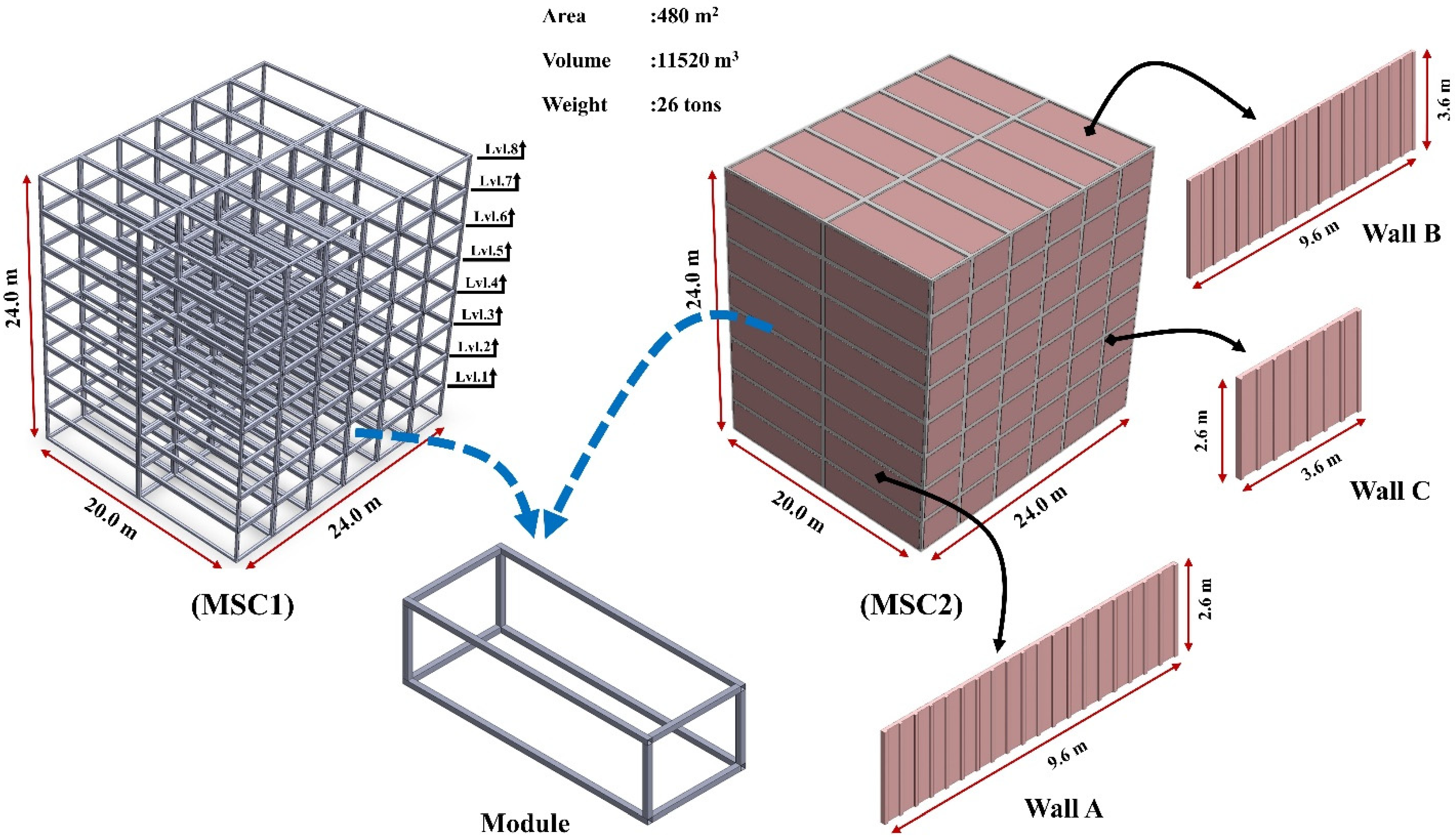

Figure 1.

Suggested modular steel construction systems MSC1 and MSC2.

Figure 1.

Suggested modular steel construction systems MSC1 and MSC2.

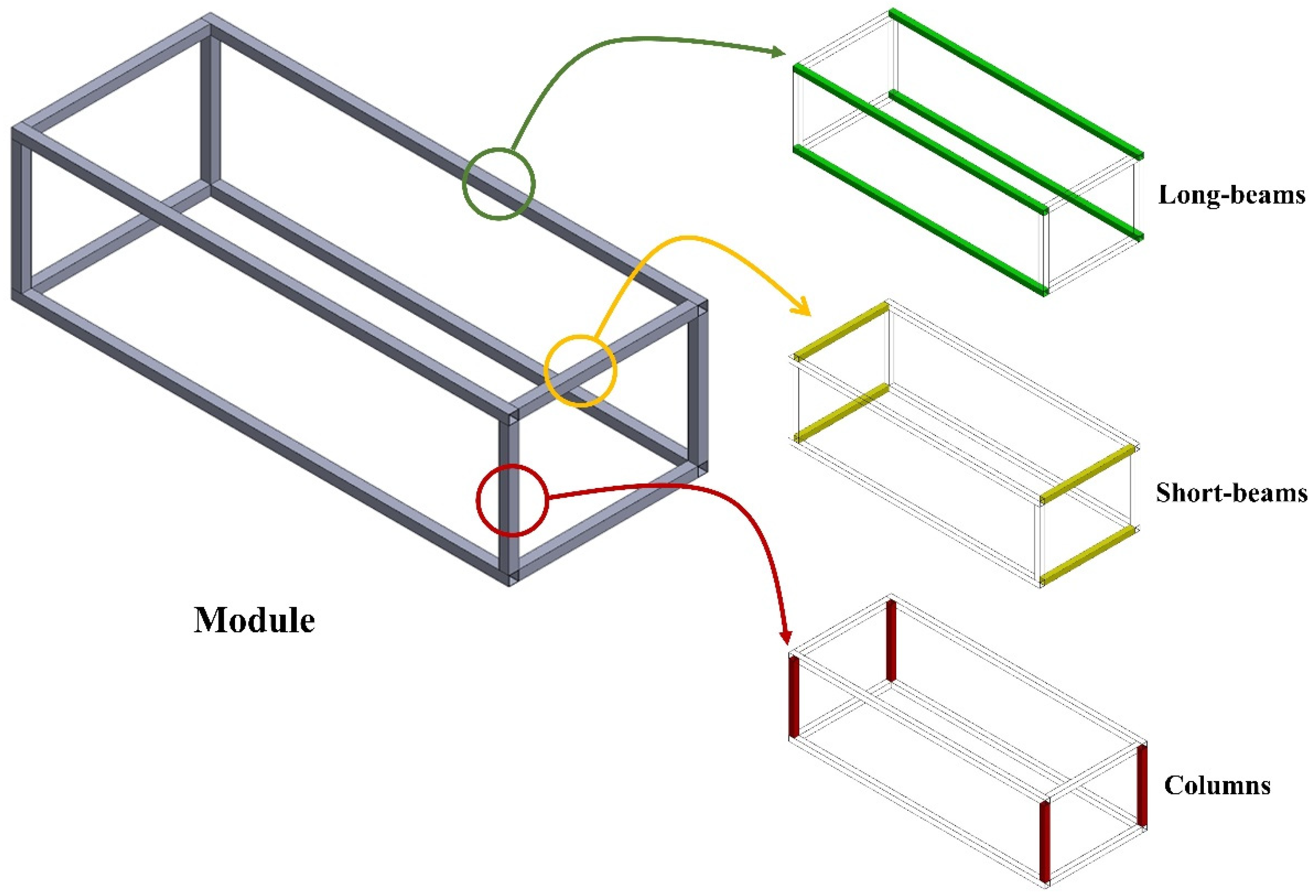

Figure 2.

Module components.

Figure 2.

Module components.

