Abstract

Circular-economy-based sustainability approaches in construction are gaining wide acceptance due to the volume of waste generation and increasing demand for natural materials. Propelled by the recent timber shortage in Australia and the issues of waste management of cardboard, this study aims to analyse the possibilities of using cardboard as a construction material, based on its initial strength and multiple recycling options. A systematic review of research papers published in the last 40 years has been undertaken using a single keyword search to select the database. The review is presented in terms of the characteristics of the cardboard, dimensional stability, durability, structural strength, design, and analysis of cardboard. Recurring themes are evaluated using a latent Dirichlet allocation approach to identify the factors that ascertain the suitability of cardboard. Analysis reveals that despite certain constraints, such as water absorption and fire resistance, cardboard can be used as a replacement for timber by overcoming such limitations. This observation has benefits for the construction industry and the recycling industry. This study found that cardboard adheres to the circular economy principles, which should inspire policymakers. The paper concludes by highlighting the current circumstances and scientific challenges that impede the usage of cardboard in construction and recommends potential works needed to address these challenges for the benefit of practitioners and researchers.

1. Introduction

Innovations in the building and construction industry play a significant role in the development of sustainable cities and communities. The hierarchy of construction and demolition (C&D) management compartmentalizes environmental impacts into six levels starting from low to high as reduce, reuse, recycle, compost, incinerate, and landfill [1]. Environmentally friendly materials in construction generally comply with the 3Rs (reduce, reuse, and recycle) concept. This area of research is crucial in the current epoch to minimize the depletion of natural resources and interference with the ecosystem. The popular circular economy (CE) framework further emphasizes the elimination of wastes dumped into landfill by the maintenance of products and materials several times (including varied usage). Such a framework requires significant innovations from researchers to deliver the best outcomes for a strong circular economy.

C&D are considered the biggest waste generators in the world, contributing to about 30% to 44% of all wastes produced globally [2,3,4]. C&D waste is expected to increase to 2.2 billion tons by 2025 [5]. The C&D waste status report in Australia in 2011 stated that around 55% of C&D waste was recovered and recycled in the year 2008–2009, and resource recovery performance is highly viable [6]. Cardboard is an organic municipal solid waste (MSW) collected from businesses in addition to household material. The National Waste Report 2018 stated that paper and cardboard comprise 46% to 57% MSW by weight of a typical household recycling bin, and about 60% of paper and cardboard waste is recycled in Australia [7]. A major proportion of cardboard is sent to landfills, which implies that a circular-economy-based approach to using cardboard is lacking in current practice. One of the ways to efficiently manage cardboard waste is to identify the possibilities of using it as an alternate construction material.

Cardboard has been used as secondary material in structures. Cardboard formwork and thermal insulation materials, such as cardboard honeycomb sandwich cores, have been used in current construction [8,9,10]. The mechanical properties of a cardboard honeycomb sandwich are acceptable for both static and random dynamic situations, and there is a linear relationship between the dynamic yield stress and logarithmic strain rate [11]. Several projects have utilized them as load-bearing and non-load-bearing partition walls and as interior components [12]. They are also widely used as a material in packaging, sculpture, and furniture design [13,14].

Cardboard possesses many advantages as a potential material for sustainable construction. It is lightweight, inexpensive, energy-saving, multi-recyclable, flexible, has significant insulation properties and can be obtained from renewable sources [15,16,17,18]. Japanese architect Shigeru Ban innovated the structural integrity of cardboard paper and used it in the form of tubes and honeycomb panels to build structures. The architect constructed shelter houses to exhibition pavilions, changing the perception of the vulnerability, strength, and stability of the cardboard. This approach prompted the use of cardboard as an alternative to traditional building materials [18,19]. Several research studies have investigated cardboard as a temporary structure, shelter house, and/or building component [20,21,22,23]. There are potential advancements in architectural design and construction techniques along with numerical modelling and analysis [12,24] that provide further credence to the investigation of cardboard.

A recent review by researchers concentrated on the application of cellulose fibre in mortar or concrete [2]. There are very few papers that analyse the use of cardboard in construction. Moreover, research undertaken in some European and Asian countries confirms that cardboard use in construction is minimal. In Australia, the recent political scenario and the wildfires resulted in a huge shortage of timber (in addition to the pandemic-induced import issues). Thousands of hectares of softwood plantations that generally supply timber to the Australian construction sector were completely damaged due to wildfires [25]. The pandemic halted imports, and the construction industry was (and is) forced to seek alternative materials that look like timber and perform like timber. Since waste generation adds another layer of complexity to the governments the world over, circular-economy-based sustainable construction materials provide possible solutions to the above situation. Based on the above discussions, this paper explores the last 40 years of cardboard used in construction with a focus on the mechanical, physical, and sustainable characteristics of cardboard to implore its applicability as a structural material for construction and its conformance to the circular economy principles.

2. Research Approach

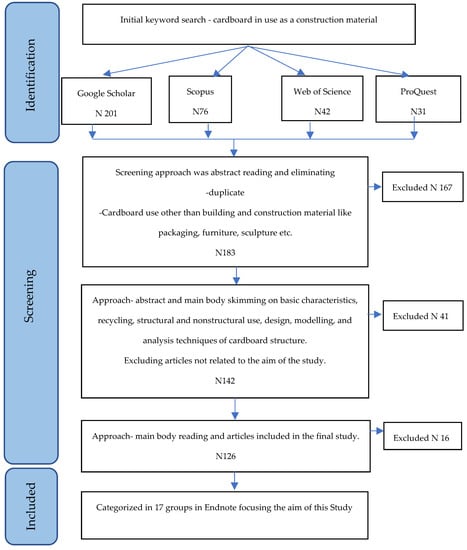

This study provides a scrupulously observed analysis of research and construction works from the 1980s. Figure 1 describes the overall strategy adopted for review in this study. First, the primary keyword/phrase of this paper was selected as ‘Cardboard as a construction material’. Then the relevant research articles were gathered from the academic research database Google Scholar, which was further extended with Scopus and Web of Science. In the first step, 183 papers were manually reviewed to find out suitable articles as per the scope of the study. Then the database was categorized with other important keywords (basic characteristics, recycling, structural and nonstructural use, modelling, and analysis techniques of cardboard structure). Finally, 126 research articles, magazines, books, and reports deemed appropriate for data collection, research, discussion, and recommendation were selected for this study (Table 1). All the articles were then compiled in an endnote group system for further analysis and interpretation, as shown in Figure 1.

