Point Cloud-Based Smart Building Acceptance System for Surface Quality Evaluation

Abstract

:1. Introduction

2. Related Works

2.1. SQE Using PCD

2.2. Surface Segmentation and Fitting

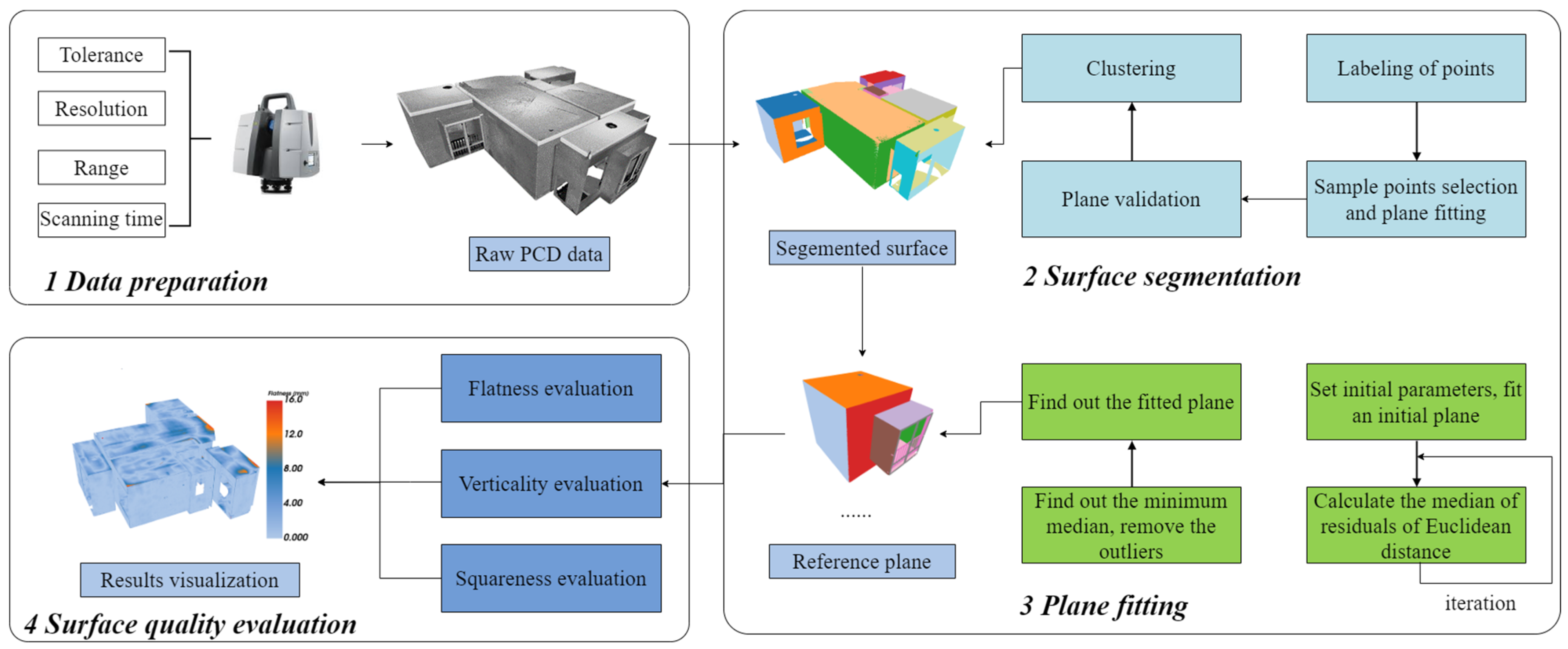

3. System Framework

- Data preparation. The PCD acquisition parameters and corresponding scanning modes are discussed by gathering the data from the literature and testing the scanner with different modes in the laboratory, in order to ensure the data quality. Then the dense PCD is registered and reduced for computational efficiency.

- Surface segmentation and plane fitting. An improved DBSCAN algorithm is introduced in this study to segment various surfaces accurately by introducing the additional processes of plane validation and coplanar parameter. Moreover, a slide window-based sampling method is applied to obtain the sample PCD for SQE. Then a revised Least Squares Method (LSM) algorithm is proposed to remove the outliers and obtain the best-fitted reference plane for the later processes.

- Automated SQE and result visualization. The flatness, verticality, and squareness evaluation are performed based on the reference plane, and a color-coded map is produced for a clear visualization.

