Condition Assessment and Seismic Upgrading Strategy of RC Structures—A Case Study of a Public Institution in Croatia

Abstract

1. Introduction

2. Materials and Methods

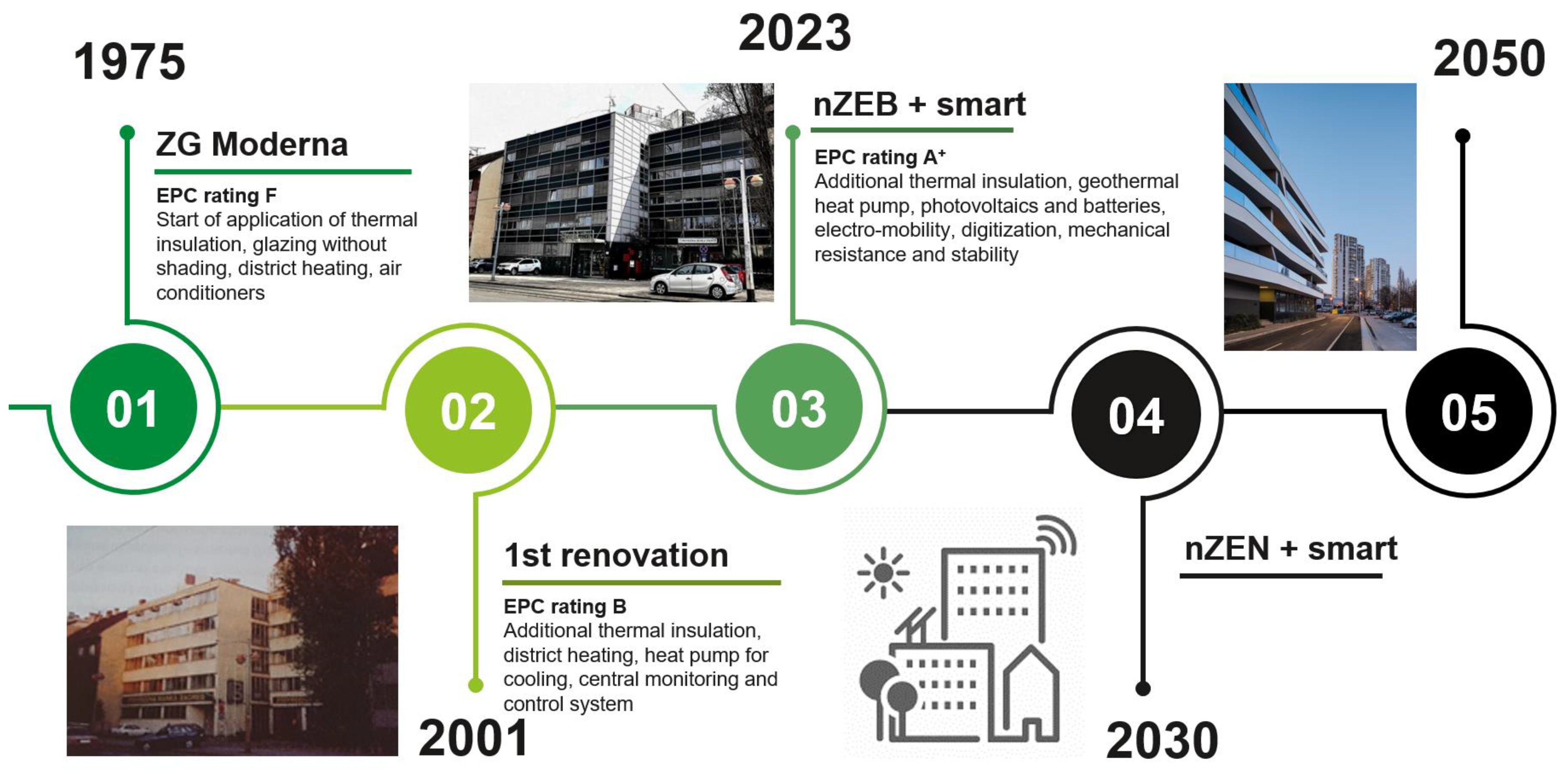

2.1. Case Study

2.1.1. Overview of the Building and Identification of the Process

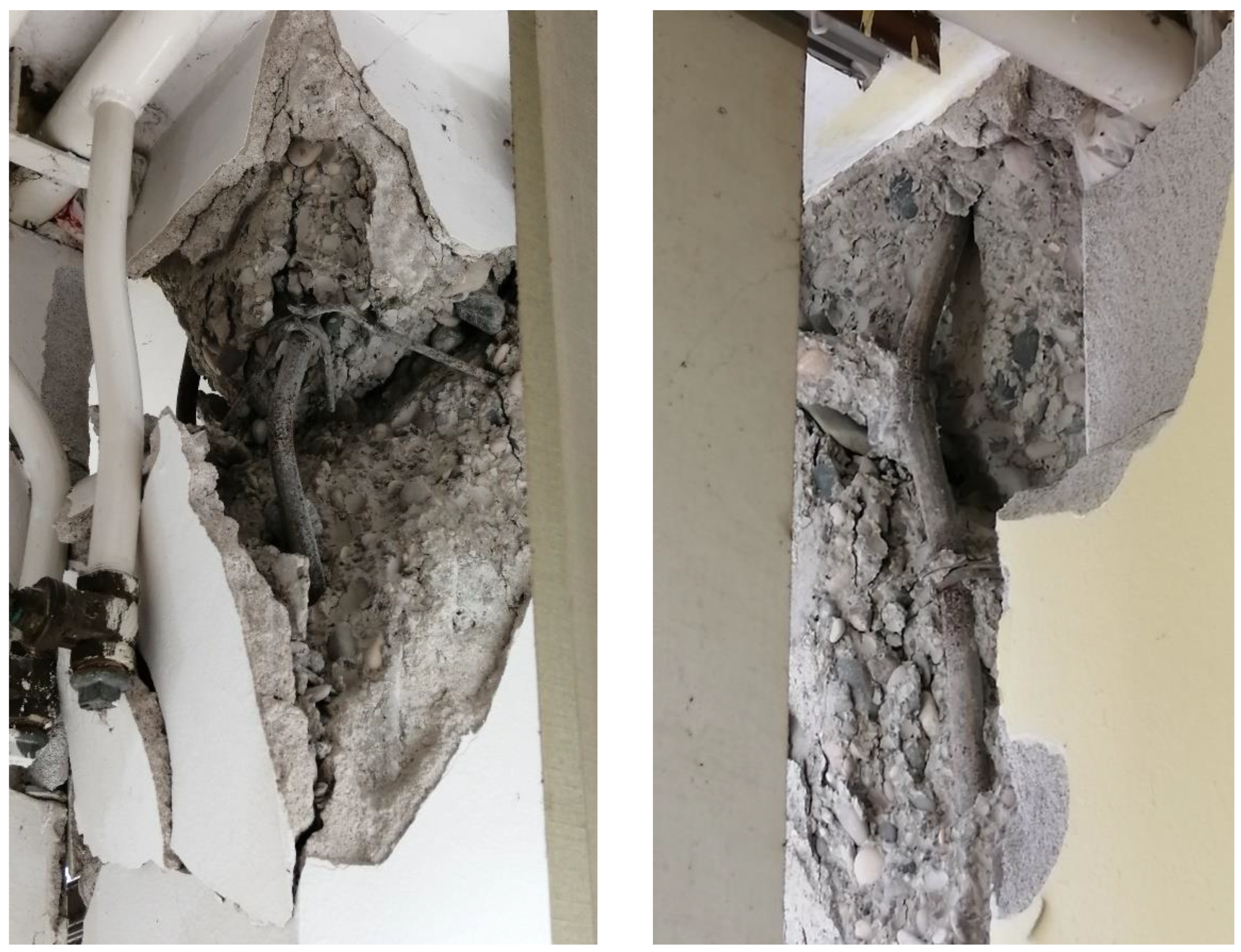

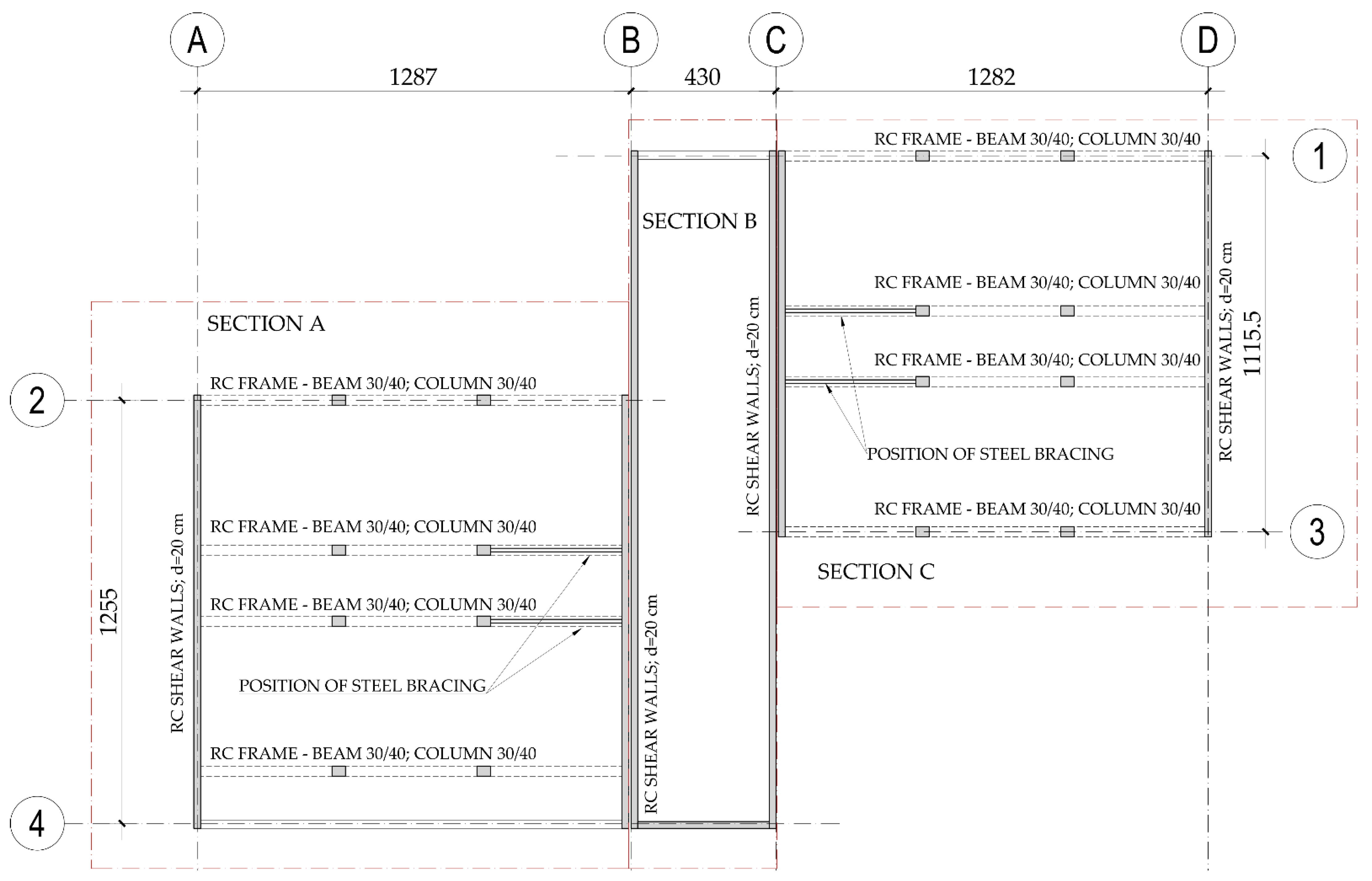

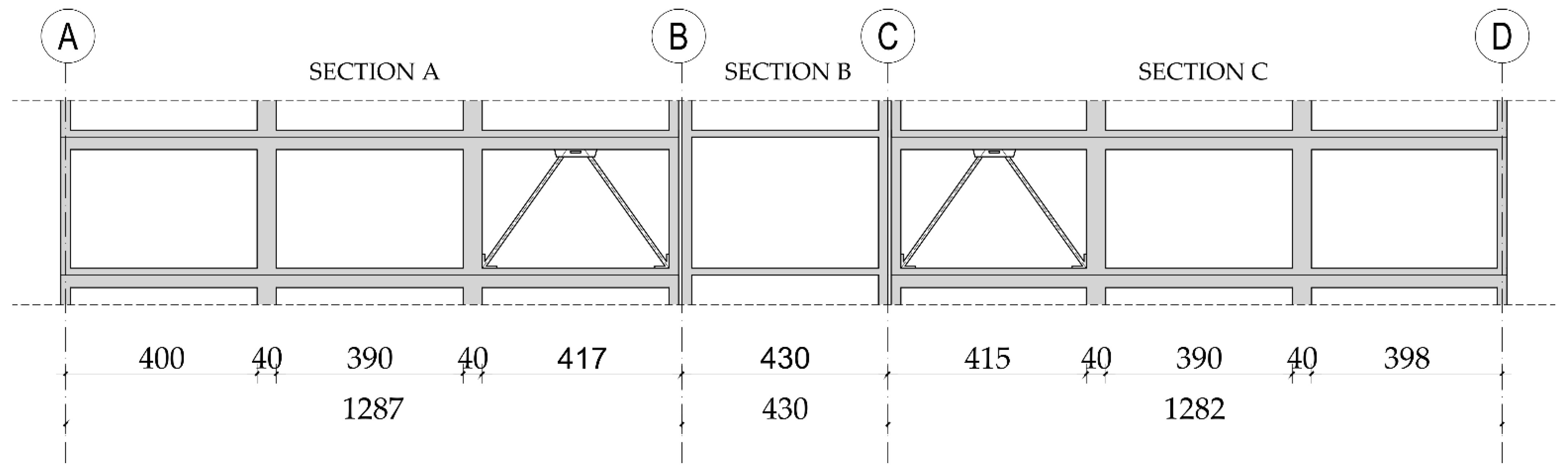

2.1.2. Structural System

2.2. Assessment Procedure

2.2.1. Seismic Assessment of Existing RC Structures—Overview