Figure 1.

Systematic review approach of the study using a PRISMA diagram.

Table 1.

Sources of reviewed papers.

The following review analyses the diverse use of cardboard in building and construction and its environmental impact. These sections will focus on (i) the mechanical characteristics of cardboard for application in construction, (ii) the potential of virgin and recycled cardboard in sustainable structural systems, (iii) limitations and/or durability of performance, (iv) dimensional stability and structural robustness, (v) modelling and analysis techniques, (vi) observation and recommendations to resolve the existing challenges to the usage of cardboard in sustainable construction.

3. Review of Selected Literature and Discussion

3.1. Physical and Mechanical Properties

Vaccari et al. [26] and Gribbon and Foerster [27] note that cardboard is a sustainable building material in terms of environmental performance. The primary raw materials for the manufacture of cardboard are recycled fibres, and they are renewable [28]. These observations suggest the multiuse of the material at the end of life. Any material that has reuse at the end of its lifecycle without being sent to landfill is deemed to conform to circular economy (CE) principles. In conjunction with sustainable forest management procedures, the paper and cardboard industry could contribute positively to climate change mitigation [26].

Cardboard is described as a lightweight material with a significant level of toughness and impact resistance [18]. In general, the mechanical behaviour of cardboard is anisotropic, nonlinear, visco-elastic-plastic, and hygroscopic [29]. However, the failure strength of cardboard is devoid of importance because it tends to creep or deform under load and only a small proportion of its total strength can be used in the long term [18]. On a positive note, it can be seen from Table 2 that the tensile and bending strengths are around 8 and 7 N/mm2, which is closer to F4 grade used in Australia. The above observations suggest the potential characteristics of cardboard as a structural material. However, with creep effects, the strength reduces by 10 times, suggesting the need for strengthening techniques for use in construction.

Table 2.

Design parameters of cardboard.

A study by Gribbon and Foerster [30] showed that even though the water absorption behaviour of cardboard panels is not particularly remarkable, thermal, and acoustic performance is noteworthy in comparison with high-performance commercialized products. Moreover, it is possible to design competitive cardboard products with promising insulation properties [32]. Table 3 shows the mechanical, thermal, and physical properties of cardboard in comparison with other building materials. Obviously, cardboard does not compare favourably with steel, brick, and concrete but shows a favourable comparison with softwood. Comparisons are favourable in terms of thermal conductivity, sound absorption, and weight, while it is inferior in terms of modulus of elasticity (MOE), stresses, and strains. Again, this comparison shows the requirement for strengthening mechanical properties or the orientation of cardboard to achieve desired strengths. For example, cardboard has been used in tubular forms to achieve high compressive strengths. From an economical perspective, cardboard is a cost-effective product, and it is possible to maintain the proper quality of material in mass production [33]. The mass production and the abundant availability are significant points for the construction industry since shipping costs can be reduced. Furthermore, the above observations pinpoint the limitations and the favourable properties similar to softwood.

Table 3.

Comparison of mechanical, thermal, and physical properties of general cardboard with other building materials [19,34].

3.2. Dimensional Stability

The dimensional stability of cardboard has been an imperative issue in its application as a construction material. In the papermaking process, fibres are oriented in the machine direction. However, many fibres could orient randomly. In the cardboard fibre network, this arrangement has a profound influence. During the drying process, fibres cannot work altogether in the pure axial direction, and when some fibres are in tension, some remain inactive, which greatly reduces the mechanical properties of cardboard [39,40]. Moreover, the durability and mechanical properties of cardboard depend on many other factors, including the type of wood, fibre size, bond, time, temperature, water content/humidity, virgin or recycle, and drying condition. Several problems related to the dimensional stability of paper products are due to hydro expansion, such as curl, and fluting [41]. The fundamental mechanism of hydro expansion in the paper is the effect of the change of the fibre cross section transferred through the fibre bonds. Research to find the available solutions for dimensional stability is still enduring [42]. Nanotechnology also introduces possible opportunities to produce improved materials. To produce a stronger material, smaller cellulose fibres (1000 times than normal fibre) can provide higher tensile strengths (214 MPa) than the typical characteristic strength (maximum of 30 MPa). In the future, it may open the extensive use of cardboard or paper products in the construction sector if dimensional stability can be achieved [43]. Some researchers use different connection techniques and design methods as well as multi-layered cardboard to achieve structural strength [44]. Therefore, there is a need for future research to develop provisions for the structural design of different connections. With the new nanotechnologies, the dimensional stability of recycled cardboard structures can be achieved, which will enable the construction industry to execute advanced cardboard technologies for temporary and permanent structures.

3.3. Comparison of Virgin vs. Recycled Cardboard

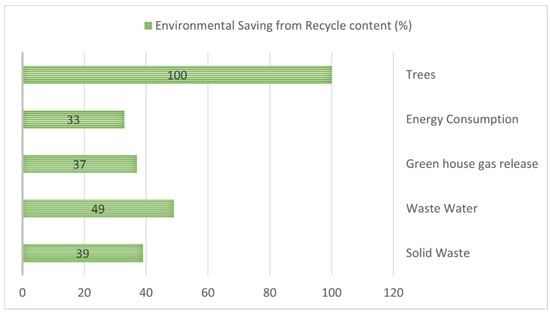

The manufacturing process for recycling paper is mostly the same as the process used for paper generated from virgin fibres or wood, excluding the cleaning of used cardboard [45]. According to the paper recycling company AMCOR, recovered papers can be recycled up to eight times [46]. However, during the recycling process, the cellulose fibres shorten and lose their strength, appearance, and colour [47]. Despite this loss in strength, recycled fibre is more environmentally sustainable during the production of paper or cardboard compared with virgin fibre. Recycling reduces the consumption of trees, energy, greenhouse gas emission, wastewater, and solid waste production [48]. It can be seen that recycling paper and cardboard are less energy intensive than cardboard and paper with virgin cellulose fibres [26]. The average embodied energy of virgin cardboard is 35.50 MJ/Kg, whereas predominantly recycled cardboard consumes 25.66 MJ/Kg embodied energy [35]. It was found from the research of Demountable Paper Dome (2003 and 2004) that virgin paper tubes can be 40% stronger than recycled paper tubes. In Wikkelhouse, it can be found that virgin cardboard can hold twice the load when compared with recycled cardboard that had not yet fully dried from glue after 24 h [49]. Figure 2 illustrates the comparison of environmental effects between virgin and recycled paper [48]. It provides important environmental benefits by saving resources and avoiding landfills. Given the advantages of recycled cardboard, it is sensible to utilize it in further applications and focus on the development of recycled cardboard strength.

