A Study on the Elastoplastic Stable Bearing Capacity of Double-Steering Prestressed Plate Columns

Abstract

1. Introduction

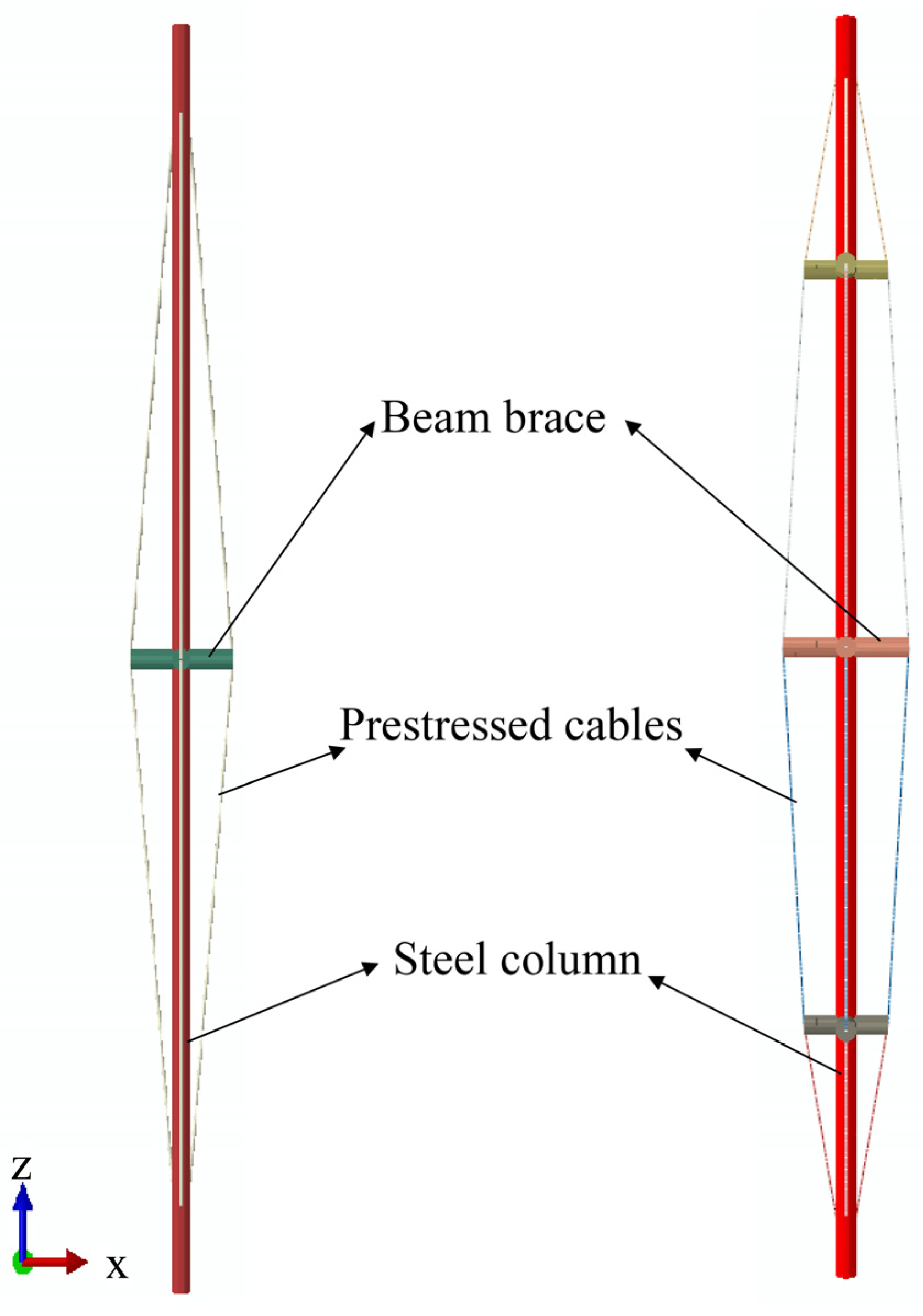

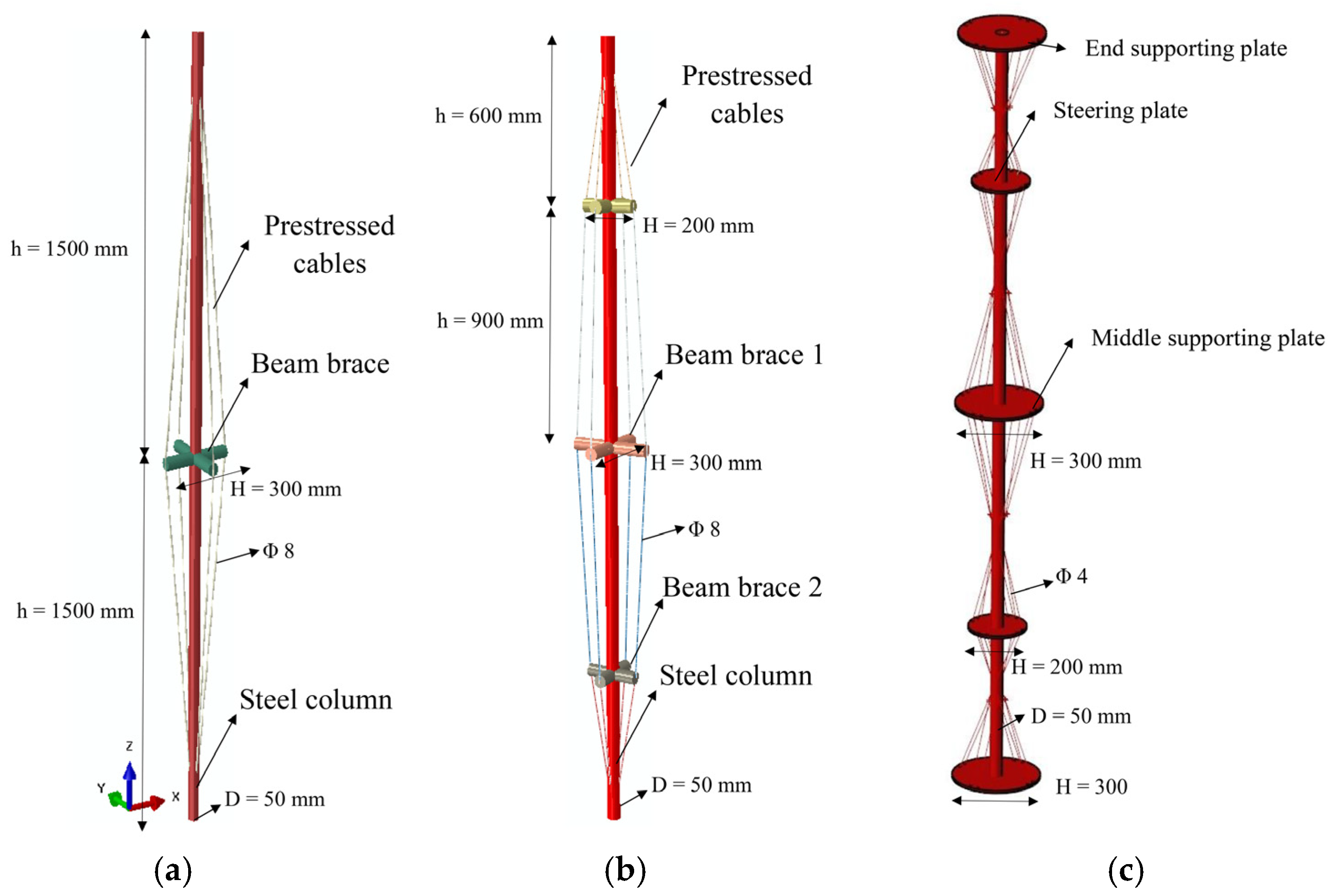

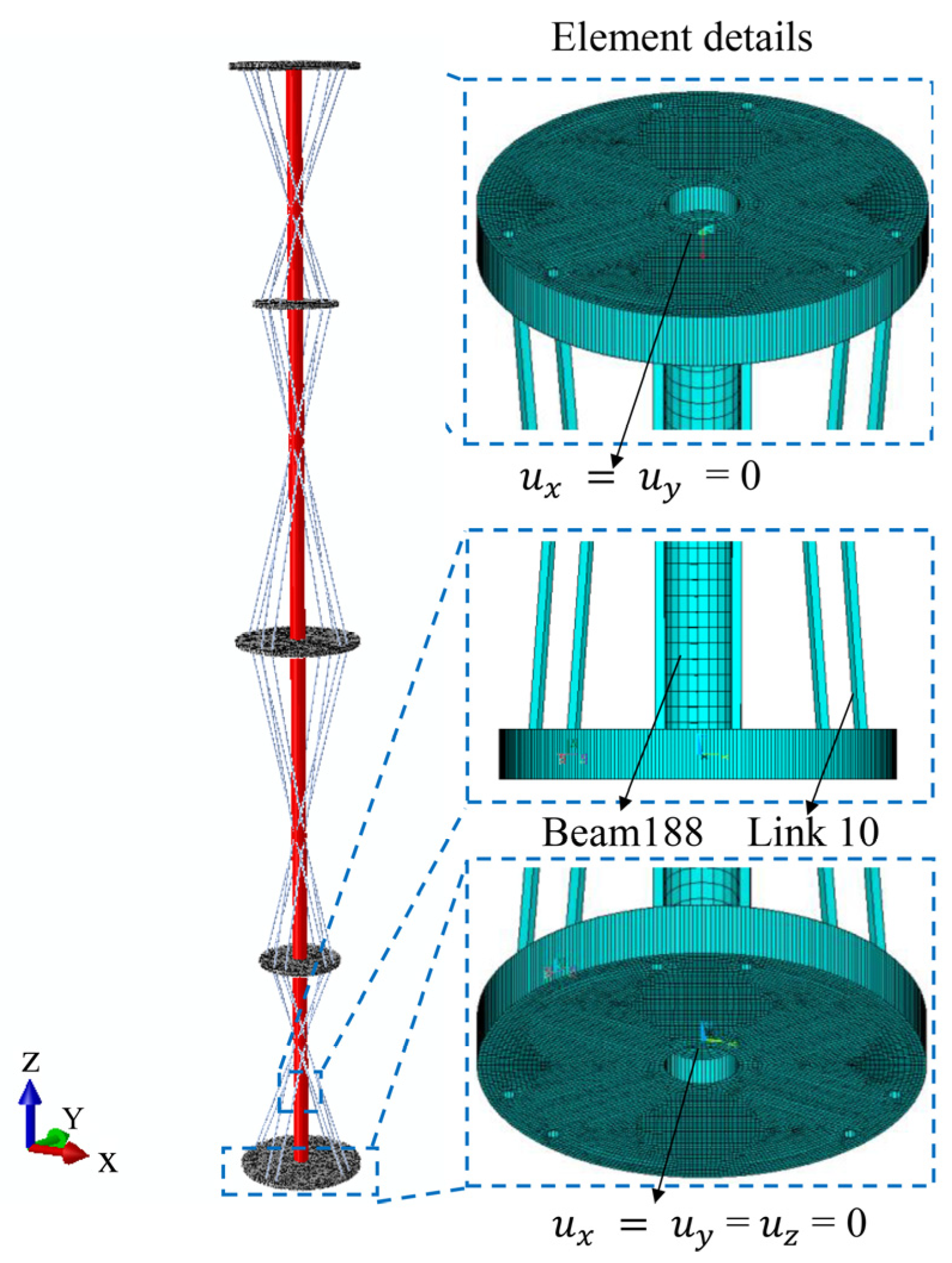

2. Calculation Model

2.1. Assumptions

- (1).

- The steel columns and transverse beam braces are simplified into beam 188 elements, with the effects of large deformation considered.

- (2).

- Prestressed cables are simplified to Link10 elements, considering only the influence of tensile stress.

- (3).

- The separable motion contact algorithm is employed for the contact between the cable and the plate brace.

- (4).

- A rigid connection is utilized between the steel column and the support brace.