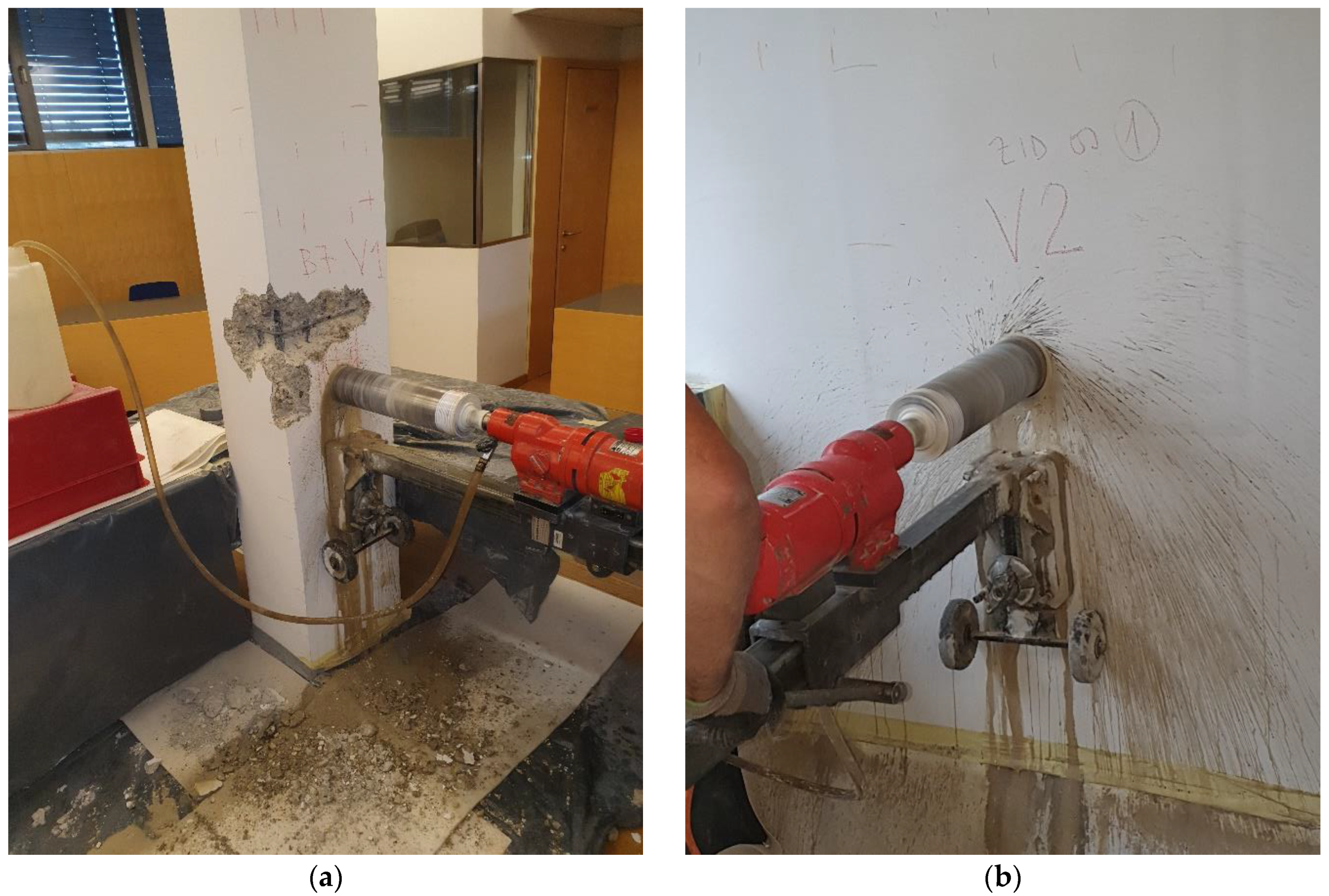

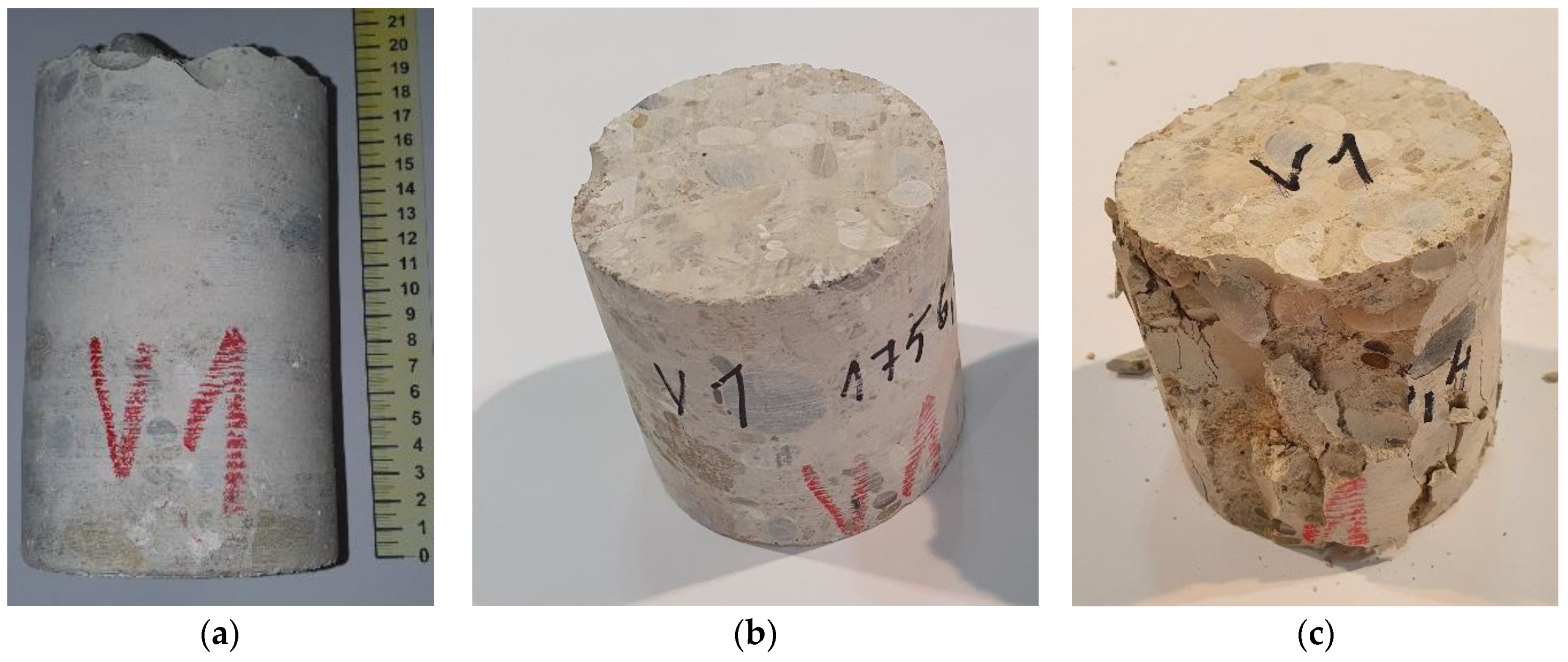

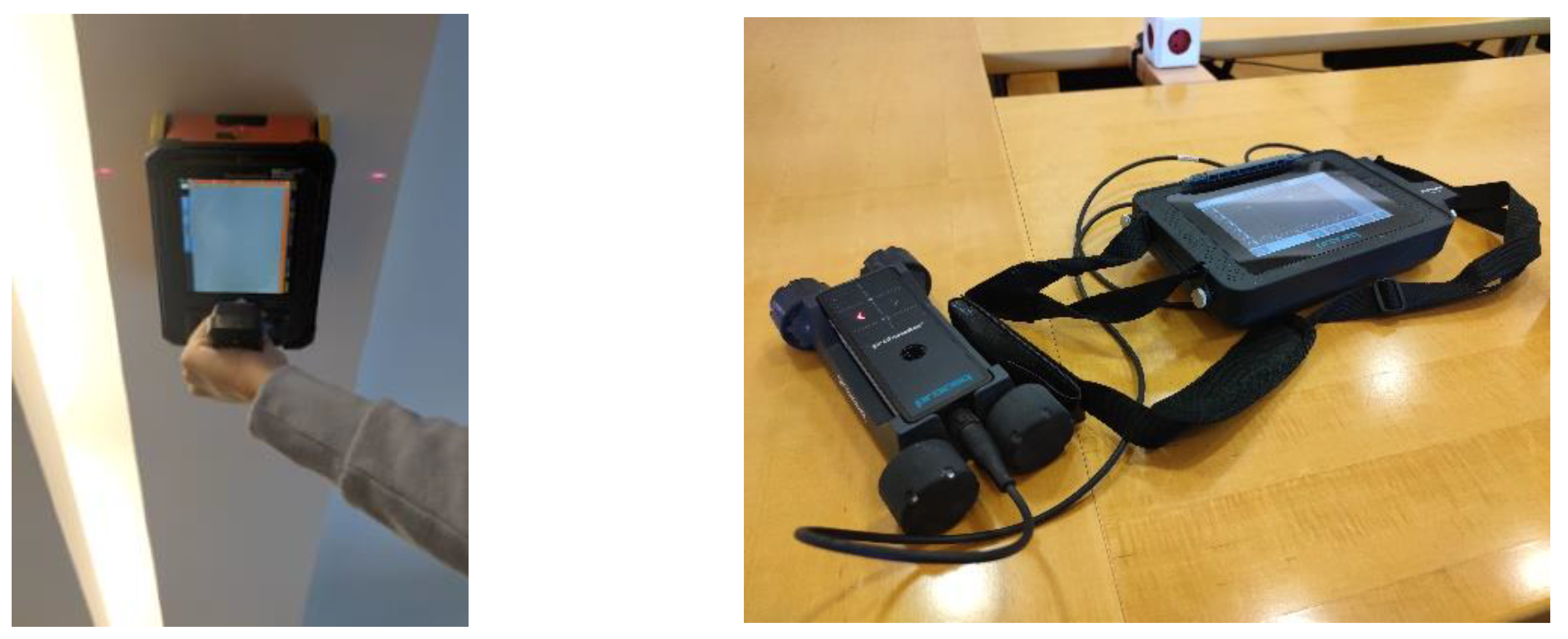

2.2.2. In Situ Measurements—Case Study Building

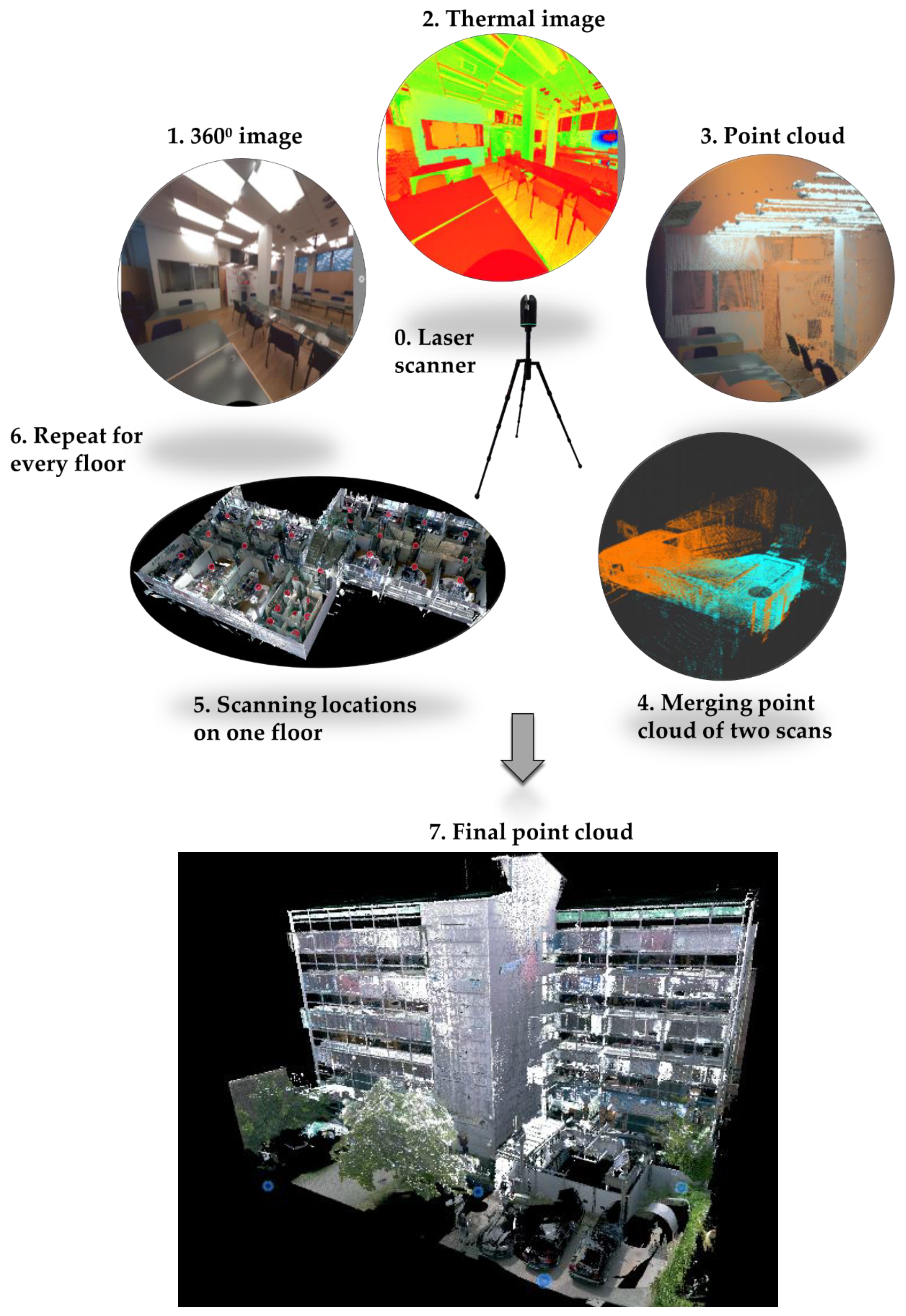

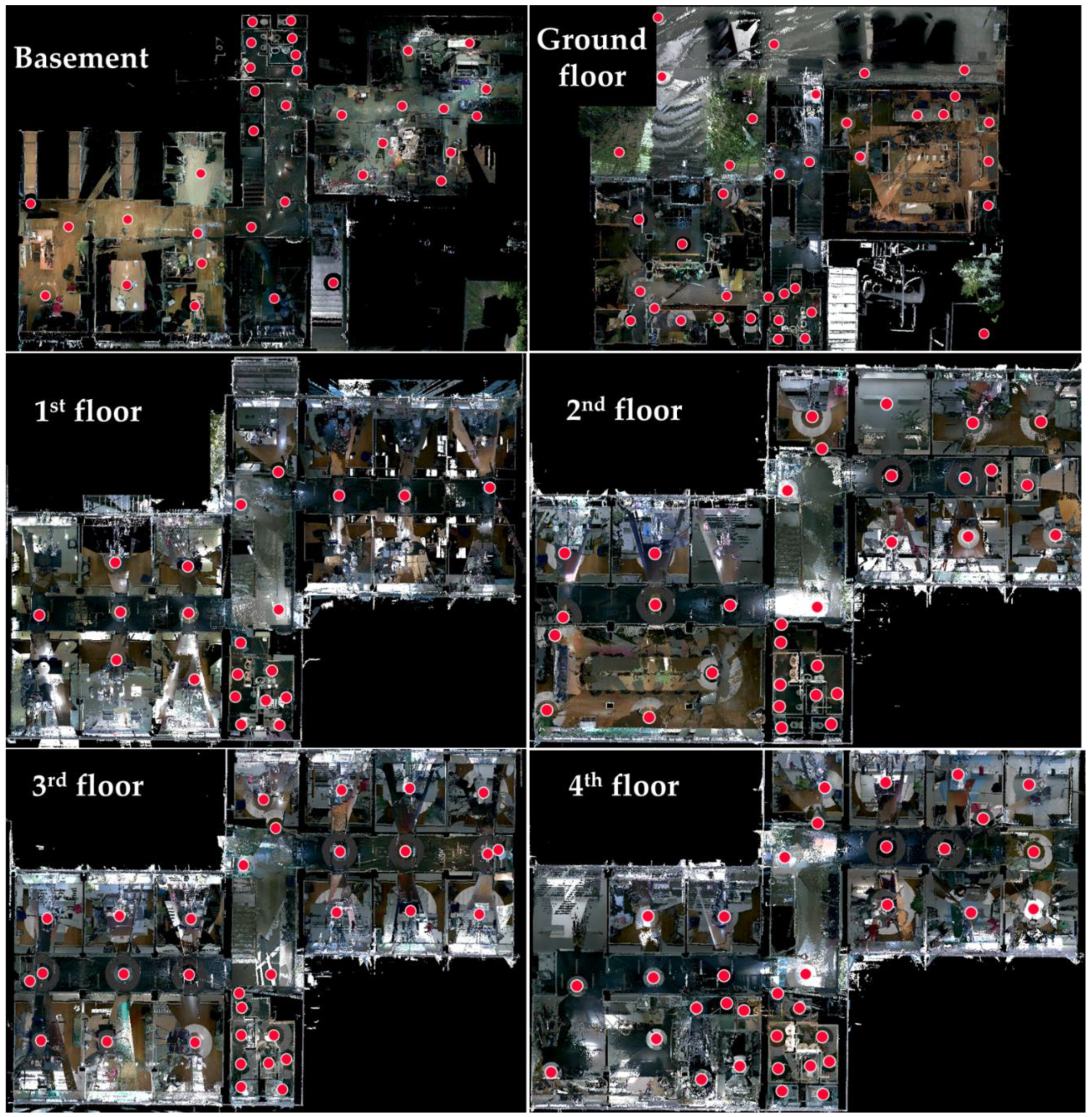

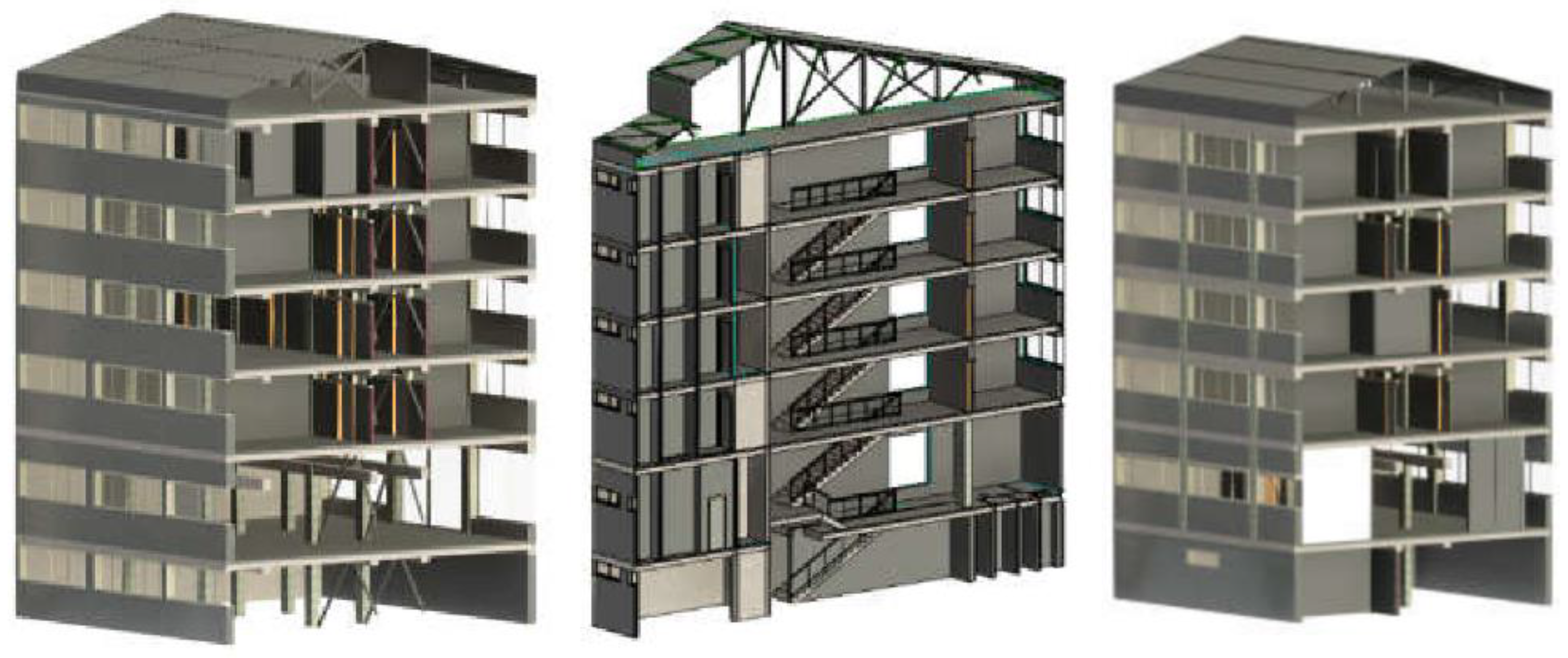

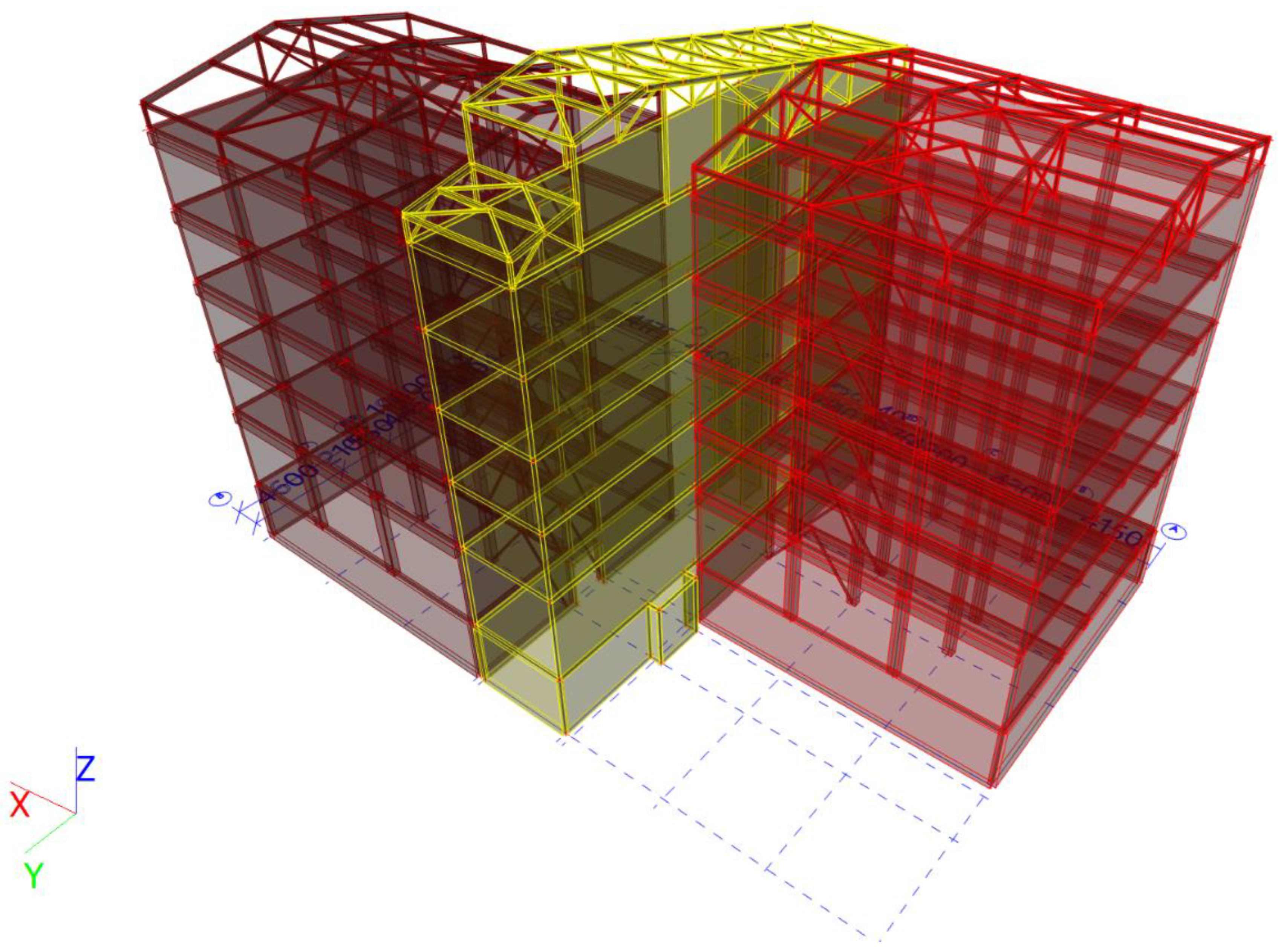

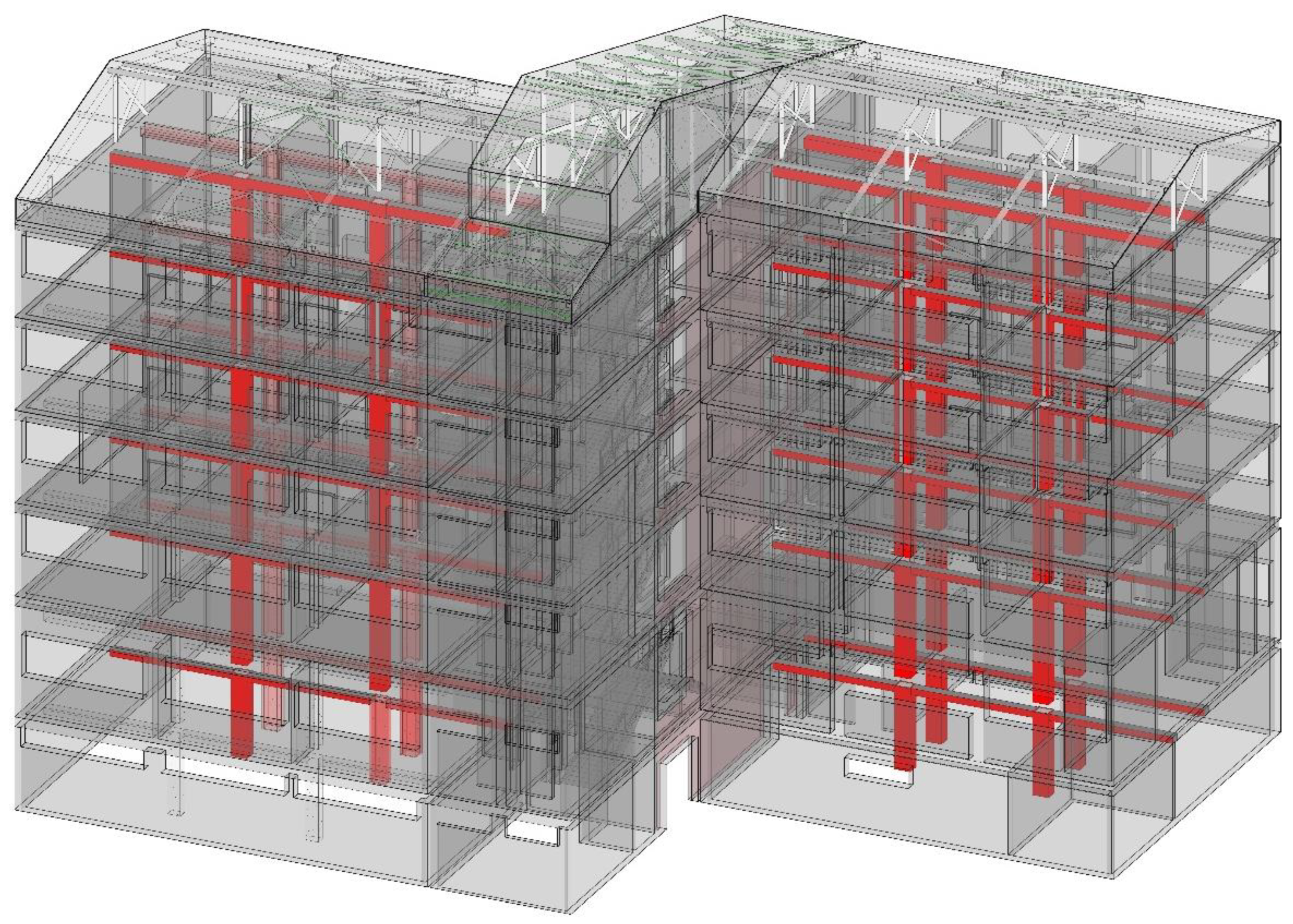

2.3. BIM Model

3. Seismic Analysis and Assessment—Numerical Modeling

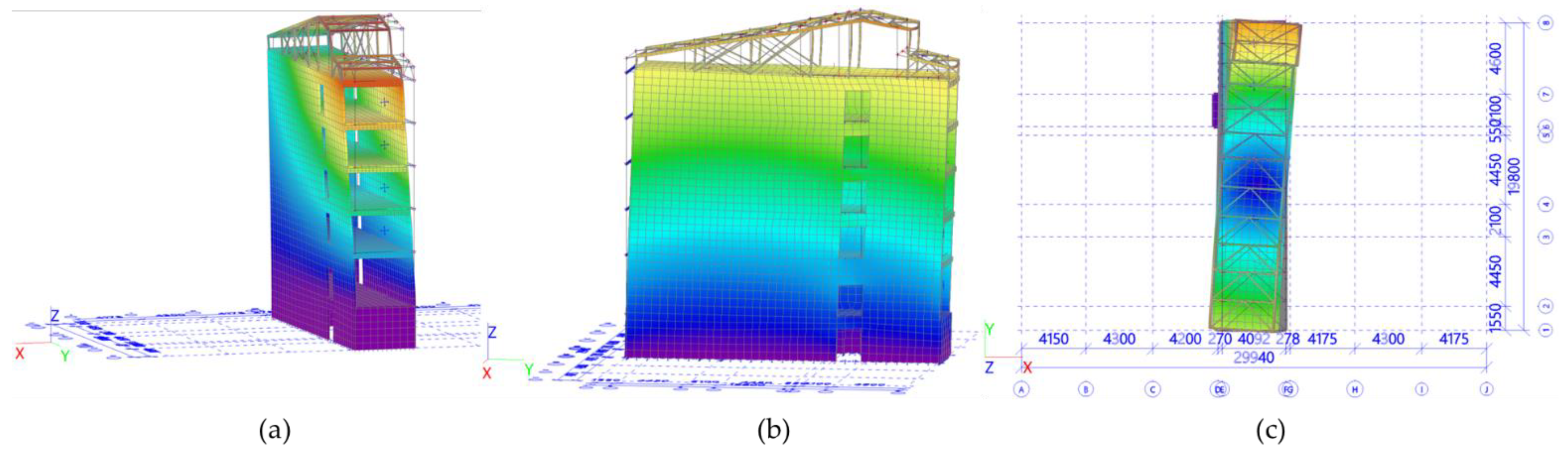

