Evaluation of Biogas and Solar Energy Coupling on Phase-Change Energy-Storage Heating Systems: Optimization of Supply and Demand Coordination

Abstract

:1. Introduction

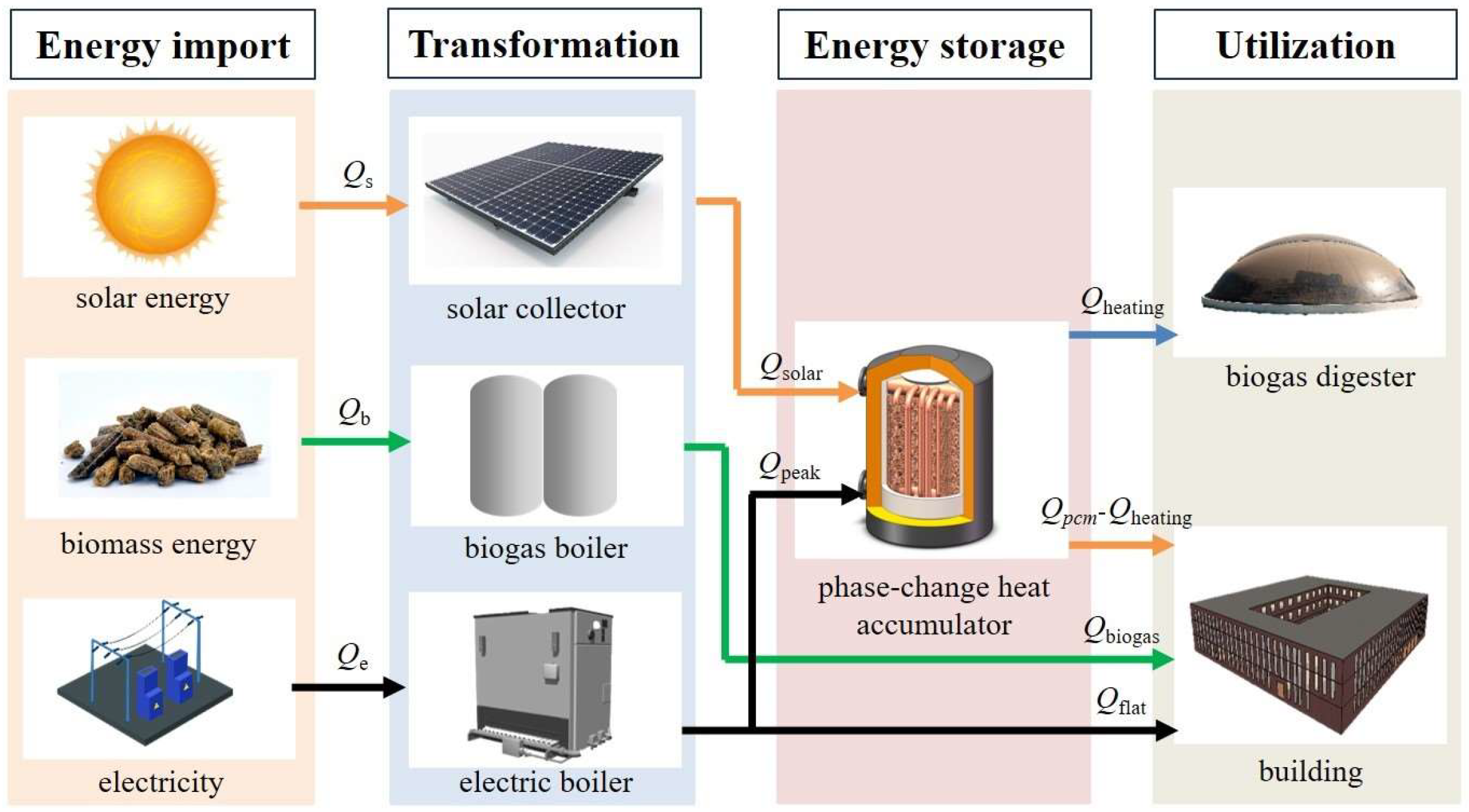

2. Building and Energy System

2.1. Case Study

2.2. Paramerters Setting

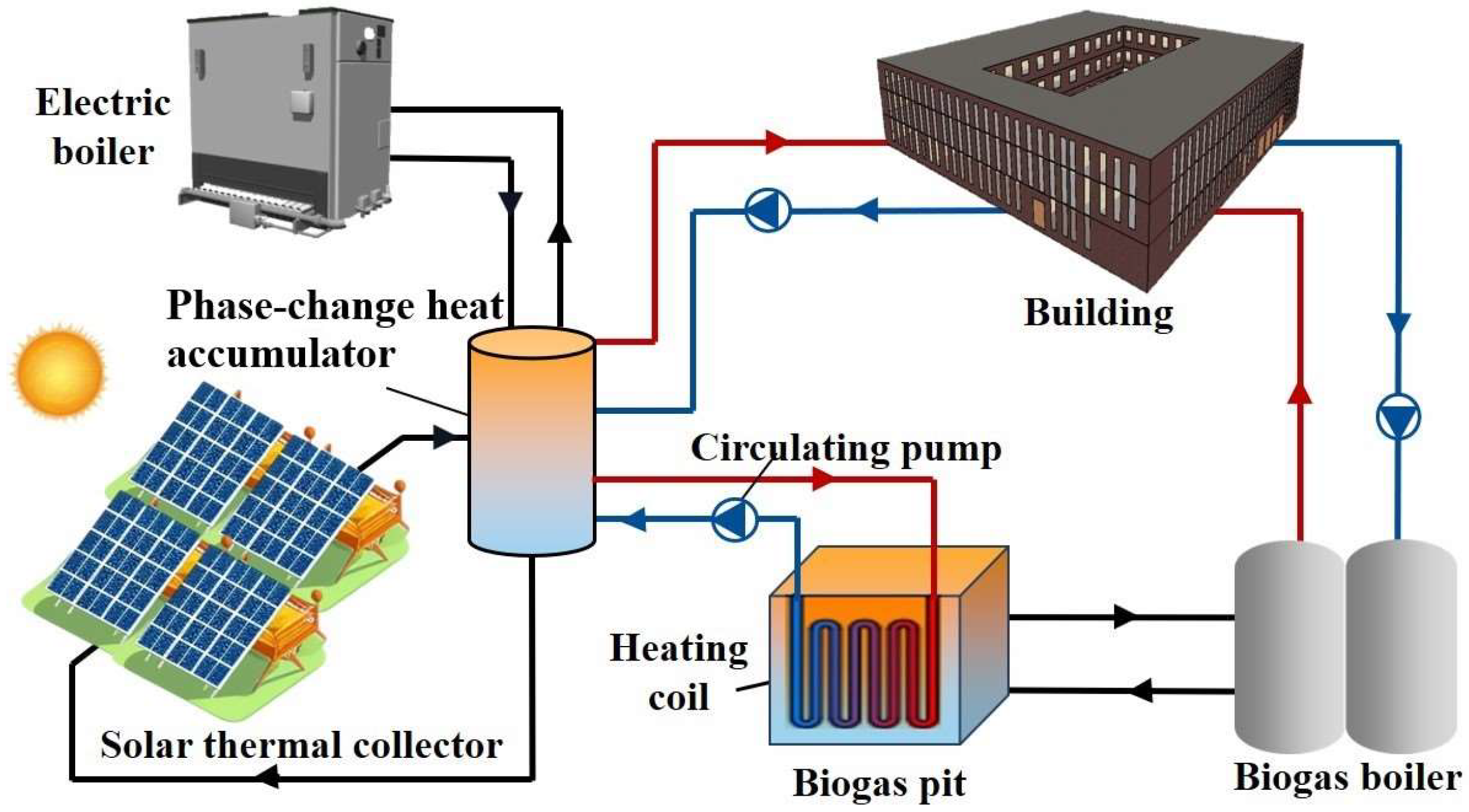

2.3. Heating System

3. Mathematical Model

3.1. System Model

3.2. Minimum Cost Optimization

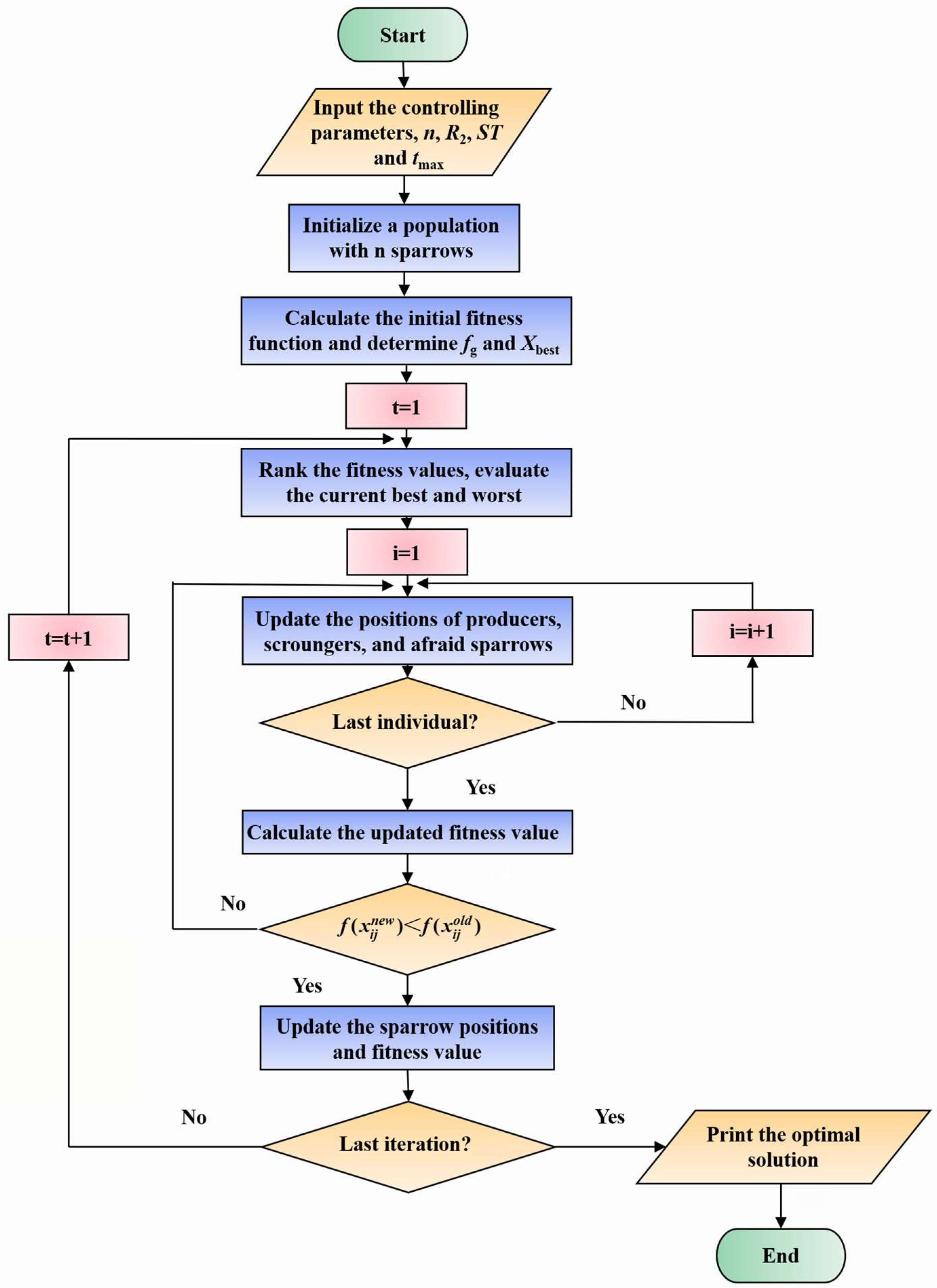

3.3. Optimization Algorithm

4. Results and Discussion

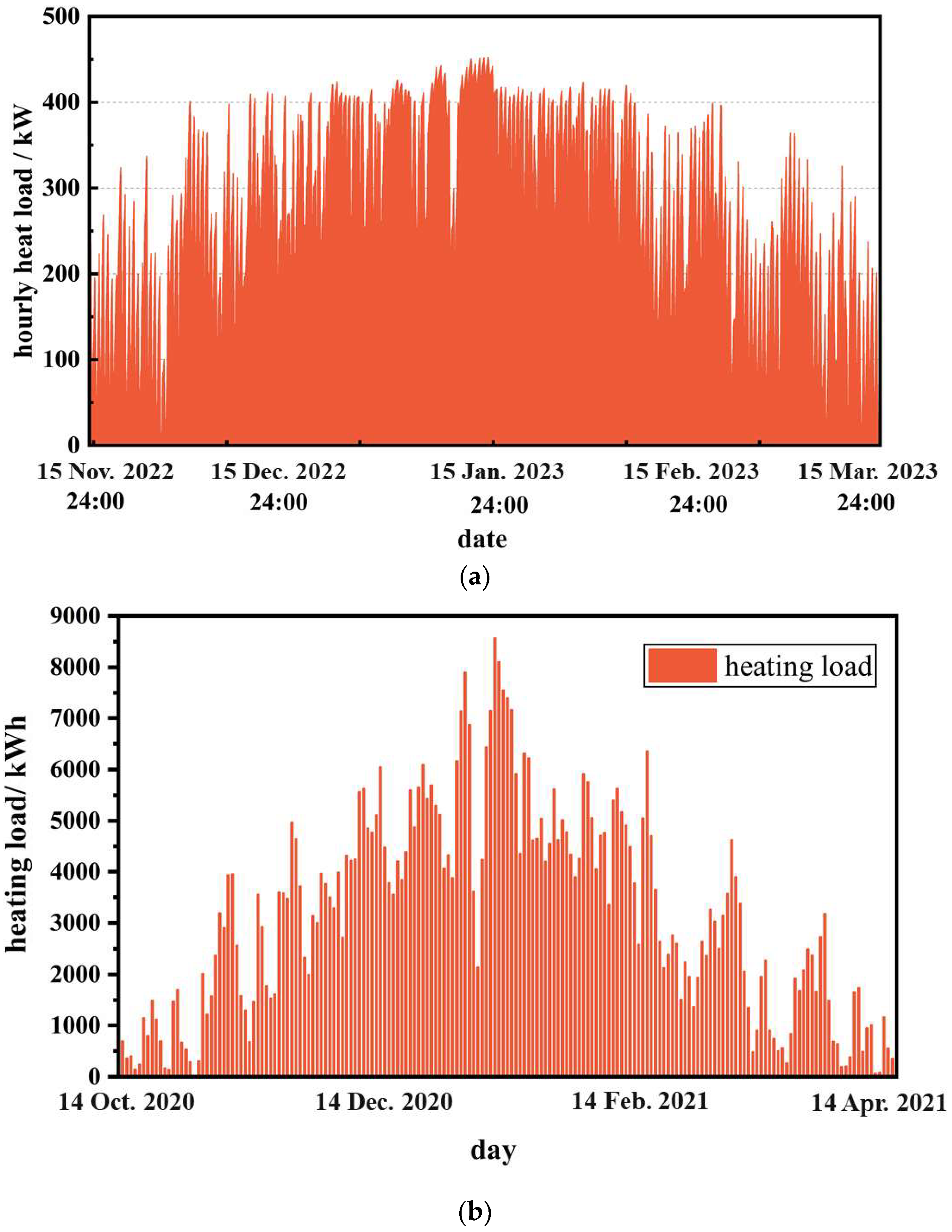

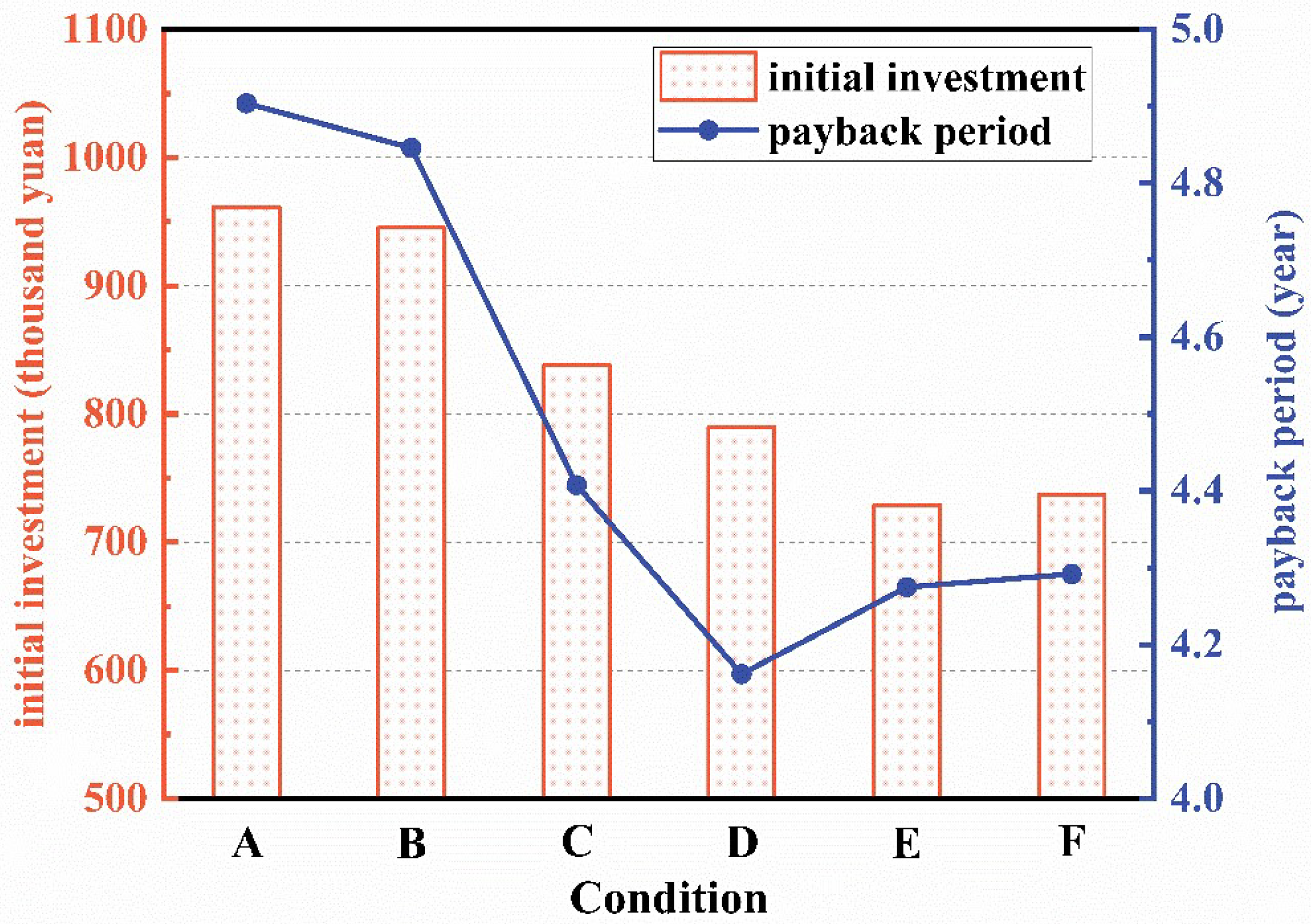

4.1. Building Heat Load and Initial Investment

