Study on the Performance of Personal Heating in Extremely Cold Environments Using a Thermal Manikin

Abstract

1. Introduction

1.1. Background

1.2. Personal Heating Measures for Cold Protection in Cold Environments

1.3. Influence of Environmental Parameters on the Cold Protective Performance of Garments

1.4. Objectives

- To investigate and quantify the effects of Ta and Va on CPP and HP;

- To analyze the effect of the new material aerogel on the CPP and HP of EHG;

- To calculate and explore the CP of different personal heating measures.

2. Methods

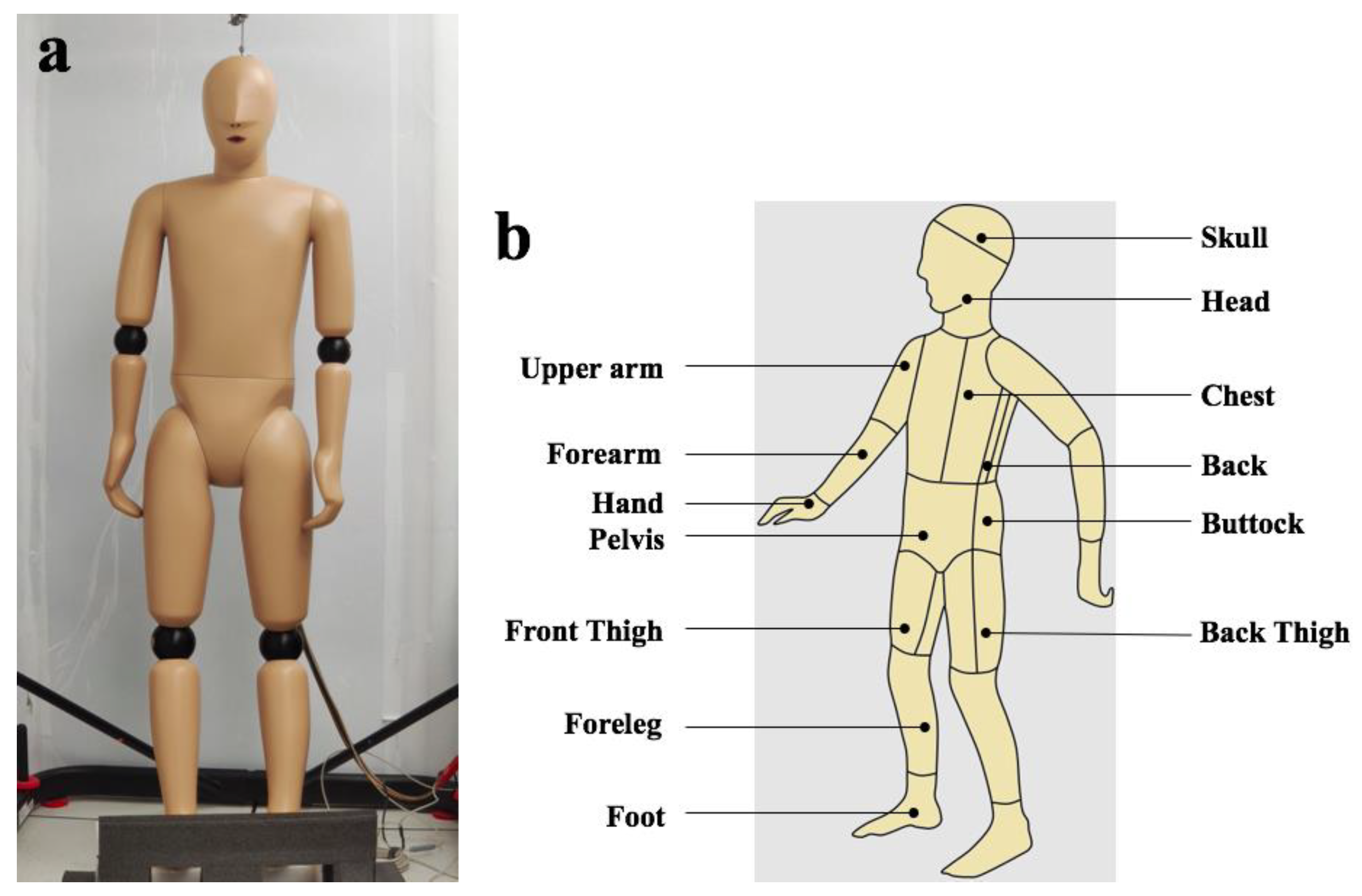

2.1. Thermal Manikin

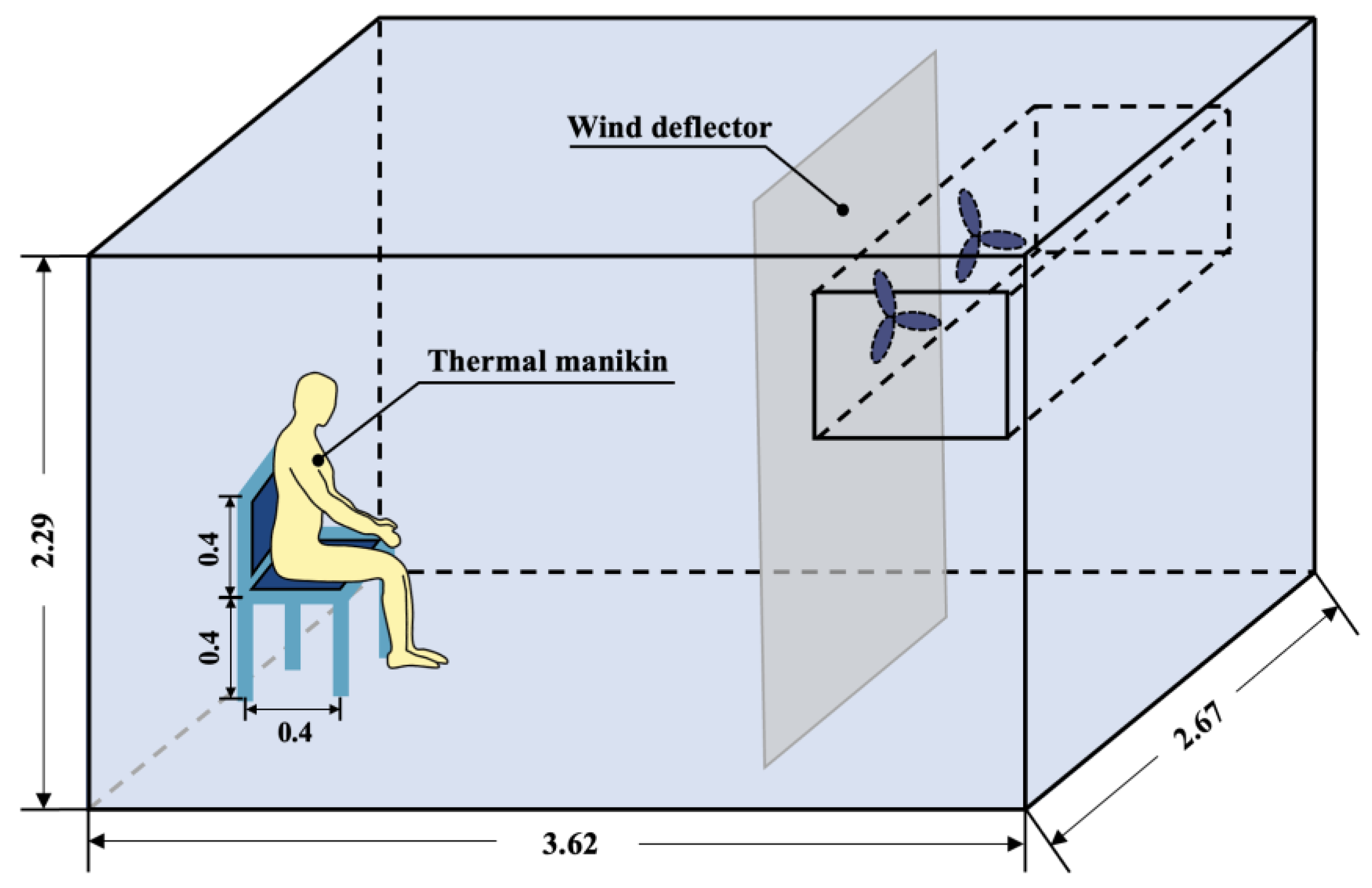

2.2. Experimental Site and Test Conditions

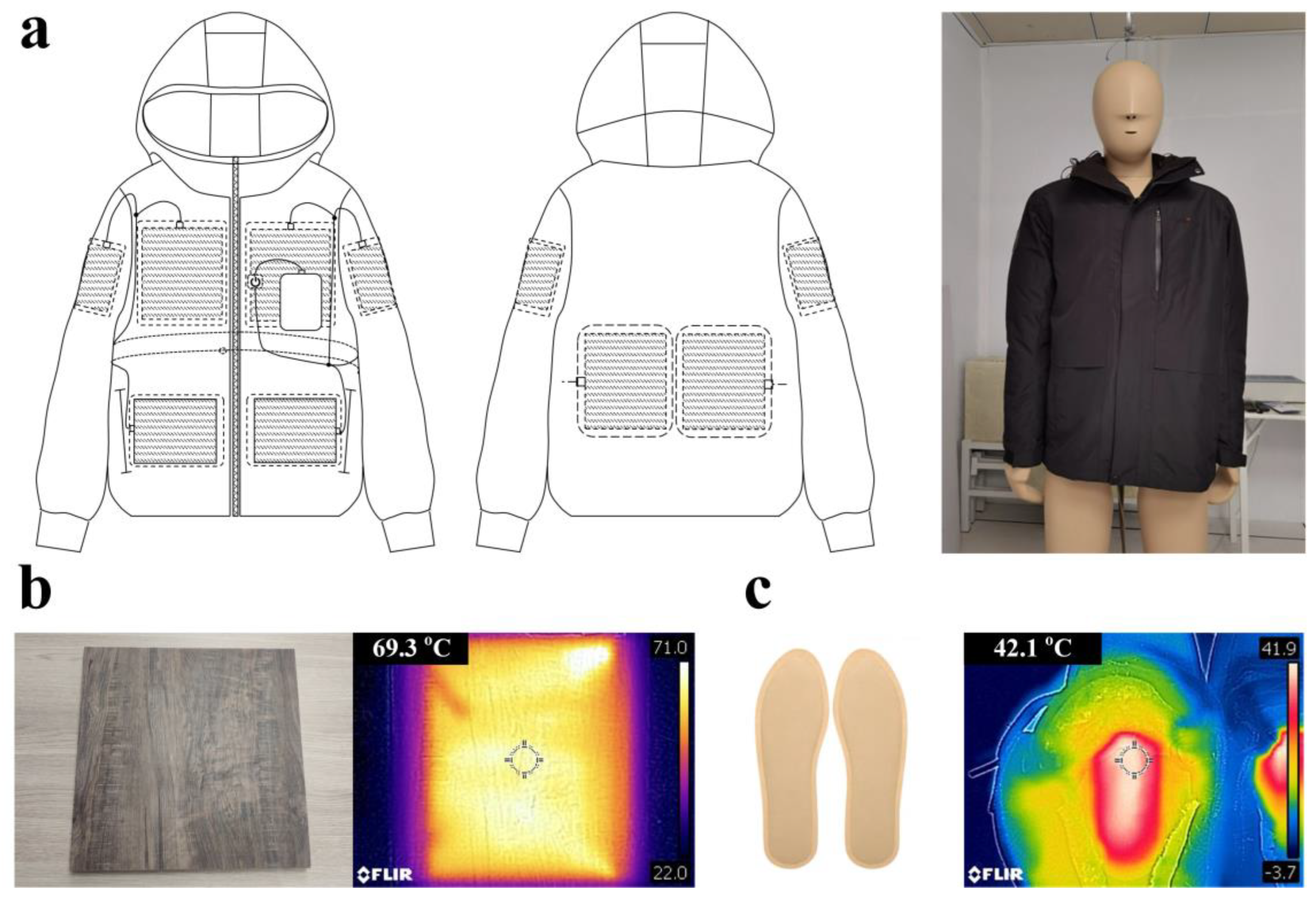

2.3. Development of Personal Heating Devices

- (a)

- The EHG (Figure 3a) was developed for this experiment, which included a jacket with aerogel insulation and graphene heating. The jacket was made up of four layers of materials, namely, windproof and waterproof materials, an aerogel insulation layer, a graphene flexible heating layer, and a fleece fabric inner layer. It well combines passive insulation and active heating in the material arrangement. The eight flexible graphene sheets were distributed in the position of the chest, abdomen, back, and upper arms for local heating. The size of each piece of graphene sheet was 10 × 15 cm for the chest and abdomen and 10 × 20 cm for the back and upper arms. The heating power of graphene sheets could be adjusted in three gears through the control button in the pocket to meet the dynamic individual heating demands. In low, medium, and high gear, the surface temperatures of graphene sheets were 35–40 °C, 40–45 °C, and 45–50 °C, respectively (measured at Ta of 20 °C), while the heating powers were 90 W/m2, 135 W/m2, 180 W/m2 correspondingly. In this experiment, the high gear was used to heat the thermal manikin locally, and the heating power was 25.2 W. The aerogel insulation layer has excellent thermal insulation properties;

- (b)

- The EHS (Figure 3b) provided heating to the buttocks of sedentary people. The heating seat was characterized by heating rapidly and uniformly. The maximum heating power was 50 W, and the maximum surface temperature could reach about 70 °C (measured at an ambient temperature of 20 °C). The other surface of the heating seat was well insulated to ensure one-way heat transmission and reduce heat loss to the environment;

- (c)

- The chemically heated insole (CHI) (Figure 3c) was similarly designed to offset fast cooling of the feet, a major both locally and whole-body in cold environments. The insole used the heat generated by the oxidation reaction between the iron powder filled inside and the air to warm the foot. The surface temperature of the heated insole can reach 42 °C, and adequate operating time was fully ensured for a single experiment.