3.1. Development of the Numerical Model

3.1.1. Definition of Seismic Load

3.1.2. Modal Analysis—Eigenmodes and Displacements

3.1.3. Modal Analysis—ULS Verifications

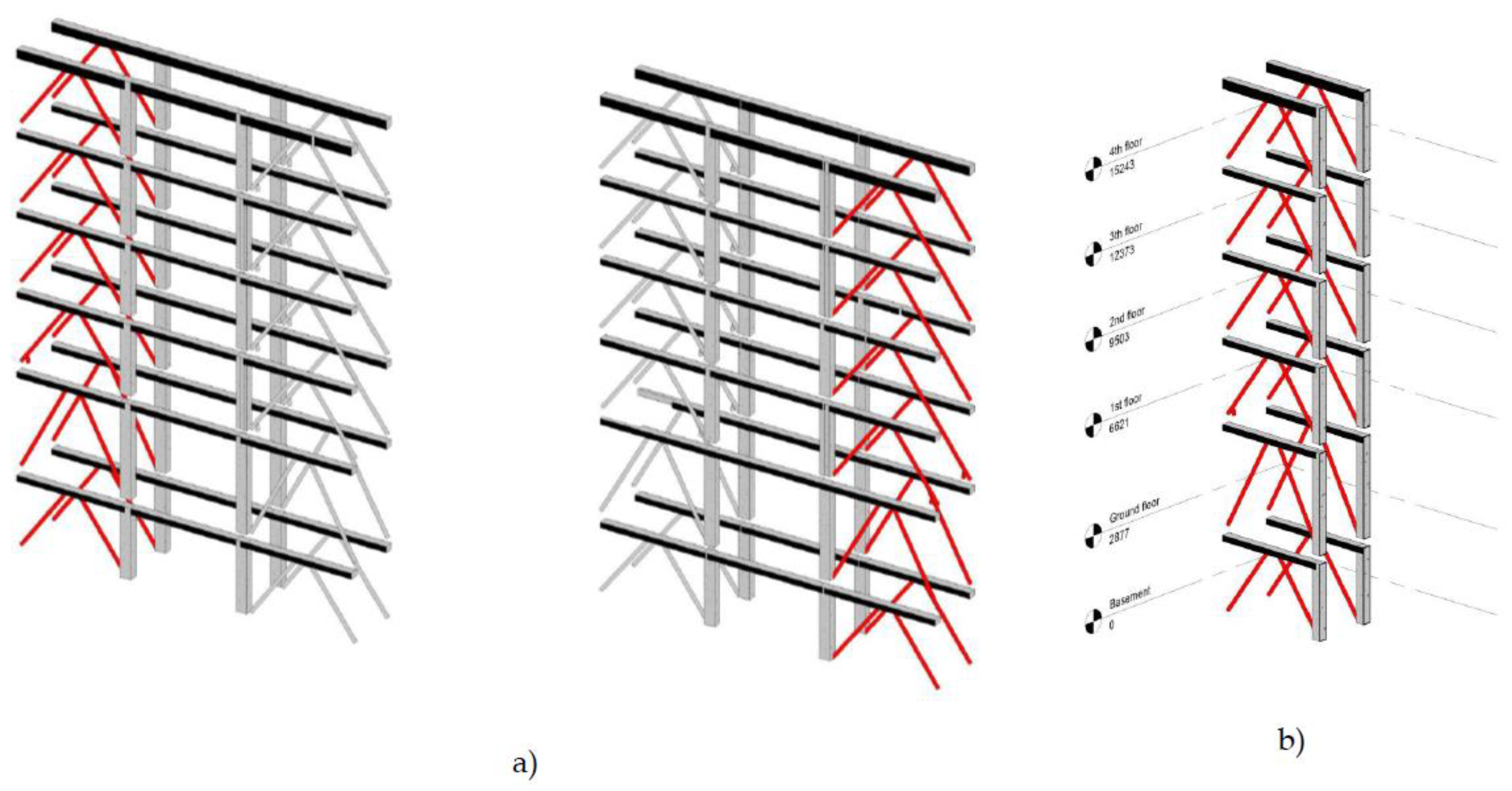

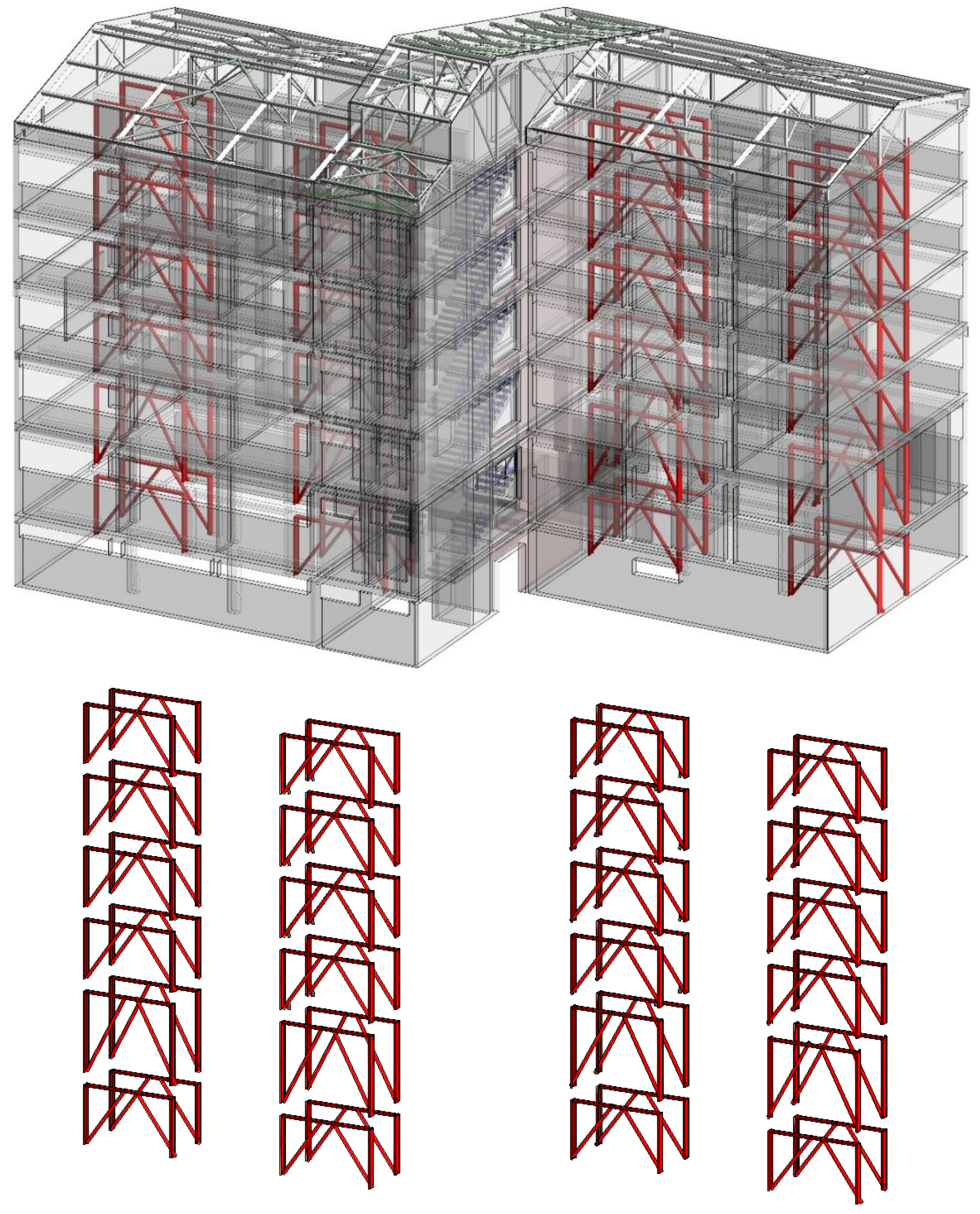

3.2. Strengthening Proposals—Case Study Building

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Penna, A.; Morandi, P.; Rota, M.; Manzini, C.F.; da Porto, F.; Magenes, G. Performance of Masonry Buildings during the Emilia 2012 Earthquake. Bull. Earthq. Eng. 2014, 12, 2255–2273. [Google Scholar] [CrossRef]

