Abstract

The building industry faces a number of prominent challenges in the coming period. In this article, we focus on productivity in construction, which lags behind other industries despite technological developments. There is an urgent need for more efficient production methods. In other words, the potential for increasing productivity in construction is enormous. As in other industries, the key to this lies in process orientation, process standardization, and digitization. Lean construction approaches offer innovative solutions here by aiming to maximize customer value while minimizing waste, applying the principles of lean production to construction processes. However, building products are distinct in nature. Efforts to standardize them have achieved partial success, but only within specific product categories and for certain customer needs. Most construction activities remain highly unique. An alternative solution lies in standardizing work processes and not the final product. By adopting this method, one can considerably decrease individuality in production without compromising the essential uniqueness of the building product. Consequently, it is crucial to gain a deeper understanding of the standardization of production processes and the dynamics within the construction sector. This article introduces a modular construction toolkit designed to standardize production processes at construction sites. This toolkit consists of a series of consistent process steps, each linked to a standard time metric. Using this classification, a production model is constructed from a select number of recurring processes, leading to an ontological representation of production. This modular approach allows diverse production processes to be compared based on productivity, as they are composed of consistent and comparable sub-processes. Such a comparison is crucial for continuous production optimization. This method also enables the pinpointing of the most wasteful processes across various construction sites. While the primary data generation use case is centred on special civil engineering (special foundation engineering), the core concepts can be applied to general building construction.

Keywords:

building industry; value stream mapping; productivity; construction site; productivity in construction; efficient production methods; process orientation; process standardization; digitization; standardization of production processes; modular construction toolkit; ontological representation of construction; optimization of construction; lean construction; lean manufacturing 1. Introduction

The construction industry accounts for a stunning annual expenditure of over $10 trillion, representing 13% of the global gross domestic product. Moreover, it employs seven percent of the global workforce, establishing itself as one of the world’s most dominant industries [1]. However, the notable absence of productivity growth within this sector raises significant concerns, given its substantial influence on national economies [2]. Experts have been monitoring this trend for a while now. The productivity and expansion of the construction industry have remained subpar, failing to meet the mean value of aggregate economic growth for several decades [3,4].

While numerous industries have seen remarkable productivity enhancements in the past decades due to technological innovations, lean processes, and digitalization, construction remains a notable exception. Since 1995, the annual growth rate of productivity has merely risen by 1.0%. In contrast, the manufacturing sector has realized an average economic surge of 2.6% [1].

This shortfall stems from several factors:

- Firstly, the inherently bespoke nature of construction projects makes it challenging to introduce standardized methodologies. Each project’s distinctiveness, coupled with the ever-changing dynamics of construction sites, renders workflows less adaptable and harder to optimize [5].

- Secondly, the construction sector exhibits a tentative approach towards the integration of new technologies. The inherent risks associated with construction, the intricate nature of projects, and a long-standing adherence to traditional practices play a part in this hesitance [6].

- Lastly, the industry’s cultural ethos presents challenges. A pervasive resistance to change coupled with inadequate training initiatives and a hesitation towards technology adoption, often serves as a barrier to potential productivity improvements [7].

Evidently, a paradigm shift in the construction industry’s modus operandi is imperative. It must evolve and adopt innovative strategies to bridge the productivity gap and align with advancements observed in other sectors.

The marked rapid progression of stationary production is largely credited to the early embrace of lean principles inspired by the model of Taiichi Ohno. The shift to just-in-time manufacturing, combined with waste reduction, triggered a transformative upswing across the industry [8].

- Within on-site construction, age-old traditional methods were firmly adhered to, largely because each building project’s unique characteristics seemingly made process standardization difficult. However, as the 21st century dawned, the construction industry began to experience a significant shift, increasingly prioritizing the integration of innovative technologies and lean principles [9,10].

- The inception of Lean Construction is attributed to the lean management principles [11]. This production philosophy was introduced in conjunction with just-in-time manufacturing [12]. Notably, during the 1973 oil crisis, the Toyota Production System (TPS) attained significant prestige due to its emphasis on waste avoidance and reduction, which improved productivity and elevated Toyota to a position of global prominence [13]. The principles—centred around waste avoidance, value creation, value stream mapping, and zero defects—infiltrated numerous production systems and sectors [14]. Some entire business models have now been restructured in accordance with Lean principles. [15]. Simultaneously, in the realm of manufacturing, production management began to be represented through mathematical equations. Thus, queueing systems [16], kanban [17], lead time [18], and cycle time [19] could be described by mathematical formulations and subsequently optimized.

- Meanwhile, the construction industry is striving to adopt the principles of lean management to achieve lean production. The Transformation Flow Value (TFV) theory has shown significant practical advantages [20]. Yet, the application of this methodology is still inconsistent. Challenges to its adoption arise not just from tactical considerations but also from the distinct nature of each construction project [21].

- Even seemingly repetitive structures such as tunnels or bore piles are subject to various external factors, including soil conditions, surface topology, neighbouring buildings, and weather conditions, making a generic description of production processes challenging. In construction, process variability is frequently offset with the use of buffers [22]. However, this approach introduces difficulties in precisely gauging the productivity of on-site construction processes [23].

This article introduces a production model. This model is a generic framework designed for describing production processes in a way that allows for meaningful productivity comparisons. It operates on a modular system where individual production modules, representing repetitive production steps, are combined to create an entire production process. This arrangement facilitates productivity comparisons across various construction sites, enabling the assessment of production flow and value streams.

Consequently, this production model introduces an additional control variable for managing construction projects. It allows for a more precise evaluation of construction site efficiency beyond relying solely on financial metrics. Evaluating construction sites solely through financial metrics tends to obscure the impact of various influencing factors and prevents a thorough analysis of production processes.