Figure 2.

Environmental effect of virgin and recycled paper [47].

3.4. Limitations/Durability Performance

As a building material, cardboard is undoubtedly limited to the effects of humidity, fire, ultraviolet light, or different chemical substances. To use cardboard successfully as an exterior building material or have exposure to such vulnerable environments, protective measures must be considered.

3.4.1. Water Absorption

Several protective measures have been discussed in different studies. Portheine [19] stated the four most common solutions as compressing the fibres, adding glue to the pulp, coating, and covering. The simple approach is to add cladding with polythene foil [44]. The Westborough School, near Southend-on-Sea in the UK, was built using a three-step process starting from the cardboard production to the cardboard outer layer. However, it did change the original characteristics of cardboard [18]. It is quite common to use coating and covering, that is, waterproof polyurethane [50], polycoated layer [18], closed-cell plastic materials [51], and so on. Likewise, in highly humid zones (above 90%) like underground mines, cardboard block treated with phenolic resin was considered an alternative solution to resist moisture [51].

3.4.2. Fire Resistance

Another huge challenge is to build cardboard material resistant to fire. Researchers have made significant efforts to establish fire resistance. Although a carbon layer during the burning process acts as a natural flame resistance for solid cardboard, it does not work well for hollow cardboard [19]. The use of artificial fire retarders (i.e., chalk, boric, intumescent paint, etc.) as a coating and/or in the pulp is a more effective protection against ignition [18,51,52]. However, the gasses emitted from the cardboard with a fire retardant during burning are more toxic than solid cardboard [19]. Some approaches were also undertaken to establish different fire models for corrugated cardboard materials [53,54]. Aptly validated fire models can be a crucial resource to be used with different flame resistance in large-scale real structures.

3.4.3. Other Hazards

Some common hazards associated with cardboard are vermin, ultraviolet rays, and burglary. Not all areas could face these problems of vermin, but some environmental conditions could enable bug infestation. Availability of hosts or routine maintenance is the key point to controlling this issue [55,56].

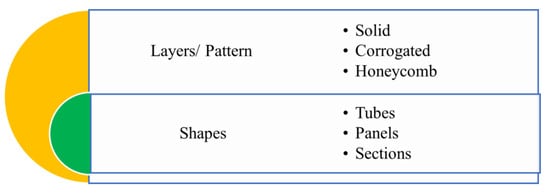

3.5. Cardboard in Construction

Cardboard in construction was expected to be a potential solution in terms of a sustainable environment. To find a perfect outcome in diverse circumstances, different types, thicknesses, layers, shapes, and patterns of cardboard are utilized in construction sectors. Reviewing the research on the application of cardboard in construction can be divided into the following categories (Figure 3):

Figure 3.

Cardboard classification based on use in construction.

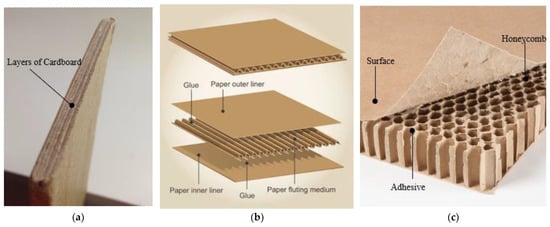

Based on the layers or pattern used in construction, cardboard can be classified as solid, corrugated, and honeycomb cardboard (Figure 4). Although solid cardboard is created from layers of sheets, corrugated cardboard can provide higher strengths and stiffness than others [12]. Corrugated cardboard was invented in 1871 by Albert L. Jones [49]. O’Neil [57] classified corrugated cardboard as per its flute types. However, solid cardboard is naturally more fire-resistant than corrugated and honeycomb cardboard. Solid cardboard is an antistrophe, where corrugated and honeycomb cardboard strength oscillates in different directions [19]. From a structural point of view, corrugated cardboard can be used as an alternative core material for sandwich panels and beams [9,58].

Figure 4.

Cardboard patterns: (a) solid paperboard [59], (b) corrugated, [60] (c) honeycomb [61].

Cardboard tubes are mainly created from solid cardboard, and it is usually in cylindrical shapes that are bonded together by adhesives. It is successfully used as structural and nonstructural members, such as columns, formwork for columns, cores, indoor partitions, and walls [27,50,62] (Figure 5 and Figure 6). Cardboard panels are usually manufactured from honeycomb cardboard and used as beams, walls, and roof panels [18]. Honeycomb cardboard is lighter in weight and has strong flexural and folding strength compared with corrugated cardboard. Corrugated cardboard is seldom used in construction, but there is potential to be used as a load-bearing component [9,63]. Formwork industries are commercially using cardboard as formwork for columns, walls, beams, and floors even in concrete bridge decks [8]. Cardboard can offer different shapes, dimensions, and disposable and modular formwork solutions in the structure. Furthermore, various shapes (L-shape, T-shape, U-shape, rectangular hollow, etc.) are produced to form large sections or create connections in tubes or panels [27]. Current cardboard buildings are based on either tube or nonstructural cardboard panels. A few design concepts such as Octatube can be found in practice.

Figure 5.

Use of cardboard as tube in construction (Takatori Catholic Church [64]).

Figure 6.

Use of cardboard as panel (Interior of Scherpontwerp, Eindhoven [65]).