2.4. Experiment Conditions

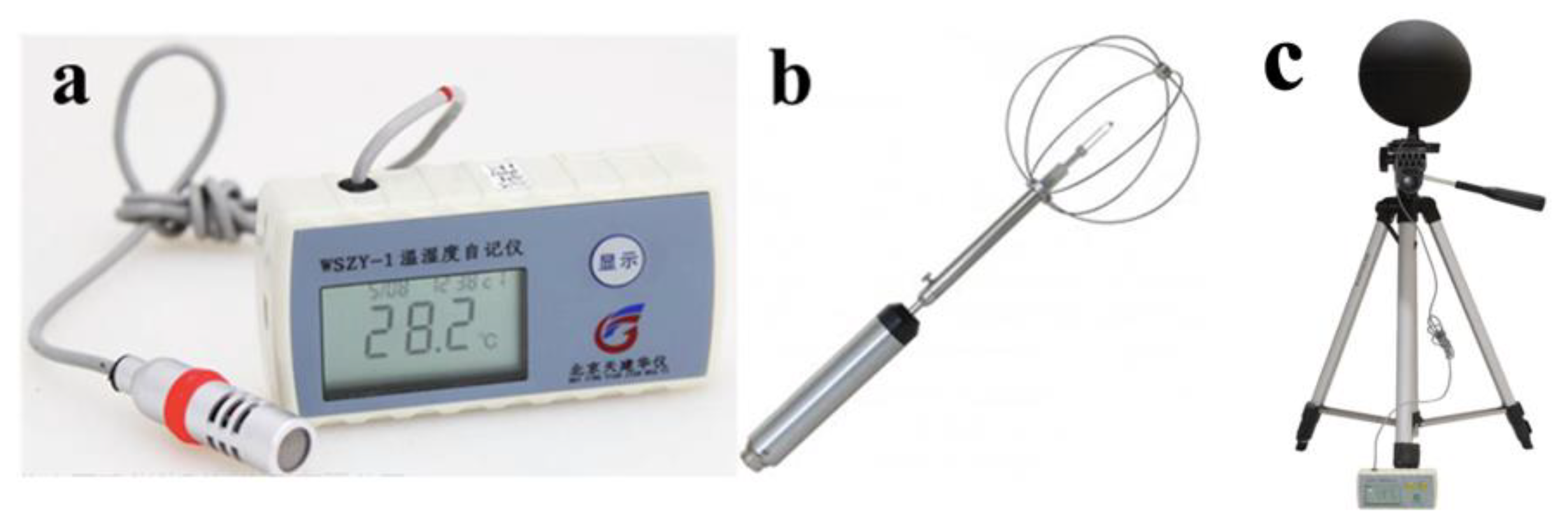

2.5. Environmental Parameters Measurement

2.6. Evaluation Indicators for Cold Protection and Heating Performance

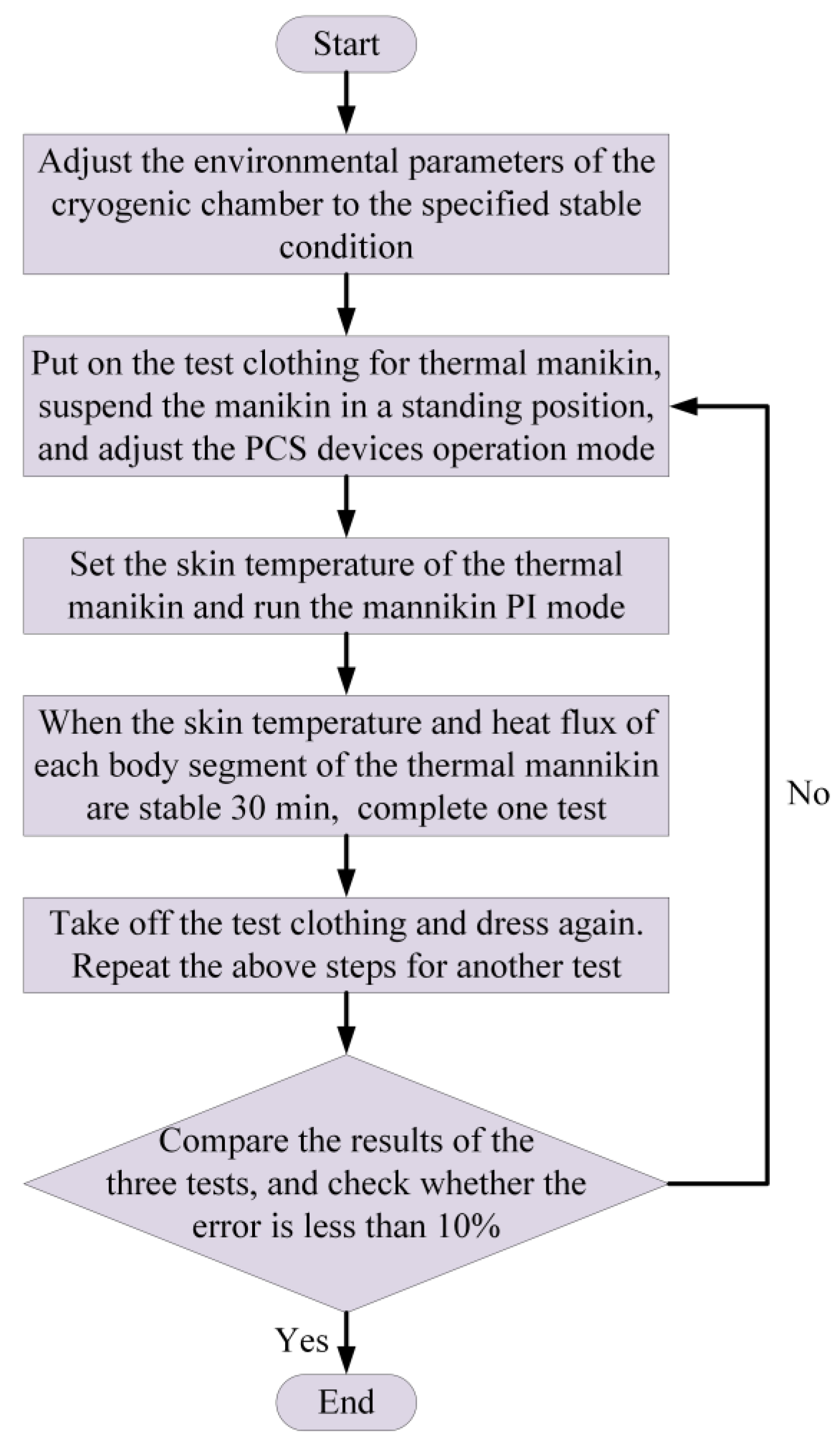

2.7. Test Procedure

2.8. Data Analysis

3. Results

3.1. Environmental Parameters

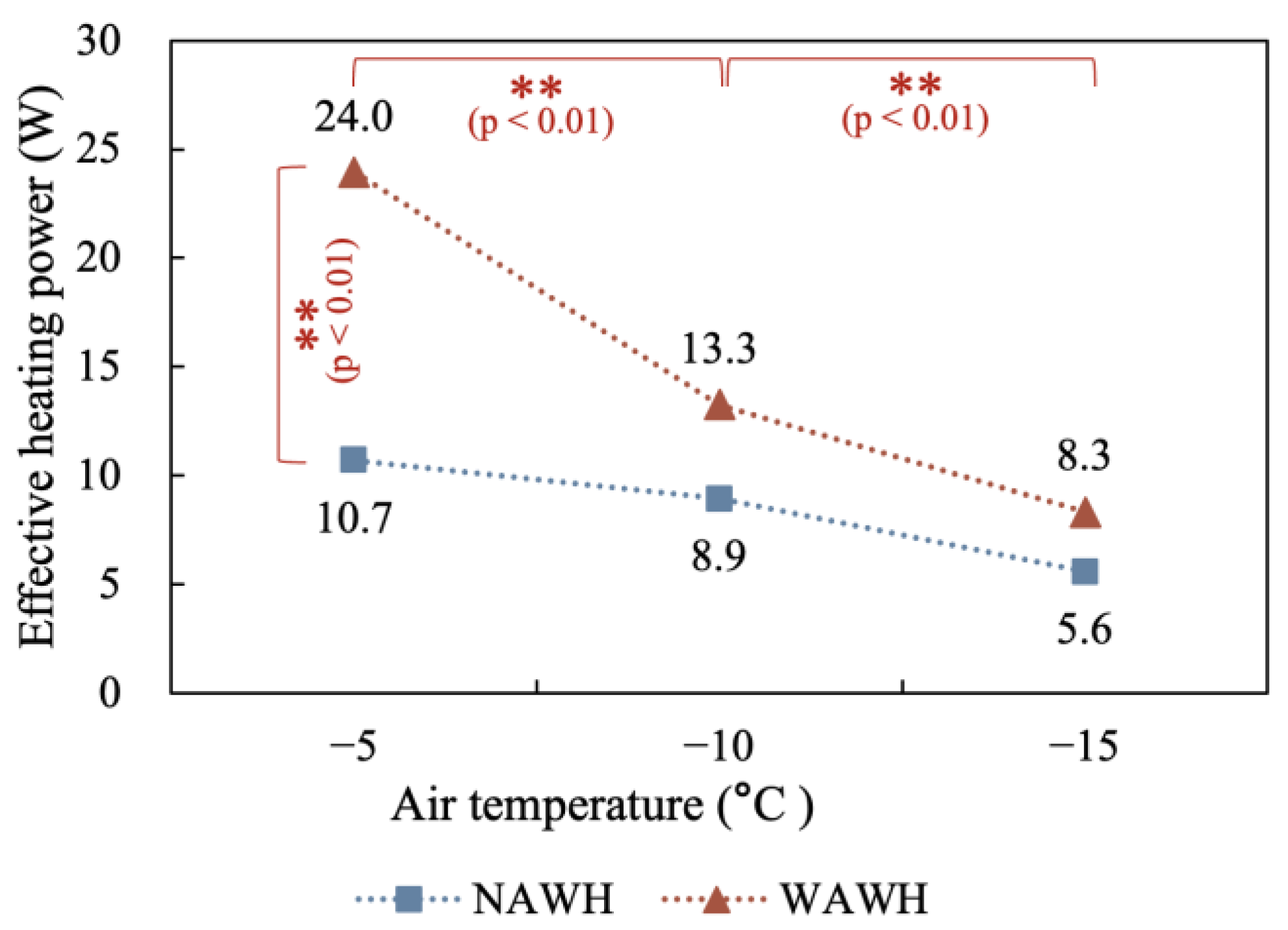

3.2. The Cold Protection and Heating Performance of Garments at Different Ta

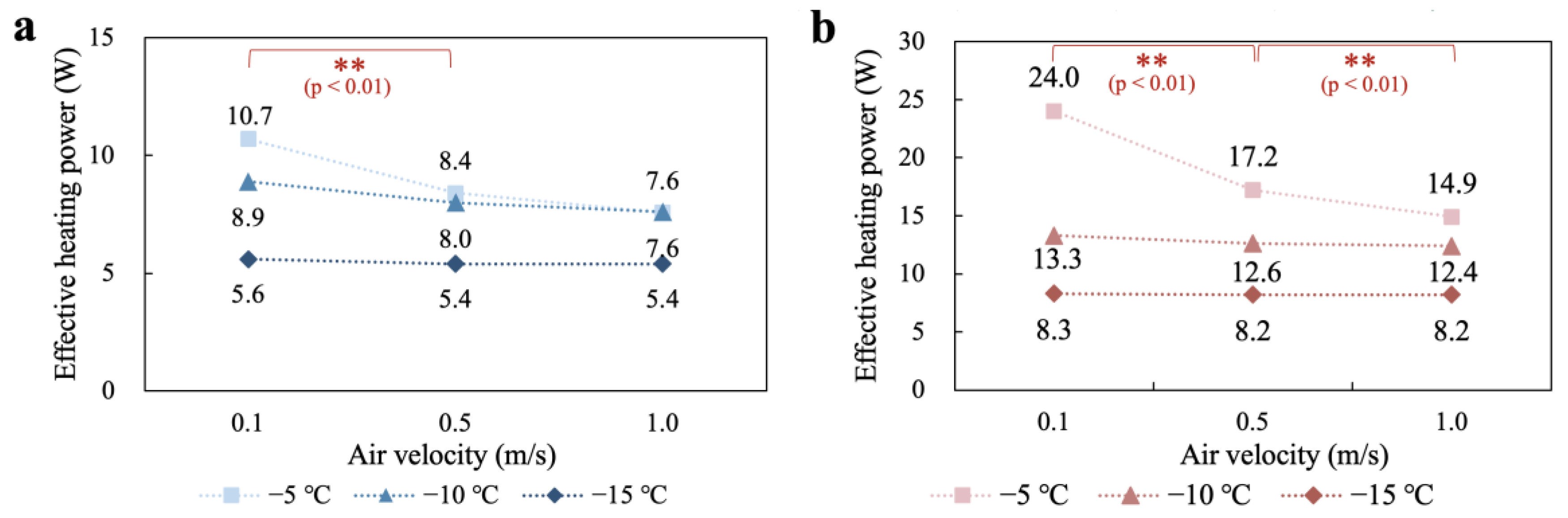

3.3. The Cold Protection and Heating Performance of Garments at Different Va

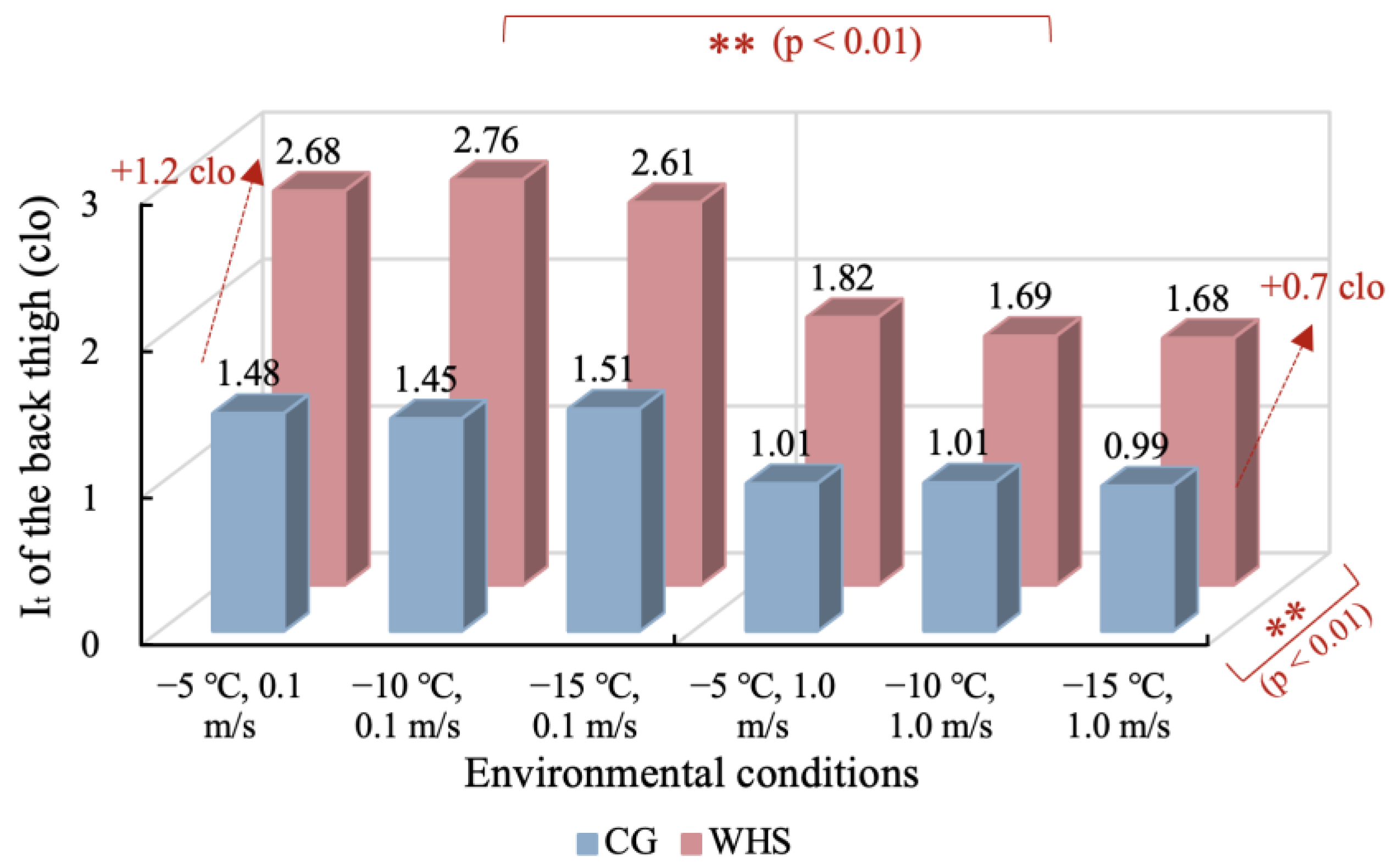

