Abstract

The construction industry impacts resource consumption and waste production and thus necessitates solutions that promote sustainable practices. In particular, it must address challenges surrounding data collection and digital management services that often hinder the recycling or reuse of materials. The purpose of this study is to develop an integrated platform-based digital tool that seamlessly incorporates circular economy principles into construction processes, with a particular focus on circular resource utilization in the building envelope components’ life cycle. This tool aims to address the challenges in the construction industry related to resource consumption, waste production, and sustainability by promoting sustainable practices and improving material management. This paper reports industrial joint research to develop an integrated platform-based digital tool that seamlessly incorporates circular economy principles into construction processes, focusing on circular resource utilization in the building envelope components life cycle. By combining different platforms and services from the previous research, this study’s results enhance and integrate comprehensive thinking approaches and services. These include promoting raw material substitution, reducing supply chain arrangement time, minimizing waste throughout the building component lifecycle, enhancing disassembly processes, and improving life cycle environmental assessments. The tool design was informed by user-driven narratives and requirements, and demo case testing procedures, ensuring usability and industry relevance. Furthermore, integration with product lifecycle management software and data management platforms enhanced data sharing and accuracy. This study highlights the potential of integrated tools to revolutionize supply chains and promote circular economy, transforming construction paradigms. They can contribute to the reshaping of material management towards environmental consciousness, fostering resource-efficient green building solutions, and enabling more circularity in the construction industry.

1. Introduction

The construction sector extensively utilizes resources and energy during its life stages. Still, there is a lack of a comprehensive life cycle perspective when implementing building components and systems, with consequential resource and energy loss occurring in end-of-life scenarios. This sector is estimated to account for 50% of all raw material usage and 36% of global energy consumption [1,2]. In the EU, around 924 million tons of waste were generated from the disposal of buildings in 2016, more than 35% of the total. Moreover, in China, a total of 2.36 billion tons of waste were generated in 2018. This production of construction waste is anticipated to rise further in the upcoming years [3]. The recycling and recovery of building materials varies greatly across the EU, with rates ranging from less than 10% to over 90%. Despite the high recycling rates of some countries, secondary materials are rarely utilized in construction. For instance, while The Netherlands recycles more than 95% of its construction waste stream, only 3–4% of secondary materials are used in the construction sector, compared to over 50% in civil engineering [4,5]. Nonetheless, building stages offer multiple opportunities to reduce waste and promote circularity, and numerous approaches and concepts have been devised by the construction industry to facilitate the shift towards a circular economy. Nonetheless, these methods often fall short in terms of reusability and are restricted to design-centric approaches. Hence, there is a pressing requirement to establish the circularity of constructions and establish corresponding evaluation mechanisms [6]. Surely, the designing stage is crucial to allow life cycle optimization, and is capable to address for making modular and easily disassembled components, aiding manufacturers to prioritize separating materials, reducing complexity, and minimizing energy use during manufacturing [7]. Yet it is essential to consider several factors when these components and materials reach their end-of-life stage, such as overseeing demolition and renovation work to ensure the quality of materials for recycling and reuse [8,9]. The actions to be taken in this last stage consist of performing material audits before demolition, devising waste management plans, segregating high-quality materials for recycling, executing precise and selective disassembly operations, preparing materials for re-utilization and recycling, and enhancing traceability, quality assessment, and certification of construction and demolition waste streams [10].

These actions occur during different stages of the life cycle of building components and require tools to facilitate their implementation. However, the construction sector faces several barriers that must be overcome to achieve these goals and ensure successful completion:

- Poor quality data and difficulty in digitizing information about the origin of waste and recycled aggregate materials;

- Lack of digital services for creating new value chains and organizing information on raw materials;

- Uncompetitive pricing of secondary materials, and lack of trust in their quality;

- A long delay between implementing circular actions and their effect on waste management;

- A need for guidance in calculating sustainability parameters for new recycled materials [11,12].

To address these barriers, the utilization of data-driven digital tools and circularity plans have emerged as a key driver for promoting not only circularity but also a low-carbon economy and social development in the construction sector. This trend has gained significant momentum globally (with different emphases depending on regional characteristics), as it challenges the factors that impede sustainable growth and progress in this industry [13,14,15,16]. In this scientific scenario, this article will present the digital composing, methodologies, development, and results of industrial joint research aimed at developing a digital tool to improve and integrate circular economy thinking and services in the building sector, focusing on building envelope components (BECs). This research was undertaken under the framework of the CE4Con (Circular Economy for Construction Industries) project. CE4Con’s objective is to develop a one-stop Integrated Platform-Based Tool (IPBT) to aid manufacturers of BECs that seek to create building envelope products tracking LCA and circularity Key Performance Indicators (KPIs) from the designing stage to the dismantling phase. Particularly, the developed digital tool aims to act in two life cycle stages of the BECs: (1) the design stage, assisting in selecting building materials for the processes and products under development, considering recycled composite, near-distance market, and low-carbon aspects; and (2) the construction and dismantling stage, supporting material auditing, product disassembly, and material pre-treatment to facilitate recycling. Finally, to validate the tool, prefabricated facade modules were chosen as real demo testers for their advantages in circular and sustainable development [17]. Indeed, the lean management and practices of that type of facade industry further contextualize CE4Con in their main research dimensions, which include data-driven intelligent decision making and activity process optimization [18].

Adopting an IPBT for circularity solutions can contribute to implementing the best practices indicated above, as opposed to the barriers that need to be overcome. The solution also provides comprehensive services to establish connections and collaborations among various construction and circular economy stakeholders.

In the following sections, this paper presents the materials and methods (Section 2) employed in this study, providing an overview of the materials used, including the cloud-based multi-sided platform for circularity data management (Section 2.1.1), the product lifecycle management software (Section 2.1.2), the Life Cycle Assessment Simulation Engine (Section 2.1.3), the augmented reality snag list and dismantling support tool (Section 2.1.4), the blockchain platform (Section 2.1.5), as well as the use cases for the demo tester (Section 2.1.6). The subsections detailing the methods encompass the explanation of the stages behind the platform’s development, including the analysis and investigation (Section 2.2.1), the adoption of an end-user-centric approach (Section 2.2.2), the definition of the platform’s functionalities and development (Section 2.2.3), and the final tool validation (Section 2.2.4). Building upon the materials identified and the methodology set up, this article presents the results (Section 3), commencing with the structure definition and data collection for circular entities (Section 3.1) and subsequently the definition of user stories and requirements (Section 3.2) to identify the most promising approach for the operational flowcharts and tool development (Section 3.3) and finally the overall tool validation for early stage tests (Section 3.4). The paper proceeds to offer insights into the discussion (Section 4), providing an analysis of the correspondence between the development’s goals and the achieved results for the integrated platform. In the conclusions (Section 5), the article summarizes the outcomes achieved and highlights open issues that point to opportunities for further investigation.

2. Materials and Methods

The following sections present the materials and methods used for developing the one-stop Integrated Platform-Based Tool (IPBT).

Software and tools integrated at the starting point of the development are considered materials for this research as well as the use case demo testers chosen to validate the IPBT. On the other hand, the methodology applied focused on an end-user-centered approach for developing the tool, which is centered on eight specific usage scenarios (e.g., Scenario #3: management of the supply chain).

2.1. Materials

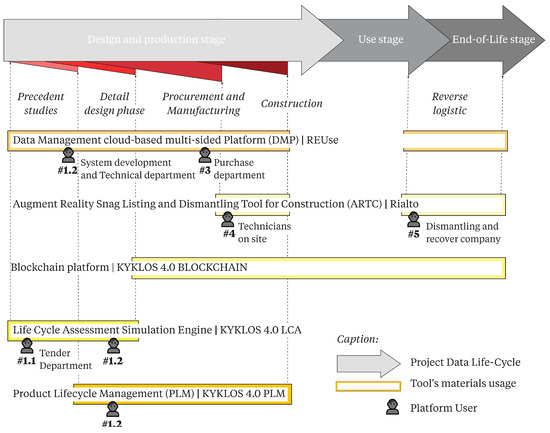

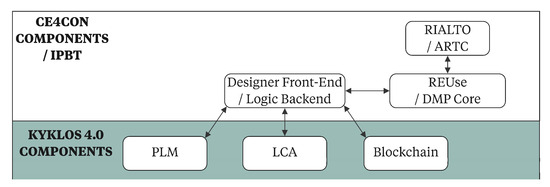

Figure 1 illustrates the software used for the IPBT implementation and typical users through the life cycle of the building components. These platforms and tools, which are considered materials of the research, include the following:

Figure 1.

