A Modified Compression Field Theory Based Analytical Model of RC Slab-Column Joint without Punching Shear Reinforcement

Abstract

:1. Introduction

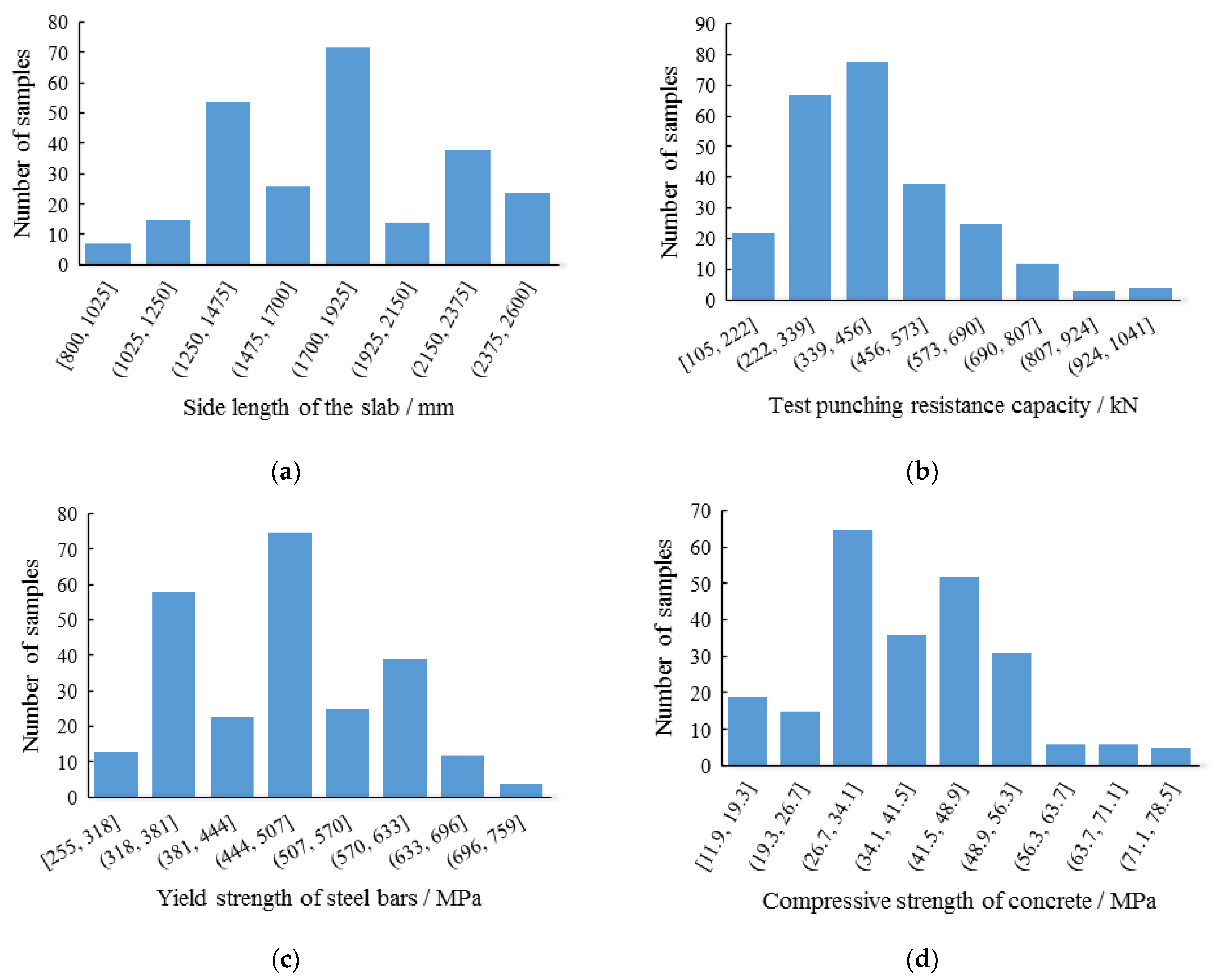

