A Bibliometric and Content Review of Carbon Emission Analysis for Building Construction

Abstract

1. Introduction

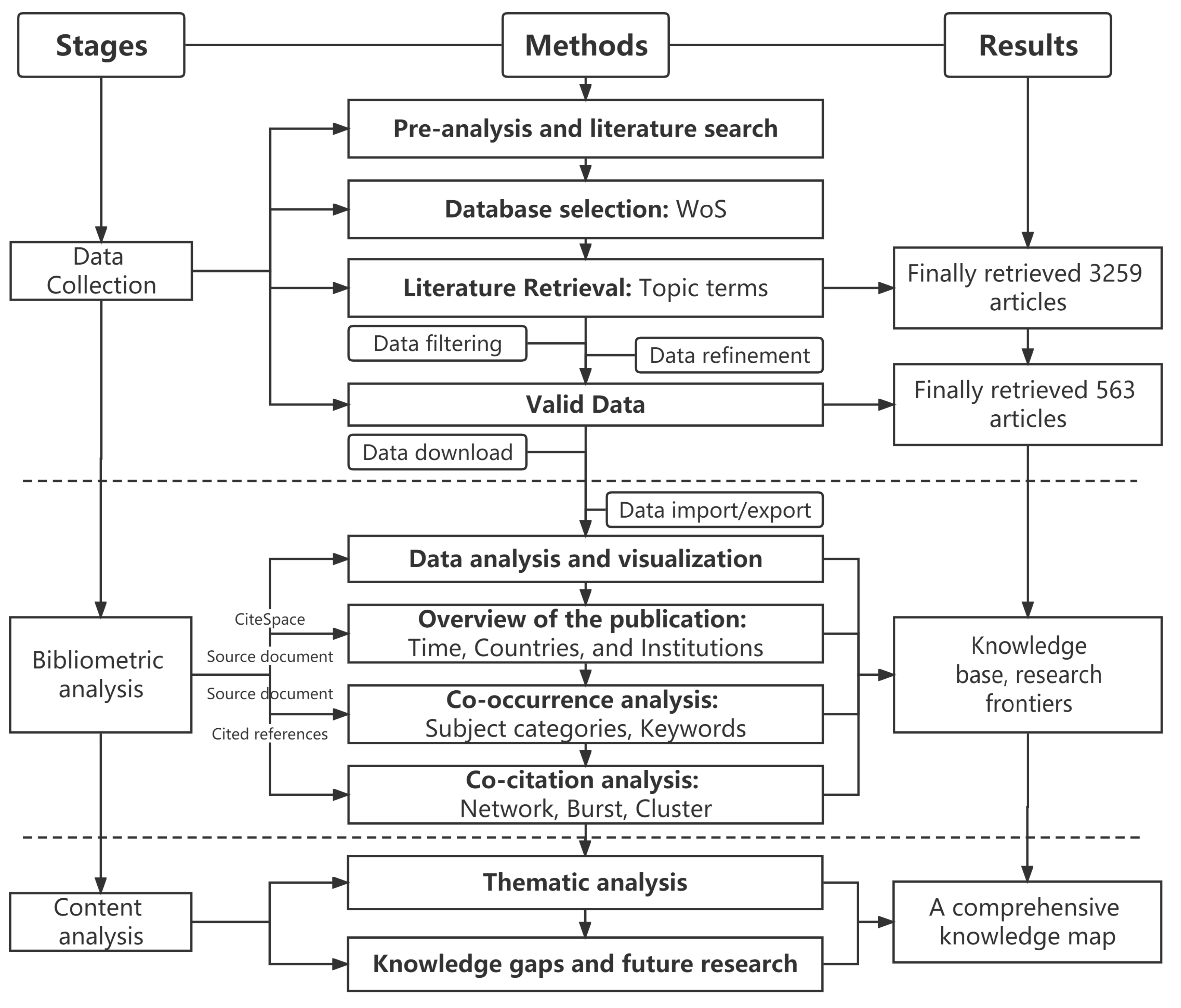

2. Methodology

2.1. Data Collection

2.1.1. Literature Retrieval

2.1.2. Exclusion Criteria

- (1)

- Each article focuses on carbon emissions in construction processes such as building material manufacture and transportation, on-site construction, and construction waste transportation and disposal.

- (2)

- To better explore cross-cutting articles, the selection process does not limit the research areas to mainstream fields such as engineering, environmental sciences technology, and building construction technology.

- (3)

- Research papers exploring the operational or dismantling phase, or articles that focus on assessing several types of sectors encompassing a specific region at a macro level, are excluded from this review.

