SMARTS-Based Decision Support Model for CMMS Selection in Integrated Building Maintenance Management

Abstract

:1. Introduction

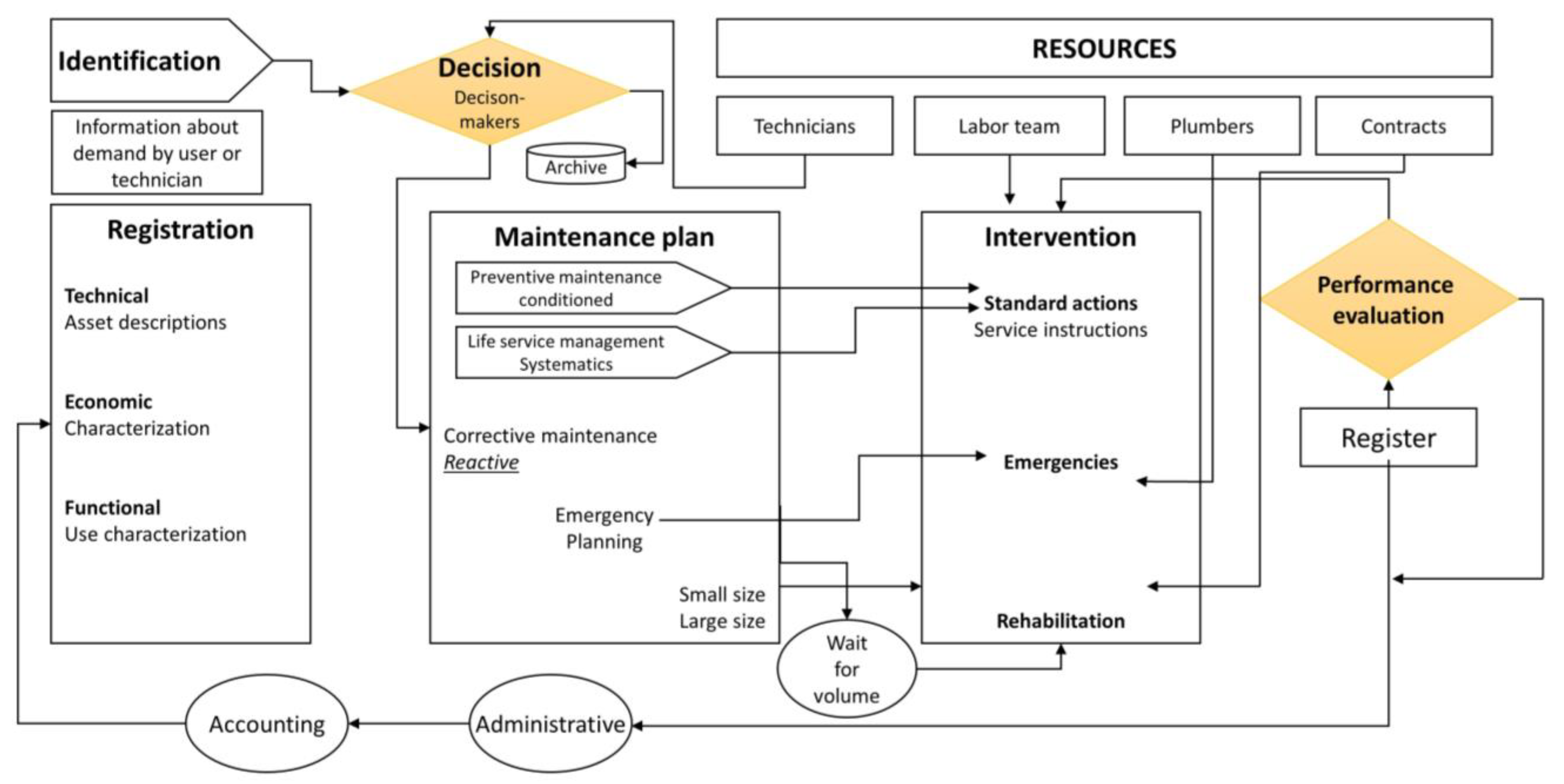

2. Toward a Decision Support Model: Integrated Maintenance System (IMS) and Building-Specific CMMS Requirements

- Identification of project and construction authors;

- Constructive description by elements;

- Project information and files;

- Relevant characteristics of constructive solutions;

- Subdivision into specialties;

- Historical report (interventions, adaptations, surveys, etc.).