Project data cycle and materials timeline.

- A cloud-based multi-sided platform for circularity data management.

- A product lifecycle management software.

- A Life Cycle Assessment Simulation Engine.

- An augmented reality snag list and dismantling support tool.

- A blockchain platform.

2.1.1. Cloud-Based Multi-Sided Platform for Circularity Data Management

To promote circularity in construction, the IPBT proposal relies on a data management cloud-based multi-sided platform (DMP). This platform allows users, such as designers, managers, quality departments, and procurement teams, to manage and obtain pertinent information, thanks to a user-friendly solution. The DMP used in this study is designed to handle digital polymorphic entities subject to changes throughout their life cycle (including rework, reuse, or recycling), and collects all the available environmental and circularity data about supplier options and storing data about their life cycle. Namely, in CE4Con, the employed DMP is REUse, which enables the recycling of composite materials through access to digitalized information and services [19]. REUse facilitates the entire value chain by matching demand for new materials with the availability of recycled products. Additionally, it gathers information on the latest materials and waste treatment processes to ensure the ongoing availability of recycled materials while also considering their technical properties. REUse was developed for the needs of the FiberEUse H2020 project [20], which conducted studies and campaigns for the same purpose [21].

2.1.2. Product Lifecycle Management Software

In addition to the so-called environmental data related to the supply chain, which are collected in the DMP, it is essential to integrate the IBPT with computer-aided technologies used by building component manufacturing companies, particularly for retrieving project data related to building materials and components. Linking the IPBT to a product lifecycle management (PLM) is essential since it acts as a central repository, enabling seamless data sharing and coordination across different project phases and users, e.g., designers and manufacturers. Through it, the IPBT would gain access to crucial data and information about materials, processes, and stakeholders. This integration enhances the accuracy of material data, improves supply chain transparency, and streamlines decision-making [22,23]. Lastly, a PLM ensures a holistic approach to sustainable construction, enabling better-informed choices throughout the entire project life cycle [24].

Specifically, the KYKLOS 4.0 PLM was integrated into the CE4Con tool. KYKLOS 4.0 is an H2020 project whose primary goal is to establish a circular manufacturing ecosystem that generates customized goods with prolonged lifespans utilizing advanced technologies [25]. By using international standard formats for data exchange and storage, the PLM is a vital contributor to CE4Con. The PLM module uses ISO 10303 standards for data exchange, sharing, and archiving, including file exchange, APIs, and web services [26].

2.1.3. Life Cycle Assessment Simulation Engine

To handle the possibility that the suppliers cannot provide all the required data for an accurate environmental assessment of the analyzed products through IPBT, it was decided to incorporate an ecological impact quantification tool. This tool can perform a Life Cycle Assessment (LCA) [27] of the product and gather secondary environmental data from external databases to fill any data gaps left by the suppliers. This can help various departments, e.g., design teams and quality departments.

Linking the IPBT to a LCA tool is crucial in achieving comprehensive sustainability goals in the construction sector [28,29]. It allows to draw a comparison of different project options based not only on economic aspects, technical factors, and end-of-life possibilities but also on relative greenhouse gas emissions and other environmental impacts [30]. The tool can detect hotspots in all aspects of the supply chain, from raw materials to manufacturing, distribution, use, and disposal. The LCA tool used for this purpose in CE4Con is also part of the ecosystem of KYKLOS 4.0 [25].

2.1.4. Augmented Reality Snag List and Dismantling Support Tool

Within the specific IPBT developed in this project, an Augment Reality Snag Listing and Dismantling Tool for Construction (ARTC), based on a mobile app, was integrated. A snag list is an auditing report performed by on-site technicians and used in construction projects. It includes a list of all the detected faults and defects in construction items [31]. In this way, the contribution of the tool to the platform can be two-fold. Firstly, the “snagging” function allows the user to take note of damages in on-site installed components so they can be more easily cataloged and remain visible during dismantling in the future. Through the use of a mobile application, it makes issue management more efficient and less time-consuming. Secondly, the dismantling section provides real-time information on the availability and recyclability of building materials and components.

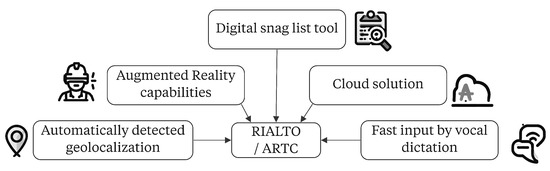

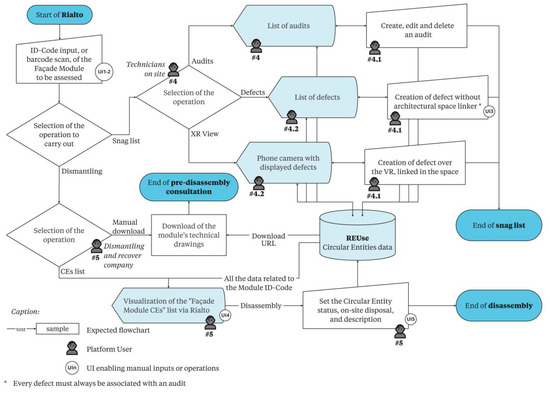

The AR-based tool developed as ARTC used in CE4Con is Rialto, which, compared to current snag list applications, adds other advanced features to the IPBT, such as the automatic location and measurements through mobile cameras and sensors, automatic displaying information over objects, overlaying and comparing design models to as-built models and voice entry capabilities. This allows for the entering of snag list entities, quickly and rapidly. Moreover, integrating Rialto with the digital platform allows bidirectional communication between devices and workers on site and the backend systems on cloud (Figure 2).

Figure 2.

Main features diagram of Rialto.

2.1.5. Blockchain Platform

Blockchain technology provides transparent, immutable, and traceable data, which makes it suitable for applications that require trust and accountability, fitting for cases such as circular economy. CE4Con can leverage blockchain to guarantee that data related to recycled and reused materials and certifications are tamper-proof and easily accessible to all stakeholders. This technology fosters trust between participants, verifies the authenticity of materials, and facilitates the development of a sustainable circular economy by providing a secure and auditable data infrastructure.

In the KYKLOS 4.0 ecosystem, the blockchain platform used in CE4CON is another essential component. It has been studied as a potential solution to the problem of securely storing designs in an immutable way that can also be verified externally.

2.1.6. The Use Case Demo Tester

While integrating these IT materials and validating the tool, a real demo tester use case was deemed necessary. In choosing the appropriate type of building envelope component (BEC) for this purpose, prefabricated and custom facade modules were selected. In the construction sector, the prefabricated facade technology brings some advantages thanks to the off-site construction in lean manufacturing, which leads to the optimization of the use of materials, enhancing the assembly and dismantling phases, and reducing waste generation, as well as saving time and money [32,33,34]. Prefabricated facades are complex and require detailed information on energy use, carbon footprint, and material sources. This makes it challenging to evaluate alternatives and disclose the data on the end-of-life stages. For this reason, the CE4Con solution has been validated on Prefabricated Modules for Curtain Walls (PMCW).

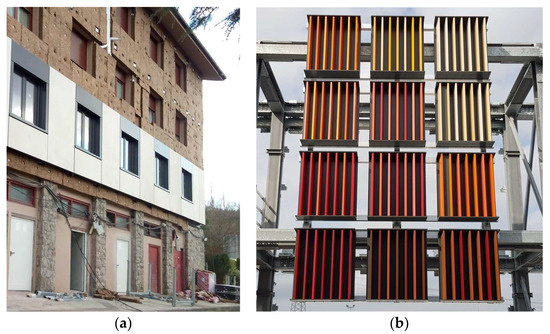

The PMCWs selected as use cases are as follows:

- Two facade modules designed in the H2020 Project RenoZeb to develop Plug and Play Facade integrating insulation and energy generation systems to address building renovation of existing stocks [35,36].

- One spandrel facade module with external aluminum fins designed for the 1 Broadgate building, a major fourteen-stores office-led development located in London [37].

Pictures of these modules are in Figure 3. These facade types offered a sufficiently broad scenario of the possibilities of materials, components, and processes that a typical PMCW can contain and a perspective in both the research scenario and the actual market.

Figure 3.

(a) Installed on-site RenoZeb facade modules; (b) 1 Broadgate project’s external aluminum fins modules mockup.

2.2. Methods

The CE4Con methodological development is divided into four stages:

- Preventive analysis and investigation of required information;

- Definition through an end-user-centric approach of the requirements of the tool;

- Definition and development of the platform functionalities;

- Tool validation.