This kind of comparison is crucial for ongoing production enhancement. Using this approach, it is possible to identify the least efficient processes across different construction sites. Consequently, the research question is framed as follows:

How can productivity on a construction site be quantified in a manner that allows for comparative analysis across different construction sites?

2. Related Work

2.1. General Standardization of Construction Processes

In the industrial sector, including construction, a process standard outlines guidelines for manufacturing, processing, or service delivery. It delineates the methods required to achieve specific quality benchmarks. Whereas product or material standards emphasize the final product’s attributes, process standards prioritize the manufacturing journey. They encompass elements such as process methodologies, quality assurance, and safety protocols. As such, the standardization of processes yields considerable advantages. Gibb and Isack found that standardization minimizes costs and positively influences processes via continual optimization. They also discerned that standardization positively affects employees, quality, and design [24]. Additionally, process standardization allows for significantly improved site logistics planning, given the precise knowledge of the duration of each process. Furthermore, standardization results in markedly fewer additions, disputes, and complaints, thereby precluding the incurrence of unforeseen costs [25]. Operational advantages also emerge from a repetitive sequence of actions, reducing the time needed for retraining and implementation. Using standardization, Fischer et al. developed a methodology for predicting delays in projects where only the actual and target times, as well as the reasons for the delay, had to be updated regularly [26].

Thus, the overarching aim is to elevate quality, mitigate risks, and enhance efficiency [27]. Although the latter objective is of paramount significance, there are currently no universally accepted standards regarding the duration of on-site construction processes within the construction industry context [28]. Such timeframes are generally determined internally by the respective companies. To do this, production processes are dissected into interlinked sub-processes. By refining these individual sub-processes, the overarching process can be optimized [29]. However, this strategy is often revisited and tailored for each distinct project [30].

The challenge of both standardizing and optimizing processes is a common theme across various industries, which has led to the creation of a multitude of different models. The following provides an overview of these production systems, serving as a foundation for our newly developed model.

According to the guideline VDI 2221, systems can be described utilizing three distinct concepts: the “functional concept”, the “structural concept”, and the “hierarchical concept” [31].

The “functional concept” views the system as a black box. The internal workings of the system are not considered or known. The focus of the concept is purely on the input, output, and observable behaviour. The “structural concept”, in contrast to the functional concept, treats the system as a white box. This approach focuses on the internal structure and workings of the system. In this view, the journey from input to output can be traced completely, understanding each step and process that occurs in between. The “hierarchical concept” views systems as part of a nested structure where every element is a system in itself, and simultaneously, each system is a part of a larger system. This approach considers systems at multiple levels. A system at one level is an element in a more complex system at a higher level, and it is composed of smaller systems at a lower level.

The breakdown of a system into sub-systems simplifies the management of intricate systems. Rather than examining the system as a whole, challenges and refinements can be addressed within pertinent sub-systems. It is common for production systems to possess a hierarchical structure. Such a design offers a clear layout where tasks, responsibilities, and authorities are distinctly delineated, streamlining the oversight and supervision of production processes. As a result, our model employs a hierarchical perspective for system description.

The hierarchical framework accentuates that system components can be interpreted as systems in their own right, while the overarching system might be perceived as a segment of a broader system. The initial phase involves pinpointing sub-systems, followed by the recognition of super-systems. This model delineates various tiers of entities and sub-entities, where each collective entity is a subset of the subsequent superior tier, and every subset forms a collective entity on the inferior tier. An exhaustive system perspective encompasses multiple strata of this system hierarchy. Delving into the hierarchy offers a multifaceted analysis of the system, whereas ascending the hierarchy deepens comprehension of its significance [32].

2.2. Production System Design in the Construction Industry

Due to the complexity of the structures [33] and the diversity of processes and materials [34] the construction industry possesses distinct characteristics and challenges that set it apart from other manufacturing environments, particularly the stationary industries [35].

The construction industry fundamentally operates on a project-based paradigm, with each structure typically regarded as a distinct project, encompassing specific goals, resources, and schedules [36]. This starkly contrasts with the stationary industries, where the production focus is typically on the continuous manufacture of standardized products. Additionally, the construction industry is typified by site dependency, wherein each project is undertaken at a specific location, significantly influencing both the work sequences and the available resources [35].

To address this issue of ‘uniqueness’, several concepts have been proposed, one of which is the notion of standard room structures [22]. Standard room structures are pre-defined building units, typically composed of several components, assembled following a standardized process [22]. They facilitate efficient design and implementation of structures by permitting process repetition and streamlined coordination between various trades.

In his thesis, Greitemann presents a model that determines the construction time, and thus the cost, by creating standard rooms and specifying quantities. Within this model, the first step entails defining the precise object requirements. Subsequently, the corresponding standard room can be selected from a database to conduct a quantity takeoff based on that model [37].

In his dissertation, Kornblum explored the concept of standardized room structures extending the idea to calculate grey energy. This model subsequently provides a foundation for determining life cycle costs. For instance, it facilitates the representation and computation of aggregate costs associated with a repair [38].

Both models operate on the premise that a building does not possess unique characteristics but can be systematized by segmenting it into modular building components. These components are repetitive sub-systems specific to certain building types. An example of such a sub-system might be an office space or a hotel room. However, the concept can be widely generalized to any repetitive sub-systems in construction.

This organizational framework introduces a meta-level, paving the way for standardization.

2.3. Value Stream Mapping in Lean Construction

We come back to the problem of monitoring productivity in construction. To also overcome the uniqueness problem in production, the concept presented can be further adapted to building production, aligning it with productivity metrics.