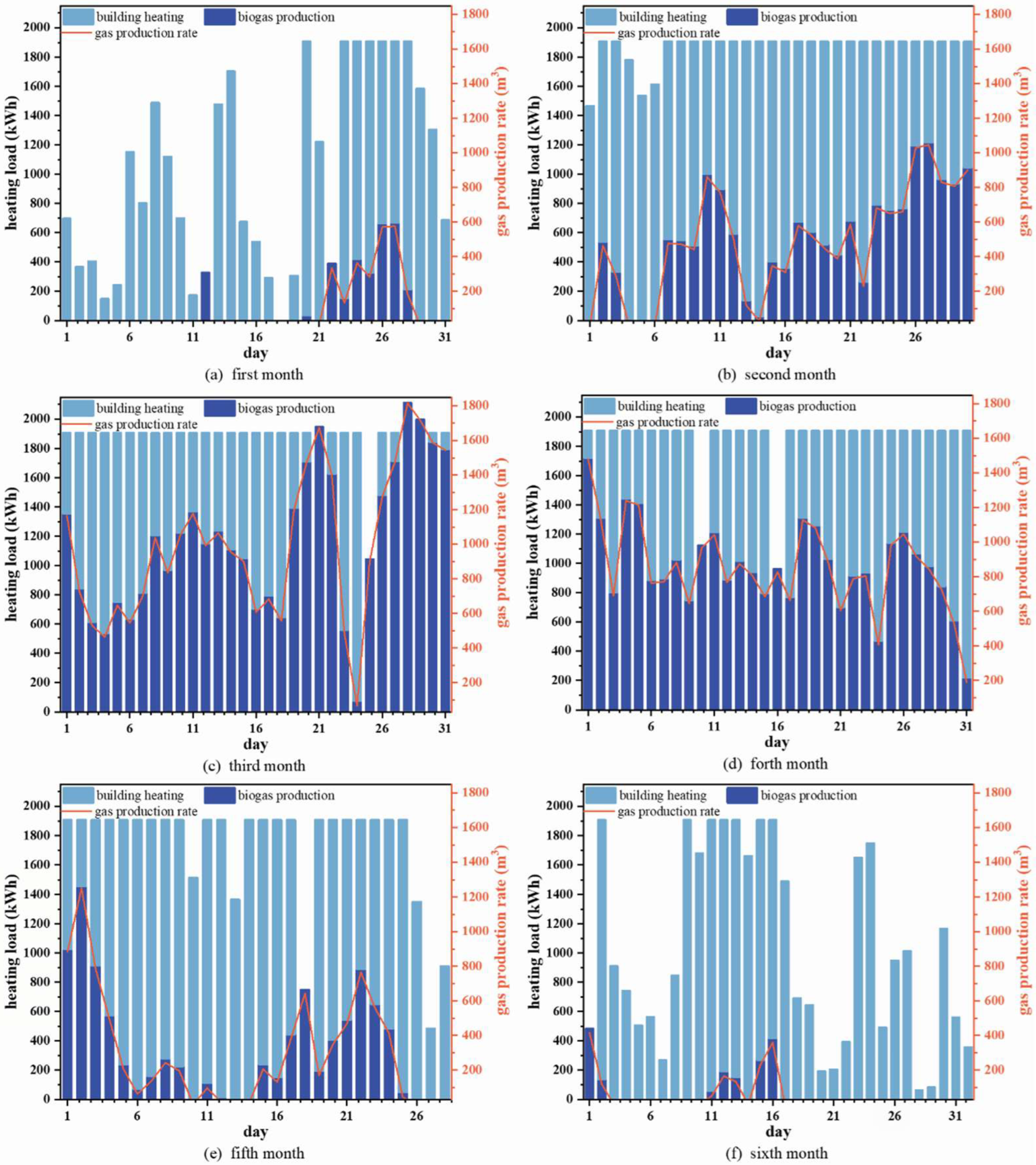

4.2. Energy Distribution under the Coordination of Supply and Demand

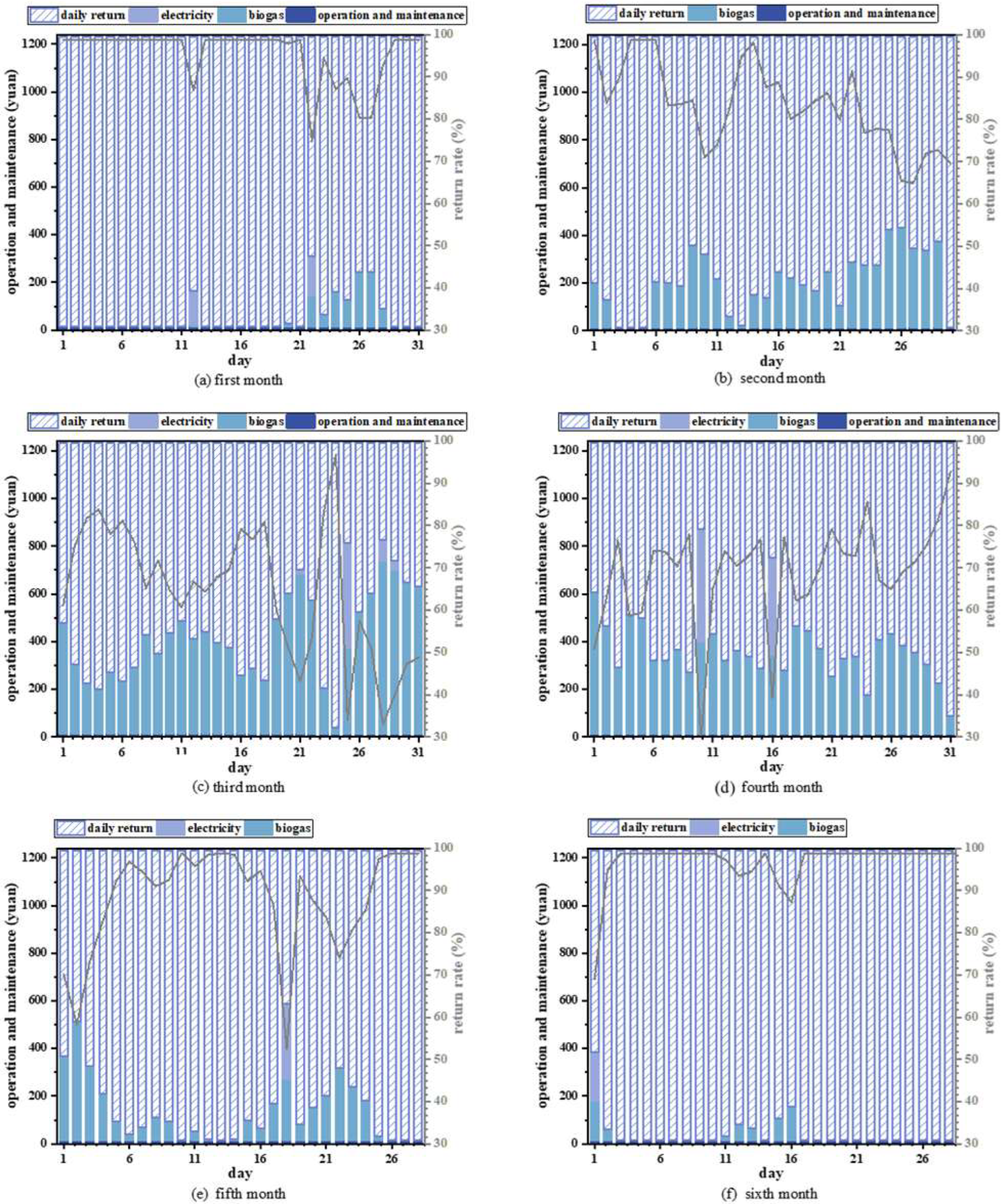

4.3. System Benefit Analysis

5. Conclusions

- (1)

- Utilizing the SSA algorithm, the minimum cost under six working conditions is determined. Combined with the annual operating cost of the heating season under different working conditions, it is found that, when the solar collector area is 677 m2 and the capacity of the phase-change heat accumulator is 1900 kWh, the shortest payback period is 4.15 years. This system achieves remarkable economic benefits and zero waste of system energy at the same time.