- Mazzoni, S.; Castori, G.; Galasso, C.; Calvi, P.; Dreyer, R.; Fischer, E.; Fulco, A.; Sorrentino, L.; Wilson, J.; Penna, A.; et al. 2016–2017 Central Italy Earthquake Sequence: Seismic Retrofit Policy and Effectiveness. Earthq. Spectra 2018, 34, 1671–1691. [Google Scholar] [CrossRef]

- Bilgin, H.; Shkodrani, N.; Hysenlliu, M.; Ozmen, H.B.; Isik, E.; Harirchian, E. Damage and Performance Evaluation of Masonry Buildings Constructed in 1970s during the 2019 Albania Earthquakes. Eng. Fail. Anal. 2022, 131, 105824. [Google Scholar] [CrossRef]

- Vlachakis, G.; Vlachaki, E.; Lourenço, P.B. Learning from Failure: Damage and Failure of Masonry Structures, after the 2017 Lesvos Earthquake (Greece). Eng. Fail. Anal. 2020, 117, 104803. [Google Scholar] [CrossRef]

- Cetin, K.O.; Altun, S.; Askan, A.; Akgün, M.; Sezerm, A.; Kıncal, C.; Özkan, C.Ö.; İpek, Y.; Unutmaz, B.; Gülerce, Z.; et al. The Site Effects in Izmir Bay of 30 October 2020, M7.0 Samos Earthquake. Soil Dyn. Earthq. Eng. 2022, 152, 107051. [Google Scholar] [CrossRef]

- Stepinac, M.; Lourenço, P.B.; Atalić, J.; Kišiček, T.; Uroš, M.; Baniček, M.; Šavor Novak, M. Damage Classification of Residential Buildings in Historical Downtown after the ML5.5 Earthquake in Zagreb, Croatia in 2020. Int. J. Disaster Risk Reduct. 2021, 56, 102140. [Google Scholar] [CrossRef]

- Government of the Republic of Croatia; The World Bank. The Croatia Earthquake—Rapid Damage and Need Assessment 2020; Government of Croatia: Zagreb, Croatia, 2020.

