Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete

Abstract

:1. Introduction

Research Significance

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of Conrete

2.3. Testing Methods

2.3.1. Fresh State Testing (Slump Test)

2.3.2. Mechanical Testing

3. Results and Discussions

3.1. Analysis of Concrete Incorporating Wheat Straw Ash as SCM

3.1.1. Slump Test

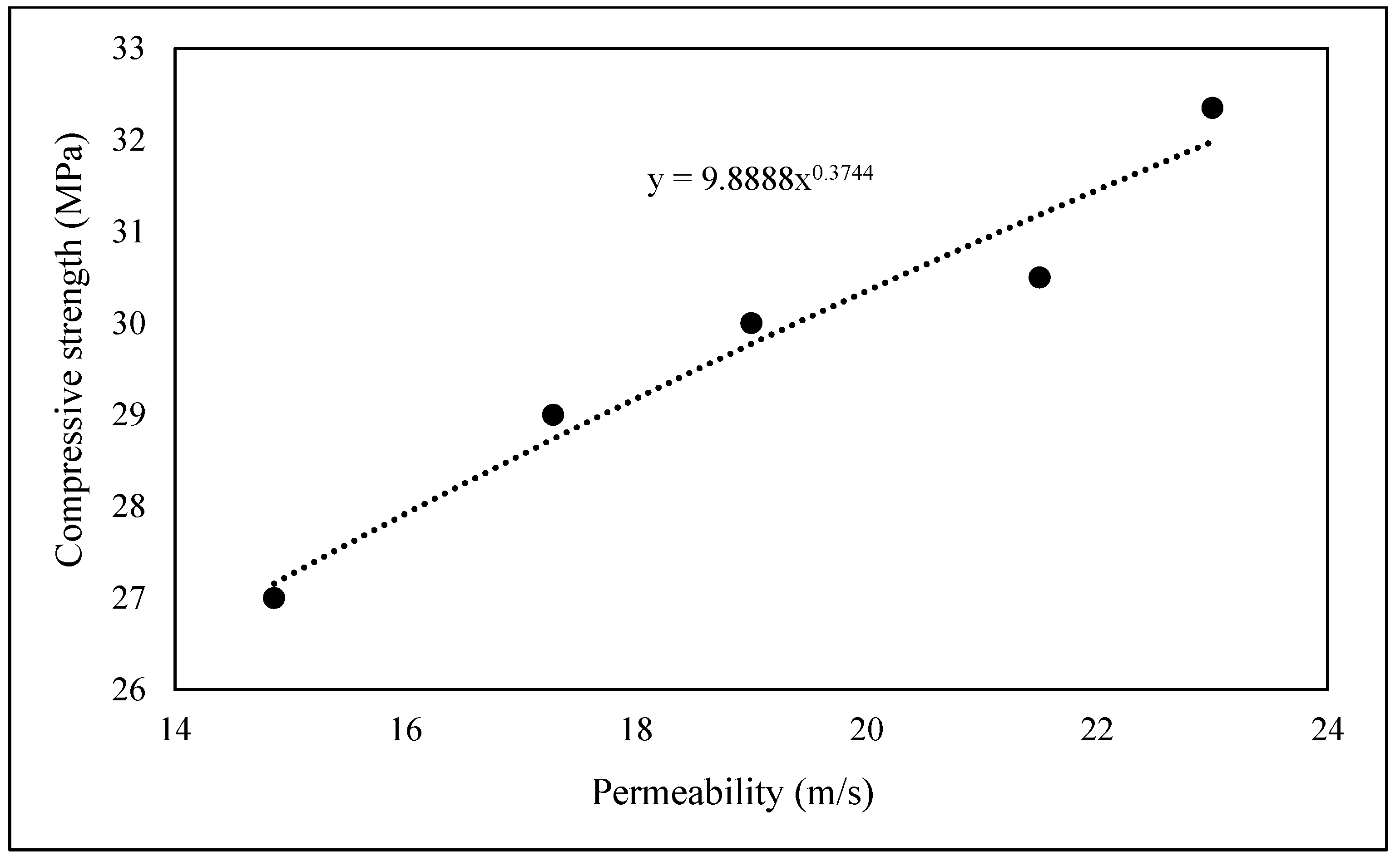

3.1.2. Compressive Strength

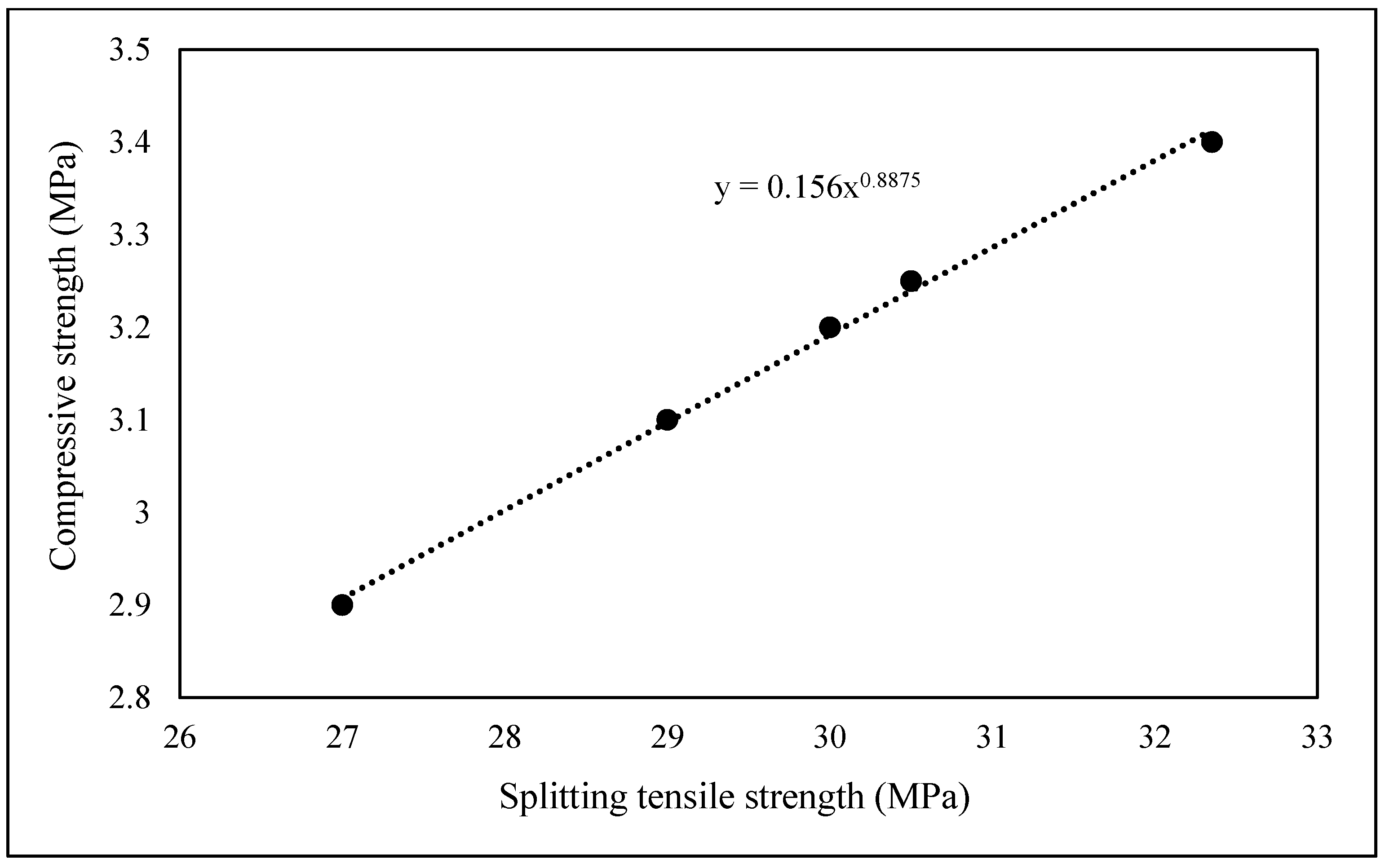

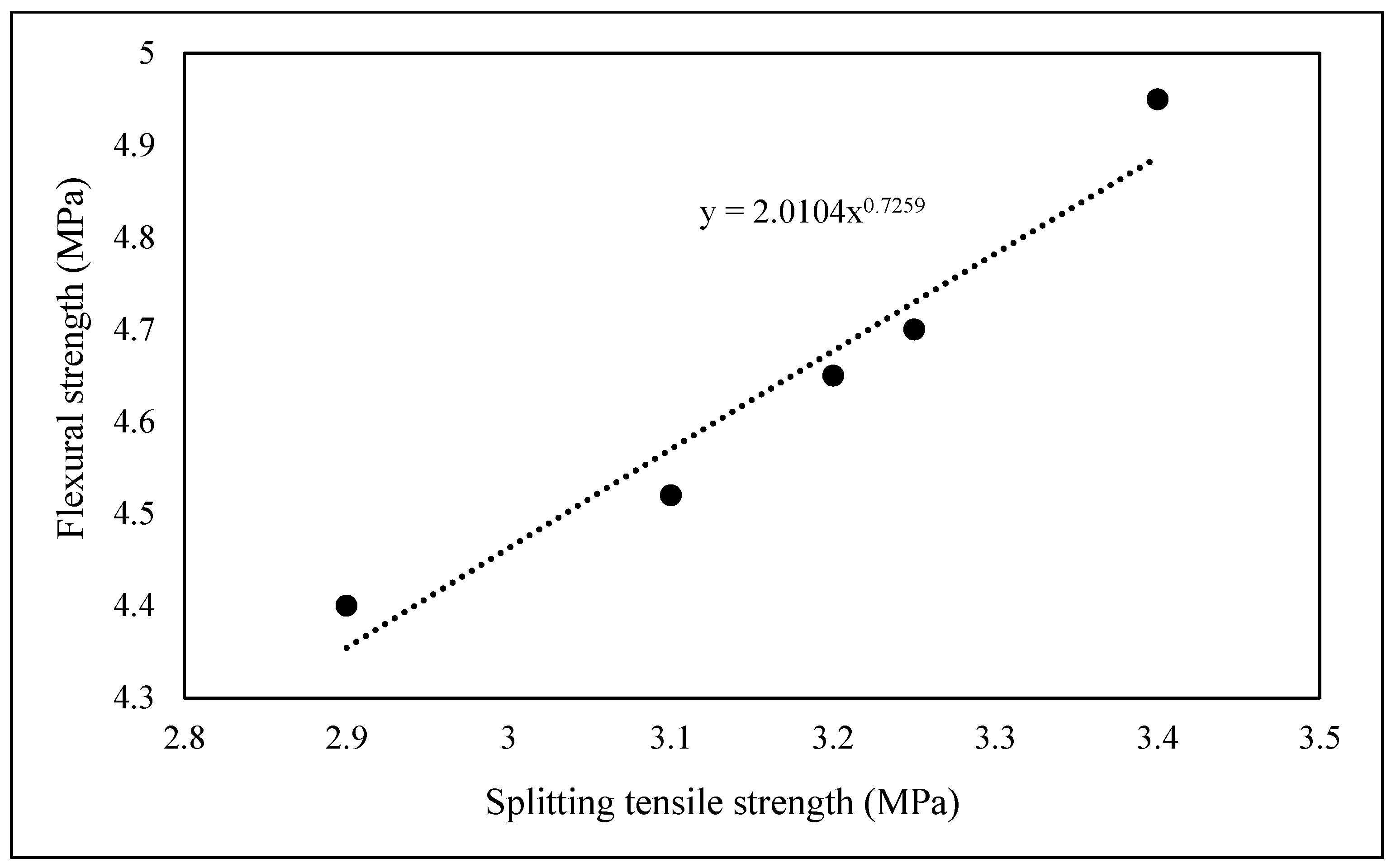

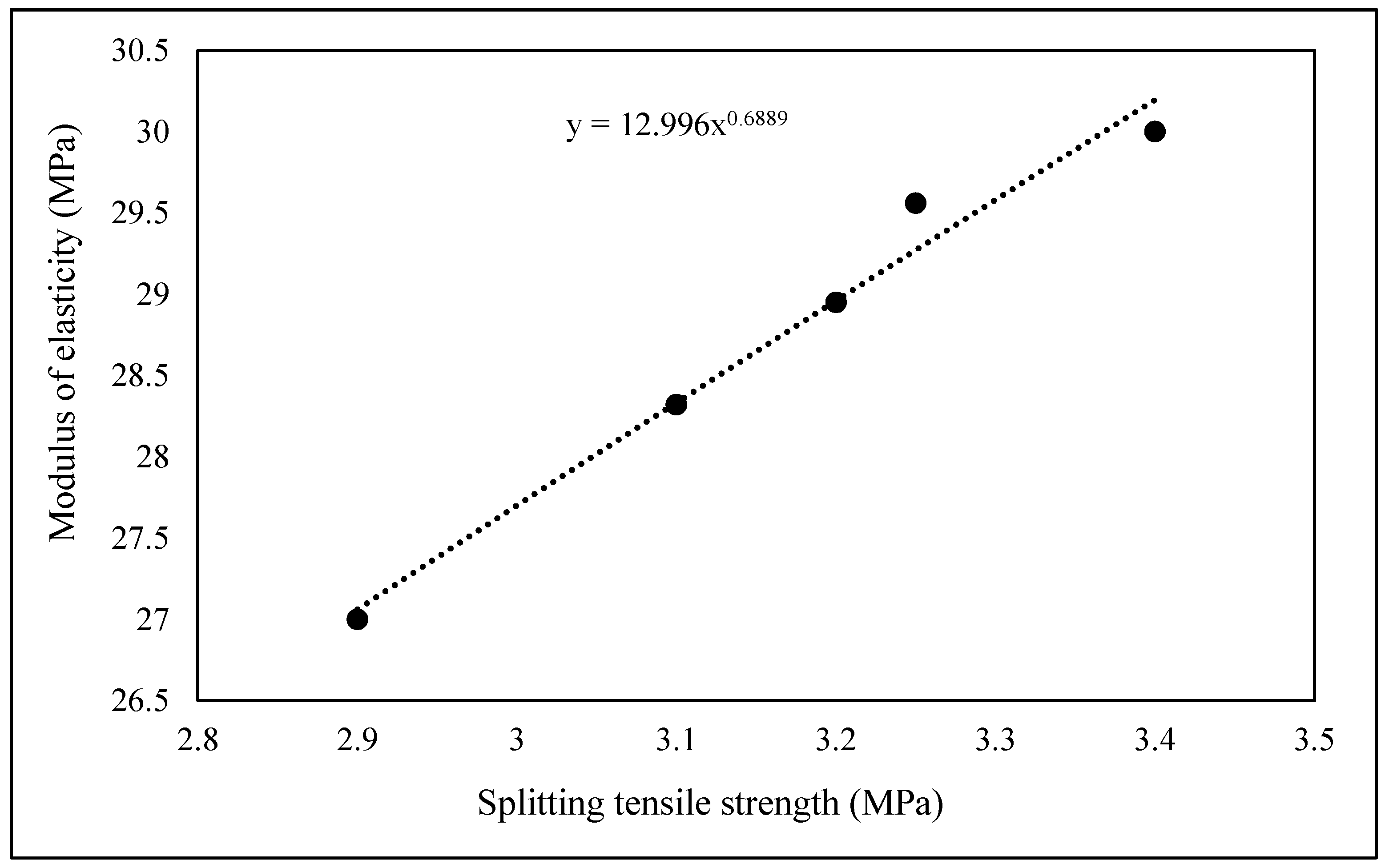

3.1.3. Splitting Tensile Strength

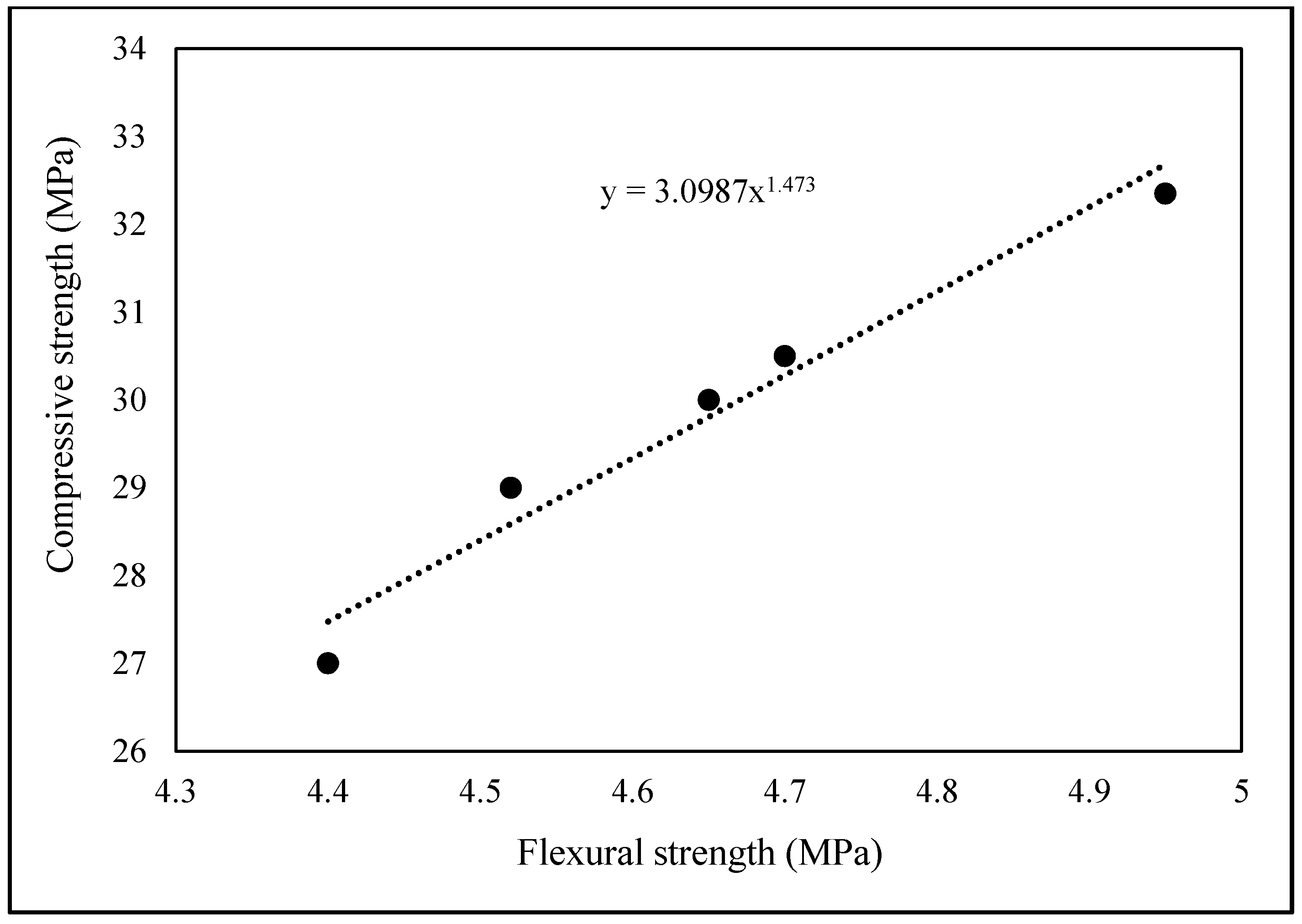

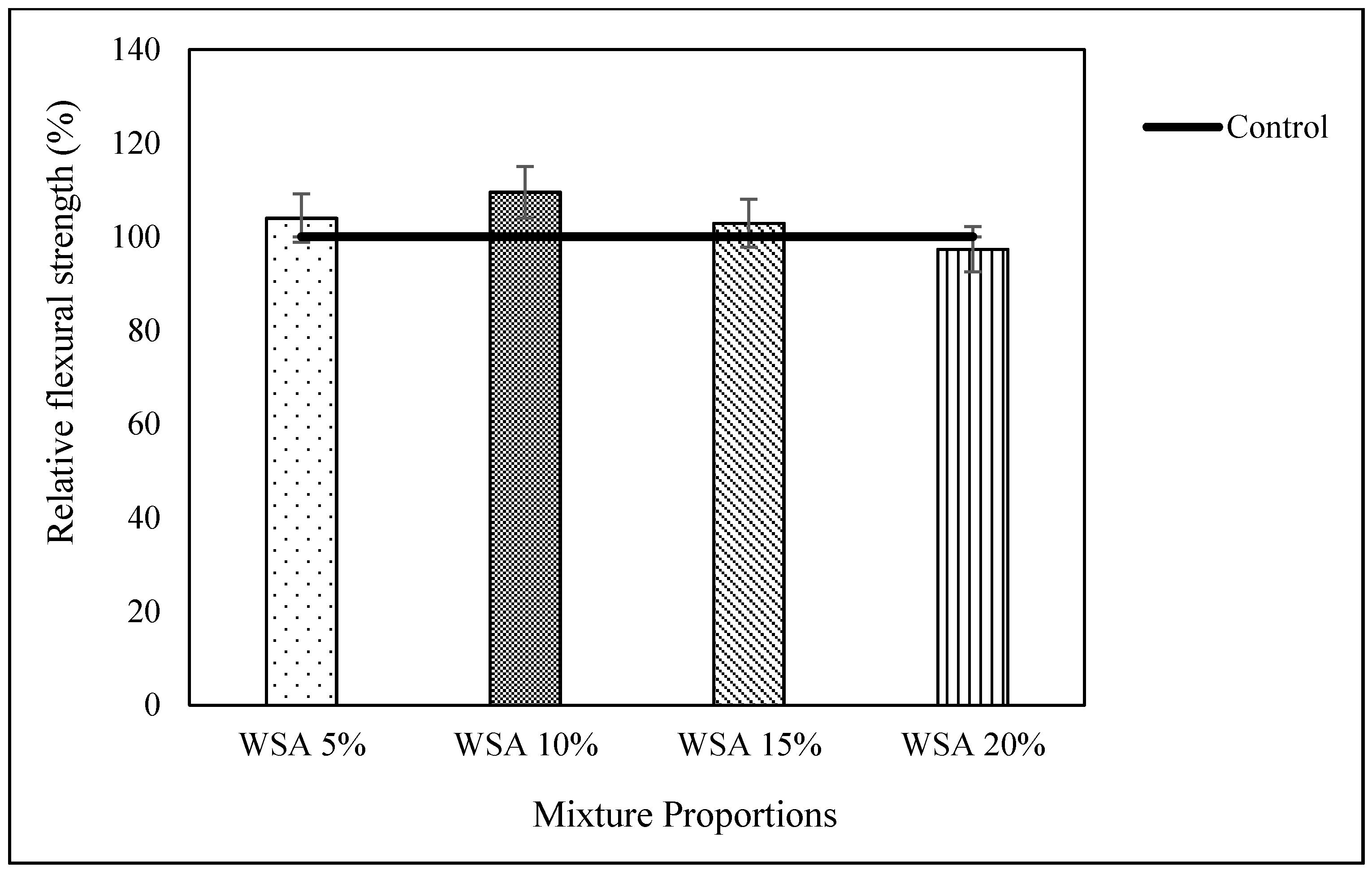

3.1.4. Flexural Strength

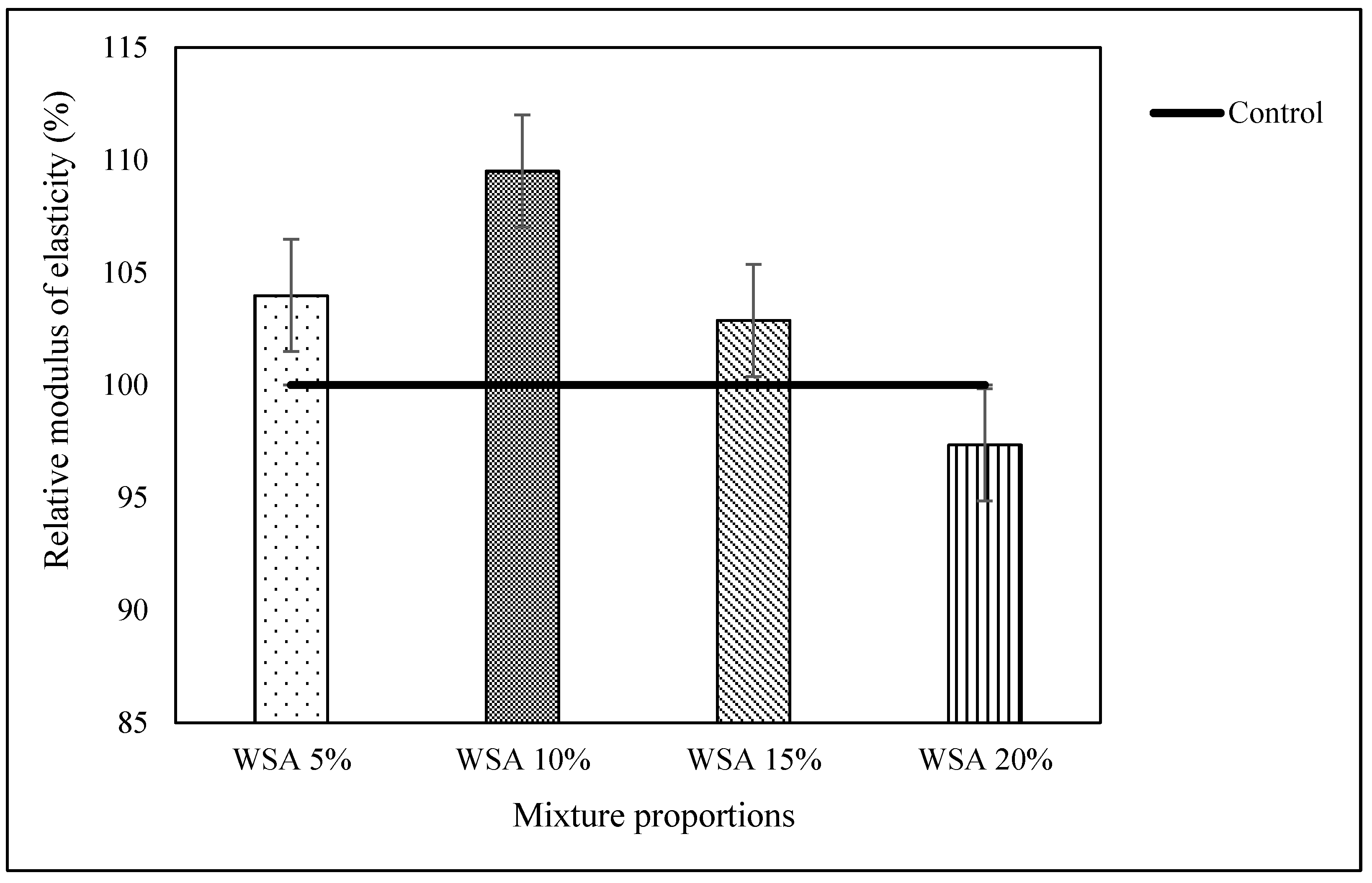