2. Experimental Database

3. Design Codes for Punching Shear Resistance

3.1. Punching Shear Design Provisions

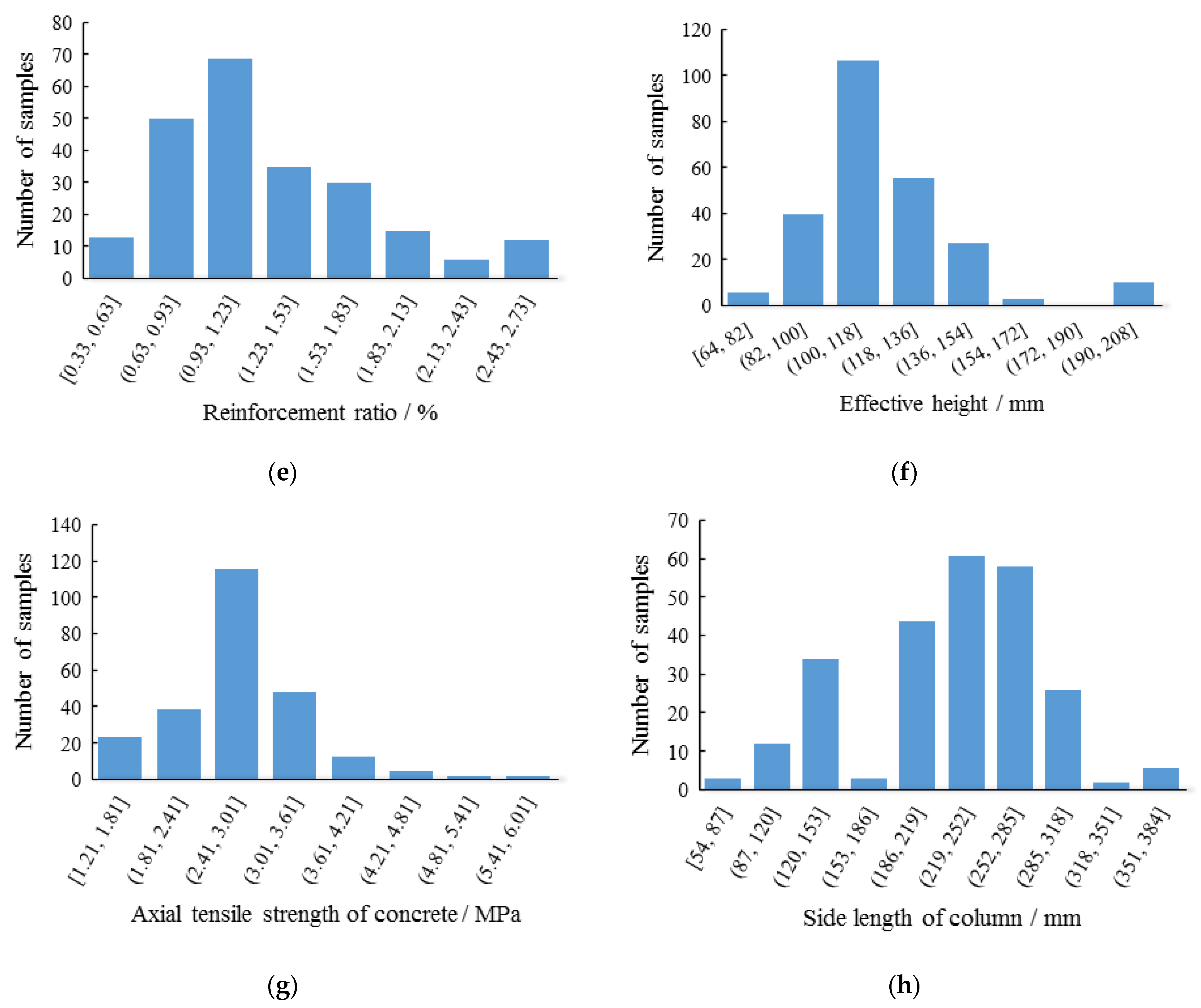

