Biomethane Microturbines as a Storage-Free Dispatchable Solution for Resilient Critical Buildings

Abstract

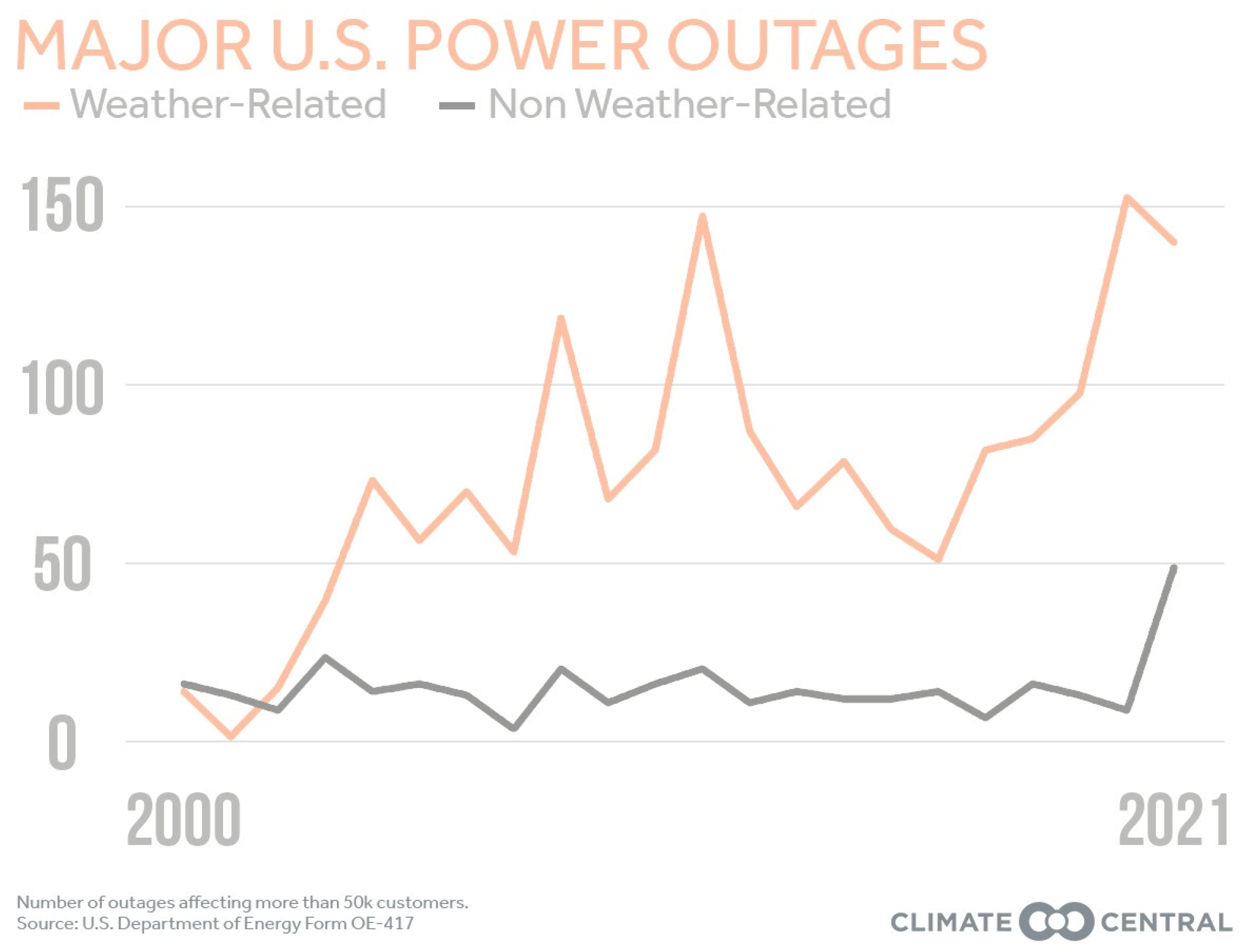

1. Introduction

Literature Review

2. Proposed Methodology

2.1. Backup System Reliability

2.1.1. Failure to Start

2.1.2. Failure to Run

2.1.3. Failure of Fuel Supply

- Diesel Fuel Supply

- Natural Gas Fuel Supply

- Correlation between electrical and natural gas interruptions

2.2. Costs and Benefits

- : net cashflow (revenues–expenses) for a specific period t;

- i: interest rate;

- t: number of time periods.

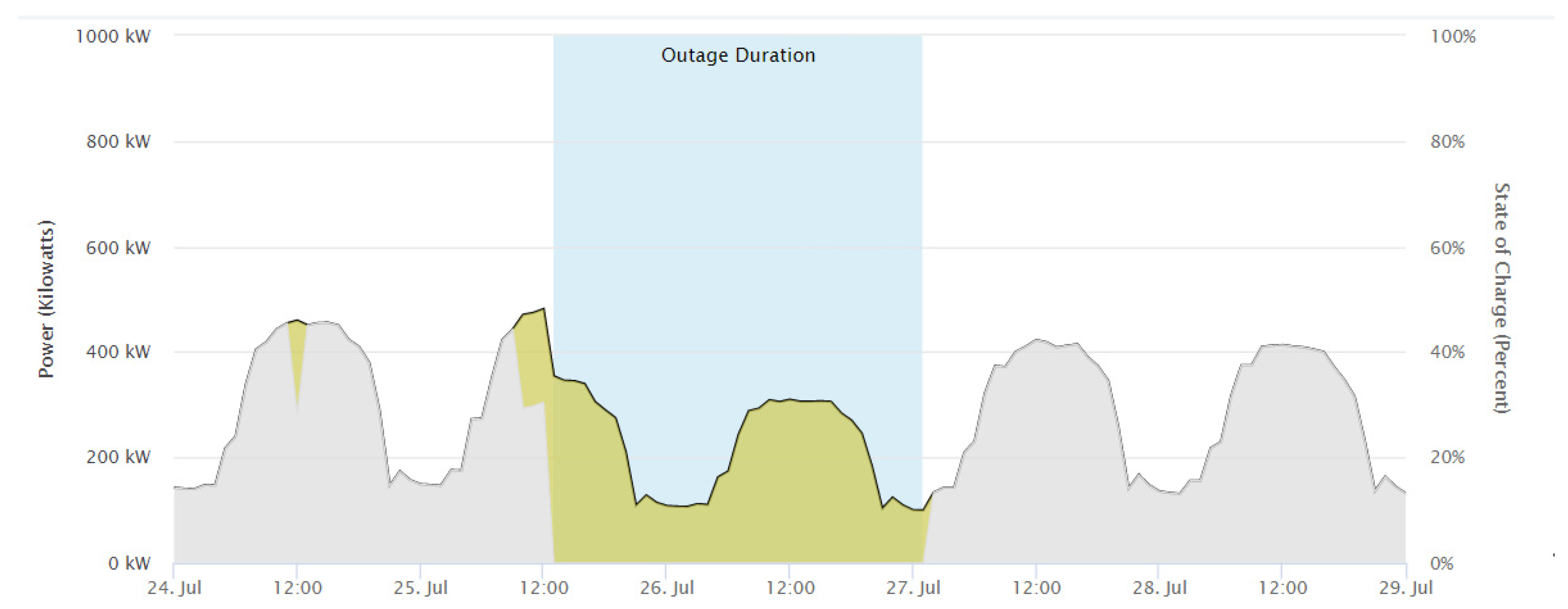

2.3. Simulation with REopt Lite

- Drivers: Energy costs and revenues, economic factors, and resilience and environmental goals;

- Technology options: Renewable generation, conventional generation, and energy storage;

- Loads: Electric loads, heating and cooling loads, and dispatchable loads.

- Once the optimization is finished, the next outputs are obtained:

- Technology recommendations;

- Optimal dispatch strategy;

- Economic outputs: Capital cost, operating cost, lifecycle cost, and net present value.

- Optimizing for grid-connected benefits and evaluating added resiliency;

- Optimizing system sizes for a given outage duration;

- Including the value of resiliency in the objective function.

- The load data reflecting one year of consumption and future loads may change (increase, decrease, and/or shift in timing).

- Optimization is based on modeling the hourly loads, generation, and storage dispatch; intra-hour variability may impact savings.

- Optimized dispatch reflects the model’s optimal forecast of modeled loads, so the results present the maximum economic potential of the modeled technologies.

- Critical loads can be difficult to estimate; this contributes uncertainty to resilience analysis.

- In case of grid outage, additional integration costs may be needed to facilitate microgrid capabilities that allow the system to operate independently.

- When operating in grid-connected mode, REopt assumes that batteries are dispatched to minimize operational costs, and they may not be at a high state of charge when the outage occurs.

3. Results and Discussion

- 611 Bordentown Ave, South Amboy, NJ, 08879.

