Development of Creep Deformations during Service Life: A Comparison of CLT and TCC Floor Constructions

Abstract

:1. Introduction

2. Materials and Methods

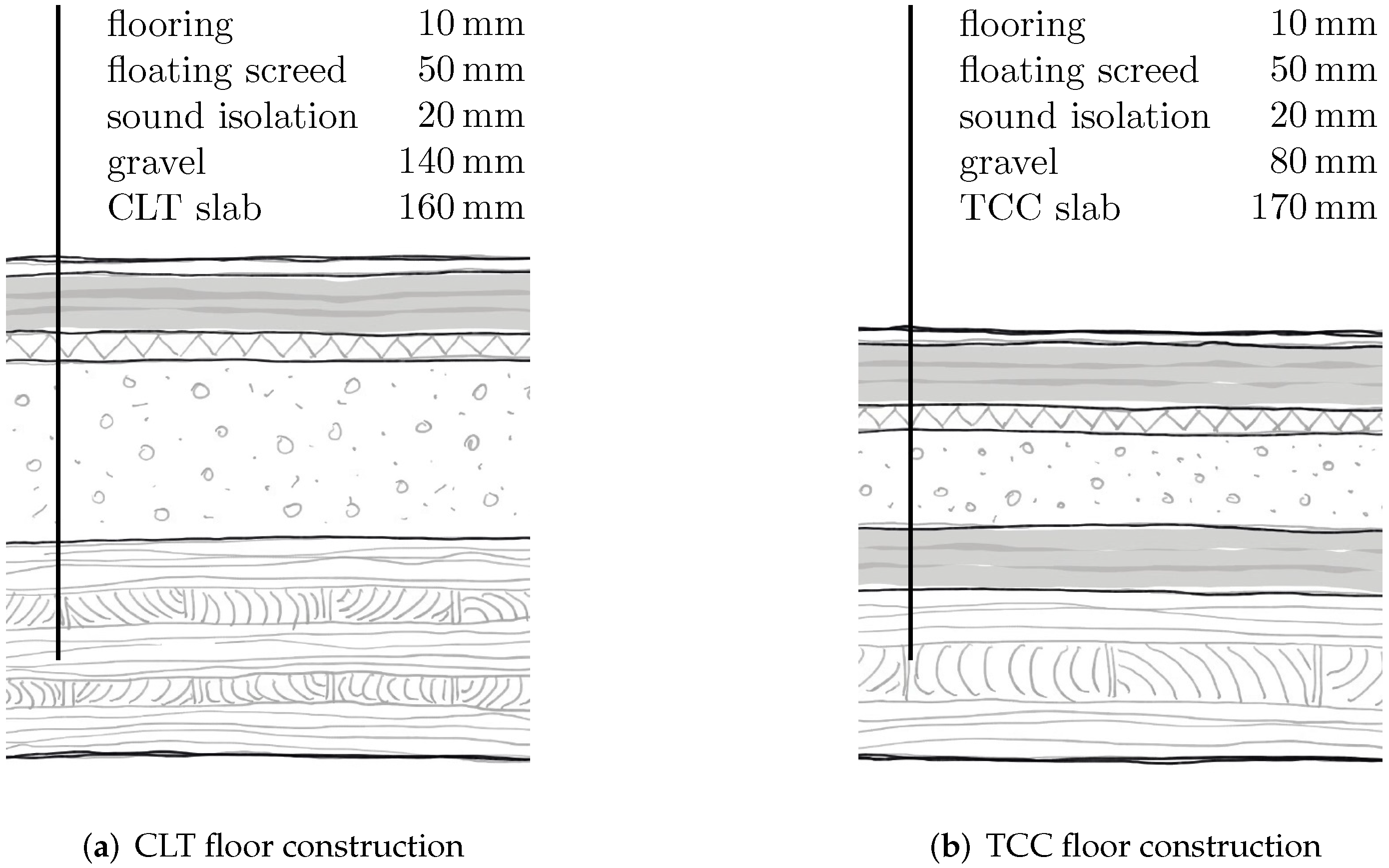

2.1. Investigated Slab Types

2.2. Time-Dependent Material Models

2.3. Structural Analysis of Composite Slabs

3. Results

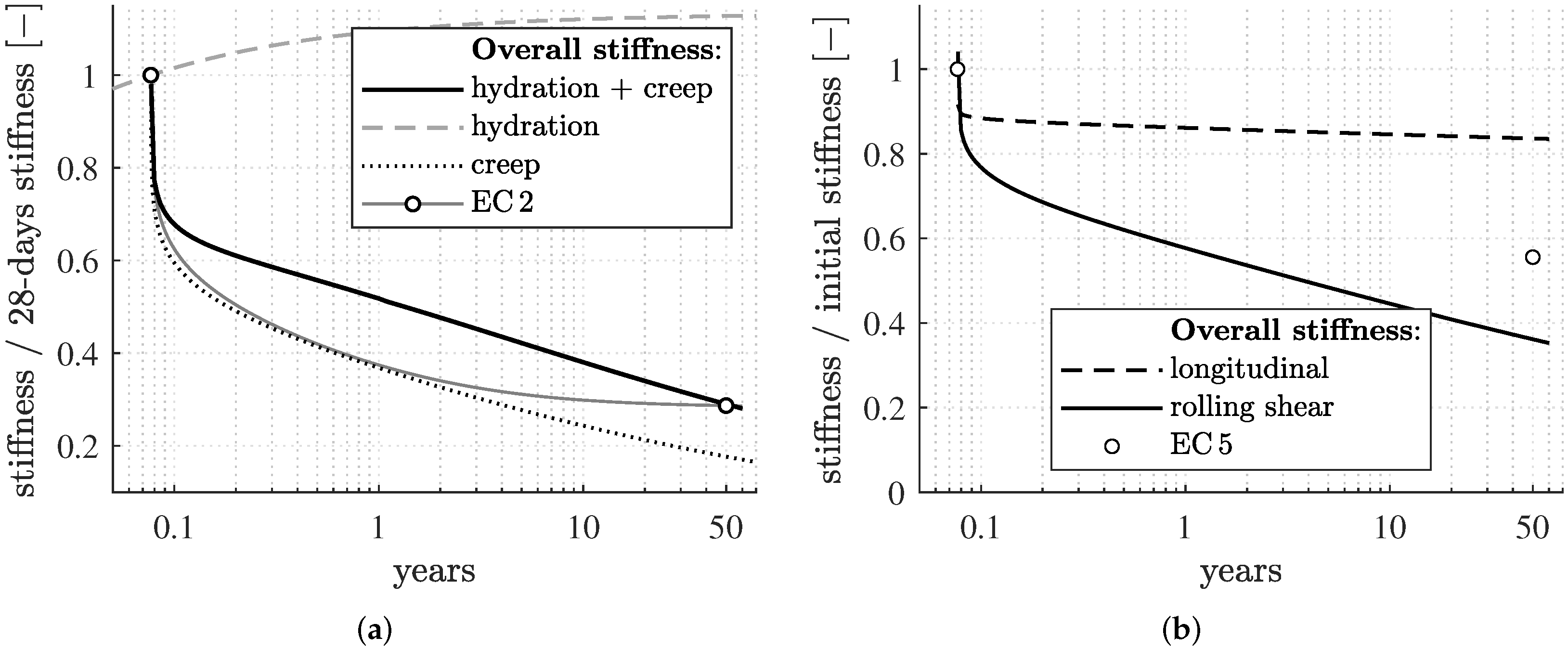

3.1. Time-Dependent Material Modeling

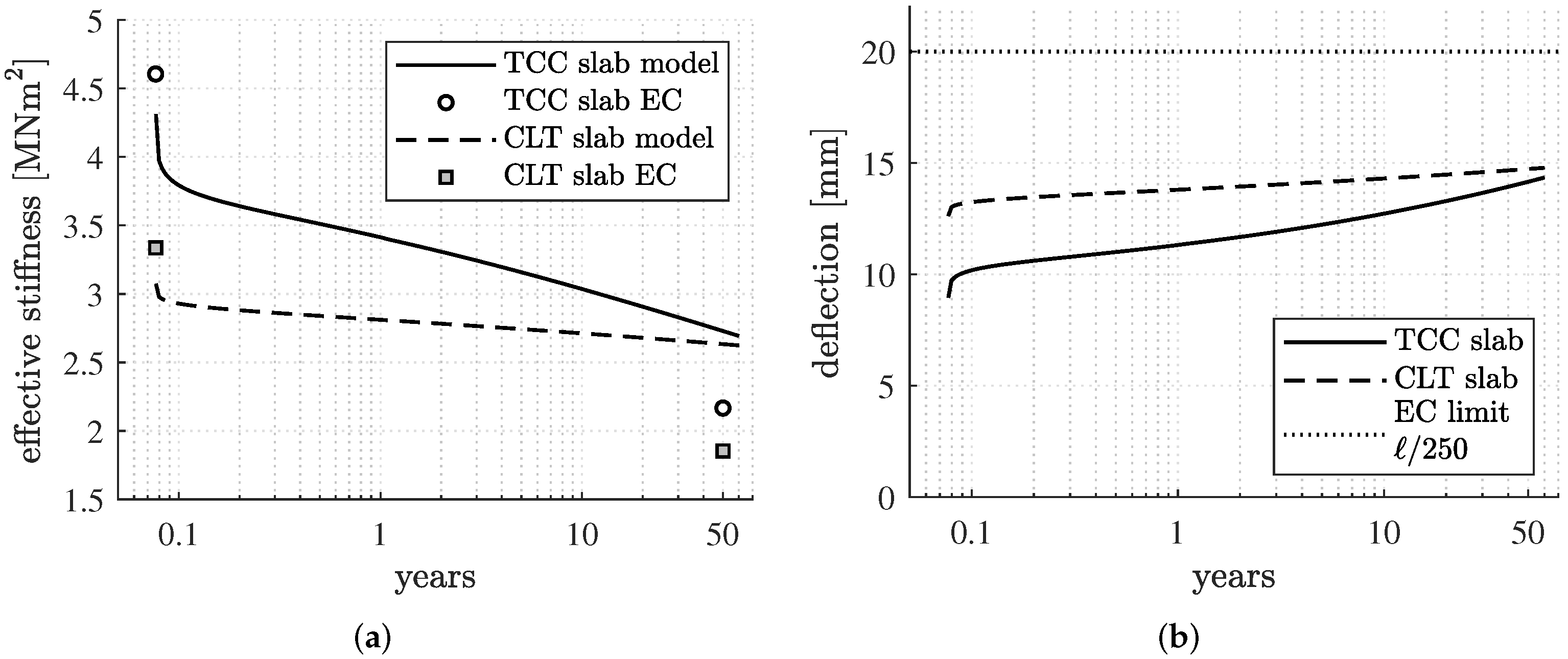

3.2. Time-Dependent Structural Analysis

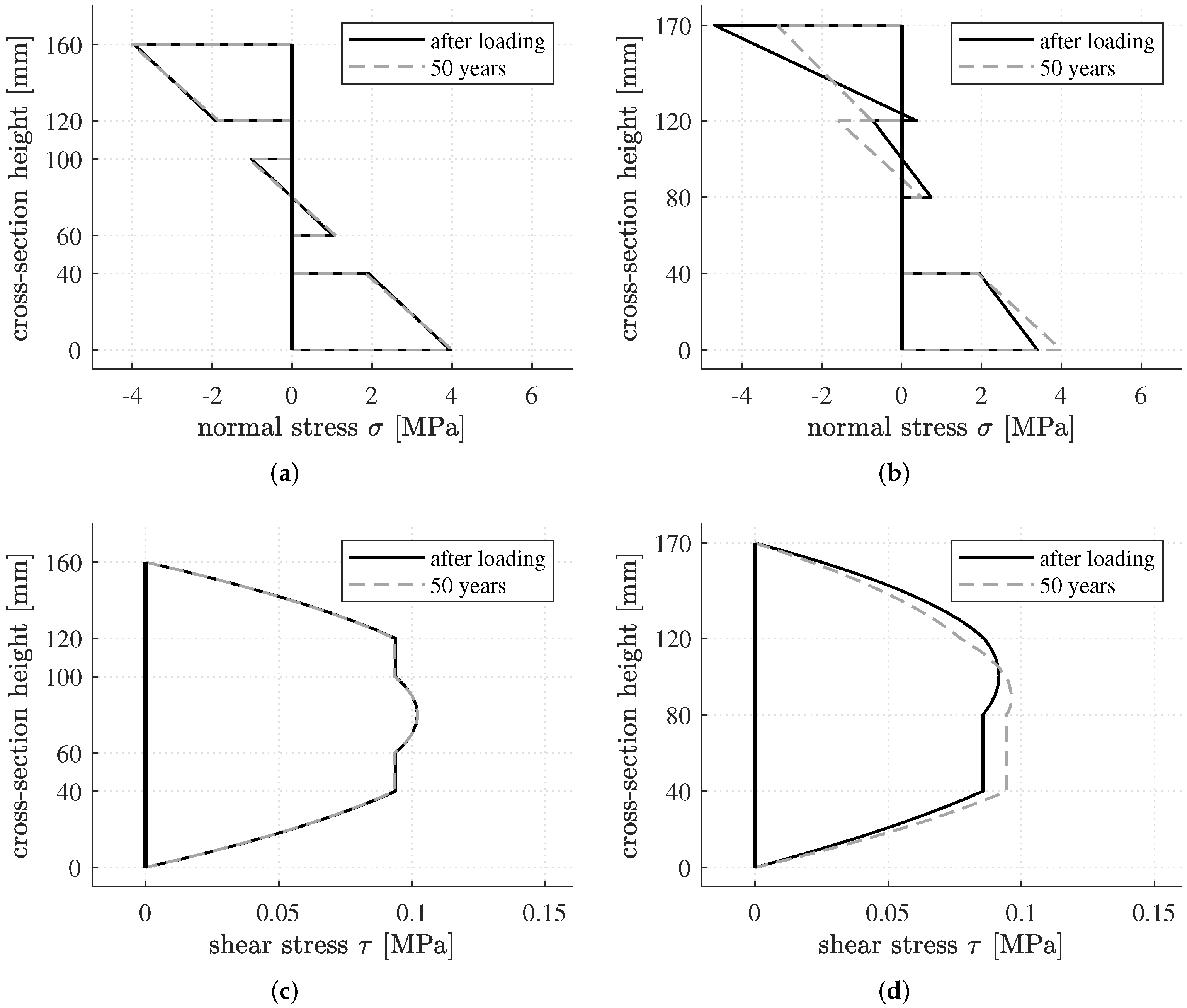

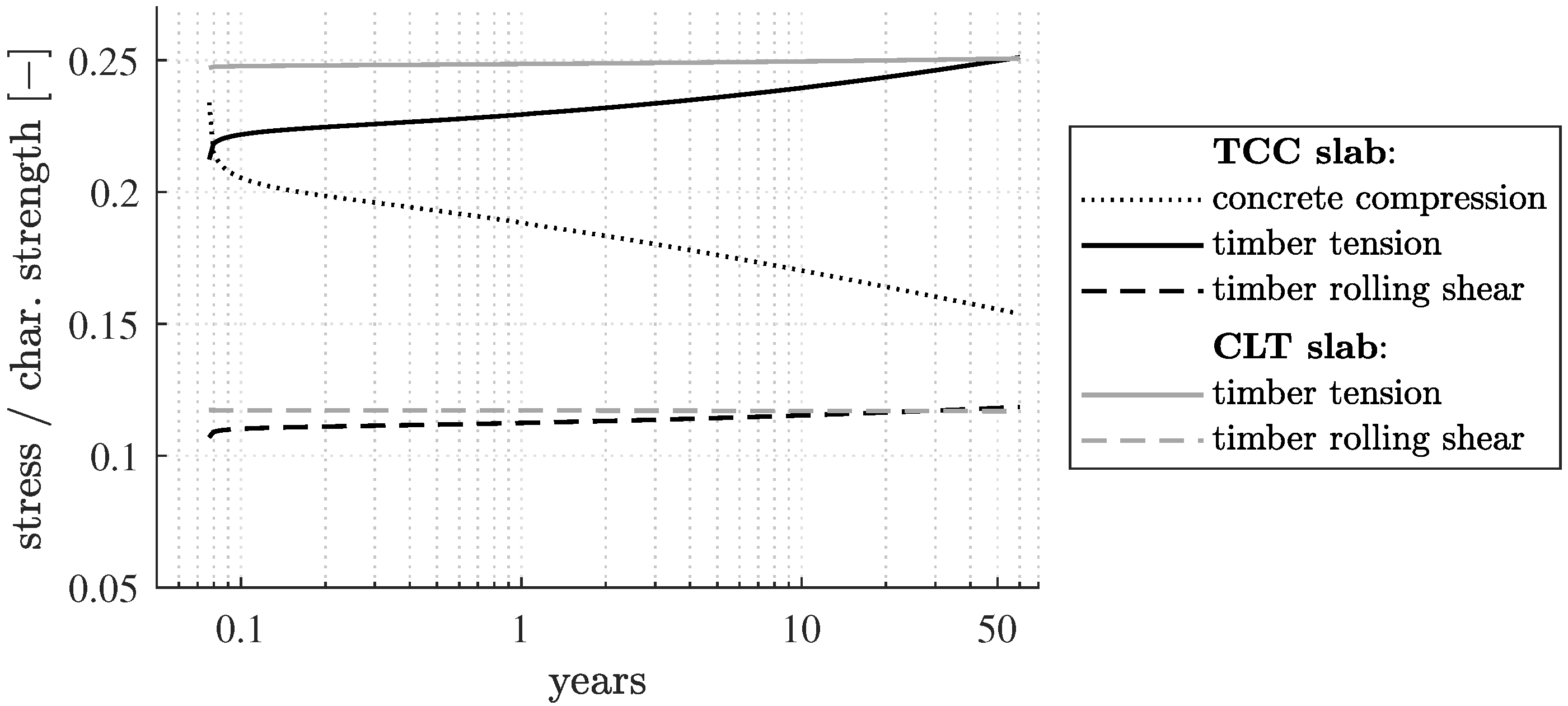

3.3. Time-Dependent Stress Distribution between the Layers

4. Discussion

5. Conclusions