- Preventive maintenance: this presupposes routines of inspection and observation of pre-pathology symptoms.

- Lifetime management: integrates the set of planned and systematic actions based on expected service life for specific construction components. It seeks to identify the need to reset a component whenever the end of life is foreseen.

- Corrective maintenance: this groups the set of actions resulting from the identification of pathological manifestations.

- Finally, the intervention group provides ways in which a building operates to be typified according to:

- Standard interventions: comprises a uniformity of the most frequent interventions. Information forms and diagnostic support procedures can be elaborated.

- Emergency interventions: a pattern of requests is sought to typify this type of intervention.

- Rehabilitation interventions: should be analyzed in a context outside the scope of maintenance.

3. Methodology

- Step 1—Goal and identification of decision-makers: this consists of identifying the value function’s purpose and the actors and organizations in the decision context.

- Step 2—Decision tree: this consists of identifying a structure (hierarchy of objectives or value tree) or list of attributes potentially relevant to eliciting values of each decision-taker or group of decision-makers. Attributes must be independent of each other. That is, the evaluation of one attribute must not depend on the evaluation of another.

- Step 3—Identification of alternatives: if the purpose of the identification does not specify the possible actions, the attribute structure of step 2 can be used to create it. The result of this step consists of a complete list of alternatives to be evaluated and becomes more significant the greater the number of attributes. Scoring rules must be well defined before the evaluation process.

- Step 4—Object evaluation matrix: consists of formulating an array of alternatives and evaluations according to each attribute (criterion or sub-criterion). Input data should be scores or physical measures, if available.

- Step 5—Dominated Options: eliminate dominated options if easily recognized by visual inspection.

- Step 6—One-dimensional utility value: defines the one-dimensional value function shape for each criterion type. If a linear function is used, it comprises a simple computational step.

- Step 7—Part 1 of the Swinging Weighting technique application: this technique calculates weights, also called substitution rates, for criteria or attributes. For its use, a hypothetical situation is initially created, in which all sub-criteria receive the worst possible evaluation. This situation is assigned a score equal to zero. Then, the decision-taker is prompted, within a criterion, to choose only a sub-criterion to receive the maximum evaluation. This sub-criterion will receive a score of 100. In the next step, the decision-taker is asked which is the second sub-criterion he would assign the maximum score, and thus, an ordering is performed.

- Step 8—Part 2 of the Swinging Weighting technique application. All multi-attribute utilities are calculated. Considering that the former received a score of 100, the decision-maker is asked what score he would assign to the second, and so on. As an example, considering three attributes that received scores of 100, 70, and 30, a sum is made, and it is possible to obtain percentage values of the weight of each.

- Step 9—Decision making. The result is obtained as defined in Equation (1) by the highest score listed in expression (1).