3.6. Structural Robustness of Cardboard in Construction

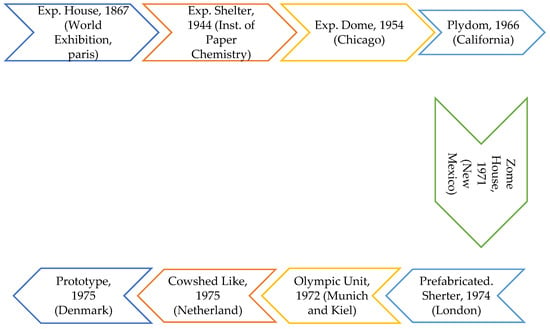

The usage of cardboard as a building material has a long history. Initially, it was established that cardboard can be used as a building material for temporary constructions, such as temporary shelters, exhibitions, or low-cost relief houses. Approaches to cardboard as a building material have been improved remarkably over the decades. As per case studies of paper structure [49], it is feasible to present the prehistory of cardboard structure via a flow chart (Figure 7).

Figure 7.

Schematic diagram of the prehistory of the cardboard structure [49].

During the initial period, cardboard was essentially used as panels or walls. All the structures were temporary construction, and coating with polyethene was the usual procedure to protect them from the weather. However, few experiments were carried out with paint (Exp. Shelter, 1944, by the Institute of Paper Chemistry, Appleton, WI, USA), fibreglass (prefabricated Olympic Unit, 1972) and aluminium lamination (Baer Zome house, 1971, Corrales, New Mexico). The stapling connection was common during the above period, and adhesive tapes were used to seal the cut edges (Cowshed Like, 1975, Netherland) [49]. These temporary structures mainly suffered from humidity and could not withstand long periods of exposure.

In the 1980s, Japanese architect Shigeru Ban established the concept of cardboard as a structural member not only in the temporary or disaster-affected zone but also as a permanent structure. The most important invention was the cardboard tube, which can act as a load-transferring structural member, such as columns, beams, and walls. To enhance the perception of cardboard as a structural member, some major cardboard constructions are depicted in Table 4 according to their types of use.

Table 4.

Examples of developments of cardboard construction with timeline.

Some world-famous temporary cardboard structures were built with an excellent design concept of the cardboard tube. Among them, Japan Pavilion, built in 2000, showed significant bending and compressive strength in different temperatures and humid conditions [69]. Its inner membrane was composed of five layers of fireproof polyethene, non-combustible paper, and a glass-fibre fabric in the middle. The outer membrane was prepared with transparent polyester fabric coated with PVC [49]. Another significant design concept was the use of a tuball space frame system of an Octatube in a paper dome structure. Paper Dome built in Amsterdam in 2003 was a leading project using this state-of-the-art dome technology. Another impressive temporary construction with corrugated cardboard was the Apeldoorn Theatre. The entire building weighed less than a large car [44].

Portable, eco-friendly, prefabricated, well-insulated cardboard structures (Wikkelhouse) are considered a solution for temporary accommodation [49,67]. As a shelter or emergency house, cardboard or paper log houses can be found on a large scale [27,68]. Inexpensive and locally available protective measures such as PVC membrane, paint, and plastic tarpaulin, are considered to protect the cardboard from exposed weather conditions. In a cardboard house (Sydney, 2004), 60 mm laminated fibreboard portable house with 1.5 year of estimated lifespan was built. At the junction, A-shaped portal frames interlocked with horizontal cardboard spacing beams were built. The outer shell was treated with varnish, and the outer membrane was coated with PVC-coated polyester fabric.

As a temporary structure, paper tubes and honeycomb panel cores provide satisfactory results for axial compression, bending, and ripping by connecting different members [49]. Cardboard tube compressive strength also increases due to the hardening of glue in exposed weather [49]. In addition, paper tube strength was found to be 40% higher for virgin fibre cardboard than the tube made with recycled fibre [51]. These strength aspects must have facilitated building the first permanent cardboard structure named ‘Library of a Poet’.

The `Library of a Poet’ in Japan is the first permanent cardboard tube structure. It showed good performance against wind load but was deformed due to temperature and humidity effects. The tubes were not exposed to weather but were connected by wooden blocks and poststressed steel bracing [49,70]. As a permanent structure, the honeycomb panel was covered with translucent PVC and glued together to build the Nemunoki Children’s Art Museum in 1999 (Shizuoka, Japan). Tests showed that the grid-core panels had a 9.5% moisture content at a relative humidity level of 60%, and a moisture content level of 15.8% at a relative humidity of 90%. Moreover, the compression strength of the panel with a moisture content of 15.8% dropped to 61% compared with the compression strength of the panel with a water content of 9.5% [49].

Another permanent construction (Paper House, 1995 (Yamanashi)) followed the S-shape configuration. It showed decent performance with an average moisture content of 8.8%; bending strength and compression was 161.3 kg/cm2 and 113.9 kg/cm2, respectively [48]. The paper arch dome at Gifu retained compressive strength up to 7% moisture content level. This retention was attributed to the wooden connections that were laminated with waterproof coverings by pure polyethylene for protection against humidity [71].

One more honeycomb sandwich panel and permanent cardboard tube structure was built in Westborough School in the United Kingdom in the year 2001. It was designed for 20 years but is still being used in 2022. Prefabricated wooden elements were glued to the cardboard as joints. Its exposed surfaces were treated for fire resistance. It was proposed from the tests that a factor of (10%) should be applied for compressive strength to avoid creep of the material since after 4 months, 10–15 mm deflection was observed on paper tubes [18,48,72].

Cardboard tubes are normally implemented as columns and walls. However, in some projects, it has been used to create roofs [30]. In the Hualin Primary School in China, the bottom parts of cardboard tube columns were damaged due to the capillary rise of water when the foundation was too low and needed alternative solutions. There is evidence that the cardboard structure could be stable in rain but starts to deteriorate due to humidity if the connection is not waterproof [49].

As a waterproofing material, PVC membrane is a popular material with other procedures, such as painting varnished, using breathable textile, and clad with timber planks, vinyl coating, aluminium foil, and clear plastic tarpaulin. Several connection types are also highlighted in the literature [44,49]. However, noncardboard connections such as wood or steel nut bolt are mostly used in both temporary- and permanent-type construction. Furthermore, interlocking or foldable cardboard connection was also used in temporary structures (Example: Cardboard House in Sydney, 2004, and cardboard Wikkelhouse, 2012).