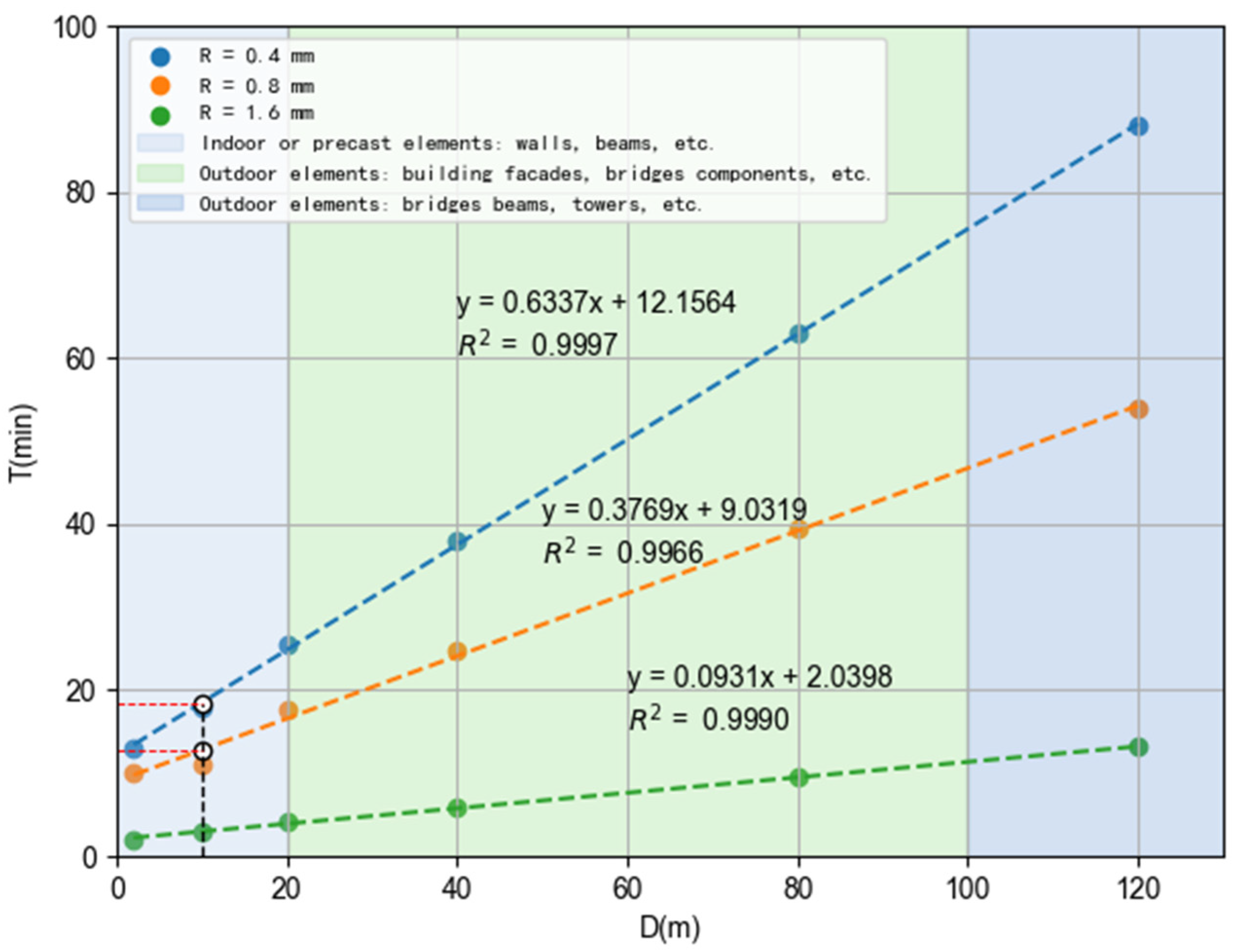

3.1. Data Preparation

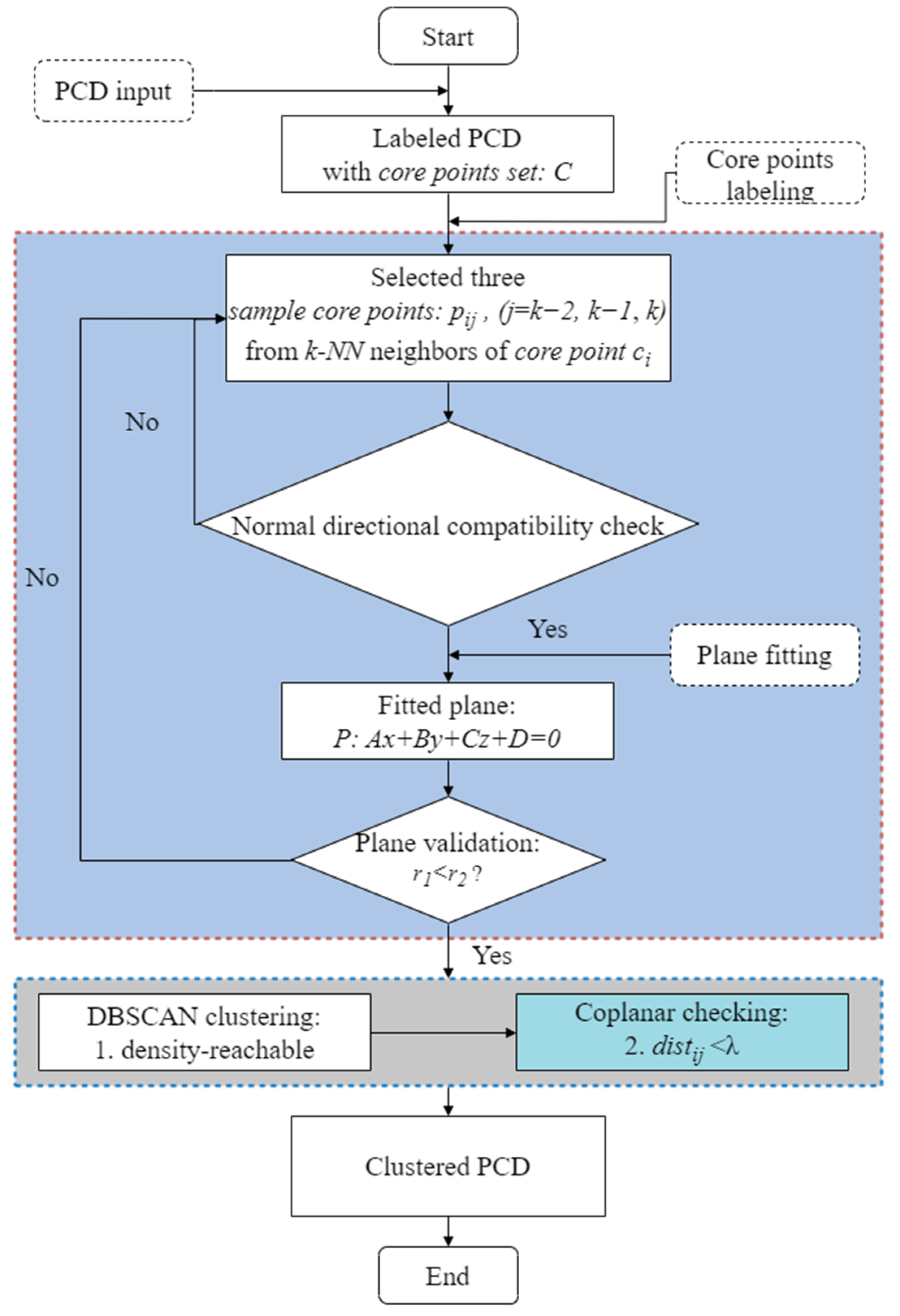

3.2. Surface Segmentation and Plane Fitting

3.2.1. Surface Segmentation Based on Improved DBSCAN

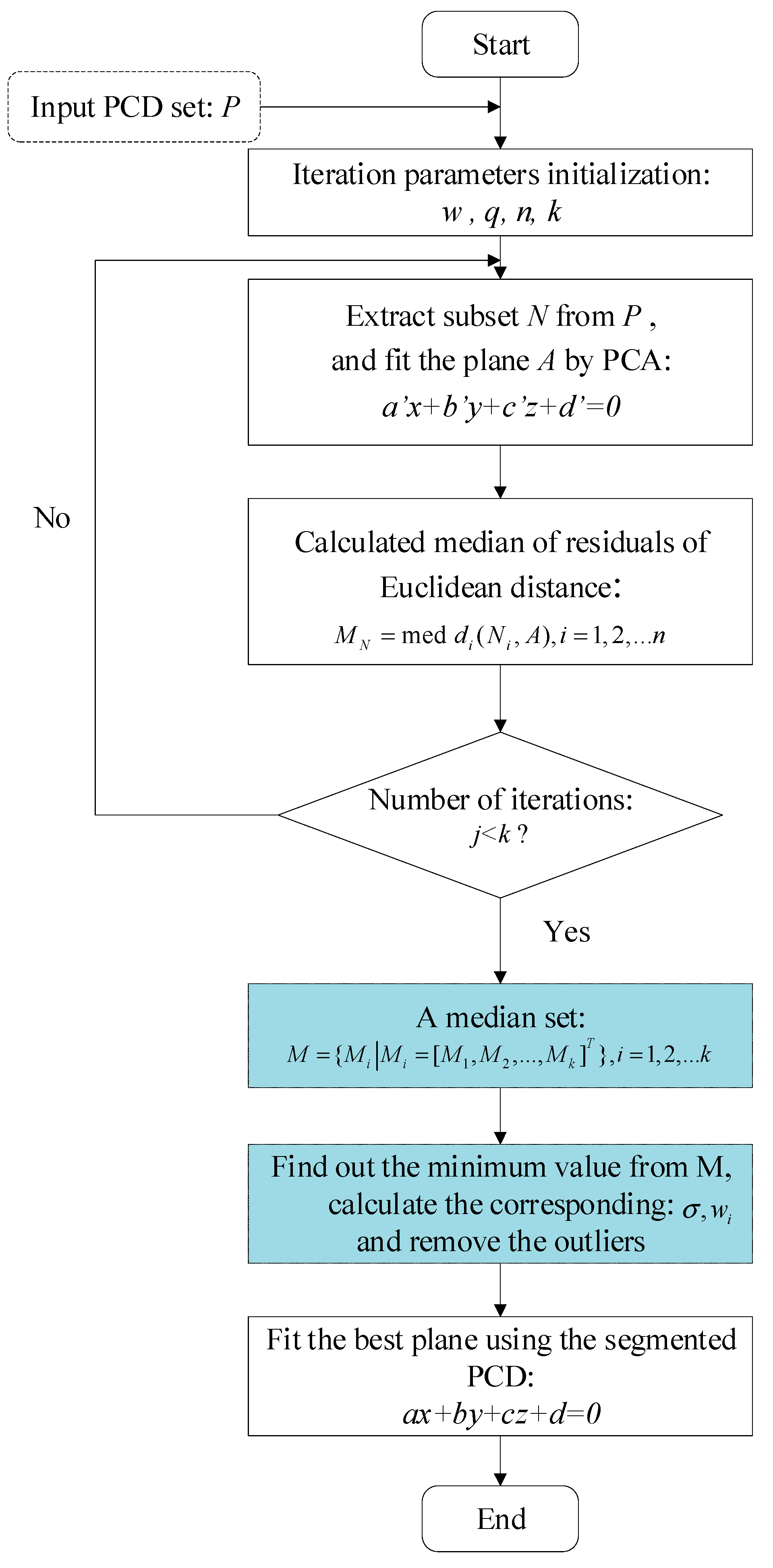

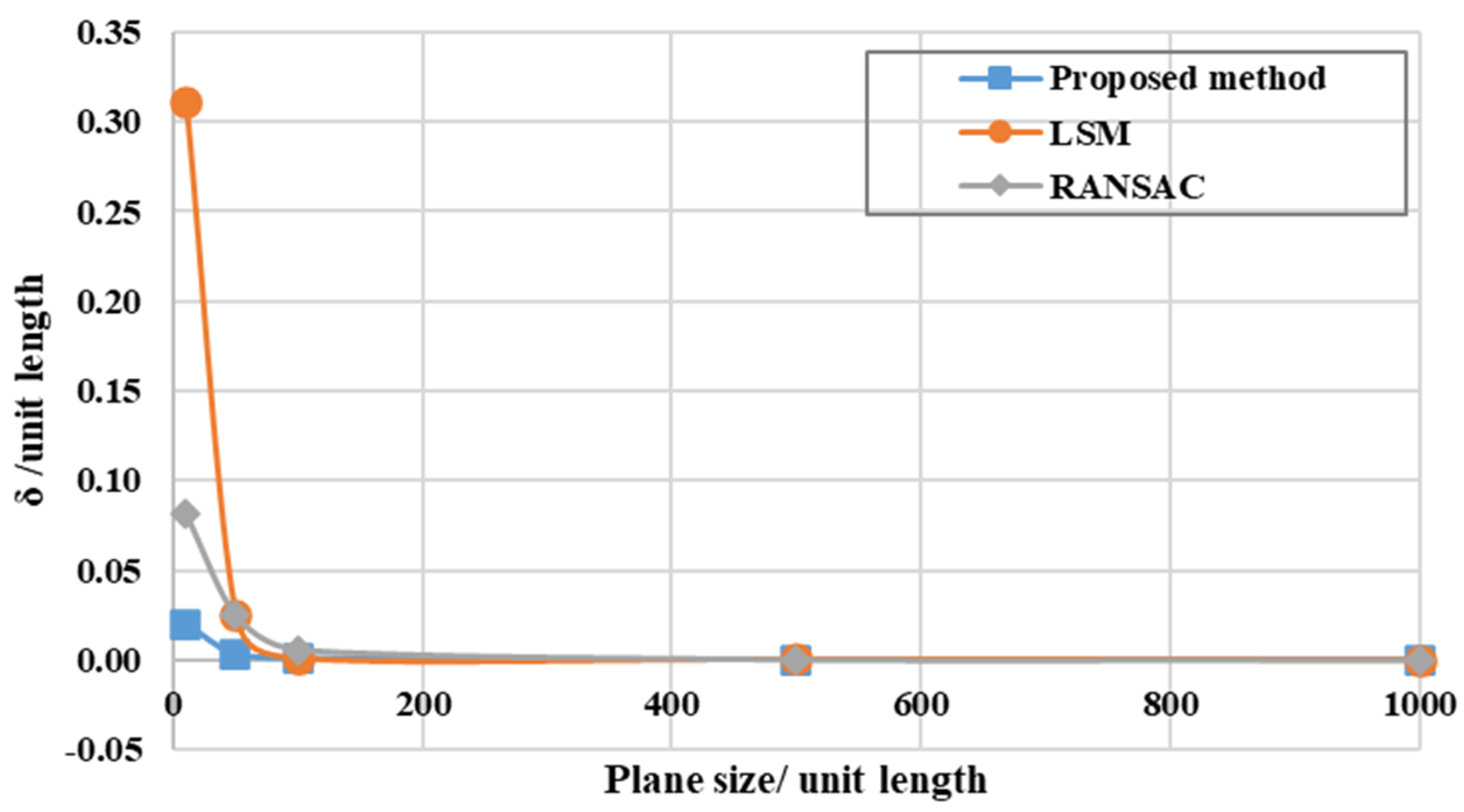

3.2.2. Plane Fitting

3.3. SQE Based on PCD

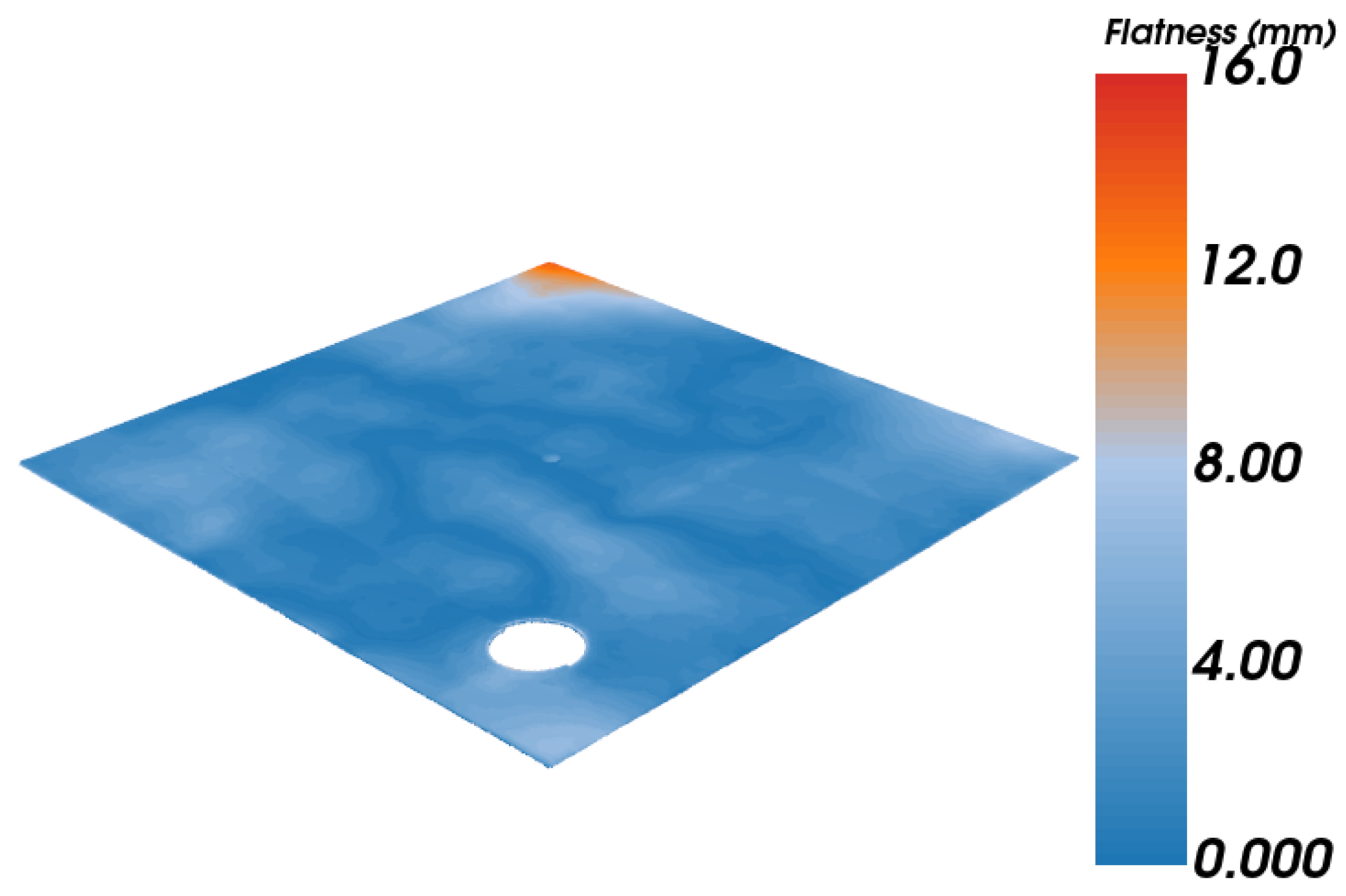

3.3.1. Flatness Evaluation (FE)

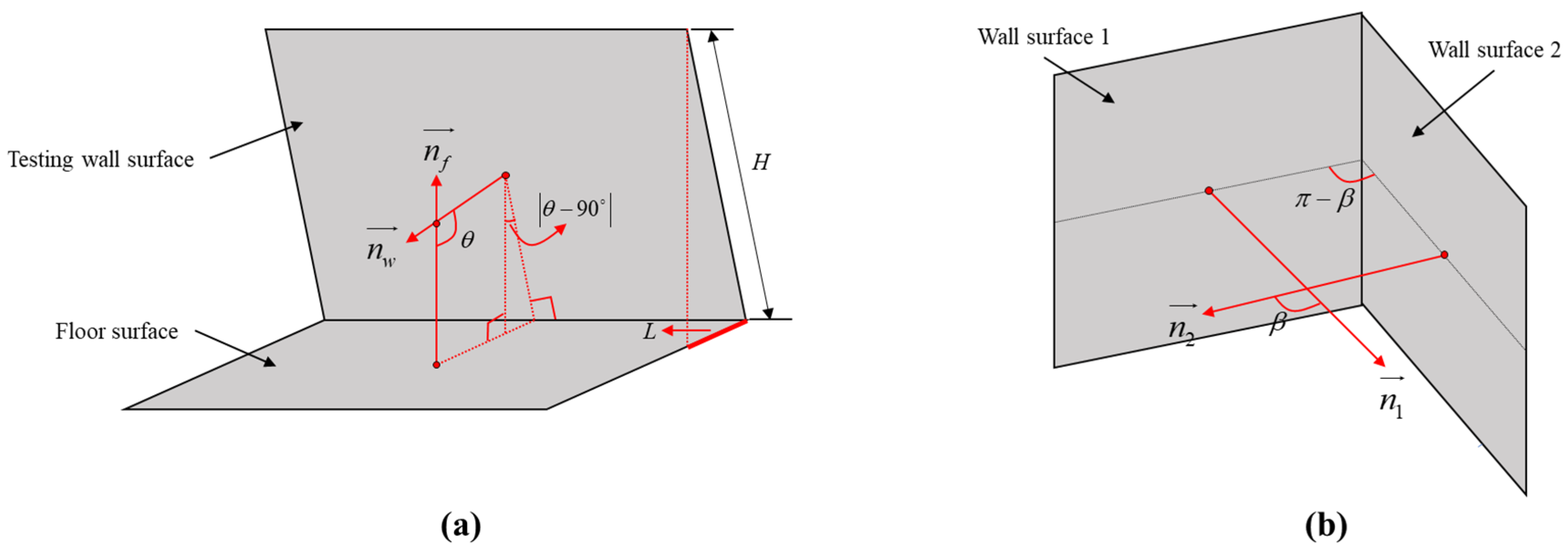

3.3.2. Verticality Evaluation (VE)

3.3.3. Squareness Evaluation (SE)

4. Experiment Validation

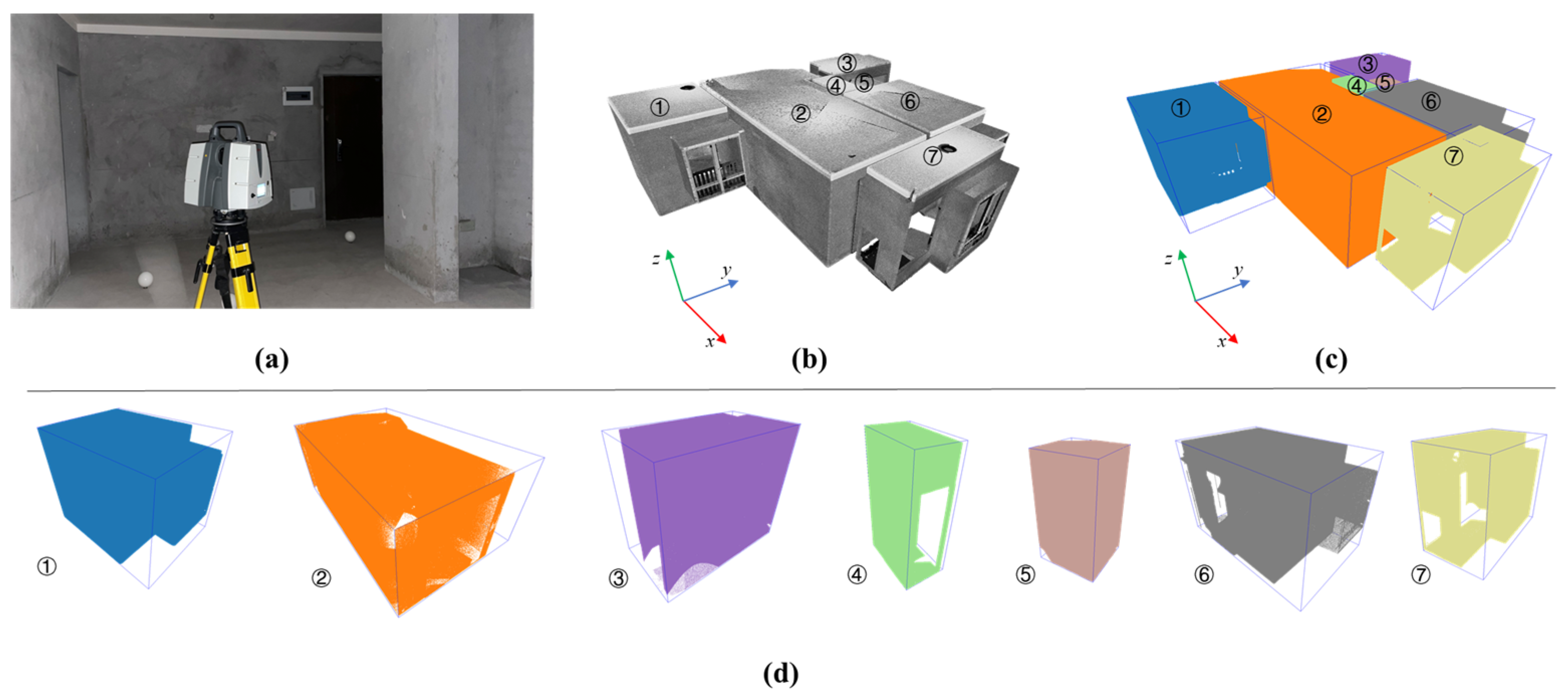

4.1. Data Collection and Pre-Processing of PCD

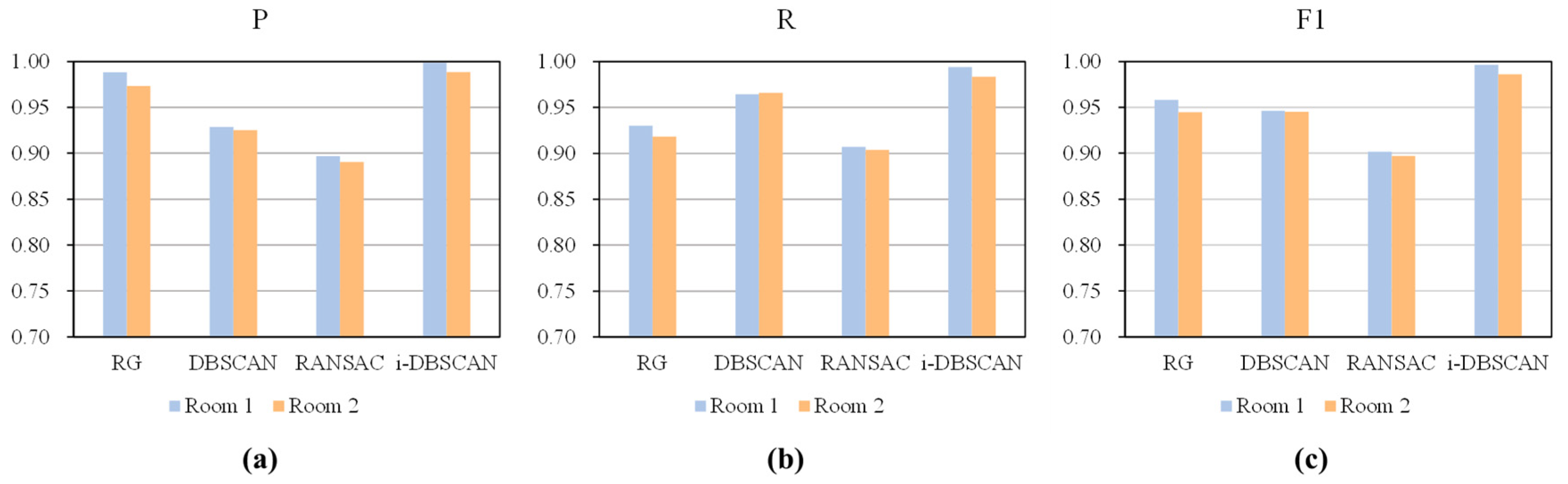

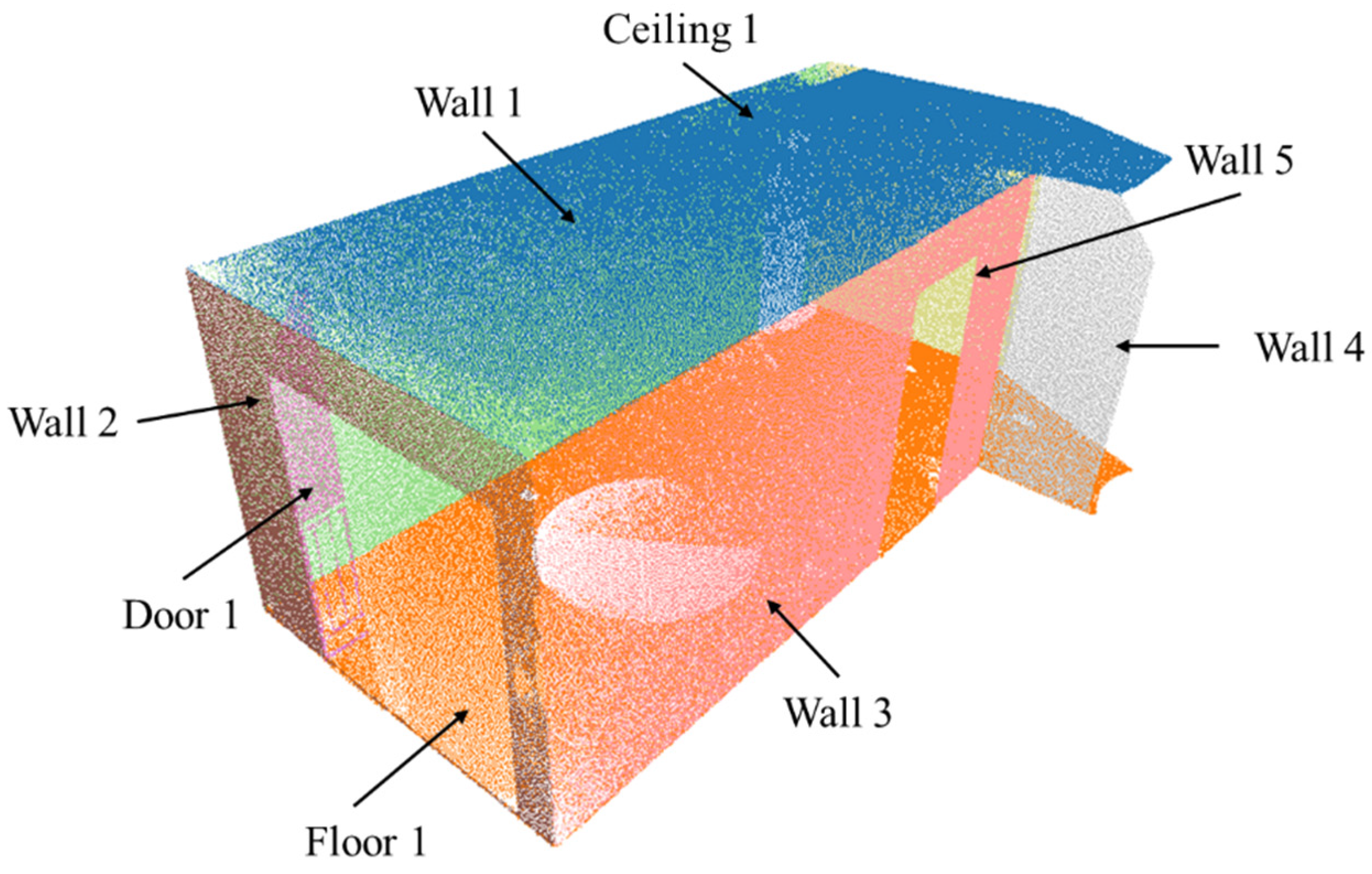

4.2. Surface Segmentation

4.3. Automatic SQE Results

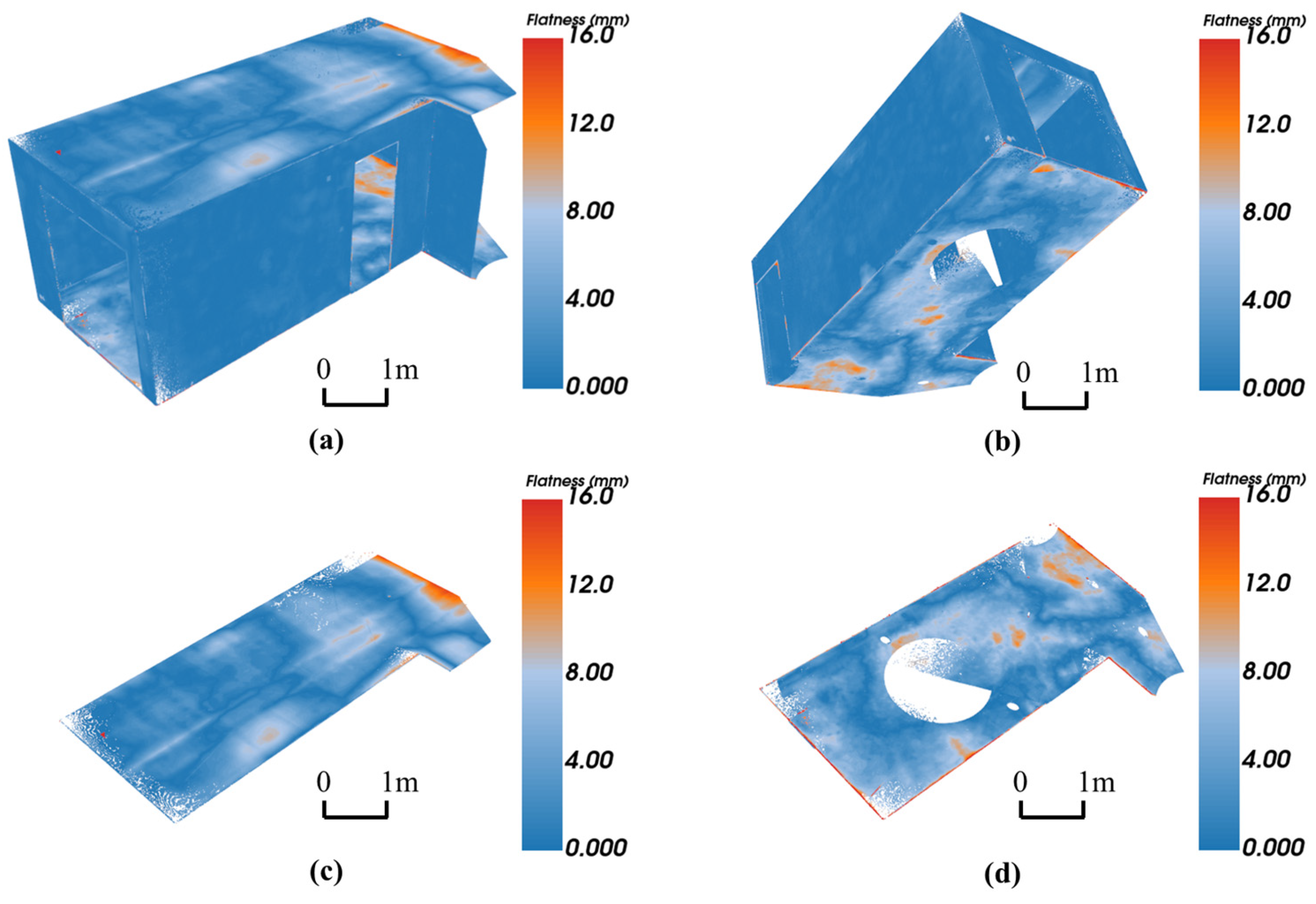

4.3.1. Flatness Evaluation Results

4.3.2. Verticality and Squareness Evaluation Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, M.-K.; Cheng, J.C.P.; Sohn, H.; Chang, C.-C. A framework for dimensional and surface quality assessment of precast concrete elements using BIM and 3D laser scanning. Autom. Constr. 2015, 49, 225–238. [Google Scholar] [CrossRef]

- Construction Industry Institute (CII). RS203-1—Making Zero Rework A Reality; Construction Industry Institute (CII): Austin, TX, USA, 2005. [Google Scholar]

- Mills, A.; Love, P.E.; Williams, P. Defect costs in residential construction. J. Constr. Eng. Manag. 2009, 135, 12–16. [Google Scholar] [CrossRef]