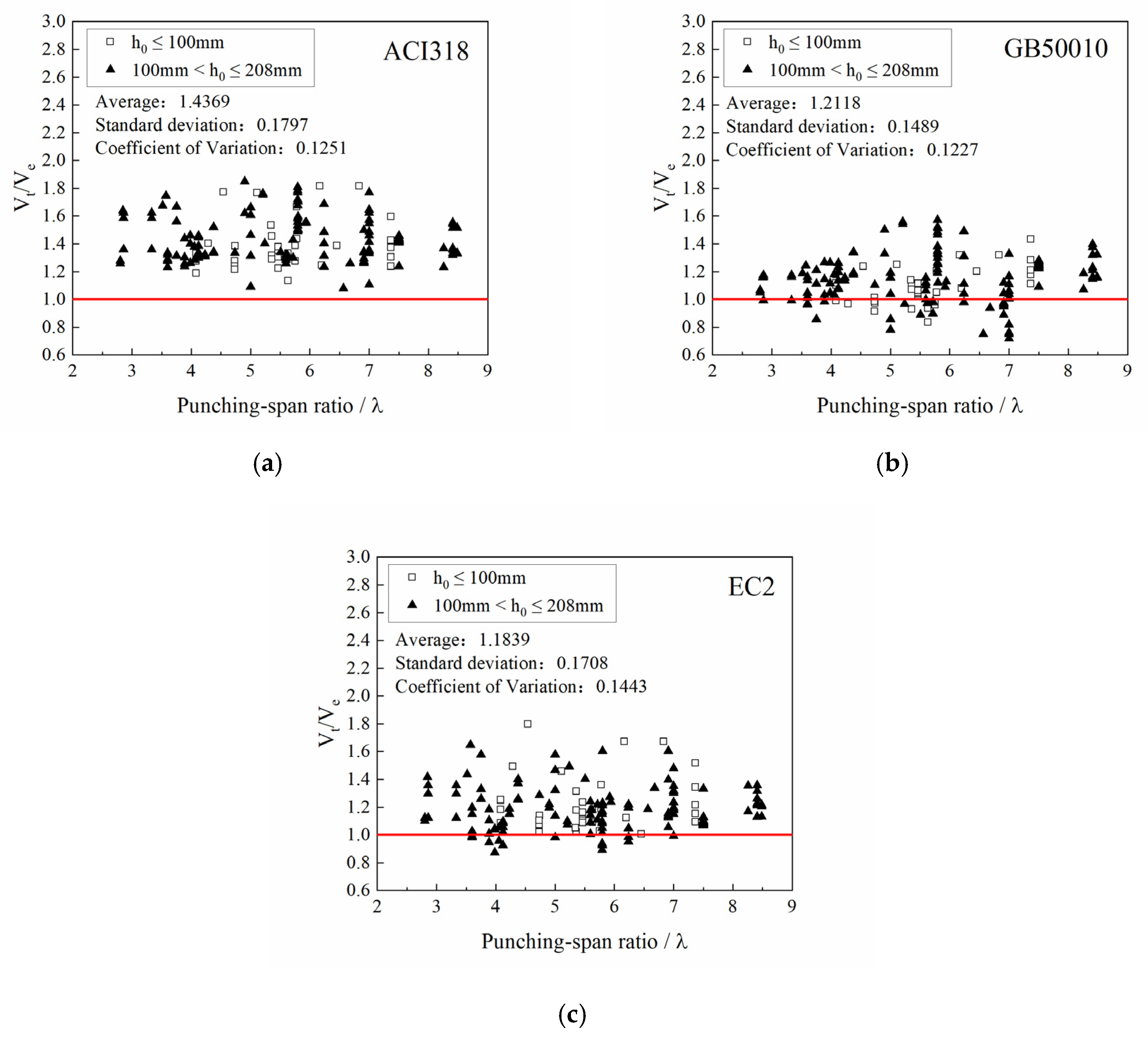

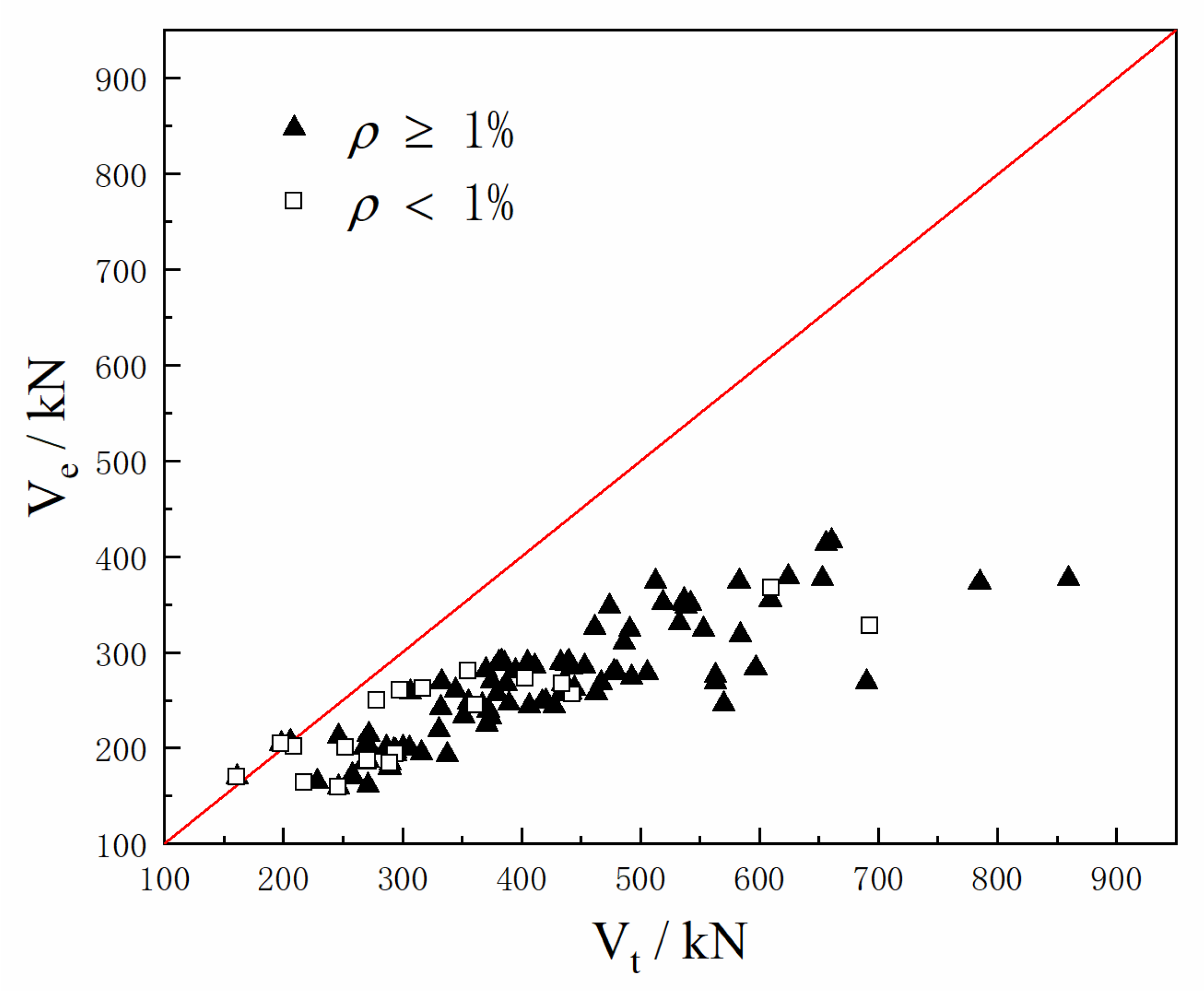