2.2. Initial Prestress

2.3. Nonlinear Analysis Methods

2.4. Line-Surface Contact Algorithm

2.5. Calculation Model

3. Results and Discussion

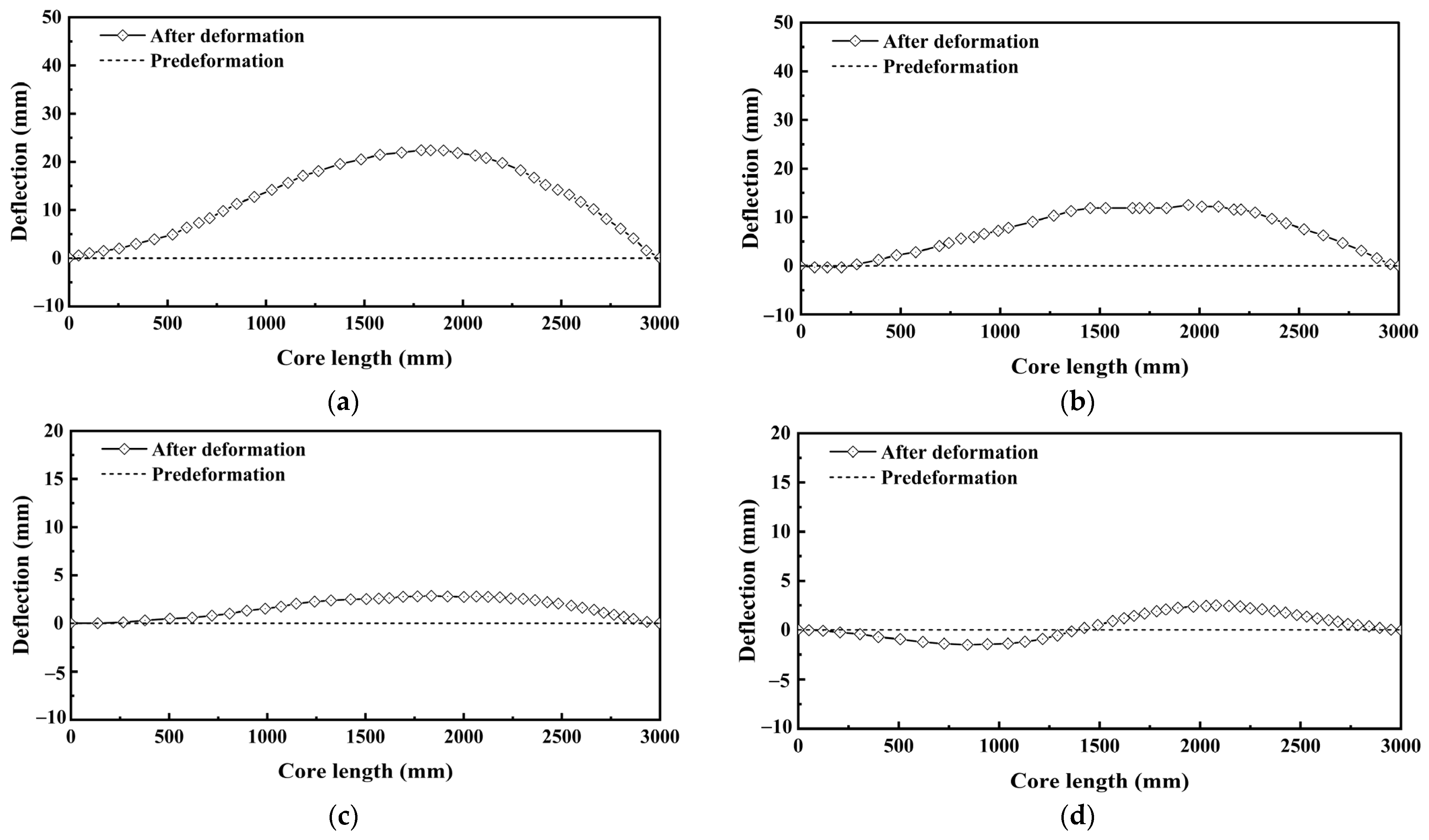

3.1. Elastoplastic Stable Bearing Capacity Analysis