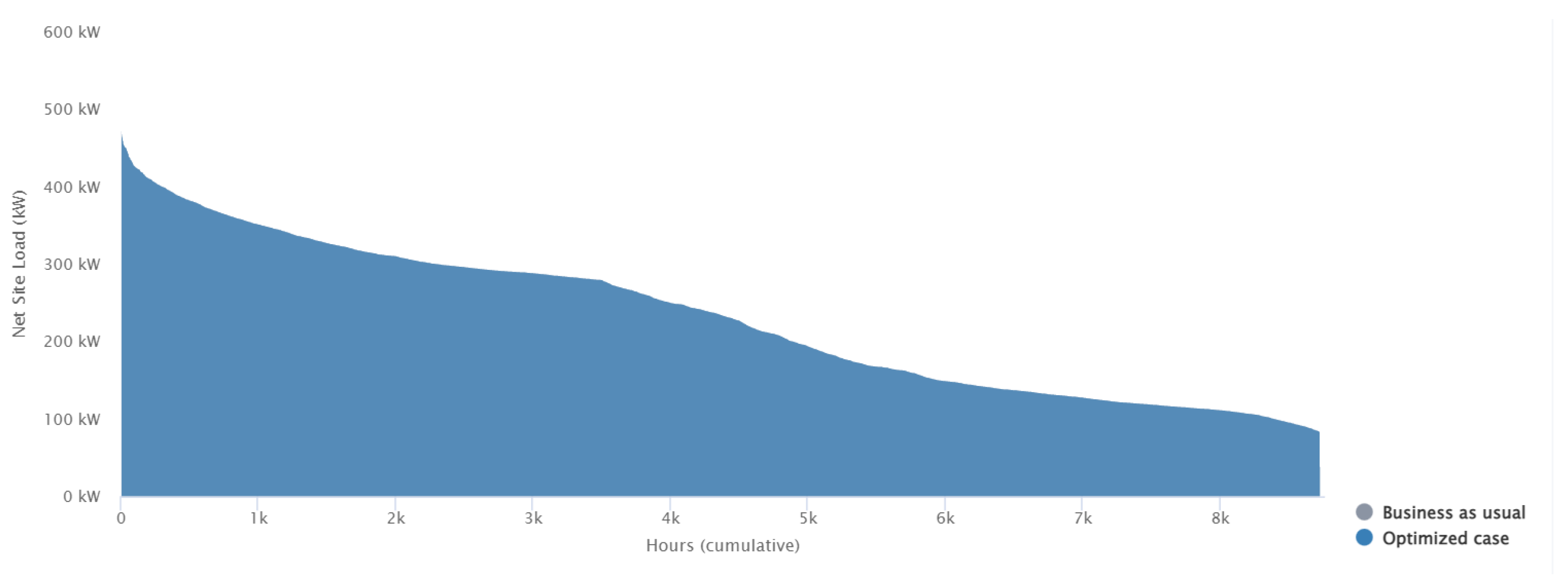

3.1. Electricity Consumption

3.2. Assumed Costs

3.3. Backup System

3.4. Average Availability Depending on the Type of Generator Used

3.5. Markets and Revenue Opportunities

3.6. Market Analysis

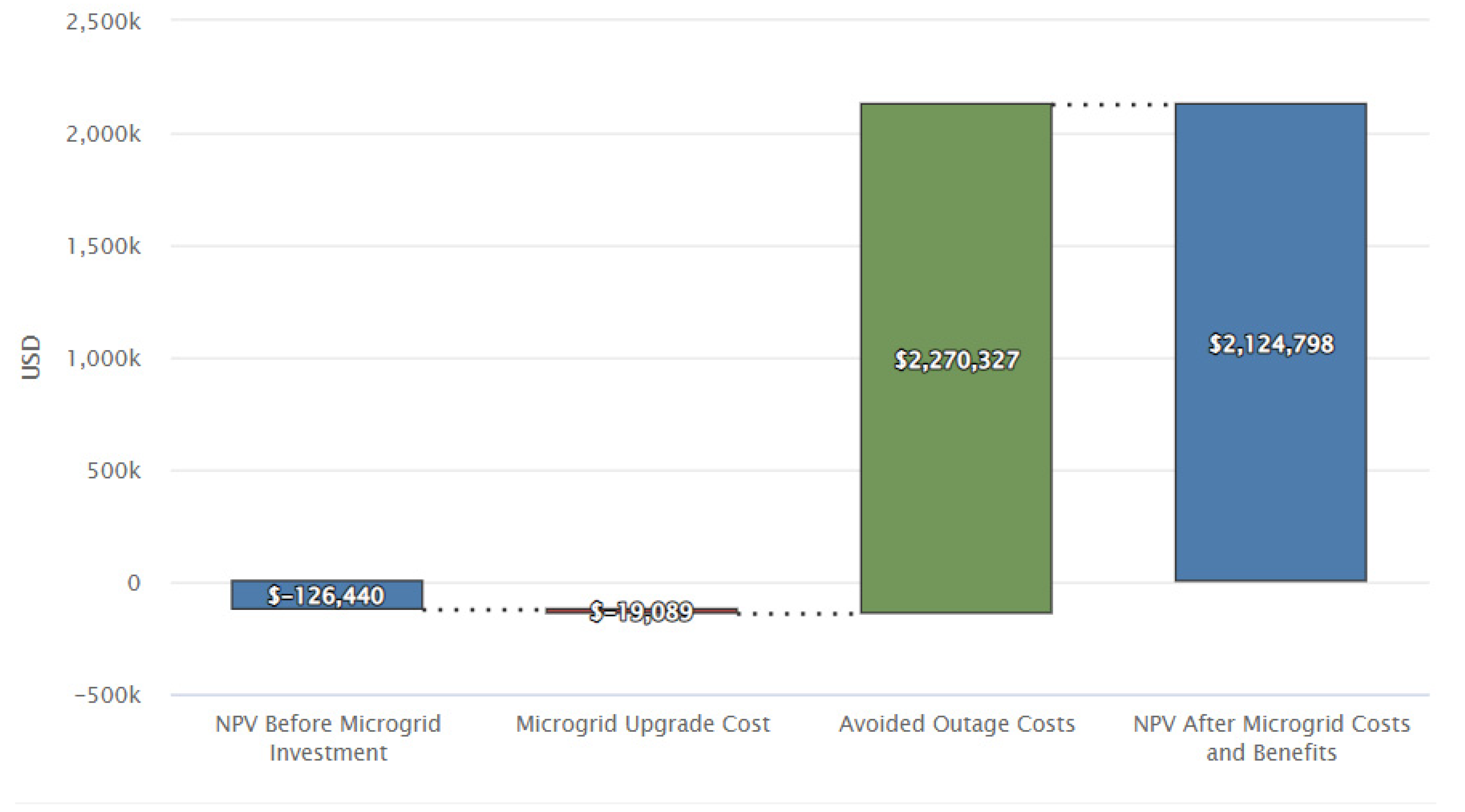

3.6.1. Diesel Engine as Storage-Free Dispatchable Solution for Critical Power Supply

- Outage duration (hours): 36 h;

- Critical load factor (%): 75%;

- Microgrid upgrade cost: 30% of system capital cost;

- Avoided outage costs: USD 3 per kWh.

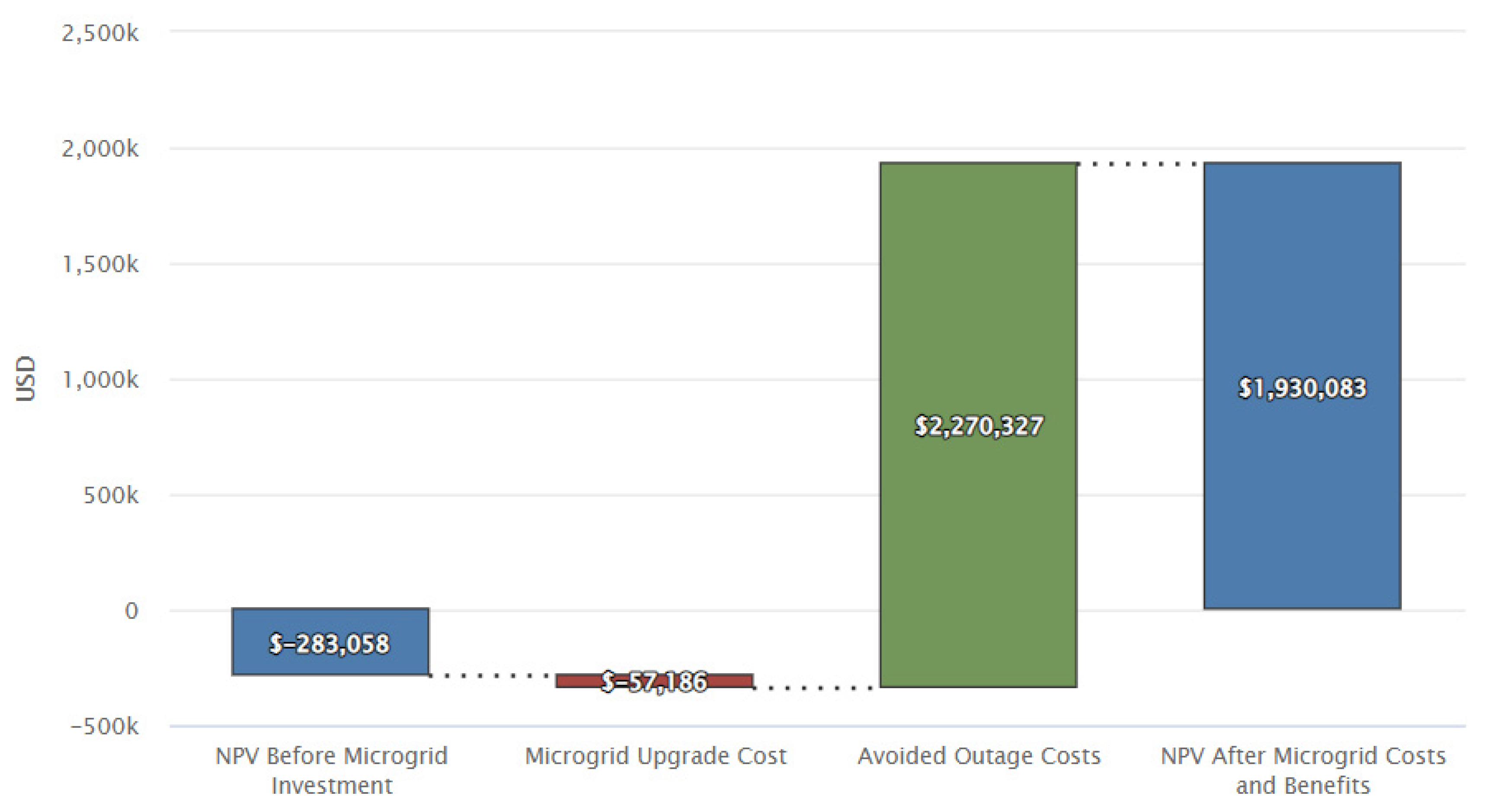

3.6.2. Natural Gas Engine as Storage-Free Dispatchable Solution

- Outage duration (hours): 36 h;