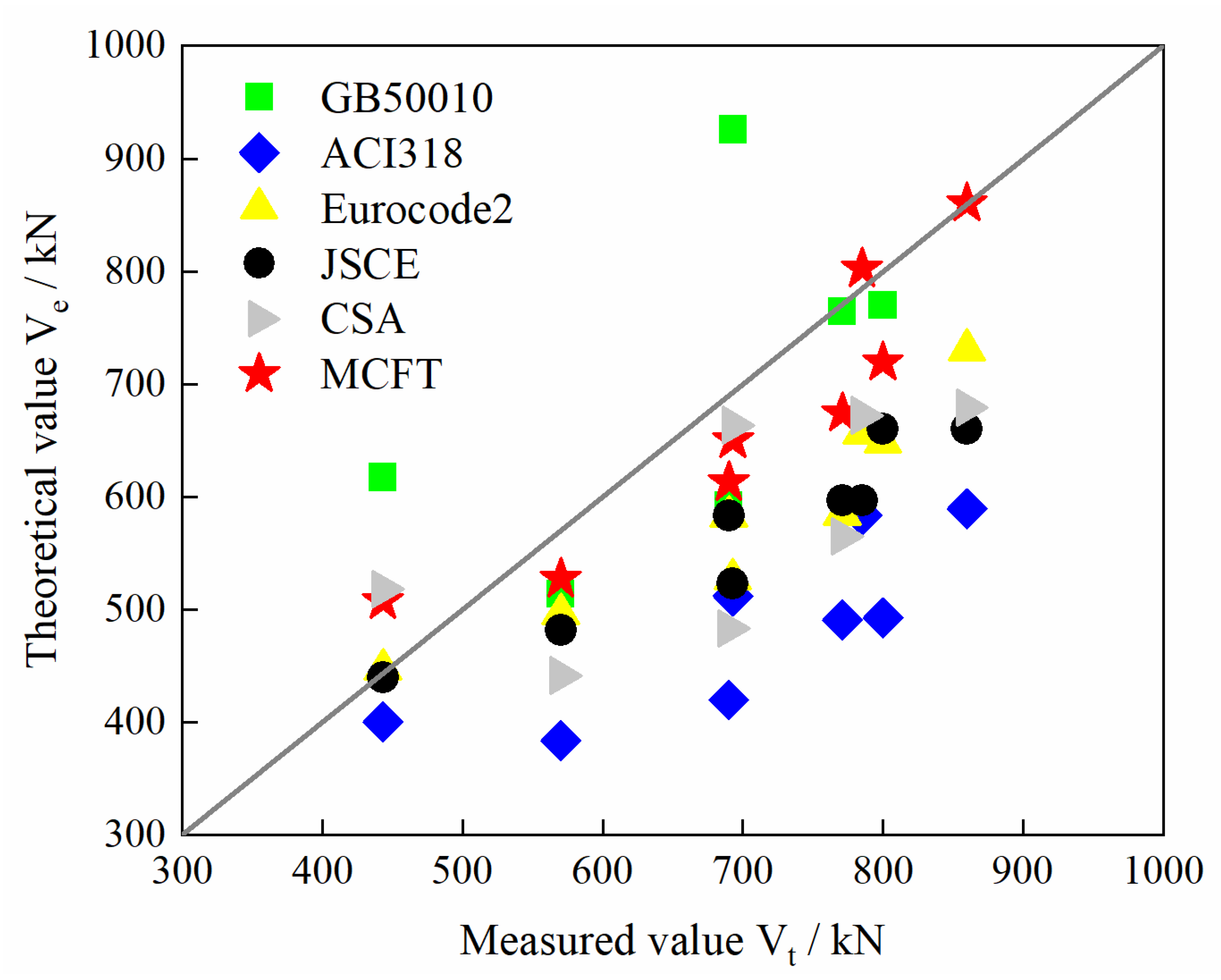

3.2. Evaluation of Design Codes

