Abstract

Eco-friendly plasters offer several advantages, including sustainability, nontoxicity, and low cost. These plasters are made with sustainable materials, such as natural fibers and starches. These materials can have different mechanical properties compared to traditional plasters, which are made with gypsum and cement. Due to the increased attention being paid to environmental issues, efforts are still being made to switch out the conventional plaster of gypsum and cement for an eco-friendlier alternative to minimize toxicity, increase effectiveness, and lower cost. In this study, the effect of novel plaster behavior under pressure on mechanical properties was investigated. The plaster investigated was an eco-friendly carbon-free BSCO plaster. A range of experimental techniques were used, such as compression testing for confirmation using ANSYS 2023 R1 software, which set ergonomic and user-friendly standards as a minimum requirement, with the overarching goal of creating stronger, lighter, and more reasonably priced structures. The results showed that eco-friendly Bilateral Specialized Company (BSCO) plasters could have comparable mechanical properties to traditional plasters. Additionally, it is suggested that eco-friendly and carbon-free plasters can be a viable alternative to traditional plasters in a variety of applications. Researchers and civil engineers can both gain from this scientific paper’s potential to replace conventional stucco with an ecologically friendly alternative that has more effective mechanical qualities.

1. Introduction

Plastering is commonly recognized as the process of utilizing a plastic mortar to coat uneven walls, ceilings, and various surfaces, to achieve a uniform, tidy, and sleek appearance. Rendering is the practice of plastering on externally visible surfaces [1,2,3,4].

Newer studies that looked at this subject have been presented. Recent research compared the strengths, longevity, fire resistance, and environmental effects of geopolymers with normal Portland concrete mixes to highlight the advantages and disadvantages of this technology and direct future research toward the material’s precise optimization [5].

The idea of this study is to comprehensively investigate the mechanical characteristics of a unique and environmentally friendly plaster material. This plaster is described as “carbon-free”, indicating that it is designed to have a minimal environmental impact. This study aims to analyze how this novel plaster performs under compression, which is a critical aspect of its mechanical behavior. To achieve this, the researchers utilize ANSYS software for simulations and analysis, allowing them to assess the plaster’s strength, resilience, and other mechanical properties. This study seeks to provide valuable insights into the feasibility of using this innovative plaster in various construction applications, particularly with a focus on sustainability and reduced environmental impact.

Cement plaster is a mixture of cement, sand, and water that is applied to walls and ceilings as a finishing material. It is commonly used in construction for its durability and strength. The mixture is typically applied in multiple layers, with each layer being allowed to dry before the next one is added. Once the final layer has been applied and dried, the surface can be painted or decorated as desired. Due to its versatility and ability to be used both indoors and outdoors, cement plaster is a great choice for a wide range of construction tasks [2]. The advantages and disadvantages of normal cement plaster are shown in Table 1.

Table 1.

Advantages and disadvantages of ordinary cement plaster.

Another study sought to create a recycled fiber-reinforced cement plaster mortar for interior use that had acceptable workability when the mixture was still fresh and had good insulating, mechanical, and adhesive qualities. It investigated how the integration of various amounts of three distinct types of cellulose fibers from recycled wastepaper affected the mortar’s workability and other physical and mechanical parameters (1:3 cement/sand ratio). The cellulose content, level of polymerization, and papermaking remnants of the wastepaper fiber (WPF) samples were applied to characterize them. The findings demonstrated the significance of fiber-reinforced cement plaster mortar composition and its bearing on cement characteristics. The potential of the fibers to control humidity inside buildings by absorbing and/or releasing water molecules, depending on the air conditions, was also emphasized as a feature of these fiber-based plaster mortars for offering healthy living options [6]. Plant-fiber-reinforced cementitious composites, when compared to conventional or enhanced concretes [7], have a lower environmental impact than conventional materials, call for fewer industrial and technological changes, and improve the life cycle assessment of the finished product [8]. However, the ultimate mechanical properties of the composites are significantly influenced by the adhesion between the fiber and matrix. The effectiveness of the reinforcement is determined by the stress transmission between the matrix and the fiber filler [9]. Poor fiber–matrix bonding, fiber aggregation, and increased porosity result in lower strength and stiffness for plant-fiber-reinforced cementitious composites, as indicated in [10]. The reciprocal compatibility of these qualities, which leads to a uniform distribution of the reinforcing fibers in the matrix, is another dominant factor influencing the mechanical properties [11]. A study of the compressed mechanical properties based on a novel BSCO plaster was missing from prior research. The BSCO plaster is regarded as one of these plastering processes. BSCO plasters are a premium type of cementitious tile adhesive that incorporates polymer modifications. They are composed of Portland cement, graded silica sand, polymeric substances, and specialized additives to enhance certain properties, fillers, and chemicals.