2.2. Bibliometric Analysis

2.3. Content Analysis

3. Results and Interpretation

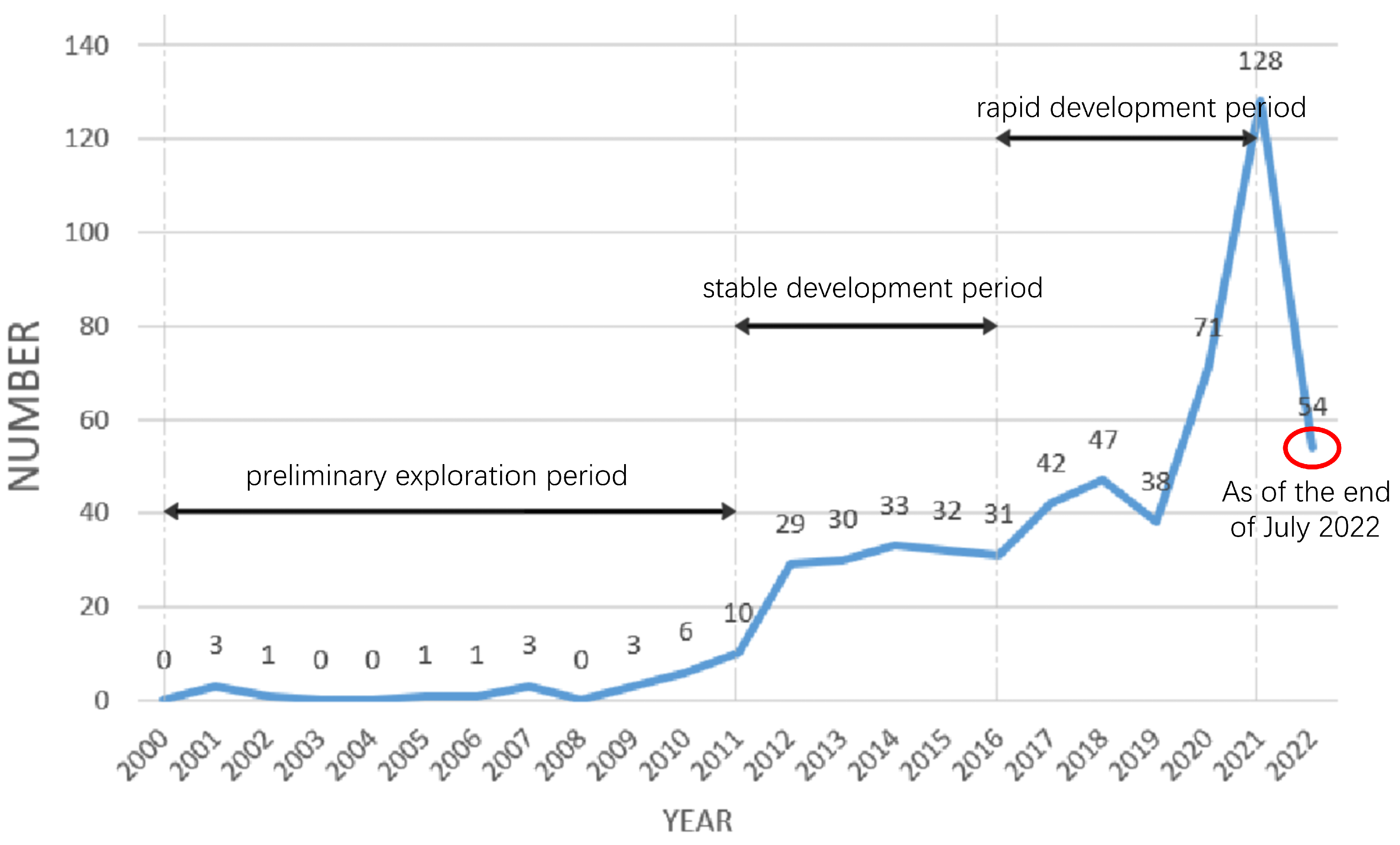

3.1. Overview of the Publication Year

3.2. Overview of Publishing Institutions and Publishing Countries

3.3. Subject Categories and Published Journals

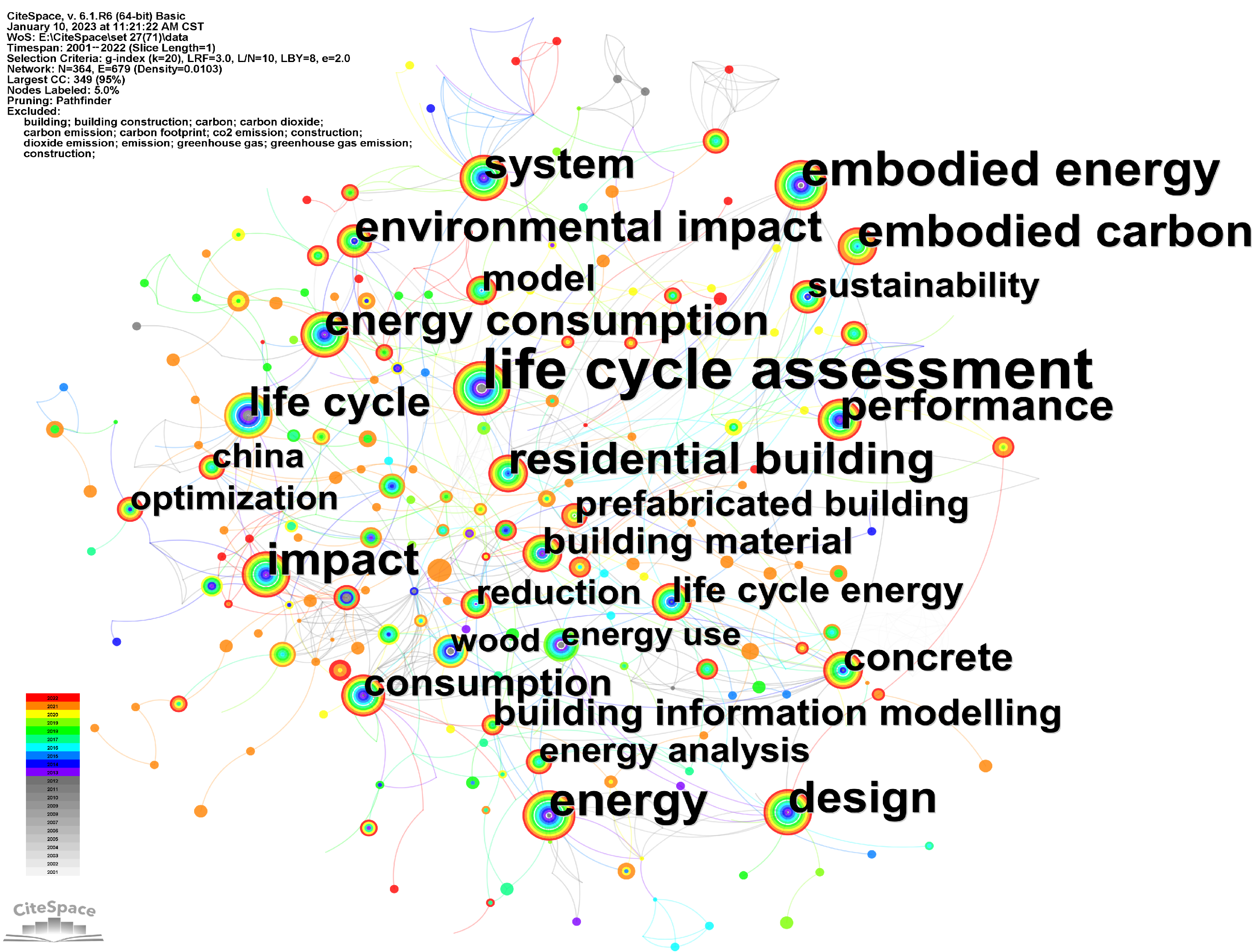

3.4. Keyword Co-Occurrence Analysis

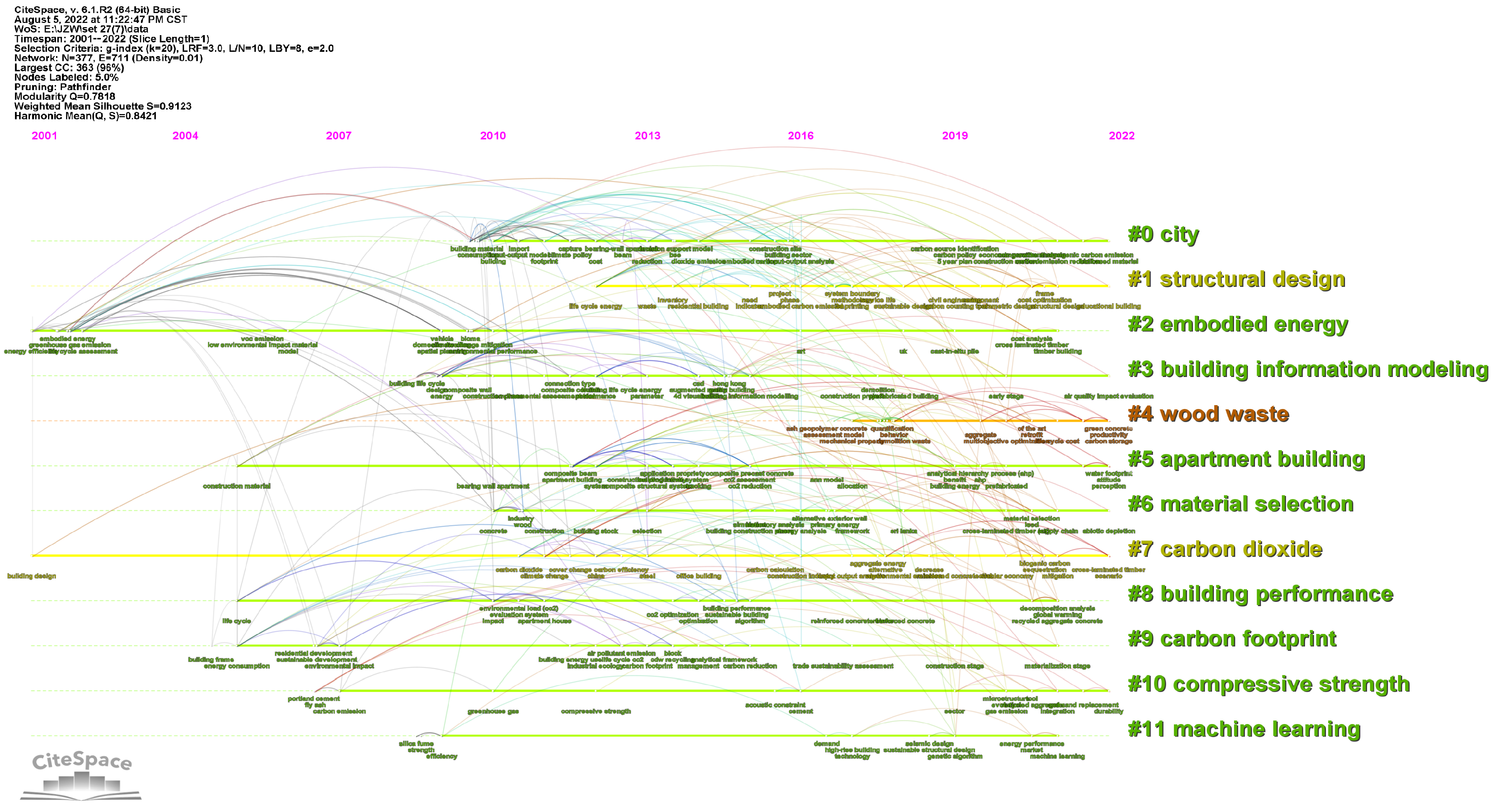

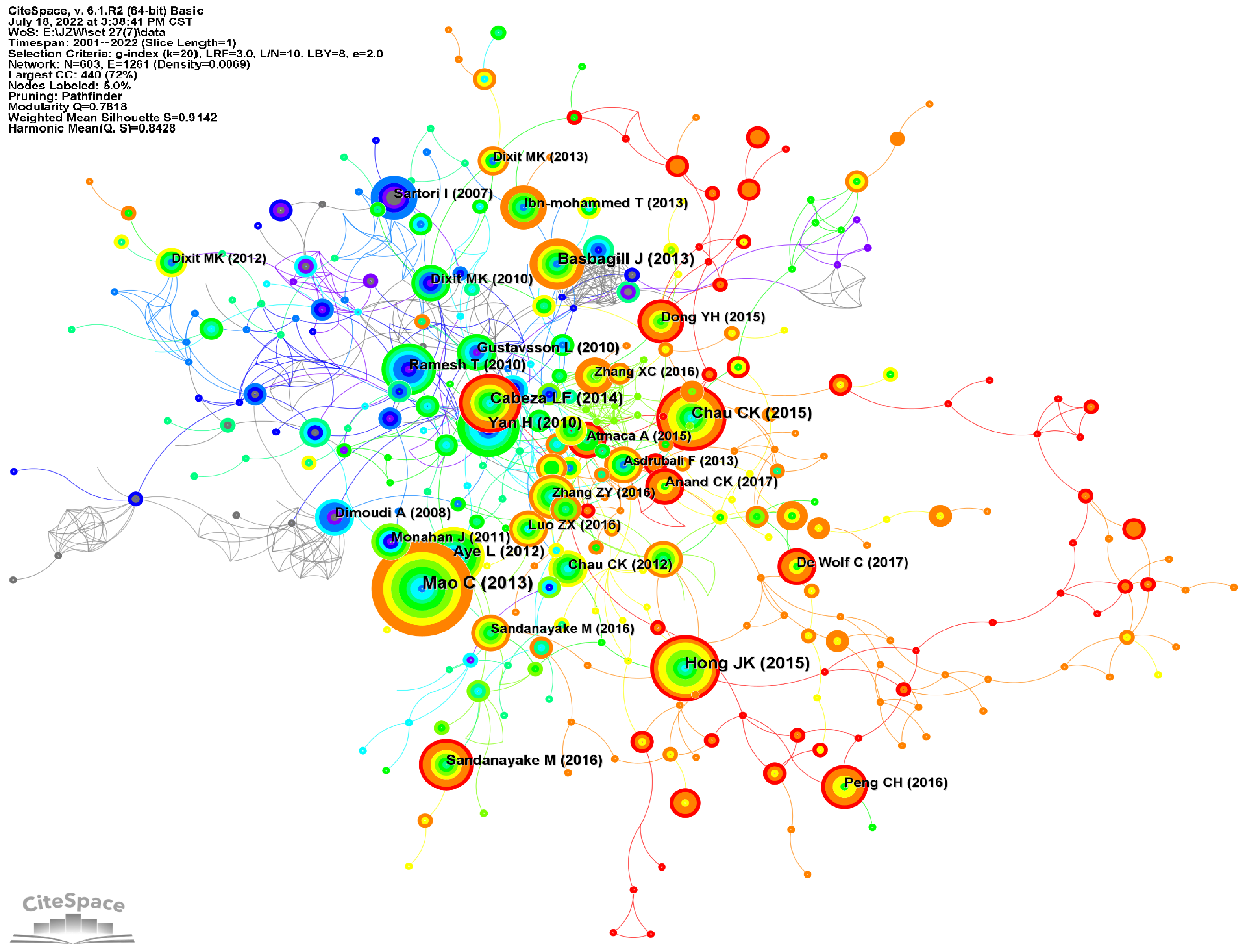

3.5. Documents Co-Citation Analysis and Cluster Analysis

3.5.1. Documents Co-Citation Network

3.5.2. Citation Bursts

3.5.3. Cluster Analysis

- (1)

- KD1 “carbon emissions sources” = cluster #1 “embodied carbon emissions” + cluster #9 “web-cyclone” + cluster #10 “residential sustainability”

- (2)

- KD2 “CECS assessment framework” = cluster #2 “life cycle assessment (LCA)” + cluster #3 “embodied carbon” + cluster #8 “reinforced concrete slab” + cluster #13 “data representativeness” + cluster #14 “life cycle CO”

- (3)

