1. Introduction

Bridges are essential infrastructure components that guarantee effective transportation systems and economic growth [

1,

2]. However, the ongoing problem of early deterioration poses a danger to these critical facilities’ durability and structural integrity. Inadequate inspection and maintenance procedures, which increase safety hazards and maintenance costs, have been primarily blamed for this issue [

3,

4]. Accordingly, the maintenance and upkeep of reinforced concrete bridges are essential to ensure the safety and longevity of these vital transportation arteries. To meet this challenge, new paradigms for bridge inspection and maintenance, which involve the development of creative solutions that can offer in-depth real-time information about the state of bridge conditions, are being developed.

The absence of conventional bridge inspection methods has become increasingly evident over time. Santarsiero et al. [

5] spotlight some of these drawbacks, hindering the ability to comprehensively understand a bridge’s health and make informed maintenance decisions. Recent advancements in computer vision technologies offer the potential for swift infrastructure inspection. However, they have not been comprehensively incorporated into deployment related to infrastructure, such as railway viaducts [

6], buildings [

7,

8], and bridges [

5]. Two critical issues identified in the research include manual data collection methods, where inspectors physically analyze distinct bridge components and record their findings. This manual approach can be time-consuming, labor-intensive, and prone to human error. A further challenge is adopting paper-based reporting systems to document inspection results. While these reports encompass valuable information, they suffer from shortcomings in accessibility, storage, and data retrieval. Information scattered across paper documents represents the challenge of retrieving historical inspection data and deriving meaningful insights [

5]. The significant consequences of these challenges involve the inability to prioritize maintenance interventions effectively, lack of well-informed maintenance decisions, and inefficient resource allocation [

9,

10,

11].

There is a burgeoning requisite for digitalization in bridge inspection practices to address these challenges. Technology integration, such as Bridge Information Modeling (BrIM), can revolutionize the inspection process. These technologies foster real-time data collection, automated data analysis, and the constitution of digital models, offering a more meticulous and accessible view of a bridge’s health over time. This, in turn, improves the potential to create data-driven maintenance decisions, reduce risks, and allocate resources effectively, as expounded by Sutter et al. [

12], Wan et al. [

13], and Byun et al. [

14].

BrIM has substantially advanced bridges’ design and construction phases, revolutionizing how infrastructure projects are planned and constructed. However, there is a noticeable gap in fully applying the potential of BrIM in the operation and maintenance (O&M) phase, particularly in streamlining the interaction between inspectors and BrIM models during on-site inspections. This deficiency has led to an absence of comprehensive remedies dedicated to efficiently and precisely managing inspection documentation for RCB. Multiple factors contribute to this gap in leveraging BrIM for bridge inspection and maintenance, including the fact that (1) BrIM models are constituted for the design and construction phases but are not incorporated into the O&M phase. This separation can yield a disconnect between the digital models and the actual condition of the RCBs, and (2) BrIM models can be highly detailed and complex, posing challenges for inspectors who require retrieving and interacting with this information efficiently during field inspections. Thus, simplifying the models for practical use during inspections is imperative.

This research aims to develop an integrated framework for inspection and maintenance intervention in reinforced concrete bridges (RCB), leveraging the potential of as-is Bridge Information Modeling (BrIM). This approach promotes precise information retrieval and constitutes a methodical centralized database that fosters seamless information sharing and empowers well-informed decision-making among diverse stakeholders. By providing a comprehensive and lucid depiction of the bridge’s current state, this approach significantly improves the management of bridge inspection and maintenance practices, leading to increased efficacy.

The structure of this paper can be delineated as follows: (1) Scrutinizing the existing literature to appraise prior research endeavors, effectively emphasizing the essentials of the presented work, and discerning the gaps the research aims to address; (2) Proposing the newly developed comprehensive framework for inspection and maintenance interventions in reinforced RCB, utilizing the capabilities of as-is Bridge Information Modeling (BrIM); (3) Rendering the developed framework into practical adoption within a real-world scenario to confirm and validate its effectiveness, and (4) Evaluating the research results, summarizing the paper’s findings, and offering suggestions for future research endeavors.

2. Literature Review

According to the Federal Highway Administration (FHWA), all states must conduct biennial routine bridge maintenance [

15]. ASCE [

16] suggests that bridges classified as structurally inadequate be maintained annually or twice yearly. These statements show that bridge maintenance is a complex and multifaceted issue that requires careful planning, regular inspections, and a risk-based approach. Proper maintenance can help extend the life of a bridge, ensure the safety of those who use it, and reduce the overall cost of infrastructure management [

17,

18].

Bridge maintenance management heavily relies on the operational inspection information conducted on-site by inspectors [

9,

19,

20]. The bridge-inspection process is a crucial task that aims to ensure the bridge’s safety and identify maintenance needs. In practice, O&M data are collected through paper-based reports; even if they are digitized, the available information remains fragmented for stakeholders who gather various types of O&M data [

21,

22]. Written inspection reports pose several obstacles, including difficulties in sharing information, loss or confusion, and communication errors with different project-involved domains. The absence of a central information platform leads to barriers, such as increased cost and time for information exchange and poor data quality accompanied by errors in data exchange. Also, no matter how informative the inspection report is, the written information remains limited and does not give a comprehensive picture of the bridge’s condition, resulting in an ineffective maintenance process, which may affect its safety and stability in the future.

In recent years, there has been a technological revolution in the construction field called Building Information Modeling (BIM), which has attracted the attention of specialists in the construction field, who deem it essential to harness this technology in various construction projects and think outside the box to fully utilize it. From this sentiment, the idea of Bridge Information Modeling (BrIM) then appeared, and it is similar to BIM except that BIM is all about buildings, while BrIM is all about bridges. It can be utilized in all the project’s phases [

10,

23,

24].

Nguyen et al. [

10] developed a BrIM-based mixed reality application that can enhance the management of bridge inspection and maintenance with the help of Microsoft HoloLens. This framework enabled the management of maintenance operations and decision-making for an existing bridge remotely from the office, eliminating the need to go to the site. Xu and Turkan [

25] developed a systematic framework for inspecting and managing bridges using camera-based unmanned aerial systems (UASs). This system was designed to detect bridge defects, which enhanced current practices’ effectiveness. The UASs were connected to computer vision algorithms that collected all inspection data, which was then stored on a BrIM model. They also noted a gap between collecting on-site inspection data and integrating it with BrIM models for bridge management [

25]. A system developed by Wan et al. [

13] incorporates the (BrIM) with the (GIS). This includes large amounts of information related to the bridge, such as assessing the bridge’s condition, managing the inspection and the information, and spatial data, facilitating all stakeholders’ cooperation. DiBernardo [

26] proposed a system that combines inspection data with 3D BrIM. Subsequently, Al-Shalabi et al. [

27] employed a 3D BrIM model in bridge inspection using BrIM, mobile devices, and cloud computing. Other related research includes that of Tanaka et al. [

28], Dang and Shim [

29], and Byun et al. [

14].

Based on the literature review, it can be inferred that a research gap exists. Many studies have utilized BrIM in the design and construction phase of bridges. However, relatively limited efforts have been taken to use BrIM during the O&M phase, focusing on facilitating the interaction between the inspector and the BrIM model during the inspection process on site. Accordingly, it can be said that there is a lack of comprehensive investigations that specifically address the efficient and accurate management of inspection documentation for reinforced concrete bridges. This gap hinders the development of a robust framework tailored to the unique requirements and challenges associated with reinforced concrete bridges.