- Li, D.; Liu, J.; Hu, S.; Cheng, G.; Li, Y.; Cao, Y.; Dong, B.; Chen, Y.F. A deep learning-based indoor acceptance system for assessment on flatness and verticality quality of concrete surfaces. J. Build. Eng. 2022, 51, 104284. [Google Scholar] [CrossRef]

- Sameer, G.; James, G.; Burcu, A.; Scott, T.; Chris, P. Running Surface Assessment Technology Review; Carnegie Mellon University: Pittsburgh, PA, USA, 2002. [Google Scholar]

- GB50204-2015; Standard, Code for Acceptance of Construction Quality of Concrete Structures. China Building Industry Press: Beijing, China, 2015.

- Tan, Y.; Li, S.; Wang, Q. Automated Geometric Quality Inspection of Prefabricated Housing Units Using BIM and LiDAR. Remote Sens. 2020, 12, 2492. [Google Scholar] [CrossRef]

- MNL-135; Tolerance Manual for Precast Concrete Construction. American Standard: Piscataway, NJ, USA, 2000.

- ACI ITG-7-09; Specification for Tolerances for Precast Concrete. American Standard: Piscataway, NJ, USA, 2009.

- EN 13670:2009; Execution of Concrete Structures. European Standard: Brussels, Belgium, 2009.

- Zhao, W.; Jiang, Y.; Liu, Y.; Shu, J. Automated recognition and measurement based on three-dimensional point clouds to connect precast concrete components. Autom. Constr. 2022, 133, 104000. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.-K.; Cheng, J.C.; Sohn, H. Automated quality assessment of precast concrete elements with geometry irregularities using terrestrial laser scanning. Autom. Constr. 2016, 68, 170–182. [Google Scholar] [CrossRef]