4. Analytical Model of Shear Punching Capacity

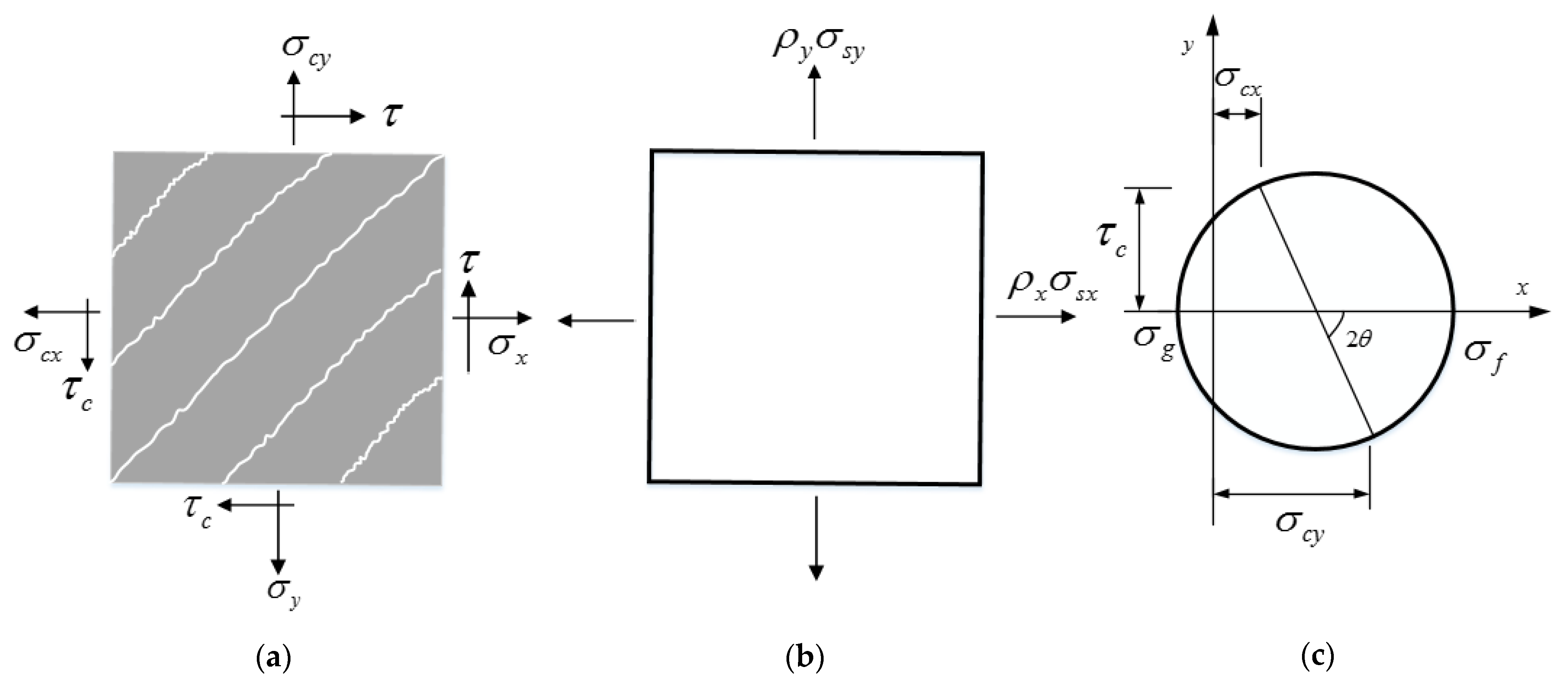