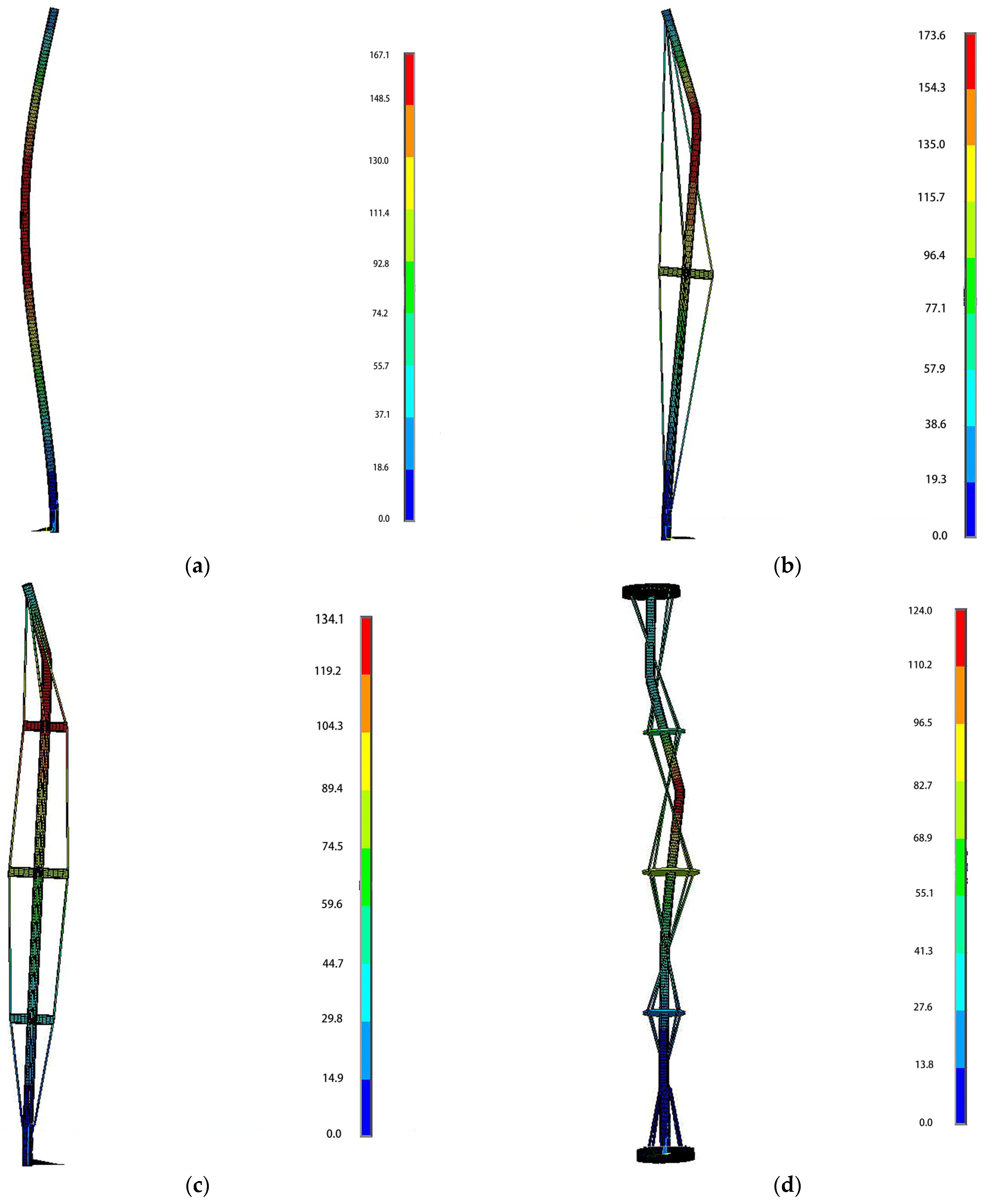

3.1.1. Plastic Deformation Stress Nephogram

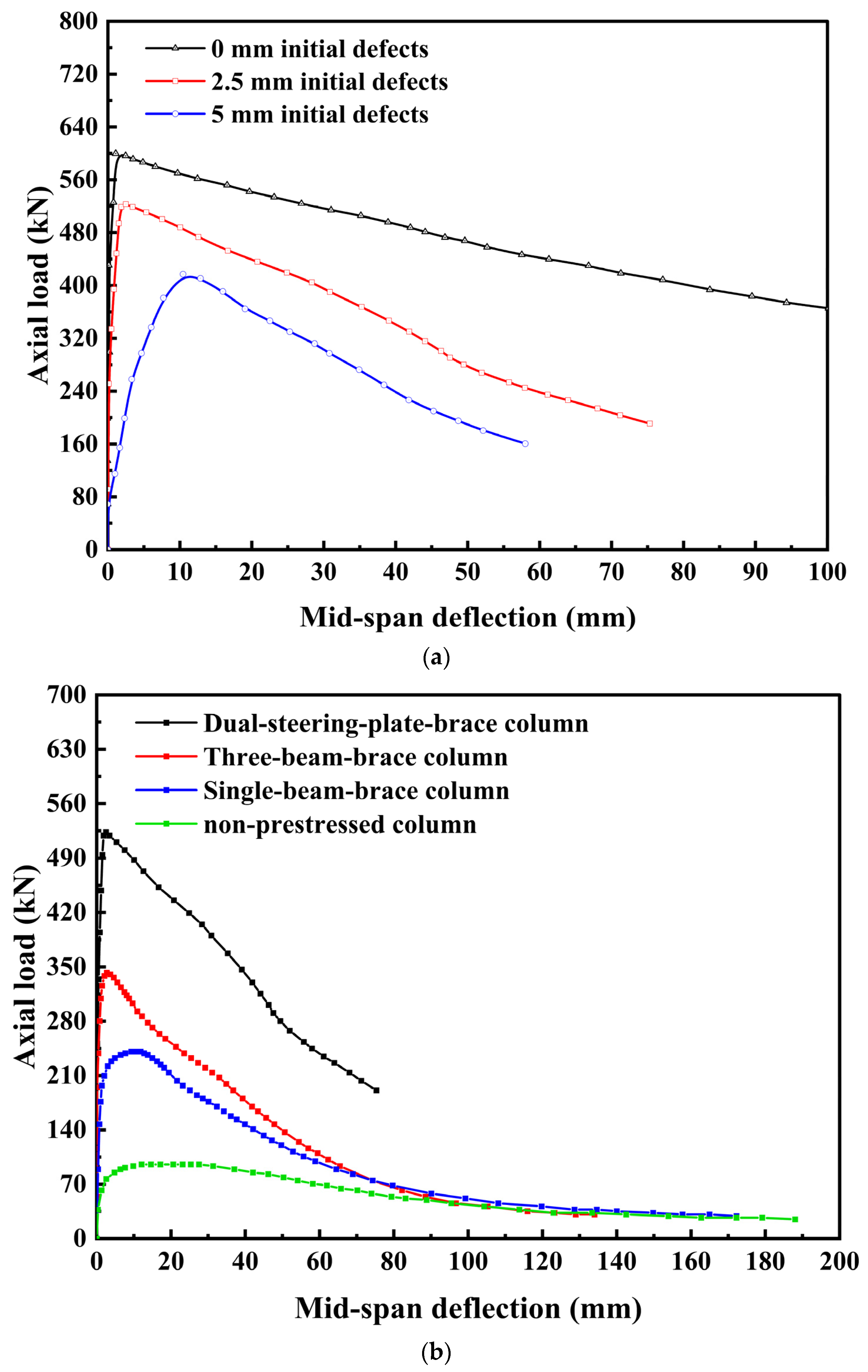

3.1.2. Relation between Axial Load and Mid Deflection

3.2. Parameter Optimization Analysis

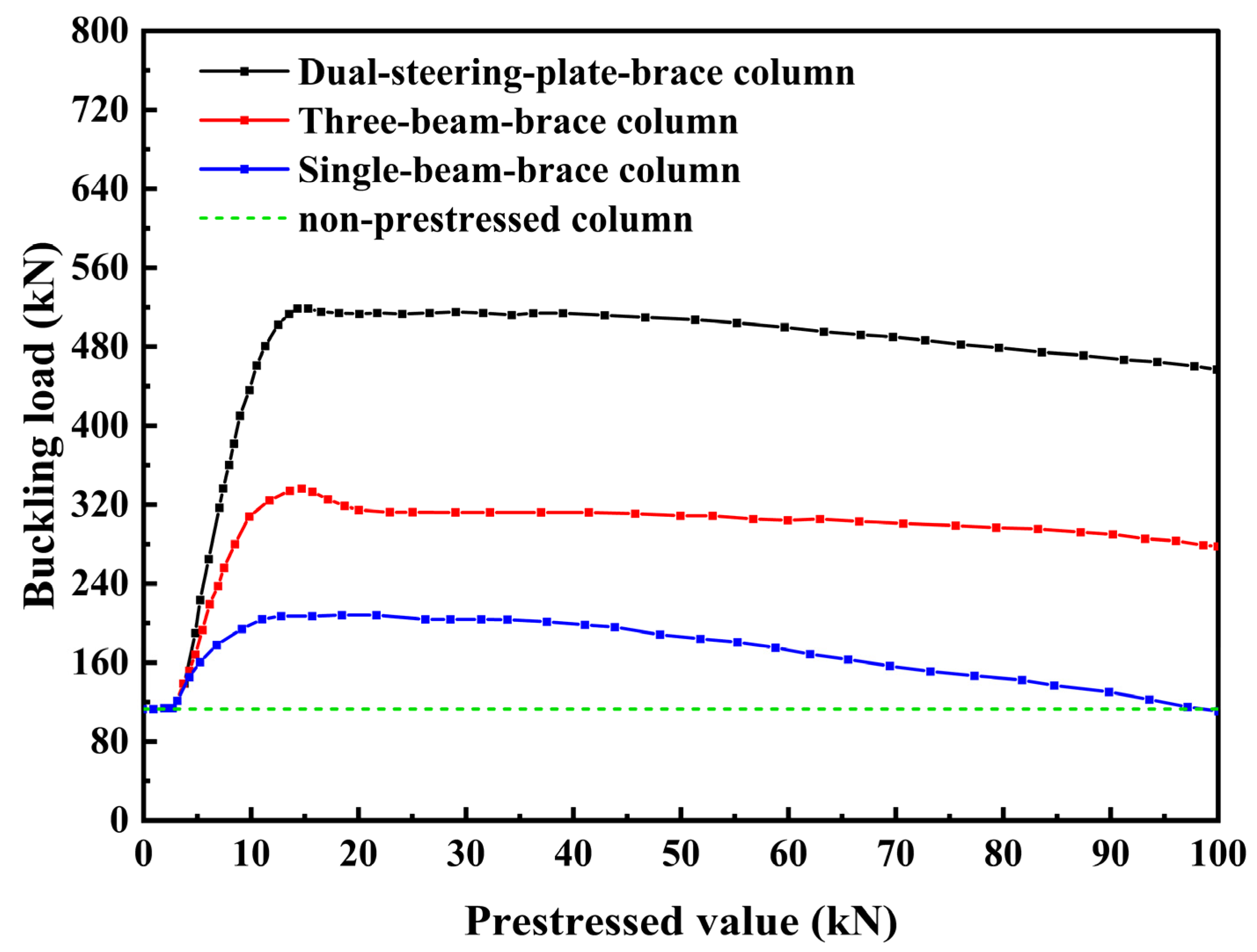

