1. Introduction

Continuous on-line monitoring of concrete structures, including their external loading, operational environment, and static/dynamic responses, holds the key to understanding the origination, formation, and progression of structural anomalies, damage, and incidents, which is critically significant for the prevention of catastrophic failures in a structure or its elements. Among the numerous monitoring approaches such as acoustic emission or piezoresistive sensors by conductive materials [

1,

2,

3,

4], the piezoelectric lead zirconate titanate (PZT)-based electro-mechanical impedance/admittance (EMI/EMA, inverse of impedance) technique has been sustainably attracting intensive interest in the field of concrete structural health monitoring (SHM), involved with the monitoring of load-induced crack damages, hydration evolution, and structural tension/compression stress development [

5,

6,

7,

8]. In the EMI technique, a PZT patch can simultaneously serve as the sensor and actuator, relying on its instantaneous direct and inverse piezoelectric effects. When the PZT transducer is attached to or embedded in a host structure via an adhesive layer/coat, its electrical signal coupled to structural information, namely mechanical impedance, could be measured as the EMA spectrum. Any damage that occurs in the vicinity of the transducer can be captured and reflected by the EMA variations. However, the application of the EMI technique for monitoring in situ engineering structures is rather complicated, due to the environmental uncertainties (such as changes in temperature, humidity, and natural hazards). In particular, environmental temperature fluctuation is regarded as an adverse factor, because the PZT transducer, bonding layer, and structure are all affected by temperature changes [

9,

10]. The variations in EMA responses due to temperature fluctuations are significant, even surpassing the changes induced by regular structural damages [

10]. Moreover, temperature fluctuations exhibit time-dependent behavior in practical scenarios, and as a result, it remains necessary to investigate the impact of the thermal hysteresis effect on the counterparts of the electro-mechanical coupled system. It could result in inaccurate alarms for damage diagnosis during the long-term SHM process if such associated effects and mechanisms remain inadequately understood.

In order to gain a better comprehension of temperature influences on the EMA-based non-destructive testing technique, many researchers have performed intensive investigations, including theoretical analyses, finite element (FE) simulations, and experimental tests. Analytical discussions about the temperature dependency of the piezoceramic sensor and its impedance characteristics showed that the shifting of resonance frequencies and fluctuations in peak response magnitude, caused by an increase in temperature, could lead to wrong conclusions regarding the damages of structures, such as steel beams, bolted pipes, and composite reinforced aluminum plates [

11,

12]. A few models regarding an aluminum cantilever beam [

13] and a fully clamped plate [

14] with attached piezoelectric wafer active sensors (PWAS) have been proposed to reveal structural responses with consideration of the temperature effect. In these models, temperature action was introduced by considering the temperature dependency of both the structure and PWAS material property, which were assumed to be uniform in each temperature condition for simplicity. In addition to an analytical investigation, the temperature effect and corresponding measurements on new piezoceramic devices such as low-cost piezoelectric diaphragms [

15], bulk ceramics, and piezoceramic composite [

16], which interacted with aluminum structures, were respectively presented. It was found that gradual shifts in the prominent resonance for the bonded PZT patch on an aluminum beam specimen moved to the left against the progressive elevating temperature [

17]. Similar experiments conducted on an aluminum beam [

18] and carbon fiber-reinforced polymer panels [

19] under a given temperature also indicated that the three major characteristics, i.e., the real part, the imaginary part, and the magnitude of the impedance signatures, exhibited the approximate resonance peaks and frequency shifts. Furthermore, FE modeling was also carried out as a complementary investigation, profiting from its easier implementation for some unattainable operations, such as taking thermal responses into consideration for an additional combination of the bonding layer. Modeling on aluminum beams bonded with the PZT patch demonstrated that the admittance signatures acquired from patches with a thicker bonding layer exhibited more severe deviations than those with a thinner one, even if subjected to the same temperature [

20,

21].

Intending to minimize the temperature impact and discriminate it from structural damages, researchers have also developed a series of methods. For example, decoupling of the impedance for the evaluation of the temperature effect indicated that the active conductance signature had high sensitivity to structural damages and was robust to temperature fluctuations [

22]. A model aimed at predicting the piezoelectric susceptance slope at any temperature to separate temperature-induced variations from those caused by sensor defects in the impedance-based SHM was also validated via an aluminum frame structure [

23]. A technique integrating a sensor array and statistical metric analysis was proposed to distinguish impedance signal changes derived from damage and/or temperature disturbance [

24], and principles of statistical process control, along with confidence intervals, were employed to detect saw cuts on aluminum panels within a temperature range, ensuring a 95% confidence interval [

25]. Other approaches such as using matric, namely the squared sum of the real impedance variation [

11], artificial neural networks [

26], and the effective frequency shift method were proposed and cogently verified by experiments on bolted flange-pipe joint, steel plate, steel truss, and PSC girder structures [

27,

28]. Recently, a polynomial interpolation-based method has been also investigated to compensate for the temperature effect on impedance measurements in SHM [

29]. These approaches aimed at reducing the variations involved with vertical and horizontal shifts in admittance/impedance signatures due to temperature deformation, thus contributing to avoiding the false detection of damages. Meanwhile, the compensation effectiveness closely relies on a comprehensive assessment of temperature influences including the thermal hysteresis effect, which is, however, not involved in previous research.

Generally, the above investigations, mainly concentrating on the coupling responses between the PZT transducer and metal structures, deemed that temperature is constant and uniform in a short time for the tested specimens under normal temperature conditions. With regard to that under extreme high-temperature conditions, the heating time is considered for oven exposure. For example, high-temperature PWAS and its attached Ti disk were subjected to oven testing for 30 min near 90 °C steps until 705 °C [

30]. Only 10 min was needed for temperature stabilization as it increased from room temperature up to 200 °C per 50 °C [

31]. Circular PWAS transducers were heated from 50 °C to 250 °C in 50 °C increments at a rate of 1–2 °C min

−1 [

32]. Sometimes, an ambient temperature was directly adopted for analyzing temperature influence, such as for a thin plate of carbon fiber-reinforced polymers bonded with a piezoelectric transducer [

33]. It is reasonable for the mentioned homogeneous metal or thin composite structures to reach thermal equilibrium in a short time, especially for surface-mounted PZT patches directly subjected to thermal etching. However, few studies have focused on the temperature effect on non-homogeneous concrete structures. Different from metal structures with their good thermal conductivity, concrete materials are non-homogeneous, porous, and have low thermal conductivity [

34]. Therefore, they need more time to realize the balance of heat distribution. An experiment on a mortar specimen with a PZT sensor inside showed temperature dependence of the electric impedance spectra; however, the specimen put in an oven for 1 h was regarded as stable at each temperature regime ranging from −20 °C to 40 °C with a heating rate of 2 °C/min [

