Effect Mechanisms of Toner and Nano-SiO2 on Early Strength of Cement Grouting Materials for Repair of Reinforced Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

2.1.2. Additive

2.2. Methods

- SEM (Version: FEI Quanta 250, Anton Paar GmbH, Graz, Austria)

- Observe the microstructure of hydration products.

- XRD (Version: AXS, Bruker Corporation, Billerica, MA, USA)

- Investigate the types of hydration products Condition: 10°/min scanning speed, 10–65° scanning angle.

- DSC (Version: SDT 650, TA Instruments, New Castle, DE, USA)

- Analyze the content of hydration products by mass and heat change. Condition: 0 –700 °C, 15 °C/min heating rate, nitrogen atmosphere.

- FTIR (Version: Nicolet 5700, Thermo Fisher Scientific—CN, Shanghai, China)

- Investigate functional group characteristics. Condition: 400–4000 cm−1 spectral.

3. Engineering Properties of the CRTS

4. Microstructure Analysis

4.1. Microstructures of the Cement Grouting Materials with Pure Toner

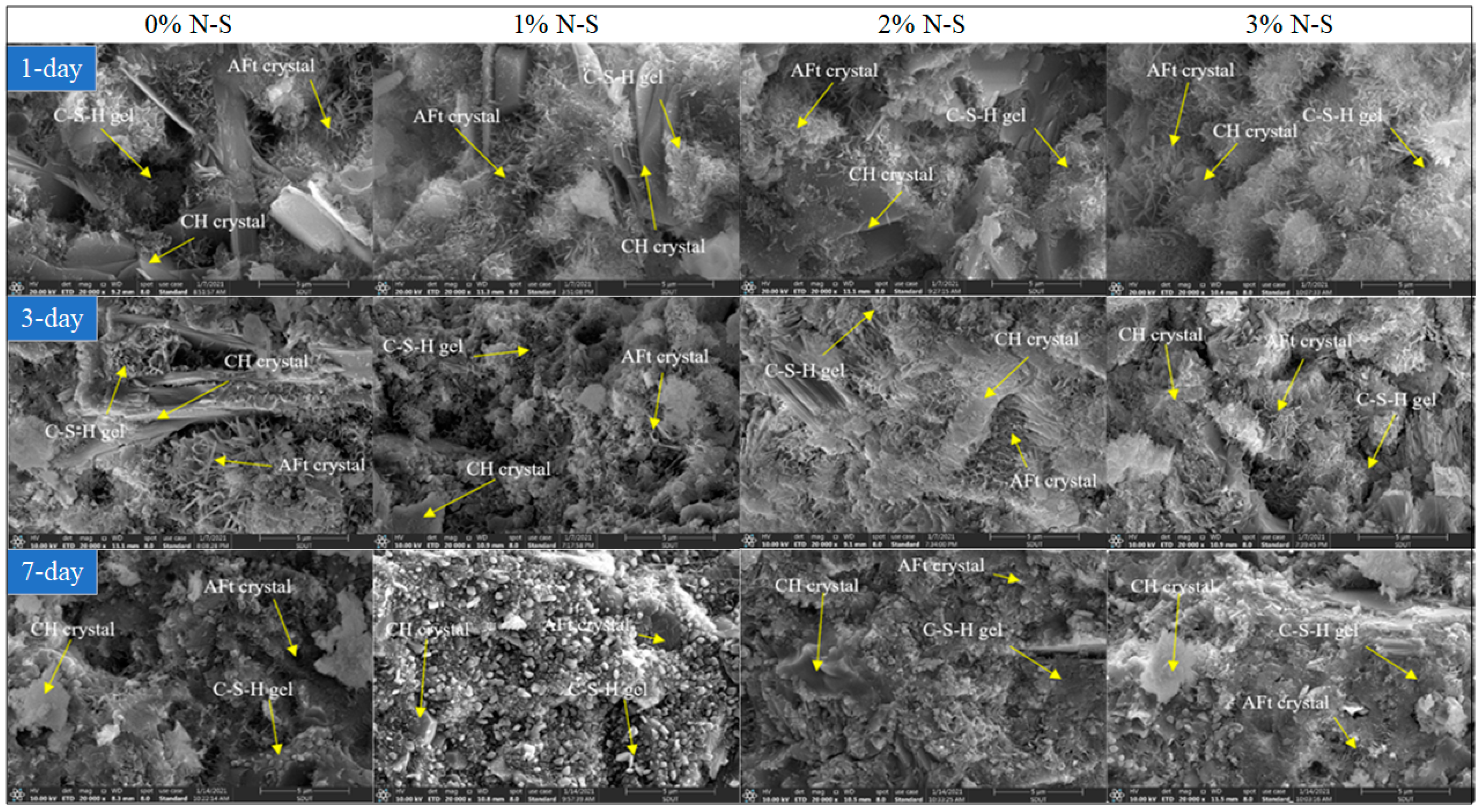

4.2. CRTS

5. Hydration Products of the CRTS

5.1. X-ray Diffraction Analysis

5.2. Differential Scanning Calorimetry

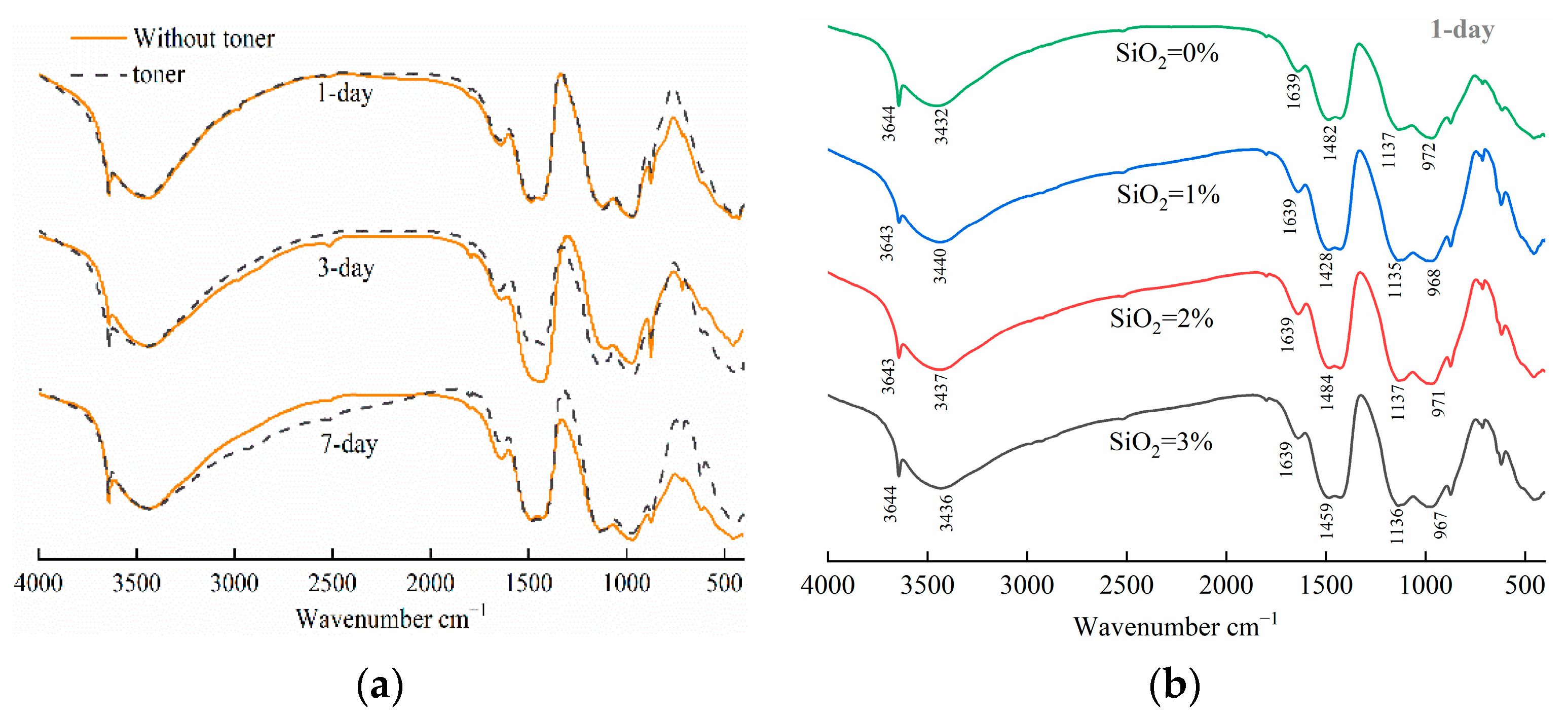

5.3. Fourier Transform Infrared Spectroscopy

6. Conclusions

- The early strength (1-day and 3-day) of the CRTS decreases with the addition of the toner, while the fluidity accordingly increases, implying the toner brings a negative impact on the engineering properties of the CRTS. The N-S is able to reduce (but not eliminate) the negative impact. With the increase of every 1% N-S, the flexural strength of 1-day, 3-day, and 7-day average increased by 11.3%, 2.9%, and 0.9%, respectively, and the compressive strength of 1-day, 3-day, and 7-day average increased by 0.8%, 0.3%, and 0.1%.