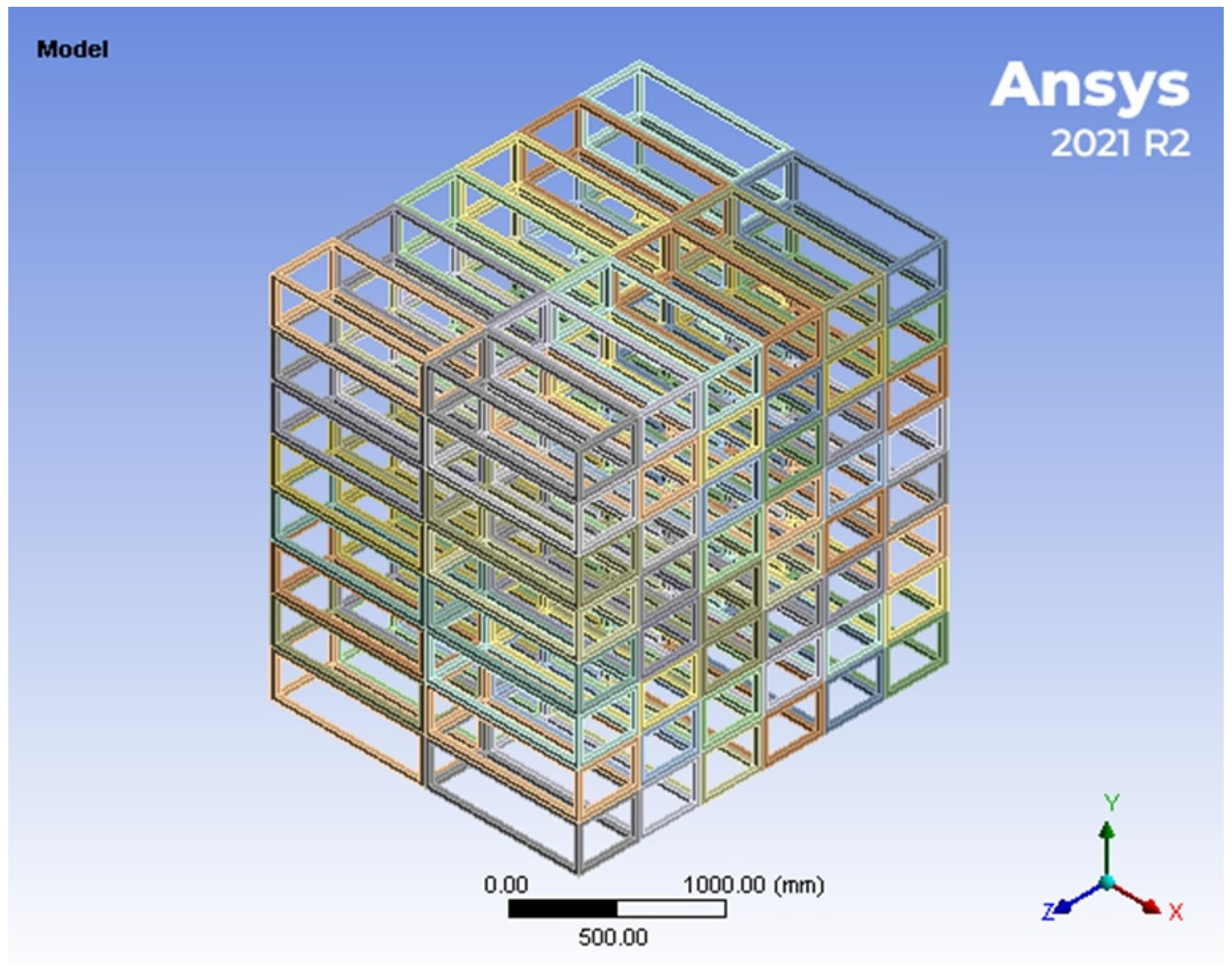

Figure 3.

MCS1 geometry detailing.

Figure 3.

MCS1 geometry detailing.

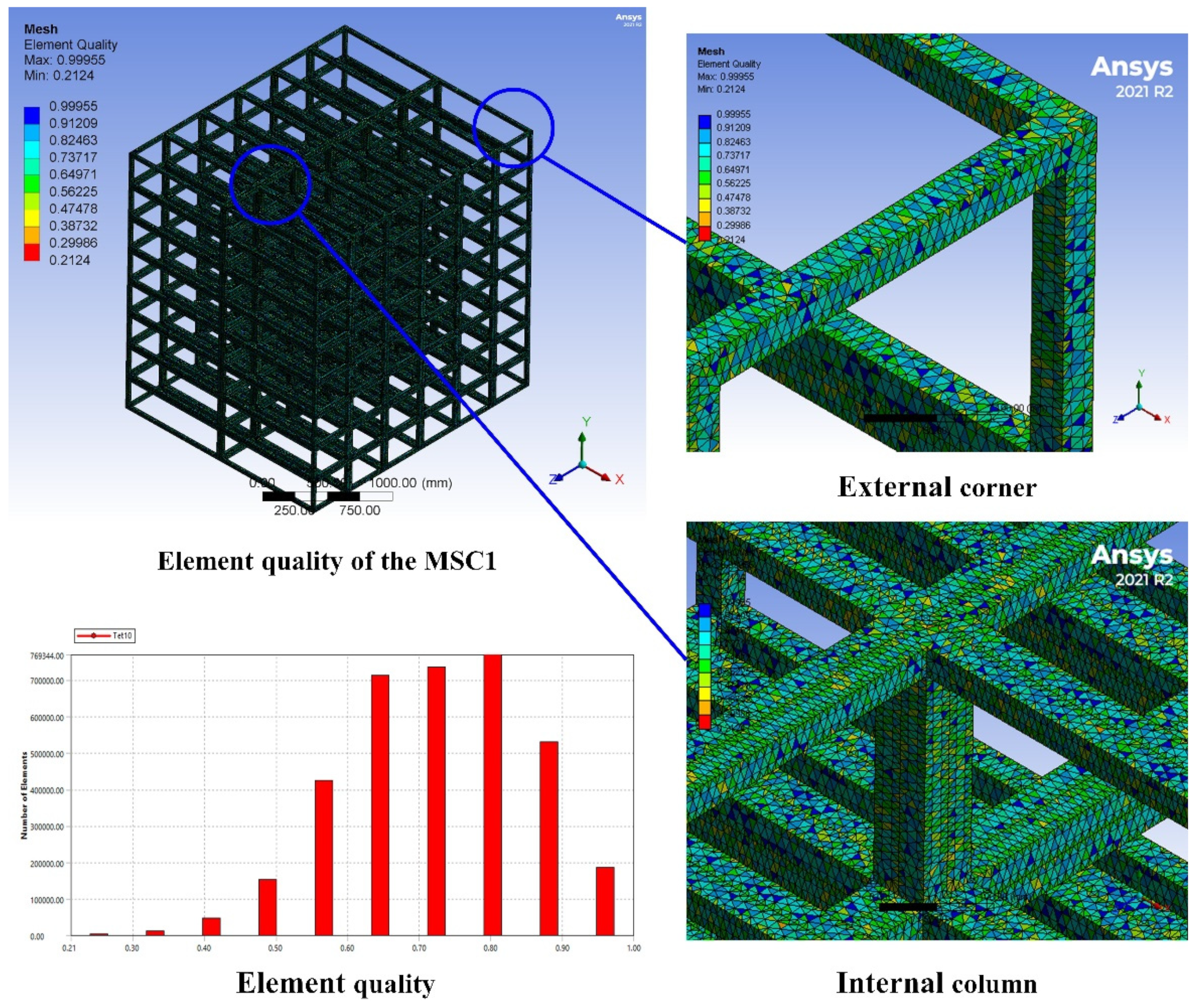

Figure 4.

MSC1 mesh quality detailing and mesh quality test.

Figure 4.

MSC1 mesh quality detailing and mesh quality test.

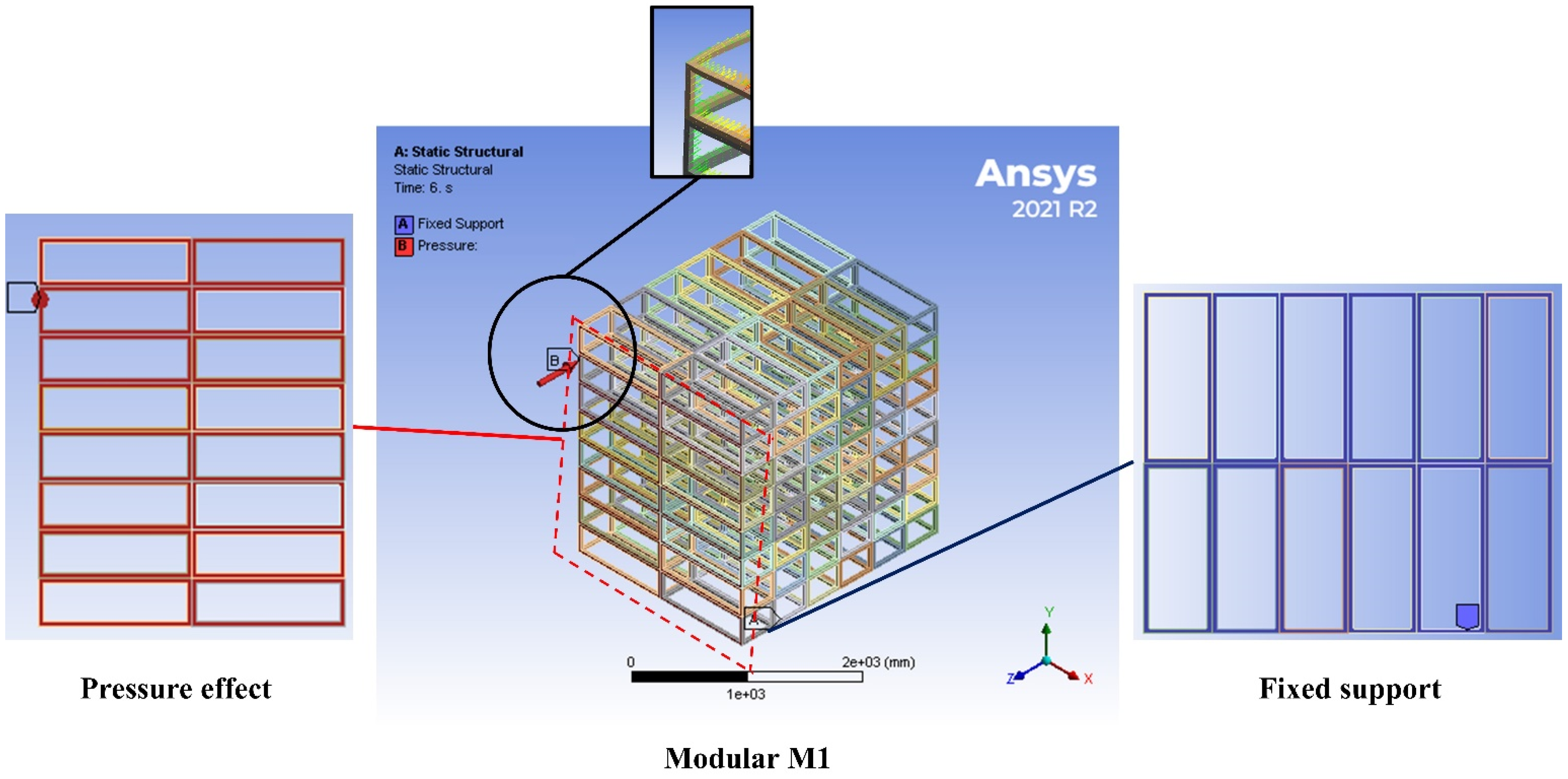

Figure 5.

MSC1 FEM boundary conditions.

Figure 5.

MSC1 FEM boundary conditions.