Bilateral Specialized Company (BSCO) plaster is a cutting-edge material that combines the strength and durability of traditional plaster with unique properties derived from its chemical composition. This advanced plaster is composed of a blend of barium, strontium, calcium, and oxygen, constituting a compound that exhibits exceptional qualities in various applications [12]. A pressure test was conducted to measure the structural integrity and load-bearing capacity of BSCO plaster. The samples were subjected to controlled pressures to ascertain their maximum stress tolerance without compromising their stability. This evaluation is essential for establishing the suitability of the material for construction projects where strength and resilience are of utmost importance [12].

Methane and other greenhouse gases are already present in the atmosphere; therefore, emissions of these gases must be limited until the system as a whole is restored to equilibrium. The results of our testing provide insights into the capabilities of BSCO plaster. By quantifying its performance under pressure and environmental pollution, we gain a comprehensive understanding of its potential advantages in construction and other relevant industries. These findings can help architects, engineers, and builders make informed decisions about incorporating BSCO plaster into their projects, thereby boosting structural integrity and longevity.

To evaluate BSCO plaster’s performance in challenging situations, this article shows expertly made samples of the material. These samples underwent rigorous testing procedures to estimate their response to both pressure and pollution.

2. Advantages and Disadvantages of Divergent Types of Plasters and Their Applications

2.1. Ordinary Cement Plaster

The properties and mechanism of ordinary cement plaster are presented briefly in this section.

2.1.1. Cracking

Cement plaster is prone to cracking due to factors like shrinkage during the drying process or movement in the building’s structure. Cracks may also result from thermal movements, foundation shifts, or prolonged exposure to moisture [13].

2.1.2. Moisture Damage

Cement plaster can absorb moisture, leading to issues such as mold growth, deterioration, and discoloration. In comparison, other materials like gypsum or earth-based plasters have better hygroscopic properties.

2.1.3. Structural Issues

Some cracks may pose a threat to the building’s structural integrity, particularly in cases of poor design, shoddy construction, or overloading. These structural cracks can appear in critical areas such as beams, columns, slabs, or footings.

2.1.4. Poor Adhesion

Plaster may not cling effectively to the substrate if the surface is improperly prepared or applied. Poor construction typically leads to several widespread flaws that are readily visible in the top layer of plaster [14].

2.1.5. Efflorescence

Efflorescence, the formation of white salts on the plaster surface due to moisture, can occur and hinder the adhesion of paints and coatings. Over time, this can lead to the deterioration of the paint and coating systems [15].

2.1.6. Mechanical Properties

Cement plaster has limited mechanical strength when compared to materials like lime mortar. This can affect its performance, especially in applications where mechanical strength is essential.

2.1.7. Adhesion Issues

Proper surface preparation is crucial for ensuring good adhesion. Poorly prepared or improperly applied plaster can lead to widespread issues with the plaster’s surface layer.

2.1.8. Uneven Texture

Textural plaster can be used to produce cool, peaceful, open atmospheres or to cost-effectively smooth over rough textured walls like blockwork and stock brick. It also serves as a neutral background for artificial materials, colors, and textures. If the plaster mix is not applied evenly or if there are inconsistencies in the substrate, it can induce an uneven texture.

2.1.9. Limited Design Options

Cement plaster has limited design options compared to other finishes such as stucco or decorative plaster.

2.1.10. Time-Consuming Application Process

Applying cement plaster requires a skilled tradesperson and can be time-consuming compared to other finishes.

2.2. Eco-Friendly Cement Plaster

2.2.1. Type of Green Cement

Ekkomaxx cement, composed of 95% fly ash and 5% renewable liquid additives, is considered an environmentally friendly cement option. It boasts several advantages shown in Table 2, including a significantly reduced carbon footprint and improved mechanical properties. Notably, it exhibits low chloride permeability, as well as sulfate attack resistance, durability, and corrosion resistance that surpass those of conventional cement. Furthermore, it demonstrates the ability to withstand thawing and freezing cycles better than traditional cement [16].

Table 2.

Advantages and disadvantages of green cement plaster.

2.2.2. Applications

Green cement plaster offers a range of applications in the construction industry due to its eco-friendly and high-performance characteristics:

Green Concrete: Green cement can be used to create sustainable concrete mixes with a reduced carbon footprint by incorporating supplementary cementitious materials (SCMs). This enhances the strength and durability of concrete structures [17].

Pavement Building: Green cement is suitable for pavement buildings, offering lower carbon emissions and enhanced durability [18].

Foundation Building: It is an excellent choice for foundations, reducing carbon footprints and providing long-term durability and strength [19].