3.1.5. Modulus of Elasticity (MOE)

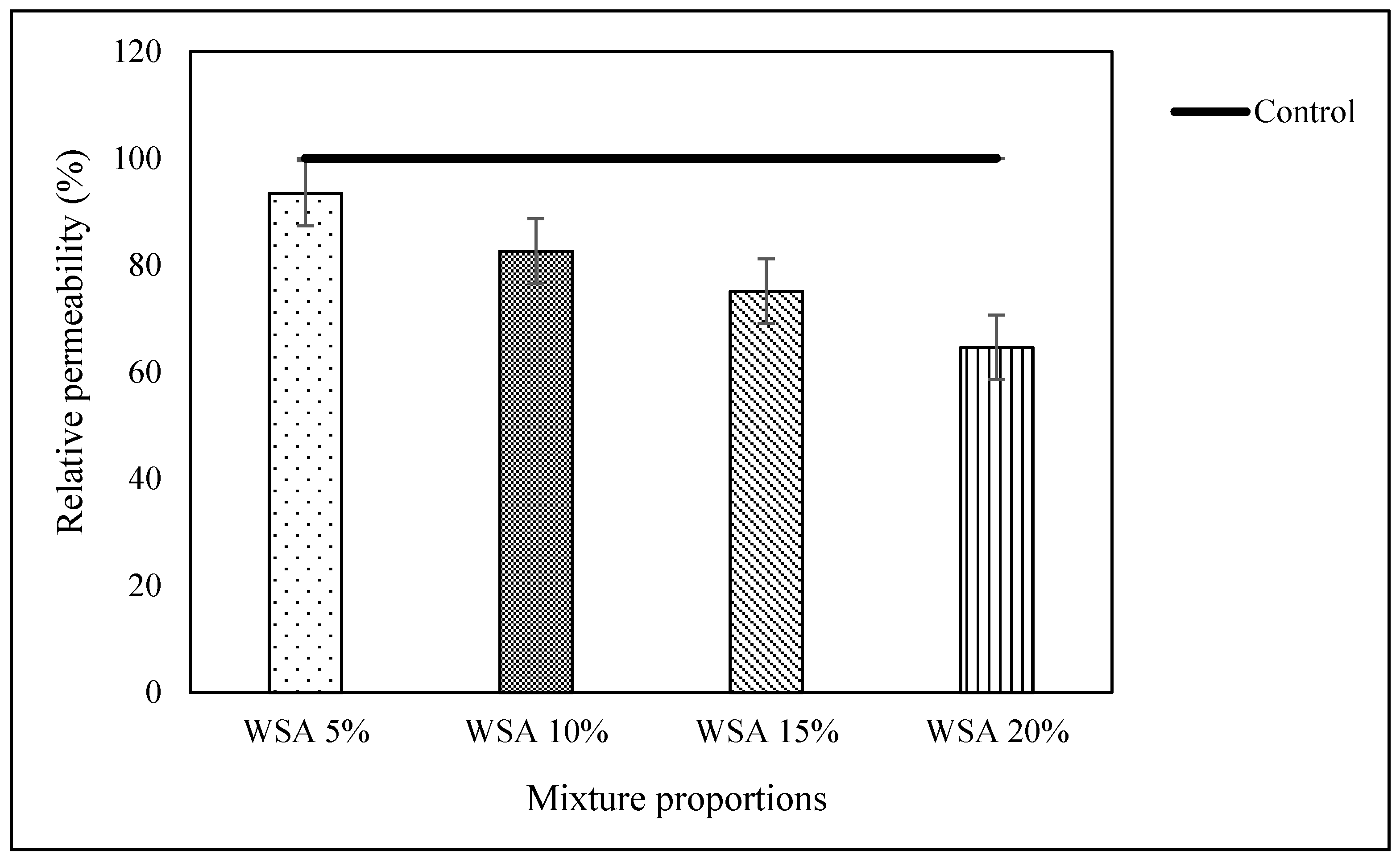

3.1.6. Permeability

4. Conclusions

- The workability of concrete declined as the quantity of PC substituted with WSA in concrete increased.

- The compressive, splitting tensile, and flexural strengths were enhanced at 10% of WSA while the lowest compressive, splitting, and flexural strengths were observed at 20% WSA substituting the mass of PC in the concrete after 28 days, respectively. However, the strength of concrete increased when WSA substituted the mass of PC by up to 10%, and then it started to drop.

- The modulus of elasticity was enhanced by utilizing the WSA as cementitious material up to a certain limit, and by further addition, to a certain limit, of WSA to the concrete, the modulus of elasticity was reduced after 28 days of curing.

- The use of wheat straw ash could also bring a financial benefit to the producers due to the obvious increase in production and to the demand from the construction sector. With such an approach, the disposal of waste wheat straw could also be practiced without compromising the ecology of planet.