4. Application and Results

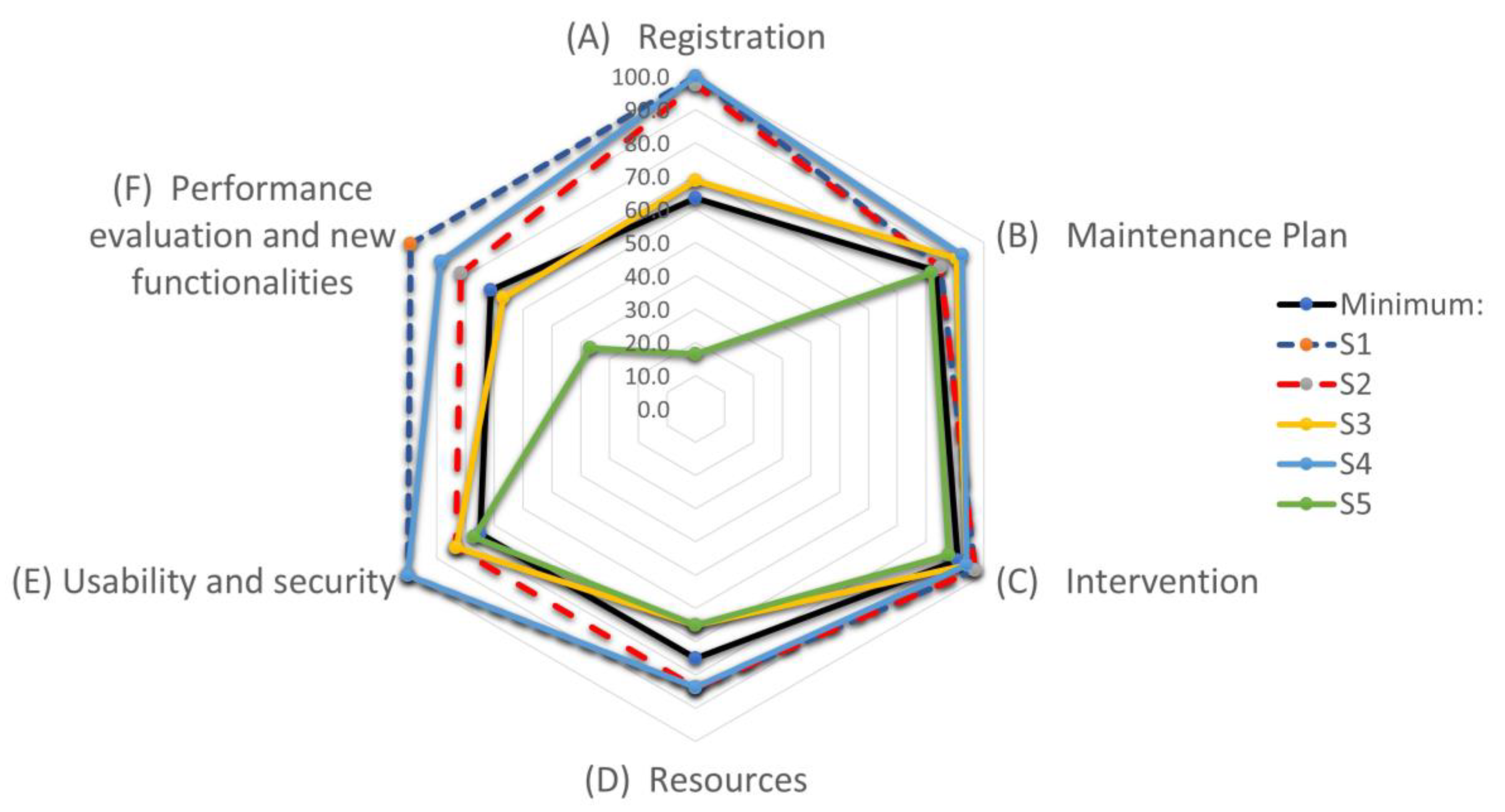

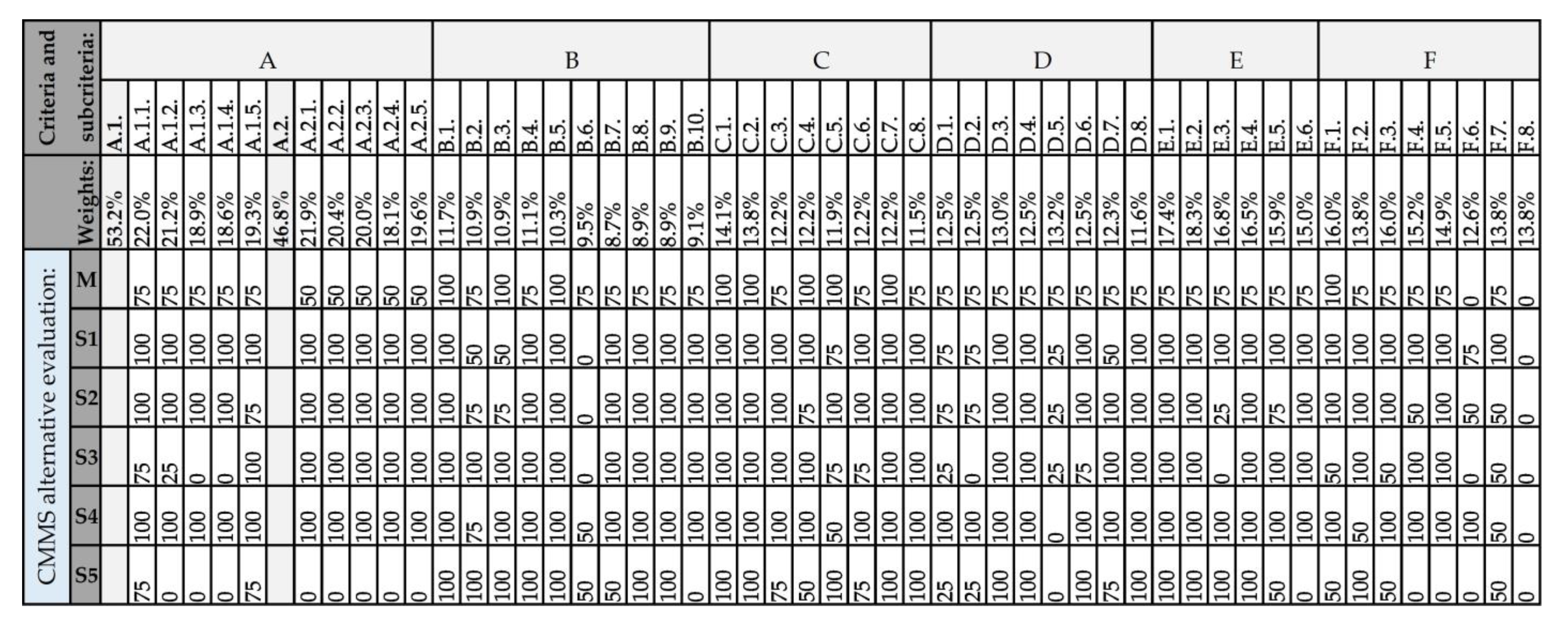

4.1. Decision Support Model Structure

4.2. Software Evaluation

5. Discussion and Conclusions

- Deeply study the criteria and sub-criteria adequacy;

- Improve the value function of the sub-criteria, as well as deepen the minimum requirements for an IMS;

- Evaluate the new demands associated with IMS, such as Industry 4.0 features;

- Quantify the impacts and growth of CMMS adoption for building management;

- Identify drivers and barriers to CMMS improvements for buildings regarding new technologies and methodologies, such as BIM, VR, AR, IoT, and others;

- Expand the current study to a more significant number of alternatives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EN 13306:2017; Maintenance—Maintenance Terminology. European Committee for Standardization: Brussels, Belgium, 2017.

- Islam, H.; Jollands, M.; Setunge, S. Life Cycle Assessment and Life Cycle Cost Implication of Residential Buildings—A Review. Renew. Sustain. Energy Rev. 2015, 42, 129–140. [Google Scholar] [CrossRef]

- Duffuaa, S.O.; Raouf, A. Planning and Control of Maintenance Systems; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-19802-6. [Google Scholar]