2.2.1. Preventive Analysis and Investigation

The first step in this methodology involves carefully selecting data that meet the requirements of the IPBT’s integrated services for circular and ecological construction components. To achieve this, specific rules and prerequisites defined by rating systems, environmental assessment methods (such as LCA), scientific literature, and construction companies’ targets are considered. This process requires a comprehensive analysis of the life cycle of BECs, gathering relevant information to accurately describe and track them, and evaluating any difficulties or practices associated with the circular economy.

2.2.2. End-User-Centric Approach

The main goal of the second phase is to define the technical requirements of the IPBT. This is completed by analyzing the typical commission job actors that could affect the life cycle of a typical PMCW and who typically manage the data highlighted in the first stage. To achieve this goal, a depicted platform-based framework that connects stakeholders involved across the construction life cycle is necessary. The data gathered in phase one, together with this framework, highlight different types of interaction with the platform-based tool and describe the actors involved and their related data inputs and outputs. This leads to the definition of roles, scenarios, and system requirements that shape the architecture of CE4Con.

2.2.3. Definition of the Platform’s Functionalities and Development

In the third phase, the design of the software architecture of the IPBT occurs. This involves establishing a relationship between the various materials that make up the one-stop tool to ensure that all the necessary data are available for the system to work effectively. In practice, this consists of defining the relationships among the various materials that will be part of CE4Con and the flowcharts useful for planning, communicating, and developing the complex processes of the IPBT. The different components are able to obtain the data from others via their APIs, which relate to the relay of product or process information.

2.2.4. Tool Validation

Lastly, functional testing, which involves systematic testing of each feature and UI evaluation, and user acceptance testing, involving feedback from end users as well as test scenarios to evaluate real-world usage, were performed to validate CE4Con functionalities.

3. Results

This section presents the development and related outcomes of t study, following the methodological stages.

3.1. Circular Entities Structure Definition and Data Collection

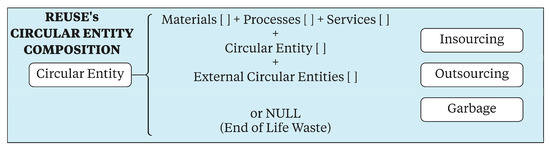

REUse, the DMP integrated into CE4Con, focuses on collecting, connecting, and enriching data to associate with digital object entities. The atomic unit of the data model is the circular entity (CE) and its attributes, which were already defined in the platform and adapted for CE4Con.

CEs are defined as representations of categories of objects, or sets of objects, with similar characteristics. In fact, in REUse, the concept of CE replaces the concept of a static product entity. It is designed as a CE, i.e., an entity that can transform itself during its life, interact with processes, re-manufacturing, and logistics, and cope with non-standardized and dynamically changing parameters. From an IT standpoint, these kinds of CEs are designed to satisfy specific architectural requirements to deal with the needs of changing parameters, such as those often encountered in the circular economy. As shown in the class diagram in Figure 4, attributes can be as numerous as required. This means that the entity data model is not predefined but can be created according to user needs. The attributes describe parameters that to help define the entity. As it is possible to add many attributes, they have been designated as expandable attributes.

Figure 4.

Definition of circular entity for company recursion in REUse.

The class diagram reflects the concept of polymorphic data. Polymorphism of data defines thedata as extensible and able to serve different product histories through high-level object-oriented design [38]. These functionalities are helpful for the first step of the methodology, which involves identifying required data and their organization in a standardized system for the adaptation to PMCW.

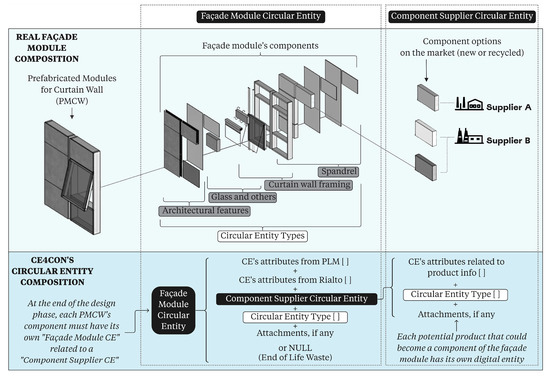

Although there is a lack of specific policies regarding construction components, there are proposed solutions that could be implemented to improve circular design [39]. These solutions include performance indicators based on legal frameworks, product circularity documents, and LCA methodology [40,41]. Regarding facade-related static and dynamic data, these encompass administrative documents, such as manuals for assembly and maintenance, detailed drawings of technical systems, components, and materials, performance statistics, and connections to building ratings and certificates. Establishing the necessary criteria must consider LCA impact categories, specific rules for labeled scopes, and other certifications [42]. Moreover, when evaluating intricate building components such as PMCW, it is crucial to categorize them by their various parts and materials. This categorization should distinguish materials with different usage cycles and lifespans [43]. Therefore, the first step consists of identifying the CEs and their attributes that need to be stored in the DMP, as previously described. To that end, the ideal life cycle of a PMCW was analyzed, with attention being paid to the components and materials that could ideally compose it. There are two classifications of CEs: those related to the PMCW, called “Façade Module CE”, and those associated with the individual materials or components that make up the module, called “Component Supplier CE”. Their definition according to the REUse logic and their association with the real component of a typical PMCW are depicted in Figure 5.

Figure 5.

Definition of the two circular entities in CE4Con.

In addition, it is essential to identify “CE Types” capable of assigning a specific field to each CE, to facilitate the association between the “Façade Module CE” and “Component Supplier CE”. These “CE Types” can be further subdivided into several “Material Types” that can encapsulate within them the categories of all the elements of the facade module (e.g., extruded profile, gaskets, glass sheet). Based on this list of keys, “Material Types”, a list of attributes describing the CEs has been developed, which is able to describe CEs during their life cycle. In Figure 6, the list of “Material Type” and each of the CEs’ attributes are listed, specifying which category they belong to and in what form this data will be collected and transmitted. It is important to note that each “Façade Module CE” is linked to a "Component Supplier CE" representing the material or component that characterizes it. Finally, Figure 6 specifies which information collected in the DMP can typically be retrieved from the PLM system and which can be uploaded or displayed on the ARTC.

Figure 6.

CE4Con’s circular entities and attributes diagram.

Considering the components of the demo cases, appropriate CEs have been gathered in REUse, focusing on authentic supplier products that could be used for the PMCW’s constitution. Additionally, the facade manufacturing company that proceeded with the demo cases conducted an internal data retrieval operation to collect the project data that would later be stored in the PLM. The collected data were then analyzed and prepared for upload to both REUse and PLM for further processing. The data collected was chosen based on industry standards and best practices found in the existing literature, ensuring it was relevant and aligned with the industry’s standards.

3.2. Definition of User Stories and Requirements

To achieve the purpose of the one-stop Integrated Platform-Based Tool (IPBT), it is necessary to create a comprehensive framework that connects stakeholders across the entire construction life cycle. Based on the data highlighted by the CE’s attribute selection, various types of interactions with the IPBT have been identified throughout the data life cycle.

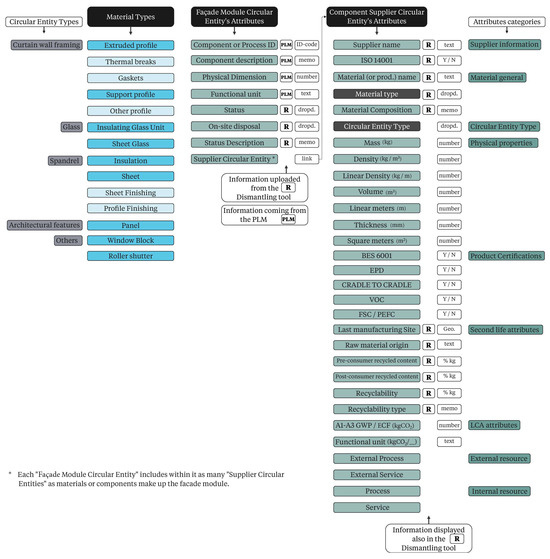

All the steps involved in the data life cycle are illustrated in Figure 7, which represents the complete life cycle processes, the roles of the users involved, and the type of platform through which they exchange data during a commission job [44]. This includes defining the types of interaction between the platform and the user (i.e., CEs and attributes upload, CEs and attributes consultation, documentation) and the types of exchanged data (i.e., project data, use phase data, end-of-life data). A list of roles and scenarios has been identified from each interaction analyzed and then described in the figure.

Figure 7.

Circular entities’ data life-cycle diagram; process and interactions with the platforms and users involved.