3. Research Methodology

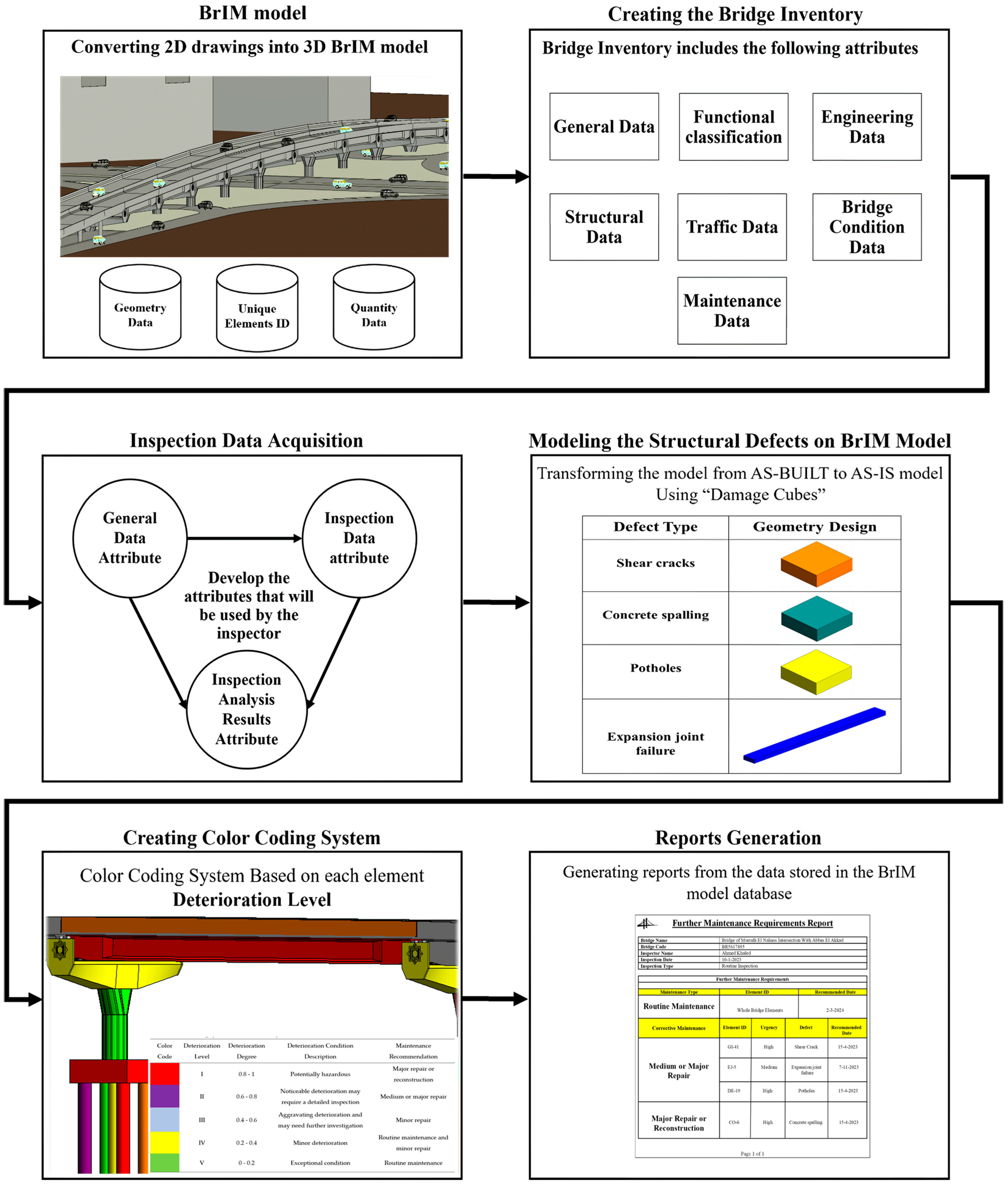

The methodology for developing the integrated framework is based on six modules of research steps for RCB inspection, maintenance evaluation, and management, namely: (1) encompassing converting 2D drawings into a 3D as-is BrIM model, (2) creating the bridge inventory, (3) inspection data acquisition, (4) modeling the structural defects on the as-is BrIM model, (5) creating color coding system, and (6) report generation, as demonstrated in

Figure 1 and as explained in the following paragraphs. As depicted in

Figure 1, the first module converts the two-dimensional (2D) drawings of the RCB into a detailed three-dimensional (3D) representation, reflecting in-depth details about the bridge’s size, materials, and geometric attributes. The subsequent module is designed to curate a meticulous database of the bridge’s characteristics, unifying all relevant bridge information within a structured semantic framework. Following is the third module, as portrayed in

Figure 1, which seeks to input the inspection outcomes into the BrIM design via three different types of data attributes. Additionally, the fourth module depicts structural flaws within the BrIM design, clearly illustrating these defects’ exact position, size, form, and traits using a proposed damage cube, as rendered in

Figure 1. The fifth module introduces a color-coding method to convey the RCB’s current condition to the concerned parties and concurrently highlight and rank sections requiring urgent intervention. Finally, the sixth module delivers exhaustive summaries based on the data diligently captured in the real-time BrIM design during the inspection phase, as shown in

Figure 1.

3.1. Converting 2D Drawings into 3D BrIM Model

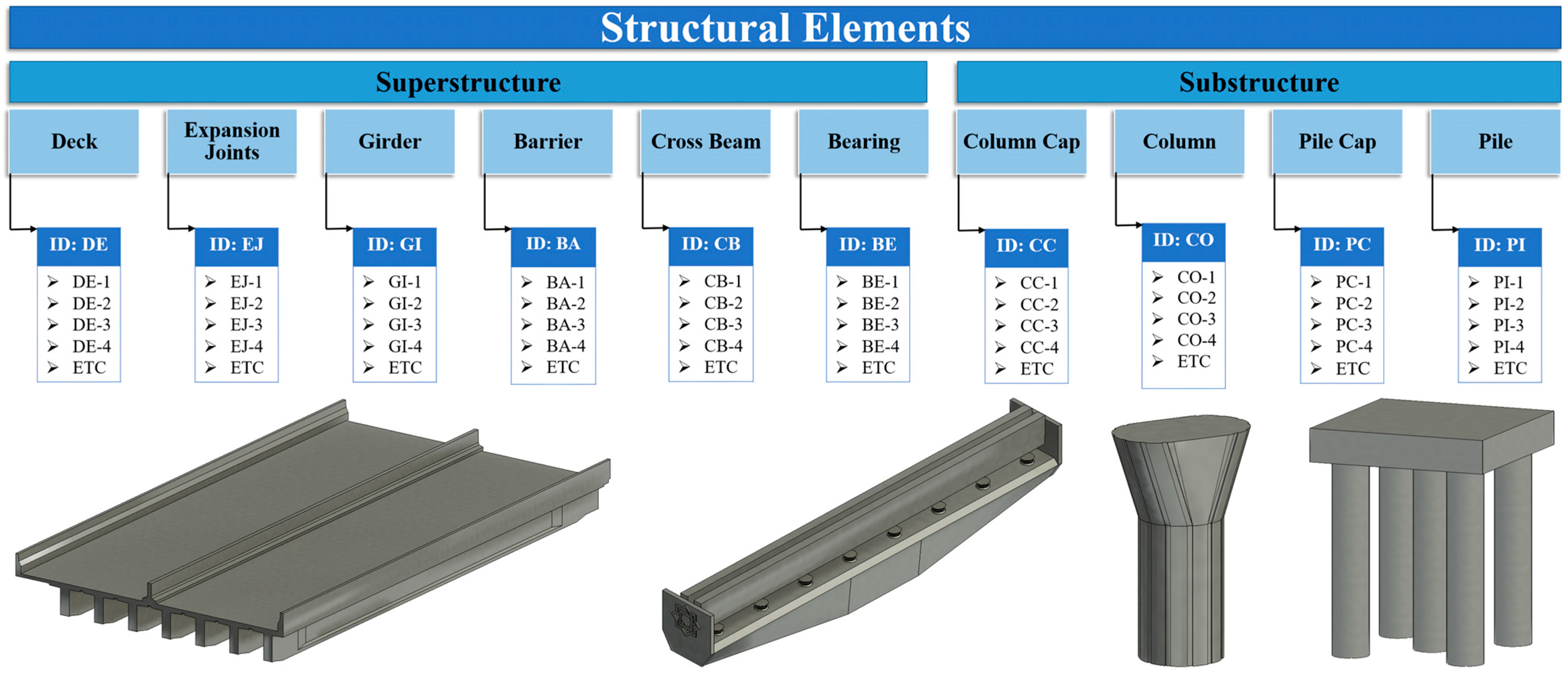

In this step, the BIM platform (such as Revit software version 2023) impeccably transforms the two-dimensional (2D) drawings of the RCB into intricate three-dimensional (3D) models, incorporating thorough details concerning the bridge’s dimensions, materials, and geometric properties.

Figure 2 exhibits an illustrative depiction of the sequential procedures undertaken throughout this process. The conversion entails constituting distinct RCB elements, such as girders, columns, and foundations, rendered in the 3D domain. Concurrently, each element obtains a unique identification (ID) for systematic preservation and streamlined identification within the inventory system. In this context, the 3D modeling conforms to the American Institute of Architects (AIA) E202 BIM Protocol stipulations, particularly the Level of Detail (LOD) 400. This mandates that the model’s components are delineated as distinct assemblies, meticulously defined by their size, shape, location, quantity, and orientation, with complete fabrication, assembly, and detailed information. Accordingly, the LOD 400 substantially enhances the efficiency and precision of inspection and maintenance data, thus engendering a more robust and decisively decision-making process.