To apply the described concept to production, it is essential to introduce a systematic description of the production process. One highly valuable existing method for accomplishing this is through the use of Value Stream Mapping (VSM). This approach fosters a systematic understanding of the production flow for the aforementioned modular “standardized room structures”. Variability and uncertainty, inherent in construction projects of a production process can be reduced by introducing standardized construction steps by means of VSM. In this concept, the production processes consist of smaller, standardizable, and repeatedly repetitive units (Production Steps).

Lean construction, based on general lean principles of the manufacturing sector, strives to minimize waste and augment customer value. Within this framework, VSM assumes a crucial role by visually representing and optimizing the flow of materials and information across the entirety of the process [39].

VSM equips professionals with the ability to perceive the current state of a process and design an ideal future state [40]. In the construction industry, VSM aids in understanding process interactions, lead times, inventory levels, and other facets of production. VSM empowers users to discern both value-added and non-value-added activities [41]. This is vital as it aids in identifying waste, such as over-production, waiting time, transportation, excessive processing, inventory, motion, and manufacturing defects [42]. Recognizing and eliminating these wastes can enhance efficiency and increase value to the customer [14,43].

In the construction sector, VSM can be employed in various ways. For instance, it can be utilized to optimize material flows [44] at the construction site, enhance coordination among trades [45] diminish waiting times and inventory levels, or improve planning and control processes [46]. With the escalating complexity of construction and the rising expectations of customers, VSM has become an indispensable tool for achieving success in lean construction [46].

2.4. Repetitiveness

Repetitive manufacturing concerns the production of distinct items in high volumes, leveraging the available capacity through fixed processes. These finished products can either be standard or assembled from standardized components, with production management predominantly determined by production rates [47]. On the other hand, construction involves creating varied products in lower volumes. It represents a process somewhere between single and batch production, aligning with the crucial stages of product and process life cycles as per Spencer’s assessment. The production duration of a construction project is relatively short and readily quantifiable when contemplating the final project product. However, the ultimate product or a specific deliverable can be divided into numerous units, instilling a degree of artificial repeatability [47]. The recurrent nature of tasks offers an opportunity to leverage previously accumulated knowledge, inevitably leading to an improvement in processes and products. High repeatability could encourage ongoing enhancements due to the similarity of the product, the ease of measurement, and comparison across construction cycles [48]. The plan-do-check-act (PDCA) cycle, consisting of four basic sequential activities, sets the groundwork for a continuous cycle of quality improvement [49,50]. In a similar vein, Six Sigma, an assortment of techniques and tools designed for process improvement, aims at the elimination of defects and a reduction in variability. Thus, a very low error probability is expected from a statistically controlled process operating at the Six Sigma level [51].

In conclusion, repetitiveness opens up opportunities for improvement through lessons learned, PDCA, Six Sigma, and variability reduction by minimizing uncertainty and restricting the cone of uncertainty at an earlier stage. From a system description perspective, repetitiveness creates a feedback loop with activities or processes. Additionally, repetitiveness forms a closed-loop system where deviations from past events can be leveraged as input for the correction and control of current and future system outputs [52,53].

2.5. Complexity

The term “complexity” is frequently utilized in literature to refer to an elusive force that can cause disruptions, potentially undermining the success of endeavours [54]. Nevertheless, it is feasible to depict the nature of complexity. A system is deemed complex if it is constituted by various interlinked components, exhibits dynamic interaction networks, and the relationships among its constituents are not simply accumulations of independent, static entities [55]. A theory rooted in chaos theory espouses a similar perspective: complexity theory suggests that crucial interacting components autonomously self-organize, leading to the emergence of potentially evolving structures that display a hierarchy of emergent system properties. These propositions underscore the significance of the interaction between internal structures in defining complexity [56,57].

Projects embody complexity. They encompass numerous interrelated stakeholders, outcomes, and activities aimed at achieving a strategic transformation. As a result, in a broad sense, projects exemplify the characteristics of complex operations [57]. Various approaches to assess, classify, and quantify project complexity have been explored in scholarly discussions. However, these methods are predominantly focused on calculations related to scheduling and activity interdependencies [58,59]. While such models allow for relative comparison of complexity among similar projects within the same sector, they are less effective on a larger scale. The Analytic Hierarchy Process (AHP) offers a more comprehensive and simpler methodology for complexity assessment. AHP can evaluate a set of pre-determined project criteria across diverse projects and assign a numerical value from zero to one for comparative complexity analysis. Despite the potential for using AHP for project clustering, no such research currently exists. Therefore, explicit data for comparing the complexity of construction projects with other industries remain unavailable [54].

Our model precisely utilizes this Analytic Hierarchy Process (AHP) in an attempt to mitigate complexity on the operational level. By meticulously examining the construction process and the pre-defined value tower, we can simplify the complexity of the construction processes.

3. Research Methodology

The research project aims to devise a novel production model, using standard modules for measuring labour productivity in building construction and civil engineering, focusing on appropriate exemplary use cases. In this article, we focus on labour productivity, but other measurements of productivity can also be applied using this model. This is necessary to determine disruptions and delays in the construction process. By knowing which processes deviate from the reference processes, it is possible to determine the causes and optimize times in subsequent projects. This allows the possibility to increase the productivity of operational construction over a certain period of time. The developed prototype is intended to serve as a demonstrator for future developments and lay the foundation for a workflow-based process analysis. It should illustrate how a comprehensive concept can be implemented concretely along one or more use cases.

This will establish a blueprint and a framework for further advancements, which will be more established in the market based on demand.

The aspects of the research and development project are encapsulated in the following work packages (WP, see also Figure 1):

- WP1: Establish a generic model based on value chain analysis for the standardization of construction processes. This will draw on existing literature and a logical research approach.

- WP2: Identify value stream processes for various use cases. In building construction, standard spaces are to be defined and described through their production processes. For civil engineering, a similar approach will be adopted. Standardized elements, such as piles, boreholes, etc. will be broken down into standardized processes. This will either be derived from the literature or based on observations on construction sites.