- Critical load factor (%): 75%;

- Microgrid upgrade cost: 30% of system capital cost;

- Avoided outage costs: USD 3 per kWh.

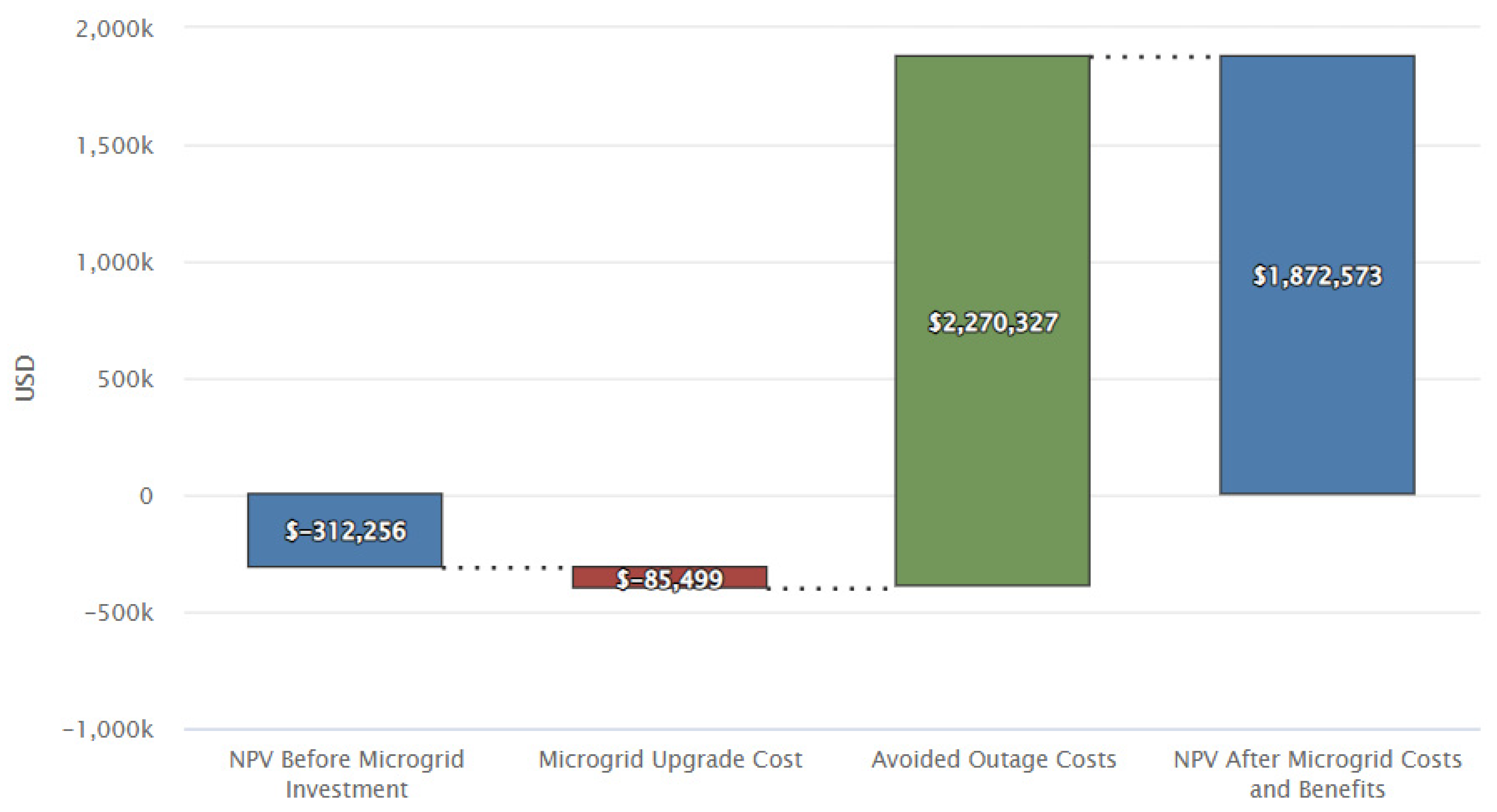

3.6.3. Biomethane Microturbine as Storage-Free Dispatchable Solution

- Outage duration (hours): 36 h;

- Critical load factor (%): 75%;

- Microgrid upgrade cost: 30% of system capital cost;

- Avoided outage costs: USD 3 per kWh.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| BTM | Biomethane microturbine |

| DG | Diesel generator |

| EFC | Electrical and fire codes |

| FTS | Failure to start |

| ICE | Interruption cost estimate |

| LCC | Lifecycle cost |

| NG | Natural gas |

| NGG | Natural gas generator |

| NPV | Net present value |

| O&M | Operation and maintenance |

| RNG | Renewable natural gas |

References

- Härö, E.; Järvensivu, S.M.; Alilehto, J.; Haravuori, P. Electricity: How Long Could We Survive without It? Sweco AB: Stockholm, Sweden; Available online: https://www.swecourbaninsight.com/urban-energy/electricity-how-long-could-we-survive-without-it/ (accessed on 26 October 2019).

- National Academies of Sciences, Engineering, and Medicine. Enhancing the Resilience of the Nation’s Electricity System; The National Academies Press: Washington, DC, USA, 2017. [Google Scholar]

- Dorf, R.D. The Electrical Engineering Handbook, 2nd ed.; CRC Press: Boca Ratón, FL, USA, 1997. [Google Scholar]

- Foster Fuels’ Mission Critical. The Effects of a Power Outage on a Business. Brookneal: Foster Fuels Emergency Response Team. Available online: https://www.fosterfuelsmissioncritical.com/power-outage-effects-businesses/ (accessed on 26 October 2019).

- Liddiard, R.; Gowreesunker, B.L.; Spataru, C.; Tomei, J.; Huebner, G. The vulnerability of refrigerated food to unstable power supplies. Energy Procedia 2017, 123, 196–203. [Google Scholar] [CrossRef]

- Oxford Business Group. The Report: Kenya 2014; Oxford Business Group: London, UK, 2014. [Google Scholar]

- World Bank. Value Lost Due to Electrical Outages (% of Sales for Affected Firms). Available online: https://data.worldbank.org/indicator/IC.FRM.OUTG.ZS (accessed on 26 October 2019).

- Ramachandran, V.; Shah, V.K.; Moss, T. How Do Ashing Firms Respond to Unreliable Power? Exploring Firm Heterogeneity Using k-Means Clustering; Center for Global Development: Washington, DC, USA, 2018. [Google Scholar]

- Kent, R. Energy Management in Plastics Processing: Strategies, Targets, Techniques, and Tools; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Topi, H.; Tucker, A. Computing Handbook: Information Systems and Information Technology; CRC: Boca Ratón, FL, USA, 2014. [Google Scholar]

- Franks, B. Taming the Big Data Tidal Wave: Finding Opportunities in Huge Data Streams with Advanced Analytics; Wiley: Chichester, UK, 2012. [Google Scholar]

- Mills, E.; Jones, R. An Insurance Perspective on U.S. Electric Grid Disruption Costs; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2016.

- U.S. Environmental Protection Agency. Valuing the Reliability of Combined Heat and Power; U.S. Environmental Protection Agency: Washington, DC, USA, 2007.

- Peters, G. Perspectives on Protecting the Electric Grid from an Electromagnetic Pulse or Geomagnetic Disturbance; U.S. Senate Committee on Homeland Security and Governmental Affairs: Washington, DC, USA, 2019. Available online: https://www.hsgac.senate.gov/imo/media/doc/Opening%20Statement-Peters-2019-02-27.pdf (accessed on 26 October 2019).

- Department of Homeland Security. Power Outage Incident Annex to the Response and Recovery Federal Interagency Operational Plans: Managing the Cascading Impacts from a Long-Term Power Outage; Department of Homeland Security: Washington, DC, USA, 2017.

- Hirschbold, M. Can Hospitals Ever Be Fully Prepared for Massive Power Outages? Schneider Electric: Rueil-Malmaison, France, 2014; Available online: https://blog.se.com/healthcare/2014/01/16/can-hospitals-ever-fully-prepared-massive-power-outages/ (accessed on 26 October 2019).