- The permeability of concrete was reduced as the content of WSA substituting the mass of PC increased at 28 days.

- The available literature suggests that WSA is absorbent due to the presence of surface pores, and hence, its use in structural applications is highly recommended for developing the durability and mechanical properties of concrete structures.

- Moreover, as can be gleaned from the mathematical equations presented in the paper, the efficiency of WSA is a significant function of the mechanical strength of concrete. Therefore, WSA could be beneficial for the durability of concrete. The correlation results between the strengths and between permeability and slump and strengths of the concrete with WSA strongly support this suggestion.

- Because the manuscript also offers a prescription for manufacturing cement with wheat straw ash, it opens new ways for scientists, readers, and graduate and post-graduate students as well as manufacturers of cement and concrete. Moreover, by expanding on the current state-of-the-art of properties and behaviors of cement and concrete containing wheat straw ash, it inspires future research and finds further support for practical applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Collaborators

References

- Zhang, J.; Liu, G.; Chen, B.; Song, D.; Qi, J.; Liu, X. Analysis of CO2 Emission for the Cement Manufacturing with Alternative Raw Materials: A LCA-based Framework. Energy Procedia 2014, 61, 2541–2545. [Google Scholar] [CrossRef]

- Bheel, N.; Memon, F.A.; Meghwar, S.L. Study of Fresh and Hardened Properties of Concrete Using Cement with Modified Blend of Millet Husk Ash as Secondary Cementitious Material. Silicon 2020, 13, 4641–4652. [Google Scholar] [CrossRef]

- Abubakr, M.; Khitab, A.; Sadiq, S.; Anwar, W.; Tayyeb, S. Evaluation of Ordinary Concrete Having Ceramic Waste Powder as Partial Replacement of Cement. In Proceedings of the International Conference on Sustainable Development in Civil Engineering, Jamshoro, Pakistan, 5–7 December 2019. [Google Scholar]

- Mangi, S.A.; Ibrahim, M.H.W.; Jamaluddin, N.; Arshad, M.F.; Memon, F.A.; Jaya, R.P.; Shahidan, S. A Review on Potential use of Coal Bottom Ash as a Supplementary Cementing Material in Sustainable Concrete Construction. Int. J. Integr. 2018, 9, 28–36. Available online: https://publisher.uthm.edu.my/ojs/index.php/ijie/article/view/2496 (accessed on 23 August 2022). [CrossRef]

- Memon, M.J.; Zulfiqar, S.; Campus, A.B.; Mirs’, K.; Jhatial, A.A.; Rid, Z.A.; Rind, T.A.; Ali, Z.; Campus, B.; Sandhu, A.R. Marble Powder as Fine Aggregates in Concrete, Engineering. Technol. Appl. Sci. Res. 2019, 9, 4105–4107. [Google Scholar] [CrossRef]

- Senthamarai, R.M.; Manoharan, P.D. Concrete with ceramic waste aggregate. Cem. Concr. Compos. 2005, 27, 910–913. [Google Scholar] [CrossRef]

- Ghorbani, S.; Taji, I.; de Brito, J.; Negahban, M.; Ghorbani, S.; Tavakkolizadeh, M.; Davoodi, A. Mechanical and durability behaviour of concrete with granite waste dust as partial cement replacement under adverse exposure conditions. Constr. Build. Mater. 2018, 194, 143–152. [Google Scholar] [CrossRef]

- Bheel, N.; Ibrahim, M.H.W.; Adesina, A.; Kennedy, C.; Shar, I.A. Mechanical performance of concrete incorporating wheat straw ash as partial replacement of cement. J. Build. Pathol. Rehabil. 2020, 6, 4. [Google Scholar] [CrossRef]

- Assefa, S.; Dessalegn, M. Production of Lightweight Concrete Using Corncob Ash as Replacement of Cement in Concrete. Am. J. Civ. Eng. 2019, 7, 17. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Khahro, S.H.; Jamaluddin, N.; Shahidan, S. Development of Supplementary Cementitious Materials: A Systematic Review. Int. J. Adv. Sci. 2020, 29, 4682–4691. Available online: http://sersc.org/journals/index.php/IJAST/article/view/17287 (accessed on 27 August 2022).

- Thomas, J.; Thaickavil, N.N.; Syamala, T.N. Supplementary Cement Replacement Materials for Sustainable Concrete. In Green Buildings and Sustainable Engineering; Springer: Singapore, 2019; pp. 387–403. [Google Scholar] [CrossRef]

- Hamada, H.M.; Yahaya, F.M.; Muthusamy, K.; Jokhio, G.A.; Humada, A.M. Fresh and hardened properties of palm oil clinker lightweight aggregate concrete incorporating Nano-palm oil fuel ash. Constr. Build. Mater. 2019, 214, 344–354. [Google Scholar] [CrossRef]

- Ashish, D.K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2019, 211, 716–729. [Google Scholar] [CrossRef]

- Khan, M.I.; Mourad, S.M.; Charif, A. Utilization of Supplementary Cementitious Materials in HPC: From rheology to pore structure. KSCE J. Civ. Eng. 2016, 21, 889–899. [Google Scholar] [CrossRef]

- Bheel, N.; Hyderabad, H.C.S.T.; Memon, A.S.; Khaskheli, I.A.; Talpur, N.M.; Talpur, S.M.; Khanzada, M.A. Effect of Sugarcane Bagasse Ash and Lime Stone Fines on the Mechanical Properties of Concrete. Eng. Technol. Appl. Sci. Res. 2020, 10, 5534–5537. [Google Scholar] [CrossRef]

- Aksoʇan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Jain, D.; Gupta, A.; Jain, H.; Scholar, M.E. Comparative Study of Concrete when Rice Husk Ash, Saw Dust Ash, Wheat Straw Ash Used as Partial Replacement of Cement in Concrete. Int. J. Sci. Res. Dev. 2015, 3, 764–767. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Atta-ur-Rehman, A.U.; Ryou, J.S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Effect of pre-treatment and content of wheat straw on energy absorption capability of concrete. Constr. Build. Mater. 2019, 224, 572–583. [Google Scholar] [CrossRef]

- Ibrahim, M.H.W.; Mangi, S.A.; Burhanudin, M.K.; Ridzuan, M.B.; Jamaluddin, N.; Shahidan, S.; Wong, Y.H.; Faisal, S.K.; Fadzil, M.A.; Ramadhansyah, P.J.; et al. Compressive and flexural strength of concrete containing palm oil biomass clinker and polypropylene fibres. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012011. [Google Scholar] [CrossRef]