- The toner and the N-S only influence the hydration progress of the CRTS rather than change the type of hydration products. Moreover, they both mainly act on the hydration process of the C3S while presenting limited effects on the C2S.

- The toner slows down the generation of the CH crystals and AFt in the early stage of the hydration process, especially for the CH crystals, so as to weaken the early strength of the CRTS. Although the N-S can expedite the conversion from generated CH crystals to C-H-S gels to partly improve the early strength, it is difficult to change the generation state of the CH crystals with the action of the toner. This is the reason why the N-S is unable to eliminate the negative impact of the toner on the early strength of the CRTS. In addition, overmuch the N-S will bring adverse effects on the hydration of the CRTS because of agglomeration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Habib, A.; Yildirim, U.; Eren, O. Column repair and strengthening using RC jacketing: A brief state-of-the-art review. Innov. Infrastruct. Solut. 2020, 5, 75. [Google Scholar] [CrossRef]

- Fukuyama, K.; Higashibata, Y.; Miyauchi, Y. Studies on repair and strengthening methods of damaged reinforced concrete columns. Cem. Concr. Compos. 2020, 22, 81–88. [Google Scholar] [CrossRef]

- Ayash, N.; Moussa, A.; Soliman, A. Repairing and strengthening of reinforced concrete cantilever slabs using glass fiber–reinforced polymer (gfrp) wraps. Structures 2020, 28, 2488–2506. [Google Scholar] [CrossRef]