- Allen-Dumas, M.R.; Binita, K.C.; Cunliff, C.I. Extreme Weather and Climate Vulnerabilities of the Electric Grid: A Summary of Environmental Sensitivity Quantification Methods; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2019.

- Yu, W.; Pollitt, M.G. Does Liberalisation Cause More Electricity Blackouts? Evidence from a Global Study of Newspaper Reports; EPRG Working Paper 0827; University of Cambridge: Cambridge, UK, 2009. [Google Scholar]

- OSCE. Protecting Electricity Networks from Natural Hazards; Organization for Security and Co-Operation in Europe: Vienna, Austria, 2016. [Google Scholar]

- Climate Central. Available online: https://www.climatecentral.org (accessed on 20 May 2023).

- Consortium for Ocean Leadership. Natural Disasters Cost U.S. A Record $306 Billion Last Year. Available online: https://oceanleadership.org/natural-disasters-cost-u-s-record-306-billion-last-year/ (accessed on 28 October 2019).

- Stewart, S.R.; Berg, R. Hurricane Florence. Hurricane Florence (AL062018) 31 August–17 September 2018; National Hurricane Center Tropical Cyclone Report; National Hurricane Center: Miami, FL, USA, 2018.

- EIA. EIA Hurricane Michael Electricity Status Report: Tracking the Electricity Impact of Hurricane Michael on the Southeastern Region of the United States; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2018.

- May, A.; Lam, K. PG&E Keeps Nearly 60,000 Northern California Customers in the Dark to Reduce Wildfire Risk. Available online: https://eu.usatoday.com/story/money/nation-now/2018/10/15/pge-voluntarily-shut-off-power-north-california-wildfires/1646686002/ (accessed on 28 October 2019).

- Munasinghe, M. Optimal Electricity Supply: Reliability, Pricing, and System Planning; World Bank: Washington, DC, USA, 1981. [Google Scholar]

- Enchanted Rock. The Affordable Microgrid: Securing Electric Reliability through Outsourcing; Enchanted Rock: Houston, TX, USA, 2018. [Google Scholar]

- The National Academies Press. The Power of Change: Innovation for Development and Deployment of Increasingly Clean Energy Technologies; The National Academies Press: Washington, DC, USA, 2016. [Google Scholar]

- Sovacool, B.K.; Sidortsov, R.V.; Jones, B.R. Energy Security, Equality and Justice; Routledge: London, UK, 2014. [Google Scholar]

- Executive Office of the President. Economic Benefits of Increasing Electric Grid Resilience to Weather Outages; Executive Office of the President: Washington, DC, USA, 2013.

- Orlando Utilities Commission. Power Quality Analysis: Protecting Your Sensitive Business Equipment. Available online: https://www.ouc.com/business/electric-services/power-quality-analysis (accessed on 3 December 2019).

- Oseni, M.O.; Pollitt, M.G. The Economic Costs of Unsupplied Electricity: Evidence from Backup Generation among African Firms; EPRG Working Paper 1326; University of Cambridge: Cambridge, UK, 2013. [Google Scholar]

- Lazard. Levelized Cost of Energy Analysis 9.0; Lazard: Boston, MA, USA, 2016. [Google Scholar]

- Dibomaa, B.S.; Tatietse, T.T. Power interruption costs to industries in Cameroon. Energy Policy 2013, 62, 582–592. [Google Scholar] [CrossRef]

- Abdisa, L.T. Power outages, economic cost, and firm performance: Evidence from Ethiopia. Util. Policy 2018, 53, 111–120. [Google Scholar] [CrossRef]

- Szakonyi, D.; Urpelainen, J. Electricity sector reform and generators as a source of backup power: The case of India. Energy Sustain. Dev. 2013, 17, 477–481. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y. Estimation of power outage costs in the industrial sector of South Korea. Energy Policy 2017, 101, 236–245. [Google Scholar] [CrossRef]

- Wolf, A.; Wenzel, L. Regional diversity in the costs of electricity outages: Results for German counties. Util. Policy 2016, 43, 195–205. [Google Scholar] [CrossRef]

- Amoaha, A.; Ferrini, S.; Schaafsma, M. Electricity outages in Ghana: Are contingent valuation estimates valid? Energy Policy 2019, 135, 110996. [Google Scholar] [CrossRef]

- Oseni, M.O. Get rid of it: To what extent might improved reliability reduce self-generation in Nigeria? Energy Policy 2016, 93, 246–254. [Google Scholar] [CrossRef]

- Phillips, J.A.; Wallace, K.E.; Kudo, T.Y.; Eto, J.H. Onsite and Electric Power Backup Capabilities at Critical Infrastructure Facilities in the United States; Argonne National Laboratory: Lemont, IL, USA, 2016.

- The Ministry of Environment—United Nations Development Programme. National Greenhouse Gas Inventory: Report and Mitigation Analysis for the Energy Sector in Lebanon; UNDP Lebanon: Beirut, Lebanon, 2015. [Google Scholar]

- The Institute of Energy Economics, Japan. IEEJ Outlook 2019. Energy Transition and a Thorny Path for 3E Challenges: Energy, Environment and Economy; The Institute of Energy Economics, Japan: Tokyo, Japan, 2018. [Google Scholar]

- Cummins Power Generation. Peaking Power: Flexible Gas Fueled Solutions for Peak Demand; Cummins Power Generation: Columbus, OH, USA, 2012. [Google Scholar]

- Logan, J.; Marcy, C.; McCall, J.; Flores-Espino, F.; Bloom, A.; Aabakken, J.; Cole, W.; Jenkin, T.; Porro, G.; Liu, C.; et al. Electricity Generation Baseline Report; National Renewable Energy Laboratory: Denver, CO, USA, 2017.

- NERC. Special Reliability Assessment: Potential Bulk Power System Impacts Due to Severe Disruptions on the Natural Gas System; North American Electric Reliability Corporation: Atlanta, Georgia, 2017. [Google Scholar]

- Shavel, I.; Hagerty, J.M.; Powers, N.; Yang, Y. Electricity Baseline Report for the US Power System Contract No. 238857; The Brattle Group: Boston, MA, USA, 2015. [Google Scholar]

- Resource Dynamics Corporation. Market Potential for Flexible Opportunity Fuels: Industrial Steam Generation and Process Heating; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2012.

- Thomsen, N.; Wagner, T.; Hoisington, A.; Schuldt, S. A sustainable prototype for renewable energy: Optimized prime-power generator solar array replacement. Int. J. Energy Prod. Manag. 2019, 4, 28–39. [Google Scholar] [CrossRef]

- The Electric Infrastructure Security (EIS) Council. Electric Infrastructure Protection Handbook II: Volume 1—Fuel Resilient Fuel Resources for Power Generation in Black Sky Events; The Electric Infrastructure Security Council: Washington, DC, USA, 2016. [Google Scholar]

- Wellington, L.G. Prepare Today: Survive Tomorrow; Blue Star Books: Santa Cruz, CA, USA, 2013. [Google Scholar]

- BP. Long Term Storage of Diesel. Available online: https://www.bp.com/content/dam/bp-country/en_au/media/fuel-news/long-term-storage-diesel.pdf (accessed on 18 December 2019).

- NESCAUM. Air Quality, Electricity, and Backup Stationary Diesel Engines in the Northeast; NESCAUM: Boston, MA, USA, 2012. [Google Scholar]

- Garcia, A.; Bailer, T.; Keogh, M.; Castelli, B. Integrating Public Health and Environmental Protection into Demand Response Programs; Center for Energy and Climate Solutions: Arlington, IL, USA, 2002. [Google Scholar]

- Ma, Z.; Eichman, J.; Kurtz, J. Fuel Cell Backup Power Unit Configuration and Electricity Market Participation: A Feasibility Study; National Renewable Energy Laboratory: Denver, CO, USA, 2017.

- Gilmore, E.A.; Lave, L.B. Increasing Backup Generation Capacity and System Reliability by Selling Electricity during Periods of Peak Demand. Available online: https://www.usaee.org/usaee2007/submissions/OnlineProceedings/7480-Gilmore_Lave_ConfProceedings.pdf (accessed on 21 December 2019).

- Nuclear Energy Institute. Regulatory Assessment Performance Indicator Guideline; Nuclear Energy Institute: Washington, DC, USA, 2013. Available online: https://www.nrc.gov/docs/ML1326/ML13261A116.pdf (accessed on 21 December 2019).

- Mrowca, B. Emergency Diesel Generator Failure Review 1999–2001; Information Systems Laboratories: Rockville, MD, USA, 2011. Available online: https://www.nrc.gov/docs/ML1125/ML11259A101.pdf (accessed on 21 December 2019).

- Robinson, D.; Atcitty, C.; Zuffranieri, J.; Arent, D. Impact of Distributed Energy Resources on the Reliability of a Critical Telecommunications Facility; Sandia National Laboratories: Albuquerque, NM, USA, 2006.

- Divine, T. Power-Generation Systems in High-Performance Buildings. Available online: https://www.csemag.com/articles/power-generation-systems-in-high-performance-buildings/?OCVALIDATE= (accessed on 26 January 2020).