- Bheel, N.; Ali, M.O.A.; Khahro, S.H.; Keerio, M.A. Experimental study on fresh, mechanical properties and embodied carbon of concrete blended with sugarcane bagasse ash, metakaolin, and millet husk ash as ternary cementitious material. Environ. Sci. Pollut. Res. 2022, 29, 5224–5239. [Google Scholar] [CrossRef]

- Kumar, A.; Bheel, N.; Ahmed, I.; Rizvi, S.H.; Kumar, R.; Jhatial, A.A. Effect of silica fume and fly ash as cementitious material on hardened properties and embodied carbon of roller compacted concrete. Environ. Sci. Pollut. Res. 2022, 29, 1210–1222. [Google Scholar] [CrossRef] [PubMed]

- Sohu, S.; Bheel, N.; Jhatial, A.A.; Ansari, A.A.; Shar, I.A. Sustainability and mechanical property assessment of concrete incorporating eggshell powder and silica fume as binary and ternary cementitious materials. Environ. Sci. Pollut. Res. 2022, 29, 58685–58697. [Google Scholar] [CrossRef] [PubMed]

- Bheel, N.; Ali, M.O.A.; Liu, Y.; Tafsirojjaman, T.; Awoyera, P.; Sor, N.H.; Bendezu Romero, L.M. Utilization of corn cob ash as fine aggregate and ground granulated blast furnace slag as cementitious material in concrete. Buildings 2021, 11, 422. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.O.; Olalusi, O.B. Engineering properties of concrete with a ternary blend of fly ash, wheat straw ash, and maize cob ash. In International Journal of Engineering Research in Africa; Trans Tech Publications Ltd.: Baech, Switzerland, 2021; Volume 54, pp. 43–55. [Google Scholar]

- FAO Cereal Supply and Demand Brief|World Food Situation|Food and Agriculture Organization of the United Nations. 2021. Available online: https://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 27 August 2022).

- Memon, S.A.; Wahid, I.; Khan, M.K.; Tanoli, M.A.; Bimaganbetova, M. Environmentally Friendly Utilization of Wheat Straw Ash in Cement-Based Composites. Sustainability 2018, 10, 1322. [Google Scholar] [CrossRef]

- Kadam, K.L.; Forrest, L.H.; Jacobson, W.A. Rice straw as a lignocellulosic resource: Collection, processing, transportation, and environmental aspects. Biomass Bioenergy 2000, 18, 369–389. [Google Scholar] [CrossRef]

- Biricik, H.; Aköz, F.; Berktay, I.; Tulgar, A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999, 29, 637–643. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Abu-Alfoul, B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002, 32, 859–863. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Engineering 2014, 2014, 832508. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Ali, S.; Kumar, H.; Rizvi, S.H.; Raza, M.S.; Ansari, J.K. Effects of Steel Fibres on Fresh and Hardened Properties of Cement Concrete. Civ. Environ. Eng. Rep. 2020, 30, 186–199. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Atta-ur-Rehman; Jeon, I.K.; Ryou, J.S. Influence of the particle size of wheat straw ash on the microstructure of the interfacial transition zone. Powder Technol. 2019, 352, 453–461. [Google Scholar] [CrossRef]

- Opiso, E.M.; Sato, T.; Otake, T.; Opiso, E.M.; Sato, T.; Otake, T. Advances in Concrete Construction. Adv. Constr. 2017, 5, 289. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mamuda, A.M. Advances in Concrete Construction. Adv. Concr. Constr. 2014, 2, 301–308. [Google Scholar] [CrossRef]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/Standards/C136 (accessed on 27 August 2022).

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/Standards/C128.htm (accessed on 27 August 2022).

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/Standards/C127.htm (accessed on 27 August 2022).

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/Standards/C29.htm (accessed on 27 August 2022).

- ASTM C143/C143M-15; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C143C143M-15A.htm (accessed on 27 August 2022).

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/Standards/C39 (accessed on 27 August 2022).

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/Standards/C496.htm (accessed on 27 August 2022).

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/Standards/C293.htm (accessed on 27 August 2022).

- BS EN 12390-8:2019; Testing Hardened Concrete Part 8: Depth of Penetration of Water under Pressure. BSI: London, UK, 2019. Available online: https://knowledge.bsigroup.com/products/testing-hardened-concrete-depth-of-penetration-of-water-under-pressure-1/standard/details (accessed on 27 August 2022).

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM: West Conshohocken, PA, USA, 2014. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C469C469M-14.html (accessed on 27 August 2022).

- Hama, S.M.; Hilal, N.N. Fresh properties of concrete containing plastic aggregate. In Use of Recycled Plastics in Eco-Efficient Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 85–114. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Trans-Atlantic Publications, Inc.: Philadelphia, PA, USA, 2012. [Google Scholar]

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Bheel, N.; Sohu, S.; Awoyera, P.; Kumar, A.; Abbasi, S.A.; Olalusi, O.B. Effect of Wheat Straw Ash on Fresh and Hardened Concrete Reinforced with Jute Fiber. Adv. Civ. Eng. 2021, 2021, 6659125. [Google Scholar] [CrossRef]

- Majeed, M.; Khitab, A.; Anwar, W.; Khan, R.B.N.; Jalil, A.; Tariq, Z. Evaluation of Concrete with Partial Replacement of Cement by Waste Marble Powder. Civ. Eng. J. 2021, 7, 59–70. [Google Scholar] [CrossRef]

- Pathan, M.A.; Lashari, R.A.; Maira, M.; Pathan, J.A. Experimental Study on the Engineering Properties of Marble Waste Powder from Hyderabad Marble Market Sindh Pakistan for Making Concrete Including Recycled Coarse Aggregates. Saudi J. Civ. Eng. 2019, 3, 51–58. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Sohu, S.; Memon, M.J.; Bhatti, N.-U.-K.; Memon, D. Eggshell powder as partial cement replacement and its effect on the workability and compressive strength of concrete. Int. J. Adv. Appl. Sci. 2019, 6, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Bheel, N.; Ali, M.O.A.; Kirgiz, M.S.; Galdino, A.G.D.S.; Kumar, A. Fresh and mechanical properties of concrete made of binary substitution of millet husk ash and wheat straw ash for cement and fine aggregate. Journal of Materials Research and Technology. 2021, 13, 872–893. [Google Scholar] [CrossRef]

- Jaya, R.P. Porous concrete pavement containing nanosilica from black rice husk ash. In New Materials in Civil Engineering; Butterworth-Heinemann: Oxford, UK, 2020; pp. 493–527. [Google Scholar] [CrossRef]