3.2.1. Effect of Prestress Value

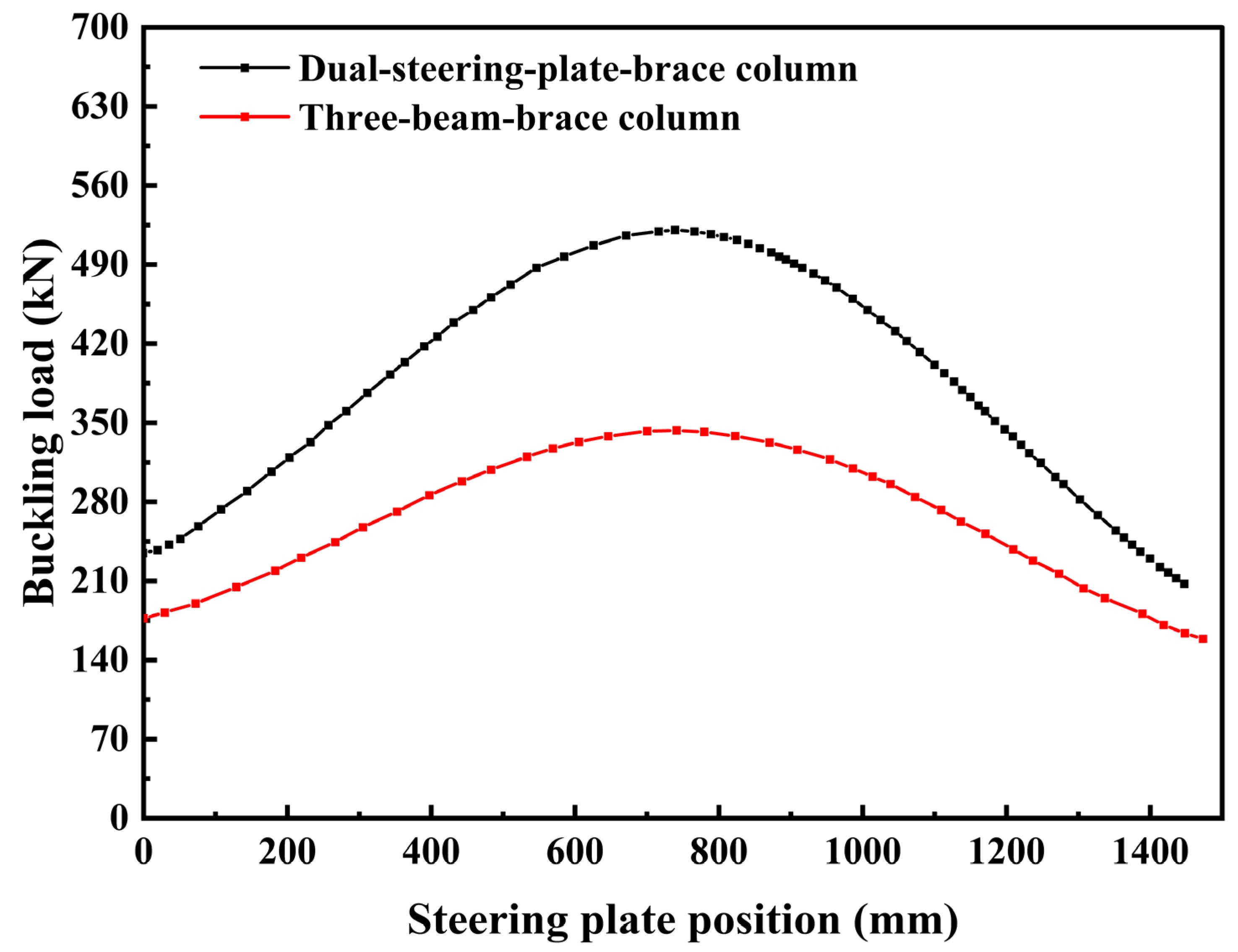

3.2.2. Effect of Steering Plate Position

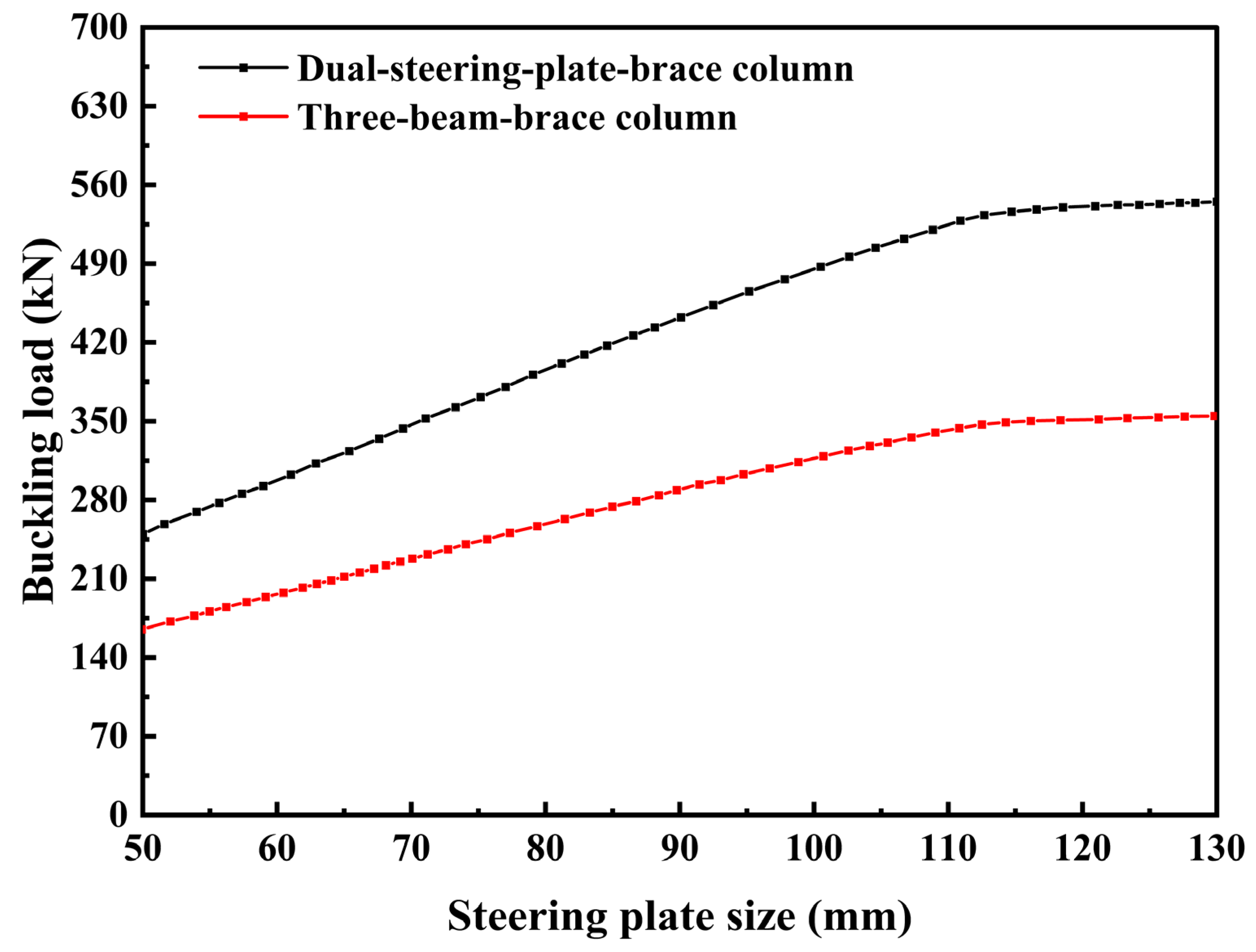

3.2.3. Effect of Steering Plate Size

4. Conclusions

- (1)