In an earthquake zone, a cardboard structure has more potential influence than a conventional one. Most temporary disaster houses can be built of cardboard, and even permanent structures, such as the Christchurch Cathedral, were also built after the devastating earthquake in 2011 [49,73]. It is important to note that the lightweight property of cardboard does not cause serious injuries or damage to occupants, unlike the heavy concrete structures.

The above discussion shows that cardboard can be used to build temporary and permanent structures. However, future research should focus on developing smart connections, joineries, and weather protection techniques, which are not only stronger and durable but also easy to install. There is a need for future research to develop recycled cardboard components that are robust as timber, thereby enabling the circular economy concept.

3.7. Modelling and Analysis Techniques

Cardboard as a packaging or interior material is a more popular option than structural elements. Christer Feller explained the steps of modelling cardboard at different structural levels [74]. Several modelling techniques are available to analyse cardboard regarding different usages. Some of them have used cardboard as a thermal material incorporated with other materials [75,76] or analysed loading conditions [77,78]. Very few studies are found in terms of numerical modelling and analysis techniques of cardboard structures (Table 5).

Table 5.

Previous research on the numerical and analytical evaluation of cardboard structure.

Limited studies have adopted finite element analysis for structural analysis of full-scale cardboard shelters under different wind conditions. It is recommended that long-size shelters will be more economical than short in terms of structural interpretation [24]. Most of the available models mainly focus on the thermal behaviour of cardboard [53,57,84,85]. Cardboard connection types, humidity, and water content have a great impact on its structural behaviour and environmental sustainability. Thus, a clear knowledge gap exists with the modelling techniques for structural load conditions.

However, cardboard material modelling is available as packaging or for other secondary purposes in construction [74,79]. Sophisticated research is mandatory in terms of analytical and numerical analysis of temporary and permanent cardboard structures in different weather and structural conditions.

In the above discussions of Section 3, if a simple data analytics technique is used, then it can be easily observed that the word “strength” alone appears more than 25 counts directly using a word document search and if indirect measures, such as stress and strain are included, the count exceeds 100. This implies a p-value of 0.8 (=100/126, i.e., words/documents reviewed as per Table 3). In data analytics terms, this approach is close to the latent Dirichlet allocation (LDA) approach. The authors have not used any software but have undertaken a strenuous manual approach. Further analysis reveals the following factors: strength, durability, cost, local availability, handling and storage, climate, skills, sustainability, recycling, building function, aesthetics, maintenance, specifications, and analysis/design, as shown in Table 6. Some of the factors, such as cost, may not have a higher word count, although they are implied significant parameters in Section 3.

Table 6.

Summary analysis of cardboard as a construction material.

Basically, the above summary tables suggests that cardboard is reasonably adequate in its current application and has the potential for further use based on its cost, availability, and sustainability factors. However, improvements are required for its development as a new material. This observation should not be construed as a limitation, rather as an opportunity, given its conformance with the CE principles. For example, characteristics of CE include minimizing waste, using a renewable resource, and replacing the end-of-life from reaching landfill by identifying other uses. As per the discussions above, using recyclable cardboard minimizes waste, it is a renewable resource, and given the use of fibres or the strengthening procedures, it can be reused without reaching the landfill.

4. Conclusions and Recommendations

As an environmentally friendly, recyclable, low-cost material, cardboard has a strong potential for uptake by the building and construction industry. The above discussions highlight that cardboard adheres to the circular economy principle in terms of multiple recycling options and a possible elimination from reaching landfill, if used as a construction material. This can lead to the reduction of deforestation of natural timber and relieve the market stress. To improve the quality and upgrade this material as a structural component, dimensional stability, resistance against moisture and fire, and numerical modelling and testing will be the primary research requirements.

It can also be concluded that cardboard is suitable for the construction of temporary structures. Its lifespan can be varied from several weeks to several years, depending on the weather condition of the region. It is a great way to recycle temporary structural material for another natural material. In the case of long-term sustainability measures, the cardboard structure design is a progressing research concept. Though several permanent structures are built with cardboard, it needs realistic protective measures for the exposed areas and continuous maintenance.

Most cardboard buildings do not consider cardboard as a connection material. Connection types of structural members seem to depend on building types. For example, in a small shelter house, PVA waterproof glue is commonly used to connect. Steel joints are becoming more popular than wooden connections and joints. On the other hand, large structures follow the design concept of an Octatube or are just connected with screws/bolts to the joint elements. Thus, proper attention must be paid to the structural connections.

Cardboard structure displays great stability in different loading conditions, including wind or earthquake effects. This lightweight and recyclable material could be the key to sustainable construction by solving its limitation. There are also opportunities to work with the prominent properties of cardboard as a structural member. Under these circumstances, nanotechnology can play an important role work with the cellulose fibre direction.

This study adopted a review of the research works from the last 40 years, in terms of cardboard as a building and structural material. This review focused only on the primary use of cardboard in structural design and construction. The findings of this study will support recognizing the present condition of these areas, and their associated technical challenges. The highlighted research gaps will pave way for further research. In addition, a software-based approach, such as MATLAB, can be used to confirm the validity of the findings from this research. Since the comparison of the reviews is based on cardboard versus timber, it should be assumed that the construction safety issues must be similar to timber. Construction safety and waste management topics, such as Li and Du [87], can be referred in this context.

Author Contributions

Conceptualization, S.V.; methodology, M.A. and S.V.; software and validation, S.V. and M.A.; formal analysis, and investigation, M.A. and S.V.; resources, M.A.; data curation, M.A. and S.N.; writing—original draft preparation, M.A.; writing—review and editing, S.V., M.A., S.N. and R.G.; visualization, supervision, project administration, funding acquisition, S.V. All authors have read and agreed to the published version of the manuscript.

Funding

Research funded by a grant from Sustainability Victoria, Melbourne, Australia; grant number C-12097 2021–2022.

Data Availability Statement

The data presented in this study are available in the respective references.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peng, C.-L.; Scorpio, D.E.; Kibert, C.J. Strategies for successful construction and demolition waste recycling operations. Constr. Manag. Econ. 1997, 15, 49–58. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Transparency Market Research. Construction Waste Market—Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2017–2025 2017. Available online: https://www.transparencymarketresearch.com/construction-waste-market.html (accessed on 12 June 2022).