- The hybrid approach considers individual time-dependent material models for the involved materials, i.e., for timber in the longitudinal direction, for timber in rolling shear direction, and for hydrating concrete. Midspan deflections of the slabs due to creep over the service life were modeled, and the load redistribution between the layers of the hybrid cross sections was investigated. Even if the cross-layers of the CLT were considered only for connecting the longitudinal layers and not for carrying normal stresses, a load redistribution from the cross layers toward the longitudinal layers due to different creep behavior of the layers was found. Due to the creep behavior, together with the ongoing hydration of the concrete layer, a significant amount of normal stresses redistribute from the concrete layer to the CLT plate during the service life.

- The comparison of the long-term deflections of the slabs shows that the CLT slab is less stiff in the beginning, but the overall stiffness reduction is smaller than for the TCC slab. After 50 years of use, the midspan deflections of both investigated slab types were quite similar. As both slab types should provide the same level of impact sound protection between floors of residential buildings, the TCC slab with a 50 mm reduced construction height would be preferred if the total construction height of a multistory building is limited.

- The introduced hybrid approach is simple, but nonetheless allows to consider advanced material models for the individual layers of the composite structure without additional software. For the future, it is desirable to validate the hybrid approach with experiments. As for future improvements of the hybrid approach, the method for the structural analysis should consider shear and normal stresses in all layers. This will allow to investigate the load redistribution between the layers in more detail.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Committee for Standardization. EN1995-1-1:2004 Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings; Swedish Standards Institute (SIS): Stockholm, Sweden, 2004. [Google Scholar]

- Borgström, E.; Fröbel, J. (Eds.) The CLT Handbook; Svenskt Trä—Swedish Wood: Stockholm, Sweden, 2019. [Google Scholar]

- Derkowski, W. Large panels buildings-the possibilities of modern precast industry. Cem. Wapno Beton 2017, 22, 414–425. [Google Scholar]

- Derkowski, W. New solutions for prefabricated floor slabs. Cem. Wapno Beton 2019, 24, 372–382. [Google Scholar]

- Neve, O.; Spencer-Allen, L. Shaking up dance floor design with timber–concrete composites. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 204–212. [Google Scholar] [CrossRef]

- Blaß, H.J.; Romani, M. Langzeitverhalten von Holz-Beton-Konstruktionen; Fraunhofer-IRB-Verlag: Stuttgart, Germany, 2002. [Google Scholar]