- Dukić, D.; Trivunić, M.; Starčev-Ćurčin, A. Computer-Aided Building Maintenance with “BASE-FM” Program. Autom. Constr. 2013, 30, 57–69. [Google Scholar] [CrossRef]

- Ismail, Z.-A. The Requirements for Maintenance Management Systems (MMS) at Malaysian Polytechnic: A Case Study. J. Qual. Maint. Eng. 2022, 28, 768–790. [Google Scholar] [CrossRef]

- Pestana, T.; Flores-Colen, I.; Pinheiro, M.D.; Sajjadian, S.M. User Perception on Key Performance Indicators in an In-Service Office Building. Infrastructures 2021, 6, 45. [Google Scholar] [CrossRef]

- Lai, J.H.K.; Hou, H.; Chiu, B.W.Y.; Edwards, D.; Yuen, P.L.; Sing, M.; Wong, P. Importance of Hospital Facilities Management Performance Indicators: Building Practitioners’ Perspectives. J. Build. Eng. 2022, 45, 103428. [Google Scholar] [CrossRef]

- Dzulkifli, N.; Sarbini, N.N.; Ibrahim, I.S.; Abidin, N.I.; Yahaya, F.M.; Nik Azizan, N.Z. Review on Maintenance Issues toward Building Maintenance Management Best Practices. J. Build. Eng. 2021, 44, 102985. [Google Scholar] [CrossRef]

- Uysal, F.; Tosun, Ö. Fuzzy TOPSIS-based Computerized Maintenance Management System Selection. J. Manuf. Technol. Manag. 2012, 23, 212–228. [Google Scholar] [CrossRef]