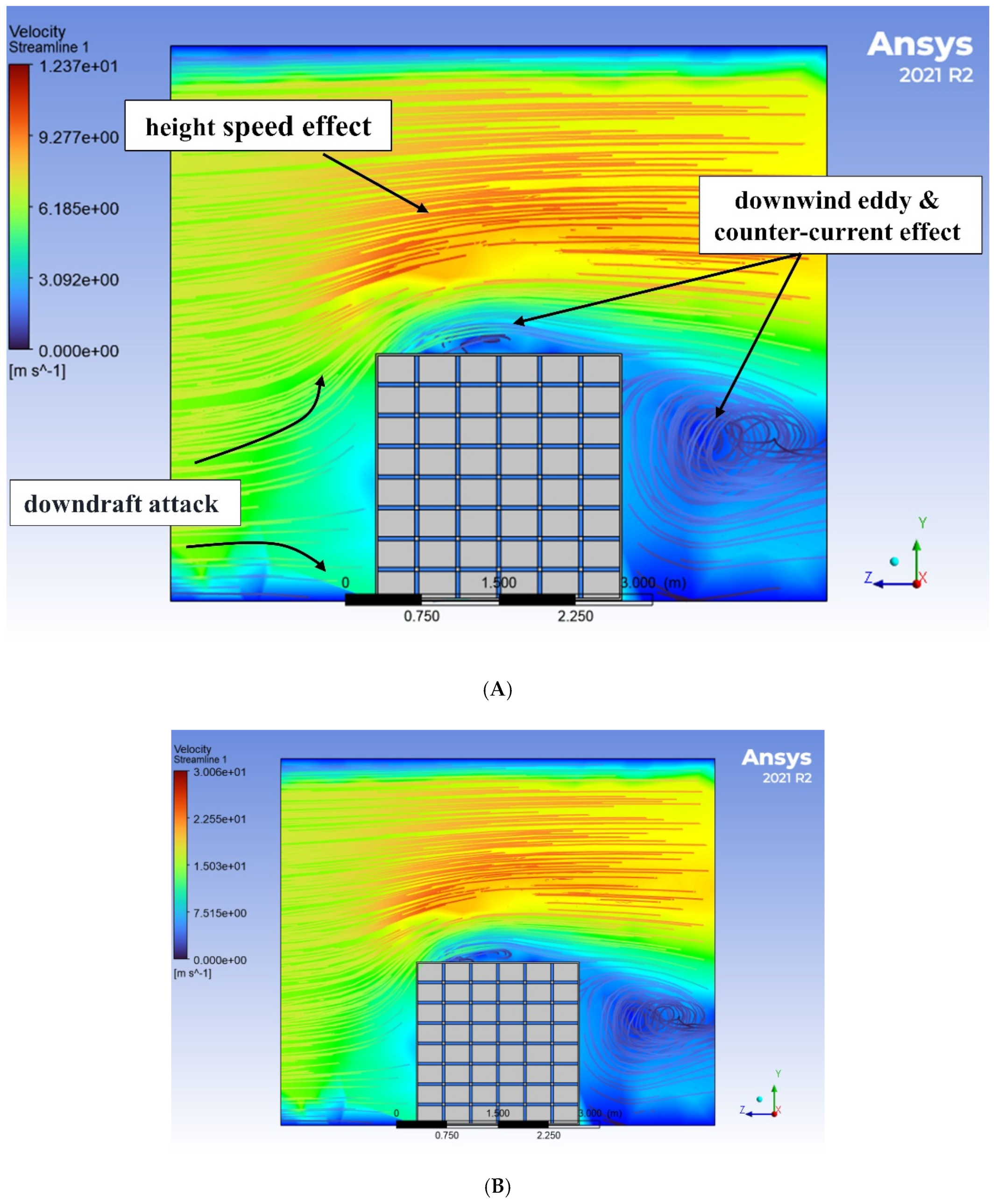

Figure 6.

MSC2 wind flow dynamic.

Figure 6.

MSC2 wind flow dynamic.

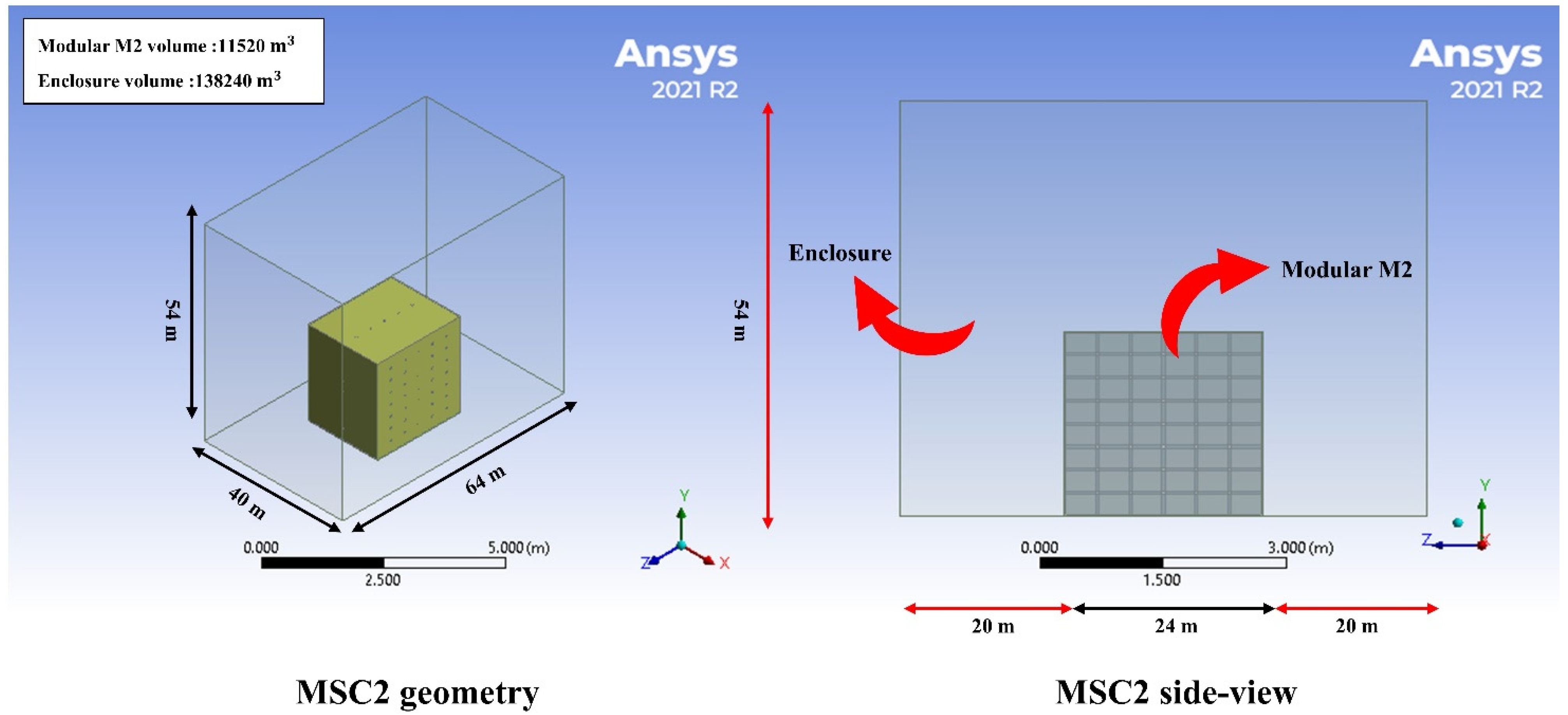

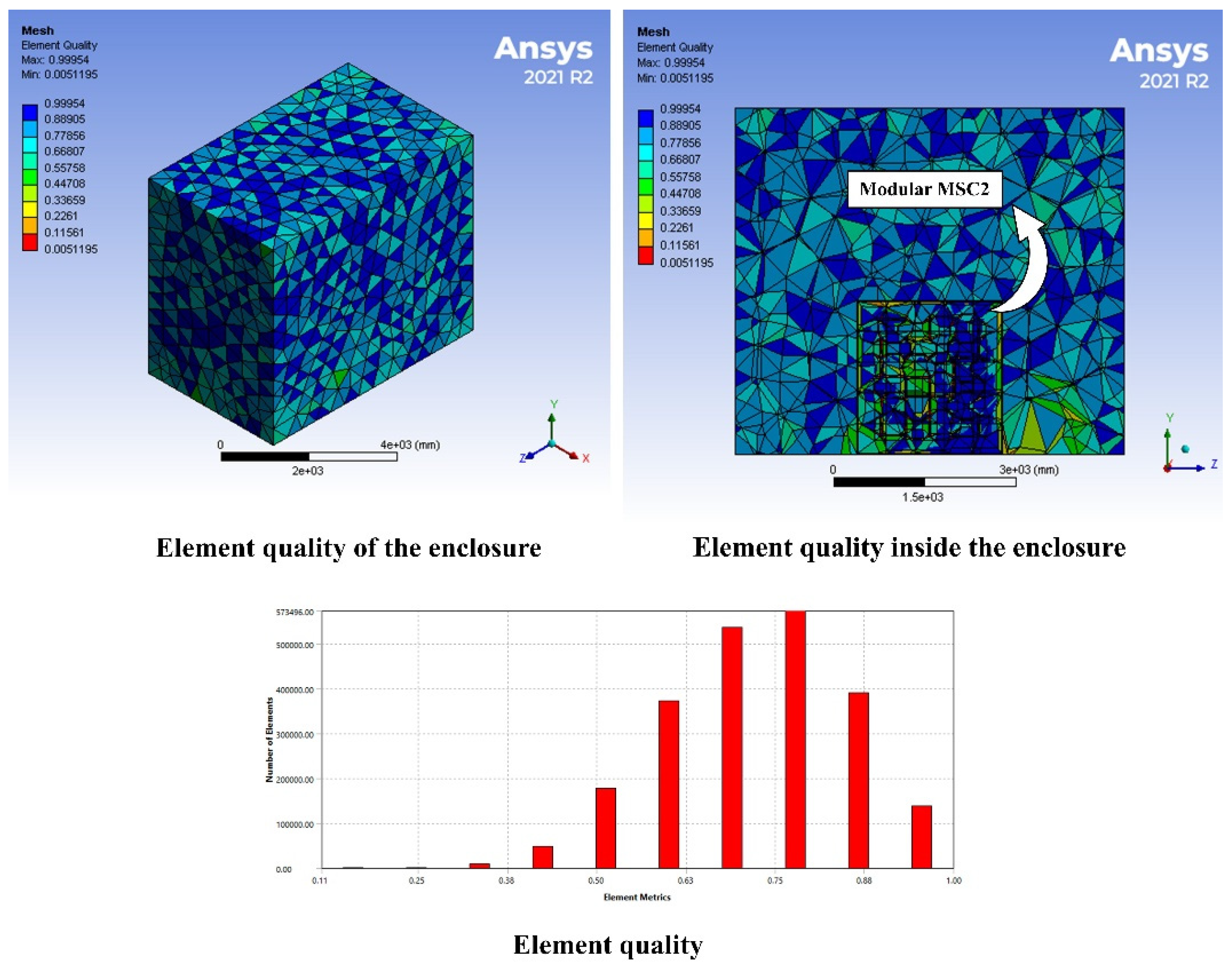

Figure 7.