- KD3 “BIM-integrated evaluation framework” = cluster #5 “building information modeling” + cluster #6 “embodied environment impact”

- (4)

- KD4 “carbon reduction” = cluster #0 “construction” + cluster #4 “climate change” + cluster #7 “modular construction”

4. Discussion

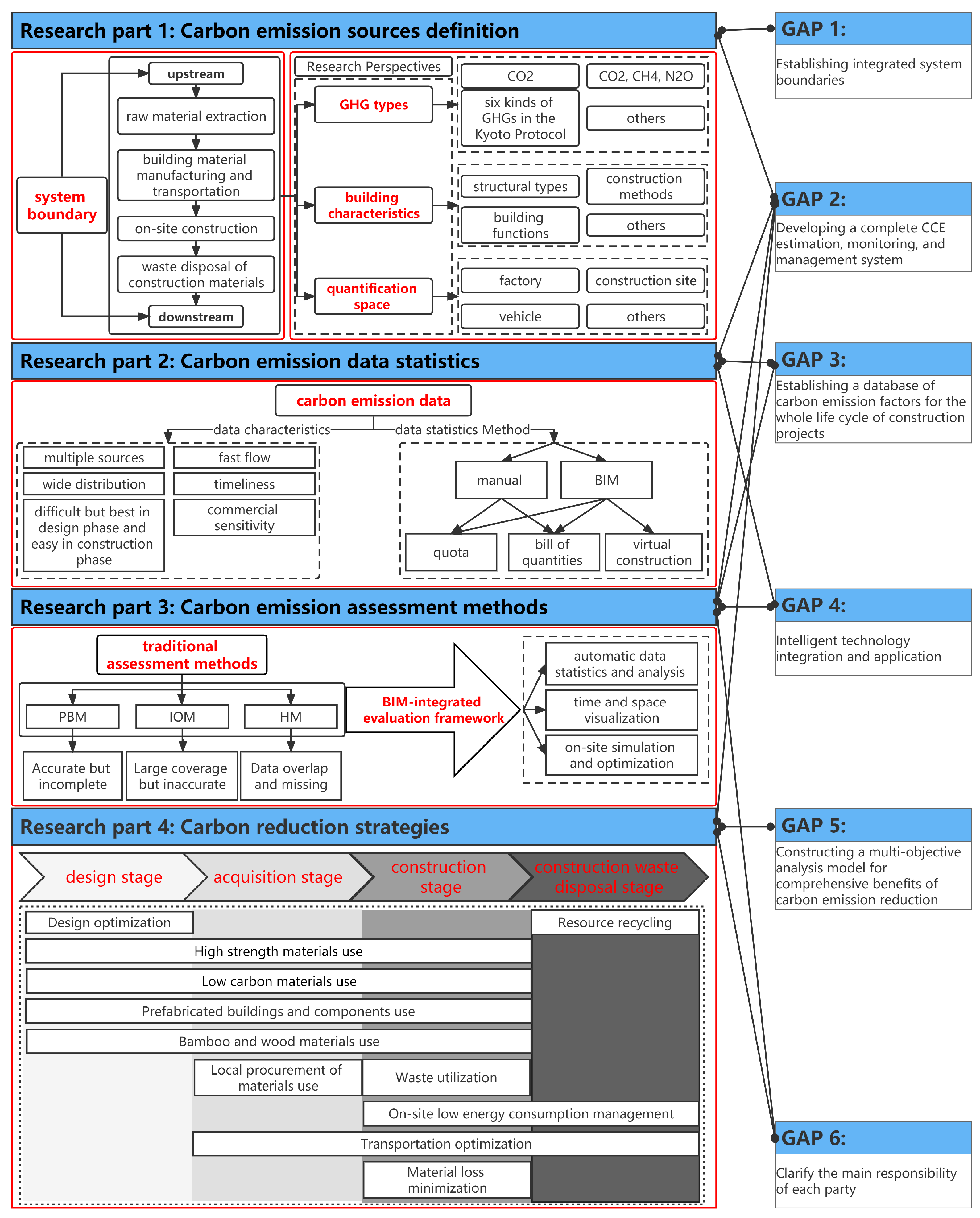

4.1. Critical Research Parts of CECS

4.1.1. Sources Definition

4.1.2. Data Statistics

- (1)

- Multiple sources. Under the common design-bid-construction model, primary building materials are selected by the general contractor or owner, labor subcontracts select auxiliary materials, and finishing materials are often selected by the owner, suggesting that statistical information on materials needs to be coordinated by multiple sources.

- (2)

- Wide distribution. The delivery of materials, the transfer of construction trash, the use of on-site construction machinery and equipment, as well as the on-site office, are all sources of carbon emissions at the job site.

- (3)

- Fast flow. The carbon source data is not only at the edges of the construction site, but also in the supply chain and, in the case of assembled buildings, in prefabrication plants. In addition, construction materials, machinery, and equipment constantly flow during construction, and the carbon source rushes with them.

- (4)

- Difficult but best in the design phase and easy in the construction phase. Detailed and accurate data (such as construction log, bill of quantities, etc.) can be collected during construction but not during the most meaningful design phase for carbon reduction [96], which means that the traditional carbon assessment cannot provide timely feedback and guidance on how to improve carbon emissions in construction effectively.

- (5)

- Timeliness. The artificial statistical data has timeliness, as a batch of materials procurement costs is different at different times, and the fuel price of construction equipment consumption also fluctuates, which is easy to cause errors based on production analysis.

- (6)

- Commercial sensitivity. The collection of CECS data requires the relevant parties to be responsible for the authenticity, accuracy, and completeness of their respective carbon emission data. Project participants may refuse to share information due to concerns about technology leaks to competitors, potential violations becoming known to the supervising party, etc. Therefore, the communication and integration of information among and within stakeholders must be carefully handled.

4.1.3. Assessment Methods

4.1.4. Carbon Reduction Strategies

4.2. Knowledge Gaps and Future Research

4.2.1. Establishing Integrated System Boundaries

4.2.2. Develop a Complete CECS Estimation, Monitoring, and Management System

4.2.3. Establishing a Database of Carbon Emission Factors for the Whole Life Cycle of Construction Projects

4.2.4. Intelligent Technology Integration and Application

4.2.5. Constructing a Multi-Objective Analysis Model for Comprehensive Benefits of Carbon Emission Reduction

4.2.6. Clarify the Main Responsibility of Each Party

5. Conclusions and Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skillington, K.; Crawford, R.H.; Warren-Myers, G.; Davidson, K. A review of existing policy for reducing embodied energy and greenhouse gas emissions of buildings. Energy Policy 2022, 168, 112920. [Google Scholar] [CrossRef]

- Kim, J.; Koo, C.; Kim, C.J.; Hong, T.; Park, H.S. Integrated CO2, cost, and schedule management system for building construction projects using the earned value management theory. J. Clean. Prod. 2015, 103, 275–285. [Google Scholar] [CrossRef]