- WP3: On-site data collection through time measurement. It is essential to consistently document the relevant boundary conditions, ensuring processes align with specific modules. For straightforward processes affected by multiple variables, a mathematical approach might be more effective than an empirical one. Continuously updating the database is crucial, especially when acquiring data points with shorter times for the considered process. For instance, using reference times one can swiftly compute a project’s lead time, making comparisons with other construction sites more straightforward.

Figure 1.

Research methodology.

In order to standardize process times, data or analytical functions have to be used. The data therefore can be obtained through observations/measurements or through process recognition, e.g., using AI. In addition, for simple processes with few influencing factors, the process times can be analytically determined using simple mathematical functions. It is important that the time measurement is available so that it can be displayed as a reference process using value stream analysis. Due to the high number of data points required, depending on the complexity of the process being analysed, automatic data acquisition is recommended.

4. Standardized Modules

4.1. General Theoretical Framework

The impetus for this model development stems from the challenges associated with measuring productivity in the construction industry. In construction project management, cost control is often the primary focus, under the assumption that it indirectly governs productivity. However, this approach overlooks the value stream or the production flow on-site. As a result, even when cost control is executed diligently, the outcome may appear “productive” without truly representing the actual labour productivity at the construction site. For instance, sourcing materials at a reduced cost might yield a significant profit, but this does not necessarily equate to heightened productivity.

While cost control for projects remains essential, it is insufficient for controlling factors that prioritize production flow. In construction, the flow of production on the job site is crucial. Prioritizing flow efficiency over resource efficiency is a basic principle of lean construction [60]. Therefore, optimizing construction flow should be a primary task of project management.

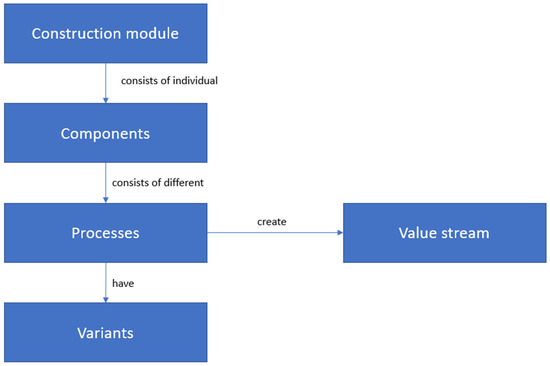

However, this method requires a universal production model that takes into account process variability in order to be suitable for improvement [61]. As previously noted, we employ a hierarchical structure for this reason. This structure relates to building components with a modular nature, which are then produced through a specific sequence of processes. The generic model embodying this concept is illustrated in the subsequent Figure 2. The individual components of the model are presented below:

Figure 2.

Model structure.

Construction module:

The term “module” is further clarified in Langenscheidt [62] or Schuh/Caesar [63]. As outlined by Brockhaus Encyclopedias, it can be broadly defined as [64]: “A specific piece of hardware (device) or software (program) that integrates as a distinct structural and functional unit within a broader system. It can be altered or substituted without necessitating alterations to the entire system. To incorporate modules into a functional system, clear interfaces must be established. Structuring systems with modular components offers the flexibility of easy adaptation to various tasks.”

Hansen [65] provides a slightly broader definition, describing modules as representations of technical systems with varying degrees of abstraction. For instance, modules might encompass form elements, individual components, assemblies, functional groups, machines, or even machine clusters, illustrating a spectrum of complexities. Hansen’s expansion of the term suggests a versatile understanding of “modules”, implying that the concept can also apply to architectural constructs.

Building upon this, we adjust Heinecker’s [66] module characteristic from factory planning to align with architectural planning: A “construction module” (essentially a technical subsection of a building) can be characterized as:

- A distinct spatial section of the building;

- Designed with a specific purpose that manifests in its structural form;

- Directly correlates with a specified level of building abstraction; and

- Can incorporate submodules.

Examples of this definition might be a bored pile wall in foundational engineering or an individual room in a building. This interpretation is considerably broader than the one typically associated with modular construction. Thus, “construction modules” are not limited to prefabricated building components but are distinct subsystems that, when integrated, create a cohesive and functional structure (building).

Building component:

A building component represents a subset of a Construction Module. To illustrate, in the examples provided, a component (or sub-module) could be a single bored pile or a wall within a room. These components can vary widely based on specific needs. For instance, the production of a bored pile might take more time in certain locations than others due to varying geological and situational factors. Similarly, room walls can differ based on their required shape and structural demands.

Production process:

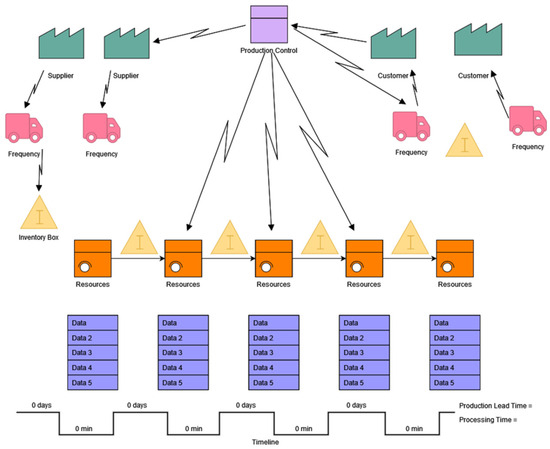

The production process encompasses the complete manufacturing procedure for a particular component. This process is charted using value stream mapping, breaking it down into distinct process steps. Value stream mapping is essential in order to model the production process in a standardized manner. It is important to note that we distinguish between production and logistics: the latter pertains to the necessary supply and delivery operations, covering both material and information flows, essential for production.