- Hyder Consulting. Construction and Demolition Waste Status Report—Management of Construction and Demolition Waste in Australia; Department of Sustainability, Water, Population and Communitie: Melbourne, Australia, 2011. [Google Scholar]

- Australian Government. Analysis of Australia’s Municipal Recycling Infrastructure Capacity; Department of Environment and Energy, Commonwealth of Australia: Canberra, Australia, 2018. [Google Scholar]

- Spottiswoode, A.J.; Bank, L.C.; Shapira, A. Investigation of paperboard tubes as formwork for concrete bridge decks. Constr. Build. Mater. 2012, 30, 767–775. [Google Scholar] [CrossRef]

- McCracken, A.; Sadeghian, P. Corrugated cardboard core sandwich beams with bio-based flax fiber composite skins. J. Build. Eng. 2018, 20, 114–122. [Google Scholar] [CrossRef]

- Betts, D.; Sadeghian, P.; Fam, A. Structural Behavior of Sandwich Beams with Flax Fiber-Reinforced Polymer Faces and Cardboard Cores under Monotonic and Impact Loads. J. Archit. Eng. ASCE 2020, 26, 04020013. [Google Scholar] [CrossRef]

- Wang, D.; Bai, Z. Mechanical property of paper honeycomb structure under dynamic compression. Mater. Des. 2015, 77, 59–64. [Google Scholar] [CrossRef]

- Ayan, Ö. Cardboard in Architectural Technology and Structural Engineering. A Conceptual Approach to Cardboard Buildings in Architecture. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2009. [Google Scholar]

- Herr, C.; Fischer, T. Constructing Cardboard Chairs for Children as a Part of Applied Structural Design Education in Architecture. Appl. Mech. Mater. 2012, 174–177, 1604–1610. [Google Scholar] [CrossRef]

- Correa, R.P.; Teixeira, P.P.; da Costa Lacerda, A.; Rumjanek, J.B.D.; Rumjanek, V.M.B.D.; Cardoso, F.S.; Madeira, L.F.; Castro, H.C. Cardboard Dinosaur: The Use of Simple Three-Dimensionality and Macroscopy Tools as a Low-Cost Strategy for Presentation of Classical Biological Themes. Creat. Educ. 2020, 11, 250–261. [Google Scholar] [CrossRef]

- Bi, L. Research on Corrugated Cardboard and its Application. Adv. Mater. Res. 2012, 535–537, 2171–2176. [Google Scholar] [CrossRef]

- Câmpean, T.; Peiu, N.; Gavrilescu, M. Alternative Uses of Paper and Cardboard in Architecture and Construction; Universitatea Tehnică “Gheorghe Asachi”: Iași, Romania, 2020. [Google Scholar]

- Russ, A.; Schwartz, J.; Boháček, Š.; Lübke, H.; Ihnat, V.; Pažitný, A. Reuse of old corrugated cardboard in constructional and thermal insulating boards. Wood Res. 2013, 58, 505–510. [Google Scholar]

- Cripps, A. Cardboard as a construction material: A case study. Build. Res. Inf. 2004, 32, 207–219. [Google Scholar] [CrossRef]

- Portheine, J. Cardboard as a Construction Material for Beach Houses. Master’s Thesis, TU Delft, Delft, The Netherlands, 2015. [Google Scholar]

- Sanematsu, H. Gimme Shelter: Implications of the Simple and the Humble in a Cardboard Fort in Context. In Proceedings of the ACM Computer Human Interaction Conference (SIG-CHI ‘12), Austin, TX, USA, 5–10 May 2012. [Google Scholar]

- Abulnour, A.H. The post-disaster temporary dwelling: Fundamentals of provision, design and construction. HBRC J. 2014, 10, 10–24. [Google Scholar] [CrossRef]

- Distefa, D.L. Precast Lightness Cardboard Architecture Responds to Emergency. Ph.D. Thesis, DICAR University of Catania, Catania, Italy, 2019. [Google Scholar]

- Diarte, J.; Shaffer, M.; Obonyo, E. Developing a Panelized Building System for Low-cost Housing using Waste Cardboard and Repurposed Wood. In Proceedings of the 18th International Conference on Non-Conventional materials and Technologies “Construction Materials & Technologies for Sustainability”, Nairobi, Kenya, 24–26 July 2019. [Google Scholar]

- El Damatty, A.; Mikhail, A.; Awad, A. Finite element modeling and analysis of a cardboard shelter. Thin-Walled Struct. 2000, 38, 145–165. [Google Scholar] [CrossRef]

- Institute, C.T. Why Is There a Shortage of Timber in Australia? 2021. Available online: https://www.ctiaustralia.edu.au/why-is-there-a-shortage-of-timber-in-australia/ (accessed on 14 May 2022).

- Vaccari, M. Enviromental Assessment of Cardboard. Master’s Thesis, Oxford Brookes University, Oxford, UK, 2008. [Google Scholar]

- Gribbon, H.; Foerster, F. Structural Engineering and Design in Paper and Cardboard-Approaches and Projects. Cardboard Archit. 2008, 7, 95. [Google Scholar]

- Latka, J.F. Paper and cardboard as sustainable materials, Paper in architecture: Research by design, engineering and prototyping. Archit. Built Environ. 2017, 19. [Google Scholar] [CrossRef]

- Eekhout, M. Cardboard Technical Research and Developments at Delft University of Technology, Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Gribbon, H.; Foerster, F. Structural Engineering and Design in Paper and Cardboard—Approaches and Projects, Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Aboura, Z.; Talbi, N.; Allaoui, S.; Benzeggagh, M. Elastic behavior of corrugated cardboard: Experiments and Modeling. Compos. Struct. 2004, 63, 53–62. [Google Scholar] [CrossRef]

- Secchi, S.; Asdrubali, F.; Cellai, G.; Nannipieri, E.; Rotili, A.; Vannucchi, I. Experimental and environmental analysis of new sound-absorbing and insulating elements in recycled cardboard. J. Build. Eng. 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Dooren, E.V.; Iersel, T.V. A House of Cardboard, Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Thermal Insulation, Passipedia—The Passive House Resource. Available online: https://passipedia.org/planning/thermal_protection/integrated_thermal_protection#u-values (accessed on 11 June 2021).