3.4. Evaluation of the Heating Performance of the Heated Seat under Different Environmental Conditions

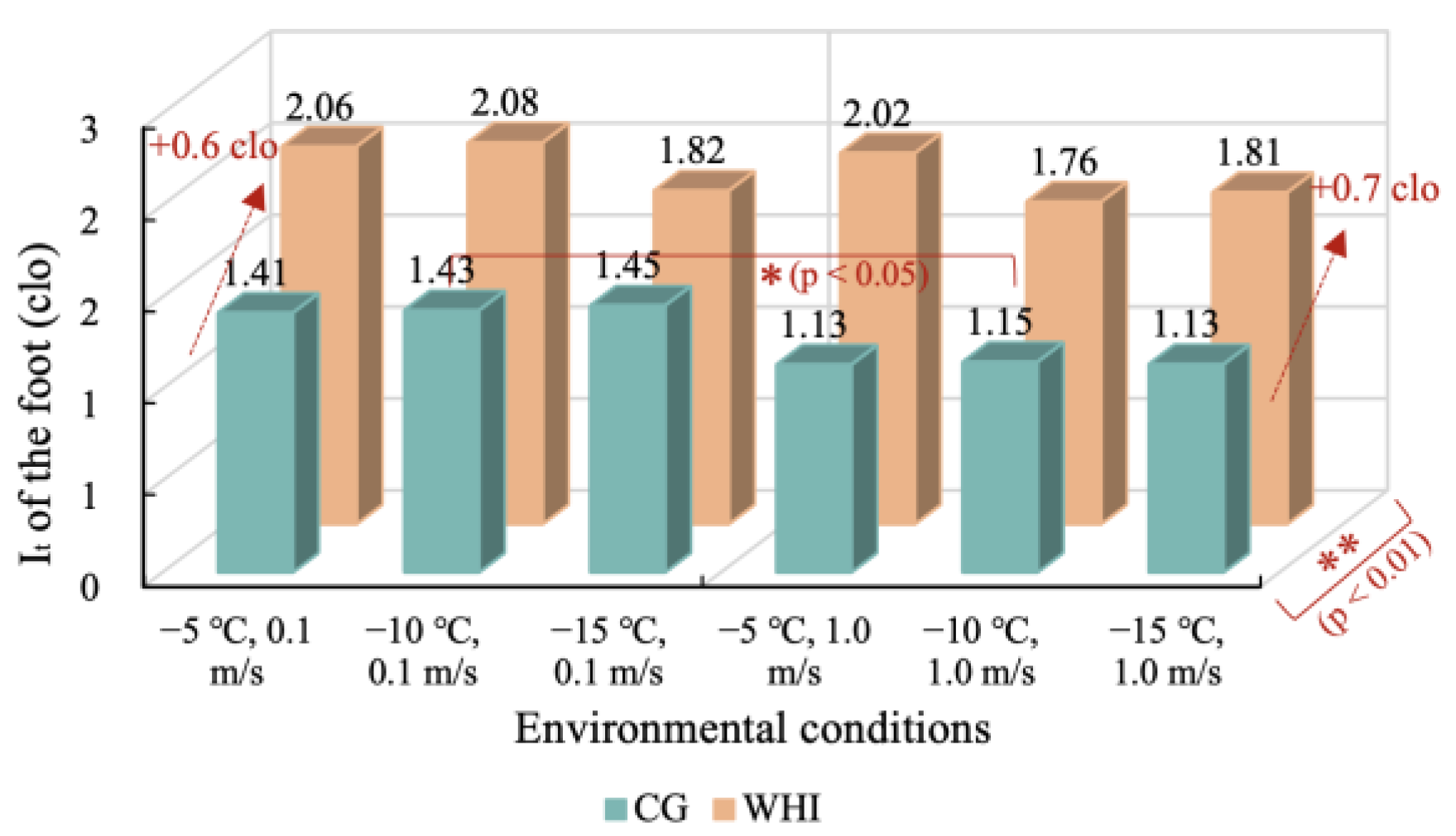

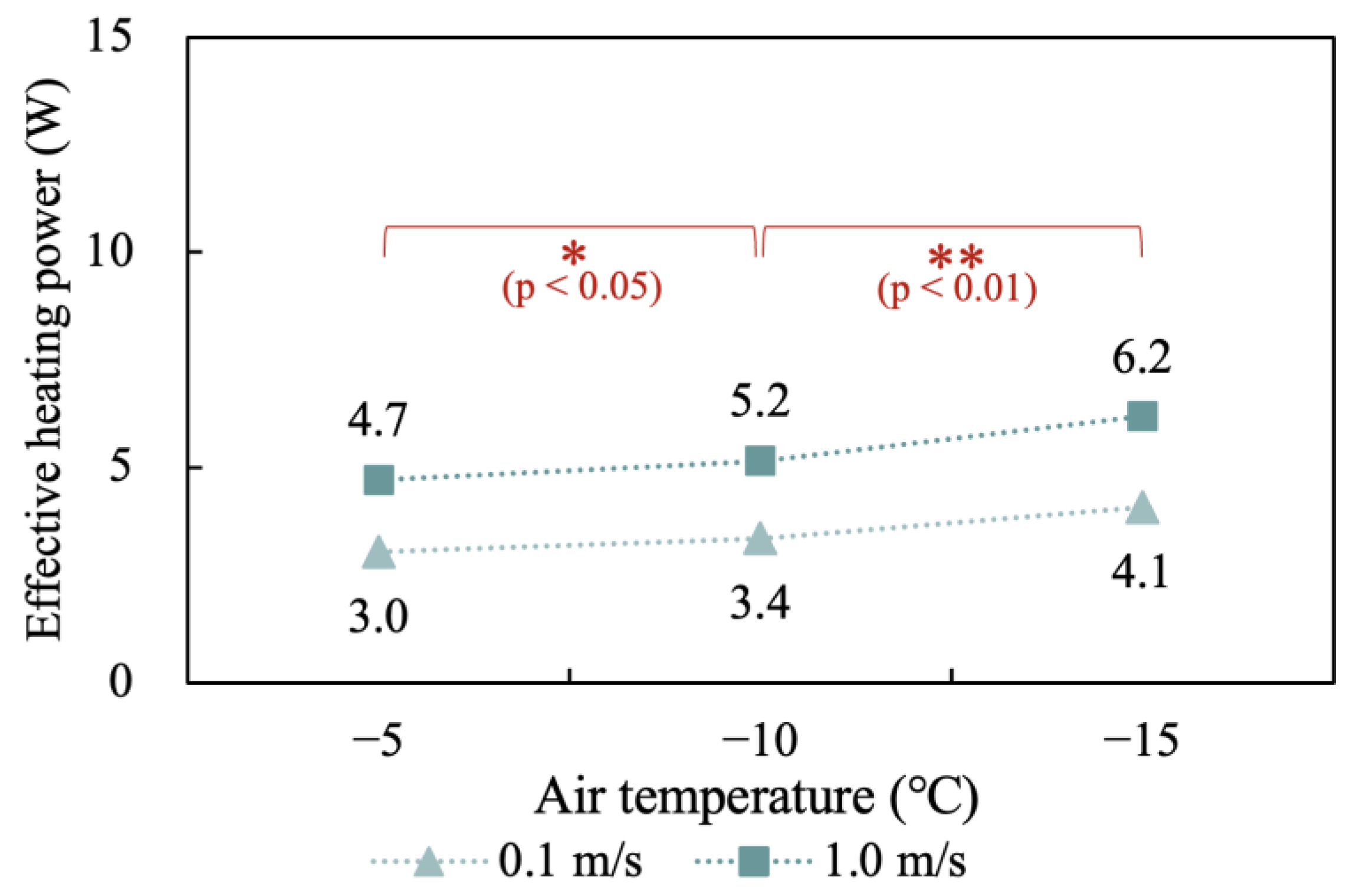

3.5. Evaluation of Insole Heating Performance under Different Environmental Conditions

4. Discussion

4.1. Influence of Environmental Parameters on Local Heating Performance

4.2. Corrective Power of Personal Heating Measures

4.3. Limitations and Future Work

5. Conclusions

- (1)

- The effects of environmental parameters on basic CPP were analyzed. Ta had no significant effect on clothing insulation. However, elevated Va significantly decreased the clothing insulation. When Va was elevated from 0 m/s to 1 m/s, the clothing insulation of typical winter garments worn by the thermal manikin decreased from 0.6 to 0.9 clo;

- (2)

- The effects of environmental parameters on the HP of different personal heating measures were analyzed. Decreased Ta and elevated Va reduced the Peff and of electrical heating measures. was no longer affected by variations in Ta and Va when dropped to a certain level (EHS: about 25%). In addition, the effect of Va is related to Ta. However, the effect of Va and Ta combination on the Peff and is challenging to clarify, and further studies on this need to be conducted in the future. For the chemical heating measure, HP instead increased with the decreased Ta and elevated Va;

- (3)

- The improvement of the new material aerogel on the CPP and HP of EHG was obtained. Icl of WANH increased by 0.2 clo, equal to the improvement of NAWH, indicating the aerogel layer provided good thermal insulation. In addition, the aerogel layer significantly improved the HP of EHG. The Peff and of WAWH were more than twice that of NAWH in a −5 °C windless environment. of WAWH was as high as 95%. However, the enhancement effect of aerogel insulation decreased with decreased Ta and elevated Va;

- (4)