- Zare, A.; Feylizadeh, M.R.; Mahmoudi, A.; Liu, S. Suitable Computerized Maintenance Management System Selection Using Grey Group TOPSIS and Fuzzy Group VIKOR: A Case Study. Decis. Sci. Lett. 2018, 7, 341–358. [Google Scholar] [CrossRef]

- Zemmouchi-Ghomari, L.; Chergui, S.; Ouadah, A. Proposal of an Approach of Selection and Impact Study of CMMS Use on Maintenance Functioning, a Case Study. In Proceedings of the 2020 1st International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Meknes, Morocco, 16–19 April 2020; pp. 1–6. [Google Scholar]

- Meira, D.; Lopes, I.; Pires, C. Selection of Computerized Maintenance Management Systems to Meet Organizations’ Needs Using AHP. Procedia Manuf. 2020, 51, 1573–1580. [Google Scholar] [CrossRef]

- Rodrigues, R.M.G.C. Gestão de Edifícios: Modelo de Simulação Técnico-Econômica. Ph.D. Thesis, Engenharia Civil, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 2001. [Google Scholar]

- Wu, S.; Neale, K.; Williamson, M.; Hornby, M. Research Opportunities in Maintenance of Office Building Services Systems. J. Qual. Maint. Eng. 2010, 16, 23–33. [Google Scholar] [CrossRef]

- Lavy, S.; Shohet, I.M. Integrated Maintenance Management of Hospital Buildings: A Case Study. Constr. Manag. Econ. 2004, 22, 25–34. [Google Scholar] [CrossRef]

- EN 15341:2009; Maintenance—Maintenance Key Performance Indicators. European Committee for Standardization: Brussels, Belgium, 2007.

- Bolshakov, N.; Celani, A.; Azhimova, L. Integrating BIM in Operation and Maintenance Stage. In Proceedings of the FORM 2022: Construction the Formation of Living Environment, Moscow, Russia, 22 April 2022; pp. 489–496. [Google Scholar]

- Rogage, K.; Greenwood, D. Data Transfer between Digital Models of Built Assets and Their Operation & Maintenance Systems. J. Inf. Technol. Constr. 2020, 25, 469–481. [Google Scholar] [CrossRef]

- Casini, M. Extended Reality for Smart Building Operation and Maintenance: A Review. Energies 2022, 15, 3785. [Google Scholar] [CrossRef]

- Villa, V.; Naticchia, B.; Bruno, G.; Aliev, K.; Piantanida, P.; Antonelli, D. IoT Open-Source Architecture for the Maintenance of Building Facilities. Appl. Sci. 2021, 11, 5374. [Google Scholar] [CrossRef]

- Jansen, S.J.T. The Multi-Attribute Utility Method. In The Measurement and Analysis of Housing Preference and Choice; Springer: Dordrecht, The Netherlands, 2011; pp. 101–125. [Google Scholar]

- Keeney, R.L. Value-Focused Thinking: A Path to Creative Decisionmaking; Harvard University Press: Cambridge, MA, USA, 1992; p. 416. [Google Scholar]

- Gomes, L.F.A.M.; Rangel, L.A.D.; Leal Junior, M.D.R. Treatment of Uncertainty through the Interval Smart/Swing Weighting Method: A Case Study. Pesqui. Oper. 2011, 31, 467–485. [Google Scholar] [CrossRef]

- Edwards, W.; Barron, F.H. SMARTS and SMARTER: Improved Simple Methods for Multiattribute Utility Measurement. Organ. Behav. Hum. Decis. Process. 1994, 60, 306–325. [Google Scholar] [CrossRef]

- Danielson, M.; Ekenberg, L.; Larsson, A.; Riabacke, M. Weighting Under Ambiguous Preferences and Imprecise Differences in a Cardinal Rank Ordering Process. Int. J. Comput. Intell. Syst. 2014, 7, 105. [Google Scholar] [CrossRef]

