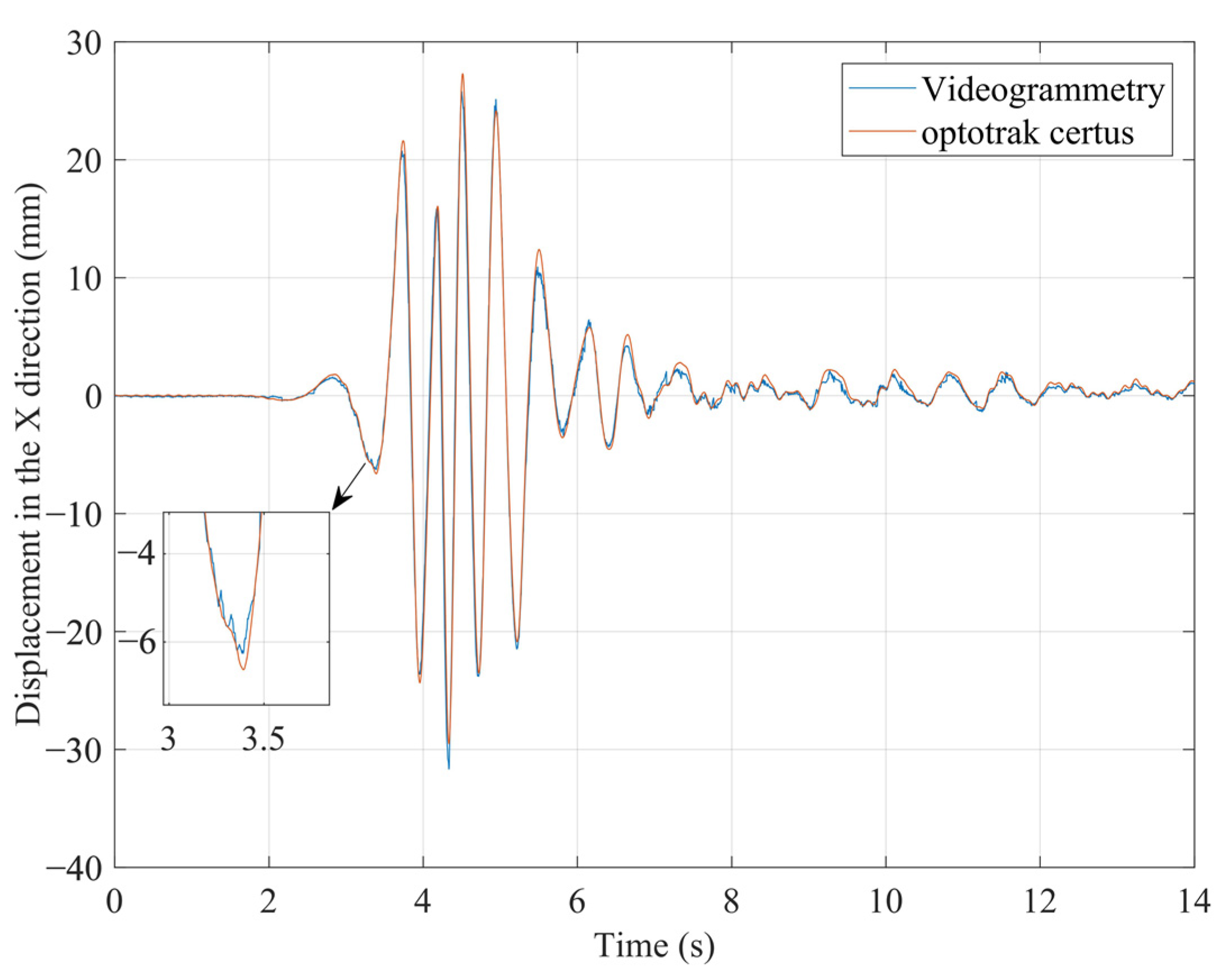

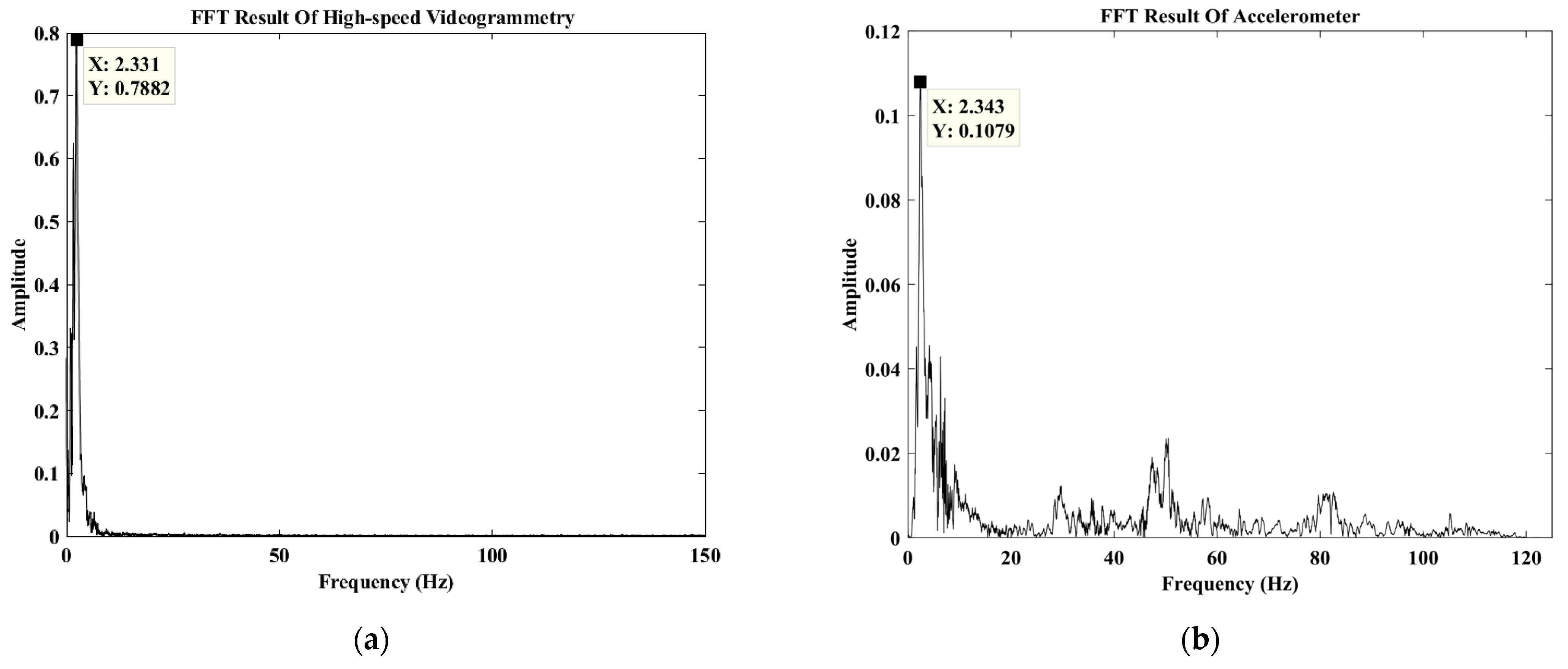

For measurement of 3D spatial coordinates, sub-millimeter accuracy can be achieved using the proposed high-speed videogrammetric-based method, with the RMSE being 0.32 mm, 0.7 mm and 0.06 mm in the X, Y and Z direction, respectively. The results from both the proposed videogrammetric method and the Optotrak Certus indicated that the proposed high-speed videogrammetric-based method had the advantage of a more extensive measurement range and rich detail of the results in the case of the same accuracy. The results from both the proposed method and the accelerometer method showed a consistent trend in acceleration and a nearly consistent natural frequency. All the results indicated that the proposed high-speed videogrammetric-based method had high accuracy and was capable of analyzing the seismic performances of the spherical reticulated shell structure.

With the advantages of non-contacted, high-frequency and 3D measurement, the proposed high-speed videogrammetric measurement method can acquire the accurate 3D dynamic response of the monitored objects. Thus, the method may be applied in more areas. For example, in the field of civil engineering, it can be used for large-scale shaking table tests, structural progressive collapse tests, etc. In the military field, it can be applied to weapons ballistic tests, etc. In the medical field, it can be applied to observe the behavioral characteristics of patients, etc. However, for the proposed high-speed videogrammetric measurement method, there are two important issues that need to be investigated. One is that it should identify and match the targets in the first image automatically in order to improve the efficiency of the obtained image sequences. The other is that the robustness of the target-tracking algorithm should be further studied to improve the stability of the obscured targets during image sequence processing.