- (2)

- The daily return rate of the multi-energy complementary heating system exceeds 30%, with biogas purification accounting for 93.68% of the operating cost. When solar energy fully meets the heating demand, the daily return reaches as high as 98.89%. In addition, it can be seen that the optimal dispatch, under the coordination of supply and demand, has significant economic and energy benefits compared with the benchmark municipal heating system.

- (3)

- The energy distribution strategy, which is based on the balance of supply and demand, ensures the production of biogas and the economic operation of the system. Meanwhile, the flexible scheduling of the system brings a large cost recovery rate for the building. This provides valuable guidance for practical projects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Niu, Z.; Gao, X.; Guo, J.; Yang, X.; He, Y.-L. Effect of filling height of metal foam on improving energy storage for a thermal storage tank. Appl. Therm. Eng. 2023, 229, 120584. [Google Scholar]

- Shen, Y.; Pan, Y. BIM-supported automatic energy performance analysis for green building design using explainable machine learning and multi-objective optimization. Appl. Energy 2023, 333, 120575. [Google Scholar] [CrossRef]

- Awan, M.B.; Ma, Z.; Lin, W.; Pandey, A.; Tyagi, V. A characteristic-oriented strategy for ranking and near-optimal selection of phase change materials for thermal energy storage in building applications. J. Energy Storage 2023, 57, 106301. [Google Scholar] [CrossRef]

- Yadollahi, M.; Saryazdi, S.M.E.; Shafaat, A.; Hafezi, M. Life cycle cost analysis of near zero energy buildings benefited from earth-sheltering. Int. J. Constr. Manag. 2022, 23, 2670–2682. [Google Scholar] [CrossRef]

- Zhang, Y.; Vand, B.; Baldi, S. A Review of Mathematical Models of Building Physics and Energy Technologies for Environmentally Friendly Integrated Energy Management Systems. Buildings 2022, 12, 238. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Chopra, K.; Kalidasan, B.; Chauhan, A.; Stritih, U.; Anand, S.; Pandey, A.K.; Sari, A.; Kothari, R. Phase change material based advance solar thermal energy storage systems for building heating and cooling applications: A prospective research approach. Sustain. Energy Technol. Assess. 2021, 47, 101318. [Google Scholar]

- Karimi, M.; Alibak, A.H.; Alizadeh, S.M.S.; Sharif, M.; Vaferi, B. Intelligent modeling for considering the effect of bio-source type and appearance shape on the biomass heat capacity. Measurement 2022, 189, 110529. [Google Scholar] [CrossRef]