The platform caters to multiple stakeholders with distinct roles. These roles are identified based on their involvement in different phases of the construction process, such as design, procurement, installation, and end-of-life considerations. By mapping out these roles, the platform design team gained insights into the range of interactions and needs to be addressed in different scenarios. A scenario accurately predicts how actors will interact with a technical system. In Appendix A, Table A1, Table A2, Table A3, Table A4, Table A5, Table A6 and Table A7 reporting these are presented. The tables include information about actors involved in the scenarios, their goals, starting points [45], and user stories. These stories describe a connected sequence of actions that should be taken by the operators [46]. By using an end-user-centric approach, scenarios are used to establish the requirements of the platform. These technical requirements form the foundation of the platform’s abilities and features, and they connect the user stories to the actual implementation of the platform. The requirements include various aspects such as user interfaces, data storage, integration with other systems, and performance metrics. Here is a list of the eight main requirements that have resulted from the analysis.

3.2.1. R.1. User Web Interface for CE and Attribute Management (REUse)

The platform necessitates an intuitive web interface administered by a backend, enabling stakeholders along the supply chain (e.g., suppliers, quality department) to update CE data and generate new entries. This interface should facilitate effortless uploading and retrieval of documentation such as Environmental Product Declarations (EPDs) for CEs.

A streamlined interface enhances user experience, facilitating data navigation and action execution. The platform acts as a collaborative hub, organizing a responsive supply chain that caters to dynamic manufacturing needs while optimizing the synergy between processing facilities and logistics services.

3.2.2. R.2. Dynamic Attributes for Comprehensive CE Descriptions (REUse)

In addition to fixed attributes, the solution must empower users to provide supplementary attributes pertinent to CE recycling, reuse, or future disposal. These dynamic attributes enrich the description of CEs, conforming to international standards and physical properties essential for end-of-life considerations.

3.2.3. R.3. Search Template for CE Identification (CE4Con’s Frontend Tool)

The platform needs a specialized search tool that can filter and identify environmentally friendly CEs based on specific parameters, exploiting key “CE Type” and “Material Types”. This search feature is vital whenever manufacturers introduce new facades to the platform, as it helps align components with CEs that meet the necessary requirements.

3.2.4. R.4. Integration with LCA Component (KYKLOS 4.0)v

Environmental data from the IPBT integrated with the LCA component align with the project data to facilitate environmental assessments, enabling sustainability evaluation and circular envelope design. An ideal platform-LCA integration empowers environmental assessment for sustainable design, aligning data sources for comprehensive LCA calculations.

3.2.5. R.5. Integration of a Conversion Factor (CE4Con’s Frontend Tool)

The LCA data can come from different suppliers, regions, or sources, each using their functional units. These units might need to be converted to a standard unit to enable meaningful comparisons and analyses. A conversion factor allows systems to transform the data into a standard unit, ensuring that LCA results are accurate and can be compared across products.

3.2.6. R.6. Integration with PLM Component (KYKLOS 4.0)

Integrating IPBT and PLM components speeds up environmental assessments, correlating project data (e.g., dimensions, profiles, glass stratigraphy) with CE attributes for efficient module assessment and end-of-life scenarios.

3.2.7. R.7. ARTC Integration for Snag List Facilitator (Rialto)

The tool must have the capability to integrate the ARTC mobile app with the DMP backend, facilitating on-site examination of mounted facades. This integration should enable technicians to utilize augmented reality (AR) to identify and monitor defects.

The inclusion of AR features with the ARTC within the tool should be emphasized, as they provide a distinct advantage for defect identification and monitoring. These AR capabilities should significantly improve accuracy and efficiency compared to currently available solutions.

3.2.8. R.8. ARTC Integration for Dismantling (Rialto)

ARTC integration with the DMP backend is a mandatory feature, enabling the retrieval of dismantling and pre-treatment data. This integration is crucial for optimizing disassembly processes and ensuring the accurate updating of end-of-life information for disassembled CEs. Operators in dismantling and recovery companies can benefit greatly from ARTC’s integration. This integration streamlines data retrieval and ensures timely updates of CE end-of-life information.

These functional requirements collectively shape a comprehensive, user-centric platform catering to the circular economy’s demands within the construction sector.

3.3. Definition of the Operational Flowcharts and Tool Development

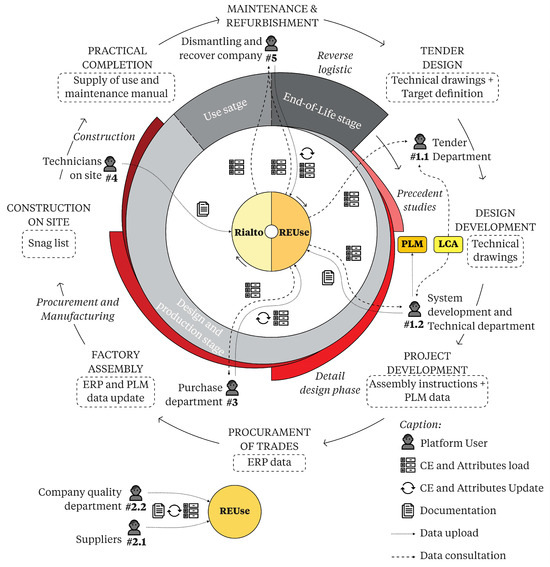

Moving forward with the application of the methodology, it focuses on the detailed planning of CE4Con as the IPBT developed in the project. As graphically summarized in Figure 8, the main integration tool, which is taking advantage of KYKLOS 4.0 components and the other materials, is a frontend tool developed for designers and the related backend logic, which is highlighted as necessary by a previous analysis. However, the DMP is the central core of the system.

Figure 8.

CE4Con’s materials integration diagram.

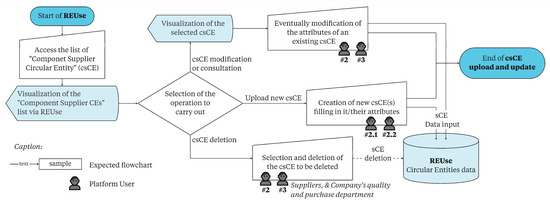

3.3.1. Multi-Sided Platform for Data Management Set Up: REUse

The DMP represents the core component for both major stages of use in CE4Con: (1) assisting in selecting building materials for the processes and products under development and (2) supporting end-of-life stage decisions. This is the first fundamental part of the platform’s operation is the “Component Supplier CE” upload. To do that, the suppliers or the manufacturing company’s quality department connect to REUse to create a new CE, and log in into the web interface of REUse where they can also modify or delete old CEs. These constitute actions available on REUse are represented in the flowchart in Figure 9. Having registered the suitable components and kept them updated, this essentially creates the base of thedata necessary for further design steps.

Figure 9.

REUse flowchart.

The objective related to the DMP core within the project was to create a sufficient number of CEs on REUse to provide diverse options for the various PMCW components within the selected demo cases. In total, 38 CEs were created, reflecting the diversity of the data required for different components and use cases. These data were adequate for comparing various options and attributes within the project’s scope, ensuring that only few attributes were left empty or non-applicable.

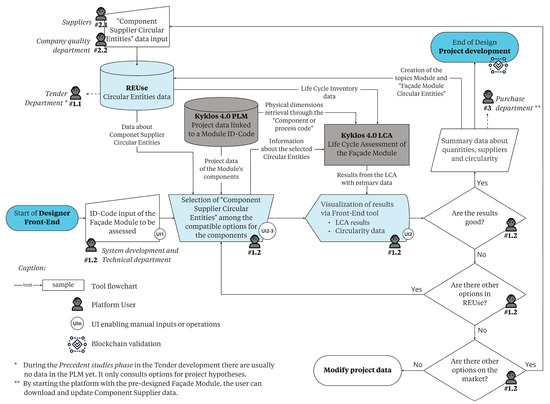

3.3.2. Frontend Tool Setup: The “Designer Interface”

The frontend is the tool conceived to move from preliminary studies to the detailed design phase in the early stages of the product life cycle. A flowchart related to the frontend tool showing integration with REUse and Kyklos 4.0 components during the design support phase is presented in Figure 10. User icons show the scenarios involved in the different parts of the process.

Figure 10.

Designer frontend tool flowchart.

As seen in Section 3.3.1, the suppliers or manufacturing company’s quality department, having registered the possible components, created and developed the DMP necessary for further design steps.

The next stage, which during the study has defined as the “Design stage”, is where integration with other materials practically happens. By accessing the frontend tool, designers can identify suppliers for each BEC with the lowest environmental impact and better circularity characteristics (Scenario #1.2).