Figure 3 shows an exemplary representation of a value stream. The bar below the key figures indicates the throughput times of the individual process steps. Subsequently, this value stream can be compared with the target times in order to measure the productivity of the construction site.

Figure 3.

Exemplary representation of value stream mapping.

Process step: This level of abstraction is the level of standardization.

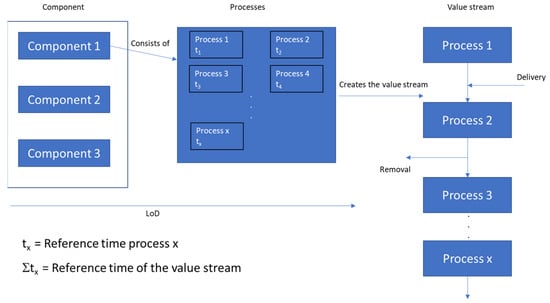

Process steps are consistently executed in a uniform manner. They are repetitive, comprising defined sequential production steps. Thus, these process steps can be described as standardizable components of a modular system. A limited assortment of distinct process steps can yield a wide variety of production processes, which can, in turn, produce a diverse array of building components. In other words, standardization at the level of process steps introduces a modular construction toolkit designed to standardize production processes at construction sites.

As an example, in the case of the bored pile wall, the drilling process can differ depending on the machine, the soil, and the type of drilling tool. If all these variants are recorded in the database by use cases, they can be used to combine a production process for each possible scenario.

This approach now allows the following procedure:

- -

- The process steps are stored in a modular system.

- -

- The process steps are given specific productivity parameters.

- -

- Value stream mapping is used to build up a production process from various process steps.

The result is a production process that is based on standardized process steps. This means that if the individual process steps are known, they can also be automatically recorded and the process times measured. In this way, actual productivity values can be derived during production. This can be achieved with automatic process recording.

In special civil engineering, automatic process capture can be implemented relatively easily since production is carried out by machines. For the most part, these construction machines are already equipped with a number of sensors, the data from which can be digitally recorded and then associated with process steps via AI pattern recognition. In building construction, corresponding methods still have to be developed. Alternatively, manual recording is a viable option.

Production step

A production step refers to a specific action in the production process that contributes to the transformation of raw materials or semi-finished products into a final product. Each step has its own requirements and uses special machines or tools, depending on the product complexity, and the duration and number of steps.

In summary, this approach allows real productivity indicators to be systematically recorded. This enables the construction industry to align its production much more closely with the production flow. With this standardized construction module kit, applicable in both structural and civil engineering, productivity in the construction sector can be seen from a fresh perspective. Subsequently, after the completion of construction sites, this model grants the ability to analyse in detail which types of processes consumed more time. If the reasons for this are identifiable, there is scope for process optimization. Additionally, just-in-time deliveries are now feasible, since the duration of each process is precisely known due to standardization. This implies that delivery and dispatch can be undertaken in real time, thereby mitigating prolonged idle and waiting periods. In Figure 4, the generic module kit is illustrated.

Figure 4.

Schematic structure of the model.

4.2. Data Gerneration

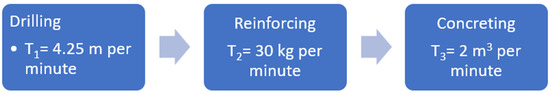

Following the development of our generic model, we initiated our first use case to gather the inaugural data for our module construction data. These data could be generated either through manual recordings or by mathematical calculation. For our first instance of data generation, we opted for manual observation of processes. Specifically, we focused on the Kelly drilling process, which was subdivided into the following three processes: drilling, reinforcing, and concreting. Numerous data recordings were executed for these points, and they now serve as the basis for further reference processes. The data were manually recorded using a tablet and then stored online in a database.

In total, we amassed more than 4000 data points across several days to ascertain a reference time for all processes. The subsoil condition of the use case amounts to wet sandy soil. The processes that were recorded were noted down in further granular detail. Table 1 elucidates the individual process steps that correspond to their respective processes. These were averaged and allocated to the respective process in the modular system. However, to attain a representative time distribution, many more investigations are imperative. Otherwise, the dispersion of the times is markedly high.

Table 1.

Subprocesses.

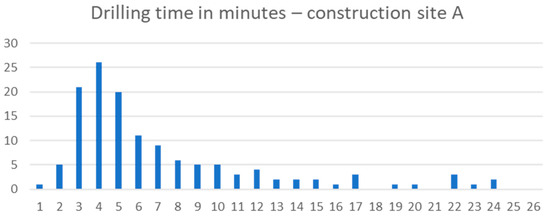

The distribution of the drilling process, as presented in Figure 5, demonstrates a substantial variability, with a factor of 24 times difference between the minimum and maximum durations. A significant portion of these delays can be attributed to idle times and inadequacies in logistics processes. By enhancing supply chain processes and advocating for just-in-time production, the solitary drilling process could be considerably reduced at several points on this construction site, thereby bolstering productivity and operational efficiency. For subsequent projects employing the Kelly drill with an auger in sandy conditions, a reference duration of 4 min is postulated. Due to the skewness of the distribution of 1.67, which is caused by delays in individual processes, the mean value of 7.15 is considerably higher than the reference value. This difference results from the consideration of delays in the mean value, while these are not included in the reference value. This duration must be adhered to for new projects. However, if the duration falls short of the reference time, the new time will be used as a reference time for future projects. This innovative methodology allows for a comparison between construction sites, enabling the recognition and exploitation of areas for optimization.

Figure 5.

Distribution of drilling durations on construction site A.

The following production process is composed of the reference times. The determined times can be used to determine reference speeds, which can also be used as a basis for future projects. In Figure 6, the Value Stream is shown with the times/speeds. The reference values for reinforcing and concreting are only example values that are presented for estimation purposes.

Figure 6.