MSC2 mesh quality detailing and mesh quality test.

Figure 7.

MSC2 mesh quality detailing and mesh quality test.

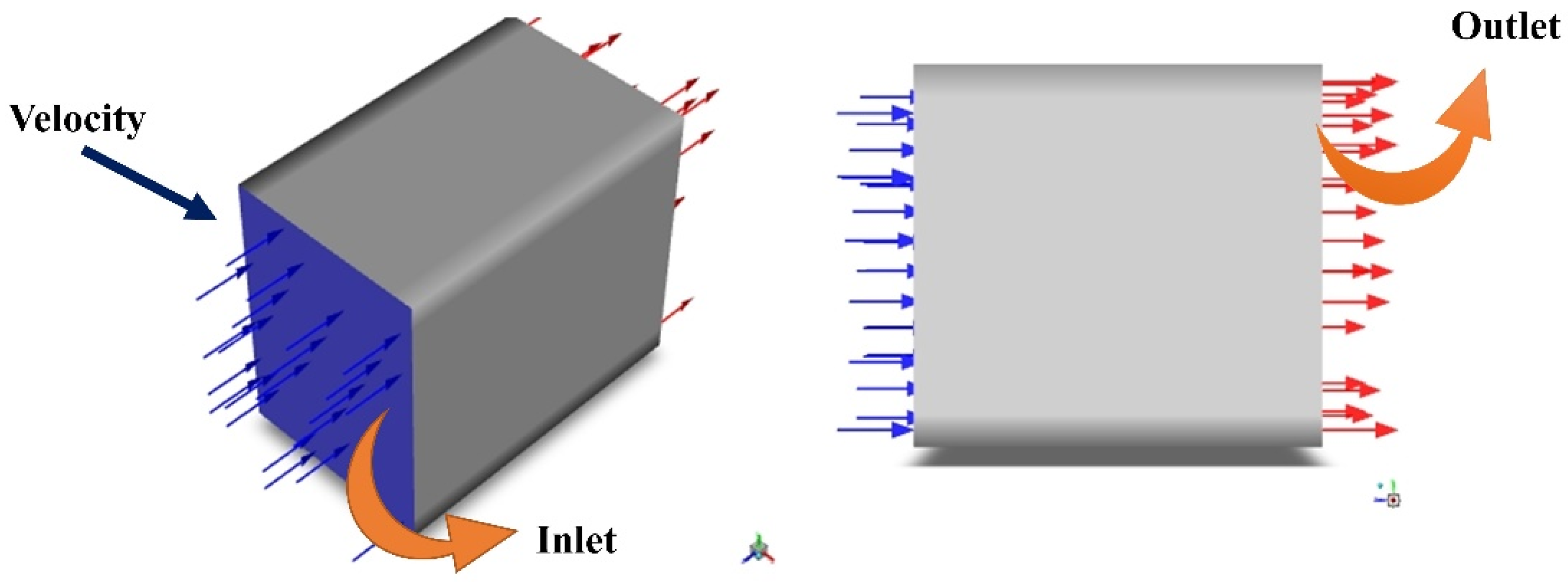

Figure 8.

Wind velocity applied on the enclosure shape.

Figure 8.

Wind velocity applied on the enclosure shape.

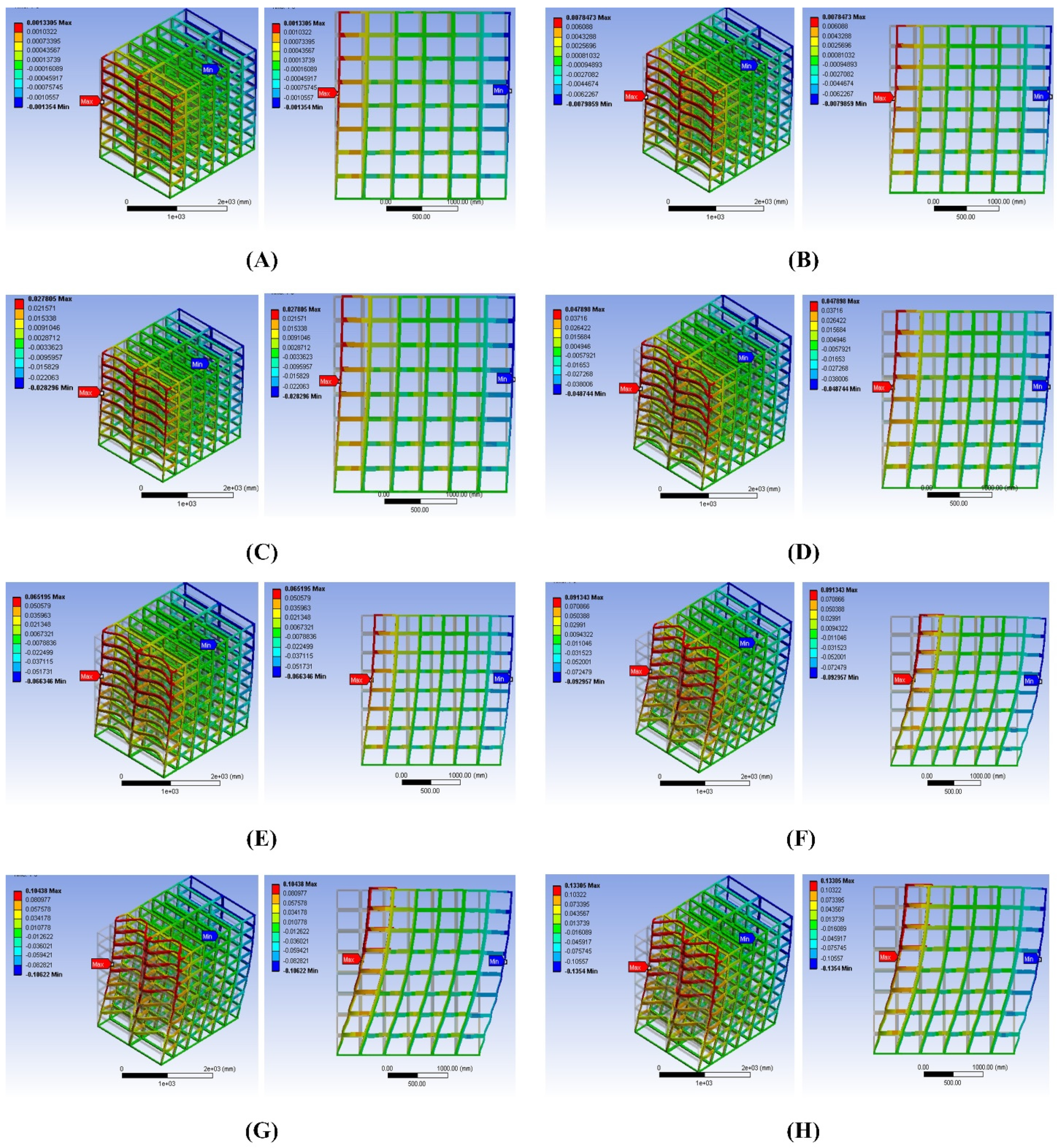

Figure 9.

Structural performance of MSC1 under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 9.

Structural performance of MSC1 under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

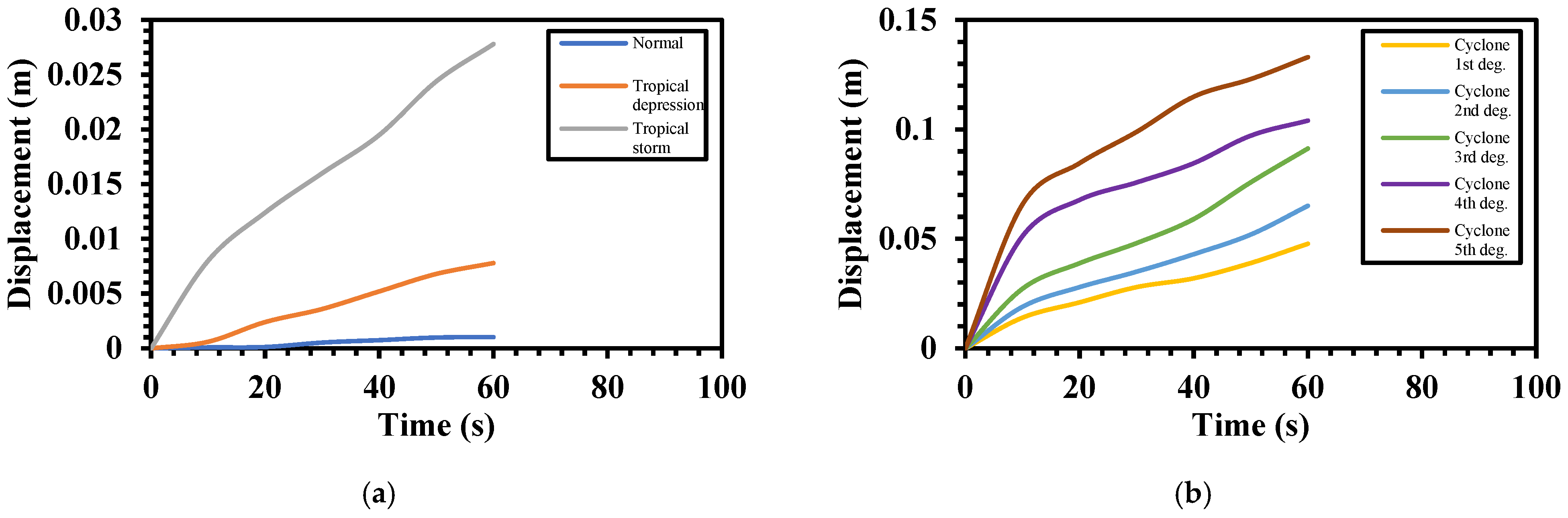

Figure 10.