- CEPI Aisbl. Key Statistics (2018)—European Pulp and Paper Industry; Confederation of European Paper Industries: Brussels, Belgium, 2018. [Google Scholar]

- Mohammad, J.; Johari, N.; Fouladi, M. Numerical Investigation on the Sound Absorption Coefficients of Malaysian Wood. In Proceedings of the 20th International Congress on Acoustics, Sydney, Australia, 23–27 August 2010. [Google Scholar]

- Ray, C.D. Calculating the Green Weight of Wood Species, PennState Extension, 30 June 2014. Available online: https://extension.psu.edu/calculating-the-green-weight-of-wood-species (accessed on 12 May 2021).

- Kang, C.W.; Kim, M.K.; Jang, E.S. An Experimental Study on the Performance of Corrugated Cardboard as a Sustainable Sound Absorbing and Insulating Material. Sustainability 2021, 13, 5546. [Google Scholar] [CrossRef]

- Sekulj, B. Structural Cardboard: Feasibility Study of Cardboard as a Long-Term Structural Material in Architecture. Master’s Thesis, Universitari en Tecnologia a l’Arquitectura, Barcelona, Spain, 2013. [Google Scholar]

- Urstöger, G.; Kulachenko, A.; Schennach, R.; Hirn, U. Microstructure and mechanical properties of free and restrained dried paper: A comprehensive investigation. Cellulose 2020, 27, 8567–8583. [Google Scholar] [CrossRef]

- Niskanen, K. Mechanics of Paper Products; De Gruyter: Berlin, Germany, 2012. [Google Scholar]

- Motamedian, H.R.; Kulachenko, A. Simulating the hygroexpansion of paper using a 3D beam network model and concurrent multiscale approach. Int. J. Solids Struct. 2019, 161, 23–41. [Google Scholar] [CrossRef]

- Kokkinos, M. Paper Microstructure. 16 September 2010. Available online: https://papercrete.wordpress.com/2010/09/16/paper-microstructure-2/ (accessed on 11 June 2021).

- Dooren, E.V.; Verheijen, F. An Overview. Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Architects, S.B. Paper Tube Structures. 2022. Available online: http://www.shigerubanarchitects.com/works.html#paper-tube-structures (accessed on 12 August 2022).

- Ark, P. Paper and Cardboard. Casey City Council. 2020. Available online: https://recyclingnearyou.com.au/paper-cardboard/CaseyVIC (accessed on 14 May 2022).

- Aciu, C.; Varvara, D.A.I.; Cobirzan, N.; Balog, A. Recycling of Paper Waste in the Composition of Plastering Mortars. Procedia Technol. 2014, 12, 295–300. [Google Scholar] [CrossRef]

- Kinsella, S. Paperwork: Comparing Recycled to Virgin Paper; The Environmental Paper Network: Asheville, NC, USA, 2012. [Google Scholar]

- Latka, J.F. Paper in Architecture Research by Design, Engineering and Prototyping, A + BE. Archit. Built Environ. 2017, 19, 1–532. [Google Scholar]

- Wikipedia. Cardboard Cathedral. Available online: https://en.wikipedia.org/wiki/Cardboard_Cathedral#cite_note-16 (accessed on 14 May 2022).

- Luzik, S.J. Development of a fire-resistant cardboard compressible block for use in stopping construction in underground mines. Fire Technol. 1993, 29, 131–153. [Google Scholar] [CrossRef]

- Eekhout, M. The Cardboard Dome as an Example of an Engineers Approach, Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- McKinnon, M.; Stoliarov, S.; Witkowski, A. Development of a pyrolysis model for corrugated cardboard. Combust. Flame 2013, 160, 2595–2607. [Google Scholar] [CrossRef]

- Chaos, M.; Khan, M.M.; Krishnamoorthy, N.; Chatterjee, P.; Wang, Y.; Dorofeev, S.B. Experiments and modeling of single- and triple-wall corrugated cardboard: Effective material properties and fire behavior. In Proceedings of the 12th International Conference and Exhibition, San Francisco, CA, USA, 31 January–2 February 2011; pp. 625–636. [Google Scholar]

- Gurevitz, J.M.; Ceballos, L.A.; Gaspe, M.S.; Alvarado-Otegui, J.A.; Enríquez, G.F.; Kitron, U.; Gürtler, R.E. Factors Affecting Infestation by Triatoma infestans in a Rural Area of the Humid Chaco in Argentina: A Multi-Model Inference Approach. PLoS Negl. Trop. Dis. 2011, 5, e1349. [Google Scholar] [CrossRef]

- Wang, C.; Cooper, R. Environmentally Sound Bedbug Management Solutions. In Urban Pest Management: An Environmental Perspective; CABI Publishing: Wallingford, Oxfordshire; Volume 4, pp. 44–63. [CrossRef]

- Mohsen, M.A.K.A.; Faggal, A.A.; El-Metwally, Y.S. Efficiency of Corrugated Cardboard as a Building Material. 2012. Available online: https://scholarship.libraries.rutgers.edu/esploro/outputs/acceptedManuscript/991031549976104646 (accessed on 14 May 2022).

- Heyden, A.V.D.; Lange, J. Assessment of the utilisation of corrugated cardboard as a core material for sandwich panels. In Proceedings of the Eurosteel, Copenhagen, Denmark, 13–15 September 2017; pp. 1716–1725. [Google Scholar]

- Online Image. Paperboard—Flatboard—Compressed Cardboard Lengths. 2018. Available online: https://embossingtapesupplies.com.au/flatboard-compressed-cardboard.html (accessed on 12 March 2022).

- Online Image. B Inbox Group, Cardboard. 2019. Available online: https://www.inboxgroup.com.au/cardboard (accessed on 12 March 2022).

- Online Image. Rebul Packaging Pty Ltd. Honeycomb Board. 2016. Available online: https://rebul.com.au/honeycomb-board/ (accessed on 14 May 2022).