- Lam, N.L.; Wallach, E.; Hsu, C.W.; Jacobson, A.; Alstone, P.; Purohit, P.; Klimont, Z. The Dirty Footprint of the Broken Grid the Impacts of Fossil Fuel Backup Generators in Developing Countries; International Finance Corporation: Washington, DC, USA, 2019. [Google Scholar]

- Samanta, P.; Kim, I.; Uryasev, S.; Penoyar, J.; Vesely, W. Emergency Diesel Generator: Maintenance and Failure Unavailability, and Their Risk Impacts; Brookhaven National Laboratory: New York, NY, USA, 1994.

- Schroeder, J.A. Enhanced Component Performance Study: Emergency Diesel Generators 1998–2016; Idaho National Laboratory: Idaho Falls, ID, USA, 2018. Available online: https://inldigitallibrary.inl.gov/sites/sti/sti/6618432.pdf (accessed on 26 January 2020).

- U.S. Nuclear Regulatory Commission. Component Reliability Data Sheets 2015 Update. Available online: https://nrcoe.inl.gov/resultsdb/publicdocs/AvgPerf/ComponentReliabilityDataSheets2015.pdf (accessed on 26 January 2020).

- Harmsen, N. Energy Market Operator Issues Mixed Blackout Forecast for SA, Victoria during Summer. Available online: https://www.abc.net.au/news/2017-09-06/aemo-forecast-mixed-blackout-risk-for-south-australia-victoria/8875798 (accessed on 26 January 2020).

- Prada, J.F. The Value of Reliability in Power Systems—Pricing Operating Reserves; Massachusetts Institute of Technology: Cambridge, MA, USA, 1999. [Google Scholar]

- Winfield, D.J. Long term reliability analysis of standby diesel generators. Reliab. Eng. Syst. Saf. 1988, 21, 293–308. [Google Scholar] [CrossRef]

- Mannan, S. Lees’ Loss Prevention in the Process Industries: Hazard Identification, Assessment and Control, 3rd ed.; Elsevier: Burlington, MA, USA, 2013; Volume 1. [Google Scholar]

- Fairfax, S.; Dowling, N.; Weidknecht, P. Reliability assessment of a large diesel generator fleet. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar]

- Working Group 9. Infrastructure Sharing during Emergencies Backup Power Subcommittee Shared Services; The Communications, Security, Reliability and Interoperability Council IV: Washington, DC, USA, 2015.

- ASCO Power Technologies. White Paper Can Building Codes Ensure Power Reliability? ASCO Power Technologies: Florham Park, NJ, USA, 2017. [Google Scholar]

- Anderson, K.; Laws, N.D.; Marr, S.; Lisell, L.; Jimenez, T.; Case, T.; Li, X.; Lohmann, D.; Cutler, D. Quantifying and monetizing renewable energy resiliency. Sustainability 2018, 10, 933. [Google Scholar]

- Grizard, E. Diesel Generators Are Not the Answer to Today’s Energy Blackouts. Available online: https://www.bloomenergy.com/blog/diesel-generators-are-not-answer-todays-energy-blackouts (accessed on 28 January 2020).

- Ruud, C. Why Not Go Green?—An Analysis of the Viability of Solar PV Mini-Grids in Tanzania; Norwegian University of Life Sciences: As, Norway, 2013. [Google Scholar]

- Vreeburg, H. Supporting Continuity: The Impact of Fuel. Available online: https://datacenter.com/news_and_insight/supporting-continuity-the-impact-of-fuel/ (accessed on 2 February 2020).

- Petrol, D.D. Distribution Systems for Natural Gas. Available online: https://www.petrol.eu/companies-and-services/business-solutions/solutions/natural-gas-distribution-systems (accessed on 2 February 2020).

- ActewAGL. Distribution 2017–21 Access Arrangement Information Act Gas Networks Asset Management Plan RY16–RY21. Available online: https://www.aer.gov.au/system/files/ActewAGL%20Distribution%20AAI%20Appendix%206.01%20-%20Asset%20Management%20Plan%20-%20July%202015.pdf (accessed on 2 February 2020).

- Generac Power Systems, Inc. Natural Gas Reliability the Pipeline Is Strong; Regional Acceptance is Growing. Available online: https://www.generac.com/Industrial/all-about/natural-gas-fuel/natural-gas-reliability/the-pipeline-is-strong (accessed on 2 February 2020).

- Bloomer, C. What Pipeline Companies Are Doing to Keep Their Operations Safe. Available online: https://cepa.com/wp-content/uploads/2018/07/2018_PipelineOperations_ENG.pdf (accessed on 2 February 2020).

- Walker, I.R. Reliability in Scientific Research: Improving the Dependability of Measurements, Calculations, Equipment and Software; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- British Geological Survey. Underground Natural Gas Storage in the UK. Available online: https://www.bgs.ac.uk/research/energy/undergroundGasStorage.html (accessed on 4 May 2020).

- Folga, S.; Talaber, L.; McLamore, M.; Kraucunas, I.; McPherson, T.; Parrott, L.; Manzanares, T. Literature Review and Synthesis for the Natural Gas Infrastructure; Argonne National Laboratory: Argonne, IL, USA, 2015.

- Natural Gas Council. Natural Gas Systems: Reliable & Resilient; Natural Gas Council: Washington, DC, USA, 2017. [Google Scholar]

- American Petroleum Institute. Supporting the American Way of Life: The Importance of Natural Gas Storage; American Petroleum Institute: Washington, DC, USA, 2016. [Google Scholar]

- U.S. Energy Information Administration. The Basics of Underground Natural Gas Storage. Available online: https://www.eia.gov/naturalgas/storage/basics/ (accessed on 4 May 2020).

- Fuel Cell and Hydrogen Energy Association. Resiliency of Stationary Fuel Cells and the Natural Gas Grid. Available online: https://www.wbdg.org/resources/resiliency-stationary-fuel-cells-and-natural-gas-grid (accessed on 4 May 2020).

- Clarke, C. On the Road to a Green Energy UK: Integrated Gas & Electricity Networks Support the Journey; Wales & West Utilities: Newport, RI, USA, 2017. [Google Scholar]

- Liss, W.; Rowley, P. Assessment of Natural Gas and Electric Distribution Service Reliability; Gas Technology Institute: Des Plaines, IL, USA, 2018. [Google Scholar]

- Li, T.; Eremia, M.; Shahidehpour, M. Interdependency of Natural Gas Network and Power System Security. IEEE Trans. Power Syst. 2008, 23, 1817–1824. [Google Scholar] [CrossRef]

- ICF. Case Studies of Natural Gas Sector Resilience Following Four Climate-Related Disasters in 2017; SoCalGas: Los Angeles, CA, USA, 2018. [Google Scholar]

- FPI. Securely Connected: An Assessment of the Contribution of Interconnectors to Security of Supply in Great Britain; FTI Consulting LLP: London, UK, 2019. [Google Scholar]

- State of New Jersey. State of New Jersey 2019 Hazard Mitigation Plan: Power Failure; State of New Jersey: Trenton, NJ, USA, 2019.

- Apt, J.; Freeman, G.; Dworkin, M. The Natural Gas Grid Needs Better Monitoring. Available online: https://issues.org/the-natural-gas-grid-needs-better-monitoring/ (accessed on 4 May 2020).

- NERC. 2013 Special Reliability Assessment: Accommodating an Increased Dependence on Natural Gas for Electric Power Phase II: A Vulnerability and Scenario Assessment for the North American Bulk Power System; North American Electric Reliability Corporation: Washington, DC, USA, 2013. [Google Scholar]

- FEMA. The California Fires Coordination Group: A Report to the Secretary of Homeland Security; Office of the Under Secretary, U.S. Department of Homeland Security: Washington, DC, USA, 2004.

- NERC. February 2011 Southwest Cold Weather Event. Available online: https://www.nerc.com/pa/rrm/ea/Pages/February-2011-Southwest-Cold-Weather-Event.aspx (accessed on 4 May 2020).

- NERC. Hurricane Sandy Event Analysis Report; North American Electric Reliability Corporation: Washington, DC, USA, 2014. [Google Scholar]

- SDG&E. San Diego Gas & Electric Company Prepared Direct Testimony of Concentric Energy Advisors Wildfire Risk Premium; San Diego Gas & Electric Company: San Diego, CA, USA, 2019. [Google Scholar]

- PG&E. Response to Notice Re California Wildfires; Pacific Gas and Electric Company: San Francisco, CA, USA, 2019. [Google Scholar]

- Office of Cybersecurity, Energy Security, and Emergency Response. California Wildfires—Energy Infrastructure Impacts October 30, 2003; Office of Cybersecurity, Energy Security, and Emergency Response: Washington, DC, USA, 2003.

- FERC. Report on Outages and Curtailments during the Southwest Cold Weather Event of February1–5, 2011: Causes and Recommendations; Federal Energy Regulatory Commission: Washington, DC, USA, 2011.

- NCDP. After Hurricane Sandy: Lessons Learned for Bolstering Energy Resilience; National Center for Disaster Preparedness at the Earth Institute: New York, NY, USA, 2013. [Google Scholar]

- DOE. Comparing the Impacts of Northeast Hurricanes on Energy Infrastructure; Office of Electricity Delivery and Energy Reliability-U.S. Department of Energy: Washington, DC, USA, 2013.