- Gergess, A.; Shabab, M.; Massouh, R. Repair of severely damaged reinforced concrete beams with high-strength cementitious grout. Transp. Res. Rec. 2020, 2674, 036119812091911. [Google Scholar] [CrossRef]

- Zhu, C.; Fang, S.; Ng, L.; Pundiene, I.; Chen, J. Flexural behavior of reinforced concrete beams strengthened by textile reinforced magnesium potassium phosphate cement mortar. Front. Mater. 2020, 7, 272. [Google Scholar] [CrossRef]

- Keong, L.; Amin, C.; Trevor, H.; Hamid, N. Performance of the steel fibre reinforced rigid concrete pavement in fatigue. Buildings 2020, 10, 186. [Google Scholar]

- Li, C.; Liu, T.; Fu, H.; Zhang, X.; Yang, Y.; Zhao, S. Test and evaluation of the flexural properties of reinforced concrete beams with 100% recycled coarse aggregate and manufactured sand. Buildings 2021, 11, 420. [Google Scholar] [CrossRef]

- Zhao, S. Bond of ribbed steel bar in high-performance steel fiber reinforced expanded-shale lightweight concrete. Buildings 2021, 11, 582. [Google Scholar] [CrossRef]

- Khedaywi, T. Study on utilising waste toner in asphalt cement. Road Mater. Pavement Des. 2014, 15, 446–454. [Google Scholar] [CrossRef]

- Parvan, M.; Voicu, G.; Bdnoiu, A. Study of hydration and hardening processes of self-sensing cement-based materials with carbon black content. J. Therm. Anal. Calorim. 2020, 139, 807–815. [Google Scholar] [CrossRef]

- Mohammad, R.I.; Nasser, A.; Wasee, A.; Mohamed, R. Feasibility of recycling waste carbon black in cement mortar production: Environmental life cycle assessment and performance evaluation. Constr. Build. Mater. 2021, 296, 123740. [Google Scholar]