- Ceccotti, A.; Fragiacomo, M.; Giordano, S. Long-term and collapse tests on a timber-concrete composite beam with glued-in connection. Mater. Struct. 2007, 40, 15–25. [Google Scholar] [CrossRef]

- Fragiacomo, M.; Gutkowski, R.; Balogh, J.; Fast, R. Long-term behavior of wood-concrete composite floor/deck systems with shear key connection detail. J. Struct. Eng. 2007, 133, 1307–1315. [Google Scholar] [CrossRef]

- To, L.; Fragiacomo, M.; Balogh, J.; Gutkowski, R.M. Long-term load test of a wood–concrete composite beam. Proc. Inst. Civ. Eng. Struct. Build. 2011, 164, 155–163. [Google Scholar] [CrossRef]

- Yeoh, D.; Fragiacomo, M.; Deam, B. Long-term performance of LVL-concrete composite beams under service load. In Proceedings of the WCTE—World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012; Volume 3, p. 3. [Google Scholar]

- Fragiacomo, M.; Lukaszewska, E. Time-dependent behaviour of timber–concrete composite floors with prefabricated concrete slabs. Eng. Struct. 2013, 52, 687–696. [Google Scholar] [CrossRef]

- Augeard, E.; Ferrier, E.; Michel, L. Mechanical behavior of timber-concrete composite members under cyclic loading and creep. Eng. Struct. 2020, 210, 110289. [Google Scholar] [CrossRef]

- Takanashi, R.; Ohashi, Y.; Ishihara, W.; Matsumoto, K. Long-term bending properties of cross-laminated timber made from Japanese larch under constant environment. J. Wood Sci. 2021, 67, 65. [Google Scholar] [CrossRef]

- Jöbstl, R.A.; Schickhofer, G. Comparative Examination of Creep of GLT and CLT Slabs in Bending. In Proceedings of the Working Commission CIB W18—Timber Structures, Bled, Slovenia, 28–31 August 2007; Volume 40, pp. 1–15. [Google Scholar]

- Schänzlin, J. Zum Langzeitverhalten von Brettstapel-Beton-Verbunddecken (About the Long Term Behaviour of Composite Floors of Board Stacks and Concrete). Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2003. [Google Scholar]

- Rüsch, H.; Jungwirth, D. Stahlbeton-Spannbeton: Berücksichtigung der Einflüsse von Kriechen und Schwinden auf das Verhalten der Tragwerke: Hubert Rüsch; Werner: Los Angeles, CA, USA, 1976; Volume 2. [Google Scholar]

- Kupfer, H.; Kirmair, H. Verformungsmoduln zur Berechnung statisch unbestimmter Systeme aus zwei Komponenten mit unterschiedlichen Kriechzahlen. Der Bauing. 1987, 62, 371–377. [Google Scholar]

- Fragiacomo, M.; Ceccotti, A. Long-term behavior of timber–concrete composite beams. I: Finite element modeling and validation. J. Struct. Eng. 2006, 132, 13–22. [Google Scholar] [CrossRef]

- Fragiacomo, M. Long-term behavior of timber–concrete composite beams. II: Numerical analysis and simplified evaluation. J. Struct. Eng. 2006, 132, 23–33. [Google Scholar] [CrossRef]

- Fragiacomo, M. Experimental behaviour of a full-scale timber-concrete composite floor with mechanical connectors. Mater. Struct. 2012, 45, 1717–1735. [Google Scholar] [CrossRef]

- Khorsandnia, N. Finite Element Analysis for Predicting the Short-Term and Longtermbehaviour of Timber-Concrete Composite Structures. Ph.D. Thesis, University of Technology, Sydney, Ultimo, Australia, 2013. [Google Scholar]

- Khorsandnia, N.; Valipour, H.; Foster, S.; Crews, K. A force-based frame finite element formulation for analysis of two- and three-layered composite beams with material non-linearity. Int. J. Non-Linear Mech. 2014, 62, 12–22. [Google Scholar] [CrossRef]

- Khorsandnia, N.; Schänzlin, J.; Valipour, H.; Crews, K. Time-dependent behaviour of timber–concrete composite members: Numerical verification, sensitivity and influence of material properties. Constr. Build. Mater. 2014, 66, 192–208. [Google Scholar] [CrossRef]