- Souza, E. Cardboard: From Industrial Workhouse to Shigeru Ban’s Master Material 24 Mar 2019. Arch Daily. Available online: https://www.archdaily.com/913567/cardboard-from-industrial-workhouse-to-shigeru-bans-master-material (accessed on 13 January 2022).

- Schütz, S. Folded Cardboard Sandwiches for Load-bearing Architectural Components. In Proceedings of the World Sustainable Built Environment Conference 2017, Hong Kong, China, 5–7 June 2017. [Google Scholar]

- Online Image, Wikipedia, Takatori Catholic Church. 20 December 2021. Available online: https://en.wikipedia.org/wiki/Takatori_Catholic_Church (accessed on 12 March 2022).

- Online Image, A Cardboard suit for Scherpontwerp, Archello 2022. Available online: https://archello.com/project/a-cardboard-suit-for-scherpontwerp (accessed on 12 August 2022).

- Iersel, T.V.; Elise, E.V. Application of Cardboard in Partitioning. Cardboard in Architecture; Eekhout, M., Verheijen, F., Visser, R., Eds.; IOS Press: Amsterdam, The Netherlands, 2008; pp. 119–129. [Google Scholar]

- Hyder Consulting. Construction and Demolition Waste Status Report—Management of Construction and Demolition Waste in Australia; Hyder Consulting: Belfast, NI, USA, 2011. [Google Scholar]

- Stevens, P. Shigeru Ban’s Disaster Relief Shelters Made from Bamboo and Paper Go on View in Sydney. 27 March 2017. Available online: https://www.designboom.com/architecture/shigeru-ban-disaster-relief-shelters-bamboo-paper-sydney-exhibition-scaf-australia-03-27-2017 (accessed on 11 June 2021).

- Dickson, M.; Hardie, G.; Leiblein, K.; Rogers, P.; Westbury, P. The Japan pavilion for the Hannover Expo 2000. In Proceedings of the IASS-2001 Conference: Theory, Design and Realization of Shell and Spatial Structures, Nagoya, Japan, 9–13 October 2001. [Google Scholar]

- Washington, C. Shigeru Ban: Building with Paper—Library of a Poet. 10 December 2012. Available online: https://clarewashington.wordpress.com/2012/12/10/shigeru-ban-building-with-paper-library-of-a-poet/ (accessed on 14 May 2022).

- Loire, F.C.V.D. Available online: https://www.frac-centre.fr/_en/art-and-architecture-collection/ban-shigeru/paper-dome-gifu-317.html?authID=18&ensembleID=56 (accessed on 7 February 2022).

- Jasiolek, A.; Latka, J.; Brzezicki, M. Comparative Analysis of Paper-based Building Envelopes for Semi-permanent Architecture: Original Proposals and Suggestions for Designers. J. Facade Des. Eng. 2021, 9, 47–72. [Google Scholar]

- Barrie, A. Cardboard Cathedral. J. Archit. Relat. Arts Interstices 2014, 15, 107. [Google Scholar]

- Fellers, C. The structure of paper and its modelling. Pap. Prod. Phys. Technol. 2009, 4, 1–24. [Google Scholar] [CrossRef]

- Fraile-Garcia, E.; Ferreiro-Cabello, J.; Pernia-Espinoza, A.; Martinez-de-Pison, F.J. Technical-economic assessment of redesigned reinforced concrete pre-slabs: Incorporating corrugated cardboard. Struct. Concr. 2019, 20, 1340–1349. [Google Scholar] [CrossRef]

- Elovenko, D.; Kräusel, V. The study of thermal conductivity of asbestos cardboard and fire clay powder to assess the possibility of their application in prefabricated structures of cylindrical housings of pressure vessels. Mater. Today Proc. 2019, 19, 2389–2395. [Google Scholar] [CrossRef]

- Suarez, B.; Muneta, M.L.M.; Sanz-Bobi, J.D.; Romero, G. Application of homogenization approaches to the numerical analysis of seating made of multi-wall corrugated cardboard. Compos. Struct. 2021, 262, 113642. [Google Scholar] [CrossRef]

- Nordstrand, T. Basic Testing and Strength Design of Corrugated Board and Containers. Ph.D. Thesis, Lund University, Lund, Sweden, 2003. [Google Scholar]

- Allaoui, S.; Aboura, Z.; Benzeggagh, M.L. Contribution to the Modelling of the Corrugated Cardboard Behaviour. In Proceedings of the 13th European Conference on Composite Materials, Stockholm, Sweden, 2–5 June 2008. [Google Scholar]

- Talbi, N.; Batti, A.; Ayad, R.; Guo, Y. An analytical homogenization model for finite element modelling of corrugated cardboard. Compos. Struct. 2009, 88, 280–289. [Google Scholar] [CrossRef]

- Abbès, B.; Guo, Y.Q. Analytic homogenization for torsion of orthotropic sandwich plates: Application to corrugated cardboard. Compos. Struct. 2010, 92, 699–706. [Google Scholar] [CrossRef]

- Minh, D.P.T. Modeling and Numerical Simulation for the Double Corrugated Cardboard under Transverse Loading by Homogenization Method. Int. J. Eng. Sci. 2017, 6, 16–25. [Google Scholar]

- Garbowski, T.; Gajewski, T. Determination of transverse shear stiffness of sandwich panels with a corrugated core by numerical homogenization. Materials 2021, 14, 1976. [Google Scholar] [CrossRef] [PubMed]

- Asdrubali, F.; Pisello, A.; D’Alessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and numerical characterization of innovative cardboard based panels: Thermal and acoustic performance analysis and life cycle assessment. Build. Environ. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- Vaccari, M. Environmental Assessment of Cardboard as a Building Material for Transitional Housing. In Proceedings of the 41st IAHS World Congress—Sustainability and Innovation for the Future, Albufeira, Portugal, 13–16 September 2016. [Google Scholar]

- Burns, J.G.; Kelleher, D.N. Case Study: The Hive–A Cardboard Tube Shell Structure. In Proceedings of the IASS Annual Symposia, Boston, MA, USA, 16–20 July 2018. [Google Scholar]

- Li, R.Y.M.; Du, H. Sustainable Construction Waste Management in Australia: A Motivation Perspective. In Construction Safety and Waste Management. Risk Engineering; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).