- Thai, K.; Choo, H.; Kaothorn, P.; Yune, Y. Experimental study on the strength behavior of cement-stabilized sand with recovered carbon black. Geomech. Eng. 2020, 23, 31–38. [Google Scholar]

- Makul, N. Modern sustainable cement and concrete composites: Review of current status, challenges and guidelines. Sustain. Mater. Technol. 2020, 25, e00155. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Alghamdi, H. A review of cementitious alternatives within the development of environmental sustainability associated with cement replacement. Environ. Sci. Pollut. Res. 2022, 29, 42433–42451. [Google Scholar] [CrossRef] [PubMed]

- Ltifi, M.; Zafar, I. Influence of nano-silica on early age and durability properties of cement mortars. Adv. Cem. Res. 2021, 33, 386–397. [Google Scholar] [CrossRef]

- Emamian, S.; Eskandari-Naddaf, H. Genetic programming-based formulation for compressive and flexural strength of cement mortar containing nano and micro silica after freeze and thaw cycles. Constr. Build. Mater. 2020, 241, 118027. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Su, D.; Yue, G.; Wang, L. Study on the influence of nanosilica sol on the hydration process of different kinds of cement and mortar properties. Materials 2021, 14, 3653. [Google Scholar] [CrossRef]

- Hosseini, P.; Abolhasani, M.; Mirzaei, F.; Anbaran, M.; Khaksari, Y.; Famili, H. Influence of two types of nanosilica hydrosols on short-term properties of sustainable white portland cement mortar. J. Mater. Civ. Eng. 2018, 30, 04017289. [Google Scholar] [CrossRef]

- Garcia, R.; Reyes, E.; Villanueva, P.; Rubia, M.; Fernandez, J.; Moragues, A. Service life and early age durability enhancement due to combined metakaolin and nanosilica in mortars for marine Applications. Materials 2020, 13, 1169. [Google Scholar] [CrossRef]

- Gerlinde, L.; Dimitrios, G.A.; Nele, D.; Marc, R.; Tom, H.; Danny, V.; Didier, S. The influence of superabsorbent polymers and nanosilica on the hydration process and microstructure of cementitious mixtures. Materials 2020, 13, 5194. [Google Scholar]

- Liu, X.; Liu, L.; Kai, L.; Li, T.; Zhao, P.; Liu, R.; Zuo, J.; Feng, F.; Surendra, P.S. Enhanced early hydration and mechanical properties of cement-based materials with recycled concrete powder modified by nano-silica. J. Build. Eng. 2022, 50, 104175. [Google Scholar] [CrossRef]

- Chithra, S.; Kumar, S.; Chinnaraju, K. The effect of Colloidal Nano-silica on workability, mechanical and durability properties of High-performance Concrete with Copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Y.; Yuan, L.; Xu, D.; Du, P.; Hou, P.; Zhou, Z.; Cheng, X.; Liu, S.; Wang, Y. Effect of nano-silica on chemical and volume shrinkage of cement-based composites. Constr. Build. Mater. 2020, 247, 118529. [Google Scholar] [CrossRef]

- Ren, J.; Zhao, H.; Zhang, L.; Zhao, Z.; Xu, Y.; Cheng, Y.; Wang, M.; Chen, J.; Wang, J. Design optimization of cement grouting material based on adaptive boosting algorithm and simplicial homology global optimization. J. Build. Eng. 2022, 49, 104049. [Google Scholar] [CrossRef]

- China Association for Engineering Construction Standardization. Technical Specification for Road Pavement; (T\CECS G: D51-01-2019); China Association for Engineering Construction Standardization: Beijing, China, 2019. [Google Scholar]

- Ren, J.; Zhao, Z.; Xu, Y.; Wang, S.; Chen, H.; Huang, J.; Xue, B.; Wang, J.; Chen, J.; Yang, C. High-fluidization, early strength cement grouting material enhanced by Nano-SiO2: Formula and mechanisms. Materials 2021, 14, 6144. [Google Scholar] [CrossRef]

| Particle Size (nm) | Specific Surface Area (m2/g) | Tinting Strength (%) | PH Value | Appearance |

|---|---|---|---|---|

| 12 | 425 | 125 | 1.7 | Black powder |

| Particle Size (nm) | Specific Surface Area (m2/g) | Bulk Density (g/cm3) | Purity (%) | Appearance |