Displacement behavior of MSC1 under (a) normal, tropical depression, and tropical storm wind flow categories and (b) cyclone wind flow categories.

Figure 10.

Displacement behavior of MSC1 under (a) normal, tropical depression, and tropical storm wind flow categories and (b) cyclone wind flow categories.

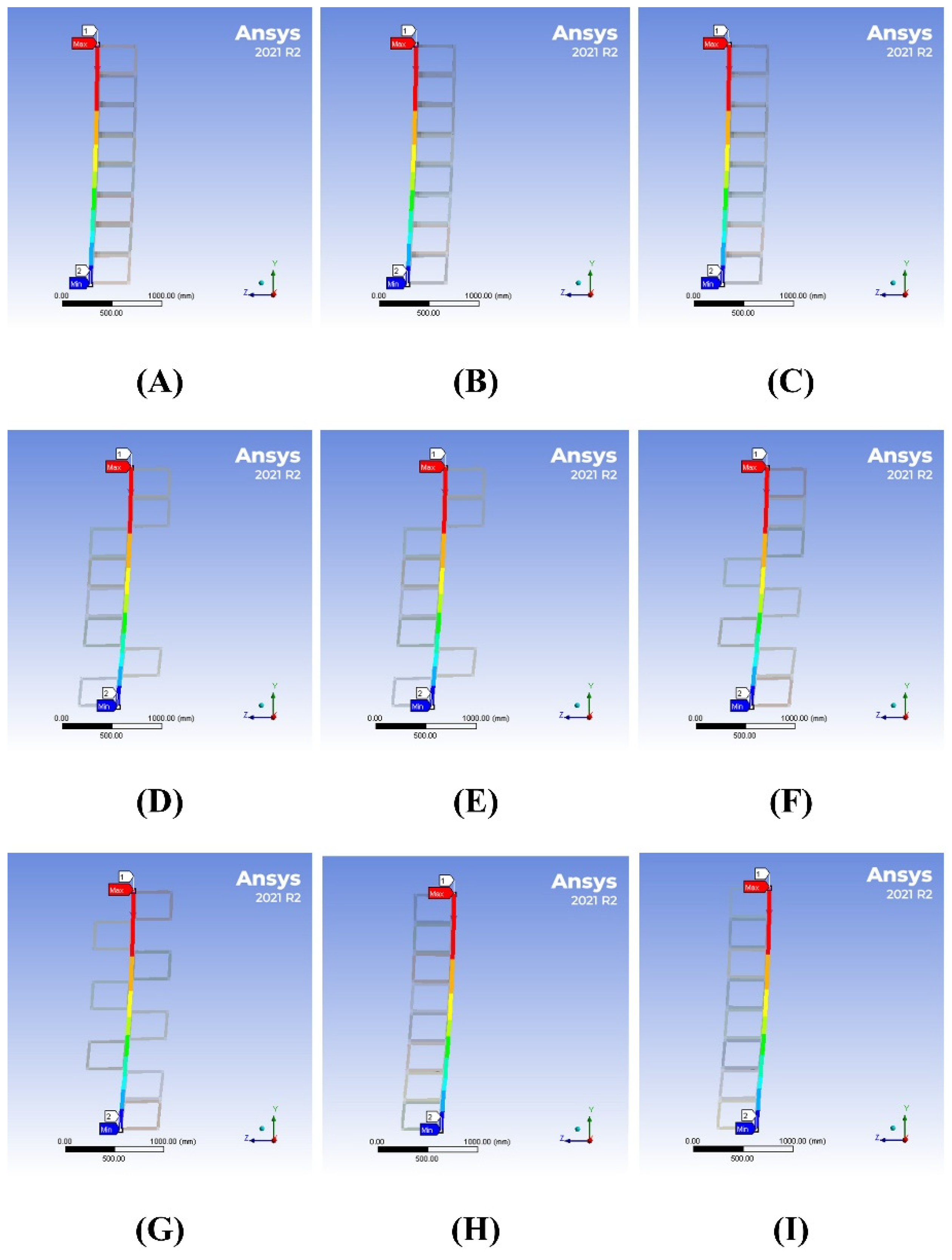

Figure 11.

(A) Right front-column, (B) mid front-column, (C) left font-column, (D) right mid-column, (E) mid mid-column, (F) left mid-column, (G) right back-column, (H) mid back-column, and (I) left back-column.

Figure 11.

(A) Right front-column, (B) mid front-column, (C) left font-column, (D) right mid-column, (E) mid mid-column, (F) left mid-column, (G) right back-column, (H) mid back-column, and (I) left back-column.

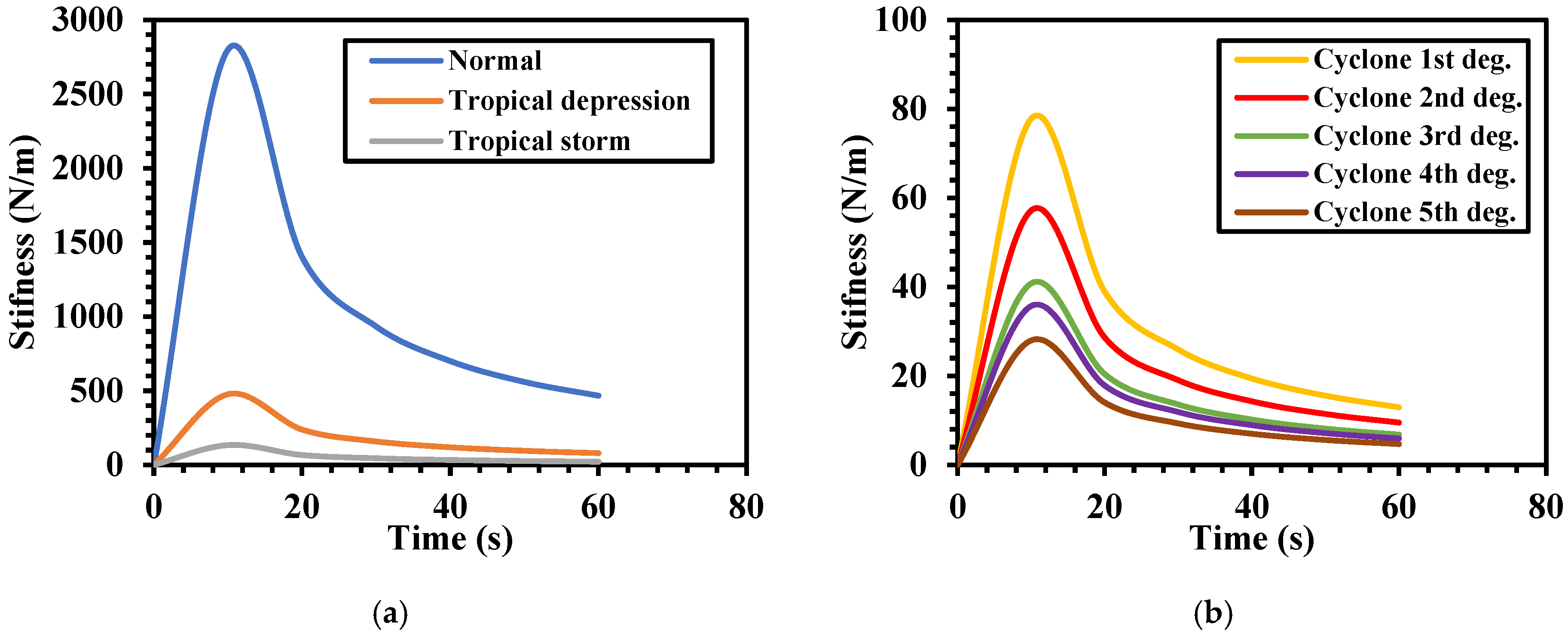

Figure 12.

MSC1 stiffness performance under (a) normal, tropical depression, and tropical storm wind flow categories and (b) cyclone wind flow categories.

Figure 12.

MSC1 stiffness performance under (a) normal, tropical depression, and tropical storm wind flow categories and (b) cyclone wind flow categories.