- Li, L.; Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y.; Feng, W.; Fang, Y.; Feng, A. Factors That Influence the Quantification of the Embodied Carbon Emission of Prefabricated Buildings: A Systematic Review, Meta-Analysis and the Way Forward. Buildings 2022, 12, 1265. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.S.; Yildiz, I.; Byon, Y.J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Lu, W.; Tam, V.W.Y.; Chen, H.; Du, L. A holistic review of research on carbon emissions of green building construction industry. Eng. Constr. Archit. Manag. 2020, 27, 1065–1092. [Google Scholar] [CrossRef]

- Joseph, V.R.; Mustaffa, N.K. Carbon emissions management in construction operations: A systematic review. Eng. Constr. Archit. Manag. 2021. [Google Scholar] [CrossRef]

- Wang, B.Z.; Zhu, Z.H.; Yang, E.; Chen, Z.; Wang, X.H. Assessment and management of air emissions and environmental impacts from the construction industry. J. Environ. Plan. Manag. 2018, 61, 2421–2444. [Google Scholar] [CrossRef]

- Dixit, M.K.; Culp, C.H.; Fernández-Solís, J.L. System boundary for embodied energy in buildings: A conceptual model for definition. Renew. Sustain. Energy Rev. 2013, 21, 153–164. [Google Scholar] [CrossRef]

- Wu, P.; Xia, B.; Pienaar, J.; Zhao, X. The past, present and future of carbon labelling for construction materials—A review. Build. Environ. 2014, 77, 160–168. [Google Scholar] [CrossRef]

- Kang, G.; Kim, T.; Kim, Y.W.; Cho, H.; Kang, K.I. Statistical analysis of embodied carbon emission for building construction. Energy Build. 2015, 105, 326–333. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y. Bibliometric analysis of global environmental assessment research in a 20-year period. Environ. Impact Assess. Rev. 2015, 50, 158–166. [Google Scholar] [CrossRef]

- Bhatt, Y.; Ghuman, K.; Dhir, A. Sustainable manufacturing. Bibliometrics and content analysis. J. Clean. Prod. 2020, 260, 120988. [Google Scholar] [CrossRef]

- Jussila, J.; Nagy, E.; Lähtinen, K.; Hurmekoski, E.; Häyrinen, L.; Mark-Herbert, C.; Roos, A.; Toivonen, R.; Toppinen, A. Wooden multi-storey construction market development—Systematic literature review within a global scope with insights on the Nordic region. Silva Fenn. 2022, 56, 10609. [Google Scholar] [CrossRef]

- He, C.; Hou, Y.; Ding, L.; Li, P. Visualized literature review on sustainable building renovation. J. Build. Eng. 2021, 44, 102622. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Sang, P. A bibliometric review of studies on construction and demolition waste management by using CiteSpace. Energy Build. 2022, 258, 111822. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Z.; Chen, C.; Hong, R.; Jin, K.; Yang, C. Visualization and bibliometric analysis of research trends on human fatigue assessment. J. Med. Syst. 2018, 42, 1–12. [Google Scholar] [CrossRef]

- Zhao, X.; Ke, Y.; Zuo, J.; Xiong, W.; Wu, P. Evaluation of sustainable transport research in 2000–2019. J. Clean. Prod. 2020, 256, 120404. [Google Scholar] [CrossRef]

- Li, L.; Liao, S.; Yuan, J.; Wang, E.; She, J. Analyzing Healthcare Facility Resilience: Scientometric Review and Knowledge Map. Front. Public Health 2021, 9, 764069. [Google Scholar] [CrossRef] [PubMed]

- Shipworth, D. A stochastic framework for embodied greenhouse gas emissions modelling of construction materials. Build. Res. Inf. 2002, 30, 16–24. [Google Scholar] [CrossRef]

- González, M.J.; García Navarro, J. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar] [CrossRef]

- Ng, S.T.; Wong, J.M.W.; Skitmore, S.; Veronika, A. Carbon dioxide reduction in the building life cycle: A critical review. Proc. Inst. Civ. Eng.–Eng. Sustain. 2012, 165, 281–292. [Google Scholar] [CrossRef]

- Stadel, A.; Eboli, J.; Ryberg, A.; Mitchell, J.; Spatari, S. Intelligent Sustainable Design: Integration of Carbon Accounting and Building Information Modeling. J. Prof. Issues Eng. Educ. Pract. 2011, 137, 51–54. [Google Scholar] [CrossRef]

- Teng, Y.; Li, K.; Pan, W.; Ng, T. Reducing building life cycle carbon emissions through prefabrication: Evidence from and gaps in empirical studies. Build. Environ. 2018, 132, 125–136. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Wong, C.L.; Tse, K.T.; Cheng, J.C.P.; Lo, I.M.C.; Chan, C.M. Parametric modelling and evolutionary optimization for cost-optimal and low-carbon design of high-rise reinforced concrete buildings. Adv. Eng. Inform. 2019, 42, 100962. [Google Scholar] [CrossRef]

- Xu, J.; Deng, Y.; Shi, Y.; Huang, Y. A bi-level optimization approach for sustainable development and carbon emissions reduction towards construction materials industry: A case study from China. Sustain. Cities Soc. 2020, 53, 101828. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, L.; Liu, J. Embodied carbon emissions of office building: A case study of China’s 78 office buildings. Build. Environ. 2016, 95, 365–371. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B. Research on the life-cycle CO2 emission of China’s construction sector. Energy Build. 2016, 112, 244–255. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.t.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Hou, J.; Yang, X.; Chen, C. Emerging trends and new developments in information science: A document co-citation analysis (2009–2016). Scientometrics 2018, 115, 869–892. [Google Scholar] [CrossRef]

- Zheng, C.; Yuan, J.; Zhu, L.; Zhang, Y.; Shao, Q. From digital to sustainable: A scientometric review of smart city literature between 1990 and 2019. J. Clean. Prod. 2020, 258, 120689. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Z.; Liu, S.; Tseng, H. Emerging trends in regenerative medicine: A scientometric analysis in CiteSpace. Expert Opin. Biol. Ther. 2012, 12, 593–608. [Google Scholar] [CrossRef]

- Zhong, B.T.; Wu, H.T.; Li, H.; Sepasgozar, S.; Luo, H.B.; He, L. A scientometric analysis and critical review of construction related ontology research. Autom. Constr. 2019, 101, 17–31. [Google Scholar] [CrossRef]

- Chen, C. Expert Review. Science Mapping: A Systematic Review of the Literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Ya Hong, D.; Ng, S.T. A life cycle assessment model for evaluating the environmental impacts of building construction in Hong Kong. Build. Environ. 2015, 89, 183–191. [Google Scholar] [CrossRef]

- Wu, H.J.; Yuan, Z.W.; Zhang, L.; Bi, J. Life cycle energy consumption and CO2 emission of an office building in China. Int. J. Life Cycle Assess. 2011, 17, 105–118. [Google Scholar] [CrossRef]

- Baek, C.; Park, S.H.; Suzuki, M.; Lee, S.H. Life cycle carbon dioxide assessment tool for buildings in the schematic design phase. Energy Build. 2013, 61, 275–287. [Google Scholar] [CrossRef]