Value Stream—Kelly drilling.

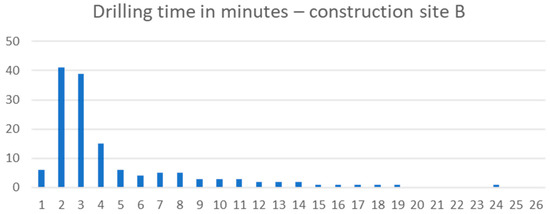

Figure 7 shows recorded data from a second construction site. With a mean value of 4.00 and a skewness of 2.87, the processes on this construction site appear to have been significantly faster and less error prone. However, the two data sets can only be compared to a very limited extent, as the influence of the different environmental conditions is not known. A comparison of data without taking the general conditions into account can easily lead to erroneous conclusions.

Figure 7.

Distribution of drilling durations on construction site B.

This is the point at which the developed model comes into play. By assigning recorded data to the individual modules, the data from similar situations can be retrieved specifically for each individual sub-process for a comparison or a prediction of process times.

5. Discussion

This paper shows the necessity of a modular approach to measure productivity in highly individual construction processes. In the following, the results are discussed against the background of the research question:

How can productivity on a construction site be quantified in a manner that allows for comparative analysis across different construction sites?

Due to the many factors that influence processes on construction sites, recorded data can often only be transferred to other situations to a limited extent. This problem can be countered with the modular structure of the developed model. Once the data have been recorded, only the appropriate combination of defined modules for each process step needs to be selected for each new construction site in order to make a prediction.

The designed model for the standardization of construction processes requires a large amount of data for comprehensive functionality. Each module is to be provided with corresponding times, which are either obtained from empirical investigations or derived by mathematical correlations. For processes such as well drilling, a simple mathematical calculation is possible due to the small number of parameters involved. However, when numerous parameters affect process time, empirical data collection becomes very complex. It is important to emphasize that the proposed model facilitates the measurement and comparison of productivity at different construction sites through standardization.

The applicability of the model extends to building construction and civil engineering. This involves the comparison of clearly delineated, easily observable or recordable processes with reference times. In many cases, it would become apparent that productivity depends on delivery processes. However, with the precise definition of reference or standard process times, enabling just-in-time delivery and acceptance becomes feasible. This implies that only the pure value-added production process determines the duration of the construction project.

6. Conclusions

The research results suggest that a significant increase in efficiency can be achieved in the construction industry by implementing the developed model. A dynamic improvement of the processes is made possible by continuously adapting the reference processes on the basis of newly acquired data, which is of particular importance in an industry as variable and adaptable as the construction industry.

In the future, it is conceivable that the scalability of the model could be expanded and that real-time data from the Internet of Things (IoT) and other digital tools could be integrated to automate data collection. This would not only improve the timeliness and accuracy of the reference processes, but also further advance the methods of analysis, such as through machine learning and artificial intelligence. This would make it possible to identify patterns and deviations in process data more quickly and enable preventive maintenance and planning in the construction industry. This would enable companies to identify potential problems at an early stage and make resource-optimized, data-based decisions.

In summary, the paper shows a promising approach to improving productivity measurement in construction and provides a basis for further research that has the potential to revolutionize the efficiency of construction processes. Given the rapid development in construction processes and technologies, it is crucial to continuously update the model and adapt it to the changing needs of the industry.

Author Contributions

Conceptualization, M.G., D.H. and K.N.; data curation, M.G., D.H. and K.N.; formal analysis, M.G., D.H. and K.N.; funding acquisition, K.N.; investigation, M.G. and K.N.; methodology, M.G., D.H. and K.N.; project administration, K.N.; resources, K.N.; validation, M.G. and D.H.; visualization, M.G. and D.H.; writing—original draft, M.G., D.H. and K.N.; writing—review and editing, M.G., D.H. and K.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy StMWi grant number IUK 641/002.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available as it was generated by the industry partner BAUER Group.

Acknowledgments

The support of the Bauer Group is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction. A route to Higher Productivity; McKinsey Global Institute: Chicago, IL, USA, 2017. [Google Scholar]

- Wigren, R.; Wilhelmsson, M. Construction investments and economic growth in Western Europe. J. Policy Model. 2007, 29, 439–451. [Google Scholar] [CrossRef]

- Howell, G.; Laufer, A.; Ballard, G. Uncertainty and project objectives. Proj. Apprais. 1993, 8, 37–43. [Google Scholar] [CrossRef][Green Version]

- Rasoulkhani, K.; Alsharef, A.; Banerjee, S.; Chowdhury, S.; Li, Q.; Mostafavi, A.; Zhu, J.; Jaselskis, E.; Stoa, R. A Process Model for Regulatory Adaptation in the Construction Industry; American Society of Civil Engineers: Reston, VI, USA, 2020. [Google Scholar]

- Sears, S.K. Construction Project Management. A Practical Guide to Field Construction Management; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ahmed, S. Barriers to Implementation of Building Information Modeling (BIM) to the Construction Industry: A Review. J. Civ. Eng. Constr. 2018, 7, 107. [Google Scholar] [CrossRef]

- Lawluvy, Y.K.; Guo, F.; Wang, K. A Framework for Assessing Strategies to Combat Individuals’ Resistance to Technological Innovation in the Construction Industry; American Society of Civil Engineers: Reston, VI, USA, 2022; pp. 974–982. [Google Scholar]

- Logu, P.; Arun Boopathi, M.; Aravinth, R.; Ganesh Kumar, S. Implementation of Lean Manufacturing in Automotive Industries. Int. J. Eng. Res. Technol. 2021, 19, 10. [Google Scholar]

- Ballard, G.; Howell, G. Implementing Lean Construction: Stabilizing Work Flow. Lean Constr. 1994, 2, 105–114. [Google Scholar]