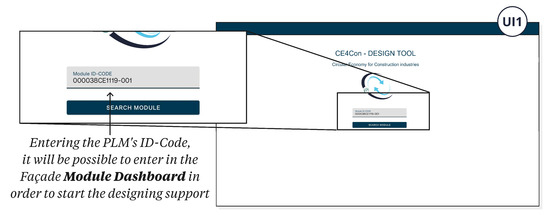

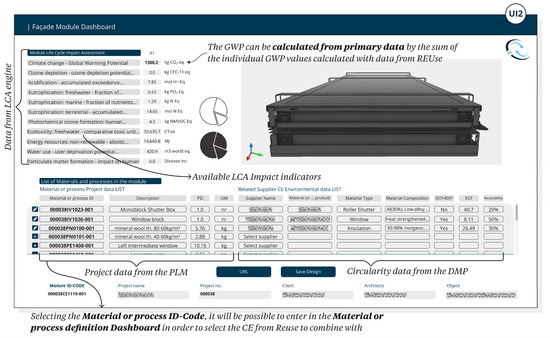

Initially, when accessed, User Interface 1 (UI1) prompts the designer to input an ID code of the PMCW (Figure 11). By entering this, the backend connects to the Kyklos 4.0 PLM service to load all the project data linked to the particular PMCW code, taking the designer to the UI2 screen, represented in Figure 12, and displaying all the information related to the PMCW being designed.

Figure 11.

Frontend tool for design support—UI1 graphic.

Figure 12.

Frontend tool for design support—UI2 graphic.

The UI2 concept presents a universal interface that allows designers to compose a list of materials from the REUse components. They can select and add materials to this interface, which consolidates the information in one place.

The “List of Materials and processes” in the facade module is automatically filled in with the data from PLM following the entry of the PMCW identification code. At the beginning of the “Design stage”, no CE from REUse was initially selected as an option for the various facade module components. By clicking on each empty entry in the list, the designer is taken to another section of the interface (UI3, Figure 13), which is the “Façade Material and Component definition Dashboard”. Here, two of the areas displayed are linked with Kyklos 4.0, and one area is linked to REUse. The designer can select the materials in the “Material type” and “Circular Entity Type” fields and enter keys for searching for possible circular entities in REUse, as identified in requirement R.3. Lastly, if necessary, they can apply a correction to the LCA attributes by inserting a conversion factor that is multiplied with the attributes depending on their functional units, and is identified in requirement R.5.

Figure 13.

Frontend tool for design support—UI3 graphic.

By selecting these two necessary data sources from the PLM service and REUse, the backend has enough data to communicate and make a REST call to the Kyklos LCA to obtain the necessary impact assessment information. Thus, it populates the “Module Life Cycle Impact Assessment” fields.

At this point, the designer has a complete overview of all the material data, process data, impact assessment data, and circular data available to them to make a suitable choice. They can confirm or modify their design until they are satisfied with the choices that have been made, after which they click on the save option and are taken back to the UI2 screen.

Moving forward, the designer clicks on the next “Material or process ID” field and proceeds to follow the steps again until the list is a complete representation of the facade design.

When the design stage is completed, UI2 will now represent a complete picture that comprises the information from all the PMCW. At this stage, all the information the designer wants to know to finalize the design is available to them in a unified interface, and the module design is complete.

As an additional feature, the designer can save their work, which creates all the “Façade Module CEs” in REUse containing the PLM information along with a link to the chosen “Component Supplier CEs”. These “Façade Module CEs” serve as the foundation for the next stages of the CE4Con process, which encompasses the construction and dismantling phases. Additionally, it is possible to make a request to the blockchain module to store these design data to ensure its immutability. This marks the end of the design phase and satisfies all the requirements of the design scenarios.

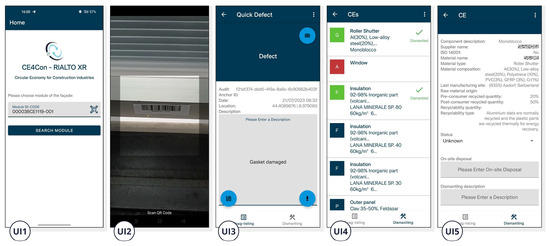

3.3.3. Rialto Platform Set up and Integration

While the frontend is the CE4Con’s implementation tool in the early stages of the process, the ARTC is the main tool for its implementation in the construction and end-of-life stages. The role of Rialto is to support the core functionalities of the REUse platform in the following two ways:

- By examining the mounted PMCW to obtain or update a snag list;

- By allowing the retrieval of dismantling and pre-treatment information to facilitate the disassembly and the update of end-of-life information of the PMCW.

The diagram shown in Figure 14 details the interaction of the users with Rialto, as well as its integration with the REUse DMP. For each functionality, the figure also reports the targeted scenarios.

Figure 14.

Rialto app flowchart.

On the Rialto home page, the user is asked to enter the unique ID code of the PMCW to be assessed. The app also supports barcode or QR code scans, which is useful because those who take care of the operations only have access to the facade and do not know the production codes that are used in the PLM. Once the facade module data have been identified, the user can navigate through the bottom navigation bar and choose between the snag listing of a given module (Scenarios #4.1 and #4.2: identification and monitoring of defects in the facade) or its dismantling (Scenario #5: end-of-life scenario). In the snag list section of the app, the user can see and edit existing audits, as well as create new ones. The same holds for defects: once an audit has been activated, it can be associated with one or multiple defects. The defect can be placed in the 3D space using the AR or just by providing a text description (written or converted from voice).

In the dismantling section, the user can download the module’s technical drawings to guide and ease the dismantling of the module. Then, through the “CEs list”, it is possible to see the list of components (i.e., circular entities) within the module. For each of them, Rialto allows the user to see the relevant properties, notify the dismantling by setting the corresponding status (dismantled, not dismantled, unknown), and provide a description of the dismantling process. Finally, textual on-site disposal describes the possible end-of-life scenario of the component.

Audits, defects, and CEs are stored both locally and in REUse through the use of REST APIs. This allows making the data available in subsequent audits as well as to other team members in real time.

Figure 15 shows some of the main screenshots of the application, namely the home page, the barcode scanning functionality, the list of circular entities in a facade module, and the dismantling of a circular entity.

Figure 15.

Rialto interface screenshots.

Rialto introduces three main innovations in the construction site: a virtual environment for team working, the adoption of on-site AR applications, and the bidirectional communication between on-site devices and workers and backend systems on remote servers or the Cloud. This allows for a virtual cooperation place where team members can meet from different locations and support/monitor people in the construction site. In this regard, compared to Rialto’s main competitors, which are often part of ecosystems with proprietary platforms, the possibility of having bidirectional communication with any CDE through APIs allows Rialto to achieve better interoperability with a variety of applications. This allowed to easily integrate Rialto with the REUse platform.

It is claimed that digital collaboration solutions, mobile and AR devices, and advanced information management platforms play a vital role in the construction sector’s digitalization [47]. AR technology merges physical surroundings with the computer-generated data, driving efficiency, accuracy, and confidence in construction projects. It reduces errors, saves manhours, and cuts costs [48].

3.4. Tool Validation

In order to validate the functionalities of CE4Con, the digital tool underwent both functional testing and user acceptance testing [49]. Efficiency evaluation is an ongoing process that requires periodic review as technology advances, user needs evolve, and business objectives shift. It is crucial to involve stakeholders, such as users and IT personnel, in the evaluation process to gain a comprehensive understanding of the tool’s efficiency from different perspectives. This holistic approach will ensure that CE4Con remains effective in meeting its intended purposes. The validation phase has been completed up to the current state of development, which is prototyping (TRL 6–7). Recognizing the importance of third-party market evaluations is critical as they provide a real-world operational and commercial environment for the tool. These external assessments are invaluable in confirming the tool’s actual functionality, mitigating cognitive biases, exploring potential business models, and delivering empirical evaluations that can significantly enhance the tool’s performance and relevance in the broader market landscape. Table 1 provides an overview of the stakeholders who were involved in validating the various development phases of the tool and those expected to participate in future market testing and evaluation.

Table 1.

Tool development process of stakeholder outline (X: actor involved in the phase; X *: the actor involved was assumed by the facade manufacturer company).

Functional testing involves a thorough and systematic examination of each function and feature of the tool, ensuring that it performed as expected. Additionally, the user interface was evaluated to ensure that it was intuitive and user-friendly. Automated testing frameworks and tools were also utilized in order to provide comprehensive coverage and demonstrate the tool’s efficiency. These tests revealed the strengths of CE4Con, as well as areas that could be further optimized. One of the notable strengths of CE4Con is its efficiency in completing tasks related to design and on-site stages. The use of “Material Types” and “Circular Entity Types” proved to be a functional approach for the agile selection of design and supply options. However, for particularly complex facade modules, assigning each element a CE can be time consuming, although still less so than traditional methods.