- Ordóñez, C.; Martínez, J.; Arias, P.; Armesto, J. Measuring building façades with a low-cost close-range photogrammetry system. Autom. Constr. 2010, 19, 742–749. [Google Scholar] [CrossRef]

- Kashani, A.G.; Crawford, P.S.; Biswas, S.K.; Graettinger, A.J.; Grau, D. Automated tornado damage assessment and wind speed estimation based on terrestrial laser scanning. J. Comput. Civ. Eng. 2014, 29, 04014051. [Google Scholar] [CrossRef]

- Zhou, Z.; Gong, J.; Guo, M. Image-based 3D reconstruction for posthurricane residential building damage assessment. J. Comput. Civ. Eng. 2015, 30, 04015015. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.-K. Applications of 3D point cloud data in the construction industry: A fifteen-year review from 2004 to 2018. Adv. Eng. Inform. 2019, 39, 306–319. [Google Scholar] [CrossRef]

- Tang, P.; Huber, D.; Akinci, B. Characterization of Laser Scanners and Algorithms for Detecting Flatness Defects on Concrete Surfaces. J. Comput. Civ. Eng. 2011, 25, 31–42. [Google Scholar] [CrossRef]

- Bosch, F.; Guenet, E. Automating surface flatness control using terrestrial laser scanning and building information models. Autom. ConStruct. 2014, 44, 212–226. [Google Scholar] [CrossRef]

- BS 8204; Bases and In-Situ Flooring. British Standards Institution (BSI): London, UK, 2009.