- City of Tracy. Exhibit B: Technical Specifications for Gasoline and Diesel Fuel Supplier 2018–2020. Available online: https://www.cityoftracy.org/documents/20180918_CC_AP.pdf (accessed on 4 May 2020).

- Willis, H.L.; Rashid, M.H. Protective Relaying: Principles and Applications, 3rd ed.; CRC Press: Boca Ratón, FL, USA, 2006. [Google Scholar]

- Clifford Power. 10 Things to Consider When Purchasing an Automatic Standby Generator for Business. Available online: https://www.cliffordpower.com/10-things-to-consider-when-purchasing-an-automatic-standby-generator-for-business/ (accessed on 4 May 2020).

- Kurtz, J.; Saur, G.; Sprik, S.; Ainscough, C. Backup Power Cost of Ownership Analysis and Incumbent Technology Comparison; National Renewable Energy Laboratory: Denver, CO, USA, 2014.

- Hudson, C.R. Cost Estimate Guidelines for Advanced Nuclear Power Technologies; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1986.

- Myers, M.L.; Fuller, L.C. A Procedure for Estimating Nonfuel Operation and Maintenance Costs for Large Steam-Electric Power Plants; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1979.

- Economic Modeling Working Group. Cost Estimating Guidelines for Generation IV Nuclear Energy Systems; OECD: Paris, France, 2007. [Google Scholar]

- Asian Development Bank. Handbook on Battery Energy Storage System; Asian Development Bank: Manila, Philippines, 2018. [Google Scholar]

- Ma, Z.; Eichman, J.; Kurtz, J. Fuel Cell Backup Power System for Grid Server and Micro-Grid in Telecommunication Applications; National Renewable Energy Laboratory: Denver, CO, USA, 2018.

- Vasallo, M.J.; Andujar, J.M.; Garcia, C.; Brey, J. A methodology for sizing backup fuel-cell/battery hybrid power systems. IEEE Trans. Ind. Electron. 2010, 57, 1964–1975. [Google Scholar] [CrossRef]

- Oluwaseun, B. Ogunmodede—Modeling and Solving Large-Scale Optimization Problems: Case Studies in Renewable Energy and Mining; Colorado School of Mines: Golden, CO, USA, 2021. [Google Scholar]

- GENERAC. Diesel, Natural Gas, Dual-Fuel, Bi-Fuel… How Do I Choose? Available online: https://www.generac.com/Industrial/all-about/selecting-the-best-fuel-option (accessed on 6 May 2020).

- Crouch, M. Fuel Cell Systems for Base Stations: Deep Dive Study; GSMA: London, UK, 2011. [Google Scholar]

- Wolfram, C. Measuring the Economic Costs of Electricity Outages. Available online: https://blogs.berkeley.edu/2012/11/07/measuring-the-economic-costs-of-electricity-outages/ (accessed on 6 May 2020).

- Schmid, E. The Cost of Blackouts in Europe. Available online: https://cordis.europa.eu/article/id/126674-the-cost-of-blackouts-in-europe (accessed on 6 May 2020).

- Anderson, K.; Hotchkiss, E.; Murphy, C. Valuing Resilience in Electricity Systems; National Renewable Energy Laboratory: Denver, CO, USA, 2019.

- Lazard. Lazard’s Levelized Cost of Energy Analysis—Version 11.0; Lazard: Boston, MA, USA, 2017. [Google Scholar]

- Kirchner, M. Understanding Backup Power System Fuel Choices: Why Diesel Remains Popular as a Fuel Supply, Engineers Have Several Additional Fuel Options from Which to Choose. Available online: https://www.csemag.com/articles/understanding-backup-power-system-fuel-choices/ (accessed on 6 May 2020).

- Stamp, J.E.; Baca, M.J.; Munoz-Ramos, K.; Schenkman, B.L.; Eddy, J.P.; Smith, M.A.; Guttromson, R.; Henry, J.M.; Jensen, R.P. City of Hoboken Energy Surety Analysis: Preliminary Design Summary; Sandia National Laboratories: Albuquerque, NM, USA, 2014.

- DOE. Backup Power Sources for DOE Facilities; U.S. Department of Energy: Washington, DC, USA, 2000.

- Center for Chemical Process Safety. Guidelines for Safe and Reliable Instrumented Protective Systems; Wiley: Chichester, UK, 2007. [Google Scholar]

- Benth, F.E.; Kholodnyi, V.A.; Laurence, P. Quantitative Energy Finance: Modeling, Pricing, and Hedging in Energy and Commodity Markets; Springer Science+Business Media: New York, NY, USA, 2014. [Google Scholar]

- NRCAN. Natural Gas in Remote and Northern Communities and Industry; Natural Resources Canada: Gatineau, QC, Canada, 2018.

- Olser, C. Diesel & Thermal Electricity Generation Options; Intergroup Consultants: Winnipeg, MB, Canada, 2011. [Google Scholar]

- Pramac. Continuous Power without the Hassle of Refueling. Available online: https://www.pramac.com/gas2 (accessed on 8 May 2020).

- Ericson, S.; Lisell, L. A flexible framework for modeling customer damage functions for power outages. Energy Syst. 2020, 11, 95–111. [Google Scholar] [CrossRef]

- United States Congress. New York Blackout of July 13, 1977: Costs and Preventive Act on: Hearing before the Subcommittee on Energy and Power of the Committee on Interstate and Foreign Commerce, House of Representatives, Ninety-Fifth Congress, Second Session; United States Congress: Washington, DC, USA, 1978.

- Erockhld. Next Generation Data Center Backup Power Systems; Enchanted Rock: Houston, TX, USA, 2018. [Google Scholar]

- Pfeifenberger, J.; Spees, K.; Chang, J.; Aydin, M.G.; Graf, W.; Cahill, P. The Future of Ontario’s Electricity Market: A Benefits Case Assessment of the Market Renewal Project; The Brattle Group: Boston, MA, USA, 2017. [Google Scholar]

- Hirwa, J.; Ogunmodede, O.; Zolan, A.; Newman, A.M. Optimizing design and dispatch of a renewable energy system with combined heat and power. Optim. Eng. 2022, 23, 1–31. [Google Scholar] [CrossRef]

- Ratkiewich, R.; Enis, J.; Resiliency and Microgrid Team; California Public Utilities Commission. Value of Resiliency—4 Pillar Methodology; Mitigation Measure Assessment and presentations by Sandia and Lawrence Berkeley National Labs: Pillar 2, USA; 2021. [Google Scholar]

- Krah, K. Reopt® Lite Overview-Resilience Analysis: Clear Sky Tampa Bay; NREL: Golden, CO, USA, 2021.

- NJ.com. Sandy Causes N.J. Supermarket to Close up Shop after 84 Years. Available online: https://www.nj.com/news/2012/11/sandy_causes_nj_supermarket_to.html (accessed on 8 May 2020).

- Public Broadcasting Service. Sandy Causes Only Supermarket in South Amboy to Close. Available online: https://www.pbs.org/video/njtoday-sandy-causes-only-supermarket-south-amboy-close/ (accessed on 8 May 2020).

- US Office of Energy Efficiency & Renewable Energy. Commercial Reference Buildings. Available online: https://www.energy.gov/eere/buildings/commercial-reference-buildings (accessed on 8 May 2020).

- Deru, M.; Field, K.; Studer, D.; Benne, K.; Griffith, B.; Torcellini, P.; Liu, B.; Halverson, M.; Winiarski, D.; Rosenberg, M.; et al. U.S. Department of Energy Commercial Reference Building Models of the National Building Stock; National Renewable Energy Laboratory: Denver, CO, USA, 2011.

- U.S. Energy Information Administration. U.S. Electric System Operating Data. Available online: https://www.eia.gov/realtime_grid (accessed on 8 May 2020).

- Anderson, K.H.; Cutler, D.S.; Olis, D.R.; Elgqvist, E.M.; Li, X.; Laws, N.D.; DiOrio, N.A.; Walker, H.A. Reopt: A Platform for Energy System Integration and Optimization; National Renewable Energy Laboratory: Denver, CO, USA, 2017.

- U.S. Energy Information Administration. Henry Hub Natural Gas Spot Price. Available online: https://www.eia.gov/dnav/ng/hist/rngwhhdD.htm (accessed on 10 May 2020).

- U.S. Energy Information Administration. Natural Gas Prices. Available online: https://www.eia.gov/dnav/ng/ng_pri_sum_dcu_SNJ_a.htm (accessed on 8 May 2020).

- COMSTAT. Natural Gas Price Forecast: 2020, 2021 and Long Term to 2050. Available online: https://comstat.comesa.int/ncszerf/natural-gas-price-forecast-2020-2021-and-long-term-to-2030 (accessed on 8 May 2020).

- DNV GL AS. Oil and Gas Forecast to 2050: Energy Transition Outlook 2017; DNV GL AS: Høvik, Norway, 2017. [Google Scholar]

- U.S. Energy Information Administration. Natural Gas. Available online: https://www.eia.gov/outlooks/aeo/pdf/AEO2020%20Natural%20Gas.pdf (accessed on 8 May 2020).