High-Rise Structures: Green cement can be applied in the construction of high-rise buildings, contributing to sustainability and environmental protection by reducing emissions and waste [18,19].

Water Treatment Plant Foundations: Green cement is valuable for the construction of water treatment plants, ensuring both structural integrity and environmental responsibility [20].

Bridges: The use of green cement in bridge construction can reduce emissions, protect natural resources, and enhance the lifespan of structures, resulting in cost savings and environmental benefits [18,19,20].

2.2.3. Eco-Friendly Cement Plaster in the Literature

In recent years, there has been a notable drive towards sustainability in the concrete industry. This is largely driven by the urgent need to reduce carbon emissions associated with traditional Portland cement production. Sustainable alternatives, such as green cement and eco-friendly plasters, are gaining prominence. These alternatives have the potential to significantly reduce carbon footprints and offer enhanced performance in various construction applications [21,22].

2.3. Thermoplastic

This section compares thermoplastic with cement plaster to evaluate its advantages and disadvantages. Thermoplastic is a type of plaster that contains insulating materials such as expanded polystyrene (EPS) or mineral wool. It is used to insulate walls and ceilings, yielding thermal insulation and curtailing heat loss in buildings. Thermoplastic can also provide sound insulation and fire resistance. It is typically applied in a layer over existing walls or as part of a new construction project [23]. The advantages and disadvantages of this plaster are depicted in Table 3.

Table 3.

Advantages and disadvantages of thermoplastics.

3. Methodology

The compressive strength of the specification was detected using a universal testing machine (UTM) in agreement with ASTM C-109 (Standard Test Method for Compressive Strength of Hydraulic Cement Mortars) (using 2 in. or 50 mm cube specimens) by applying C109/C109M [24]. This section presents the methodology of this study, including the method of specimen preparation, compression test, ANSYS program steps, and emissions test.

3.1. Preparation of Specimens

BSCO plaster is a cement-based powder completely mixed with water according to the manufacturer’s instructions. Accordingly, 500 mL of water was mixed with 2 kg of powder to make the plaster. The liquid was poured into seven 50 mm 3 cubic molds, as shown in Figure 1. The sample preparation was then finished after three days of drying and hardening without water spray. Figure 1 reveals the stages of specimen preparation of the plaster.

Figure 1.

Samples after being removed from the molds with simulated ones.

3.2. Specimen Dimensions

The samples in the shape of a cube had dimensions of 50 mm × 50 mm × 50 mm. The specimens for this research were given a standard size by these measurements, allowing for accurate and dependable testing and analysis of the material’s mechanical characteristics.

3.3. Compression Test

The ability of a structure or material to withstand load on its surface without cracking or deformation is referred to as compression strength. When a material is compressed, its size shrinks, and when it is tensioned, its dimensions rise. The gradual loading procedure is repeated until the specimen fails [25]. The strength of compression is defined as the load at failing divided by the cross-section area of the specimen. The percentage of the greatest force applied to the cross-section area of the specimen is used to compute the typical compressive strength of the specimen. For this test, the cubes were removed from the molds after three days, as illustrated in Figure 1, and tested for compressive strength. It was observed that there were no problems related to removal from the molds, and no other problems appeared related to the curing phase. The cubes were placed in a universal testing machine (UTM), and a load was applied with a speed of 1 mm/min until the cubes failed. The strength and behavior of the material under a compressive load were calculated.

3.4. The ANSYS Program

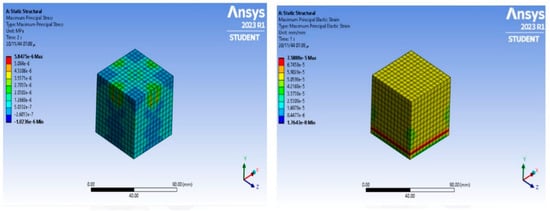

The ANSYS program exhibits the capacity to optimize a variety of features, consisting of boundary conditions and geometrical design. It may combine different physics and carry out analysis [26]. It makes use of particular inputs and compares product behavior to physics. The main simulation-driven layout tool utilized in this study was the ANSYS software program Discovery. To establish the boundary conditions, a dynamic explicit/implicit approach was applied, with a fixed support employed at the bottom of the sample and a displacement support implemented at the top of the BSCO plaster samples as shown in Figure 2. The ANSYS software program Discovery combines interactive geometry modeling, high-fidelity simulation, and real-time physics simulation within a single, user-friendly interface, yielding comprehensive capabilities for analysis and design; therefore, simulation was carried out to compare experimental curves with simulated ones. This allowed for a more accurate analysis of the behavior of the eco-friendly plaster.