35]. In the previous study by the first author and his colleagues [

36], a quantification investigation of the temperature influence on EMA-based concrete structural damage detection was performed through theoretical, numerical, and experimental analysis, where healthy/damaged concrete specimens heated in an oven for 1 h were employed for EMA measurements of bonded and embedded PZT sensors. However, the temperature influence on concrete structural monitoring in the above studies was assumed to be stable under a given time. To comprehensively assess the impact of heating time, the primary author recently imposed surfaced-bonded PZT sensors on a concrete structure and implemented a heating procedure as long as 180 min. The outcomes indicated a strong correlation between the heating time and the temperature-induced effects on EMA spectra [

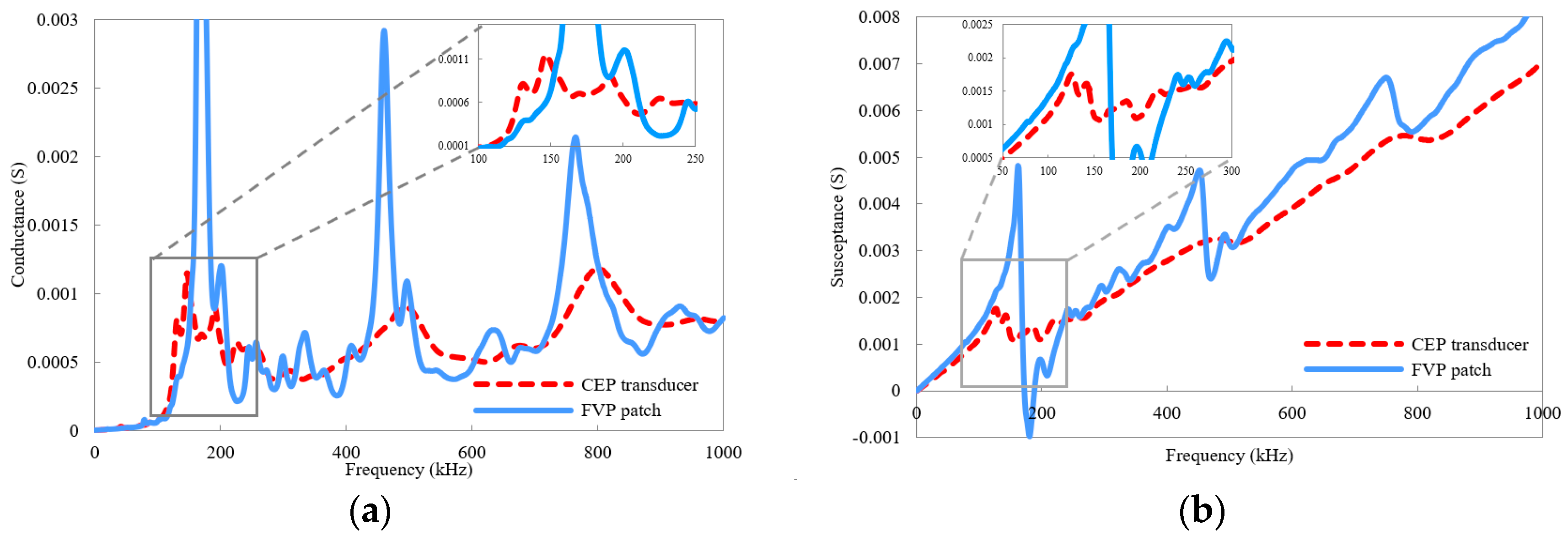

37]. The difference was that surface-bonded PZT sensors are less affected by the thermal hysteresis of the inner part of concrete, while the embedded ones are constrained by the surrounding concrete being invertible from such a hysteresis effect. Unfortunately, time-varying thermal hysteresis effects on the EMA spectrum of the embedded PZT transducer inside the concrete structure have remained unresolved until now.