- Borgonovo, E.; Marinacci, M. Decision Analysis under Ambiguity. Eur. J. Oper. Res. 2015, 244, 823–836. [Google Scholar] [CrossRef]

| Authors | Criteria | Sub Criteria |

|---|---|---|

| [12] | Compatibility and portability | Integration level with other software; Portability to mobile devices |

| Performance | Ease of in-house customization; Functional fitness; Modules’ availability (integration and extension); Reports (availability, reliability, and customization); Updates’ availability | |

| Security | Access control; Backup availability | |

| Supplier-related | Online support; Proximity (technical assistance); Reputation and experience in the industry; Training and consulting services | |

| Factors usability | Ease of learning; Ease of operation; User-friendly graphical interface | |

| [9] | Cost | Purchasing cost; Updating cost |

| Data and Reporting | Documentation and training; Easy data transfer; Reports accuracy | |

| Performance | Compatibility with organizational structure; Ease of use; Implementation time | |

| Quality | Efficiency; Functionality; Maintainability; Portability; Reliability; Usability | |

| Technical | Cross-module integration; Flexibility for customization; Technical support | |

| [10] | Costs | Software’s implementation cost; Software’s purchase cost; Software’s update and upgrade costs |

| Data management | Number of available reports in software; Privatization of software; Software’s accuracy of reports | |

| Performance | Software’s flexibility; Software’s technical characteristics; Software’s user-friendliness | |

| Software Implementation | Aggregation level with other management software applications; Ease of implementation | |

| Software security | Automatic system for backup; Security methods to protect systems against illegal access | |

| [11] | Architecture; Flexibility; Functions; Language; License: portability; Scalability; Simplicity; Types of maintenance. | There was no division into sub-criteria by authors |

| (A) Registration. |

| (A.1) General information. Software must allow the registration of: |

| A.1.1. Functional records: institution or condominium identifications and address; Information on the types of uses of the building; Identification of those responsible for the operation of the building (manager, liquidator, etc.); Numbering of licenses and deadlines (Examples: get used and leave the fire department) |

| A.1.2. Construction data—Dates of technical delivery, obtaining and sealing of permits (Example: fire department), start and end of construction; Identification of the technician responsible for the enterprise; Measures and indicators (number of floors, built-up areas, total area, perimeter, occupancy rates, among others) |

| A.1.3. Designers, builders, and technological consultancies (during the design and construction phases): functional classification of projects, the scope of services, identification and contacts of companies or professionals, start and end dates of services |

| A.1.4. Designers, builders, and technological consultancies completed (during the phases of use and operation): functional classification of projects, the scope of services, identification and contacts, start and end dates of services |

| A.1.5. Registration of elements—Functional classification, involving a structure with subdivisions from the enterprise to the source element of maintenance; Description of the maintenance source element; Location of assets and elements sources of maintenance; Specifications of the materials used, concerning models and brand; Specification of service life of materials and components |

| (A.2) Access to documents. You must upload these files in software: |

| A.2.1. Projects in digital files |

| A.2.2. Approvals documents and project permits during construction |

| A.2.3. Codes and conventions on the use of the building (e.g., condominium convention), manuals and specifications on the use of the building |

| A.2.4. Consulting Reports and Technological Control |

| A.2.5. Budgets and spreadsheets |

| (B) Maintenance Plan. The software must allow: |

| B.1. Receipt of demand identification (called), validated by decision making |

| B.2. Record the description of procedures (inspection, cleaning, preventive maintenance, corrective maintenance), according to the element of maintenance source and/or functional assembly |

| B.3. Classification of the registration into categories (inspection, cleaning, preventive maintenance, corrective maintenance), according to the element source of maintenance and/or functional assembly |

| B.4. Schedule of tasks related to maintenance routines, according to the functional structure of the element’s sources of maintenance |

| B.5. Service order forwarding, through the software, to the team that will perform the designated activities in the task scheduled |

| B.6. Present a pre-existing database with typical procedures for cleaning, inspection, and maintenance operations of buildings |

| B.7. Record the identification of utilization indicators, and reading of operating parameters after an inspection or in real time (regardless of the mode of registration) |

| B.8. Record evaluation of the general state performance after inspection |

| B.9. Record general state cleaning, and deterioration, among other information after inspection |

| B.10. Issuing alert about the need for replacement of components due to the end of their useful life or due to failure recorded by a sensor or any other type of registration |

| (C) Intervention. The software must allow: |

| C.1. Typification of intervention demand: standard, emergency, rehabilitation |