3.5. Emission Test

An industrial flue gas analyzer is a device that is used to measure the composition of flue gases from industrial combustion processes. The analyzer can measure a variety of discrete pollutants, such as carbon monoxide, nitrogen oxides, sulfur dioxide, and particulate matter. A little mixture began to form, so for a time, the thermocouple was moved closer to the mixture by 2–3 cm, and readings were collected continuously. Emissions tests were conducted to determine if there were any pollutants emissions during the production process or use of eco-friendly plaster. In this study, the type of flue gas analyzer used was the Kane 988 automotive Diagnostic Exhaust Gas Analyzer.

4. Results and Discussion

This section presents the results and the discussion of the mechanical characteristics concurring with the compression test for seven samples and the emission results.

4.1. Compression Stress Results

The compression power check results are explained in Figure 3, together with the load in kilonewtons and the position in millimeters. Due to its inability to endure compression stress, the plaster pattern created using cement containing blended powder exhibits brittleness. The presumed fracture was precisely in the center of the sample as the plaster pattern was placed and put through the compression test.

In this test, seven specimens were experimentally tested to obtain the mechanical properties, and Table 4 discloses the calculated mechanical properties.

Table 4.

Mechanical property results after compression test.

- Yield Strength (0.98 MPa): This is the amount of stress at which a material begins to deform plastically. It represents the point at which the material no longer returns to its original shape after the applied stress is removed. It is typically measured in megapascals (MPa).

- Ultimate Strength (6.72 MPa): This is the maximum stress that a material can withstand without breaking. It is also known as the tensile strength and is measured in megapascals (MPa).

- Modulus of Elasticity (560 MPa): This property, often denoted as Young’s Modulus, measures a material’s stiffness or its ability to deform elastically under an applied load. It quantifies the relationship between stress and strain in the elastic region of a material. It is measured in megapascals (MPa).

- Stiffness (16.17 N/m2): Stiffness is a measure of how resistant a material is to deformation when subjected to an external force. It is typically measured in newtons per square meter (N/m2), which is equivalent to pascals (Pa).

- Toughness (0.04 J/m2): Toughness quantifies a material’s ability to absorb energy before fracturing. It is the amount of energy per unit volume (joules per square meter, J/m2) a material can absorb before breaking.

- Poisson’s Ratio (0.0018): Poisson’s ratio is a dimensionless number that describes the ratio of lateral contraction (negative strain) to axial extension (positive strain) when a material is stretched or compressed. It is used to understand a material’s response to deformation.

These properties are essential for understanding how a material behaves under various mechanical loads and are critical for engineering and materials science applications.

Reasons for Using ANSYS Simulation Software:

ANSYS is a widely recognized and versatile finite element analysis (FEA) simulation software. It is often chosen for engineering and materials science simulations for several reasons:

- Comprehensive Capabilities: ANSYS offers a wide range of tools and capabilities for simulating various physical phenomena, including structural, thermal, fluid dynamics, and electromagnetic simulations. This versatility makes it suitable for a broad spectrum of engineering and scientific applications.

- Accuracy and Reliability: ANSYS is known for its accuracy and reliability in predicting the real-world behaviors of materials and structures. It is capable of providing highly accurate results, which is crucial in research, development, and validation.

- Wide User Base: Many engineers, scientists, and researchers are trained in ANSYS, which fosters collaboration and ease of use in academic and industrial settings.

- Customization: ANSYS allows for customization and parameterization of simulations, making it possible to tailor the software to specific research needs.

- Validation and Comparison: ANSYS enables researchers to validate their simulations by comparing the results with experimental data. This validation process helps ensure the accuracy and reliability of the simulated outcomes, enhancing the trustworthiness of research findings.

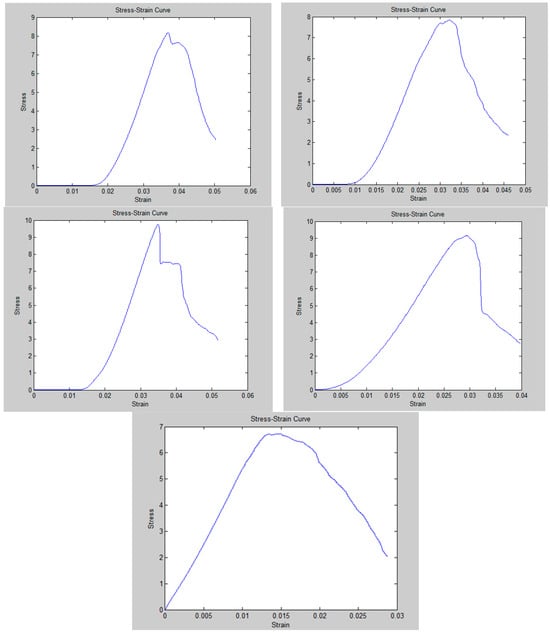

Figure 2 shows the stress-strain curves for the seven BSCO plaster samples obtained from the simulation compression test. The curves show that the samples exhibit a linear elastic behavior up to a certain strain level (yield point), after which they exhibit a non-linear plastic behavior. The yield point and the ultimate strength of the samples vary depending on the composition of the BSCO plaster and the curing conditions. Figure 3 illustrates how the curves converge.