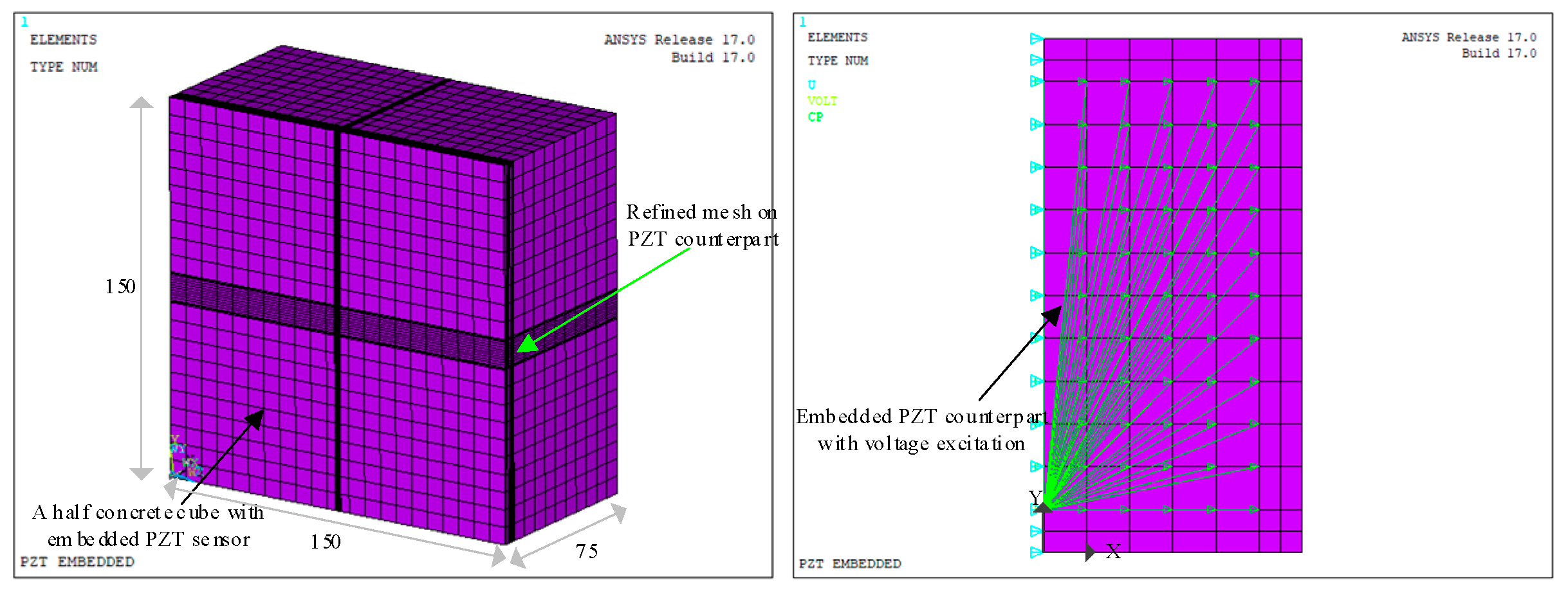

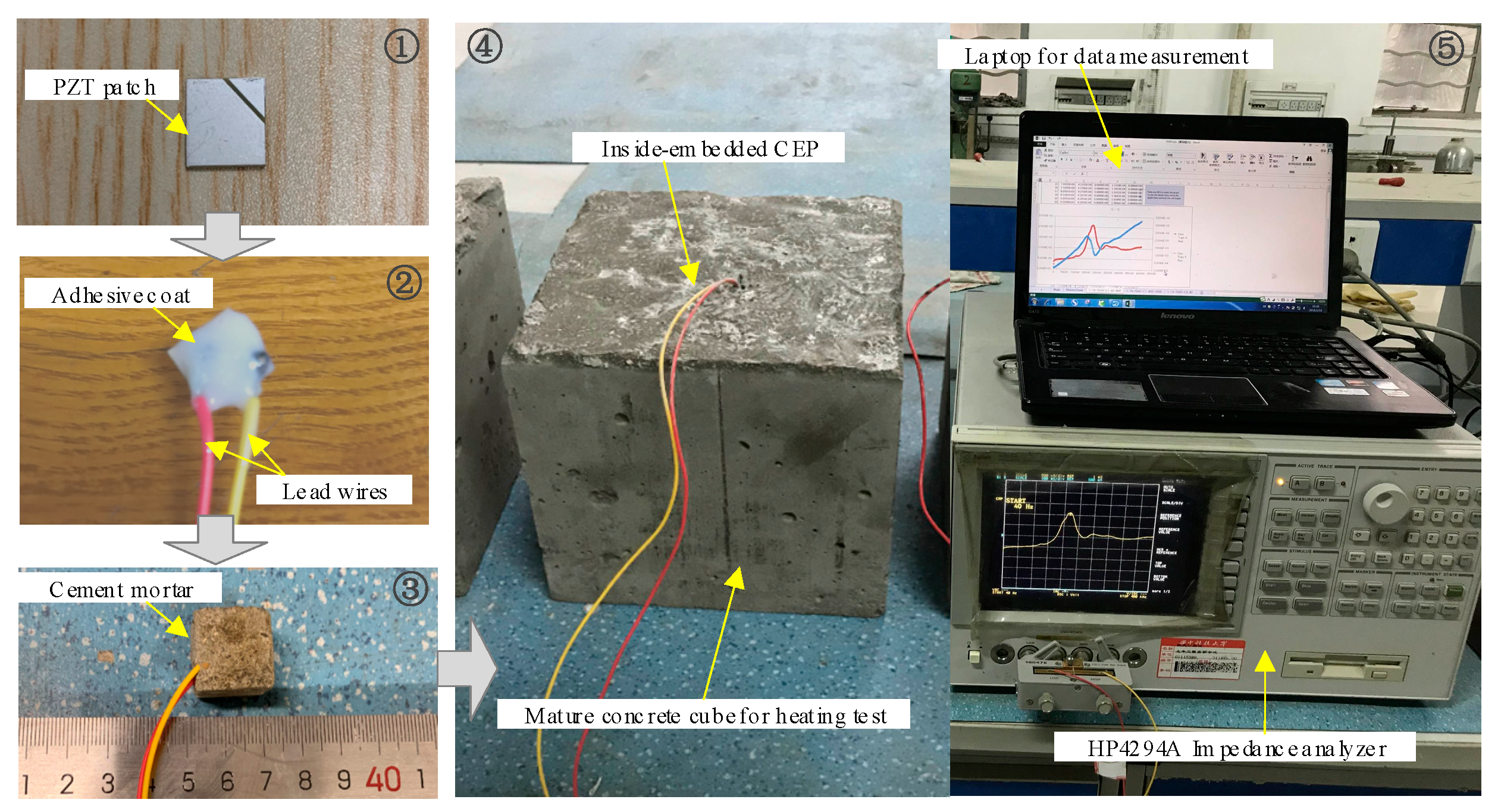

This paper, as a continuation of the previous paper [

37], investigated the thermal hysteresis effect on the EMA monitoring of an embedded PZT sensor in a concrete structure using numerical modeling and experimental tests. In the numerical modeling, a 3D FE model for a concrete cube installed with a cement-embedded PZT (CEP) sensor was first generated in ANSYS version 17.0. Thermal hysteresis effect modeling was achieved by full consideration of the temperature gradient on the concrete, the PZT sensor, and its coating layer with incremental temperatures from 30 °C to 60 °C. In the experiment, a concrete cube was cast to undergo a thermal test at four distinct temperatures: 30 °C, 45 °C, 60 °C, and 75 °C, respectively. Under each condition, the cube was consistently heated for 180 min in an oven, with EMA measurements monitored every 10 min. Features of the EMA spectra and statistical indices called the baseline unvaried/varied root mean square deviation (RMSD/RMSDk) were mathematically correlated to thermal transmission. The major contributions of this article could be specified as:

- (1)

The thermal hysteresis effect in thermal transmission was first investigated via the EMA monitoring of the embedded PZT transducer inside the concrete structure.

- (2)

A new methodology for compensation of the thermal hysteresis effect on the EMA spectrum was proposed using the frequency and magnitude values of the maximum resonance peak.

The rest of this article is organized into four parts.

Section 2 gives a brief introduction to the principle of the embedded PZT model in the EMI technique, while numerical analysis and experimental investigations on the thermal hysteresis effect on the EMA spectra and its compensation are introduced in

Section 3 and

Section 4, respectively. Finally, concluding remarks are made in

Section 5.