The error rate assessment considered both the frequency and severity of errors. Still, no high-severity errors were found during development. While a few marginal errors did occur infrequently, which were resolved before the validation phase. Finally, workflow integration was also evaluated in order to minimize disruption to existing processes. Integration between CE4Con and Kyklos 4.0 components was achieved through APIs. The adaptability of the tool to different workflows and systems was assessed, considering the data formats, protocols, and compatibility. The validation stage of the digital tool’s efficiency assessment provided confirmation of its performance. Overall, the tool demonstrated a high level of efficiency in tasks completion, resources utilization, and error management.

On the other hand, the user acceptance testing (UAT) plays a vital role in evaluating user satisfaction with a given tool. This process involves obtaining feedback from end users or stakeholders to ensure that the tool meets their needs [50]. The UAT applied in the validation of CE4Con is an integral part of the adoption process and methodology, and is based on the Concerns-Based Adoption Model [51]. That is why adoption of new technologies and innovations is a complex process that involves multifaceted factors, including social, cognitive, and developmental aspects. Therefore, any attempts to facilitate technology adoption must address a broad range of concerns, from emotional to factual to contextual. The primary objective of the UAT is to obtain validation and acceptance of the CE4Con IT platform by users and pilots. Acceptability is evaluated through a survey questionnaire that covers various aspects such as the environment, setup and deployment, usability, training, handling of new business requirements, collaboration channels, and tester knowledge; the survey asked for an evaluation from 1 (strongly negative) to 5 (strongly positive). Participants reported being either satisfied or very satisfied with the functionalities they were concerned with and found the environment adequate or very suitable for development. Table 2 reports average evaluations of the UAT carried out in CE4Con.

Table 2.

Summary of CE4Con UAT results (1: strongly negative; 5: strongly positive).

4. Discussion

This chapter provides a comprehensive analysis of the outcomes obtained during CE4Con, with a discussion on how the achievements have contributed to addressing the barriers that hinder circular transition in the construction sector.

4.1. Quality and Digitization of Circularity Data

The REUse platform within CE4Con provides a comprehensive and centralized repository to collect the technical data on various materials and products available on the market. Besides collecting data about leftover and dismantled materials from BECs, this can enable stakeholders to make informed decisions about raw material substitutions. Moreover, the integration of REUse with Kyklos 4.0 components ensures seamless data sharing and enhances the availability of information functional for decision making during the entire life cycle process. The project has made progress in researching working strategies to reduce the setup time needed for supply chain organization. This platform integration allows for streamlined communication and matchmaking between manufacturing companies and suppliers, promoting efficient reuse and recycling of materials, which is also enabled due to the tracking of materials and components throughout their life cycle.

Furthermore, blockchain integration introduces a layer of transparency, traceability, and immutability to the circular economy ecosystem. Besides standardizing the data formats and protocols, reinforcing accountability [52], and elevating the level of certification and transparency of materials and components within the construction industry, this integration is expected to enhance the tracking of reusable materials according to predefined scenarios. However, the construction industry appears unwilling to adopt blockchain technologies. Many stakeholders lack the necessary knowledge and expertise to implement and use blockchain effectively in their operations. Education and training are essential but time-consuming processes.

4.2. Digital Services for Circular Management Support

The CE4Con interface for building materials suppliers and manufacturing companies envisions a future where construction waste and second-hand materials can be reintroduced into their businesses, further optimizing resource utilization. The projected achievement of a reduction in setup time signifies the potential of the platform to revolutionize supply chain processes. In addition, a streamlined interface enhances user experience, facilitating data navigation and action execution. The platform acts as a collaborative hub, organizing a responsive supply chain that caters to dynamic manufacturing needs while optimizing the synergy between processing facilities and logistics services. For all those reasons, it helps to overcome the barrier of limited existing digital services for creating new value chains and organizing information on raw materials.

As anticipated, the design phase is the most crucial step to reduce the environmental impact of building envelope components. In this sense, CE4Con’s design support interface was developed, and became a vital point of the value proposition.

4.3. Secondary Materials Warranty and Cost Analysis Considerations

CE4Con can reduce waste by matching supplier production waste with potential buyers or recycling facilities. However, businesses’ lack of confidence in products from reverse logistics may be a detriment to their use. To address this lack of trust in secondary material quality, CE4Con has implemented some valuable features. First, the transparent and traceable information system can contribute to this goal. Blockchain technology ensures accountability, maintaining detailed records and documentation for each batch of component suppliers. Moreover, the inclusion of reputable and established suppliers of recycled materials among the platform users is crucial. Suppliers with specific certifications and a track record of providing high-quality materials are more likely to instill trust. However, while CE4Con offers the conditions for using virtuous materials, it is necessary to acknowledge that the ultimate decision lies with the designer using the platform.

CE4Con faced challenges when it came to integrating economic evaluation aspect within its functions. Gathering the precise economic data from the circular entity providers proved to be difficult, which made it challenging to incorporate a feature that would allow for a direct component cost comparison. Unlike the certified data on environmental impact or product composition, component costs can vary and are dependent on numerous factors. This makes it inaccurate to rely on stored prices in enterprise resource planning software, as previous purchase costs may have differed, and component suppliers are often hesitant to publish their prices, which would also have to be continually updated on REUse. As of this point, it has not been possible to integrate effective economic evaluation features while considering the materials embedded in CE4Con. However, as the time required for material identification and organizing reverse logistics can be reduced, significant cost reductions for recycling and new product manufacturing can be achieved.

4.4. Accelerating Circular Actions Implementation and Waste Management

In addition to the design phase, the second stage of the BEC’s life cycle in which CE4Con focuses is the disassembly and disposal part. In this stage, the challenge of long delays between implementing circular actions is addressed with Rialto functions, which offer a significant contribution. Rialto integrates Kyklos 4.0 PLM and REUse to collect comprehensive material and component information for PMCWs, which is essential for monitoring, reporting, and efficiently dismantling operations. In this way, CE4Con can enable a real-time data update system for tracking circular initiatives. This allows stakeholders to input and access data as soon as changes occur, documenting and tracking recycling or reusing materials. To expedite the process further, CE4Con can integrate with existing waste management systems used by construction companies and municipalities, thanks to standardized languages. This integration would allow for efficient communication between circular actions taken on the platform and waste collection and processing activities.

Additionally, the implementation of a snag listing support function in Rialto enhances the ability to catalog damages and defects during the facade’s lifecycle which aids in keeping a log of performed maintenance operations up to date. The project aims to reduce the dismantling time, and Rialto can play a crucial role in achieving this goal by expediting the retrieval of essential information, thereby enhancing disassembly processes and contributing to project timelines.

4.5. Supporting Guidance about Sustainable and Circular Parameters

The CE4Con project aims to promote holistic sustainability evaluation in the construction industry by integrating the methodology for environmental assessment and encouraging the use of primary data, which significantly improves the accuracy of analysis [53]. To achieve this, the platform combines the primary project data from the Kyklos PLM with primary environmental data from suppliers’ information uploaded on REUse. The goal is to bring the adoption of LCA practices to 100% for all products analyzed in the platform, while also using secondary data provided by the Kyklos LCA when the primary data are unavailable. This achievement signifies the contribution of CE4Con-like tools to promoting sustainability in construction.

By using CE4Con, stakeholders can define Key Performance Indicators (KPIs) to assess circularity based on their scope and targets. These KPIs could include metrics such as waste reduction, supply chain setup time, successful material matches, and increased components reuse. By quantifying these outcomes, CE4Con users can demonstrate their effectiveness in promoting circular economy practices, track progress toward sustainability goals, and make data-driven decisions for future projects. Likewise, Rialto functionalities enable users to set KPIs related to waste reduction on site and receive regular updates on their achievement (e.g., percentage of materials sent to reverse logistics instead of end-of-life processes). This transparency can motivate stakeholders to take more immediate action. However, it is important to note that sustainability standards and best practices evolve over time. Therefore, CE4Con should commit to keeping its standards up to date with the latest developments in sustainability assessment methodologies.

The CE4Con solution presents a robust framework for promoting circular economy practices in the construction sector. The achievements of the project highlight the potential of the IPBT to reshape traditional construction processes, optimize resource utilization, and foster sustainable building practices for a more environmentally conscious industry.