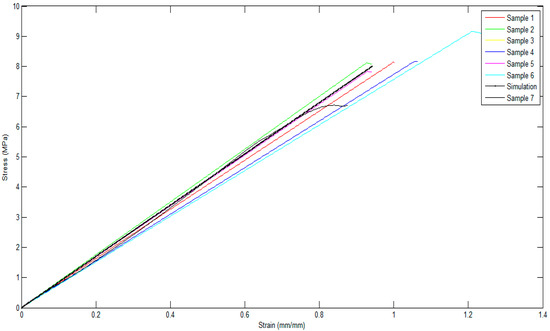

ANSYS simulation software is employed to conduct simulations and compare the resulting curves with the experimental data, thereby validating the accuracy and reliability of the simulation results. Figure 4 manifest the simulation results for the seven samples. The stress and strain diagram gives a graphical representation of the material’s behavior under compression and mechanical properties. Among the seven samples tested, the results showed that, at a strain of 1.21, sample 6 exhibited a stress of 9.1 MPa. Additionally, at a strain of 0.93, the stress recorded for the same sample was 8 MPa. The results of the seven specimens of BSCO plaster on which the compression test was conducted are presented, along with the simulation curve.

Figure 2.

Stress and strain values were obtained from the simulation compression test.

The figure also shows that the simulation results are in good agreement with the experimental data. This validates the accuracy and reliability of the simulation results.

The stress-strain curve is a graphical representation of the material’s behavior under compression. It shows how the stress in the material changes as the strain increases. The curve can be divided into two main regions: the elastic region and the plastic region.

In the elastic region, the material behaves in a linear elastic manner. This means that the stress is directly proportional to the strain. The slope of the curve in this region is known as Young’s modulus. Young’s modulus is a measure of the stiffness of the material.

In the plastic region, the material behaves in a non-linear manner. This means that the stress is not directly proportional to the strain. The yield point is the point on the curve where the material transitions from elastic to plastic behavior. The ultimate strength is the maximum stress that the material can withstand before it fails.

The stress–strain curve in Figure 2 shows that the BSCO plaster samples exhibit a linear elastic behavior up to a strain of approximately 1%. At this point, the samples yield and begin to exhibit a non-linear plastic behavior. The ultimate strength of the samples varies depending on their composition and curing conditions.

Figure 3.

The stress and strain diagram provides a graphical representation of the material’s behavior under compression and mechanical properties.

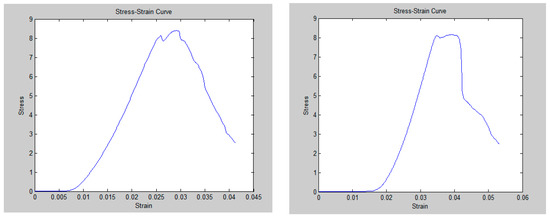

The compression load and position curves of samples 1–7 is featured in Figure 4. These figures express the stress and strain curves obtained during compression testing of the seven test specimens. These curves make it easy to visualize the behavior of the material during compression testing and give information about the stress and strain values at disparate points in the testing process.

As explained in Figure 4, there is a relation between strain and stress for the seven samples and stress varies by strain. For the seven samples, the stress increment started at strains 0–0.02 and reached its maximum at strains 0.03–0.04.

Figure 4.

Compression load and position curves of samples 1–7.

In Figure 4, the seven individual graphs represent the stress–strain curves obtained during the compression testing of the seven different test specimens. Each curve corresponds to one specific sample (samples 1 to 7), and they illustrate how the material behaves when subjected to a compressive load.

Strain vs. Stress: The x-axis typically represents strain, which is a measure of how much the material deforms under the applied load. The y-axis represents stress, which quantifies the force experienced by the material per unit area.

Differences Between Curves: The primary objective of Figure 4 is to highlight the variations in behavior among the seven samples. These differences are explained as follows:

- Starting Points: Look at where each curve begins. Some samples may exhibit stress at very low strains (near 0), indicating initial stiffness. Others might start at slightly higher strains, suggesting some initial deformation under minimal load.

- Slope: Examine the steepness of each curve. A steeper slope indicates a material’s ability to withstand stress while undergoing relatively minimal deformation, which may be an indicator of higher stiffness.