3.2. Creating the Bridge Inventory

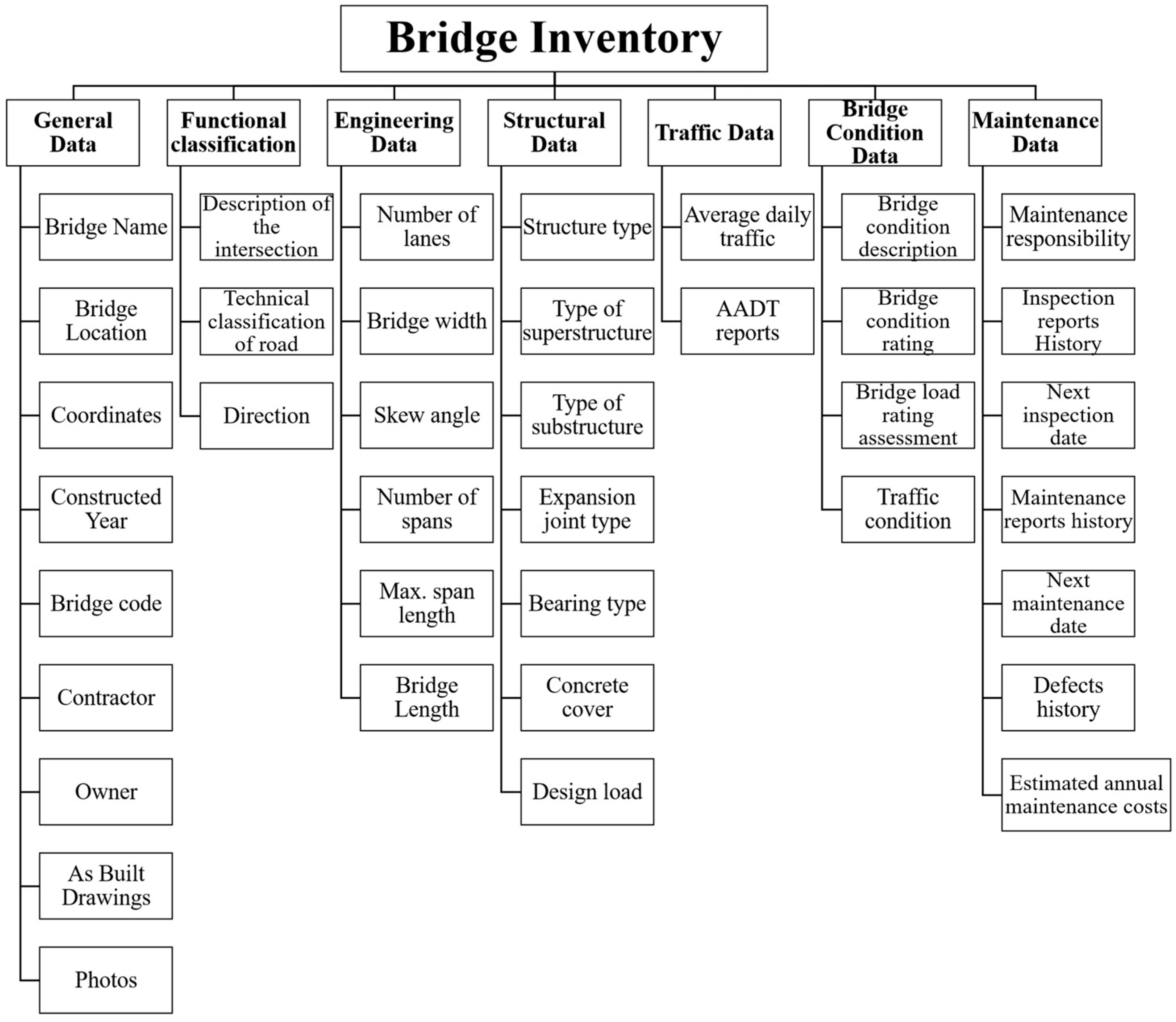

The bridge inventory system symbolizes a pivotal tool, empowering decision-makers to perpetually monitor and manage the RCB condition over its operational lifespan. The primary objective of this step is to establish an intricately detailed repository of the bridge’s data and attributes, consolidating all bridge-relevant data within a coherent semantic database. By incorporating the inventory data into the as-is BrIM model, access to the information becomes facile, enabling thorough examination and garnering invaluable insights into the bridge’s condition and imminent maintenance requirements. This semantic database can also assist decision-makers in proactively discerning potential issues early and developing comprehensive maintenance strategies to forestall costly and potentially prospective issues.

Figure 3 illustrates the primary attributes and pertinent sub-attributes constituting the bridge inventory for a robust and well-informed approach to bridge management.

3.3. Inspection Data Acquisition

During the RCB’s inspection, the comprehensive report compiled by the inspector must incorporate all pertinent details portraying the actual condition of the diverse RCB elements. This entails rigorously identifying and documenting any existing defects, a diligent assessment of the condition of the inspected elements through an appropriate rating system, and including the required field tests, such as destructive and non-destructive approaches for sustainable structural integrity and health of the bridge components. Drawing upon the record-keeping amassed during the inspection process, the inspector’s burden of importance is offering recommendations for efficaciously maintaining the deteriorated elements, fostering a proactive approach to addressing potential issues, and upholding the bridge’s long-term sustainability. Consequently, the inspector records the inspection findings under three categories: General Data, Inspection Data, and Inspection Analysis Results.

The General Data attributes include element ID, structural material, geometric information, compressive strength (Fcu), yield strength (Fy), concrete cover thickness, maintenance history, and inspection history. Correspondingly, the Inspection Data attributes encompass inspection data, inspector name, inspection type, defect type, defect geometric information, defect image, defect causes, inspector comment, required tests, following inspection type, and date. Ultimately, the Inspection Analysis Results incorporate deterioration condition description, deterioration degree and level, maintenance recommendations, and prospective maintenance date.

3.4. Modeling the Structural Defects on the BrIM Model

A crucial aspect substantially impacting the inspection report’s quality, routinely instigating potential information loss, emanates when structural defects in an RCB element are merely mentioned in written notice while being photographed distinctly using a camera. The accumulation of copious amounts of data during inspection can bewilder and impede its systematic architecture. Therefore, the proposed approach prioritizes a factual description of the defects unveiled during the inspection process within the as-is BrIM model. It includes a designated 3D geometric representation (

Figure 4), depicting each defect type’s actual location and dimensions. This 3D geometric depiction aims to vividly visualize the structural defects’ definite location, dimensions, shape, and characteristics. This presentation imparts stakeholders engaged in bridge maintenance a lucid apprehension, enhancing their capability to comprehend the defects’ attributes and make permissive, knowledgeable decisions.

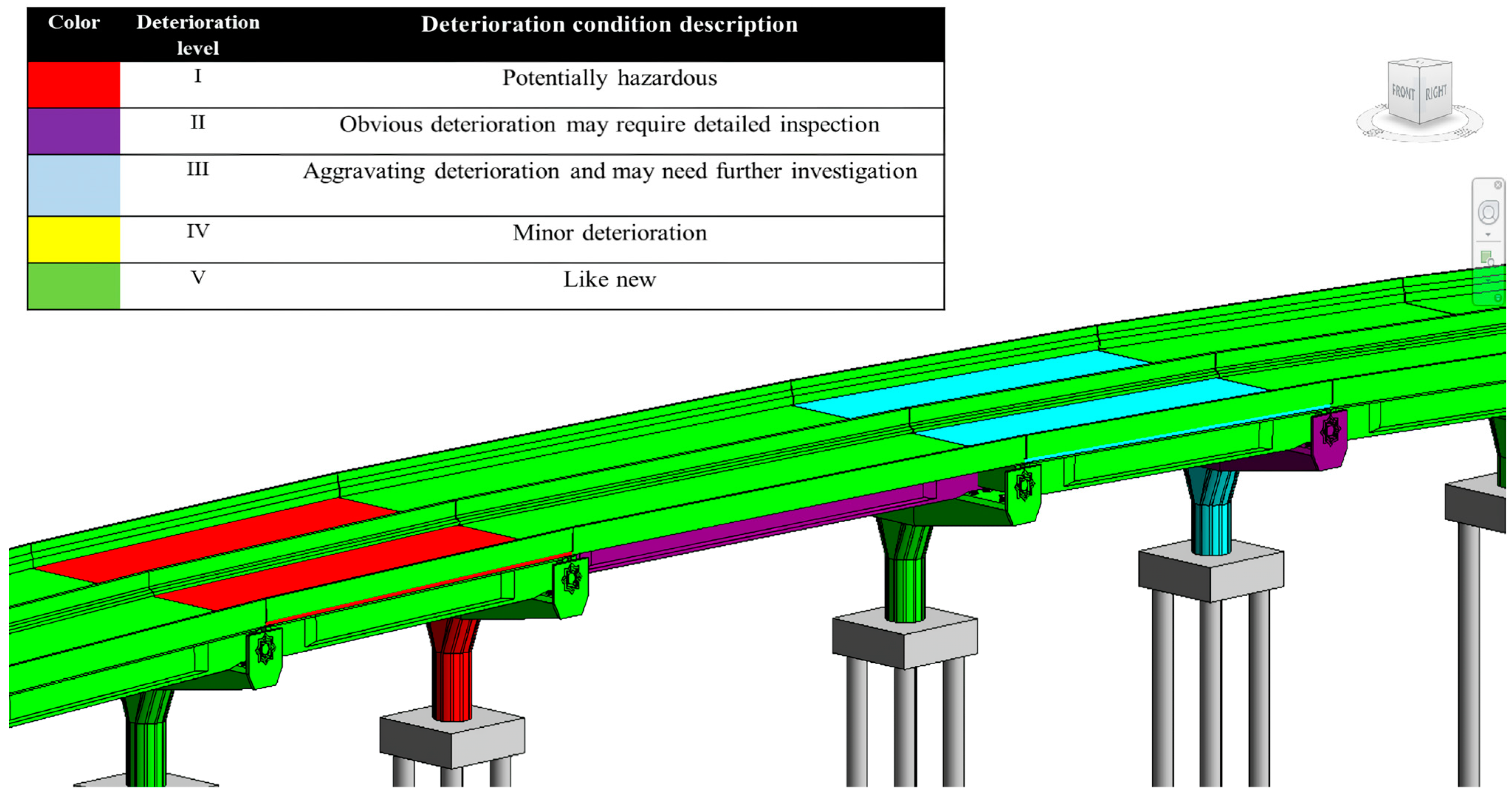

3.5. Creating Color Coding System

Upon the inspector’s appraisal of the degradation level of each scrutinized RCB element, the as-is BrIM model triggers an automatic alteration of the element’s color, adhering to the predefined color coding system elaborated in

Table 1. The color coding system is pivotal in lucidly presenting the RCB’s current state to the stakeholders embroiled in the project. Consequently, even before delving into a comprehensive examination of the inspection data, these stakeholders gain a high level of information apropos to the current condition. This proactive presentation empowers responsible parties to promptly identify and prioritize areas necessitating immediate attention, effectively enhancing the maintenance management process’s efficacy. The formulated color scheme adheres to several guidelines: it is designed to be straightforward and intuitive, ensuring clarity and ease of comprehension for inspection findings. The selected color scale is distinguishable and consistently maintains uniform significance across every bridge element. The color arrangement is diverging, where red signifies a potentially hazardous condition, purple indicates a noticeable deterioration level, light blue points to an aggravating deterioration level, yellow highlights a minor deterioration level, and green portrays an exception condition (see

Table 1 for reference).

Determining the deterioration level and degree of bridge components is systematic and rigorous, encompassing visual observations, direct measurements, and advanced testing methods. The process is initiated with a meticulous visual examination of the bridge’s components to identify signs of degradation, encompassing indications such as evident cracks, corrosion, spalling, and other deterioration. Afterward, a series of direct measurements can be implemented, encompassing crack width and depth, measuring the concrete cover, and corrosion rate measurements. In instances demanding deeper insights, the inspector can conduct non-destructive testing to detect internal flaws and moisture in concrete elements and analyze the concrete’s strength, permeability, and composition. Upon a comprehensive appraisal through the abovementioned stages, the inspector is well-equipped to categorically ascertain the deterioration level and degree of the diverse bridge components.