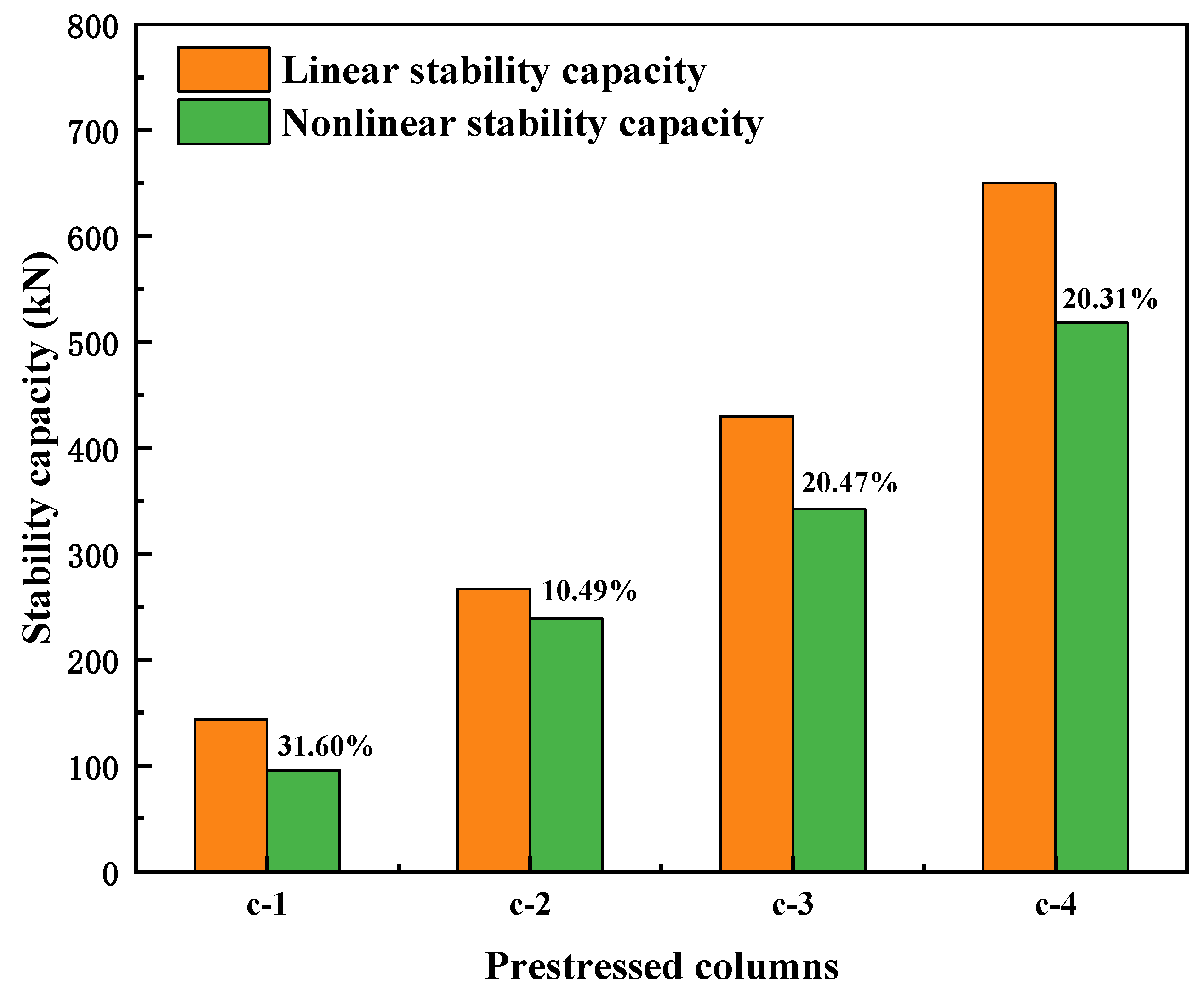

- The elastic stable bearing capacity of four types of pressure-bearing columns is analyzed. Owing to the rationality of the end constraints and the prestressed arrangement, the new type of prestressed column exhibits a 5.41-fold increase compared to ordinary non-prestressed columns. In contrast, traditional prestressed columns with identical parameters show only a 2.49–3.55-fold increase, underscoring the more reasonable stress distribution in the new type of prestressed column.

- (2)

- With relatively small prestress (<15 kN), the bearing capacity swiftly reaches its optimal value. The buckling load remains stable at between 15 and 45 kN of the prestressed value. Beyond 45 kN, the buckling load value gradually declines. At a prestressed value of 120 kN, the value nearly triples, while the buckling load value decreases by approximately 15.3%.

- (3)

- The steering plate’s position markedly influences the bearing capacity, with an optimal value observed. At a 750 mm height, the buckling load value peaks; as the steering plate’s height decreases from 750 to 50 mm, the maximum buckling load significantly diminishes. A reduction of 50 mm in the steering plate’s height results in a nearly twofold decrease in the buckling load.

- (4)

- The steering plate’s size profoundly affects the buckling load value of the dual steering brace column. With a 50 mm radius, the buckling load value is 245 kN. As the steering plate’s size increases, the buckling load value escalates, displaying a linear trend. When the distance between the center column and the steering hole reaches 115 mm, the buckling load value attains 518 kN and begins to stabilize. These research findings provide a theoretical foundation for the practical engineering application of a new type of prestressed column.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Suzuki, Y.; Lignos, D. Experimental evaluation of steel columns under seismic hazard-consistent collapse loading protocols. J. Struct. Eng. 2021, 147, 04021020. [Google Scholar] [CrossRef]

- Klasson, A.; Crocetti, R.; Hansson, E.F. Slender steel columns: How they are affected by imperfections and bracing stiffness. Structures 2016, 8, 35–43. [Google Scholar] [CrossRef]

- Harries, K.A.; Peck, A.J.; Abraham, E. Enhancing stability of structural steel sections using frp. Thin-Walled Struct. 2009, 47, 1092–1101. [Google Scholar] [CrossRef]

- Saito, D.; Wadee, M.A. Post-buckling behaviour of prestressed steel stayed columns. Eng. Struct. 2008, 30, 1224–1239. [Google Scholar] [CrossRef]

- Ma, T.; Liu, X.; Hu, Y.; Chung, K.; Li, G. Structural behaviour of slender columns of high strength s690 steel welded h-sections under compression. Eng. Struct. 2018, 157, 75–85. [Google Scholar] [CrossRef]

- Kim, M.; Mehdi, A.I.; Hayat, U. Spatial stability of pre-stressed mono-symmetric steel beams with un-bonded/bonded deviators under compression and end moments. J. Constr. Steel Res. 2022, 189, 107078. [Google Scholar] [CrossRef]