- Awad, T.; Guardiola, J.; Fraíz, D. Sustainable Construction: Improving Productivity through Lean Construction. Sustainability 2021, 24, 13877. [Google Scholar] [CrossRef]

- Palange, A.; Dhatrak, P. Lean manufacturing a vital tool to enhance productivity in manufacturing. Mater. Today Proc. 2021, 46, 729–736. [Google Scholar] [CrossRef]

- Dekier, Ł. The Origins and Evolution of Lean Management System. J. Int. Stud. 2012, 5, 46–51. [Google Scholar] [CrossRef]

- Liker, J.K.; Convis, G.L. The Toyota Way to Lean Leadership. Achieving and Sustaining Excellence through Leadership Development; McGraw-Hill’s Access Engineering; McGraw-Hill Education LLC: New York, NY, USA, 2012. [Google Scholar]

- Ohno, T. Das Toyota-Produktionssystem; Campus Verlag: Frankfurt am Main, Germany, 2013. [Google Scholar]

- Balocco, R.; Cavallo, A.; Ghezzi, A.; Berbegal-Mirabent, J. Lean business models change process in digital entrepreneurship. Bus. Process Manag. J. 2019, 7, 1520–1542. [Google Scholar] [CrossRef]

- Duenyas, I.; Hopp, W.J. Estimating variance of output from cyclic exponential queueing systems. Queueing Syst. 1990, 7, 337–353. [Google Scholar] [CrossRef]

- Bitran, G.R.; Chang, L. A Mathematical Programming Approach to a Deterministic Kanban System. Manag. Sci. 1987, 33, 427–441. [Google Scholar] [CrossRef]

- Karmarkar, U.S. Lot Sizes, Lead Times and In-Process Inventories. Manag. Sci. 1987, 33, 409–418. [Google Scholar] [CrossRef]

- Goyal, S.; Singhal, S. Technical Paper Response: Determination of Manufacturing Cycle Time in Multi-stage Production Systems. Int. J. Oper. Prod. Manag. 1989, 9, 60–63. [Google Scholar] [CrossRef]

- Igwe, C.; Hammad, A.; Nasiri, F. Influence of lean construction wastes on the transformation-flow-value process of construction. Int. J. Constr. Manag. 2020, 22, 1–7. [Google Scholar] [CrossRef]

- Project Management Institute. Construction extension to the PMBOK Guide; Project Management Institute Inc.: Newtown Square, PE, USA, 2016. [Google Scholar]

- Poshdar, M.; González, V.A.; Raftery, G.M.; Orozco, F. Characterization of Process Variability in Construction. J. Constr. Eng. Manag. 2014, 11, 5014009. [Google Scholar] [CrossRef]

- Chan, P.; Kaka, A. Construction Productivity Measurement: A Comparison of Two Case Studies. In Proceedings of the 20th Annual ARCOM Conference, Edinburgh, UK, 1–3 September 2004. [Google Scholar]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Vokurka, R.J.; Lummus, R.R. The Role of Just-In-Time in Supply Chain Management. Int. J. Logist. Manag. 2000, 11, 89–98. [Google Scholar] [CrossRef]

- Fischer, M.; Garcia-Lopez, N.P.; Morkos, R. Making Each Workhour Count: Improving the Prediction of Construction Durations and Resource Allocations. In Advanced Computing Strategies for Engineering; Smith, I.F.C., Domer, B., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2018; pp. 273–295. [Google Scholar]

- Mor, R.S.; Bhardwaj, A.; Singh, S.; Sachdeva, A. Productivity gains through standardization-of-work in a manufacturing company. J. Manuf. Technol. Manag. 2019, 6, 899–919. [Google Scholar] [CrossRef]

- Aapaoja, A.; Haapasalo, H. The Challenges of Standardization of Products and Processes in Construction. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, UK, 1992. [Google Scholar]

- Hoffman, G.J.; Thal, A.E., Jr.; Webb, T.S.; Weir, J.D. Estimating Performance Time for Construction Projects. J. Manag. Eng. 2007, 23, 193–199. [Google Scholar] [CrossRef]

- Association of German Engineers. Design of Technical Products and Systems—Model of Product Design; Association of German Engineers: Harzgerode, Germany, 2019; p. 2221. [Google Scholar]

- Mesarovic, M.D. Systems Theoretic Approach to Formal Theory of Problem Solving. In Theoretical Approaches to Non-Numerical Problem Solving; Springer: Berlin/Heidelberg, Germany, 1970; pp. 161–178. [Google Scholar] [CrossRef]

- Mitchell, W.J. Constructing Complexity. In Computer Aided Architectural Design Futures; Springer: Berlin/Heidelberg, Germany, 2005; pp. 41–50. [Google Scholar] [CrossRef]

- Heaton, R.; Martin, H.; Chadee, A.; Milling, A.; Dunne, S.; Borthwick, F. The Construction Materials Conundrum: Practical Solutions to Address Integrated Supply Chain Complexities. J. Constr. Eng. Manag. 2022, 148, 04022071. [Google Scholar] [CrossRef]

- Paez, O.; Salem, S.; Solomon, J.; Genaidy, A. Moving from lean manufacturing to lean construction: Toward a common sociotechnological framework. Hum. Factors Ergon. Manuf. 2005, 15, 233–245. [Google Scholar] [CrossRef]

- Zwikael, O. Critical planning processes in construction projects. Constr. Innov. 2009, 9, 372–387. [Google Scholar] [CrossRef]

- Greitemann, P.N. Determination of the Construction Time Frame at the Initiation of a Project; Technische Universität München: Munich, Germany, 2018. [Google Scholar]

- Kornblum, F.S. Determination of Construction and Maintenance Cost as Well as the Consumption of Embodied Energy during Construction and Operation of Real Estate; Technische Universität München: Munich, Germany, 2018. [Google Scholar]