|---|---|---|---|---|

| 15 | 600 | 0.21 | 99.8 | White grainy |

| Toner | Fluidity (s) | Flexural Strength (MPa) | Compressive Strength (MPa) | Shrinkage Rate (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1-Day | 3-Day | 7-Day | 1-Day | 3-Day | 7-Day | 7-Day | 28-Day | ||

| Yes | 11.41 | 2.31 | 7.16 | 9.61 | 8.76 | 22.63 | 30.28 | 0.018 | 0.113 |

| No | 10.38 | 3.43 | 8.18 | 10.66 | 10.91 | 26.02 | 34.38 | 0.019 | 0.108 |

| Nona-SiO2 Content (%) | Fluidity(s) | Flexural Strength (MPa) | Compressive Strength (MPa) | Shrinkage Rate (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1-Day | 3-Day | 7-Day | 1-Day | 3-Day | 7-Day | 7-Day | 28-Day | ||

| 0 | 11.41 | 2.31 | 7.16 | 9.61 | 8.76 | 22.63 | 30.28 | 0.018 | 0.113 |

| 1 | 11.89 | 2.81 | 7.47 | 9.76 | 9.91 | 23.62 | 31.85 | 0.024 | 0.105 |

| 2 | 12.34 | 3.05 | 7.69 | 9.92 | 10.79 | 24.69 | 31.56 | 0.017 | 0.112 |

| 3 | 12.92 | 3.16 | 7.81 | 9.86 | 11.21 | 25.26 | 31.22 | 0.022 | 0.110 |

| Standard | 9–13 | - | - | ≥2 | - | - | 10–30 | - | <0.5 |

| SiO2(%) | SI (150~200 °C) | SII (400~450 °C) | Total Mass Loss (0~700 °C) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1-Day | 3-Day | 7-Day | 1-Day | 3-Day | 7-Day | 1-Day | 3-Day | 7-Day | |

| 0 | 2.9 | 6.0 | 8.2 | 2.9 | 5.2 | 5.0 | 88.4 | 82.6 | 78.4 |

| 1 | 3 | 6.4 | 9.5 | 2.6 | 3.4 | 5.2 | 86.5 | 80.0 | 78.1 |

| 2 | 3.7 | 7.1 | 7.4 | 2.4 | 3.5 | 4.2 | 85.7 | 79.2 | 77.8 |

| 3 | 4.3 | 7.2 | 8.1 | 2.7 | 3.4 | 3.7 | 85.5 | 78.5 | 76.9 |

| N0 | 4.6 | 7.1 | 8.1 | 2.5 | 4.8 | 3.4 | 85.2 | 77.5 | 75.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Chen, J.; Wang, J.; Zhuang, S.; Chen, H.; Zhao, H.; Wang, C.; Zhang, L.; Li, M.; Li, G.; et al. Effect Mechanisms of Toner and Nano-SiO2 on Early Strength of Cement Grouting Materials for Repair of Reinforced Concrete. Buildings 2022, 12, 1320. https://doi.org/10.3390/buildings12091320

Zhao Z, Chen J, Wang J, Zhuang S, Chen H, Zhao H, Wang C, Zhang L, Li M, Li G, et al. Effect Mechanisms of Toner and Nano-SiO2 on Early Strength of Cement Grouting Materials for Repair of Reinforced Concrete. Buildings. 2022; 12(9):1320. https://doi.org/10.3390/buildings12091320

Chicago/Turabian StyleZhao, Zedong, Jingchun Chen, Jian Wang, Shenghan Zhuang, Haiwei Chen, Hongbo Zhao, Chunguang Wang, Lin Zhang, Min Li, Gen Li, and et al. 2022. "Effect Mechanisms of Toner and Nano-SiO2 on Early Strength of Cement Grouting Materials for Repair of Reinforced Concrete" Buildings 12, no. 9: 1320. https://doi.org/10.3390/buildings12091320

APA StyleZhao, Z., Chen, J., Wang, J., Zhuang, S., Chen, H., Zhao, H., Wang, C., Zhang, L., Li, M., Li, G., & Ren, J. (2022). Effect Mechanisms of Toner and Nano-SiO2 on Early Strength of Cement Grouting Materials for Repair of Reinforced Concrete. Buildings, 12(9), 1320. https://doi.org/10.3390/buildings12091320