- ACI 302.1R-96; Guide for Concrete Floor and Slab Construction. A.C.I. (ACI): Miami, FL, USA, 2004.

- ACI 117-06; Specifications for Tolerances for Concrete Construction and Materials and Commentary. A.C.I. (ACI): Miami, FL, USA, 2006.

- Bosché, F. Plane-based registration of construction laser scans with 3D/4D building models. Adv. Eng. Inform. 2012, 26, 90–102. [Google Scholar] [CrossRef]

- Li, D.; Liu, J.; Feng, L.; Zhou, Y.; Liu, P.; Chen, Y.F. Terrestrial laser scanning assisted flatness quality assessment for two different types of concrete surfaces. Measurement 2020, 154, 107436. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, J.; Feng, S.; Li, D.; Zhang, S.; Qi, H.; Cheng, G.; Chen, Y.F. Towards automatic flatness quality assessment for building indoor acceptance via terrestrial laser scanning. Measurement 2022, 203, 111862. [Google Scholar] [CrossRef]

- Shih, N.-J.; Wang, P.-H. Using Point Cloud to Inspect the Construction Quality of Wall Finish. In Proceedings of the Architecture in the Network Society, Copenhagen, Denmark, 15–18 September 2004; pp. 573–578. [Google Scholar] [CrossRef]

- Nuttens, T.; Stal, C.; De Backer, H.; Schotte, K.; Van Bogaert, P.; De Wulf, A. Methodology for the ovalization monitoring of newly built circular train tunnels based on laser scanning: Liefkenshoek Rail Link (Belgium). Autom. Constr. 2014, 43, 1–9. [Google Scholar] [CrossRef]