3.6. Report Generation

The culmination of the proposed approach is the report-generation process, portraying the final stage. This pivotal step incorporates comprehensive reports banking on the information and data thoroughly chronicled within the as-is BrIM model during the inspection. Diverging from conventional methods, the management authorities responsible for RCB maintenance and inspection operations gain unfettered access to the as-is BrIM model, promoting diverse report types without resorting to manual or digital report formation. As a result, the arduous report-generation task is streamlined, obliterating the risk of information mislaying or confusion.

Multiple exemplars of the reports retrieved from the as-is BrIM model encompass the following: (1) Master Report, encompassing all data amassed during the inspection process; (2) Bridge Defects Data Report, comprehensively detailing diverse defective bridge elements; (3) Condition Assessment Report, presenting the bridge’s current condition status; (4) Non-Destructive Requirements Report, delineating future non-destructive testing prerequisites; (5) Maintenance Requirements Report, outlining forthcoming maintenance operations for the bridge; and (6) Inspection Requirements Report, providing an overview of future bridge maintenance operations. By employing this reporting approach, stakeholders attain unprecedented efficiency and accuracy in managing the bridge’s maintenance and inspection initiatives.

The guidelines for report generation typically comprise several vital elements, including standardizing the collection and documentation of data during the inspection process. This standardization ensures consistency in data gathering. Second, guidelines address data organization within the BrIM model to facilitate retrieval and maintain uniformity of data. Third, predefined report templates are provided for each report type, outlining the necessary information and specifying how data should be presented, streamlining the report-creation process. Additionally, the guidelines encompass data integration, highlighting the importance of extracting data from diverse sources within the BrIM model to ensure comprehensive reports. Quality assurance and validation procedures are also implemented to verify the accuracy and reliability of the data used in report generation. Lastly, the guidelines ensure the incorporation of visual elements, such as charts, graphs, or images, to enhance the clarity and visual appeal of the reports.

4. Model Testing

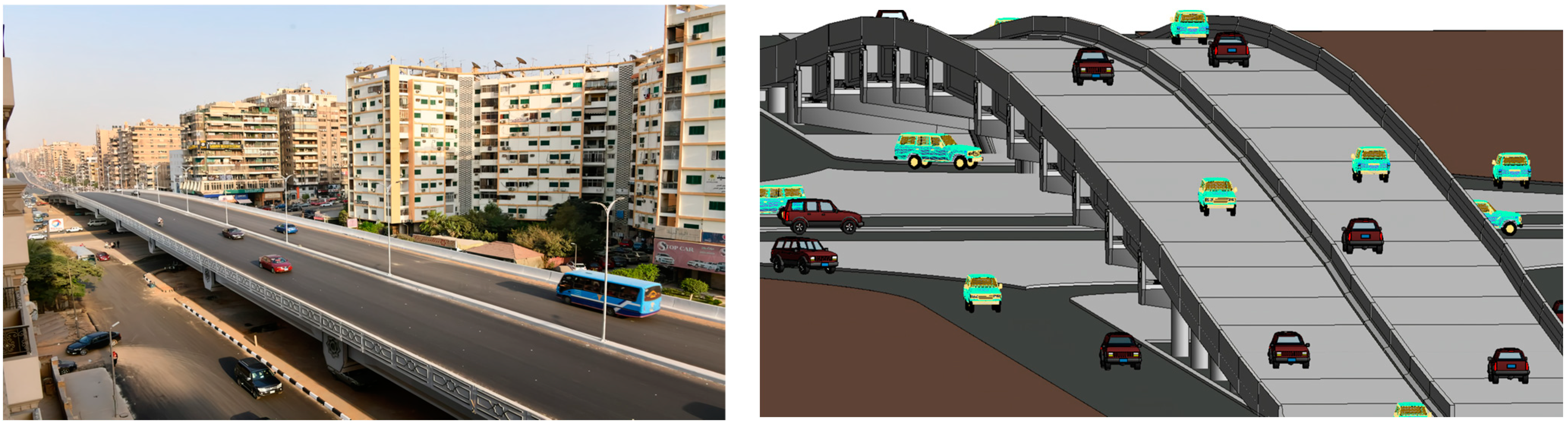

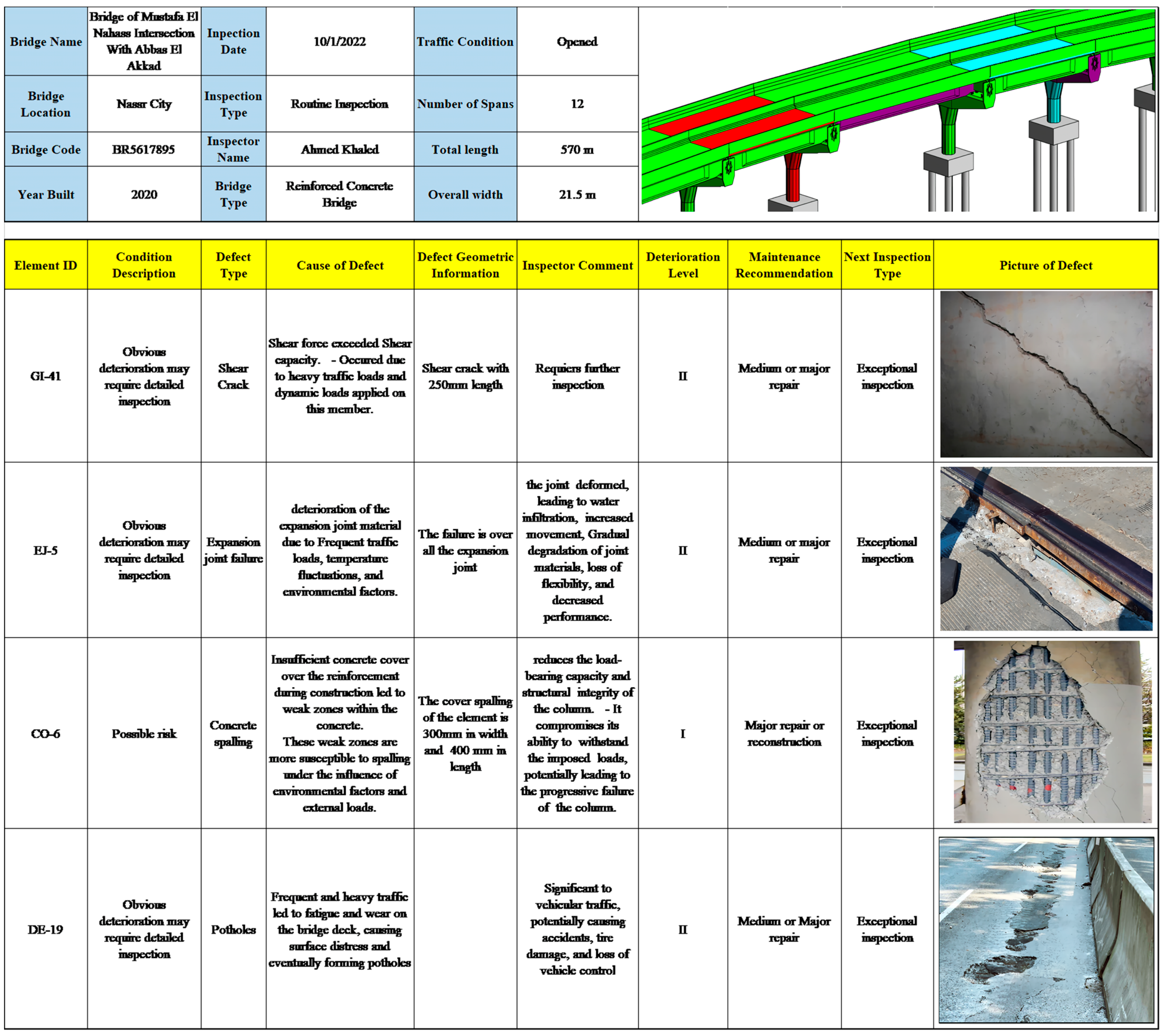

The developed framework is tested via a practical implementation on an actual bridge project, as depicted in

Figure 5. The validation and verification of the developed approach will be attained by conducting a routine inspection process on this specific bridge on 10 January 2023. The chosen bridge for practical implementation is a reinforced concrete bridge located at the Mustafa El Nahass Street intersection with Abbas El Akkad Street in Nasr City, Cairo, Egypt, with a length of 570 m and a width of 21.5 m. It comprises three lanes in each direction, and the central span length measures 37 m. Notably, the bridge encompasses 80 girders, with 8 within each span. The bridge’s age is 12 years, rendering it a representative model for this comprehensive inspection and maintenance approach.

4.1. Converting 2D Drawings into 3D BrIM Model

The inaugural phase of the proposed approach centers around transforming 2D drawings into a semantic 3D as-is BrIM model. Scrupulously examining and scrutinizing the 2D drawings, as portrayed in

Figure 5, has bolstered the comprehensive identification of all essential elements and intricate details to be consummately integrated into the Revit platform for modeling. A panoramic depiction of the bridge’s architectural components is eloquently presented in

Figure 5. A distinct and exclusive ID is thoughtfully elected to each element throughout the Revit platform’s profound rendering of the RCB model. This prudent measure ensures seamless preservation and facile identification of each component within the integrated inventory system.

Figure 6 visually encapsulates the elegantly designed coding system governing the RCB elements, promising a coherent and impeccably organized approach to data management and the RCB model’s maintenance.