- The CP values of different personal heating measures were calculated and investigated. In the nine environmental conditions in this study, the CP of EHG (WAWH), EHG (NAWH), EHS, and CHI could reach 5.8–8.4 K, 3.2–4.3 K, 1.9–3.9 K, and 0.3–1.1 K, respectively. However, the energy efficiency ratio of thermal comfort of CHI (the improvement of thermal comfort/energy consumption) is substantial, although the CP value of CHI was the lowest. Therefore, the actual application effect of personal heating measures should be further studied by human subject experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ai | Surface area of segment i (m2) |

| CHI | Chemically heated insole |

| CP | Corrective power (K) |

| CPP | Cold protective performance |

| EHG | Electrically heated garment |

| EHS | Electrically heated seat |

| EHT | Equivalent homogenous temperature (°C) |

| EHV | Electrically heated vest |

| fcl | Area factor |

| fi | Ratio of the surface area of segment i to the total surface area |

| HP | Heating performance |

| Hi | Heat flow of segment i (W/m2) |

| Hin | Input heating power (W/m2) |

| Ia | Boundary insulation (clo) |

| It | Total insulation (clo) |

| It, i | Local total insulation of segment i (clo) |

| Icl | Effective clothing insulation (clo) |

| K | Proportional constant |

| Pi | Heating power of segment i (W/m2) |

| Peff | Effective heating power (W/m2) |

| t | Time (s) |

| Ta | Air temperature (°C) |

| Tg | Globe temperature (°C) |

| Tmr | Mean radiant temperature (°C) |

| Tin | Internal temperature (°C) |

| Tskin | Skin temperature (°C) |

| Tskin, i | Skin temperature of segment i (°C) |

| Tset | Setting skin temperature (°C) |

| Va | Air velocity (m/s) |

| Heat conversion efficiency | |

| Heating efficiency | |

| Integral constant |

References

- Pinkerton, K.E.; Felt, E.; Riden, H.E. Extreme Weather Resulting from Global Warming is an Emerging Threat to Farmworker Health and Safety. J. Agric. Saf. Health 2019, 25, 189–190. [Google Scholar] [CrossRef] [PubMed]

- Pörtner, H.-O.; Roberts, D.C. Climate Change 2022: Impacts, Adaptation and Vulnerability; IPCC: Geneva, Switzerland, 2022.

- Patil, P. Effects of a cold-water stressor on psychomotor and cognitive functioning in humans. Physiol. Behav. 1995, 58, 1281–1286. [Google Scholar] [CrossRef]

- Anttonen, H.; Virokannas, H. Assessment of cold stress in outdoor work. Arct. Med. Res. 1994, 53, 40–48. [Google Scholar]

- Taylor, L.; Watkins, S.L.; Marshall, H.; Dascombe, B.J.; Foster, J. The Impact of Different Environmental Conditions on Cognitive Function: A Focused Review. Front. Physiol. 2016, 6, 372. [Google Scholar] [CrossRef] [PubMed]

- Van Marken Lichtenbelt, W.D.; Schrauwen, P. Implications of nonshivering thermogenesis for energy balance regulation in humans. Am. J. Physiol. Regul. Integr. Comp. Physiol. 2011, 301, R285–R296. [Google Scholar] [CrossRef]

- Tansey, E.A.; Johnson, C.D. Recent advances in thermoregulation. Adv. Physiol. Educ. 2015, 39, 139–148. [Google Scholar] [CrossRef]

- Deschênes, O.; Moretti, E. Extreme Weather Events, Mortality, and Migration. Rev. Econ. Stat. 2009, 91, 659–681. [Google Scholar] [CrossRef]

- Ma, N.; Lu, Y.; Xu, F.; Dai, H. Development and performance assessment of electrically heated gloves with smart temperature control function. Int. J. Occup. Saf. Ergon. 2020, 26, 46–54. [Google Scholar] [CrossRef]

- Iserson, K.V. Glove and mitten protection in extreme cold weather: An Antarctic study. Int. J. Circumpolar Health 2016, 75, 33564. [Google Scholar] [CrossRef]

- Brajkovic, D.; Ducharme, M.B.; Frim, J. Influence of localized auxiliary heating on hand comfort during cold exposure. J. Appl. Physiol. 1998, 85, 2054–2065. [Google Scholar] [CrossRef]

- Streets, D.F. Cold Chamber Trial of Electrically Heated Gloves, Mitts and Insoles for Rapier Operators and AFV Crewmen; Report APRE 18/74; Army Personnel Research Establishment: Farnborough, UK, 1974.

- Rapaport, S.I.; Fetcher, E.S.; Shaub, H.G.; Hall, J.F. Control of Blood Flow to the Extremities at Low Ambient Temperatures. J. Appl. Physiol. 1949, 2, 61–71. [Google Scholar] [CrossRef]

- Ducharme, M.B.; Brajkovic, D.; Frim, J. The effect of direct and indirect hand heating on finger blood flow and dexterity during cold exposure. J. Therm. Biol. 1999, 24, 391–396. [Google Scholar] [CrossRef]

- Brajkovic, D.; Ducharme, M.B. Finger dexterity, skin temperature, and blood flow during auxiliary heating in the cold. J. Appl. Physiol. 2003, 95, 758–770. [Google Scholar] [CrossRef]

- Zhang, H.; Arens, E.; Zhai, Y. A review of the corrective power of personal comfort systems in non-neutral ambient environments. Build. Environ. 2015, 91, 15–41. [Google Scholar] [CrossRef]

- Li, D. The relationship between thermal insulation value of clothing and assembled clothing. J. Text. Res. 1997, 18, 23–25. [Google Scholar] [CrossRef]

- Havenith, G.; Nilsson, H.O. Correction of clothing insulation for movement and wind effects, a meta-analysis. Eur. J. Appl. Physiol. 2004, 92, 636–640. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.V.M.; Gaspar, A.R.; Francisco, S.C.; Quintela, D.A. Convective heat transfer from a nude body under calm conditions: Assessment of the effects of walking with a thermal manikin. Int. J. Biometeorol. 2012, 56, 319–332. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Lee, H. Evaluation of an Electrically Heated Vest (EHV) Using a Thermal Manikin in Cold Environments. Ann. Occup. Hyg. 2009, 54, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Gao, C.; Holmér, I. Effects of Air Velocity and Clothing Combination on Heating Efficiency of an Electrically Heated Vest (EHV): A Pilot Study. J. Occup. Environ. Hyg. 2010, 7, 501–505. [Google Scholar] [CrossRef]

- Song, W.; Lai, D.; Wang, F. Evaluating the cold protective performance (CPP) of an electrically heated garment (EHG) and a chemically heated garment (CHG) in cold environments. Fibers Polym. 2015, 16, 2689–2697. [Google Scholar] [CrossRef]

- Luo, M.; Arens, E.; Zhang, H.; Ghahramani, A.; Wang, Z. Thermal comfort evaluated for combinations of energy-efficient personal heating and cooling devices. Build. Environ. 2018, 143, 206–216. [Google Scholar] [CrossRef]

- Tang, Y.; Su, Z.; Yu, H.; Zhang, K.; Li, C.; Ye, H. A database of clothing overall and local insulation and prediction models for estimating ensembles’ insulation. Build. Environ. 2022, 207, 108418. [Google Scholar] [CrossRef]

- ISO 9920:2007; Ergonomics of the Thermal Environment—Estimation of the Thermal Insulation and Evaporation Resistance of a Clothing Ensemble. International Organization for Standardization: Geneva, Switzerland, 2007.

- ASTM F1291-16; Standard Test Method for Measuring the Thermal Insulation of Clothing Using Heated Manikin. ASTM International: West Conshohocken, PA, USA, 2016.