- Peak Stress: Identify the points where the stress reaches its maximum value on each curve. Note that the stress varies by strain, and this peak value is an indicator of the maximum load the material can withstand before failure.

- Post-Peak Behavior: Observe how stress changes after reaching its peak value. Some materials may exhibit a sudden drop in stress after the peak (brittle behavior), while others may gradually decrease stress (ductile behavior).

Implications: Explain the implications of these differences. For instance, you could discuss how certain samples may be more resilient under compression, while others may deform more readily. Additionally, consider discussing the practical applications or consequences of these varying stress–strain behaviors.

By comparing the seven graphs and explaining the differences between them, you provide a detailed understanding of how different samples of the material respond to compression, which is essential for drawing conclusions on their performance and suitability for specific applications.

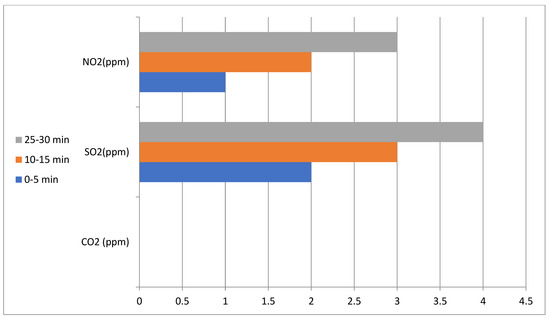

4.2. Emission Test Results

Emission studies were performed to evaluate whether any pollutants were released during the manufacturing process or the usage of eco-friendly plaster. Hence, using a gas analyzer for the specimens in this study, the CO2, SO2, and NO2 in ppm were recorded for 30 min; the recorded time was 5 min after each 10 min of nonrecorded time. The outcomes were typical. A rise in SO2 was seen when the material was measured with an emission meter, as indicated in Table 5 and Figure 5. The outcomes demonstrate that the concentration of SO2 (ppm) throughout the intervals of 0 to 5, 10 to 15, and 25 to 30 min is higher than the concentrations of CO2 and NO2. Despite this rise, this material is regarded as environmentally friendly due to its crucial role in achieving zero carbon emissions. This aspect contributes to reducing greenhouse gas emissions, enhancing sustainability, and promoting health and cost savings. It is a promising choice for the future of construction.

Table 5.

Emissions result at three divergent times.

Table 5.

Emissions result at three divergent times.

| Time | CO2 (ppm) | SO2 (ppm) | NO2 (ppm) |

|---|---|---|---|

| 0–5 min | 0 | 2 | 1 |

| 10–15 min | 0 | 3 | 2 |

| 25–30 min | 0 | 4 | 3 |

Figure 5.

Comparison between gas emissions at various time durations.

This suggests that despite the observed increase in SO2 (sulfur dioxide) emissions when measuring the eco-friendly plaster, it is still considered environmentally friendly. This may seem counterintuitive, but there are several reasons why it is considered so:

- Established Limits and Regulations: In environmental science and regulations, there are established limits and guidelines for emissions of various pollutants, including SO2. These limits are set to ensure that emissions do not reach levels that are harmful to the environment or human health. If the measured SO2 emissions fall within these established limits, they can be considered environmentally friendly because they comply with regulatory standards.

- Context of Emissions: The context in which the emissions occur matters. In some cases, minor emissions of certain pollutants, like SO2, can be considered acceptable if they are related to a process or material that contributes to significant environmental benefits. For example, if the plaster is used in a construction context that significantly reduces carbon emissions (as indicated by “achieving zero carbon emissions” in the text), then the relatively small increase in SO2 emissions might be outweighed by the overall positive environmental impact.

- Net Environmental Benefit: The term “environmentally friendly” is not solely based on the absence of emissions but on a net assessment of the environmental impact. If the use of this plaster leads to a significant reduction in greenhouse gas emissions, improved sustainability, and health benefits (e.g., improved indoor air quality), it can be considered environmentally friendly in a broader context.

- Future Potential: The text also suggests that this plaster is a “promising choice for the future of construction”. This implies that the material may be part of a larger sustainability and environmental improvement strategy, and the increase in SO2 emissions may be a relatively small trade-off for the greater environmental benefits it offers.

In summary, while the increase in SO2 emissions might raise concerns on its own, the assessment of whether the plaster is environmentally friendly takes into account a broader context, including compliance with regulations, net environmental impact, and its contribution to sustainability and reduced carbon emissions. It is seen as a positive choice for the environment based on a holistic evaluation of its effects.