- Stepinac, M.; Kisicek, T.; Renić, T.; Hafner, I.; Bedon, C. Methods for the Assessment of Critical Properties in Existing Masonry Structures under Seismic Loads—The ARES Project. Appl. Sci. 2020, 10, 1576. [Google Scholar] [CrossRef]

- Vlašić, A.; Srbić, M.; Skokandić, D.; Ivanković, A.M. Post-Earthquake Rapid Damage Assessment of Road Bridges in Glina County. Buildings 2022, 12, 42. [Google Scholar] [CrossRef]

- Moretić, A.; Stepinac, M.; Lourenço, P.B. Seismic Upgrading of Cultural Heritage—A Case Study Using an Educational Building in Croatia from the Historicism Style. Case Stud. Constr. Mater. 2022, 17, e01183. [Google Scholar] [CrossRef]

- Republic of Croatia, Ministry of Physical Planning, Construction and State Assets. Croatian Technical Regulation for Building Structures; Official Gazette 17/17, 75/20, 7/22; Ministry of Physical Planning, Construction and State Assets: Zagreb, Croatia, 2022. (In Croatian)

- Goverment of Croatia. Integrated National Energy and Climate Plan for the Republic of Croatia for the Period 2021–2030; Government of Croatia: Zagreb, Croatia, 2019.

- Goverment of Croatia. Long-Term Strategy for Refurbishment of National Building Stock until 2050; Government of Croatia: Zagreb, Croatia, 2020.

- Law on the Reconstruction of Earthquake-Damaged Buildings in the City of Zagreb, Krapina-Zagorje County and Zagreb County (NN 102/2020). Available online: https://mpgi.gov.hr/naslovna-blokovi-133/singled-out/reconstruction-of-the-city-of-zagreb-and-krapina-zagorje-county/reconstruction-of-earthquake-damaged-buildings-in-the-city-of-zagreb-and-krapina-zagorje-county/13723 (accessed on 1 June 2022).

- EN 1998–1; Eurocode 8: Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings. European Committee for Normalization: Brussels, Belgium, 2004.

- EN 1998–3; Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Skokandić, D.; Vlašić, A.; Kušter Marić, M.; Srbić, M.; Mandić Ivanković, A. Seismic Assessment and Retrofitting of Existing Road Bridges: State of the Art Review. Materials 2022, 15, 2523. [Google Scholar] [CrossRef]

- Penelis, G.G.; Penelis, G.G. Concrete Buildings in Seismic Regions; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Sajid, S.H.; Ali, S.M.; Carino, N.J.; Saeed, S.; Sajid, H.U.; Chouinard, L. Strength Estimation of Concrete Masonry Units Using Stress-Wave Methods. Constr. Build. Mater. 2018, 163, 518–528. [Google Scholar] [CrossRef]

- Mesquita, E.; Martini, R.; Alves, A.; Antunes, P.; Varum, H. Non-Destructive Characterization of Ancient Clay Brick Walls by Indirect Ultrasonic Measurements. J. Build. Eng. 2018, 19, 172–180. [Google Scholar] [CrossRef]

- Martini, R.; Carvalho, J.; Barraca, N.; Arêde, A.; Varum, H. Advances on the Use of Non-Destructive Techniques for Mechanical Characterization of Stone Masonry: GPR and Sonic Tests. Procedia Struct. Integr. 2017, 5, 1108–1115. [Google Scholar] [CrossRef]

- Wai-Lok Lai, W.; Dérobert, X.; Annan, P. A Review of Ground Penetrating Radar Application in Civil Engineering: A 30-Year Journey from Locating and Testing to Imaging and Diagnosis. NDT E Int. 2018, 96, 58–78. [Google Scholar] [CrossRef]

- Meola, C. Infrared Thermography of Masonry Structures. Infrared Phys. Technol. 2007, 49, 228–233. [Google Scholar] [CrossRef]

- Santini, S.; Forte, A.; Sguerri, L. The Structural Diagnosis of Existing Rc Buildings: The Role of Nondestructive Tests in the Case of Low Concrete Strength. Infrastructures 2020, 5, 100. [Google Scholar] [CrossRef]

- Kušter Marić, M.; Vlašić, A.; Ivanković, A.M.; Bleiziffer, J.; Srbić, M.; Skokandić, D. Assessment of Reinforcement Corrosion and Concrete Damage on Bridges Using Non-Destructive Testing. Gradjevinar 2019, 71, 843–862. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G. Une Approche Fractale Pour La Détection de Dommages Aux Structures de Béton et de Maçonnerie Par Les Techniques d’ Émission Acoustique; Bruit: Paris, France, 2019. [Google Scholar]

- HZN HRN EN 12504–1:2019; Ispitivanje Betona u Konstrukcijama—1. Dio: Izvađeni Ispitni Uzorci—Uzimanje, Pregled i Ispitivanje Tlačne Čvrstoće. Croatian Standards Institute: Zagreb, Croatia, 2019.

- HZN HRN EN 12390–3:2019; Ispitivanje Očvrsnuloga Betona—3. Dio: Tlačna Čvrstoća Ispitnih Uzoraka. Croatian Standards Institute: Zagreb, Croatia, 2019.

- HZN HRN EN 13791:2019; Ocjena in-Situ Tlačne Čvrstoće u Konstrukcijama i Predgotovljenim Betonskim Dijelovima. Croatian Standards Institute: Zagreb, Croatia, 2019.

- HZN HRN EN 206:2016; Beton—Specifikacija, Svojstva, Proizvodnja i Sukladnost. Croatian Standards Institute: Zagreb, Croatia, 2016.

- Wang, X. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors. Constr. Econ. Build. 2012, 12, 101–102. [Google Scholar] [CrossRef]

- Chelson, D.E. The Effects of Building Information Modeling on Construction Site Productivity. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2010. Volume 53. [Google Scholar]

- Shipley, R.; Utz, S.; Parsons, M. Does Adaptive Reuse Pay? A Study of the Business of Building Renovation in Ontario, Canada. Int. J. Herit. Stud. 2006, 12, 505–520. [Google Scholar] [CrossRef]

- Pepe, M.; Costantino, D.; Garofalo, A.R. An Efficient Pipeline to Obtain 3D Model for HBIM and Structural Analysis Purposes from 3D Point Clouds. Appl. Sci. 2020, 10, 1235. [Google Scholar] [CrossRef]

- Remondino, F. Heritage Recording and 3D Modeling with Photogrammetry and 3D Scanning. Remote Sens. 2011, 3, 1104–1138. [Google Scholar] [CrossRef]

- SCIA. SCIA—Structural Analysis & Design Software; SCIA: London, UK, 2021. [Google Scholar]

- Kisicek, T.; Stepinac, M.; Renic, T.; Hafner, I.; Lulic, L. Strengthening of Masonry Walls with FRP or TRM. J. Croat. Assoc. Civ. Eng. 2020, 72, 937–953. [Google Scholar] [CrossRef]

- Pampanin, S.; Bolognini, D.; Pavese, A. Performance-Based Seismic Retrofit Strategy for Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer Composites. ASCE J. Compos. Constr. 2007, 11, 211–226. [Google Scholar] [CrossRef]

- Faggiano, B.; Iovane, G.; Salzillo, D.; Mazzolani, F.M.; Landolfo, R. Dissipative Bracing Systems for Seismic Upgrading of New and Existing Timber Structures. Int. J. Archit. Herit. 2021, 15, 289–312. [Google Scholar] [CrossRef]

- Barazzetti, L.; Banfi, F.; Brumana, R.; Gusmeroli, G.; Previtali, M.; Schiantarelli, G. Cloud-to-BIM-to-FEM: Structural Simulation with Accurate Historic BIM from Laser Scans. Simul. Model. Pract. Theory 2015, 57, 71–87. [Google Scholar] [CrossRef]

- Funari, M.F.; Hajjat, A.E.; Masciotta, M.G.; Oliveira, D.V.; Lourenço, P.B. A Parametric Scan-to-FEM Framework for the Digital Twin Generation of Historic Masonry Structures. Sustainability 2021, 13, 11088. [Google Scholar] [CrossRef]