- Khorsandnia, N.; Schänzlin, J.; Valipour, H.; Crews, K. Coupled finite element-finite difference formulation for long-term analysis of timber–concrete composite structures. Eng. Struct. 2015, 96, 139–152. [Google Scholar] [CrossRef]

- Schänzlin, J.; Fragiacomo, M. Analytical derivation of the effective creep coefficients for timber-concrete composite structures. Eng. Struct. 2018, 172, 432–439. [Google Scholar] [CrossRef]

- Nie, Y.; Valipour, H. Experimental and numerical study of long-term behaviour of timber-timber composite (TTC) connections. Constr. Build. Mater. 2021, 304, 124672. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN1992-1-1:2011 Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; Swedish Standards Institute (SIS): Stockholm, Sweden, 2011. [Google Scholar]

- Möhler, K. Über das Tragverhalten von Biegeträgern und Druckstäben mit zusammengesetzten Querschnitten und Nachgiebigen Verbindungsmitteln; Habilitation; Technical University of Karlsruhe: Karlsruhe, Germany, 1956. (In German) [Google Scholar]

- Jiang, Y.; Crocetti, R. CLT-concrete composite floors with notched shear connectors. Constr. Build. Mater. 2019, 195, 127–139. [Google Scholar] [CrossRef]

- Jorge, L.; Schänzlin, J.; Lopes, S.; Cruz, H.; Kuhlmann, U. Time-dependent behaviour of timber lightweight concrete composite floors. Eng. Struct. 2010, 32, 3966–3973. [Google Scholar] [CrossRef]

- Wallner-Novak, M.; Koppelhuber, J.; Pock, K. Cross-Laminated Timber Structural Design—Basic Design and Engineering Principles according to Eurocode; proHolz: Innsbruck, Austria, 2014. [Google Scholar]

- Fink, G.; Kohler, J.; Brandner, R. Application of European design principles to cross laminated timber. Eng. Struct. 2018, 171, 934–943. [Google Scholar] [CrossRef]

- International Federation for Structural Concrete (fib—fédération internationale du béton). fib Model Code for Concrete Structures 2010; Ernst & Sohn: Hoboken, NJ, USA, 2013. [Google Scholar]

- Toratti, T. Creep of Timber Beams in Variable Environment. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, 1992. [Google Scholar]

- Eitelberger, J.; Bader, T.; de Borst, K.; Jäger, A. Multiscale prediction of viscoelastic properties of softwood under constant climatic conditions. Comput. Mater. Sci. 2012, 55, 303–312. [Google Scholar] [CrossRef]

- Königsberger, M.; Irfan-ul Hassan, M.; Pichler, B.; Hellmich, C. Downscaling Based Identification of Nonaging Power-Law Creep of Cement Hydrates. J. Eng. Mech. 2016, 142, 04016106. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN1990:2010 Eurocode—Basis of Structural Design; Swedish Standards Institute (SIS): Stockholm, Sweden, 2010. [Google Scholar]

- European Committee for Standardization. EN1991-1-1:2010 Eurocode 1: Actions on Structures—Part 1-1: General Actions—Densities, Self-Weight, Imposed Loads for Buildings; Swedish Standards Institute (SIS): Stockholm, Sweden, 2010. [Google Scholar]

- European Committee for Standardization. EN 338:2016 Structural Timber—Strength Classes; Swedish Standards Institute (SIS): Stockholm, Sweden, 2016. [Google Scholar]

- Boltzmann, L. Zur Theorie der elastischen Nachwirkung [On the theory of creep recovery]. Ann. Der Phys. 1878, 241, 430–432. [Google Scholar] [CrossRef]

- Ausweger, M.; Binder, E.; Lahayne, O.; Reihsner, R.; Maier, G.; Peyerl, M.; Pichler, B. Early-Age Evolution of Strength, Stiffness, and Non-Aging Creep of Concretes: Experimental Characterization and Correlation Analysis. Materials 2019, 12, 207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Committee for Standardization. CEN/TS 19103 Technical Specification for Eurocode 5: Design of Timber Structures—Structural Design of Timber-Concrete Composite Structures—Common Rules and Rules for Buildings; Austrian Standards International: Vienna, Austria, 2021. [Google Scholar]