- Sadi, M.; Behzadi, A.M.; Alsagri, A.S.; Chakravarty, K.H.; Arabkoohsar, A. An innovative green multi-generation system centering around concentrating PVTs and biomass heaters, design and multi-objective optimization. J. Clean. Prod. 2022, 340, 130625. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Egemose, C.W.; Bastien, D.; Fretté, X.; Birkved, M.; Sohn, J.L. Human Toxicological Impacts in Life Cycle Assessment of Circular Economy of the Built Environment: A Case Study of Denmark. Buildings 2022, 12, 130. [Google Scholar] [CrossRef]

- Picardo, A.; Soltero, V.M.; Peralta, M.E.; Chacartegui, R. District heating based on biogas from wastewater treatment plant. Energy 2019, 180, 649–664. [Google Scholar]

- Xu, Z.; Wu, H.; Wu, M. Energy performance and consumption for biogas heat pump air conditioner. Energy 2010, 35, 5497–5502. [Google Scholar]

- Hua, Z.; Li, J.; Zhou, B.; Or, S.W.; Chan, K.W.; Meng, Y. Game-theoretic multi-energy trading framework for strategic biogas-solar renewable energy provider with heterogeneous consumers. Energy 2022, 260, 125018. [Google Scholar]

- Bambokela, J.E.; Belaid, M.; Muzenda, E.; Nhubu, T. Developing a Pilot Biogas-Solar PV System for Farming Communities in Botswana: Case of Palapye. Procedia Comput. Sci. 2022, 200, 1593–1604. [Google Scholar] [CrossRef]

- Gul, E.; Baldinelli, G.; Bartocci, P.; Shamim, T.; Domenighini, P.; Cotana, F.; Wang, J.; Fantozzi, F.; Bianchi, F. Transition toward net zero emissions—Integration and optimization of renewable energy sources: Solar, hydro, and biomass with the local grid station in central Italy. Renew. Energy 2023, 207, 672–686. [Google Scholar]

- Alkhamis, T.; El-Khazali, R.; Kablan, M.; Alhusein, M. Heating of a biogas reactor using a solar energy system with temperature control unit. Sol. Energy 2000, 69, 239–247. [Google Scholar]

- Tiwari, S.; Bhatti, J.; Tiwari, G.; Al-Helal, I. Thermal modelling of photovoltaic thermal (PVT) integrated greenhouse system for biogas heating. Sol. Energy 2016, 136, 639–649. [Google Scholar]

- Xue, X.; Lv, J.; Chen, H.; Xu, G.; Li, Q. Thermodynamic and economic analyses of a new compressed air energy storage system incorporated with a waste-to-energy plant and a biogas power plant. Energy 2022, 261, 125367. [Google Scholar]

- Wang, G.; Song, Y.; Cao, S.; Duan, J. Novel adaptive power distribution master–slave control strategy for a biogas–solar–wind battery islanded microgrid based on a microturbine. Electr. Power Syst. Res. 2023, 224, 109743. [Google Scholar]

- Su, X.; Shao, X.; Geng, Y.; Tian, S.; Huang, Y. Optimization of feedstock and insulating strategies to enhance biogas production of solar-assisted biodigester system. Renew. Energy 2022, 197, 59–68. [Google Scholar]

- Cao, Y.; Dhahad, H.A.; Togun, H.; Haghghi, M.A.; Anqi, A.E.; Farouk, N.; Rosen, M.A. Seasonal design and multi-objective optimization of a novel biogas-fueled cogeneration application. Int. J. Hydrogen Energy 2021, 46, 21822–21843. [Google Scholar]

- Arslan, M.; Yılmaz, C. Design and optimization of multigeneration biogas power plant using waste heat recovery System: A case study with Energy, Exergy, and thermoeconomic approach of Power, cooling and heating. Fuel 2022, 324, 124779. [Google Scholar] [CrossRef]

- Castley, J.; Azimov, U.; Combrinck, M.; Xing, L. Modeling and optimization of combined cooling, heating and power systems with integrated biogas upgrading. Appl. Therm. Eng. 2022, 210, 118329. [Google Scholar]

- Mousavi, S.A.; Toopshekan, A.; Mehrpooya, M.; Delpisheh, M. Comprehensive exergetic performance assessment and tech-no-financial optimization of off-grid hybrid renewable configurations with various dispatch strategies and solar tracking systems. Renew Energy 2023, 210, 40–63. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Liu, Y.; Wang, D.; Zhuang, Z.; Quan, M. Energy, exergy, and economic analysis of a centralized solar and biogas hybrid heating system for rural areas. Energy Convers. Manag. 2023, 276, 116591. [Google Scholar]

- Vassalle, L.; Passos, F.; Rosa-Machado, A.T.; Moreira, C.; Reis, M.; de Freitas, M.P.; Ferrer, I.; Mota, C.R. The use of solar pre-treatment as a strategy to improve the anaerobic biodegradability of microalgal biomass in co-digestion with sewage. Chemosphere 2022, 286, 131929. [Google Scholar]