- Nuri Cihat, O.; Murat, K.; Omer, T. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Seo, M.S.; Kim, T.; Hong, G.; Kim, H. On-Site Measurements of CO2 Emissions during the Construction Phase of a Building Complex. Energies 2016, 9, 599. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X. Comparison and sensitivity analysis of embodied carbon emissions and costs associated with rural house construction in China to identify sustainable structural forms. J. Clean. Prod. 2021, 293, 126190. [Google Scholar] [CrossRef]

- Boqiang, L.; Hongxun, L. CO2 mitigation potential in China’s building construction industry: A comparison of energy performance. Build. Environ. 2015, 94, 239–251. [Google Scholar] [CrossRef]

- Yao, F.; Liu, G.; Ji, Y.; Tong, W.; Du, X.; Li, K.; Shrestha, A.; Martek, I. Evaluating the Environmental Impact of Construction within the Industrialized Building Process: A Monetization and Building Information Modelling Approach. Int. J. Env. Res. Public Health 2020, 17, 8396. [Google Scholar] [CrossRef]

- Su, X.; Zhang, X. A detailed analysis of the embodied energy and carbon emissions of steel-construction residential buildings in China. Energy Build. 2016, 119, 323–330. [Google Scholar] [CrossRef]

- Kong, A.; Kang, H.; He, S.; Li, N.; Wang, W. Study on the Carbon Emissions in the Whole Construction Process of Prefabricated Floor Slab. Appl. Sci. 2020, 10, 2326. [Google Scholar] [CrossRef]

- Liu, G.; Chen, R.; Xu, P.; Fu, Y.; Mao, C.; Hong, J. Real-time carbon emission monitoring in prefabricated construction. Autom. Constr. 2020, 110, 102945. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.; Fan, L.C.H.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Liu, G.; Gu, T.; Xu, P.; Hong, J.; Shrestha, A.; Martek, I. A production line-based carbon emission assessment model for prefabricated components in China. J. Clean. Prod. 2019, 209, 30–39. [Google Scholar] [CrossRef]

- Mohamed Abdul Ghani, N.M.A.; Egilmez, G.; Kucukvar, M.; Bhutta, M.K.S. From green buildings to green supply chains. Manag. Environ. Qual. Int. J. 2017, 28, 532–548. [Google Scholar] [CrossRef]

- Chen, J.; Shen, L.; Song, X.; Shi, Q.; Li, S. An empirical study on the CO2 emissions in the Chinese construction industry. J. Clean. Prod. 2017, 168, 645–654. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnonen, J.M.; Junnila, S. Input–output and process LCAs in the building sector: Are the results compatible with each other? Carbon Manag. 2017, 8, 155–166. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Ogungbile, A.J.; Shen, G.Q.; Wuni, I.Y.; Xue, J.; Hong, J. A Hybrid Framework for Direct CO2 Emissions Quantification in China’s Construction Sector. Int. J. Env. Res. Public Health 2021, 18, 11965. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Luo, Z.; Xu, X.; Cang, Y.; Yang, L. Assessing the embodied carbon reduction potential of straw bale rural houses by hybrid life cycle assessment: A four-case study. J. Clean. Prod. 2021, 303, 127002. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Hu, Z.Z.; Lin, J.R.; Zhang, J.P. A review on 3D spatial data analytics for building information models. Arch. Comput. Methods Eng. 2020, 27, 1449–1463. [Google Scholar] [CrossRef]

- Teng, Y.; Xu, J.; Pan, W.; Zhang, Y. A systematic review of the integration of building information modeling into life cycle assessment. Build. Environ. 2022, 221, 109260. [Google Scholar] [CrossRef]

- Li, X.J.; Lai, J.y.; Ma, C.y.; Wang, C. Using BIM to research carbon footprint during the materialization phase of prefabricated concrete buildings: A China study. J. Clean. Prod. 2021, 279, 123454. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Li, H.; Wang, H.; Huang, T.; Luo, E.; Li, V. Toward low-carbon construction processes: The visualisation of predicted emission via virtual prototyping technology. Autom. Constr. 2013, 33, 72–78. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, S.; Luo, L.; Liao, L. A building information modeling-based carbon emission measurement system for prefabricated residential buildings during the materialization phase. J. Clean. Prod. 2020, 264, 121728. [Google Scholar] [CrossRef]

- Martin, R.; Alexander, H.; Guillaume, H.; Alexander, P. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, J. BIM-based information system for econo-enviro-friendly end-of-life disposal of construction and demolition waste. Autom. Constr. 2021, 125, 103611. [Google Scholar] [CrossRef]

- Liu, Z.; Osmani, M.; Demian, P.; Baldwin, A. A BIM-aided construction waste minimisation framework. Autom. Constr. 2015, 59, 1–23. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Andersen, C.E.; Rasmussen, F.N.; Habert, G.; Birgisdóttir, H. Embodied GHG Emissions of Wooden Buildings—Challenges of Biogenic Carbon Accounting in Current LCA Methods. Front. Built Environ. 2021, 7, 729096. [Google Scholar] [CrossRef]

- Younis, A.; Dodoo, A. Cross-laminated timber for building construction: A life-cycle-assessment overview. J. Build. Eng. 2022, 52, 104482. [Google Scholar] [CrossRef]

- Javed, U.; Khushnood, R.A.; Memon, S.A.; Jalal, F.E.; Zafar, M.S. Sustainable incorporation of lime-bentonite clay composite for production of ecofriendly bricks. J. Clean. Prod. 2020, 263, 121469. [Google Scholar] [CrossRef]

- Yoon, Y.C.; Kim, K.H.; Lee, S.H.; Yeo, D. Sustainable design for reinforced concrete columns through embodied energy and CO2 emission optimization. Energy Build. 2018, 174, 44–53. [Google Scholar] [CrossRef]

- Omar, W.M.S.W.; Doh, J.H.; Panuwatwanich, K.; Miller, D. Assessment of the embodied carbon in precast concrete wall panels using a hybrid life cycle assessment approach in Malaysia. Sustain. Cities Soc. 2014, 10, 101–111. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S.; Luo, W.; Li, C.Q. Estimation and comparison of environmental emissions and impacts at foundation and structure construction stages of a building—A case study. J. Clean. Prod. 2017, 151, 319–329. [Google Scholar] [CrossRef]

- Wang, S.; Sinha, R. Life Cycle Assessment of Different Prefabricated Rates for Building Construction. Buildings 2021, 11, 552. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Hou, K.; Yao, G. Carbon emissions factor evaluation for assembled building during prefabricated component transportation phase. Energy Explor. Exploit. 2020, 39, 385–408. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X. Sustainable design of reinforced concrete structural members using embodied carbon emission and cost optimization. J. Build. Eng. 2021, 44, 102940. [Google Scholar] [CrossRef]