4.2. Creating the Bridge Inventory

The comprehensive bridge inventory attributes have been impeccably incorporated into the as-is BrIM database, endowing the entities liable for RCB management with invaluable data. This multifaceted database promotes a holistic understanding of the RCB’s structure from multiple perspectives, empowering more competent and informed management of maintenance and inspection endeavors.

Figure 7a illustrates the attributes successfully incorporated into the as-is BrIM model. For instance, to access the structural drawings of the bridge, users can readily navigate to the project information section. Users can peruse the specific drawings entailing examination by opting for the As-Built Drawing selection, as

Figure 7b exemplifies.

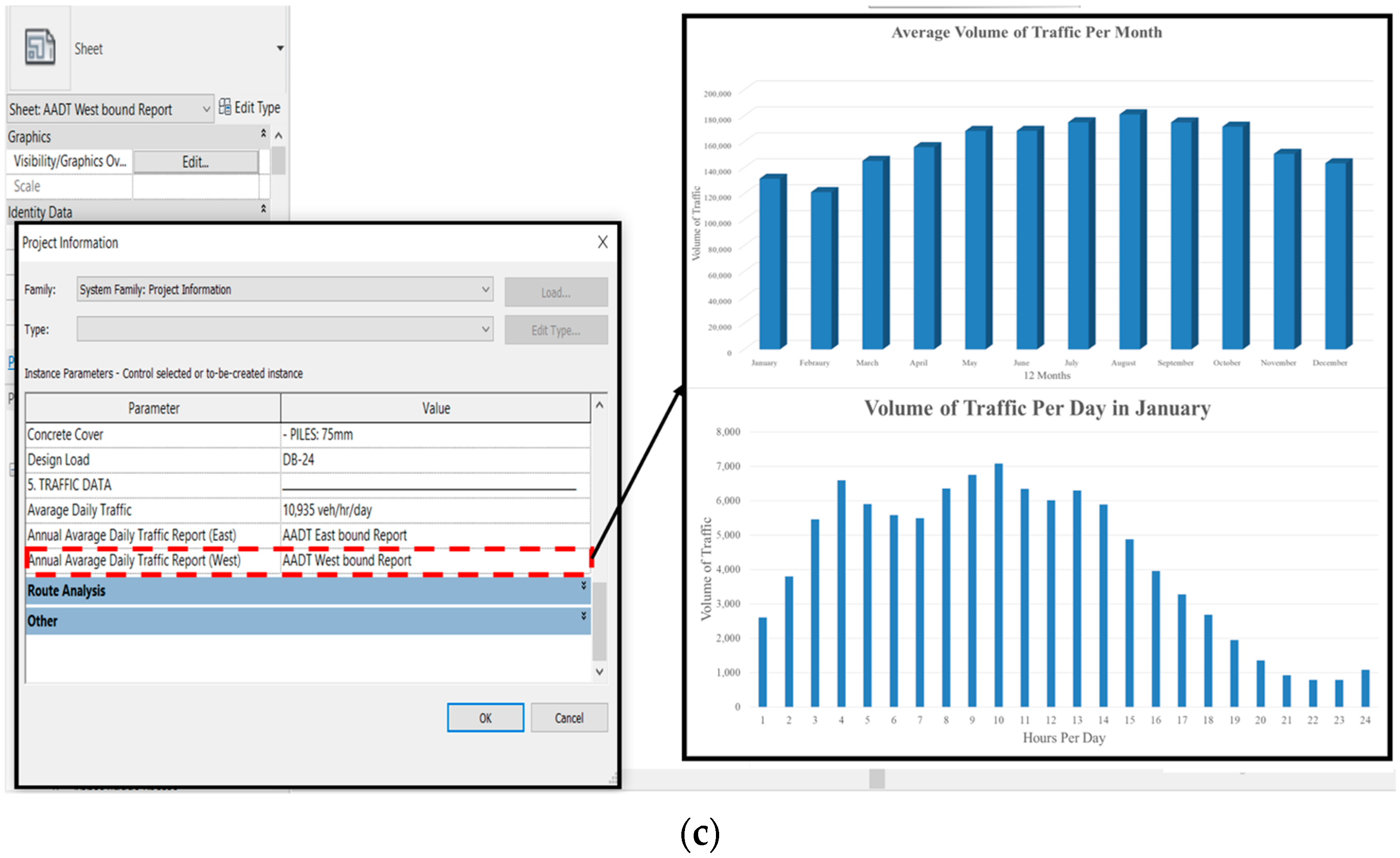

In addition, the Traffic Data Attribute encompasses crucial information involving Average Daily Traffic (ADT) and Annual Average Daily Traffic (AADT) uncovered through periodic reports. This attribute enables accurate traffic-related details, empowering decision-makers to plan inspection and maintenance operations for the RCB strategically. Further, it portrays a vital indicator to ensure the bridge’s traffic flow remains within permissible limits. Users can access the corresponding eastbound or westbound report by navigating to the AADT icon, as

Figure 7c shows.

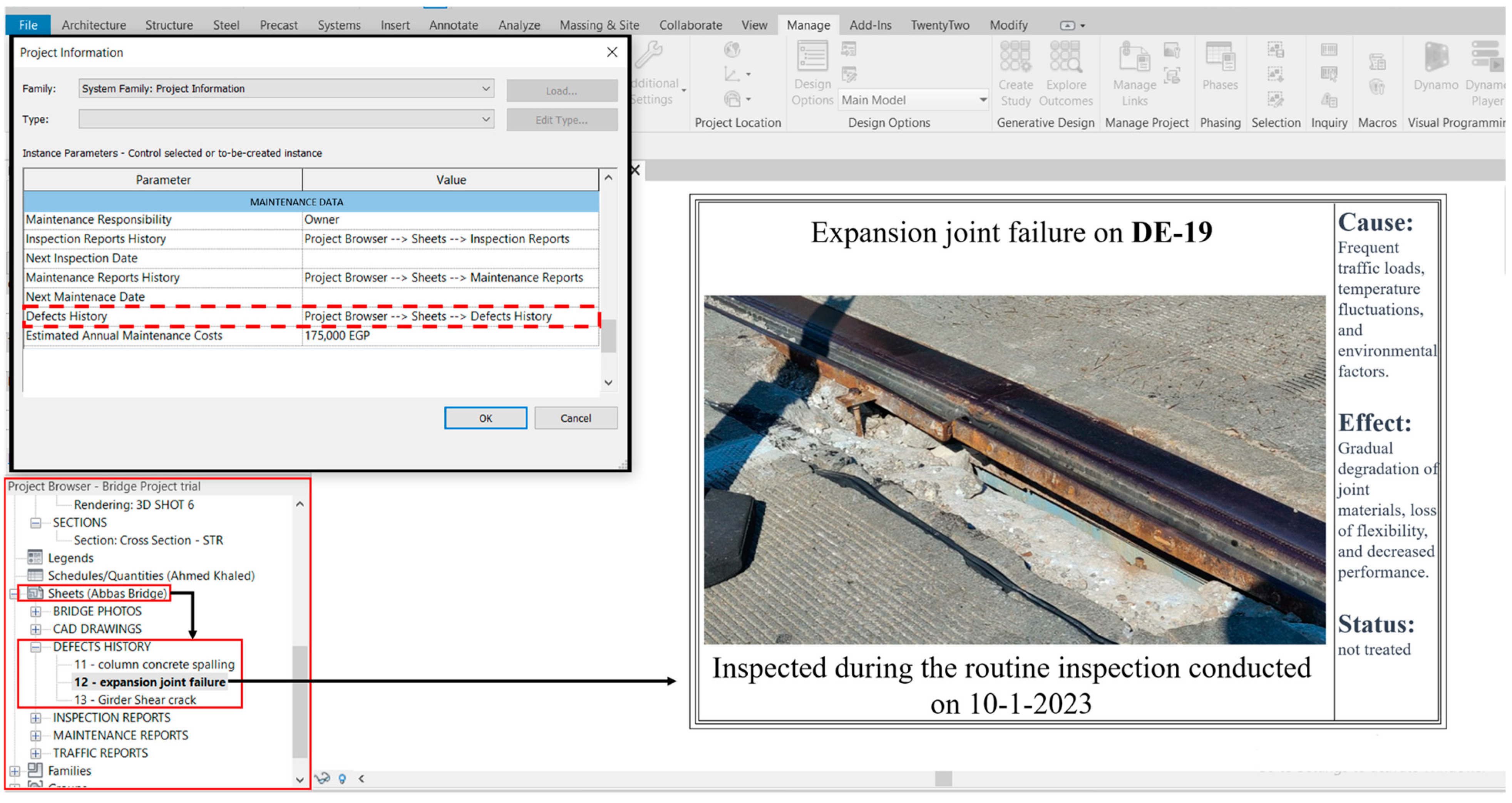

Under the Maintenance Data Attribute, vital information and documents are encompassed, such as maintenance responsibility, inspection history, next inspection date, maintenance history, next maintenance date, defect history, and estimated annual maintenance costs. To access the inspection reports history, users can use the project browser to preview all antecedent reports derived from RCB inspection processes, as shown in

Figure 8. This feature offers the convenience of browsing through inspection reports within the as-is BrIM model, ensuring centralized and up-to-date data retrieval. In this specific bridge, four inspection operations were conducted, including the initial inspection post-construction and three routine annual inspections.

Nevertheless, the defect history domain can be accessed analogously, as exhibited in

Figure 8. This field provides a comprehensive inventory of all defects spotted in the RCB, whether repaired or not. Additionally, it furnishes details regarding each defect’s type, cause, effect, discovery date, and current status. Apropos of the “next inspection date” and “next maintenance date” are determined through the analysis and results of the latest inspection process on the RCB. Functioning as reminders for imminent significant operations, whether maintenance or inspection tasks, these pivotal dates stand intrinsically linked with their corresponding operation types. These two fields facilitate efficient planning and informed decision-making, giving users a concise overview of the anticipated inspection and maintenance activities within the RCB.