- Castellazzi, G.; D’Altri, A.M.; Bitelli, G.; Selvaggi, I.; Lambertini, A. From Laser Scanning to Finite Element Analysis of Complex Buildings by Using a Semi-Automatic Procedure. Sensors 2015, 15, 18360–18380. [Google Scholar] [CrossRef]

| NDT Method | Devices/Test | What Is Measured? | How Is It Measured? | References |

|---|---|---|---|---|

| Visual inspection | / | Damage degree, usability of the building | Without a device, using qualitative analysis and experience | Penelis and Penelis [18] |

| Reinforcement location and type | Impact drill | Location and type of reinforcement | Concrete cover is removed till the reinforcement is visible | / |

| Stress wave transmission | Ultrasonic Pulse Velocity (UPV) test/Resonant frequency (RF) test | Compressive strength of concrete | UPV—two transducers are placed on two sides of the specimen after which the time of wave travel is measured; RF—a piezometric sensor is used with different attachment techniques to obtain resonant frequency | Sajid et al. [19] |

| Ultrasonic velocity testing | Impact hammer and accelerometer | Characterization of wall homogeneity and variability | On opposite sides of the wall, an impact hammer and an accelerometer are placed. The mechanical impulse is generated by the hammer striking the material and the signal is then received by the accelerometer. | Mesquita et al. [20] |

| Surface penetrating radar | Ground Penetrating Radar (GPR) | Location (depth) of reinforcement, thickness of elements, position of voids and moisture content | The device is placed on the measured surface and moved along a linear axis (with a calibration needed) transmitting radio wave signals into a structure and detecting echoes | Martini et al. [21] Wai-Lok Lai, Dérobert and Annan [22] |

| Infrared thermography | Thermography cameras Visual IR thermometers | Defects in the building envelope, the monitoring of reinforcing steel in concrete, the detection of moisture etc. | The element is under thermal stimulation and its surface temperature variation is monitored | Meola [23] |

| Compression Test | Drilling equipment, compression testing machine | Compressive strength | Cylindrical specimens are extracted from the structure and tested in the laboratory with the compression machine | Santini et al. [24] |

| Tensile test | Drilling equipment, Tensile testing machine | Tensile test of steel reinforcement | Steel reinforcement is extracted from the structure and tested in the laboratory | Santini et al. [24] |

| Pull-out method | Pull-out equipment | Cubic compression strength | Force needed to extract a small conical concrete sample by the pull-out equipment | Santini et al. [24] |

| Half-cell potential measurement (Profometer) | Open circuit potential measurement of reinforcing steel | Concrete cover depth and location of the reinforcement; half cell potential (indicator for corrosion of reinforcement) | The electrode is connected to the uncoated rebar, and the electrical circuit is completed with the saturated solution on the concrete surface | Kušter Marić et al. [25] |

| Wenner probe | Non-destructive—on the surface of the concrete | Surface electrical resistivity of concrete—used for evaluation of reinforcement corrosion | The device is based on the Wenner probe principle—four electrodes are in contact with the surface, closing the electrical circuit | Kušter Marić et al. [25] |

| Schmidt hammer | Non-destructive—on the surface of the concrete | The compression strength of the concrete | The device is placed on the surface of the concrete and the rebound of the hammer is measured for the compression strength estimation | Kušter Marić et al. [25] |

| Acoustic emission | The damage evolution and crack formation in concrete or masonry | A group of transducers are set to record signals, then locate the precise area of their origin by measuring the time for the sound to reach different transducers. | Carpintier et al. [26] |

| Analysis Method | Type | Advantages | Disadvantages |

|---|---|---|---|

| Response spectrum method | Linear analysis | Easy to use Provide periods and eigenmodes Provides base shear | Conservative for regular structures Does not take into account load redistribution after plastic hinges are formed |

| Fundamental mode method | |||

| Time series analysis | |||

| Pushover analysis | Non–linear analysis | Provide capacity of the structure Provides limit displacements | Complex Requires M- φ curve for each element Does not define prevailing failure mode for higher eigenmodes |

| Time history analysis | |||

| Probabilistic and sampling methods |

| Position | Breaking Force [kN] | Compressive Strength [Mpa] |

|---|---|---|

| Column ground floor | 238.50 | 31.27 |

| Wall second floor | 203.50 | 26.75 |

| Return Period | PGA | Explanation |

|---|---|---|

| 95 years | 0.12 g | Used for validation of displacements for new and existing structures. |

| 225 years | 0.18 g | Used for seismic assessment based on Croatian standard for post-earthquake assessment and strengthening |

| 475 years | 0.24 g | Used for ULS validation |

| Section | Displacement for 95 Years [mm] | Limit Displacement = H/500 [mm] | Utilization |

|---|---|---|---|

| A | 20.18 | 34.70 | 58% |

| B | 26.22 | 75% | |

| C | 22.73 | 65% |

| Story | H [m] | Ux [mm] | Uy [mm] | Utotal [mm] | Ui-Ui-1 [mm] | Ui/200 [mm] | Utilization |

|---|---|---|---|---|---|---|---|

| 0 | 0.00 | 0.00 | 0.00 | 0.00 | / | / | / |

| 1 | 3.73 | 6.00 | 0.30 | 6.01 | 5.91 | 18.65 | 32% |

| 2 | 6.61 | 11.10 | 0.50 | 11.11 | 5.10 | 14.40 | 35% |

| 3 | 9.49 | 16.60 | 0.70 | 16.61 | 5.50 | 14.40 | 38% |

| 4 | 12.37 | 21.80 | 0.80 | 21.81 | 5.20 | 14.40 | 36% |

| 5 | 15.25 | 26.22 | 1.22 | 27.13 | 4.61 | 14.40 | 32% |

| Section | Total Displacement U(i) [mm] | Limitation [mm] | Utilization | ||

|---|---|---|---|---|---|

| A | 20.18 | 33.09 | 50.00 | 66% | |

| B | 26.22 | 33.09 | 34.71 | 69% | |

| C | 22.73 | 34.71 | 69% |

| NEd,max [kN] | NEd,min [kN] | FX,Ed [kN] | FY,Ed [kN] | MX,Ed [kNm] | MY,Ed [kNm] |

| 4531.32 | 2377.75 | 43.51 | 1327.20 | 7455.07 | 31.05 |

| L [cm] | b [cm] | h [cm] | d = 0.9 × L [cm] | h/L | fcd [kN/cm2] |

| 1255.00 | 20.00 (30.00 in the basement) | 1840.00 | 1129.50 | 1.45 | 1.667 |

| fcd [kN/cm2] | fyd [kN/cm2] | l [cm] | b [cm] | z = 0.9 × d [cm] | As [cm2] | µ | Utilization |

| 1.667 | 23.48 | 1285.00 | 30.00 | 1028.00 | 98.69 | 0.60 | 143% |

| NEd,min [kN] | MX,Ed [kNm] | Vdd [kN] | Vid [kN] | Vfd [kN] | VRd,s [kN] | VEd [kN] | |

| 1255.00 | 7455.07 | 579.29 | 0.00 | 346.95 | 926.24 | 1327.20 |

| Beam | Bending Moment—Span [kNm] | Hogging Moment—Support [kNm] | Shear Force—Support [kN] |

| 71.61 | 118.54 | 118.32 | |

| Column | Axial force [kN] | Shear Force [kN] | Bending moment [kNm] |

| 1348.85 | 63.18 | 122.83 |

| Beam | Bending Moment—Span | Hogging Moment—Support | Shear Force—Support |

| 92% | N/A | 103% | |

| Column | Axial force | Shear Force | Bending moment |

| 63% | 173% | 52% |

| Proposed Method | Explanation | Advantages | Disadvantages |

|---|---|---|---|

| FRP jacketing—RC beams and columns | Increase in the cross-sectional capacity of existing RC frames, no effect on global stiffness distribution | Cost-effective; does not require complete closure | No effect on lateral stiffness; majority of walls require shotcrete strengthening |

| Additional steel bracing | Slight increase in the lateral stiffness, reduction in the load effects in beams | Does not require complete closure; similar to the previous strengthening | Dimension of the new bracing; slight increase in stiffness; walls require shotcrete |

| New RC perimeter walls in direction X | Significant increase in the lateral stiffness, global behavior of the structure changed, reduction in load effects in RC frames | Complete redistribution of stiffness; no additional strengthening required | Very expensive; requires new windows and façade; requires new foundations |

| New steel frames connected to the existing RC frames | Steel frames transfer complete lateral force to the foundations, RC frames do not require seismic verification, redistribution of global stiffness | Lateral stiffness increased by 30% cost-effective; does not require heavy demolition work | Challenging connection through the RC slabs; requires new foundation pads in the basement; basement walls require shotcrete |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stepinac, M.; Skokandić, D.; Ožić, K.; Zidar, M.; Vajdić, M. Condition Assessment and Seismic Upgrading Strategy of RC Structures—A Case Study of a Public Institution in Croatia. Buildings 2022, 12, 1489. https://doi.org/10.3390/buildings12091489

Stepinac M, Skokandić D, Ožić K, Zidar M, Vajdić M. Condition Assessment and Seismic Upgrading Strategy of RC Structures—A Case Study of a Public Institution in Croatia. Buildings. 2022; 12(9):1489. https://doi.org/10.3390/buildings12091489

Chicago/Turabian StyleStepinac, Mislav, Dominik Skokandić, Karlo Ožić, Margareta Zidar, and Matija Vajdić. 2022. "Condition Assessment and Seismic Upgrading Strategy of RC Structures—A Case Study of a Public Institution in Croatia" Buildings 12, no. 9: 1489. https://doi.org/10.3390/buildings12091489

APA StyleStepinac, M., Skokandić, D., Ožić, K., Zidar, M., & Vajdić, M. (2022). Condition Assessment and Seismic Upgrading Strategy of RC Structures—A Case Study of a Public Institution in Croatia. Buildings, 12(9), 1489. https://doi.org/10.3390/buildings12091489