- Bosch, F.; Biotteau, B. Terrestrial laser scanning and continuous wavelet transform for controlling surface flatness in construction–a first investigation. Adv. Eng. Inf. 2015, 29, 591–601. [Google Scholar] [CrossRef]

- Puri, N.; Valero, E.; Turkan, Y.; Bosché, F. Assessment of compliance of dimensional tolerances in concrete slabs using TLS data and the 2D continuous wavelet transform. Autom. Constr. 2018, 94, 62–72. [Google Scholar] [CrossRef]

- Neza, I.; Mohamed, M.I.; Syafuan, W.M. Surface Waviness Evaluation of Two Different Types of Material of a Multi-Purpose Hall Using Terrestrial Laser Scanner (TLS). IOP Conf. Ser. Mater. Sci. Eng. 2022, 1229, 012002. [Google Scholar] [CrossRef]

- Han, D.; Rolfsen, C.N.; Hosamo, H.; Bui, N.; Dong, Y.; Zhou, Y.; Guo, T.; Ying, C. Automatic detection method for verticality of bridge pier based on BIM and point cloud. In ECPPM 2021-eWork and eBusiness in Architecture, Engineering and Construction, Proceedings of the 13th European Conference on Product & Process Modelling (ECPPM 2021), Moscow, Russia, 15–17 September 2021, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; p. 6. [Google Scholar]

- Riveiro, B.; González-Jorge, H.; Varela, M.; Jáuregui, D.V. Validation of terrestrial laser scanning and photogrammetry techniques for the measurement of vertical underclearance and beam geometry in structural inspection of bridges. Measurement 2013, 46, 784–794. [Google Scholar] [CrossRef]