2. Embedded PZT Model in EMI Technique

There are commonly two categories of PZT sensors that interact with a target structure in the EMI technique, namely surface-bonded and inside-embedded. For the surface-bonded one, Liang et al. [

38] proposed a one-dimensional impedance model to reveal the energy transfer and consumption of a PZT-driven active system, where the target structure is assumed as a one-degree-of-freedom spring-mass-damper system. When imposing a voltage excitation in the thickness direction (‘3’) of the patch with a size of

l ×

b ×

h, extensional strain is consequently produced, motivating structural responses as mechanical strain, as shown in

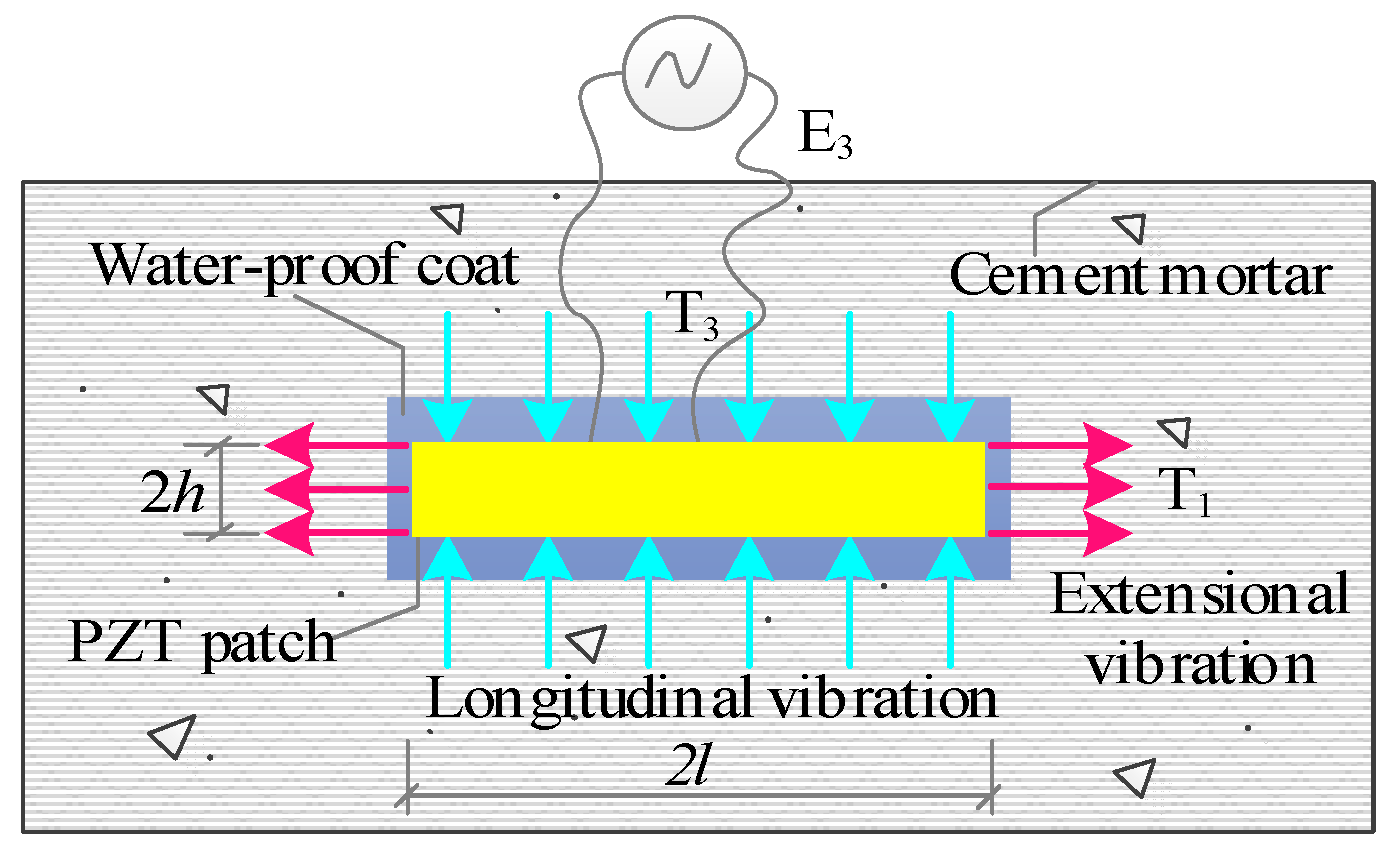

Figure 1. Such strain is conversely transferred to the patch to generate an electrical signal called the EMA spectrum. In this way, any damages affected by structural impedance could be directly identified by EMA variations. For the 1D model of a surface-bonded patch, only vibration in the length (‘1’) direction is considered, and the vibrations along the width (‘2’) and thickness (‘3’) directions can be ignored.

However, concerning an embedded PZT transducer, the dynamic interactions between the patch and the structure are significantly influenced by its longitudinal vibration in the ‘3’ direction, as noted in [

39]. Since it is closer to reality when considering both the extensional and longitudinal vibrations in ‘1’ and ‘3’ directions for the embedded transducer, a two-dimensional model of the PZT–adhesive coat–structural interaction has been developed [

40], as shown in

Figure 2. The coupling of the electrical parameters (electrical field:

E3; electrical displacement:

D3) and the mechanical parameters (mechanical strain:

S1,

S3; mechanical stress:

T1,

T3) can be expressed as:

where

is the electric permittivity at constant stress;

is the complex Young’s modulus at constant electric field;

denotes the dielectric loss factor;

is the mechanical loss factor;

,

are Poisson’s ratios;

d31,

d33 are the piezoelectric strain constants. With the aid of the definition for effective mechanical impedance, the EMA formula of the embedded PZT model shown in

Figure 2 can be derived as [

40]:

where

b,

l, and

h are the width, length, and thickness of the PZT patch, respectively;

and

are the effective impedance of the PZT transducer and structure, respectively;

denotes the wave number related to the angular frequency

;

is the density of the patch.

n denotes the value of the mechanical coupling coefficient.

In Equation (4), it is clear that the EMA value at any frequency point is closely associated with both the piezoelectric parameters and structural properties including mass, stiffness, and damping. In addition to structural damages, other parameters such as the piezoelectric strain constant and electric permittivity could also alter the EMA values, when they vary with temperature change [

11]. Consequently, the EMA formula can be deemed as a function related to the temperature variable. In order to quantify the EMA variations caused by temperature, root mean square deviation (RMSD) is deemed as one of the most effective indices in the EMI technique [

10], which is expressed as:

where

and

are the pristine and corresponding EMA values of the PZT at the

ith sample point for each

kth case. Different from RMSD for assessing the accumulated variation compared to the healthy state, a baseline-varied index, namely RMSDk, is also improved to differentiate and evaluate the absolute variations of each condition, which is expressed as [

40]:

where

is the EMA spectrum at the

ith sample point and considered the baseline at the prior state. The general and absolute variations in the EMA spectra throughout the heating process could be effectively evaluated by utilizing these indices. The next section covers the numerical analysis of the thermal hysteresis effect.

5. Conclusions

This paper numerically and experimentally investigated the thermal hysteresis effect and its compensation on the EMA monitoring of a concrete structure with an embedded PZT sensor.