- Carl, J.; Talbott, S. Distributed Power in the United States: Prospects and Policies; Hoover Institution Press: Stanford, CA, USA, 2013. [Google Scholar]

- California Council on Science and Technology. Biomethane in California Common Carrier Pipelines: Assessing Heating Value and Maximum Siloxane Specifications; California Council on Science and Technology: Sacramento, CA, USA, 2018. [Google Scholar]

- Lambert, M. Biogas: A Significant Contribution to Ashingtonng Gas Markets? Oxford University: Oxford, UK, 2017. [Google Scholar]

- Milbrandt, A.; Bush, B.; Melaina, M. Biogas and Hydrogen Systems Market Assessment; National Renewable Energy Laboratory: Golden, CO, USA, 2016.

- National Petroleum Council. Renewable Natural Gas for Transportation: An Overview of the Feedstock Capacity, Economics, and GHG Emission Reduction Benefits of RNG as a Low-Carbon Fuel; National Petroleum Council: Washington, DC, USA, 2012. [Google Scholar]

- Cooley, D.; Murray, B.; Ross, M.; Lee, M.Y.; Yeh, K. An Economic Evaluation of North Carolina’s Landfill Biogas Development Potential; Duke Nicholas Institute: Durham, NC, USA, 2013. [Google Scholar]

- New York Economic Development Corporation. Hunts Point Anaerobic Digestion Feasibility Study; New York Economic Development Corporation: New York, NY, USA, 2010. [Google Scholar]

- Summers, M.D.; Williams, D.W.; Yazdani, R.; De Long, S.K. Optimizing Biogas Production from Organic Waste through RNA/DNA Molecular Testing; California Energy Commission: Sacramento, CA, USA, 2015.

- Ely, C.; Williams, R.; Martynowicz, T.; Kosusko, M. Evaluating Biogas Management Technologies. Available online: https://www.biocycle.net/2016/10/24/evaluating-biogas-management-technologies/ (accessed on 11 June 2020).

- U.S. Energy Information Administration. Petroleum & Other Liquids. Available online: https://www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=PET&s=EMD_EPD2D_PTE_NUS_DPG&f=W (accessed on 10 May 2020).

- U.S. Energy Information Administration. Conversion Factors. Available online: https://www.eia.gov/outlooks/aeo/pdf/appg.pdf (accessed on 10 May 2020).

- U.S. Energy Information Administration. Thermal Conversion Factor Source Documentation. Available online: https://www.eia.gov/totalenergy/data/monthly/pdf/sec12_a_doc.pdf (accessed on 10 May 2020).

- U.S. Energy Information Administration. Petroleum & Other Liquids. Gasoline and Diesel Fuel Update. Available online: https://www.eia.gov/petroleum/gasdiesel/ (accessed on 10 May 2020).

- U.S. Energy Information Administration. Electricity. Available online: https://www.eia.gov/outlooks/aeo/pdf/AEO2020%20Electricity.pdf (accessed on 10 May 2020).

- Energy STAR. Energy STAR Building Manual. 11. Facility Type: Supermarkets and Grocery Stores. Revised January 2008; Energy STAR: Charlotte, NC, USA, 2008. [Google Scholar]

- DSO Electric Cooperative. Managing Energy Costs in Grocery Stores; DSO Electric Cooperative: Solomon, KS, USA, 2004. [Google Scholar]

- Rosales-Asensio, E.; de Simón-Martín, M.; Rosales, A.-E.; Colmenar-Santos, A. Solar-plus-storage benefits for end-users placed at radial and meshed grids: An economic and resiliency analysis. Int. J. Electr. Power Energy Syst. 2021, 128, 106675. [Google Scholar] [CrossRef]

- Generac. MD500, 15.2 L, 500 kW: Industrial Diesel Generator Set; Generac Power Systems: Waukesha, WI, USA, 2019. [Google Scholar]

- Generac. MG500, 25.8 L, 500 kW: Industrial Spark-Ignited Generator Set; Generac Power Systems: Waukesha, WI, USA, 2019. [Google Scholar]

- Badea, N. Design for Micro-Combined Cooling, Heating and Power Systems; Springer: Berlin, Germany, 2015. [Google Scholar]

- Portland General Electric. Non-Solar Distributed Generation Market Research; Portland General Electric: Portland, OR, USA, 2015. [Google Scholar]

- Goldstein, L.; Hedman, B.; Knowles, D.; Freedman, S.I.; Woods, R.; Schweizer, T. Gas-Fired Distributed Energy Resource Technology Characterizations; National Renewable Energy Laboratory: Golden, CO, USA, 2003.

- Omogoye, O.S.; Ogundare, A.B.; Akanji, I.O. Development of a cost-effective solar/diesel independent power plant for a remote station. J. Energy 2015, 2015, 828745. [Google Scholar] [CrossRef][Green Version]

- Powermag. Diesel Gensets Aim at the Future. Available online: https://www.powermag.com/diesel-gensets-aim-at-the-future/ (accessed on 11 May 2020).

- U.S. Energy Information Administration. Table 8.2. Average Tested Heat Rates by Prime Mover and Energy Source, 2008–2018. Available online: https://www.eia.gov/electricity/annual/html/epa_08_02.html (accessed on 11 May 2020).

- U.S. Energy Information Administration. Table A6 Approximate Heat Rates for Electricity, and Heat Content of Electricity. Available online: https://www.eia.gov/totalenergy/data/browser/index.php?tbl=TA6#/?f=A&start=1949&end=2019&charted=5-6-7-8 (accessed on 11 May 2020).

- U.S. Energy Information Administration. Table 8.1. Average Operating Heat Rate for Selected Energy Sources. Available online: https://www.eia.gov/electricity/annual/html/epa_08_01.html (accessed on 11 May 2020).

- Energy and Environmental Analysis. Advanced Microturbine System: Market Assessment; Oak Ridge National Laboratory: Washington, DC, USA, 2003.

- Groh, S.; Van der Straeten, J.; Lasch, B.E.; Gershenson, D.; Leal Filho, W.; Kammen, D.M. Decentralized Solutions for Developing Economies Addressing Energy Poverty through Innovation; Springer Briefs in Energy: Berlin, Germany, 2015. [Google Scholar]

- Oktoviano, G.; Dipti, S. Sustainable Energy Solutions for Remote Areas in the Tropics; Springer: Berlin, Germany, 2020. [Google Scholar]

- FERC. 2010 ISO/TRO Metrics Report, ISO New England (ISO-NE): Appendix F; Federal Energy Regulatory Commission: Washington, DC, USA, 2010.

- FERC. 2015 ISO/TRO Metrics Report; Federal Energy Regulatory Commission: Washington, DC, USA, 2015.

- Capstone Turbine Corporation. Secure Power Uninterruptible Power Solutions. Available online: https://d16a519alwszqc.cloudfront.net/_f59d74a9c2538abc9cedbf55d1d830c6/capstoneturbine/db/204/6496/file/Secure+Power+Brochure_lowres.pdf (accessed on 13 June 2020).

- United States General Accounting Office. Energy Markets: Additional Actions Would Help Ensure That FERC’s Oversight and Enforcement Capability Is Comprehensive and Systematic; United States General Accounting Office: Washington, DC, USA, 2003.

- PJM. New Jersey State Report: July 2017; PJM: Norristown, PA, USA, 2017. [Google Scholar]

- OpenEI. Rate Schedule GLP—General Lighting and Power Service. Available online: https://openei.org/apps/USURDB/rate/view/5d0a74865457a33e46474944 (accessed on 13 May 2020).

- Public Service and Gas Company. Tariff for Electric Service; Public Service Electric and Gas Company: Newark, NJ, USA, 2018. [Google Scholar]

- PSEG. Summary of Electric and Gas Rate Schedules: For Commercial and Industrial Customers; Public Service Electric and Gas Company: Newark, NJ, USA, 2019. [Google Scholar]

- State of New Jersey: Board of Public Utilities. BGS Auction. Available online: https://www.state.nj.us/bpu/about/divisions/energy/bgs.html (accessed on 13 May 2020).

- Interruption Cost Estimate (ICE) Calculator. Lawrence Berkeley Nationa Laboratory and Nexant, Inc. Available online: https://icecalculator.com/interruption-cost (accessed on 13 May 2020).

| Event | Year | Power Outages (Total Number of Users) | Natural Gas Interruptions (Total Number of Users) | Percentage of Coinciding Interruptions |

|---|---|---|---|---|

| California wildfires 2003 [94] | 2003 | 58,700 [99] | 1000 [99] | 1.70% |

| February 2011 Southwest Cold Weather Event [95] | 2011 | 4,400,000 [100] | 50,000 [100] | 1.13% |

| Hurricane Sandy (New Jersey) [96] | 2012 | 2,615,291 [101,102] | 32,000 [101,102] | 1.22% |

| Hurricane Sandy (New York) [96] | 2012 | 2,097,933 [101,102] | 80,000 [101] | 3.06% |

| California wildfires 2017 (San Diego Gas & Electric Company) [97] | 2017 | 85,000 [89] | 4800 [89] | 5.65% |

| California wildfires 2017 (Pacific Gas and Electric Company) [98] | 2017 | 359,000 [89] | 42,000 [89] | 11.70% |

| Type of Failure | Reference Estimate | Lower Range | Upper Range |

|---|---|---|---|

| Failure to start (standby demand) [68] | 0.67% | 0.33% | 1.48% |

| Failure to start (load demand) [68] | 0.15% | 0.08% | 0.3% |

| Failure to run (standby demand) [68] | 0.172% | 0.086% | 0.346% |

| Failure to run (load demand) [68] | 0.086% | 0.043% | 0.173% |

| Diesel fuel supply [40,103] | 36 h | 18 h | 72 h |

| Fuel supply failure (natural gas long-duration) [89,94,95,96,97,98,99,100,101,102] | 1.5% | 0.75% | 3% |