- Singh, B.; Garg, S.K.; Sharma, S.K. Value stream mapping: Literature review and implications for Indian industry. Int. J. Adv. Manuf. Technol. 2011, 53, 799–809. [Google Scholar] [CrossRef]

- Lasa, I.S.; Laburu, C.O.; Vila, R.d.C. An evaluation of the value stream mapping tool. Bus. Process Manag. J. 2008, 14, 39–52. [Google Scholar] [CrossRef]

- Ramani, P.V.; Ksd, L.K.L. Application of lean in construction using value stream mapping. Eng. Constr. Arch. Manag. 2019, 28, 216–228. [Google Scholar] [CrossRef]

- Shou, W.; Wang, J.; Wu, P.; Wang, X.; Chong, H.-Y. A cross-sector review on the use of value stream mapping. Int. J. Prod. Res. 2017, 55, 3906–3928. [Google Scholar] [CrossRef]

- Nübel, K.; Bühler, M.M.; Jelinek, T. Federated Digital Platforms: Value Chain Integration for Sustainable Infrastructure Planning and Delivery. Sustainability 2021, 13, 8996. [Google Scholar] [CrossRef]

- Yu, H.; Tweed, T.; Al-Hussein, M.; Nasseri, R. Development of Lean Model for House Construction Using Value Stream Mapping. J. Constr. Eng. Manag. 2009, 135, 782–790. [Google Scholar] [CrossRef]

- Arbulu, R.; Tommelein, I.; Walsh, K.; Hershauer, J. Value stream analysis of a re-engineered construction supply chain. Build. Res. Inf. 2003, 31, 161–171. [Google Scholar] [CrossRef]

- Gunduz, M.; Naser, A. Value Stream Mapping as a Lean Tool for Construction Projects. Int. J. Struct. Civ. Eng. Res. 2018, 8, 69–74. [Google Scholar] [CrossRef]

- Spencer, M.S.; Cox, J.F. An analysis of the product-process matrix and repetitive manufacturing. Int. J. Prod. Res. 1995, 33, 1275–1294. [Google Scholar] [CrossRef]

- Cho, K.; Hong, T.; Hyun, C. Scheduling model for repetitive construction processes for high-rise buildings. Can. J. Civ. Eng. 2011, 38, 36–48. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H. Research on Engineering Quality Management Based on PDCA Cycle. IOP Conf. Ser. Mater. Sci. Eng. 2019, 490, 062033. [Google Scholar] [CrossRef]

- Liu, J.; Cai, J. Construction Cost Control Based on PDCA Cycle. Int. J. Simul. Syst. Sci. Technol. 2016. [Google Scholar] [CrossRef]

- Taghizadegan, S. Essentials of Lean Six Sigma; Elsevier Science: Burlington, VT, USA, 2010. [Google Scholar]

- Hopp, W.J. Factory Physics; Waveland Press: Long Grove, IL, USA, 2011. [Google Scholar]

- Tomczak, M.; Jaśkowski, P. Scheduling repetitive construction projects: Structured literature review. J. Civ. Eng. Manag. 2022, 6, 422–442. [Google Scholar] [CrossRef]

- Vidal, L.-A.; Marle, F.; Bocquet, J.-C. Modelling Project Complexity. DS 42. In Proceedings of ICED 2007, the 16th International Conference on Engineering Design, Paris, France, 28–31 July 2007; pp. 625–626. [Google Scholar]

- Baccarini, D. The concept of project complexity—A review. Int. J. Proj. Manag. 1996, 4, 201–204. [Google Scholar] [CrossRef]

- Curlee, W.; Gordon, R.L. Complexity Theory and Project Management; Wiley: Hoboken, NJ, USA, 2010; ISBN 9780470545966. [Google Scholar]

- Kerzner, H. Using the Project Management Maturity Model. Strategic Planning for Project Management; Wiley: Hoboken, NJ, USA, 2019; ISBN 9781119530824. [Google Scholar]

- Nassar, K.M.; Hegab, M.Y. Developing a Complexity Measure for Project Schedules. J. Constr. Eng. Manag. 2006, 6, 554–561. [Google Scholar] [CrossRef]

- Kaimann, R.A. Coefficient of Network Complexity. Manag. Sci. 1974, 21, 172–177. [Google Scholar] [CrossRef]

- Modig, N.; Åhlström, P. This is Lean. Resolving the Efficiency Paradox; Rheologica Publishing: Stockholm, Sweden, 2021. [Google Scholar]

- Tommelein, I.D. Impact of Variability and Uncertainty on Product and Process Development. In Building Together for a Better Tomorrow in an Increasingly Complex World. Proceedings of the Congress, Orlando, FL, USA, 20–22 February 2000; American Society of Civil Engineers: Reston, VA, USA, 2000. [Google Scholar]

- Langenscheidt. Fremdwörterbuch. 2023. Available online: http://www.langenscheidt.de/ (accessed on 14 September 2023).

- Schuh, G.; Caesar, C. Variantenorientierte Produktgestaltung—Standardisierung und Modularisierung von Serienprodukten. Konstruktion 1989, 4, 207–211. [Google Scholar]

- Brockhaus Enzyklopedias. 2023 Module (Informatik). Available online: https://brockhaus.de/ecs/enzy/article/modul-informatik (accessed on 14 September 2023).

- Hansen, F. Konstruktionswissenschaft: Grundlagen und Methoden; Hanser: Munich, Germany, 1974. [Google Scholar]

- Heinecker, M. Methodik zur Gestaltung und Bewertung wandelbarer Materialflusssysteme. Fördertechnik—Materialfluss—Logistik; Utzverlag GmbH: Munich, Germany, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).