| C.2. Indication and referral to the team that will carry out the intervention (contracted company, permanent team, emergency guidance) in case of unplanned emergencies |

| C.3. Registration and provision of access by the team responsible for the type forms and technical information of conduct |

| C.4. Management and control of small and large demands that will lead to the need for rehabilitation |

| C.5. Record the progress of implementation of the intervention, with beginning and end |

| C.6. Record the performance evaluation after the intervention performed |

| C.7. Photo registration, reports, or similar |

| C.8. Registration of projects and any other document prepared after the intervention |

| (D) Resources. The software must allow: |

| D.1. Identification and registration of information on current contracts with third-party companies |

| D.2. Identification of permanent employee registration and over-notice |

| D.3. Material inventory control |

| D.4. Issuing orders or communications for requisitioning materials |

| D.5. Control of financial resources |

| D.6. Identification and registration of the allocation of costs (appropriation) in each intervention |

| D.7. Identification and registration of the allocation (appropriation) of materials in each intervention |

| D.8. Issuance of information report of resources consumed (material or financial) for technical and economic registration after confirmation of services and expenses |

| (E) Usability and Security. The software must allow: |

| E.1. Operation via smartphone or tablet |

| E.2. Operation of the system through a web application |

| E.3. Communication of calls (or service orders, alerts, among others) through external communication to the software (email, SMS, among others) |

| E.4. Schedule data backup in a scheduled manner |

| E.5. Providing online support during business hours |

| E.6. Providing training through online or EAD videos |

| (F) Performance evaluation of maintenance and functionalities incorporation. The software must allow: |

| F.1. Set up KPIs according to available information or database and generate reports |

| F.2. QR code generation for asset identification and opening of user calls |

| F.3. Possibility of reporting configuration: Service Level Agreement (ANS), failures, among others |

| F.4. Connection with Business Intelligence (BI) software |

| F.5. Connection to sensors and/or controllers for reading data |

| F.6. Use of Near-Field Communication (NFC) in equipment |

| F.7. Customization of solution for the customer that is not in the commercial proposal |

| F.8. Access the elements sources of maintenance and registration through virtual reality, augmented reality, and BIM |

| Software | Features Listed on the Commercial Website |

|---|---|

| S1 | Asset management, mobile app, service orders, requests, preventive maintenance, reports and dashboards, IOT sensors, supplier management, and multiple languages. |

| S2 | Registration of assets, maintenance plan, and work orders with the possibility to attach manuals, QR Code or NFC identification, resource control, evaluation of the work performed, IoT sensors, and condition-based maintenance (CBS). |

| S3 | Maintenance planning, maintenance indicators, inventory management, procedure library, service order requests, preventive maintenance, metrics with or without sensors, team chats, and expense indicators. |

| S4 | Preventive maintenance plans, reports, corrective maintenance, audits, inventory management, and real-time information. |

| S5 | Dashboard, QR code, automation of routines, reports and graphs, geolocation of technicians, performance indicators, inventory management, and service level agreement. |

| Evaluation | Points |

|---|---|

| Yes, fully meets the requirements | 100 |

| Strongly meets requirements | 75 |

| Partially meets requirements | 50 |

| Deficiently meets requirements | 25 |

| Do not meet requirements | 0 |

| Do not apply | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, R.C.; Sousa, H.; Gondim, I.A. SMARTS-Based Decision Support Model for CMMS Selection in Integrated Building Maintenance Management. Buildings 2023, 13, 2521. https://doi.org/10.3390/buildings13102521

Rodrigues RC, Sousa H, Gondim IA. SMARTS-Based Decision Support Model for CMMS Selection in Integrated Building Maintenance Management. Buildings. 2023; 13(10):2521. https://doi.org/10.3390/buildings13102521

Chicago/Turabian StyleRodrigues, Rui Calejo, Hipólito Sousa, and Ivo Almino Gondim. 2023. "SMARTS-Based Decision Support Model for CMMS Selection in Integrated Building Maintenance Management" Buildings 13, no. 10: 2521. https://doi.org/10.3390/buildings13102521

APA StyleRodrigues, R. C., Sousa, H., & Gondim, I. A. (2023). SMARTS-Based Decision Support Model for CMMS Selection in Integrated Building Maintenance Management. Buildings, 13(10), 2521. https://doi.org/10.3390/buildings13102521