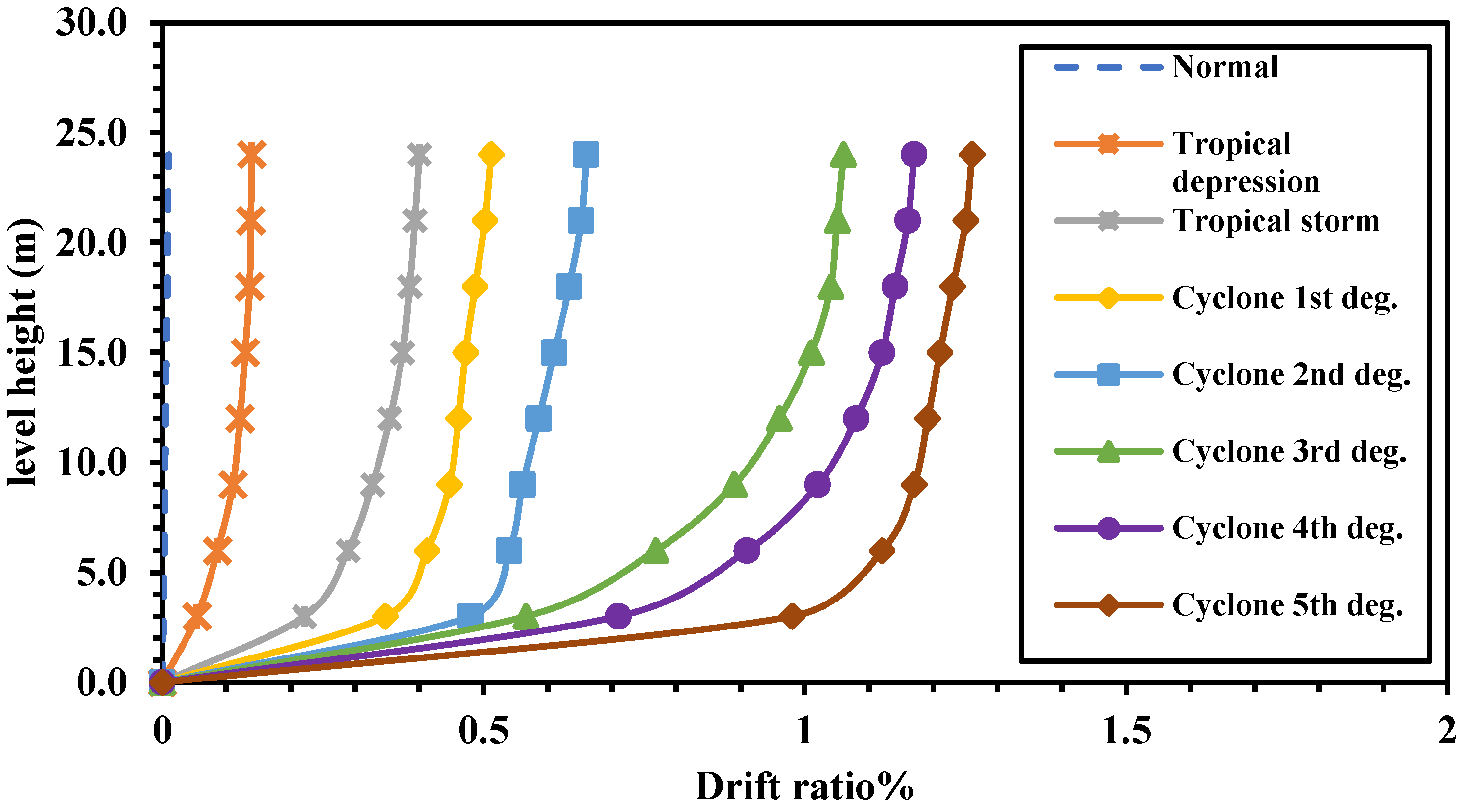

Figure 13.

MSC1 modular system drift ratio under selected wind flow categories.

Figure 13.

MSC1 modular system drift ratio under selected wind flow categories.

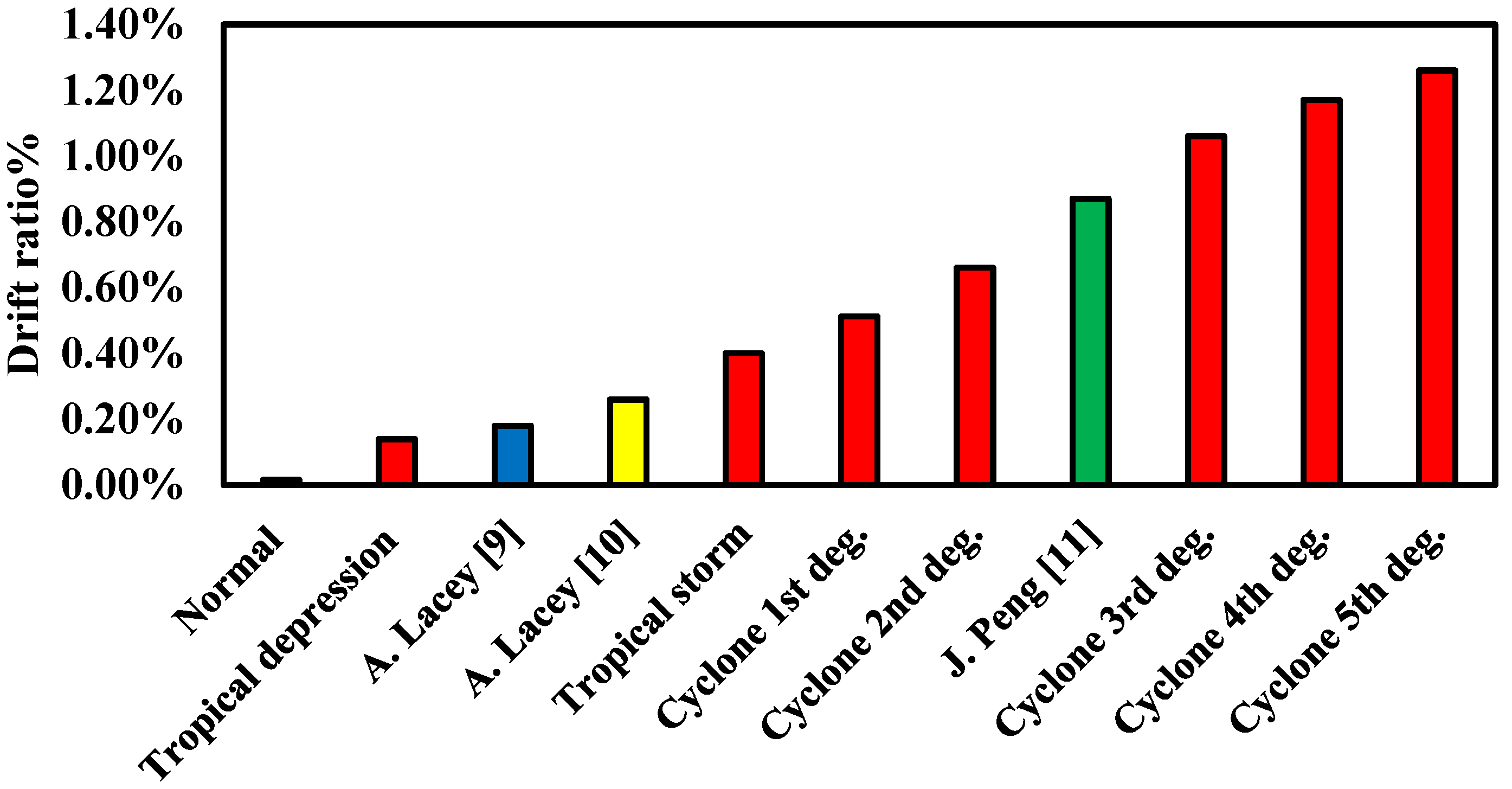

Figure 14.

Modular systems’ drift ratio compression.

Figure 14.

Modular systems’ drift ratio compression.

Figure 15.

MSC1 stain energy performance under (a) normal, tropical depression, and tropical storm wind flow categories, and (b) cyclone wind flow categories.

Figure 15.

MSC1 stain energy performance under (a) normal, tropical depression, and tropical storm wind flow categories, and (b) cyclone wind flow categories.

Figure 16.

Wind flow velocity applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 16.

Wind flow velocity applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 17.

Wind velocity results of the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 17.

Wind velocity results of the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