5. Conclusions

In response to the need for sustainable practices within the construction industry, this study has developed an Integrated Platform-Based Tool (IPBT) with a high-potential solution for the design, construction, and disassembly management and innovation of BECs. It combines a Data Management Platform (DMP), an Augmented Reality Snag Listing and Dismantling Tool (ARTC), and integrates the LCA simulation engine, PLM software, and blockchain technology. This IPBT, named CE4Con, explored a wide range of services, including environmental and circularity assessments, supply chain optimization, and circular material management. CE4Con’s achievement of information integration and interoperability empowers stakeholders with accessible and trustworthy data, driving efficiency and collaboration within the construction industries across different phases of the BECs’ life cycle. User stories played a key role in shaping the tool’s functionalities. They were taken into consideration, ensuring a user-centric design approach focused on industrial and label needs. The platform’s interface was carefully customized for different user categories, optimizing usability and ensuring the integration of investigated requirements. Demo cases provided evidence of the platform’s effectiveness and successful integration with its components. The data collections in DMP were executed with proficiency, resulting in a robust and diverse dataset. The integration of its primary environmental data into the Kyklos LCA through the DMP database significantly enhances the accuracy and reliability of environmental assessments. However, further developments and accurate economic data from suppliers would be necessary for implementing cost analysis considerations of potential materials and components. Active engagement of manufacturing suppliers can enable robust economic assessments and a clearer understanding of the cost implications of recycling and using recycled materials. As these platforms evolve and more suppliers join them, the potential for achieving economic benefits through enhanced cost comparisons becomes increasingly viable.

The project outlines other potential avenues for future advancements. An area of notable potential lies in the possible integration of IPBTs with Digital Product Passports (DPPs) and Digital Building logbook frameworks. By collecting and organizing data regarding products’ end-of-life dispositions, they can contribute to standardized DPPs, which streamline future disassembly processes and reverse logistics [54]. Furthermore, the establishment of Digital Building logbooks offers comprehensive and accessible repositories of building information from inception to completion. Acknowledged by the European Commission, these logbooks hold promise in promoting sustainability. To maximize their adoption, a systematic and enhanced approach to data capture, processing, exchange, and storage is essential [55].

A further and influential possible development is the integration of the ecosystem logic within the supply chain, marking a pivotal development in fostering virtuous networks in the construction and deconstruction industry. IPBTs have the potential to connect waste providers, producers, constructors, manufacturers, designers, and various stakeholders with waste recyclers and reverse logistics providers. This incentivizes sustainable practices and drives demand for eco-friendly materials. IPBTs have become a catalyst for market transformation, encouraging innovation in material design and waste management. This aligns with the global shift towards sustainability and circular economy practices and allows for the exploration of diverse alternatives [56].

In conclusion, CE4Con serves as an example of how integrated solutions can bring a transformation in traditional construction practices. By fostering resource efficiency and sustainability, these solutions have the capacity to make a significant impact on the construction industry’s environmental impact and waste output. By adopting a circular economic outlook and a resolute commitment to responsible material management, the platform offers a direction towards a sustainable future for the construction industry.

Author Contributions

Conceptualization, L.M., E.A.C. and A.P.; methodology, L.M., M.D. and A.P.; software, M.D., I.F. and P.P.; validation, L.M. and A.P.; formal analysis, L.M., M.D. and I.F.; investigation, L.M. and M.D.; resources, E.A.C., P.P. and A.P.; data curation, L.M.; writing—original draft preparation, L.M. and M.D.; writing—review and editing, L.M., M.D., I.F., E.A.C., P.P. and A.P.; visualization, L.M.; supervision, E.A.C., P.P. and A.P.; project administration, E.A.C.; funding acquisition, E.A.C., P.P. and A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the European Project H2020 “KYKLOS 4.0” under grant agreement no. 872570.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author, with the permission of third parties. The data are not publicly available due to the third parties’ privacy regulations.

Acknowledgments

The results in this study as well as this study are part of the results obtained in the CE4Con project: “Circular Economy for Construction Industries” (2023). This information only reflects the author’s views and neither the Agency nor the Commission are responsible for any use that may be made of the information contained herein.

Conflicts of Interest

The authors declare that they have no financial interest or personal relationships that could have influenced the work presented in this article.

Appendix A

This section summarizes scenarios by describing the types, goals, and operations of different CE4Con users.

Table A1.

Scenario #1 summary table.

Table A1.

Scenario #1 summary table.

| Scenario #1: Curtain Wall Module Design (Attribution of Circular Entities) | |

|---|---|

| Purpose Identify and select Component Supplier Circular Entities (CEs) for the facade module materials and components designed. | |

| User Unit system developers, tender, and system developer department. | Equipment Laptop (CE4Con’s frontend tool). |

| Input Project data regarding unit components (from PLM). Those have to match with existing Component Supplier CEs. The system department provides the “Disassembly instruction” document useful for end-of-life information. | Output Facade module CEs. |

| Starting Point A new facade module from the manufacturer has to be added to the platform through a frontend tool in order to evaluate and select Component Supplier CEs depending on their environmental impact and circularity value. | |

| CE4CON solution With a frontend tool, the platform will permit searching for the Component Supplier CEs that satisfy the parameters required and to choose the feasible option with the lowest CO2eq impact and with the highest recycled content. This can encourage adoption of more virtuous materials in the design of new products. | |

Scenario

| |

Table A2.

Scenario #2.1 summary table.

Table A2.

Scenario #2.1 summary table.

| Scenario #2.1: Addition of Component Supplier Circular Entities in the Database (the Supplier) | |

|---|---|

| Purpose Provide new Component Supplier Circular Entities (CEs) available for the market, or update ones already in the platform. Eventually, upload documentation (e.g., EPD, etc.). | |

| User Materials, components, or treatments from the supplier. | Equipment Laptop (REUse). |

| Input Component Supplier CEs and their attributes of their new products, update of their Component Supplier CEs. | Output Component Supplier CEs information. |

| Starting Point New materials, components, or treatments from the supplier have to be added to the platform as CE available for the customers. | |

| CE4CON solution Upload on REUse information about the products in order to make it easier for the clients to access the needed data. This can help in organizing new supply chain, reducing setup time. Moreover, REUse services could be used by suppliers to optimize recycling of production waste. | |

Scenario

| |

Table A3.

Scenario #2.2 summary table.

Table A3.

Scenario #2.2 summary table.

| Scenario #2.2: Addition of Component Supplier Circular Entities in the Database (Quality Department) | |

|---|---|

| Purpose Provide new Component Supplier Circular Entities (CEs) available for the market, or update ones already in the platform. Eventually, upload documentation (e.g., EPD, etc.). | |

| User Quality department. | Equipment Laptop (REUse). |

| Input Component Supplier CEs and their attributes of their new products, update of their Component Supplier CEs, and eventually update the attributes of the facade module CEs. | Output Old Component Supplier CEs. |

| Starting Point New element materials, components, or treatment singled out from the quality department have to be added to the platform as the available Component Supplier CE for the manufacturing company. | |

| CE4CON solution Upload on REUse information about the products in order to make it easier for the clients to access the needed data. This can help in organizing new supply chain, reducing setup time. Moreover, REUse services could be used by suppliers to optimize recycling of production waste. | |

Scenario

| |

Table A4.

Scenario #3 summary table.

Table A4.

Scenario #3 summary table.

| Scenario #3: Management of the Effective Supply Chain | |

|---|---|

| Purpose Support the procurement of facade modules’ components. | |

| User Purchase department. | Equipment Laptop (CE4Con’s frontend tool). |

| Input Update the attributes of the facade module circular entities (CEs). | Output Component Supplier CEs selected during the design development for the units. |

| Starting Point The materials and components that will be part of the assembled module have to be purchased and supplied. Eventually, the Component Supplier CEs’ attributes selected during the design have to be updated. | |

| CE4CON solution The purchase department has the ability to preview which suppliers are able to meet project requirements, including from a sustainability standpoint, that have already been selected by system designers. This speeds up and facilitates the process of retrieving materials and components. | |

Scenario

| |

Table A5.

Scenario #4.1 summary table.

Table A5.

Scenario #4.1 summary table.

| Scenario #4.1: Snag List: Identification of Defects in the Installed Facade | |

|---|---|

| Purpose Performing the examination of the installed facade modules to obtain a snag list (faults and defects description). | |

| User Technician on site. | Equipment Android mobile device (Rialto). |

| Input Mounted facade. | Output Snag list on the facade thanks to XR. |

| Starting Point User#4.1 arrives and needs to add a defect after auditing. | |

| CE4CON solution Through Rialto, the possibility is offered to group all building snag lists related to the facade in one place. These indications will then also be visible during disassembly because they are saved in REUse. | |

Scenario

| |

Table A6.