- Li, G.; Chen, B.; Zhu, B.; Yang, Z.; Ge, H.; Liu, Y. Axially loaded square concrete-filled steel tubular long columns made of high-strength materials: Experimental investigation, analytical behavior and design. J. Build. Eng. 2022, 58, 104994. [Google Scholar] [CrossRef]

- Kambal, M.E.M.; Jia, Y. Theoretical and experimental study on flexural behavior of prestressed steel plate girders. J. Constr. Steel Res. 2018, 142, 5–16. [Google Scholar] [CrossRef]

- Smith, R.J.; McCaffrey, G.T.; Ellis, J.S. Buckling of a single-crossarm stayed column. J. Struct. Div. 1975, 101, 219–235. [Google Scholar] [CrossRef]

- Temple, M. Buckling of stayed columns. J. Struct. Div. 1977, 103, 839–851. [Google Scholar] [CrossRef]

- Osofero, A.I.; Wadee, M.A.; Gardner, L. Experimental study of critical and post-buckling behaviour of prestressed stayed columns. J. Constr. Steel Res. 2012, 79, 226–241. [Google Scholar] [CrossRef]

- Martins, J.P.; Shahbazian, A.; Simões da Silva, L.; Rebelo, C.; Simões, R. Structural behaviour of prestressed stayed columns with single and double cross-arms using normal and high strength steel. Arch. Civ. Mech. Eng. 2016, 16, 618–633. [Google Scholar] [CrossRef]

- Wadee, M.A.; Gardner, L.; Hunt, T. Buckling mode interaction in prestressed stayed columns. Proc. Inst. Civ. Eng. Struct. Build. 2013, 166, 403–412. [Google Scholar] [CrossRef]

- Li, Y.; Li, B.; Yin, X.; Han, Z. Buckling analysis of a new type of double-steering prestressed plate column. Buildings 2023, 13, 2574. [Google Scholar] [CrossRef]

- Liang, Q.Q.; Xie, Y.M.; Steven, G.P. Generating optimal strut-and-tie models in prestressed concrete beams by performance-based optimization. ACI Struct. J. 2001, 98, 226–232. [Google Scholar]

- Ma, Q.; Ohsaki, M.; Chen, Z.; Yan, X. Multi-objective optimization for prestress design of cable-strut structures. Int. J. Solids Struct. 2019, 165, 137–147. [Google Scholar] [CrossRef]

- Wang, H.; Li, P.; Wu, M. Crossarm length optimization and post-buckling analysis of prestressed stayed steel columns. Thin-Walled Struct. 2019, 144, 106371. [Google Scholar] [CrossRef]

- Chen, Y.; Yan, J.; Sareh, P.; Feng, J. Feasible prestress modes for cable-strut structures with multiple self-stress states using particle swarm optimization. J. Comput. Civ. Eng. 2020, 34, 04020003. [Google Scholar] [CrossRef]

- Li, H.; Ren, L.; Jia, Z.; Yi, T.; Li, D. State-of-the-art in structural health monitoring of large and complex civil infrastructures. J. Civ. Struct. Health Monit. 2016, 6, 3–16. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, G.; Jiao, Z.; Zhao, L. Intelligent safety assessment of prestressed steel structures based on digital twins. Symmetry 2021, 13, 1927. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y. Intelligent prediction of prestressed steel structure construction safety based on bp neural network. Appl. Sci. 2022, 12, 1442. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, G.; Zhang, A.; Huang, C. Intelligent tensioning method for prestressed cables based on digital twins and artificial intelligence. Sensors 2020, 20, 7006. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Lapira, L.; Wadee, M.A.; Gardner, L.; Pirrera, A.; Groh, R.M. Probing in situ capacities of prestressed stayed columns: Towards a novel structural health monitoring technique. Philos. Trans. R. Soc. A 2023, 381, 20220033. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Qiang, X.; Xing, Z.; Jiang, X. Buckling in prestressed stayed beam–columns and intelligent evaluation. Eng. Struct. 2022, 255, 113902. [Google Scholar] [CrossRef]

- Budd, C.; Hunt, G.; Kuske, R. Asymptotics of cellular buckling close to the maxwell load. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2001, 457, 2935–2964. [Google Scholar] [CrossRef]

- Orlando, D.; Gonçalves, P.; Rega, G.; Lenci, S. Nonlinear dynamics and sensitivity to imperfections in augusti’s model. J. Mech. Mater. Struct. 2011, 6, 1065–1078. [Google Scholar] [CrossRef][Green Version]

- Gilardi, G.; Sharf, I. Literature survey of contact dynamics modelling. Mech. Mach. Theory 2002, 37, 1213–1239. [Google Scholar] [CrossRef]

- Wadee, M.A.; Gardner, L.; Osofero, A. Design of prestressed stayed columns. J. Constr. Steel Res. 2013, 80, 287–298. [Google Scholar] [CrossRef]

- Wang, Y.C.; Ju, N.P.; Zhao, J.J.; Xiang, X.Q. Formation mechanism of landslide above the mined out area in gentle inclined coal beds. J. Eng. Geol. 2013, 21, 61–68. [Google Scholar]

- Zhao, J.J.; Ma, Y.T.; Lin, B.; Lan, Z.Y.; Shi, W.B. Geomechanical mode of mining landslides with gently counter-inclined bedding—A case study of Madaling landslide in Guizhou Province. Chin. J. Rock Mech. Eng. 2016, 35, 2217–2224. [Google Scholar]

| h (mm) | H (mm) | D (mm) | |

|---|---|---|---|

| Single-beam-brace column | 1500 | 300 | 50 |

| 1500 | |||

| Three-beam-brace column | 600 | 200 | 50 |

| 900 | |||

| 900 | 300 | ||

| 600 | |||

| Dual-steering-plate-brace column | 600 | 200 | 50 |

| 900 | |||

| 900 | 300 | ||

| 600 |

| Lateral Deformation (mm) | Non-Prestressed Column (kN) | Single-Beam-Brace Column (kN) | Three-Beam-Brace Column (kN) | Dual-Steering-Plate-Brace Column (kN) |