This describes the measurement of emissions from the eco-friendly plaster, which included monitoring CO2 (carbon dioxide), SO2 (sulfur dioxide), and NO2 (nitrogen dioxide). The measurement was conducted using a gas analyzer for 30 min, with a specific recording pattern. The emissions were measured as follows:

- Instrumentation: A gas analyzer, which is a specialized instrument designed for the measurement and analysis of gases in the air, was employed for this purpose. Gas analyzers are capable of detecting and quantifying specific gases, such as CO2, SO2, and NO2, in parts per million (ppm) or other relevant units.

- Sampling Period: The measurement duration was 30 min. During this period, the gas analyzer continuously monitored and recorded the concentrations of the specified gases.

- Recording Pattern: The recording pattern was structured as follows: The gas analyzer recorded data for 5 min and then had a 10 min period where no data was recorded. This pattern was likely repeated throughout the 30 min measurement period.

- Data Analysis: The data collected using the gas analyzer was analyzed to determine the concentrations of CO2, SO2, and NO2 in parts per million (ppm) during different time intervals. The specific time intervals mentioned in the text were 0 to 5 min, 10 to 15 min, and 25 to 30 min.

- Comparison: The concentrations of these gases, especially SO2, were compared over the specified time intervals. As mentioned in the text, the concentration of SO2 was found to be higher than that of CO2 and NO2 during these intervals, which indicates the increase in SO2 emissions when the eco-friendly plaster was tested.

The goal of this emission measurement was to assess whether the use of the eco-friendly plaster led to the release of specific pollutants. Despite the increase in SO₂ emissions, the plaster was deemed environmentally friendly based on a broader assessment, which took into account its role in achieving zero carbon emissions, reducing greenhouse gas emissions, enhancing sustainability, and promoting health and cost savings, as explained in the text. The measurement was likely part of a comprehensive evaluation of the material’s environmental impact.

5. Conclusions

In this research, the primary focus was on investigating the mechanical properties of BSCO plaster (BRP). The main objective of this study was to examine the speed and mechanical behavior of this specific plaster, which has received limited attention in recent research. The experiments and tests conducted aimed to address this knowledge gap and provide valuable insights into the material’s properties and characteristics.

The research included compression simulations performed using ANSYS software, which revealed significant data regarding the material’s strength. Contrasting the experimental data with the simulation results helped in understanding the material’s performance. Additionally, an emissions analysis was conducted.

The findings from the compression tests indicated that the final strength of the plaster was measured at 6.72 MPa. However, it is important to clarify that the claim of being “carbon-free” was not supported by the experimental data. The use of such strong terminology is not accurate without a detailed comparative emissions analysis with other types of plasters. Therefore, it is not accurate to assert that BSCO plaster provides “zero emissions” or aims for “net negative emissions” based solely on the experimental results presented.

In conclusion, the research findings suggest that BSCO plaster exhibits notable strength and sustainability characteristics, making it a potentially promising material for various applications. However, any claims of its environmental benefits should be based on a comprehensive and comparative evaluation of emissions and environmental impact relative to other types of plaster to establish its eco-friendliness accurately.

Author Contributions

Conceptualization, M.A.A.; Methodology, M.A.A.; Software, M.A.A.; Validation, M.A.A.; Formal analysis, M.A.A.; Investigation, A.D.A.; Resources, M.A.A.—original draft, M.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The datasets used during the current study are available from the corresponding author upon reasonable request.

Acknowledgments

The researchers would like to thank the Deanship of Scientific Research, Qassim University, for funding the publication of this project.

Conflicts of Interest

The authors affirm that there are no conflict of interest to disclose. The founders did not have any involvement in this study’s design, data collection, analysis, interpretation, manuscript writing, or decision to publish the results.

Correction Statement

This article has been republished with a minor correction to the Acknowledgments ("Researchers would like to thank the Deanship of Scientific Research, Qassim for providing funding to cover the publication fees associated with this project." should be changed to "The researchers would like to thank the Deanship of Scientific Research, Qassim University, for funding the publication of this project."). This change does not affect the scientific content of the article.

References

- Akhter, J.S.; Ahmad, A.; Sharma, R.K.; Singh, R.; Mohd, A. Polymers/graphenederivative–based nanocomposites as electrode materials for supercapacitors. In Advances in Electronic Materials for Clean Energy Conversion and Storage Applications; Woodhead Publishing: Sawston, UK, 2023; pp. 451–474. [Google Scholar]

- Gharpedia.Com. 2023. Available online: https://gharpedia.com/blog/cement-plaster/ (accessed on 14 May 2023).