4.3. Inspection Data Acquisition

This section will unveil the three attributes designated to each RCB element in the as-is BrIM model, intended to be adopted and populated by the inspector during the inspection task. As pinpointed earlier, the study encompasses a routine inspection operation performed on this RCB on 10 January 2023. Commencing from this juncture, the inspector unearthed during this inspection endeavor will be elucidated in the below subsections.

4.3.1. General Data Attribute

The general data attribute primarily hosts comprehensive data concerning the diverse RCB elements. This attribute comprises crucial details, including element ID, structural material, geometric data, Fcu, Fy, 2D drawings, maintenance history, and the inspection history of each element, as depicted in

Figure 9. These data will equip the inspector with a plethora of relevant data, fostering a more profound apprehension of each element’s condition. This enhanced comprehension will, in turn, facilitate the inspector’s capability to embark on the data-collection process during the forthcoming inspection procedure with a crystal-clear perspective.

The general data attribute further supports the inspector, or any individual involved in RCB maintenance management, to peruse previous maintenance and inspection reports for any RCB element. For instance,

Figure 9 illustrates that column CO-6 underwent a routine inspection on 12 January 2022, during which a defect was unveiled. Consequently, the inspector undertaking the forthcoming inspection will possess prior knowledge of this element’s history, warranting a more thorough examination due to its previous defect detection, as signified in the last report.