- Er’min, W.; Jiming, W.; Fei, Y.; Shengdeng, S.; Xuyang, Y. Detection of flatness and verticality of buildings based on 3D laser scanning technology. Bull. Surv. Mapp. 2019, 6, 85–88. [Google Scholar]

- Kim, M.-K.; Sohn, H.; Chang, C.-C. Automated dimensional quality assessment of precast concrete panels using terrestrial laser scanning. Autom. Constr. 2014, 45, 163–177. [Google Scholar] [CrossRef]

- Tang, X.; Wang, M.; Wang, Q.; Guo, J.; Zhang, J. Benefits of Terrestrial Laser Scanning for Construction QA/QC: A Time and Cost Analysis. J. Manag. Eng. 2022, 38, 05022001. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, Y.; Li, J. Review on automated quality inspection of precast concrete components. Autom. Constr. 2023, 150, 104828. [Google Scholar] [CrossRef]

- Armeni, I.; Sener, O.; Zamir, A.R.; Jiang, H.; Brilakis, I.; Fischer, M.; Savarese, S. 3D Semantic Parsing of Large-Scale Indoor Spaces. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 1534–1543. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, Y.; Vanhullebusch, S.; Mestdagh, R.; Cui, Z.; Li, J. Smart building demolition and waste management frame with image-to-BIM. J. Build. Eng. 2022, 49, 104058. [Google Scholar] [CrossRef]

- Macher, H.; Landes, T. Grussenmeyer, From Point Clouds to Building Information Models: 3D Semi-Automatic Reconstruction of Indoors of Existing Buildings. Appl. Sci. 2017, 7, 1030. [Google Scholar] [CrossRef]

- Pu, S.; Vosselman, G. Knowledge based reconstruction of building models from terrestrial laser scanning data. ISPRS J. Photogramm. Remote Sens. 2009, 64, 575–584. [Google Scholar] [CrossRef]

- Khoshelham, K.; Díaz-Vilariño, L. 3D Modelling of Interior Spaces: Learning the Language of Indoor Architecture. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, XL-5, 321–326. [Google Scholar] [CrossRef]

- Xie, Y.; Tian, J.; Zhu, X.X. Linking Points with Labels in 3D: A Review of Point Cloud Semantic Segmentation. IEEE Geosci. Remote Sens. Mag. 2020, 8, 38–59. [Google Scholar] [CrossRef]

- Hulik, R.; Spanel, M.; Smrz, P.; Materna, Z. Continuous plane detection in point-cloud data based on 3D Hough Transform. J. Vis. Commun. Image Represent. 2014, 25, 86–97. [Google Scholar] [CrossRef]

- Limberger, F.A.; Oliveira, M.M. Real-time detection of planar regions in unorganized point clouds. Pattern Recognit. 2015, 48, 2043–2053. [Google Scholar] [CrossRef]

- Rabbani, T. Efficient Hough Transform for Automatic Detection of Cylinders in Point Clouds. In Proceedings of the ISPRS Working Groups, Enschede, The Netherlands, 12–14 September; 2005; pp. 60–65. Available online: https://www.isprs.org/PROCEEDINGS/XXXVI/3-W19/papers/060.pdf (accessed on 29 September 2023).

- Camurri, M.; Vezzani, R.; Cucchiara, R. 3D Hough transform for sphere recognition on point clouds: A systematic study and a new method proposal. Mach. Vis. Appl. 2014, 25, 1877–1891. [Google Scholar] [CrossRef]

- Adam, A.; Chatzilari, E.; Nikolopoulos, S.; Kompatsiaris, I. H-RANSAC: A hybrid point cloud segmentation combining 2D and 3D data. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, IV-2, 1–8. [Google Scholar] [CrossRef]

- Oh, S.; Lee, D.; Kim, M.; Kim, T.; Cho, H. Building Component Detection on Unstructured 3D Indoor Point Clouds Using RANSAC-Based Region Growing. Remote Sens. 2021, 13, 161. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Czarnuch, S. Automatic Super-Surface Removal in Complex 3D Indoor Environments Using Iterative Region-Based RANSAC. Sensors 2021, 21, 3724. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Ahmed, W.; Li, N.; Fan, W.; Xiang, H.; Wang, M. Semantic Geometric Modelling of Unstructured Indoor Point Cloud. ISPRS Int. J. Geo-Inf. 2018, 8, 9. [Google Scholar] [CrossRef]

- Wang, C.; Ji, M.; Wang, J.; Wen, W.; Li, T.; Sun, Y. An Improved DBSCAN Method for LiDAR Data Segmentation with Automatic Eps Estimation. Sensors 2019, 19, 172. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhao, D.; Cheng, D.; Zhang, J.; Tian, D. A Fast and Precise Plane Segmentation Framework for Indoor Point Clouds. Remote Sens. 2022, 14, 3519. [Google Scholar] [CrossRef]

- Zhao, B.; Hua, X.; Yu, K.; Xuan, W.; Chen, X.; Tao, W. Indoor Point Cloud Segmentation Using Iterative Gaussian Mapping and Improved Model Fitting. IEEE Trans. Geosci. Remote Sens. 2020, 58, 7890–7907. [Google Scholar] [CrossRef]

- Rebolj, D.; Pučko, Z.; Babič, N.Č.; Bizjak, M.; Mongus, D. Point cloud quality requirements for Scan-vs-BIM based automated construction progress monitoring. Autom. Constr. 2017, 84, 323–334. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiang, Z.; Zhang, X.; Wang, Y.; Han, D.; Ying, C. Mechanical state inversion method for structural performance evaluation of existing suspension bridges using 3D laser scanning. Comput. Aided Civ. Infrastruct. Eng. 2022, 37, 650–665. [Google Scholar] [CrossRef]

- Srivastava, S.; Semwal, E.; Grover, C.; Pande, H.; Tiwari, P.S.; Raghavendra, S. Agrawal, Performance Analysis of Terrestrial Laser Scanners for Point Cloud Integration, (n.d.). Available online: https://www.researchgate.net/profile/Esha-Semwal/publication/344376969_Performance_Analysis_of_Terrestrial_Laser_Scanners_for_Point_Cloud_Integration/links/5feef18d299bf1408861260a/Performance-Analysis-of-Terrestrial-Laser-Scanners-for-Point-Cloud-Integration.pdf (accessed on 29 September 2023).

- Elsherif, A.; Gaulton, R.; Mills, J. Four dimensional mapping of vegetation moisture content using dual-wavelength terrestrial laser scanning. Remote Sens. 2019, 11, 2311. [Google Scholar] [CrossRef]

| Category | GB 50204-2015 [6] | PCI MNL-135 [8] | ACI-ITG-7M [9] | EN 13670 [10] | |

|---|---|---|---|---|---|

| Verticality [mm] | Structural column/wall | 5 (H ≤ 6000); | 5/2400 | 6/3000 | 25 |

| 10 (H > 6000) | |||||

| Non-structural column | 2 | 5/2400 | 6/3000 | 25 | |

| Flatness [mm] | - | 8 | 6/3000 | ±1/8 in. per 10 ft ±1/2 in. maximum | 9/2000 (Molded surface) |