- Wang, J.; Liu, J.; Li, C.; Zhou, Y.; Wu, J. Optimal scheduling of gas and electricity consumption in a smart home with a hybrid gas boiler and electric heating system. Energy 2020, 204, 117951. [Google Scholar]

- Fei, F.; Gao, L.; Zhang, R.; Zhou, J.; Weng, P.; Huo, L. Research on optimization of biogas cogeneration system for farms based on characteristics of supply and demand coordination. Acta Energiae Solaris Sin. 2023, 44, 231–237. [Google Scholar]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

| Partition | ||||||

|---|---|---|---|---|---|---|

| 0.49 | 2.80 | 0.92 | 0.24 | 0.32 | 1.80 |

| Three Dimensions | L | W | H |

|---|---|---|---|

| size (m) | 57.9 | 57.0 | 11.7 |

| 0 | 10 | 10 | 10 | 10 | 10 | 10 |

| 1 | 10 | 10 | 10 | 10 | 10 | 10 |

| 2 | 10 | 10 | 10 | 10 | 10 | 10 |

| 3 | 10 | 10 | 10 | 10 | 10 | 10 |

| 4 | 10 | 10 | 10 | 10 | 10 | 10 |

| 5 | 10 | 10 | 10 | 10 | 10 | 10 |

| 6 | 10 | 10 | 10 | 10 | 10 | 10 |

| 7 | 10 | 10 | 10 | 10 | 10 | 10 |

| 8 | 50 | 10 | 50 | 10 | 50 | 10 |

| 9 | 95 | 10 | 95 | 10 | 95 | 10 |

| 10 | 95 | 10 | 95 | 10 | 95 | 10 |

| 11 | 95 | 10 | 95 | 10 | 95 | 10 |

| 12 | 80 | 10 | 80 | 10 | 80 | 10 |

| 13 | 80 | 10 | 80 | 10 | 80 | 10 |

| 14 | 95 | 10 | 95 | 10 | 95 | 10 |

| 15 | 95 | 10 | 95 | 10 | 95 | 10 |

| 16 | 95 | 10 | 95 | 10 | 95 | 10 |

| 17 | 95 | 10 | 95 | 10 | 95 | 10 |

| 18 | 30 | 10 | 30 | 10 | 30 | 10 |

| 19 | 30 | 10 | 30 | 10 | 30 | 10 |

| 20 | 10 | 10 | 10 | 10 | 10 | 10 |

| 21 | 10 | 10 | 10 | 10 | 10 | 10 |

| 22 | 10 | 10 | 10 | 10 | 10 | 10 |

| 23 | 10 | 10 | 10 | 10 | 10 | 10 |

| Initial Investment | Operation | ||

|---|---|---|---|

| Item | Cost | Item | Cost |

| solar collector (Ns) | 400 CNY/m2 | biogas purification (Nc) | 0.4 CNY/m3 |

| composite PCM (Nt) | 185 CNY/kg | flat electricity (Nf) | 0.4267 CNY/kWh |

| biogas pit (Fbiogas) (size: 5 m × 5 m × 10 m; numbers: 12) | 20,000 CNY | valley electricity (Nv) | 0.3604 CNY/kWh |

| biogas boiler (Fbiogas) | 65,000 CNY/600 kW | maintenance (Fmain) | 1500 CNY/year |

| electric boiler (Felectric) | 30,000 CNY/300 kW | labor cost (Flabor) | 1000 CNY/year |

| attachments (Fat) | 15,000 CNY | ||

| Condition | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| date | 11 January 2023 | 12 January 2023 | 13 January 2023 | 3 January 2023 | 9 January 2023 | 15 December 2022 |

| heat load/kWh | 8567.37 | 8104.66 | 7550.87 | 7144.28 | 6440.61 | 6049.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Gao, X.; Li, Z.; Yang, X.; Hu, Y. Evaluation of Biogas and Solar Energy Coupling on Phase-Change Energy-Storage Heating Systems: Optimization of Supply and Demand Coordination. Buildings 2023, 13, 2712. https://doi.org/10.3390/buildings13112712

Liu Z, Gao X, Li Z, Yang X, Hu Y. Evaluation of Biogas and Solar Energy Coupling on Phase-Change Energy-Storage Heating Systems: Optimization of Supply and Demand Coordination. Buildings. 2023; 13(11):2712. https://doi.org/10.3390/buildings13112712

Chicago/Turabian StyleLiu, Zemin, Xinyu Gao, Ze Li, Xiaohu Yang, and Yukun Hu. 2023. "Evaluation of Biogas and Solar Energy Coupling on Phase-Change Energy-Storage Heating Systems: Optimization of Supply and Demand Coordination" Buildings 13, no. 11: 2712. https://doi.org/10.3390/buildings13112712

APA StyleLiu, Z., Gao, X., Li, Z., Yang, X., & Hu, Y. (2023). Evaluation of Biogas and Solar Energy Coupling on Phase-Change Energy-Storage Heating Systems: Optimization of Supply and Demand Coordination. Buildings, 13(11), 2712. https://doi.org/10.3390/buildings13112712