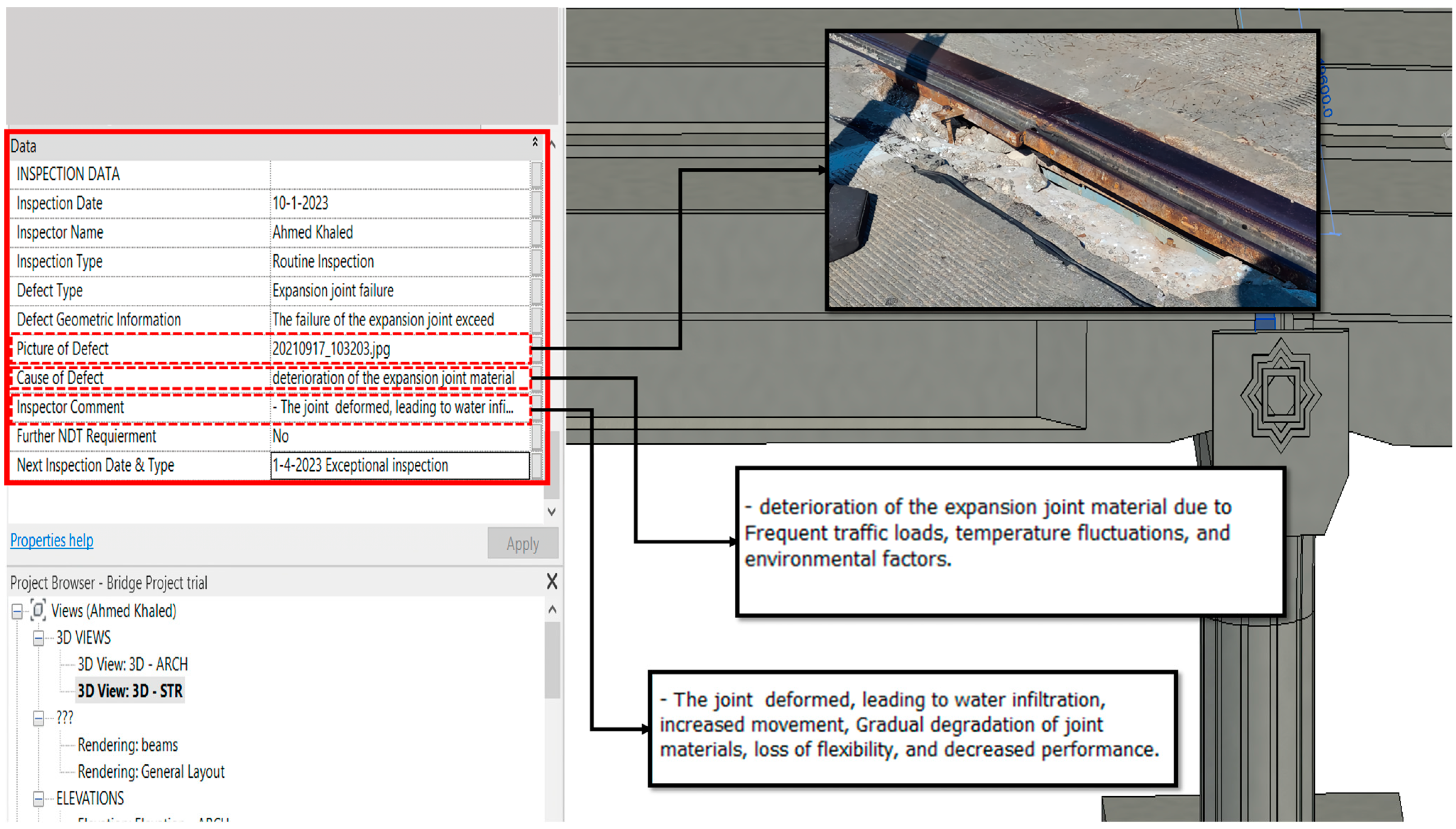

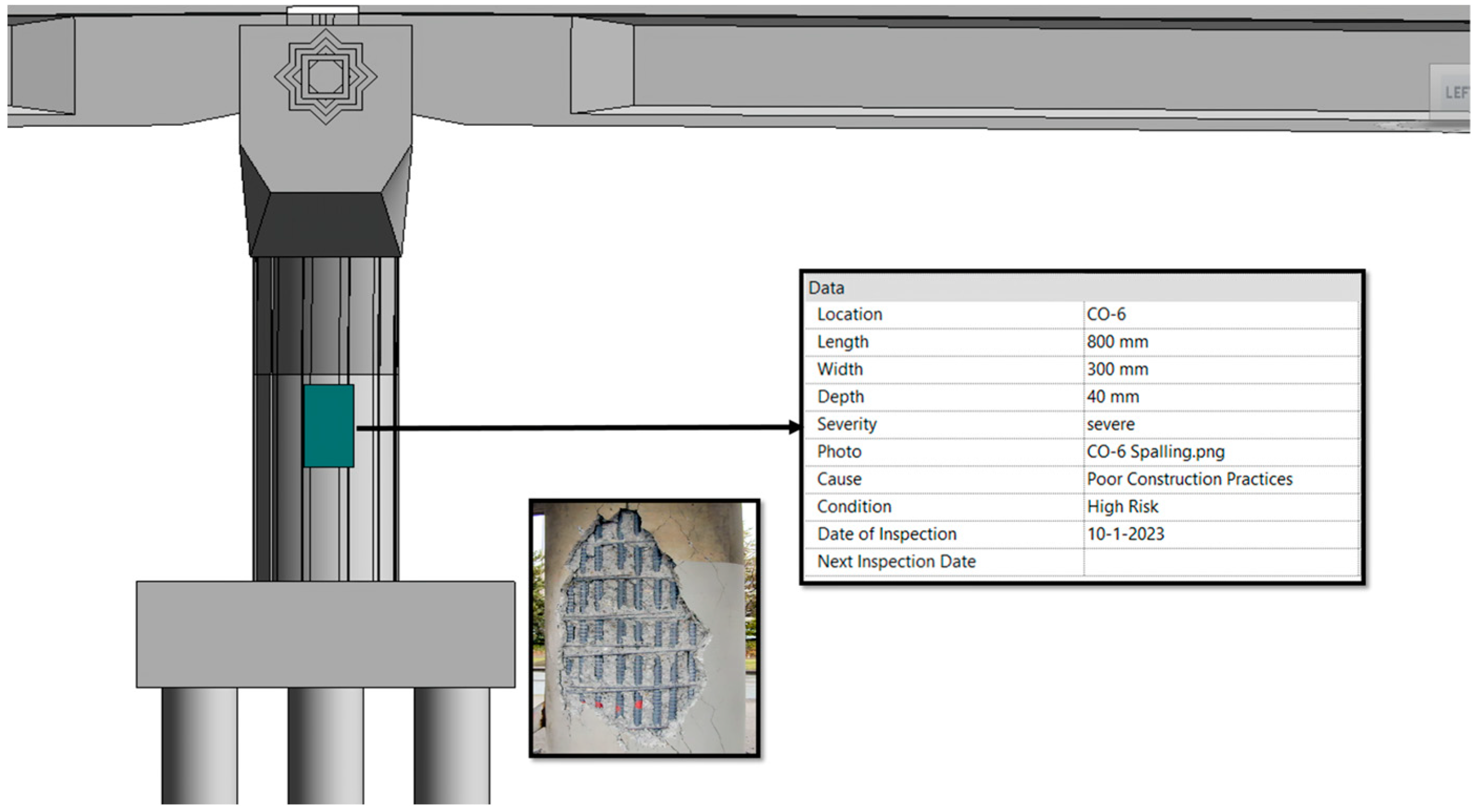

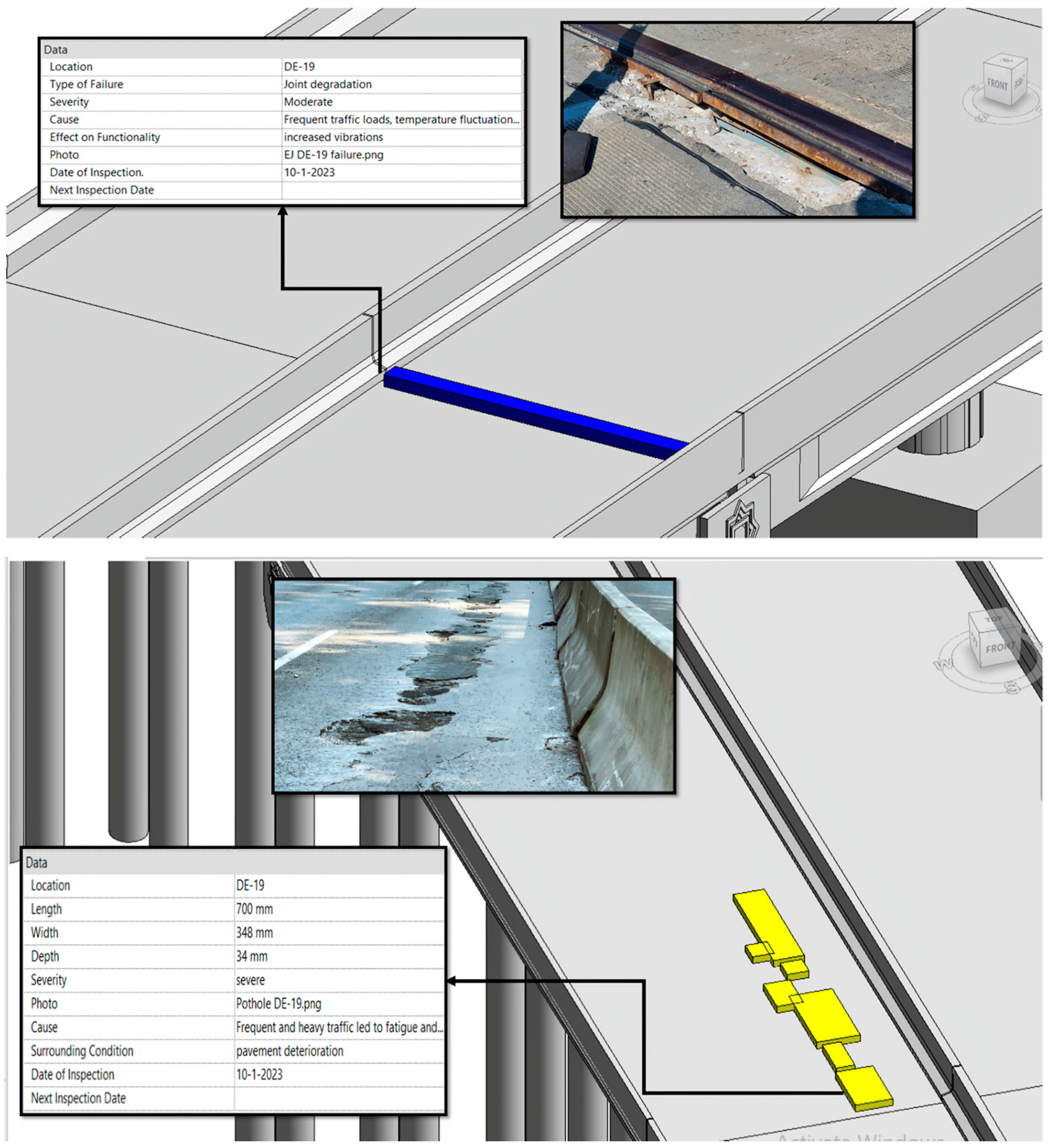

4.3.2. Inspection Data Attribute

The inspection data attribute is a comprehensive repository, accommodating all inspection-related data and enabling maintenance managers to seamlessly access, input, and administer the information amassed during the inspection procedure. Notably, by leveraging the capabilities of the as-is BrIM approach, the responsible authority gains the facility to navigate the as-is BrIM model effortlessly. This process allows discerning critical occurrences such as concrete spalling in columns, the specific failure encountered at the expansion joint, or potholes in the concrete deck, as depicted in

Figure 10. Furthermore, insightful details concerning the causative factors of these defects and pertinent comments raised by the inspector furnish the responsible authority with the requisite information to undertake reasonable measures in devising a maintenance and repair course of action (see

Figure 10).