- Delorme, V.A.; Tran, H.T. Towards Low Carbon Buildings. Master’s Thesis, Lund University, Lund, Sweden, 2023. [Google Scholar]

- Khan, M.B.; Shafiq, N.; Waqar, A.; Imran, M. Production of Biochar from Waste Biomass Feedstock and Its Applications in Sustainable Construction. J. Xi’an Shiyou Univ. Nat. Sci. Ed. 2023, 19, 662–690. [Google Scholar]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. cement matrix materials: How nanofiller can help a sustainability approach for smart construction applications—A review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef]

- Stevulova, N.; Vaclavik, V.; Hospodarova, V.; Dvorský, T. Recycled Cellulose Fiber Reinforced Plaster. Materials 2021, 14, 2986. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, J.; Duan, Z. Strategies to accelerate CO2 sequestration of cement-based materials and their application prospects. Constr. Build. Mater. 2022, 314, 125646. [Google Scholar] [CrossRef]

- Filho, A.S.; Parveen, S.; Rana, S.; Vanderlei, R.; Fangueiro, R. Micro-structure and mechanical properties of microcrystalline cellulose-sisal fiber reinforced cementitious composites developed using cetyltrimethylammonium bromide as the dispersing agent. Cellulose 2021, 28, 1663–1686. [Google Scholar] [CrossRef]

- Fujiyama, R.; Darwish, F.; Pereira, M.V. Mechanical characterization of sisal reinforced cement mortar. Theor. Appl. Mech. Lett. 2014, 4, 061002. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Basak, R.K.; Adhikari, B.; Majumder, S.B. Improvement of the mechanical properties of jute fibre reinforced cement mortar: A statistical approach. Constr. Build. Mater. 2013, 38, 776–784. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Chitte, C.J.; Sonawane, Y.N. Study on causes and prevention of cracks in building. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 453–461. [Google Scholar] [CrossRef]

- Kolawole, J.T.; Olalusi, O.B.; Orimogunje, A.J. Adhesive bond potential of compressed stabilised earth brick. Structures 2020, 23, 812–820. [Google Scholar] [CrossRef]

- Fobbe, N.; Goetz-Neunhoeffer, F.; Foerthner, S.; Foerster, H.; Jansen, D. Drying of gypsum plaster prisms: Prevention of visible sodium sulfate efflorescence through calcium formate addition. Mater. Struct. 2023, 56, 125. [Google Scholar] [CrossRef]

- Danish, A.; Salim, M.U.; Ahmed, T. Trends and developments in green cement “A sustainable approach”. Sustain. Struct. Mater. Int. J. 2019, 2, 45–60. [Google Scholar]

- Arachchi, K.K.; Selvaratnam, A.; Gamage, J.C.P.H.; De Silva, G.I.P. Green composite plaster with modified morphology for enhanced thermal comfort in buildings. Case Stud. Constr. Mater. 2021, 15, e00611. [Google Scholar]

- Sivakrishna, A.; Adesina, A.; Awoyera, P.O.; Kumar, K.R. Green concrete: A review of recent developments. Mater. Today Proc. 2020, 27, 54–58. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials–An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Sakthieswaran, N.; Sophia, M. Prosopis juliflora fibre reinforced green building plaster materials—An eco-friendly weed control technique by effective utilization. Environ. Technol. Innov. 2020, 20, 101158. [Google Scholar]

- González Sánchez, B.; Navarro Ezquerra, A.; Ramírez-Casas, J.; Rosell Amigó, J.R. Traditional gypsum pavements with natural aditives. In Proceedings of the ICBBM 2021: 4th International Conference on Bio-based Building Materials, Barcelona, Spain, 16–18 June 2021; International Union of Laboratories and Experts in Construction Materials, Systems and Structures (RILEM): Bagneux, France; pp. 452–458. [Google Scholar]

- Qu, S.S.; Chen, Y.; Lv, Y. Centrifuge shaking table tests on a friction pendulum bearing isolated structure with a pile foundation in soft soil. Earthq. Struct. 2022, 23, 517–526. [Google Scholar]

- Jamieson, E.; McLellan, B.; van Riessen, A.; Nikraz, H. Comparison of embodied energies of Ordinary Portland Cement with Bayer-derived geopolymer products. J. Clean. Prod. 2015, 99, 112–118. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2020.

- Chen, H.; Alamnie, M.M.; Barbieri, D.M.; Zhang, X.; Liu, G.; Hoff, I. Comparative study of indirect tensile test and uniaxial compression test on asphalt mixtures: Dynamic modulus and stress-strain state. Constr. Build. Mater. 2023, 366, 130187. [Google Scholar] [CrossRef]

- Pakawan, T.; Puttapitukporn, T.; Atthi, N.; Sripumkhai, W.; Pattamang, P.; Klunngien, N.; Jeamsaksiri, W. Compressive behaviors of micropillar sheets made of PDMS material using the finite element method. Eng. J. 2020, 24, 73–84. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).