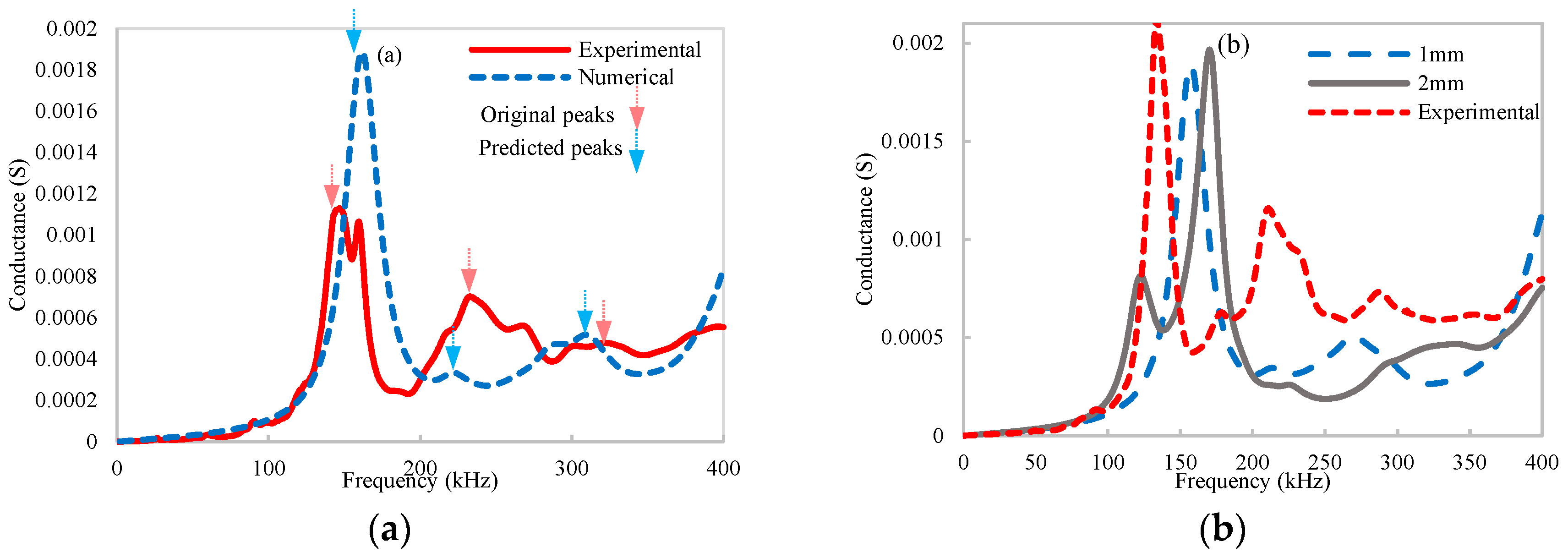

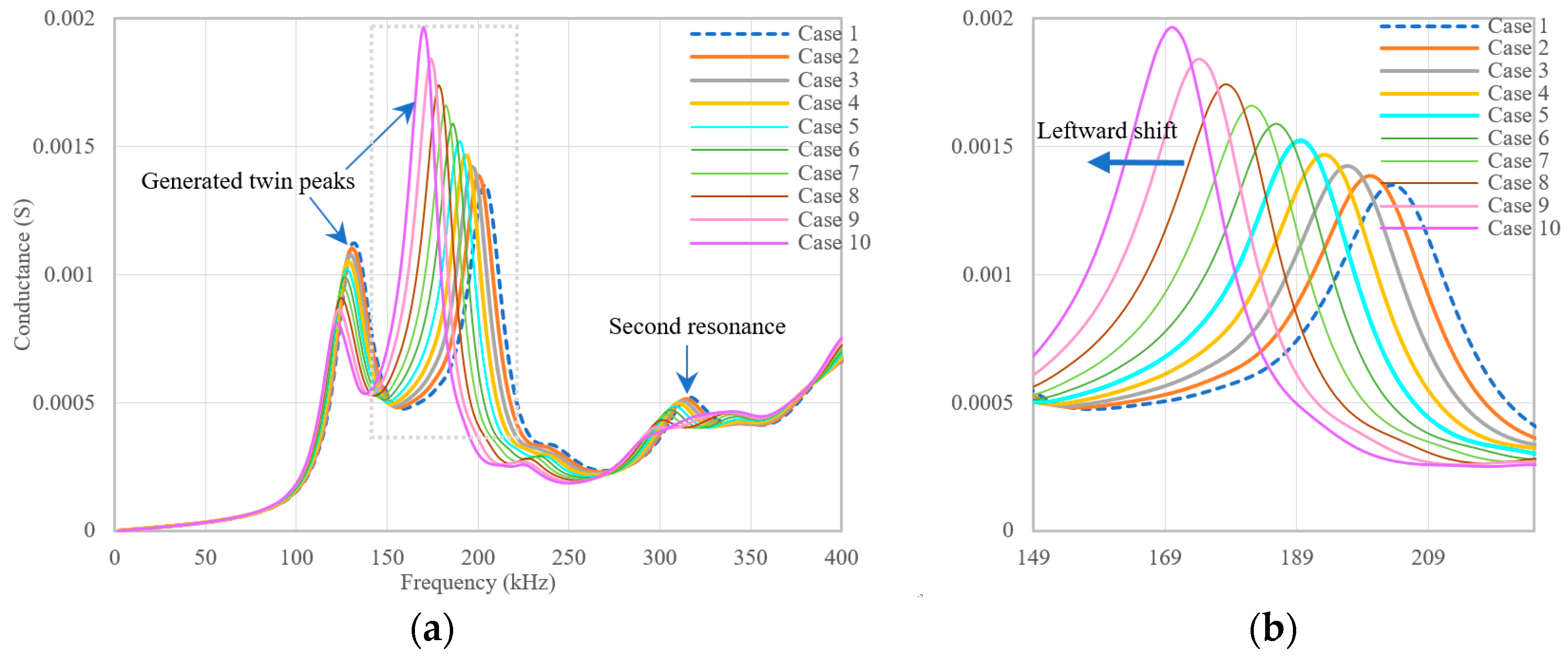

In the numerical modeling part, a 3D FE model for a concrete cube installed with an embedded PZT sensor was generated and employed for thermal transmission analysis from 30 °C to 60 °C. The modeling results demonstrated that (1) the heat transfer progress amplifies the temperature-induced EMA variations, where resonance peaks in conductance spectra shift with a frequency reduction and magnitude increment. (2) The maximum frequency shift and RMSD index of the sensor with a thin coat are magnified in comparison with those of the sensor with a thick one (6.5 and 5.4 times in this study, respectively) at the end of heating, which reveals significant aggravation of the thermal hysteresis effect by an increase in coat thickness.