- Xiong, J.; Lian, Z.; Zhang, H. Physiological response to typical temperature step-changes in winter of China. Energy Build. 2017, 138, 687–694. [Google Scholar] [CrossRef]

- Sullivan-Kwantes, W.; Haman, F.; Kingma, B.R.M.; Martini, S.; Gautier-Wong, E.; Chen, K.Y.; Friedl, K.E. Human performance research for military operations in extreme cold environments. J. Sci. Med. Sport 2021, 24, 954–962. [Google Scholar] [CrossRef]

- Deng, Y.; Cao, B.; Yang, H.; Liu, B. Effects of local body heating on thermal comfort for audiences in open-air venues in 2022 Winter Olympics. Build. Environ. 2019, 165, 106363. [Google Scholar] [CrossRef]

- Deng, Y.; Cao, B.; Liu, B.; Zhu, Y. Effects of local heating on thermal comfort of standing people in extremely cold environments. Build. Environ. 2020, 185, 107256. [Google Scholar] [CrossRef]

- Luo, M.; Wang, Z.; Zhang, H.; Arens, E.; Filingeri, D.; Jin, L.; Ghahramani, A.; Chen, W.; He, Y.; Si, B. High-density thermal sensitivity maps of the human body. Build. Environ. 2020, 167, 106435. [Google Scholar] [CrossRef]

- Tanabe, S.; Kobayashi, K.; Nakano, J.; Ozeki, Y.; Konishi, M. Evaluation of thermal comfort using combined multi-node thermoregulation (65MN) and radiation models and computational fluid dynamics (CFD). Energy Build. 2002, 34, 637–646. [Google Scholar] [CrossRef]

- Shitzer, A.; Arens, E.; Zhang, H. Compilation of basal metabolic and blood perfusion rates in various multi-compartment, whole-body thermoregulation models. Int. J. Biometeorol. 2016, 60, 1051–1064. [Google Scholar] [CrossRef]

- Wu, J.; Sun, B.; Hu, Z.; Li, L.; Zhu, H. Physiological responses and thermal sensation during extremely cold exposure (−20 °C). Build. Environ. 2021, 206, 108338. [Google Scholar] [CrossRef]

| Body Segment | Area (m2) | Body Segment | Area (m2) |

|---|---|---|---|

| Left/Right (L/R). Foot | 0.053 | Scull | 0.054 |

| L/R. Foreleg | 0.115 | L/R. Hand | 0.0457 |

| L/R. front Thigh | 0.0957 | L/R. Forearm | 0.042 |

| L/R. back Thigh | 0.0957 | L/R. Upper arm | 0.083 |

| Pelvis | 0.046 | L/R. Side Chest | 0.0894 |

| Back side | 0.076 | L/R. Side Back | 0.0894 |

| Head | 0.08 | Total | 1.6738 |

| Condition Number | Clothing Combination/Improvement Measure |

|---|---|

| 1 | Without aerogel layer, without local heating (CG) |

| 2 | With aerogel layer, without local heating (WANH) |

| 3 | Without aerogel layer, with local heating (NAWH) |

| 4 | With aerogel layer, with local heating (WAWH) |

| 5 | With heated seat (WHS) |

| 6 | With heated insoles (WHI) |

| Garment Description | Materials | Size | Weight (g) |

|---|---|---|---|

| Hat | Acrylic fiber | – | 98 |

| Scarf | Acrylic fiber | – | 156 |

| Mask | Cotton | – | 12 |

| Long-sleeved sweater | Fabric: cotton Lining: polyester fiber | XL | 440 |

| Jacket | Fabric: polyester fiber Lining: fleece Filler: aerogel | XL | 1800 |

| Gloves | Fabric: poly urethane leather Lining: long fuzz | – | 202 |

| Warm pants | Fabric: cotton Lining: short fuzz | XL | 418 |

| Windproof trousers | Fabric: polyester fiber Lining: fleece | XL | 364 |

| Socks | Cotton | – | 32 |

| Cotton-padded shoes | Fabric: suede Lining: short fuzz | 42 (Europe) | 682 |

| Measured Parameter | Instrument | Specification | Manufacturer |

|---|---|---|---|

| Ta and RH | WSZY-1 thermometer | Accuracy: ±0.3 °C and ±3% Range: −40–100 °C and 0–100% | TianJianhuayi Co., Ltd., Beijing, China |

| Tg | HQZY-1 globe thermometer | Accuracy: ±0.3 °C Range: −20–80 °C | TianJianhuayi Co., Ltd., Beijing, China |

| v | Swema-03 Omnidirectional anemometer | Accuracy: ±0.04 m/s Range: 0.05–3.00 m/s | Swema AB Co., Ltd., Farsta, Sweden |

| Planned | Measured | ||||

|---|---|---|---|---|---|

| Ta (°C) | Va (m/s) | Ta (°C) | Va (m/s) | RH (%) | Tmr (°C) |

| −5 | 0.1 | −4.9 ± 0.2 | <0.10 | 70 ± 3 | −4.3 ± 0.2 |

| −10 | 0.5 | −10.1 ± 0.1 | 0.51 ± 0.05 | −9.4 ± 0.3 | |

| −15 | 1.0 | −14.6 ± 0.2 | 1.10 ± 0.10 | −14.3 ± 0.2 | |

| Ta (°C) | NAWH | WAWH |

|---|---|---|

| −5 | 42% | 95% |

| −10 | 35% | 52% |

| −15 | 22% | 33% |

| Va (m/s) | −5 °C | −10 °C | −15 °C | |||

|---|---|---|---|---|---|---|

| NAWH | WAWH | NAWH | WAWH | NAWH | WAWH | |

| 0 | 42% | 95% | 35% | 52% | 22% | 33% |

| 0.5 | 33% | 68% | 32% | 50% | 21% | 33% |

| 1 | 30% | 59% | 30% | 49% | 21% | 33% |

| Ta (°C) | Va (m/s) | |

|---|---|---|

| 0 | 1 | |

| −5 | 23% | 25% |

| −10 | 24% | 24% |

| −15 | 25% | 26% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Deng, Y.; Cao, B. Study on the Performance of Personal Heating in Extremely Cold Environments Using a Thermal Manikin. Buildings 2023, 13, 362. https://doi.org/10.3390/buildings13020362

Li S, Deng Y, Cao B. Study on the Performance of Personal Heating in Extremely Cold Environments Using a Thermal Manikin. Buildings. 2023; 13(2):362. https://doi.org/10.3390/buildings13020362

Chicago/Turabian StyleLi, Sishi, Yue Deng, and Bin Cao. 2023. "Study on the Performance of Personal Heating in Extremely Cold Environments Using a Thermal Manikin" Buildings 13, no. 2: 362. https://doi.org/10.3390/buildings13020362

APA StyleLi, S., Deng, Y., & Cao, B. (2023). Study on the Performance of Personal Heating in Extremely Cold Environments Using a Thermal Manikin. Buildings, 13(2), 362. https://doi.org/10.3390/buildings13020362