| Monthly Peak Demand (kW) | |

|---|---|

| Month | |

| January | 344.89 |

| February | 322.55 |

| March | 362.03 |

| April | 356.71 |

| May | 389.22 |

| June | 453.46 |

| July | 481.46 |

| August | 469.61 |

| September | 415.77 |

| October | 387.56 |

| November | 375.90 |

| December | 348.00 |

| TOTAL ENERGY (kWh) | 2,018,760 |

| AVERAGE LOAD (kW) | 230.45 |

| MAXIMUM ANNUAL PEAK DEMAND (kW) | 481.46 |

| Generator Type | DG | NGG | BMT |

|---|---|---|---|

| Fixed, one-time expenses incurred on the purchase (USD/kW) [119,124] | 264 | 792 | 1185 |

| Operation and maintenance costs (USD/kW/year) [121] | 20 | 30 | 8 |

| Annual increase in maintenance costs | 2% | 2% | 2% |

| Variation in Fuel Costs and Electricity Tariffs | |

|---|---|

| Cost of natural gas (USD/kWh), Year 0 [141,142,143,144,145] | 753.2 |

| Cost of biomethane (USD/kWh), Year 0 [146,147,148,149,150,151,152,153,154] | 2840 |

| Cost of diesel (USD/kWh), Year 0 [155,156,157] | 5504 |

| Cost of diesel (USD/gallon), Year 0 [155] | 11.73 |

| Cost of electricity | Variable according to tariff |

| Annual increase in the cost of natural gas [143,144,145] | 2.2% |

| Annual increase in the cost of biomethane [146] | 2.5% |

| Annual increase in the cost of diesel [158] | 1.3% |

| Annual increase in the cost of electricity [159] | −0.15% |

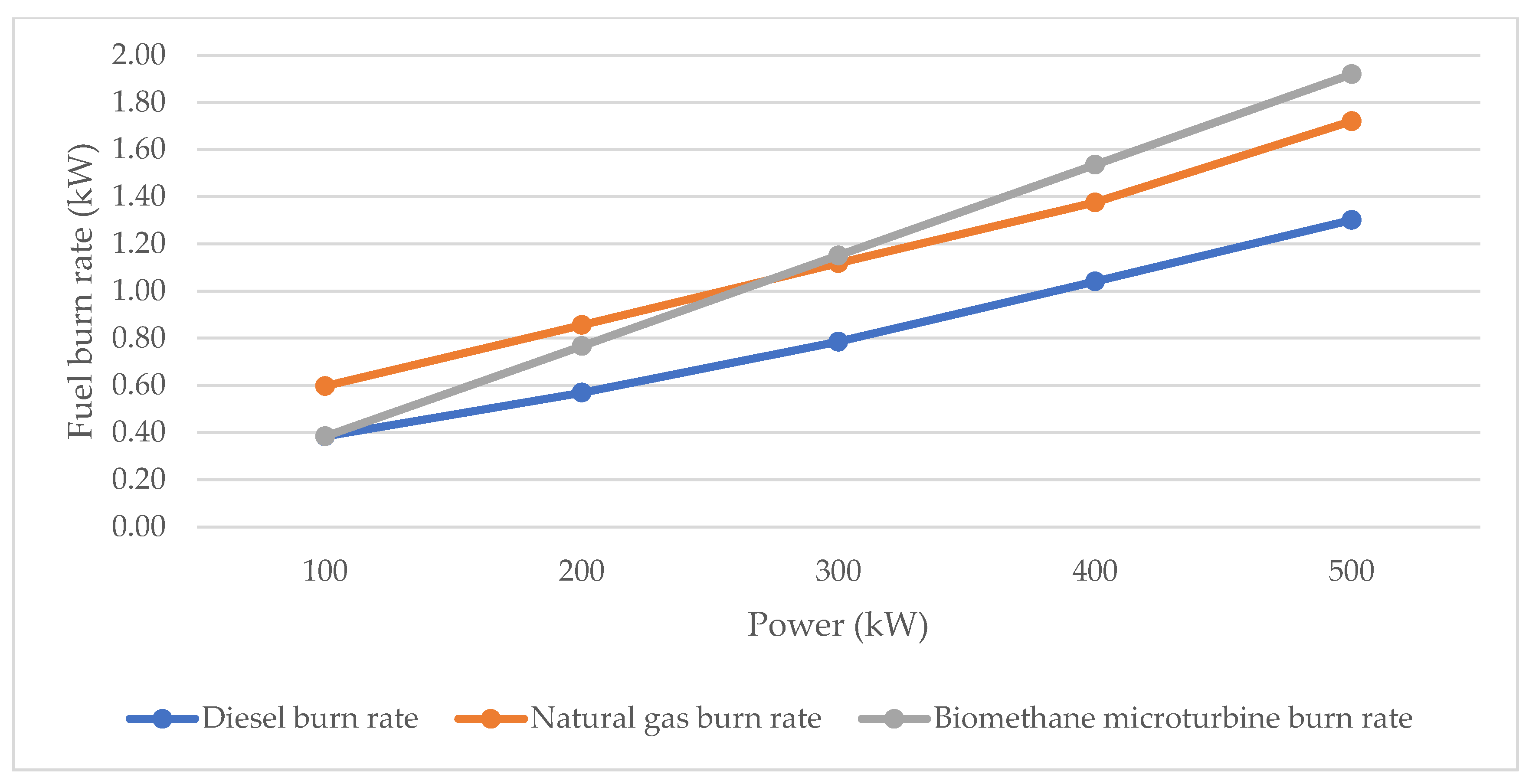

| Generator Type | Diesel (l/h) [163] | Diesel (US Gallon/h) | Diesel (kW) | Natural Gas (m3/h) [164] | Natural Gas (kW) | Biomethane Microturbine (l/h) | Biomethane Microturbine (kW) [165,166,167] |

|---|---|---|---|---|---|---|---|

| Percentage of load at 25% | 42.28 | 11.17 | 454.26 | 72 | 747.33 | 44.74 | 480.64 |

| Percentage of load at 50% | 66.28 | 17.51 | 712.16 | 103 | 1069.71 | 89.22 | 958.34 |

| Percentage of load at 75% | 91.42 | 24.15 | 981.79 | 135 | 1397.95 | 133.93 | 1438.98 |

| Percentage load at 100% | 121.13 | 32.00 | 1301.24 | 166 | 1720.33 | 178.67 | 1919.62 |

| Generator Type | Diesel Engine | Natural Gas Engine | Biomethane Microturbine |

|---|---|---|---|

| Plant size (MW) | 0.35 to 0.5 | 0.35 to 0.5 | 0.35 to 0.5 |

| Fuel cost (USD/kWh) | 5504 | 753.2 | 2840 |

| Amount of thermal energy needed to generate one electrical kWh (heat rate) [170,171,172,173] | 3.08 | 2.64 | 3.27 |

| Fixed operation and maintenance costs (USD/kW-y) | 20 | 30 | 8 |

| Variable operation and maintenance costs (USD/kW-y) | 0 | 0 | 0 |

| Costs necessary for the construction of the plant without considering interest rates | 264 | 792 | 1185 |

| Interest rate [119,174,175] | 8.3% | 8.3% | 8.3% |

| Mortgage period (years) | 20 | 20 | 20 |

| Year | 2010 | 2011 | 2012 | 2013 |

|---|---|---|---|---|

| Diesel reliability (%) | 93.3 | 93.2 | 92.2 | 93.5 |

| Natural gas reliability (%) Difference (taking diesel engine reliability as a reference) (%) | 95.8 +2.5 | 95.9 +2.7 | 96.1 +3.9 | 96.4 +2.9 |

| Biomethane microturbines (%) (Set of 7 microturbines working in an emergency backup mode) Difference (taking diesel engine reliability as a reference) (%) | 99.9 +6.6 | 99.9 +6.7 | 99.9 +7.2 | 99.9 +6.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosales-Asensio, E.; de Loma-Osorio, I.; Açıkkalp, E.; Borge-Diez, D. Biomethane Microturbines as a Storage-Free Dispatchable Solution for Resilient Critical Buildings. Buildings 2023, 13, 2516. https://doi.org/10.3390/buildings13102516

Rosales-Asensio E, de Loma-Osorio I, Açıkkalp E, Borge-Diez D. Biomethane Microturbines as a Storage-Free Dispatchable Solution for Resilient Critical Buildings. Buildings. 2023; 13(10):2516. https://doi.org/10.3390/buildings13102516

Chicago/Turabian StyleRosales-Asensio, Enrique, Iker de Loma-Osorio, Emin Açıkkalp, and David Borge-Diez. 2023. "Biomethane Microturbines as a Storage-Free Dispatchable Solution for Resilient Critical Buildings" Buildings 13, no. 10: 2516. https://doi.org/10.3390/buildings13102516

APA StyleRosales-Asensio, E., de Loma-Osorio, I., Açıkkalp, E., & Borge-Diez, D. (2023). Biomethane Microturbines as a Storage-Free Dispatchable Solution for Resilient Critical Buildings. Buildings, 13(10), 2516. https://doi.org/10.3390/buildings13102516