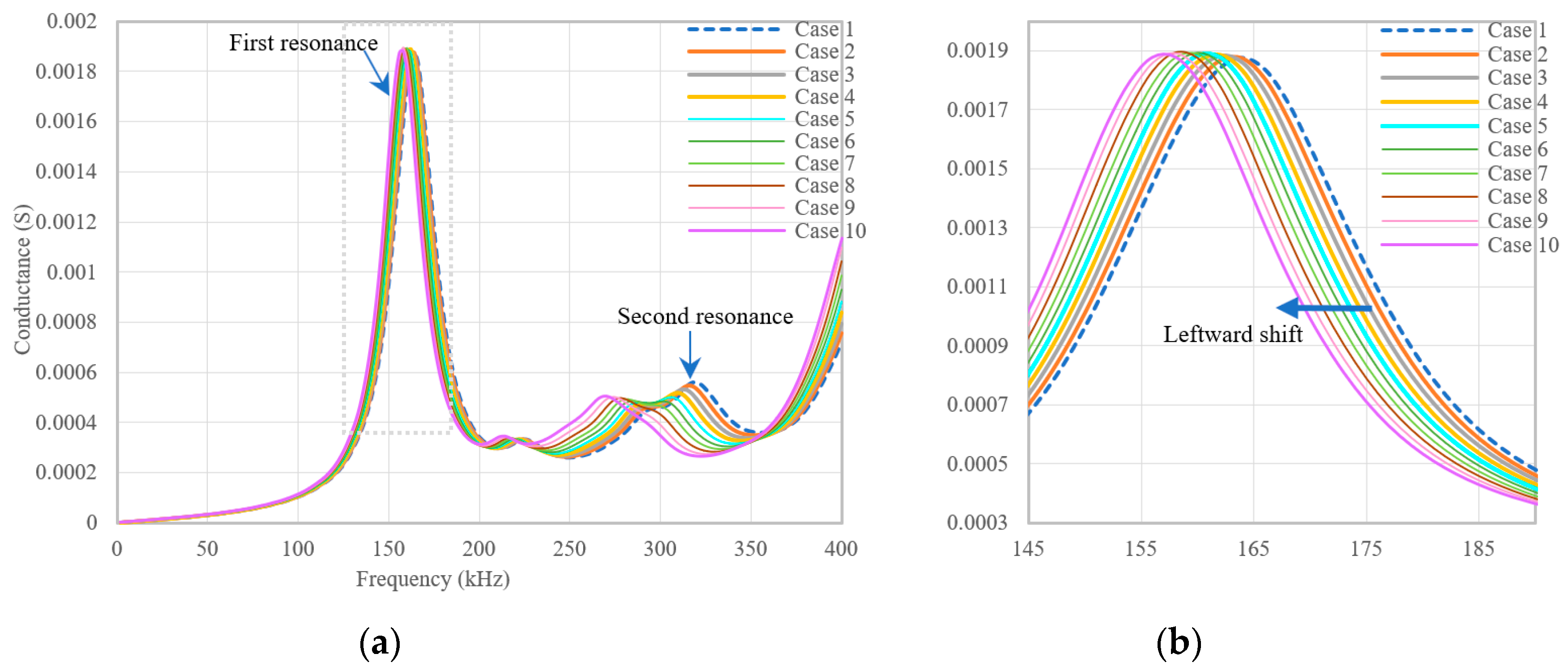

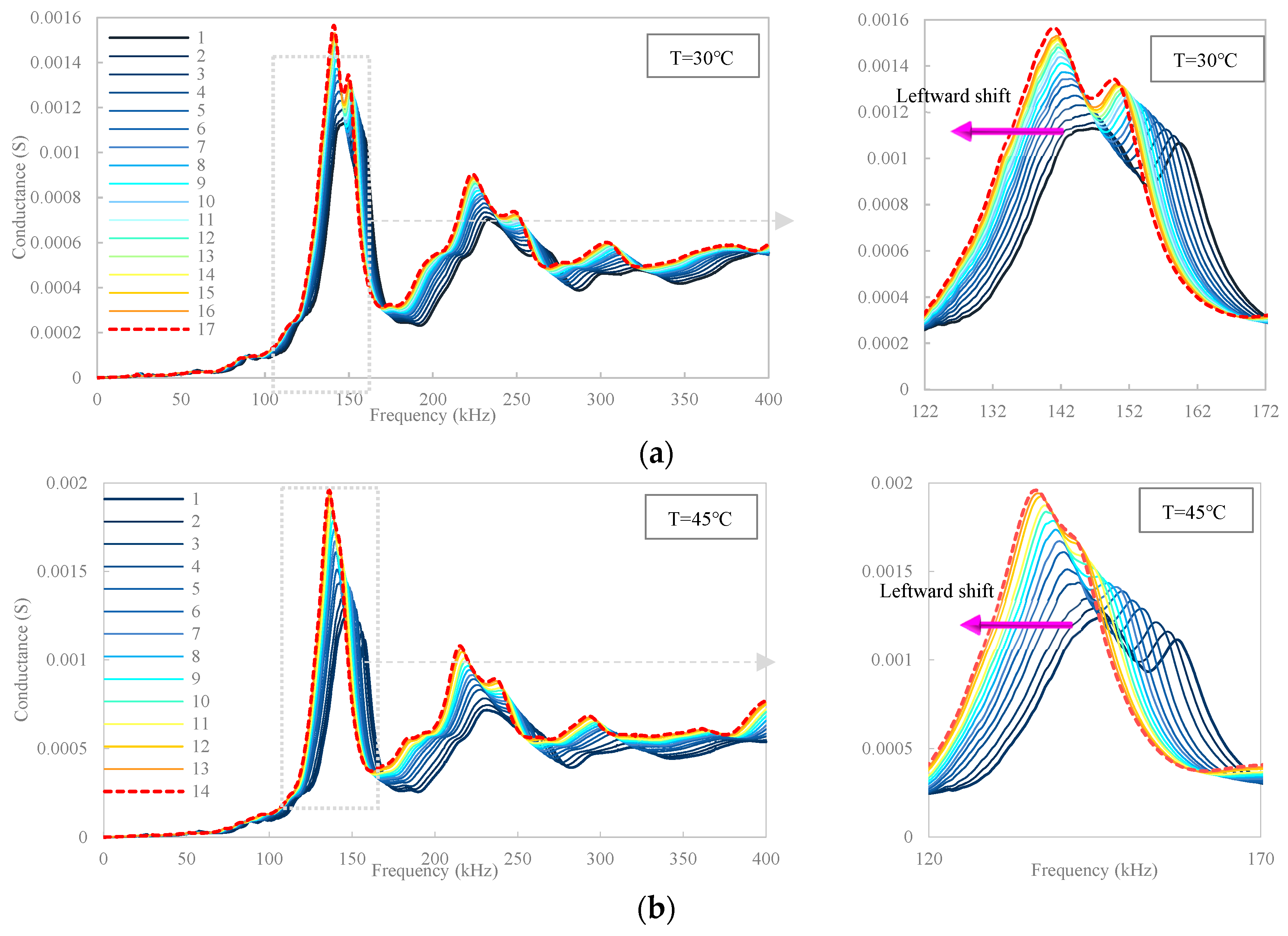

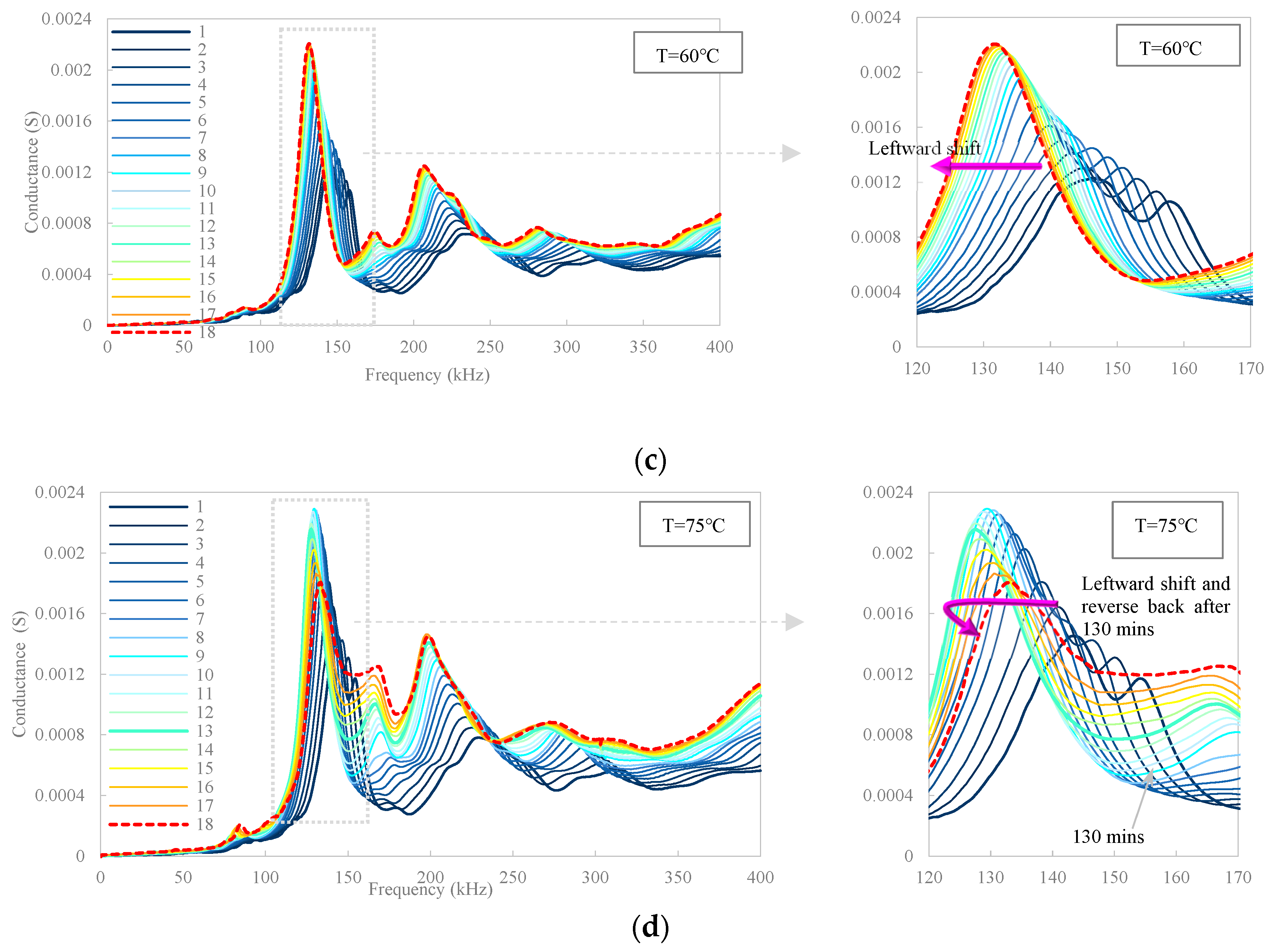

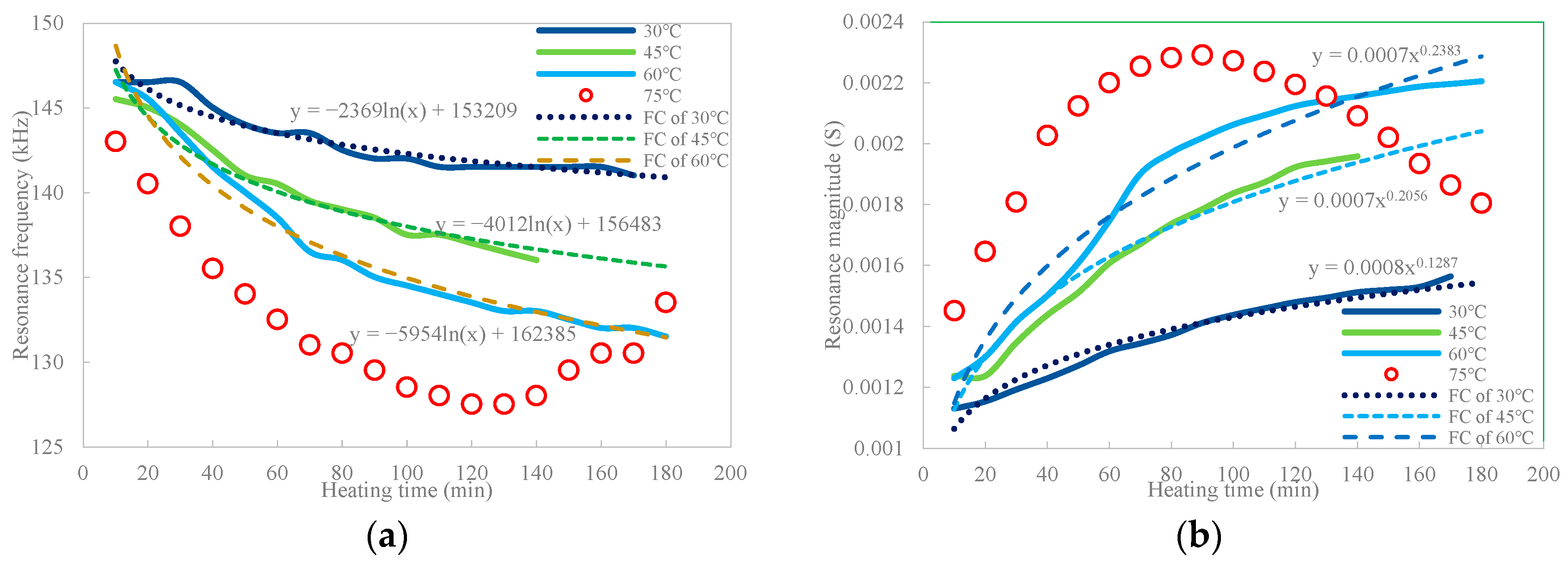

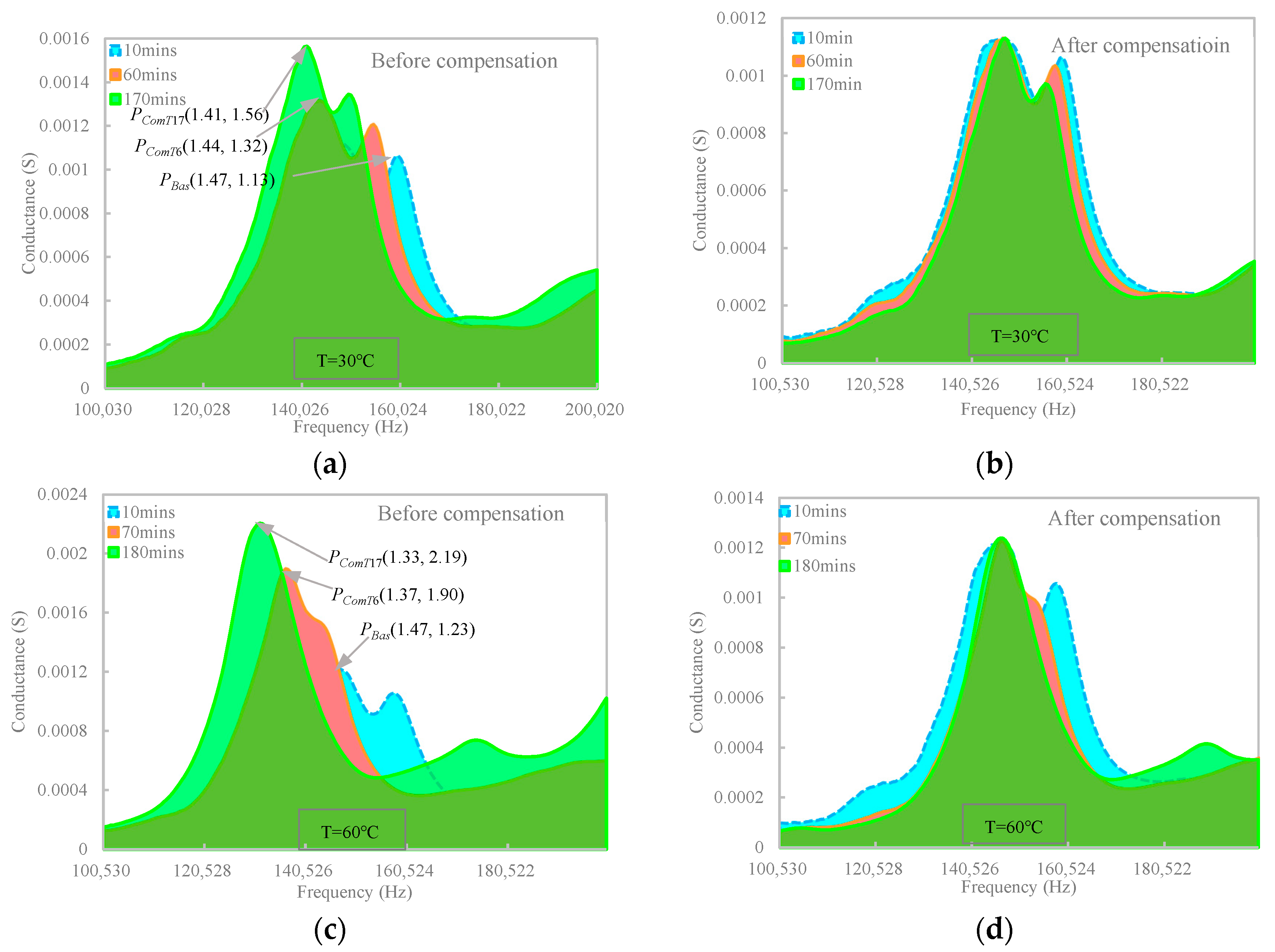

In the experimental investigation, a concrete cube installed with a CEP sensor was cast for a thermal test, which was heated for 180 min at four elevated temperatures of 30 °C, 45 °C, 60 °C, and 75 °C, respectively. Experimental results, as a cogent validation of the numerical results, indicated that (1) the heat transfer progress mainly causes gradual leftward and upward shifts in the resonance peaks of the EMA spectra in all temperature cases, which are amplified by temperature elevation. (2) Phase frequency and resonance amplitude aligned with heat transfer time were found to be in accordance with the negative Napierian logarithm and positive power functions, respectively. (3) Quantification of the EMA variation using RMSD/RMSDk indices also satisfied the Napierian logarithm and the