Scenario #4.2 summary table.

Table A6.

Scenario #4.2 summary table.

| Scenario #4.2: Snag List: Monitoring of Defects in the Installed Facade | |

|---|---|

| Purpose Performing the examination of defects in the installed facade module that were detected in previous audits. | |

| User Technician on site. | Equipment Android mobile device (Rialto). |

| Input Mounted facade, AR snag list. | Output Snag list on the facade thanks to XR. |

| Starting Point User#4.2 arrives and has to audit the facade. | |

| CE4CON solution Through Rialto it is possible to view and retrieve both in a summary list and through XR the facade defects. | |

Scenario

| |

Table A7.

Scenario #5 summary table.

Table A7.

Scenario #5 summary table.

| Scenario #5: End-of-Life Scenario | |

|---|---|

| Purpose Retrieve dismantling and pre-treatment information and use it to plan the dismantling of the facade modules. Update end-of-life information on the dismantled circular entities in the platform. | |

| User Operator of the dismantling and recovery company. | Equipment Android mobile device (Rialto). |

| Input Existing facade module CEs and related component supplier CEs’ attributes. | Output End-of-life information about the CEs in the facade. |

| Starting Point Information about the facade to dismantle and its circular entities already in the platform. | |

| CE4CON solution Facilitate the disassembly and the update of end-of-life information of the facade, time reduction, and related reduction in cost. | |

Scenario

| |

References

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular Economy in the Building and Construction Sector: A Scientific Evolution Analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A Systematic Review of Circular Economy Research in the Construction Industry. Smart Sustain. Built Environ. 2020, 11, 39–64. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- Migliore, M.; Talamo, C.; Paganin, G. Construction and Demolition Waste. In Strategies for Circular Economy and Cross-Sectoral Exchanges for Sustainable Building Products: Preventing and Recycling Waste; Migliore, M., Talamo, C., Paganin, G., Eds.; Springer Tracts in Civil Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 45–76. [Google Scholar] [CrossRef]

- European Commission: Energy, Climate Change, Environment. Construction and Demolition Waste. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 7 August 2023).

- Charef, R.; Lu, W.; Hall, D. The Transition to the Circular Economy of the Construction Industry: Insights into Sustainable Approaches to Improve the Understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Zeng, R.; Chini, A.; Ries, R. Innovative Design for Sustainability: Integrating Embodied Impacts and Costs during the Early Design Phase. Eng. Constr. Archit. Manag. 2020, 28, 747–764. [Google Scholar] [CrossRef]

- Sparrevik, M.; de Boer, L.; Michelsen, O.; Skaar, C.; Knudson, H.; Fet, A.M. Circular Economy in the Construction Sector: Advancing Environmental Performance through Systemic and Holistic Thinking. Environ. Syst. Decis. 2021, 41, 392–400. [Google Scholar] [CrossRef]

- Charef, R. Supporting Construction Stakeholders with the Circular Economy: A Trans-Scaler Framework to Understand the Holistic Approach. Clean. Eng. Technol. 2022, 8, 100454. [Google Scholar] [CrossRef]

- Díaz-López, C.; Bonoli, A.; Martín-Morales, M.; Zamorano, M. Analysis of the Scientific Evolution of the Circular Economy Applied to Construction and Demolition Waste. Sustainability 2021, 13, 9416. [Google Scholar] [CrossRef]

- Charef, R.; Morel, J.-C.; Rakhshan, K. Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Kirchherr, J.; Hekkert, M.; Bour, R.; Kostense-Smit, E.; Muller, J. Breaking the Barriers to the Circular Economy; Deloitte: London, UK, 2017. [Google Scholar]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P.; Olawumi, T.O. Modeling the Principal Success Factors for Attaining Systemic Circularity in the Building Construction Industry: An International Survey of Circular Economy Experts. Sustain. Prod. Consum. 2023, 37, 268–283. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Hosseini, M.R.; Kocaturk, T.; Arnel, T.; Garofano, N.T. Circular Economy in the Australian AEC Industry: Investigation of Barriers and Enablers. Build. Res. Inf. 2023, 51, 56–68. [Google Scholar] [CrossRef]

- Xing, Z.; Huang, J.; Wang, J. Unleashing the Potential: Exploring the Nexus between Low-Carbon Digital Economy and Regional Economic-Social Development in China. J. Clean. Prod. 2023, 413, 137552. [Google Scholar] [CrossRef]

- Jemal, K.M.; Kabzhassarova, M.; Shaimkhanov, R.; Dikhanbayeva, D.; Turkyilmaz, A.; Durdyev, S.; Karaca, F. Facilitating Circular Economy Strategies Using Digital Construction Tools: Framework Development. Sustainability 2023, 15, 877. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of Modularity to the Circular Economy: A Systematic Review of Literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. Lean Manufacturing Applications in Prefabricated Construction Projects. Autom. Constr. 2023, 150, 104790. [Google Scholar] [CrossRef]

- European Commission: Funding & Tender Opportunities. rEUse Platform. Available online: https://ec.europa.eu/info/funding-tenders/opportunities/portal/screen/opportunities/horizon-results-platform/36709;resultId=36709;isExactMatch=false (accessed on 7 August 2023).

- Large Scale Demonstration of New Circular Economy Value-Chains Based on the Reuse of End-of-Life Fiber Reinforced Composites|FiberEUse Project|Fact Sheet|H2020. CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/730323/it (accessed on 7 August 2023).

- Arabsolgar, D.; Musumeci, A. FiberEUse: Large-Scale Demonstration of New Circular Economy Value Chains Based on the Reuse of End-of-Life Fiber-Reinforced Composites—A Circular It Platform to Manage Innovative Design and Circular Entities. Proceedings 2021, 65, 23. [Google Scholar] [CrossRef]

- Avvaru, V.S.; Bruno, G.; Chiabert, P.; Traini, E. Integration of PLM, MES and ERP Systems to Optimize the Engineering, Production and Business. In Product Lifecycle Management Enabling Smart X; Nyffenegger, F., Ríos, J., Rivest, L., Bouras, A., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2020; pp. 70–82. [Google Scholar] [CrossRef]

- Lennartsson, M.; André, S.; Elgh, F. PLM Support for Design Platforms in Industrialized House-Building. Constr. Innov. 2021, 23, 265–286. [Google Scholar] [CrossRef]

- Cholewa, M.; Minh, L.H.B. PLM Solutions in the Process of Supporting the Implementation and Maintenance of the Circular Economy Concept in Manufacturing Companies. Sustainability 2021, 13, 10589. [Google Scholar] [CrossRef]

- An Advanced Circular and Agile Manufacturing Ecosystem based on Rapid Reconfigurable Manufacturing Process and Individualized Consumer Preferences|KYKLOS 4.0 Project|Fact Sheet|H2020. CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/872570/it (accessed on 7 August 2023).

- ISO 10303-1:2021(En); Industrial Automation Systems and Integration—Product Data Representation and Exchange. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso:10303:-1:ed-2:v1:en (accessed on 29 August 2023).

- Farjana, S.H.; Mahmud, M.A.P.; Huda, N. Chapter 1—Introduction to Life Cycle Assessment. In Life Cycle Assessment for Sustainable Mining; Farjana, S.H., Mahmud, M.A.P., Huda, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–13. [Google Scholar] [CrossRef]

- Di Maria, A.; Eyckmans, J.; Van Acker, K. 26—Use of LCA and LCC to Help Decision-Making between Downcycling versus Recycling of Construction and Demolition Waste. In Advances in Construction and Demolition Waste Recycling; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2020; pp. 537–558. [Google Scholar] [CrossRef]

- Francart, N.; Malmqvist, T. Investigation of Maintenance and Replacement of Materials in Building LCA. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032027. [Google Scholar] [CrossRef]

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for Applying LCA-Based Environmental Impact Assessment Tools in the Early Stages of Building Design. Build. Environ. 2018, 133, 228–236. [Google Scholar] [CrossRef]

- Sommerville, J.; Craig, N.; Bowden, S. The Standardisation of Construction Snagging. Struct. Surv. 2004, 22, 251–258. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A Quantitative and Qualitative Evaluation of the Sustainability of Industrialised Building Systems: A Bibliographic Review and Analysis of Case Studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar] [CrossRef]

- Kragh, M.K.; Jakica, N. 21—Circular Economy in Facades. In Rethinking Building Skins; Gasparri, E., Brambilla, A., Lobaccaro, G., Goia, F., Andaloro, A., Sangiorgio, A., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2022; pp. 519–539. [Google Scholar] [CrossRef]