- Bheel, N.; Jokhio, M.A.; Abbasi, J.A.; Lashari, H.B.; Qureshi, M.I.; Qureshi, A.S. Rice Husk Ash and Fly Ash Effects on the Mechanical Properties of Concrete, Engineering. Technol. Appl. Sci. Res. 2020, 10, 5402–5405. [Google Scholar] [CrossRef]

- Krishna, N.K.; Sandeep, S.; Mini, K.M. Study on concrete with partial replacement of cement by rice husk ash. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012109. [Google Scholar] [CrossRef]

- Mangi, S.A.; Ibrahim, M.W.; Jamaluddin, N.; Shahidan, S.; Arshad, M.; Memon, S.A.; Jaya, R.P.; Mudjanarko, S.W.; Setiawan, M.I. Influence of ground coal bottom ash on the properties of concrete. Int. J. Sustain. Constr. Eng. Technol. 2018, 9, 26–34. [Google Scholar] [CrossRef]

- Mangi, S.A.; Ibrahim, M.H.W.; Jamaluddin, N.; Arshad, M.F.; Mudjanarko, S.W. Recycling of Coal Ash in Concrete as a Partial Cementitious Resource. Resources 2019, 8, 99. [Google Scholar] [CrossRef]

- Ahmed, M.; Khan, M.K.D.; Wamiq, M. Effect of concrete cracking on the lateral response of RCC buildings. Asian J. Civ. Eng. Build. Hous. 2008, 9, 25–34. [Google Scholar]

- Geron, F.D.R.L.; Paultre, P. Prediction of Modulus of Rupture of Concrete. Mater. J. 2000, 97, 193–200. [Google Scholar] [CrossRef]

- ACI Committee 363 State-of-the-Art Report on High-Strength Concrete; ACI 363R-92; American Concrete Institute: Farmington Hills, MI, USA, 1997.

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, Pearson. 2002. Available online: https://www.pearson.com/uk/educators/higher-education-educators/program/Mindess-Concrete-2nd-Edition/PGM478675.html (accessed on 27 August 2022).

- Oluokun, F.A.; Burdette, E.G.; Deatherage, J.H. Splitting Tensile Strength and Compressive Strength Relationships at Early Ages. Mater. J. 1991, 88, 115–121. [Google Scholar] [CrossRef]

- Carneiro, F.L.L.B.; Barcellos, A. Concrete Tensile Strength, International Union of Testing and Research Laboratories for Materials and Structures (RILEM). Bulletin 1953, 13, 97–123. [Google Scholar]

- ACI 318-99/318R-99; Building Code Requirements for Structural Concrete & Commentary. ACI: Farmington Hills, MI, USA, 1997. Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/5152 (accessed on 27 August 2022).

- Carino, N.J.; Lew, H.S. Re-examination of the relation between splitting tensile and compressive strength of normal weight concrete. J. Proc. 1982, 79, 214–219. [Google Scholar]

- Raphael, J.M. Tensile strength of concrete. J. Proc. 1984, 81, 158–165. [Google Scholar]

- Gardner, N.J.; Sau, P.L.; Cheung, M.S. Strength Development and Durability of Concretes Cast and Cured at 0 °C. Materials 1984, 85, 529–536. [Google Scholar] [CrossRef]

- Qudoos, A.; Ullah, Z.; Atta-ur-Rehman; Baloch, Z. Performance Evaluation of the Fiber-Reinforced Cement Composites Blended with Wheat Straw Ash. Adv. Civ. Eng. 2019, 2019, 1835764. [Google Scholar] [CrossRef] [Green Version]

- Ataie, F.F.; Riding, K.A. Influence of agricultural residue ash on early cement hydration and chemical admixtures adsorption. Constr. Build. 2016, 106, 274–281. [Google Scholar] [CrossRef]

- International Association for Engineering Geology. Classification of rocks and soils for engineering geological mapping part I: Rock and soil materials. Bull. Int. Assoc. Eng. Geol. 1979, 19, 364–371. [Google Scholar] [CrossRef]

| Binder | Compound (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | SO3 | |

| WSA | 67.34 | 6.44 | 4.36 | 10.60 | 0.47 | 1.85 |

| PC | 20.78 | 5.11 | 3.17 | 60.22 | 0.18 | 2.86 |

| Types of Aggregate | Physical Properties of Aggregates | |||

|---|---|---|---|---|

| Fineness Modulus (−) | Specific Gravity (g/cm3) | Bulk Density (Compacted) (kg/m3) | Water Absorption (%) | |

| Fine aggregate | 2.15 | 2.61 | 1845 | 1.3 |

| Coarse aggregate | 6.75 | 2.65 | 1630 | 0.75 |

| Types of Concrete | Proportion of Mixture (kg/m3) | |||||

|---|---|---|---|---|---|---|

| PC | WSA | Fine Aggregate | Coarse Aggregate | Water | Water-to-Binder Ratio | |

| Control | 373 | 0 | 560 | 1120 | 187 | 0.50 |

| WSA 5% | 354.3 | 18.6 | 560 | 1120 | 187 | 0.50 |

| WSA 10% | 335.7 | 37.3 | 560 | 1120 | 187 | 0.50 |

| WSA 15% | 317.05 | 55.95 | 560 | 1120 | 187 | 0.50 |

| WSA 20% | 298.4 | 74.6 | 560 | 1120 | 187 | 0.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katman, H.Y.B.; Khai, W.J.; Bheel, N.; Kırgız, M.S.; Kumar, A.; Khatib, J.; Benjeddou, O. Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete. Buildings 2022, 12, 1363. https://doi.org/10.3390/buildings12091363

Katman HYB, Khai WJ, Bheel N, Kırgız MS, Kumar A, Khatib J, Benjeddou O. Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete. Buildings. 2022; 12(9):1363. https://doi.org/10.3390/buildings12091363

Chicago/Turabian StyleKatman, Herda Yati Binti, Wong Jee Khai, Naraindas Bheel, Mehmet Serkan Kırgız, Aneel Kumar, Jamal Khatib, and Omrane Benjeddou. 2022. "Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete" Buildings 12, no. 9: 1363. https://doi.org/10.3390/buildings12091363

APA StyleKatman, H. Y. B., Khai, W. J., Bheel, N., Kırgız, M. S., Kumar, A., Khatib, J., & Benjeddou, O. (2022). Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete. Buildings, 12(9), 1363. https://doi.org/10.3390/buildings12091363