power-function. (4) Anomalies in the resonance frequency and amplitude behaviors at a temperature of 75 °C indicated that potential distortion of EMA spectra of embedded PZT transducer could be induced by high-temperature generation. (5) Furthermore, a new methodology using frequency and magnitude shifts of the maximum resonance peak was attempted to compensate for the thermal hysteresis effect. Compensating results indicated that the conductance area increment induced by heating growth was significantly reduced by approximately 6 and 7 times for the two selected temperatures, which is promising for future applications.

Although promising results were attained, there are still limitations. (i) Since an anomaly in the resonance frequency and amplitude behaviors was observed at a temperature of 75 °C, the limited temperature range in this study warrants more investigations into the behavior of the embedded PZT patch under a wider range of extremely high temperatures. (ii) Inconsistencies that existed in some resonance peaks of the signatures after compensation also left a gap for improving the robustness of the proposed algorithm, relying on extensional tests under extreme temperatures. (iii) The proposed compensation technique is likely not suitable for compensation under minor temperature fluctuations due to the randomness of resonance peaks, particularly when encountering complex situations mixed with structural damage. (iv) Compensating for the extreme high-temperature effect in the EMA technique is also worth further investigation. (v) Some loss of valuable information may occur merely based on the CC indicator-based assessment for compensation, and accordingly, new indicators are supposed to be built up to evaluate the compensation effect in a more comprehensive way. (vi) Extending the approach into practice still faces the challenge that baseline data of EMA measurements might not be always available in real-world scenarios, hence developing a baseline-free compensation method may be more useful in practice.