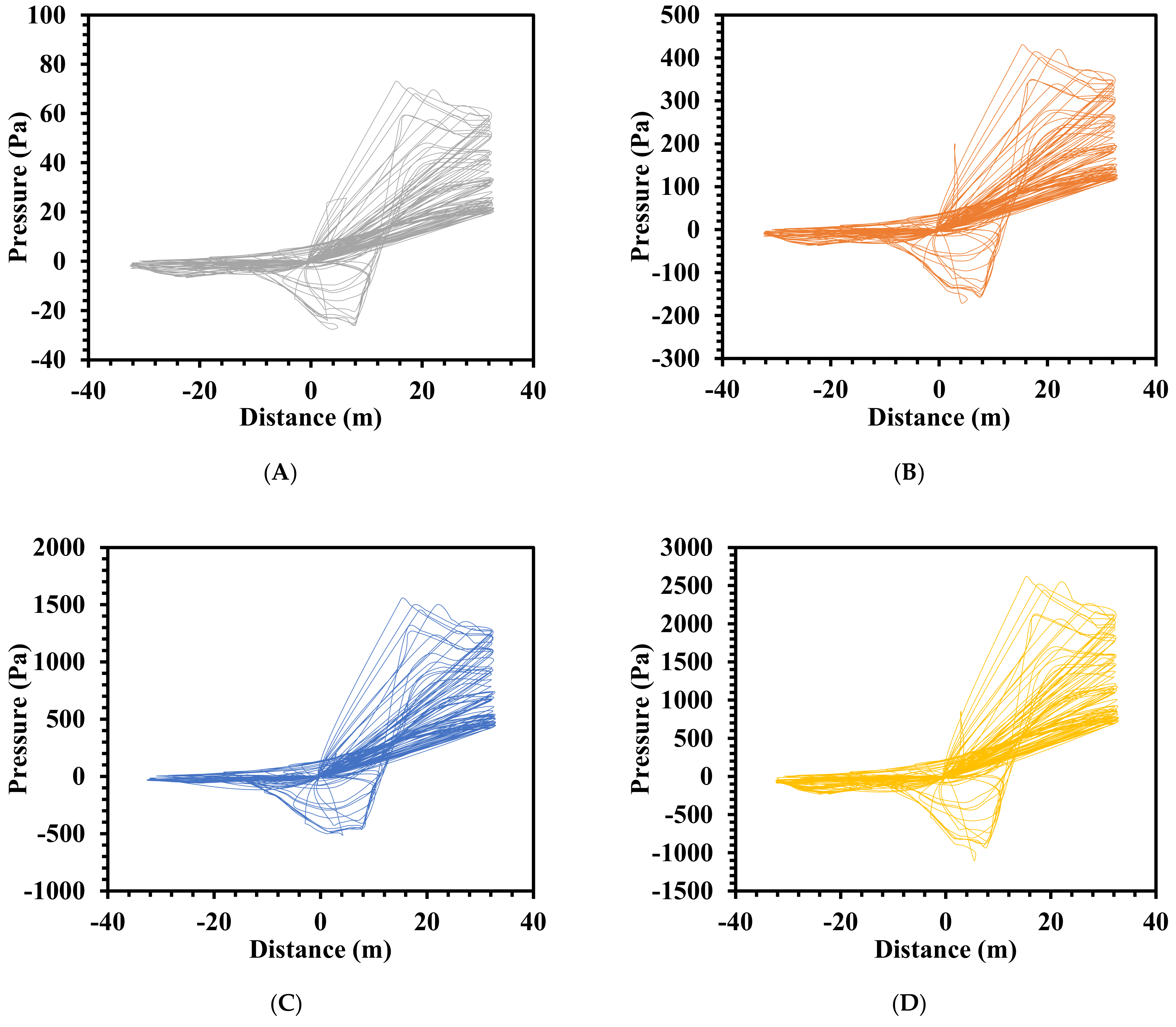

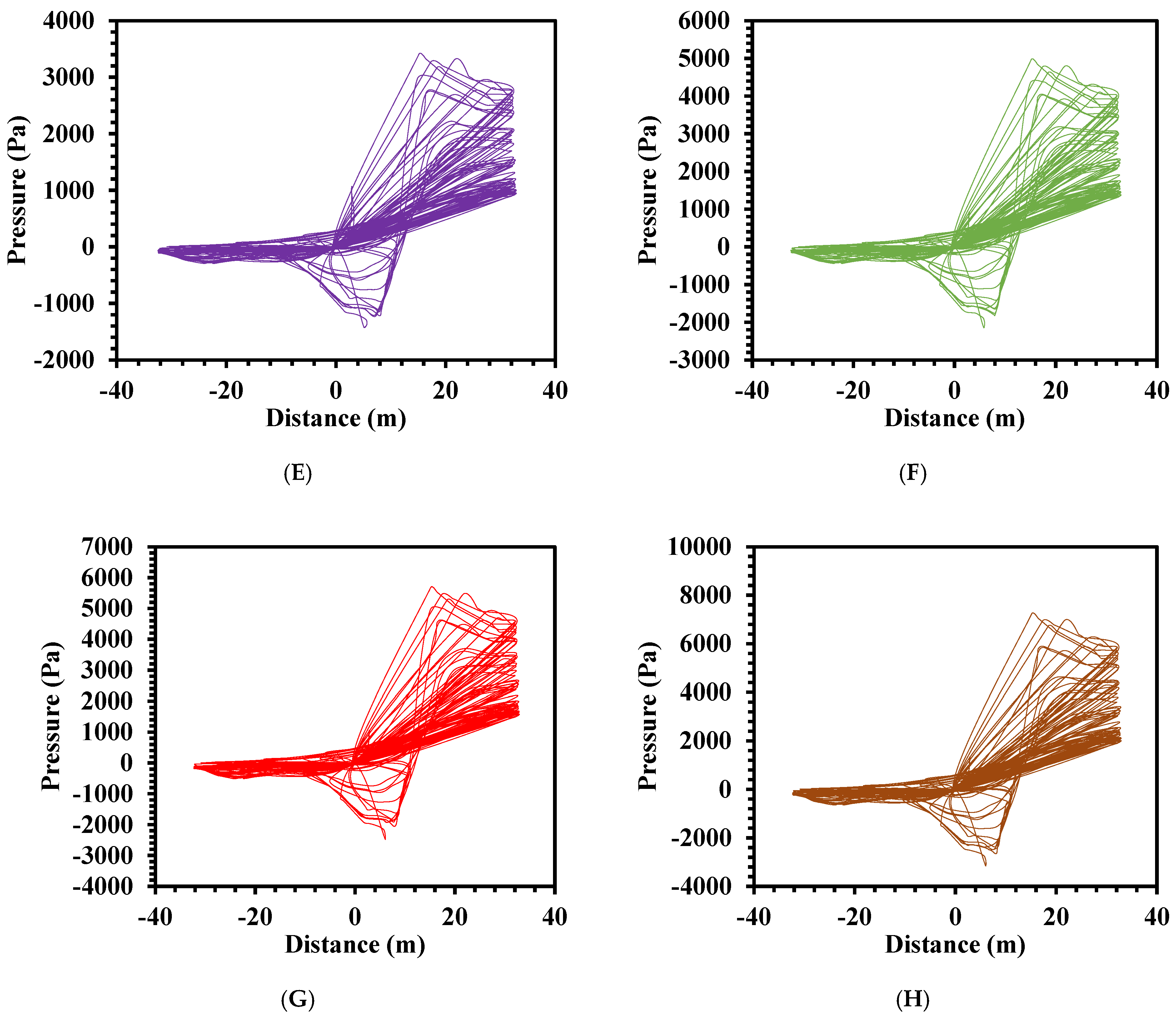

Figure 18.

Dynamic wind flow pressure results applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 18.

Dynamic wind flow pressure results applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