|---|---|---|---|---|

| 5 | 84.7 | 233.8 | 332.2 | 511.8 |

| 10 | 91.5 | 240.6 | 298.3 | 488.1 |

| 15 | 94.9 | 230.5 | 274.5 | 461.1 |

| 20 | 94.9 | 206.7 | 274.5 | 437.3 |

| 25 | 94.9 | 189.8 | 237.3 | 420.3 |

| 30 | 91.5 | 176.2 | 213.6 | 393.2 |

| 35 | 88.1 | 159.3 | 196.6 | 369.4 |

| 40 | 84.7 | 145.7 | 183.1 | 338.9 |

| 45 | 81.3 | 132.2 | 159.3 | 305.1 |

| 50 | 77.9 | 118.6 | 138.9 | 277.9 |

| 55 | 74.5 | 105.1 | 125.4 | 254.2 |

| 60 | 67.7 | 94.9 | 108.4 | 240.6 |

| 65 | 64.4 | 88.1 | 98.3 | 223.7 |

| 70 | 61.1 | 81.4 | 84.7 | 203.3 |

| 75 | 57.6 | 74.5 | 77.9 | 193.2 |

| 80 | 54.2 | 67.8 | 64.4 | - |

| 85 | 50.8 | 64.4 | 57.6 | - |

| 90 | 47.4 | 57.6 | 50.8 | - |

| 95 | 44.1 | 54.2 | 47.4 | - |

| 100 | 40.6 | 50.8 | 44.1 | - |

| 105 | 37.2 | 47.4 | 40.6 | - |

| 110 | 33.8 | 44.1 | 40.6 | - |

| 115 | 33.8 | 44.1 | 33.8 | - |

| 120 | 33.8 | 44.1 | 33.8 | - |

| 125 | 30.5 | 40.1 | 33.8 | - |

| 130 | 30.2 | 37.3 | 33.5 | - |

| 135 | 30.5 | 37.3 | 30.5 | - |

| 140 | 30.5 | 37.3 | 30.5 | - |

| 145 | 33.8 | 33.4 | 30.5 | - |

| 150 | 30.5 | 33.9 | 27.1 | - |

| 155 | 27.1 | 33.9 | 27.1 | - |

| 160 | 23.7 | 30.5 | 27.1 | - |

| 175 | 20.3 | 30.5 | 23.7 | - |

| 180 | - | - | - | - |

| 185 | - | - | - | - |

| 190 | - | - | - | - |

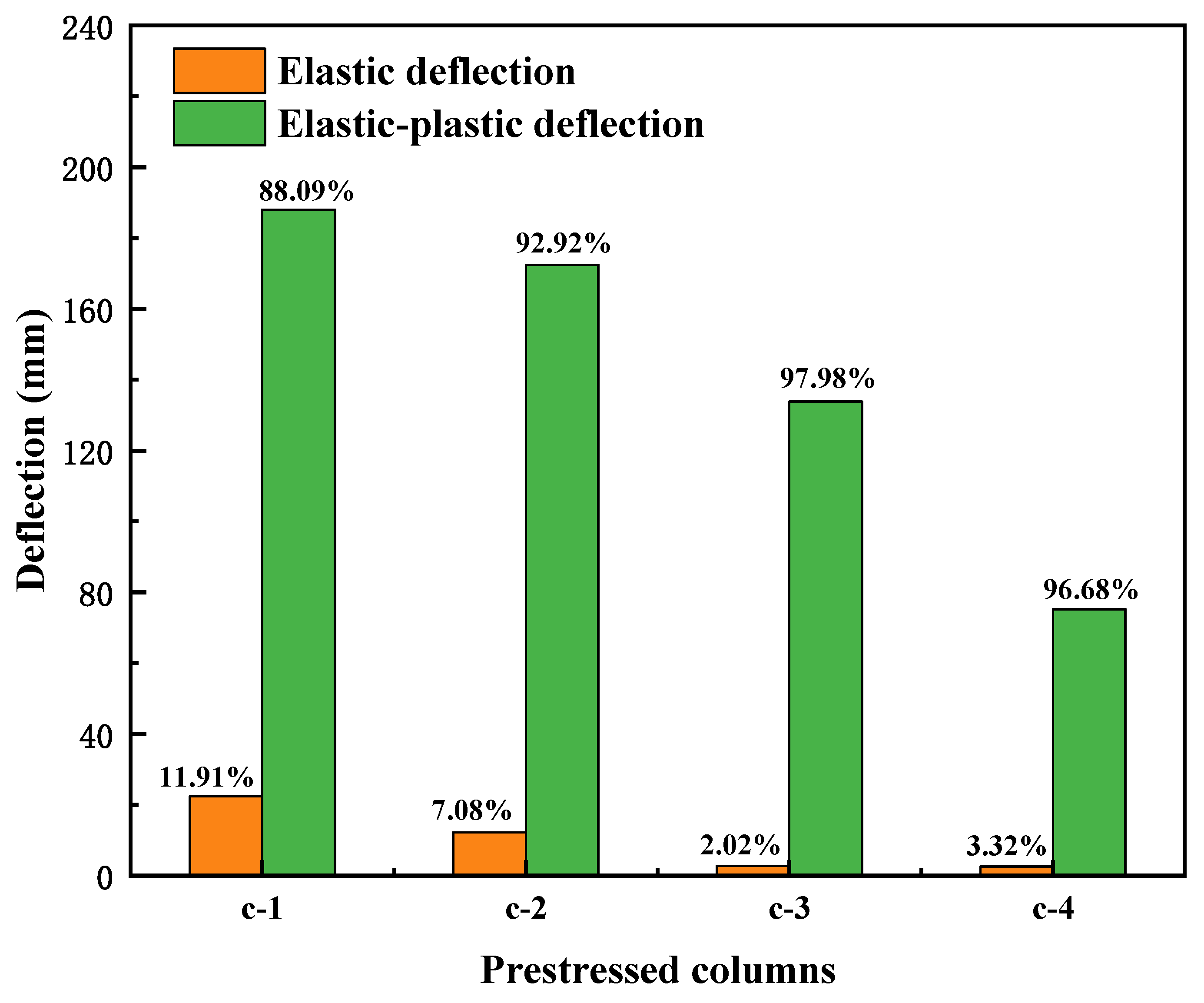

| Pu/kN | Pcr/kN | φ | δu/mm | δd/mm | εeq/10−3 | |

|---|---|---|---|---|---|---|

| Non-prestressed column (c-1) | 95.8 | 144 | 0.665 | 22.4 | 188 | 22.714 |

| Single-beam-brace column (c-2) | 239 | 267 | 0.895 | 12.2 | 172.4 | 16.104 |

| Three-beam-brace column (c-3) | 342 | 430 | 0.795 | 2.7 | 133.8 | 14.09 |

| Dual-steering-plate-brace column (c-4) | 518 | 650 | 0.798 | 2.5 | 75.2 | 1.021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, B.; Yin, X.; Han, Z.; Li, Z. A Study on the Elastoplastic Stable Bearing Capacity of Double-Steering Prestressed Plate Columns. Buildings 2023, 13, 3083. https://doi.org/10.3390/buildings13123083

Li Y, Li B, Yin X, Han Z, Li Z. A Study on the Elastoplastic Stable Bearing Capacity of Double-Steering Prestressed Plate Columns. Buildings. 2023; 13(12):3083. https://doi.org/10.3390/buildings13123083

Chicago/Turabian StyleLi, Yanying, Bailong Li, Xinsheng Yin, Zhiying Han, and Zhipeng Li. 2023. "A Study on the Elastoplastic Stable Bearing Capacity of Double-Steering Prestressed Plate Columns" Buildings 13, no. 12: 3083. https://doi.org/10.3390/buildings13123083

APA StyleLi, Y., Li, B., Yin, X., Han, Z., & Li, Z. (2023). A Study on the Elastoplastic Stable Bearing Capacity of Double-Steering Prestressed Plate Columns. Buildings, 13(12), 3083. https://doi.org/10.3390/buildings13123083