- Lyu, F.; Shao, H.; Zhang, W. Comparative analysis about carbon emission of precast pile and cast-in-situ pile. Energy Rep. 2022, 8, 514–525. [Google Scholar] [CrossRef]

- Liu, T.Y.; Ho, S.J.; Tserng, H.P.; Tzou, H.K. Using a Unique Retaining Method for Building Foundation Excavation: A Case Study on Sustainable Construction Methods and Circular Economy. Buildings 2022, 12, 298. [Google Scholar] [CrossRef]

- Li, X.J.; Zheng, Y.d. Using LCA to research carbon footprint for precast concrete piles during the building construction stage: A China study. J. Clean. Prod. 2020, 245, 118754. [Google Scholar] [CrossRef]

- Xu, K.; Kang, H.; Wang, W.; Jiang, P.; Li, N. Carbon Emission Estimation of Assembled Composite Concrete Beams during Construction. Energies 2021, 14, 1810. [Google Scholar] [CrossRef]

- O’Neill, B.C.; Oppenheimer, M. Dangerous climate impacts and the Kyoto Protocol. Science 2002, 296, 1971–1972. [Google Scholar] [CrossRef]

- Xinying, C.; Xiaodong, L.; Yimin, Z.; Zhihui, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Lin, C.L.; Chiang, W.H.; Weng, Y.S.; Wu, H.P. Assessing the anthropogenic carbon emission of wooden construction: An LCA study. Build. Res. Inf. 2022, 1–20. [Google Scholar] [CrossRef]

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 emissions reduction in high-rise concrete office buildings using different material use options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Najjar, M.K.; Figueiredo, K.; Evangelista, A.C.J.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A. Life cycle assessment methodology integrated with BIM as a decision-making tool at early-stages of building design. Int. J. Constr. Manag. 2019, 22, 541–555. [Google Scholar] [CrossRef]

- Ya Hong, D.; Lara, J.; Peggy, C.; Poon, C.S. Comparing carbon emissions of precast and cast-in-situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

- Han, Q.; Chang, J.; Liu, G.; Zhang, H. The Carbon Emission Assessment of a Building with Different Prefabrication Rates in the Construction Stage. Int. J. Environ. Res. Public Health 2022, 19, 2366. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Leng, J. Quantitative research on embodied carbon emissions in the design stage: A case study from an educational building in China. J. Asian Archit. Build. Eng. 2022, 21, 1182–1192. [Google Scholar] [CrossRef]

- Sudarsan, J.S.; Vaishampayan, S.; Parija, P. Making a case for sustainable building materials to promote carbon neutrality in Indian scenario. Clean Technol. Environ. Policy 2022, 24, 1609–1617. [Google Scholar] [CrossRef]

- Son, S.; Park, K.; Fitriani, H.; Kim, S. Embodied CO2 Reduction Effects of Composite Precast Concrete Frame for Heavily Loaded Long-Span Logistics Buildings. Sustainability 2021, 13, 1060. [Google Scholar] [CrossRef]

- Nahangi, M.; Guven, G.; Olanrewaju, B.; Saxe, S. Embodied greenhouse gas assessment of a bridge: A comparison of preconstruction Building Information Model and construction records. J. Clean. Prod. 2021, 295, 126388. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Stochastic analysis of embodied emissions of building construction: A comparative case study in China. Energy Build. 2017, 151, 574–584. [Google Scholar] [CrossRef]

- Gustavsson, L.; Sathre, R. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 2006, 41, 940–951. [Google Scholar] [CrossRef]

- Rodrigo, M.N.N.; Perera, S.; Senaratne, S.; Jin, X. Review of Supply Chain Based Embodied Carbon Estimating Method: A Case Study Based Analysis. Sustainability 2021, 13, 9171. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Assessment of embodied carbon emissions for building construction in China: Comparative case studies using alternative methods. Energy Build. 2016, 130, 330–340. [Google Scholar] [CrossRef]

- Wan Omar, W.M.S. A hybrid life cycle assessment of embodied energy and carbon emissions from conventional and industrialised building systems in Malaysia. Energy Build. 2018, 167, 253–268. [Google Scholar] [CrossRef]

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-Cycle Assessment Modeling of Construction Processes for Buildings. J. Infrastruct. Syst. 2010, 16, 199–205. [Google Scholar] [CrossRef]

- Malmqvist, T.; Nehasilova, M.; Moncaster, A.; Birgisdottir, H.; Nygaard Rasmussen, F.; Houlihan Wiberg, A.; Potting, J. Design and construction strategies for reducing embodied impacts from buildings—Case study analysis. Energy Build. 2018, 166, 35–47. [Google Scholar] [CrossRef]

- Aboshia, A.M.A.; Rahmat, R.A.; Zain, M.F.M.; Ismail, A. Enhancing mortar strengths by ternary geopolymer binder of metakaolin, slag, and palm ash. Int. J. Build. Pathol. Adapt. 2017, 35, 438–455. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly Ash-Based Eco-Efficient Concretes: A Comprehensive Review of the Short-Term Properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Jayasinghe, A.; Orr, J.; Ibell, T.; Boshoff, W.P. Minimising embodied carbon in reinforced concrete flat slabs through parametric design. J. Build. Eng. 2022, 50, 104136. [Google Scholar] [CrossRef]

- Jayasinghe, A.; Orr, J.; Ibell, T.; Boshoff, W.P. Minimising embodied carbon in reinforced concrete beams. Eng. Struct. 2021, 242, 112590. [Google Scholar] [CrossRef]

- Ismail, M.A.; Mueller, C.T. Minimizing embodied energy of reinforced concrete floor systems in developing countries through shape optimization. Eng. Struct. 2021, 246, 112955. [Google Scholar] [CrossRef]

- Choi, S.W.; Oh, B.K.; Park, H.S. Design technology based on resizing method for reduction of costs and carbon dioxide emissions of high-rise buildings. Energy Build. 2017, 138, 612–620. [Google Scholar] [CrossRef]

- Yeo, D.; Potra, F.A. Sustainable Design of Reinforced Concrete Structures through CO2 Emission Optimization. J. Struct. Eng. 2015, 141, B4014002. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, Turkey. Energy Build. 2015, 102, 417–431. [Google Scholar] [CrossRef]

- Marey, H.; Kozma, G.; Szabó, G. Effects of Using Green Concrete Materials on the CO2 Emissions of the Residential Building Sector in Egypt. Sustainability 2022, 14, 3592. [Google Scholar] [CrossRef]

- Bheel, N.; Khoso, S.; Baloch, M.H.; Benjeddou, O.; Alwetaishi, M. Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Env. Sci. Pollut. Res. Int. 2022, 29, 52399–52411. [Google Scholar] [CrossRef] [PubMed]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Ramirez-Benavides, S.; Mejia de Gutierrez, R.; Orobio, A. Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact. Materials 2021, 14, 1275. [Google Scholar] [CrossRef] [PubMed]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative Life Cycle Assessment of Mass Timber and Concrete Residential Buildings: A Case Study in China. Sustainability 2021, 14, 144. [Google Scholar] [CrossRef]