| 15/2000 (Not molded surface) | |||||

| Squareness [mm] | - | 10/2000 | - | ±1/8 in. per 6 ft, ±1/2 in. maximum | - |

| Scanning Mode | Maximum Range (m) | Resolution (mm) | Scanning Time (min) |

|---|---|---|---|

| 1 | 2 | 0.4 | 13 |

| 2 | 10 | 0.4 | 18 |

| 3 | 20 | 0.4 | 25 |

| 4 | 40 | 0.4 | 38 |

| 5 | 80 | 0.4 | 63 |

| 6 | 120 | 0.4 | 88 |

| 7 | 2 | 0.8 | 10 |

| 8 | 10 | 0.8 | 11 |

| 9 | 20 | 0.8 | 18 |

| 10 | 40 | 0.8 | 25 |

| 11 | 80 | 0.8 | 39 |

| 12 | 120 | 0.8 | 54 |

| 13 | 2 | 1.6 | 2 |

| 14 | 10 | 1.6 | 3 |

| 15 | 20 | 1.6 | 4 |

| 16 | 40 | 1.6 | 6 |

| 17 | 80 | 1.6 | 10 |

| 18 | 120 | 1.6 | 13 |

| LSM | RANSAC | Proposed Method | ||

|---|---|---|---|---|

| Without Gaussian noise | a | 0.4082 | 0.4082 | 0.4082 |

| b | 0.8165 | 0.8165 | 0.8165 | |

| c | −0.4082 | −0.4082 | −0.4082 | |

| d | 0.4082 | 0.4082 | 0.4082 | |

| δ | 2.3075 × 10−14 | 4.0058 × 10−16 | 1.8998 × 10−16 | |

| With Gaussian noise | a | 0.4230 | 0.4121 | 0.4080 |

| b | 0.8105 | 0.8186 | 0.8165 | |

| c | −0.4053 | −0.4001 | −0.4085 | |

| d | 0.3683 | 0.3414 | 0.4109 | |

| δ | 0.3112 | 0.0810 | 0.0201 |

| Plane Name | A | B | C | D | δ | Max. dist/m | Satisfaction Rate/% |

|---|---|---|---|---|---|---|---|

| Ceiling | 0.0009 | −0.0008 | 1.0000 | −1.5069 | 2.54 × 10−3 | 0.0216 | 95.36 |

| Floor | 0.0003 | −0.0011 | 1.0000 | 1.3322 | 2.87 × 10−3 | 0.0552 | 89.21 |

| Wall 1 | 0.0013 | 1.0000 | 0.0006 | −4.8684 | 5.58 × 10−4 | 0.0059 | 99.96 |

| Wall 2 | −1.0000 | 0.0010 | 0.0000 | −6.1567 | 6.84 × 10−4 | 0.0013 | 99.95 |

| Wall 3 | −0.0010 | −1.0000 | 0.0005 | 1.6980 | 4.75 × 10−4 | 0.0066 | 99.94 |

| Wall 4 | −1.0000 | −0.0003 | −0.0007 | −0.7066 | 2.94 × 10−4 | 0.0087 | 99.95 |

| Wall 5 | −1.0000 | 0.0004 | −0.0007 | 1.1170 | 5.01 × 10−4 | 0.0098 | 99.98 |

| Room Number | Wall Number | Theta/Degree | L/mm |

|---|---|---|---|

| Room 1 | wall 1 | 90.0201 | 0.9946 |

| wall 2 | 90.0116 | 0.5764 | |

| wall 3 | 90.0499 | 2.4743 | |

| wall 4 | 89.9983 | 0.0859 | |

| wall 5 | 89.9653 | 1.7236 | |

| Room 2 | wall 1 | 90.0248 | 1.2280 |

| wall 2 | 90.0173 | 0.8593 | |

| wall 3 | 89.9131 | 4.3092 | |

| wall 4 | 90.0591 | 2.9291 | |

| wall 5 | 90.0588 | 2.9174 | |

| Room 3 | wall 1 | 90.1174 | 5.8240 |

| wall 2 | 90.3253 | 16.1374 | |

| wall 3 | 90.1381 | 6.8517 | |

| wall 4 | 90.1232 | 6.1122 | |

| wall 5 | 90.3229 | 16.0185 | |

| wall 6 | 89.6756 | 16.0912 | |

| wall 7 | 89.6281 | 18.4488 | |

| Room 4 | wall 1 | 90.6448 | 31.9839 |

| wall 2 | 90.0113 | 0.5623 | |

| wall 3 | 89.2573 | 36.8408 | |

| wall 4 | 89.9903 | 0.4800 | |

| Room 5 | wall 1 | 90.0458 | 2.2723 |

| wall 2 | 89.9416 | 2.8953 | |

| wall 3 | 90.0435 | 2.1591 | |

| Room 6 | wall 1 | 90.0999 | 4.9559 |

| wall 2 | 90.0420 | 2.0833 | |

| wall 3 | 90.0262 | 1.2977 | |

| wall 4 | 90.0227 | 1.1254 | |

| Room 7 | wall 1 | 89.8022 | 9.8097 |

| wall 2 | 89.9969 | 0.1530 | |

| wall 3 | 89.7262 | 13.5829 | |

| wall 4 | 89.9337 | 3.2863 |

| Room Number | Wall Number | Squareness | |

|---|---|---|---|

| Radian | Degree | ||

| Room 1 | wall 1, wall 2 | 1.5712 | 90.0215 |

| wall 2, wall 3 | 1.5704 | 89.9758 | |

| wall 3, wall 4 | 1.5717 | 90.0530 | |

| wall 5, wall 1 | 1.5680 | 89.8395 | |

| Room 2 | wall 1, wall 2 | 1.5705 | 89.9825 |

| wall 2, wall 3 | 1.5708 | 90.0019 | |

| wall 3, wall 4 | 1.5721 | 90.0720 | |

| wall 5, wall 1 | 1.5699 | 89.9481 | |

| Room 3 | wall 1, wall 2 | 1.5697 | 89.9347 |

| wall 2, wall 3 | 1.5725 | 90.0982 | |

| wall 4, wall 5 | 1.5708 | 89.9991 | |

| wall 5, wall 6 | 1.5603 | 89.3998 | |

| wall 6, wall 7 | 1.5668 | 89.7729 | |

| wall 7, wall 1 | 1.5852 | 90.8271 | |

| Room 4 | wall 1, wall 2 | 1.5702 | 89.9665 |

| wall 2, wall 3 | 1.5773 | 90.3717 | |

| wall 3, wall 4 | 1.5763 | 90.3148 | |

| wall 4, wall 1 | 1.5712 | 90.0235 | |

| Room 5 | wall 1, wall 2 | 1.5704 | 89.9795 |

| wal2, wall 3 | 1.5704 | 89.9789 | |

| Room 6 | wall 1, wall 2 | 1.5724 | 90.0904 |

| wall 2, wall 3 | 1.5709 | 90.0085 | |

| wall 3, wall 4 | 1.5704 | 89.9784 | |

| wall 4, wall 1 | 1.5718 | 90.0603 | |

| Room 7 | wall 1, wall 2 | 1.5687 | 89.8787 |

| wall 2, wall 3 | 1.5703 | 89.9695 | |

| wall 3, wall 4 | 1.5707 | 89.9938 | |

| wall 4, wall 1 | 1.5723 | 90.0845 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, D.; Chai, S.; Wei, M.; Wu, H.; Shen, N.; Zhou, Y.; Ding, Y.; Hu, K.; Hu, X. Point Cloud-Based Smart Building Acceptance System for Surface Quality Evaluation. Buildings 2023, 13, 2893. https://doi.org/10.3390/buildings13112893

Cai D, Chai S, Wei M, Wu H, Shen N, Zhou Y, Ding Y, Hu K, Hu X. Point Cloud-Based Smart Building Acceptance System for Surface Quality Evaluation. Buildings. 2023; 13(11):2893. https://doi.org/10.3390/buildings13112893

Chicago/Turabian StyleCai, Dongbo, Shaoqiang Chai, Mingzhuan Wei, Hui Wu, Nan Shen, Yin Zhou, Yanchao Ding, Kaixin Hu, and Xingyi Hu. 2023. "Point Cloud-Based Smart Building Acceptance System for Surface Quality Evaluation" Buildings 13, no. 11: 2893. https://doi.org/10.3390/buildings13112893

APA StyleCai, D., Chai, S., Wei, M., Wu, H., Shen, N., Zhou, Y., Ding, Y., Hu, K., & Hu, X. (2023). Point Cloud-Based Smart Building Acceptance System for Surface Quality Evaluation. Buildings, 13(11), 2893. https://doi.org/10.3390/buildings13112893