- Massaro, F.M.; Malo, K.A. Long-term behaviour of norway spruce glulam loaded perpendicular to grain. Eur. J. Wood Wood Prod. 2019, 77, 821–832. [Google Scholar] [CrossRef]

- Schniewind, A.P. Recent progress in the study of the rheology of wood. Wood Sci. Technol. 1968, 2, 188–206. [Google Scholar]

- Tong, D.; Brown, S.A.; Corr, D.; Cusatis, G. Wood creep data collection and unbiased parameter identification of compliance functions. Holzforschung 2020, 74, 1011–1020. [Google Scholar] [CrossRef]

- Allemand, C.; Lebée, A.; Manthey, M.; Forêt, G. Characterization of rolling ang longitudinal shear creeps for cross laminated timber panels. In Proceedings of the 8th International Network on Timber Engineering Research (INTER) Meeting, Karlsruhe, Germany, 16–19 August 2021. (online meeting). [Google Scholar]

- Akter, S.T.; Binder, E.; Bader, T.K. Moisture and short-term time-dependent behavior of Norway spruce clearwood under compression perpendicular to the grain and rolling shear. Wood Mater. Sci. Eng. 2022. submitted for publication. [Google Scholar]

- Scholz, A. Ein Beitrag zur Berechnung von Flächentragwerken aus Holz. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2004. [Google Scholar]

- Shi, B.; Liu, W.; Yang, H. Experimental investigation on the long-term behaviour of prefabricated timber-concrete composite beams with steel plate connections. Constr. Build. Mater. 2021, 266, 120892. [Google Scholar] [CrossRef]

| Load Type | Design Situation/ Layer | CLT Slab Thickness [mm] | Load [kN/m2] | TCC Slab Thickness [mm] | Load [kN/m2] |

|---|---|---|---|---|---|

| live load | characteristic | - | 1.50 | - | 1.50 |

| quasi-permanent | - | 0.45 | - | 0.45 | |

| self weight | flooring | 10 | 0.20 | 10 | 0.20 |

| floating screed | 50 | 1.00 | 50 | 1.00 | |

| sound insulation | 20 | 0.03 | 20 | 0.03 | |

| gravel | 140 | 2.38 | 80 | 1.36 | |

| concrete layer | - | - | 50 | 1.20 | |

| CLT | 160 | 0.71 | 120 | 0.53 | |

| ∑ | 380 | 4.32 | 330 | 4.32 | |

| SLS loads | characteristic | 5.82 | 5.82 | ||

| quasi-permanent | 4.77 | 4.77 |

| Time Incident | Stiffness Values | CLT Slab Deflection | TCC Slab Deflection | EC 5 Limit |

|---|---|---|---|---|

| 28 days (loading time) | GPa | 14 mm (82%) | 10 mm (59%) | 17 mm () |

| MPa | ||||

| GPa | ||||

| 50 years | GPa | 20 mm (100%) | 17 mm (85%) | 20 mm () |

| MPa | ||||

| GPa |

| Material Direction | Rheological Model | Parameters | |

|---|---|---|---|

| longitudinal | fractional Zener | GPa | GPa |

| GPa | |||

| rolling shear | power-law | MPa | MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binder, E.; Derkowski, W.; Bader, T.K. Development of Creep Deformations during Service Life: A Comparison of CLT and TCC Floor Constructions. Buildings 2022, 12, 239. https://doi.org/10.3390/buildings12020239

Binder E, Derkowski W, Bader TK. Development of Creep Deformations during Service Life: A Comparison of CLT and TCC Floor Constructions. Buildings. 2022; 12(2):239. https://doi.org/10.3390/buildings12020239

Chicago/Turabian StyleBinder, Eva, Wit Derkowski, and Thomas K. Bader. 2022. "Development of Creep Deformations during Service Life: A Comparison of CLT and TCC Floor Constructions" Buildings 12, no. 2: 239. https://doi.org/10.3390/buildings12020239

APA StyleBinder, E., Derkowski, W., & Bader, T. K. (2022). Development of Creep Deformations during Service Life: A Comparison of CLT and TCC Floor Constructions. Buildings, 12(2), 239. https://doi.org/10.3390/buildings12020239