- Žemaitis, P.; Linkevičius, E.; Aleinikovas, M.; Tuomasjukka, D. Sustainability impact assessment of glue laminated timber and concrete-based building materials production chains—A Lithuanian case study. J. Clean. Prod. 2021, 321, 129005. [Google Scholar] [CrossRef]

- Sun, M.; Peng, H.; Wang, S. Cost-Sharing Mechanisms for A Wood Forest Product Supply Chain under Carbon Cap-and-Trade. Sustainability 2018, 10, 4345. [Google Scholar] [CrossRef]

- Xu, X.; Xu, P.; Zhu, J.; Li, H.; Xiong, Z. Bamboo construction materials: Carbon storage and potential to reduce associated CO2 emissions. Sci. Total Environ. 2022, 814, 152697. [Google Scholar] [CrossRef]

- Kim, B.; Lee, H.; Park, H.; Kim, H. Greenhouse Gas Emissions from Onsite Equipment Usage in Road Construction. J. Constr. Eng. Manag. 2012, 138, 982–990. [Google Scholar] [CrossRef]

- Li, H.X.; Zhang, L.; Mah, D.; Yu, H. An integrated simulation and optimization approach for reducing CO2 emissions from on-site construction process in cold regions. Energy Build. 2017, 138, 666–675. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: A case of developing country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Jipa, A.; Dillenburger, B. 3D Printed Formwork for Concrete: State-of-the-Art, Opportunities, Challenges, and Applications. 3D Print. Addit. Manuf. 2022, 9, 84–107. [Google Scholar] [CrossRef] [PubMed]

- Miller, D.; Doh, J.H.; Mulvey, M. Concrete slab comparison and embodied energy optimisation for alternate design and construction techniques. Constr. Build. Mater. 2015, 80, 329–338. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. Mathematical modelling of embodied energy, greenhouse gases, waste, time–cost parameters of building projects: A review. Build. Environ. 2013, 59, 23–37. [Google Scholar] [CrossRef]

- Chen, G.Q.; Chen, H.; Chen, Z.M.; Zhang, B.; Shao, L.; Guo, S.; Zhou, S.Y.; Jiang, M.M. Low-carbon building assessment and multi-scale input–output analysis. Commun. Nonlinear Sci. Numer. Simul. 2011, 16, 583–595. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

| Rank | Journal Title | No. of Articles | Total Citations | Ave. Citations per Article | Ave. Citations per Year |

|---|---|---|---|---|---|

| 1 | Journal of Cleaner Production | 75 | 2180 | 29.07 | 272.5 |

| 2 | Sustainability | 62 | 510 | 8.23 | 46.36 |

| 3 | Energy and Buildings | 55 | 2660 | 48.36 | 204.62 |

| 4 | Building and Environment | 33 | 1878 | 56.91 | 110.47 |

| 5 | Journal of Building Engineering | 17 | 100 | 5.88 | 25 |

| 6 | Renewable Sustainable Energy Reviews | 17 | 2127 | 125.12 | 177.25 |

| 7 | International Journal of Life Cycle Assessment | 14 | 941 | 67.21 | 58.81 |

| 8 | Sustainable Cities and Society | 14 | 405 | 28.93 | 36.82 |

| 9 | Resources Conservation and Recycling | 13 | 469 | 36.08 | 24.68 |

| 10 | Buildings | 11 | 178 | 16.18 | 29.67 |

| Strength of Burst | Start of Burst | End of Burst | 2001–2022 | Pub. Year | References |

|---|---|---|---|---|---|

| 13.21 | 2012 | 2015 |  | 2007 | Sartori et al. (2007) |

| 10.53 | 2010 | 2016 |  | 2008 | Dimoudi et al. (2008) |

| 10.05 | 2013 | 2018 |  | 2009 | Yan et al. (2009) |

| 8.95 | 2013 | 2018 |  | 2010 | Ramesh et al. (2010) |

| 8.02 | 2016 | 2020 |  | 2015 | Hong et al. (2015) |

| 8 | 2011 | 2015 |  | 2007 | Nassen et al. (2007) |

| 7.32 | 2010 | 2014 |  | 2006 | Junnila et al. (2006) |

| 6.89 | 2012 | 2015 |  | 2010 | Dixit et al. (2010) |

| 6.43 | 2010 | 2015 |  | 2007 | Asif et al. (2007) |

| 6.39 | 2011 | 2014 |  | 2005 | Li et al. (2005) |

| 6.28 | 2012 | 2018 |  | 2009 | Gustavsson et al. (2009) |

| 6.24 | 2012 | 2017 |  | 2007 | Ortiz et al. (2007) |

| 6.11 | 2014 | 2017 |  | 2009 | Bribian et al. (2009) |

| 6.04 | 2012 | 2014 |  | 2005 | Gonzalez et al. (2005) |

| 5.98 | 2013 | 2016 |  | 2009 | Goggins et al. (2009) |

| 5.89 | 2020 | 2022 |  | 2018 | Pomponi et al. (2018) |

| 5.83 | 2019 | 2020 |  | 2017 | Li et al. (2017) |

| 5.8 | 2012 | 2016 |  | 2007 | Huberman et al. (2007) |

| 5.8 | 2012 | 2016 |  | 2009 | Gustavsson et al. (2009) |

| 5.66 | 2020 | 2022 |  | 2016 | Peng et al. (2016) |

| 5.66 | 2020 | 2022 |  | 2020 | Rock et al. (2020) |

| 5.56 | 2015 | 2018 |  | 2012 | Wu et al. (2012) |

| 5.43 | 2017 | 2020 |  | 2015 | Chou et al. (2015) |

| 5.38 | 2012 | 2016 |  | 2008 | Blengini et al. (2008) |

| 5.36 | 2020 | 2022 |  | 2017 | De Wolf et al. (2017) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jiang, Z.; Li, L.; Qi, Y.; Sun, J.; Jiang, Z. A Bibliometric and Content Review of Carbon Emission Analysis for Building Construction. Buildings 2023, 13, 205. https://doi.org/10.3390/buildings13010205

Wang Y, Jiang Z, Li L, Qi Y, Sun J, Jiang Z. A Bibliometric and Content Review of Carbon Emission Analysis for Building Construction. Buildings. 2023; 13(1):205. https://doi.org/10.3390/buildings13010205

Chicago/Turabian StyleWang, Yuanhang, Zhiwen Jiang, Lingzhi Li, Yujun Qi, Jianwei Sun, and Zhangzhang Jiang. 2023. "A Bibliometric and Content Review of Carbon Emission Analysis for Building Construction" Buildings 13, no. 1: 205. https://doi.org/10.3390/buildings13010205

APA StyleWang, Y., Jiang, Z., Li, L., Qi, Y., Sun, J., & Jiang, Z. (2023). A Bibliometric and Content Review of Carbon Emission Analysis for Building Construction. Buildings, 13(1), 205. https://doi.org/10.3390/buildings13010205