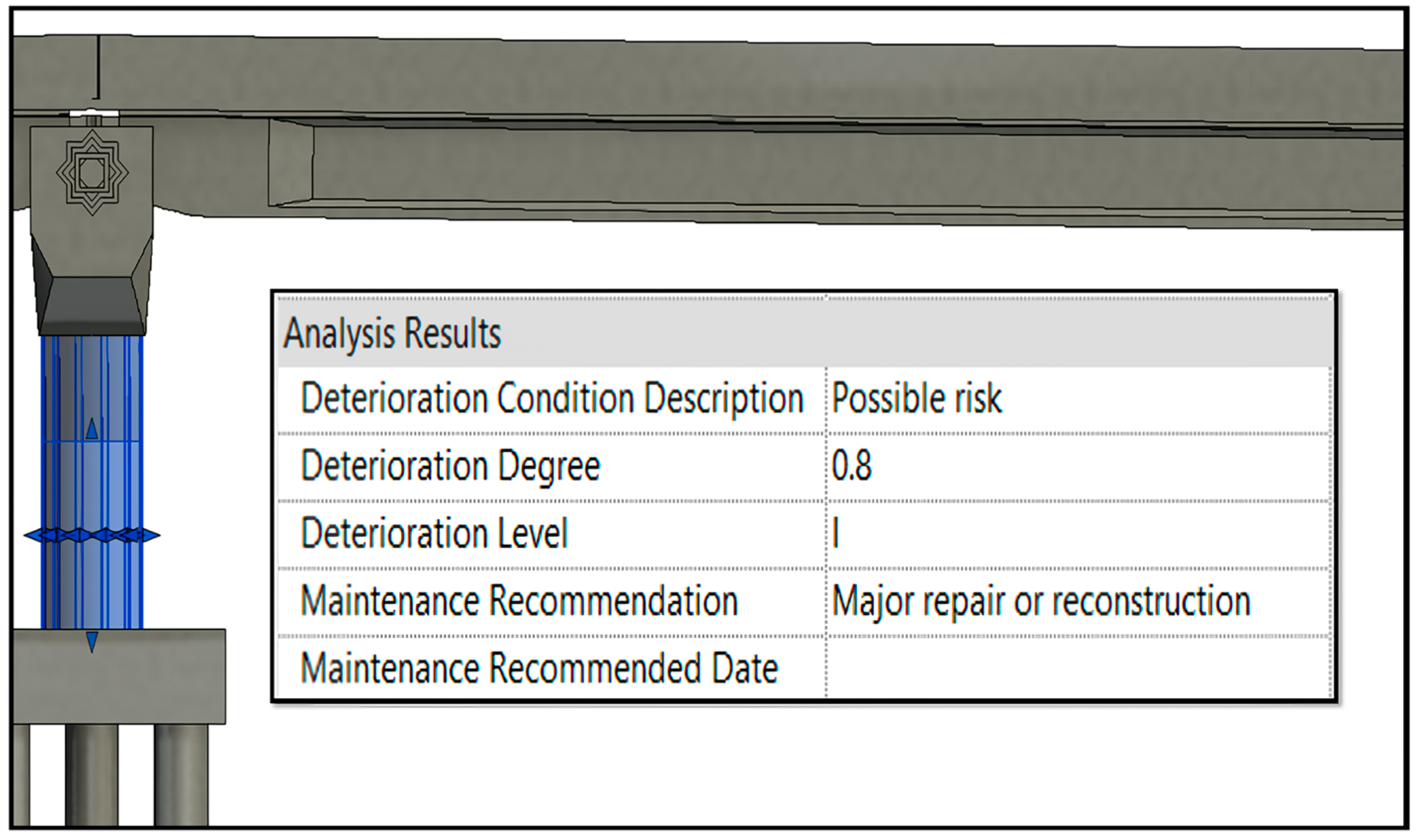

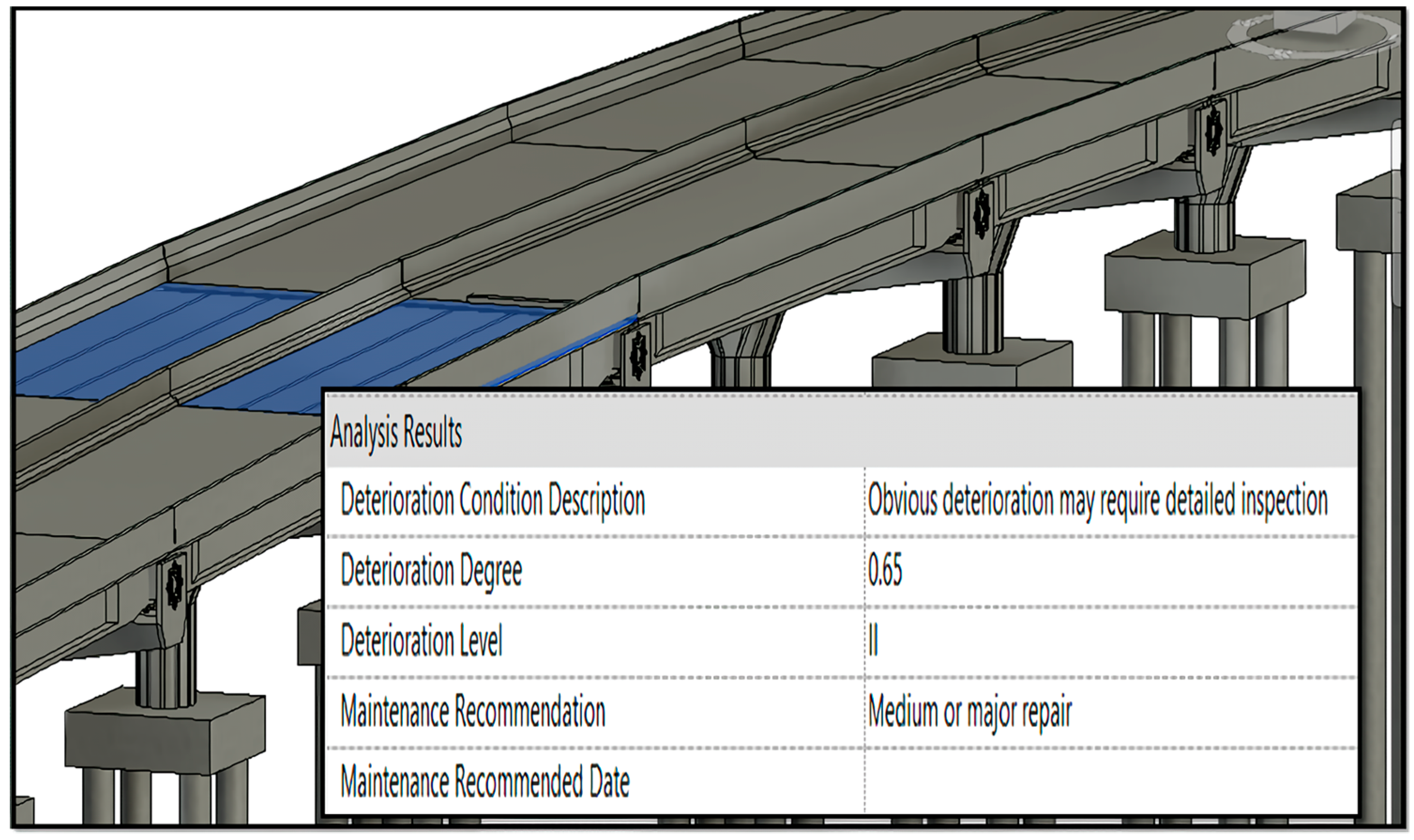

4.3.3. Inspection Analysis Results

The inspection analysis results attribute assumes the role of the ultimate documentation platform where the inspector conveys their comprehensive assessment of the element’s condition, predicated on their astute discernment. In this context, it is the inspector’s purview to meticulously detail the level, degree, and extent of deterioration encountered in the inspected element, culminating in a discerning recommendation for the requisite maintenance type, as delineated in

Table 1. This step culminates in the final inspection process step for a specific element. The recommended date, however, is determined by the relevant bridge maintenance management authorities, not the inspector.

Figure 11 presents a preview, wherein the inspector adeptly expounds on the level, degree, and extent of deterioration in conformity with the prescribed scale (refer to

Table 1), artfully documenting their findings within the inspection analysis results attribute.

4.4. Modeling the Structural Defects on the BrIM Model

As previously mentioned, the creation of designated 3D geometric representations accurately depicts the RCB’s condition, seamlessly incorporated within the elements hosting defects in their respective and factual locations. The actual size of the detected defects inherently dictates the dimensions of these 3D geometric representations, as shown in

Figure 12. Consequently, the responsible entities overseeing bridge maintenance management, upon accessing the as-is BrIM model, are afforded the unique opportunity to behold the RCB’s authentic current state in a 3D rendering, permitting them to visualize cracks and imperfections in their actual and accurate dimensions. This remarkable capability enhances the efficacy of maintenance management, as the as-is BrIM model supports stakeholders in perceiving the RCB’s current condition without the imperative for an on-site visit. To exemplify, as conveyed via the designated 3D geometric representations, the image on the left side in

Figure 12 depicts a concrete spalling. In contrast, the image on the right side displays an expansion joint failure.

4.5. Creating Color Coding System

The inspector diligently preserves all retrieved data upon consummating the embracive inspection process. Given the extensive nature of the inspection process, encompassing numerous bridge elements, the resulting information is voluminous, as exemplified in this case study. To facilitate the responsible authorities entrusted with the essential management of RCB maintenance, a judiciously devised color coding system has been seamlessly incorporated into adequately examining the inspection outcomes. This system bestows upon the authorities an expeditious visualization of the bridge’s condition and its manifold components, thus affording a comprehensive view of the overall state of the bridge. Moreover, it supports identifying prioritized areas requiring prompt attention and repair activities. The coding system is meticulously designed to convey the level of deterioration inherent in each bridge element, as eloquently presented in

Figure 13.

4.6. Report Generation

The retrieval of inspection and maintenance reports from an as-is BrIM model is a substantial leap forward compared to the conventional method of manual data digitization. The conventional approach is characterized by its intricacy, challenges, time-intensive nature, and error susceptibility. These issues arise due to the arduous task of manually restoring information about the entire bridge, leading to inaccuracies. In contrast, in as-is BrIM models, all data related to these operations have already been meticulously pre-entered, fostering an environment of heightened efficiency, accuracy, and error reduction. Consequently, employing as-is BrIM models for inspection and maintenance reporting is preferred over the conventional paper-based approach. The as-is BrIM model’s accessibility to schedules enables users to effortlessly select the required parameters, facilitating the seamless generation of comprehensive reports, as vividly demonstrated in

Figure 14.

5. Conclusions

In conclusion, this research underscores the critical importance of RCB in ensuring efficient transportation systems and driving economic growth. However, the persistent issue of early deterioration substantially threatens these vital infrastructure components’ longevity and structural integrity. The primary rationale beyond this problem has been inadequate inspection and maintenance procedures, which not only escalate safety risks but also result in soaring maintenance costs. Adopting innovative RCB inspection and maintenance paradigms is imperative to address these challenges. These paradigms must encompass developing creative solutions capable of providing in-depth, real-time information about the condition of RCBs. Conventional inspection methods have proven insufficient over time, characterized by manual data-collection processes that are time-consuming, labor-intensive, and prone to errors. Moreover, reliance on paper-based reporting systems has hindered accessibility and data retrieval, leading to an inefficient use of valuable information.

The consequences of these challenges are far-reaching, encompassing the inability to prioritize maintenance interventions effectively, make informed decisions, and allocate resources efficiently. There is a pressing requisite for digitalization in bridge inspection practices to bridge this gap, and the integration of technologies, including BrIM, exhibits significant promise. BrIM has already demonstrated its transformative potential in bridges’ design and construction phases. However, a noticeable void exists in fully harnessing its capabilities in the O&M phase, specifically in facilitating seamless interaction between inspectors and BrIM models during on-site inspections. This research intends to fill this void by developing an integrated framework for inspection and maintenance in RCB, utilizing as-is BrIM. This approach enables precise data retrieval and establishes a centralized database that facilitates seamless information sharing among stakeholders. By providing a comprehensive and accurate representation of a bridge’s current state, this framework significantly enhances the management of bridge inspection and maintenance practices, ultimately leading to increased efficacy. A case study conducted on a concrete bridge served as a practical validation of the developed framework. The results highlight the potential of the BrIM framework to revolutionize the administration of bridge inspection and maintenance procedures, offering significant advantages, particularly in addressing a key drawback of traditional maintenance and inspection approaches by enhancing the documentation of the inspection and maintenance process for RCB. This developed approach allows for the systematic and comprehensive recording of bridge data, enabling maintenance authorities to overcome the limitations associated with traditional techniques.

Although the presented work has attained its objective, overcoming some of its limitations may extend its novelty and significant contribution. This initiative focuses primarily on RCBs; thus, broadening the framework’s feasibility to other bridges and infrastructure may offer a more comprehensive solution. Moreover, the presented research may not delve profoundly into data-standardization issues. Standardizing data formats and structures is essential for seamless incorporation with BrIM models and should be examined thoroughly. Further, this research might not extensively convey practical challenges in deploying the BrIM framework, such as cost, technical expertise, and compatibility with existing systems. These real-world challenges can influence the applicability of widespread adoption. Also, the research may not have scrutinized the long-term performance of the BrIM-based approach in real-world implementation.

Future recommendations for expanding this research may encompass improving the interoperability and incorporation of BrIM with existing infrastructure management systems by proposing standardized protocols and interfaces for seamless data transmission. A thorough cost–benefit examination of deploying the BrIM framework for RCB inspection and maintenance is also imperative. In addition, developing user-friendly interfaces and mobile implementations tailored for inspectors in the field can promote the practical implementation of BrIM. Addedly, appraising the environmental and sustainability impacts of implementing BrIM-based bridge inspection and maintenance can be incorporated with the developed approach. Ultimately, it is imperative to develop insights into the future initiatives of the presented framework through automation via merging advanced sensing technologies, encompassing sensors, drones, and Internet Of Things (IoT) devices to foster real-time data acquisition; adopt machine learning and Artificial Intelligence (AI) to automatically examine amassed data, discern patterns of deterioration, and predict potential areas of concern; and create a cloud-based platform to promote data access and retrieval among all correlated parties to notify with changes and identified issues in real-time.

6. Managerial Implications

The research on developing an integrated BrIM framework for inspection and maintenance in RCBs has several significant managerial implications for infrastructure management and maintenance authorities. These implications include: (1) enhancing decision-making processes related to bridge inspection and maintenance. Managers can make more informed decisions based on real-time data and accurate bridge condition representations; (2) optimizing resource allocation and funds to address critical maintenance needs promptly; (3) identifying structural defects and safety hazards more effectively by proactively addressing safety issues, reducing the risk of accidents and ensuring the safety of the users; (4) creating predictive maintenance schedules via employing historical inspection data and real-time information; (5) enhancing communication with various stakeholders, including government agencies, contractors, and engineers; (6) contributing to better asset management initiatives by maintaining a comprehensive inventory of RCB components, tracking conditions over time, and planning for asset replacement or rehabilitation, and finally, (7) assisting in regulatory compliance by ensuring that inspection data and maintenance activities comply with industry standards and governmental regulations.