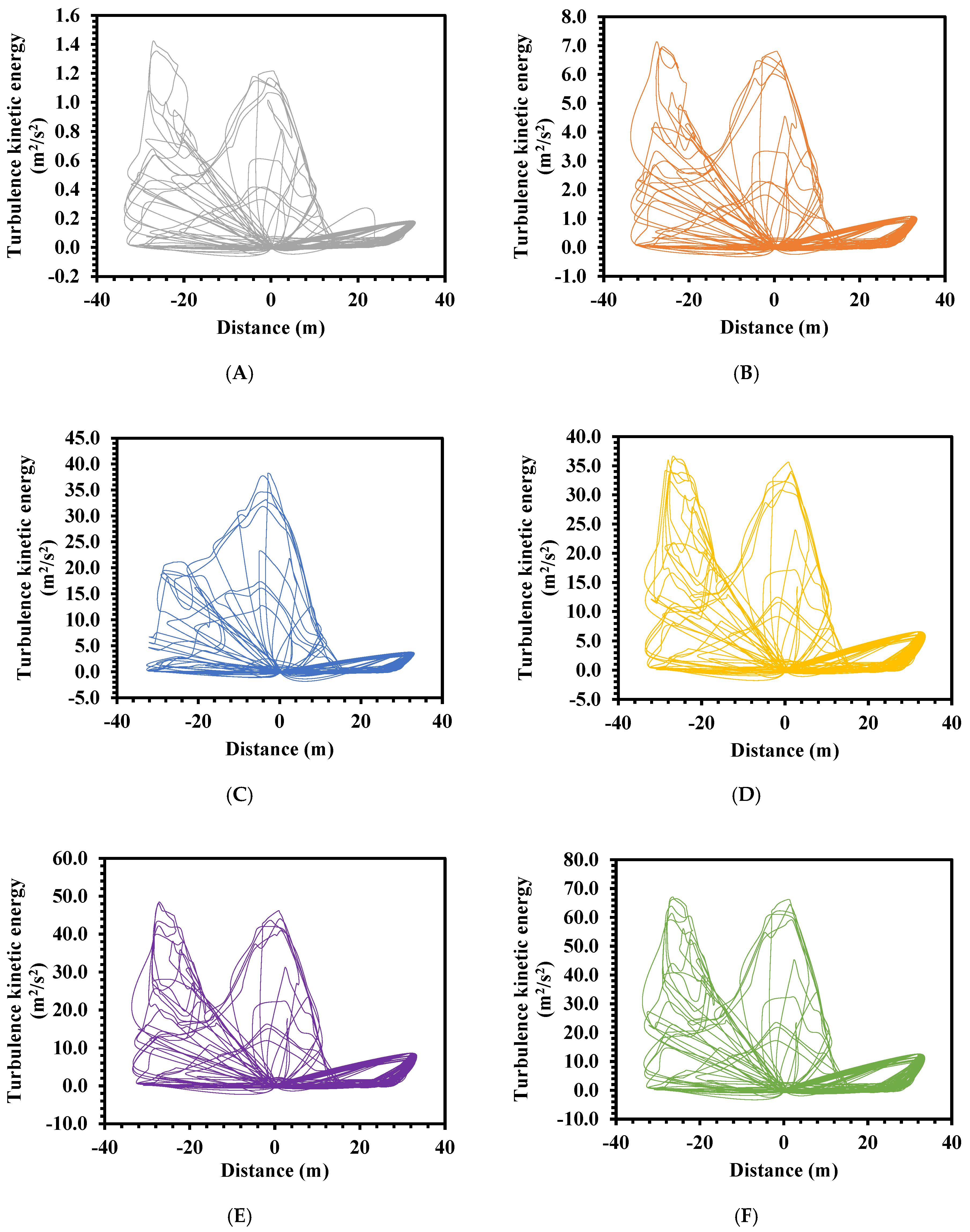

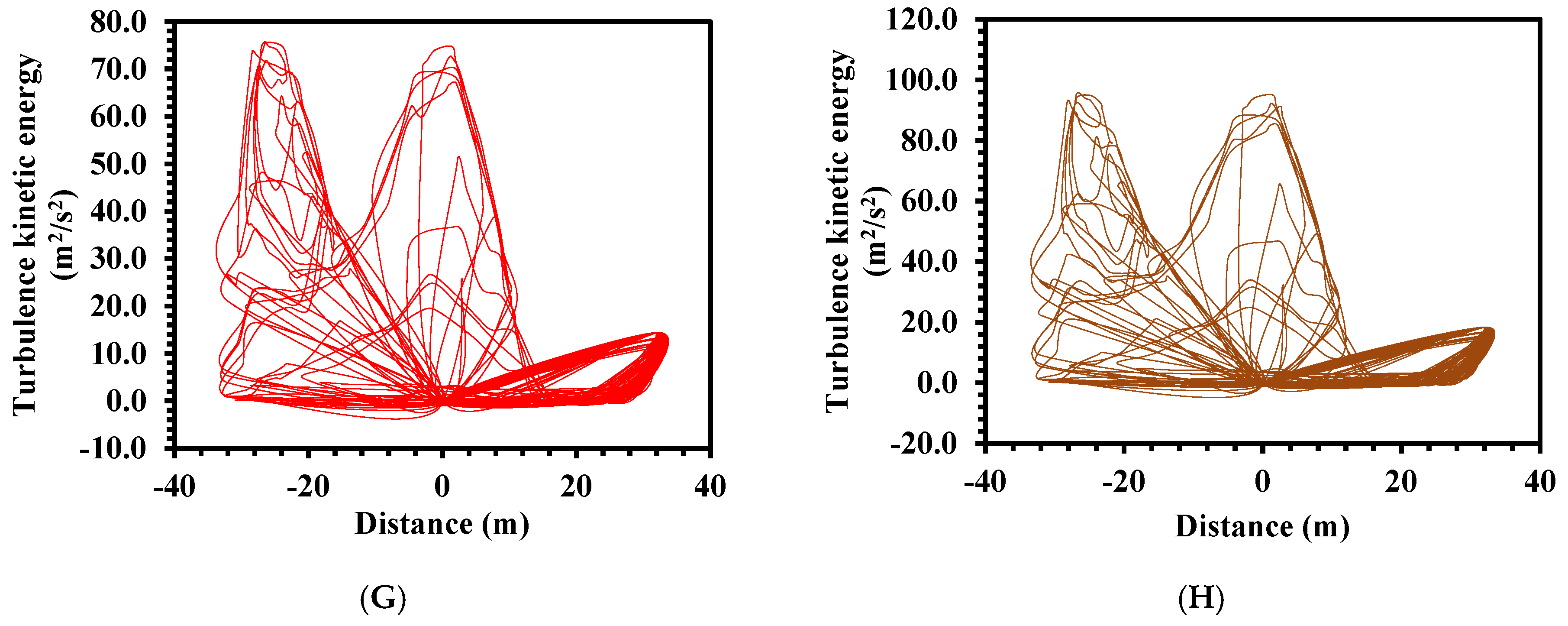

Figure 19.

Turbulent kinetic energy (TKE) results applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Figure 19.

Turbulent kinetic energy (TKE) results applied on the MSC2 modular system under (A) normal, (B) tropical depression, (C) tropical storm, (D) cyclone 1st, (E) cyclone 2nd, (F) cyclone 3rd, (G) cyclone 4th, and (H) cyclone 5th wind flow loading categories.

Table 1.

Existing articles on wind flow impact on the PPVC modular system.

Table 1.

Existing articles on wind flow impact on the PPVC modular system.

| Ref. | Modular Type | Wind Type | Design Code | FEM Software | Structure Performance | Wind Flow Dynamic |

|---|

| Displacement | Stiffness | Drift ratio | Strain Energy | Wind Velocity | Dynamic Pressure | TKE |

|---|

| [9] | Steel | Normal | AS 1170-2 | SAP2000 | - | - | Inter-story | - | - | - | - |

| [10] | Steel | Normal | AS 1170-2 | SAP2000 | - | Initial | Inter-story | - | - | - | - |

| [11] | Steel–concrete | Cyclone 2nd | AS 1170-2 | ABAQUS | Defamation | - | Overall | - | - | - | - |

| [12] | Concrete | Tropical storm | - | ABAQUS | SCLVD | - | - | - | - | - | - |

| Present study | Steel | Extreme | E.C 1 EN 1991-1-4/E.C 3 EN 1993-1-1 | ANSYS | Local/Global | Overall | Interstory/Overall | Overall | ✓ | ✓ | ✓ |

Table 2.

Proposed modular system element details.

Table 2.

Proposed modular system element details.

| Parameter | MSC1 | MSC2 |

|---|

| SHS Column (mm) | 200 × 200 × 12.6 | 200 × 200 × 12.6 |

| SHS Long beam (mm) | 200 × 200 × 12.6 | 200 × 200 × 12.6 |

| SHS Short beam (mm) | 200 × 200 × 12.6 | 200 × 200 × 12.6 |

| Wall A (cm) | - | 960 × 260 × 20 |

| Wall B (cm) | - | 960 × 360 × 20 |

| Wall C (cm) | - | 360 × 260 × 20 |

Table 3.

Proposed modular system material specifications.

Table 3.

Proposed modular system material specifications.

| Module Elements | Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Position Ratio | Density (Kg/m3) |

|---|

| SHS column | Mild | 275 | 370 | 210 | 0.3 | 7850 |

| SHS long beam | 275 | 370 | 210 | 0.3 | 7850 |

| SHS short beam | 275 | 370 | 210 | 0.3 | 7850 |

| Wall A | 275 | 370 | 210 | 0.3 | 7850 |

| Wall B | 275 | 370 | 210 | 0.3 | 7850 |

| Wall C | 275 | 370 | 210 | 0.3 | 7850 |

Table 4.

Saffir–Simpson wind speed scale [

14,

15] and wind design results.

Table 4.

Saffir–Simpson wind speed scale [

14,

15] and wind design results.

| Wind Category | Saffir–Simpson Wind Speed Scale (m/s) [14,15] | Design Wind Pressure (kN/m2) | Force (kN) |

|---|

| Normal | 7.0 | 30.625 | 14,700.0 |

| Tropical depression | 17.0 | 180.625 | 86,700.0 |

| Tropical storm | 32.0 | 640.0 | 307,200.0 |

| Cyclone 1st degree | 42.0 | 1102.5 | 529,200.0 |

| Cyclone 2nd degree | 49.0 | 1500.625 | 720,300.0 |

| Cyclone 3rd degree | 58.0 | 2102.5 | 1,009,200.0 |

| Cyclone 4th degree | 62.0 | 22.5 | 1,153,200.0 |

| Cyclone 5th degree | 70.0 | 3062.5 | 14,70,000.0 |

Table 5.

MSC1 displacement formula under selected wind flow categories.

Table 5.

MSC1 displacement formula under selected wind flow categories.

| Wind Flow Categories | Chart Equation | R-Squared % |

|---|

| Normal | | 94.7% |

| Tropical depression | | 98.2% |

| Tropical storm | | 98.3% |

| Cyclone 1st deg. | | 97.5% |

| Cyclone 2nd deg. | | 97.8% |

| Cyclone 3rd deg. | | 97.9% |

| Cyclone 4th deg. | | 88.5% |

| Cyclone 5th deg. | | 86.7% |

Table 6.

MSC1 stiffness formulas under selected wind flow categories.

Table 6.

MSC1 stiffness formulas under selected wind flow categories.

| Wind Flow Categories | Chart Equation | R-Squared % |

|---|

| Normal | | 77.1% |

| Tropical depression | | 77.1% |

| Tropical storm | | 77.1% |

| Cyclone 1st deg. | | 77.1% |

| Cyclone 2nd deg. | | 77.1% |

| Cyclone 3rd deg. | | 77.1% |

| Cyclone 4th deg. | | 77.1% |

| Cyclone 5th deg. | . | 77.1% |

Table 7.

MSC1 modular system strain energy under selected wind flow categories.

Table 7.

MSC1 modular system strain energy under selected wind flow categories.

| Category | Chart Equation | R-Squared % |

|---|

| Normal | | 92.1% |

| Tropical depression | | 92.1% |

| Tropical storm | | 92.1% |

| Cyclone 1st deg. | | 89.3% |

| Cyclone 2nd deg. | | 89.1% |

| Cyclone 3rd deg. | | 89.3% |

| Cyclone 4th deg. | | 89.8% |

| Cyclone 5th deg. | | 89.8% |

Table 8.

MSC1 modular system strain energy under selected wind flow categories.

Table 8.

MSC1 modular system strain energy under selected wind flow categories.

| Category | Chart Equation | R-Squared % |

|---|

| Normal | | 92.3% |

| Tropical depression | | 92.3% |

| Tropical storm | | 92.3% |

| Cyclone 1st deg. | | 92.3% |

| Cyclone 2nd deg. | | 92.3% |

| Cyclone 3rd deg. | | 92.3% |

| Cyclone 4th deg. | | 92.3% |

| Cyclone 5th deg. | | 92.3% |

Table 9.

MSC1 modular system wind velocity, dynamic wind flow pressure, and turbulence kinetic energy formulas.

Table 9.

MSC1 modular system wind velocity, dynamic wind flow pressure, and turbulence kinetic energy formulas.

| Category | Wind Velocity | Dynamic Pressure | TKE |

|---|

| Chart Equation | R-Squared % | Chart Equation | R-Squared % | Chart Equation | R-Squared % |

|---|

| Normal | | 26.6% | | 44.8% | | 23.4% |

| Tropical dep. | | 28.2% | | 46.4% | | 22.2% |

| Tropical storm | | 24.2% | | 46.4% | | 10.6% |

| Cyclone 1st deg. | | 32.5% | | 48.5% | | 27.4 |

| Cyclone 2nd deg. | | 31.5% | | 47.2% | | 25.4% |

| Cyclone 3rd deg. | | 32.5% | | 46.3% | | 25.5% |

| Cyclone 4th deg. | | 32.6% | | 48.1% | | 20.7% |

| Cyclone 5th deg. | | 31.3% | | 47.8% | | 25.6% |