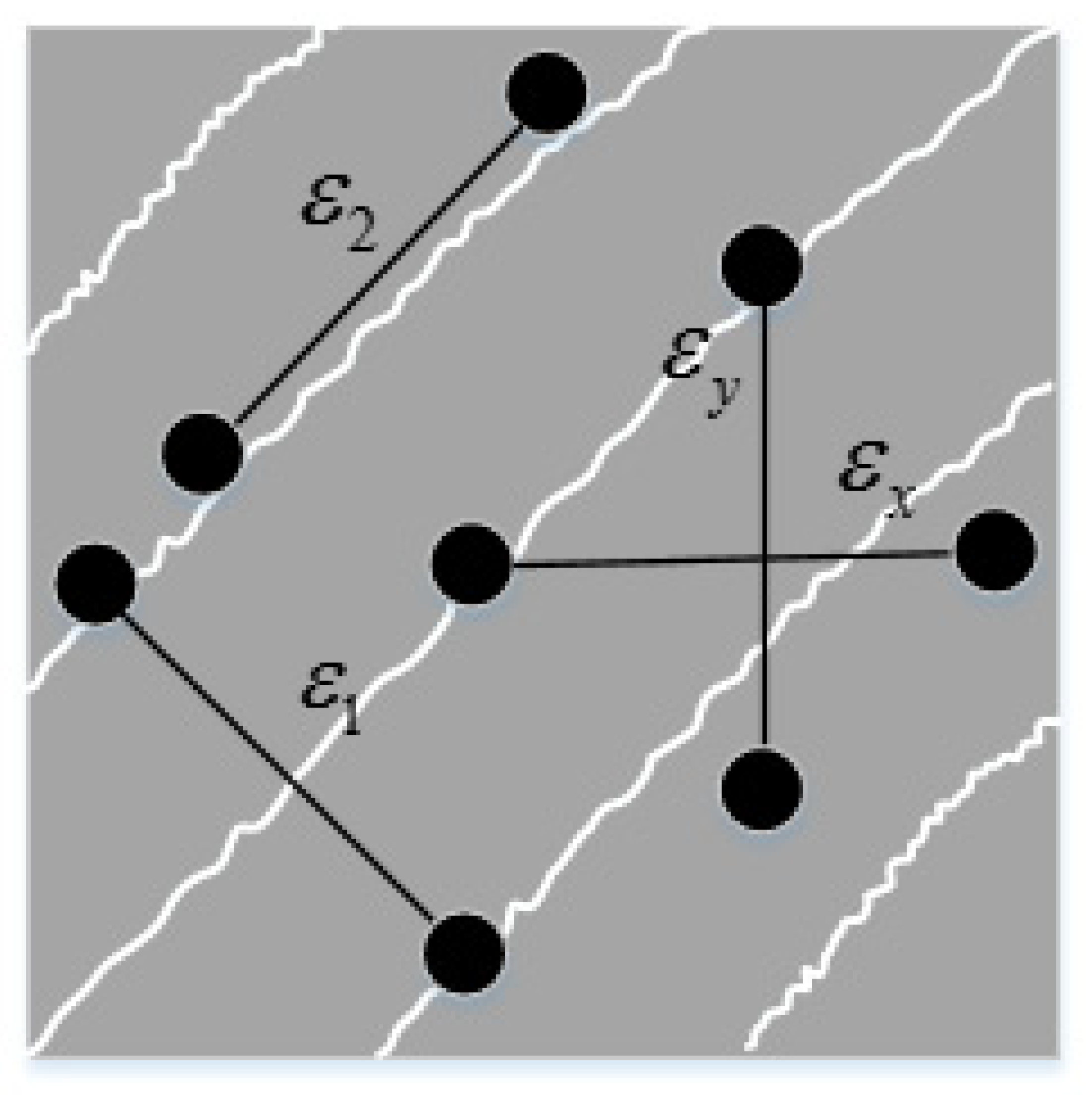

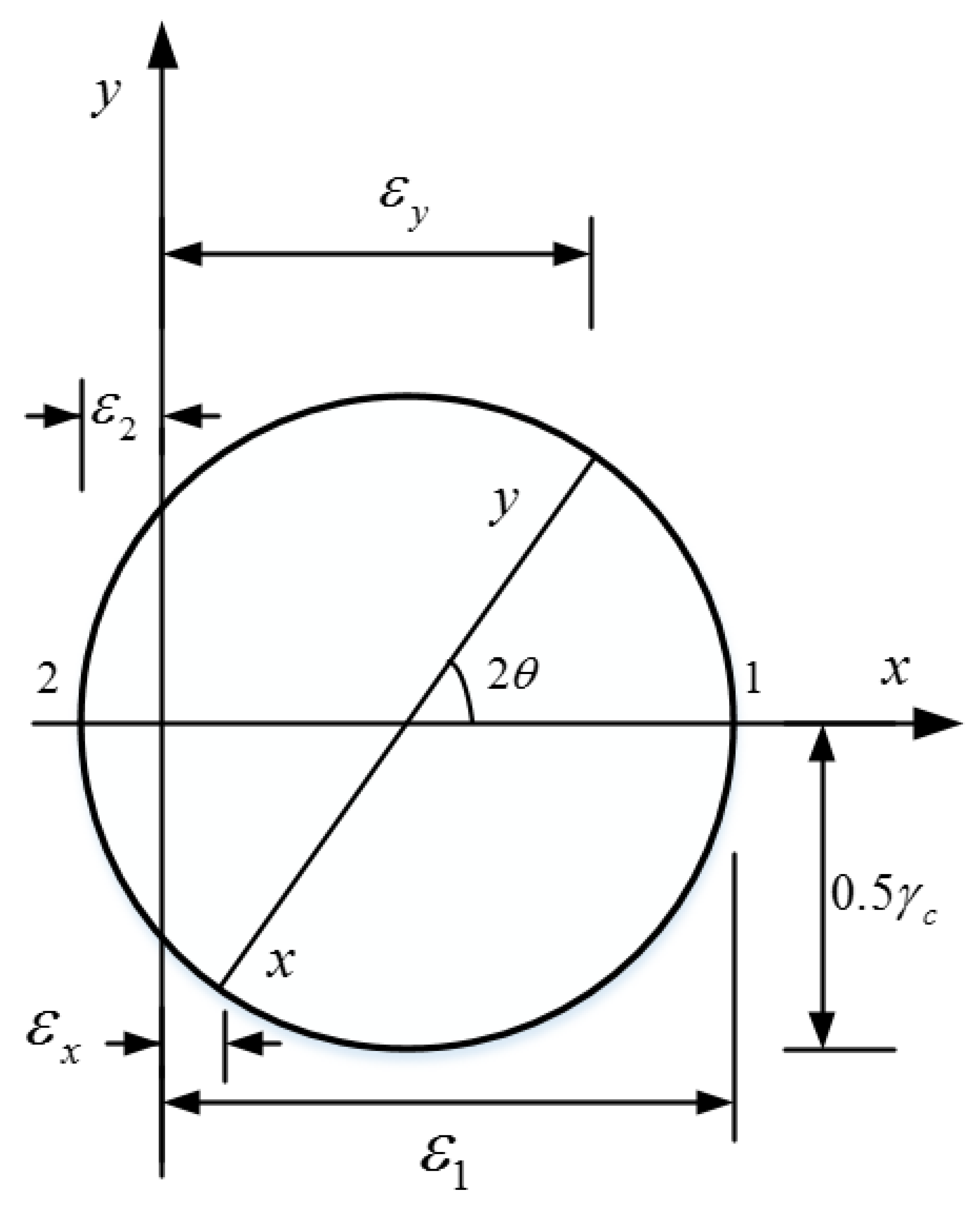

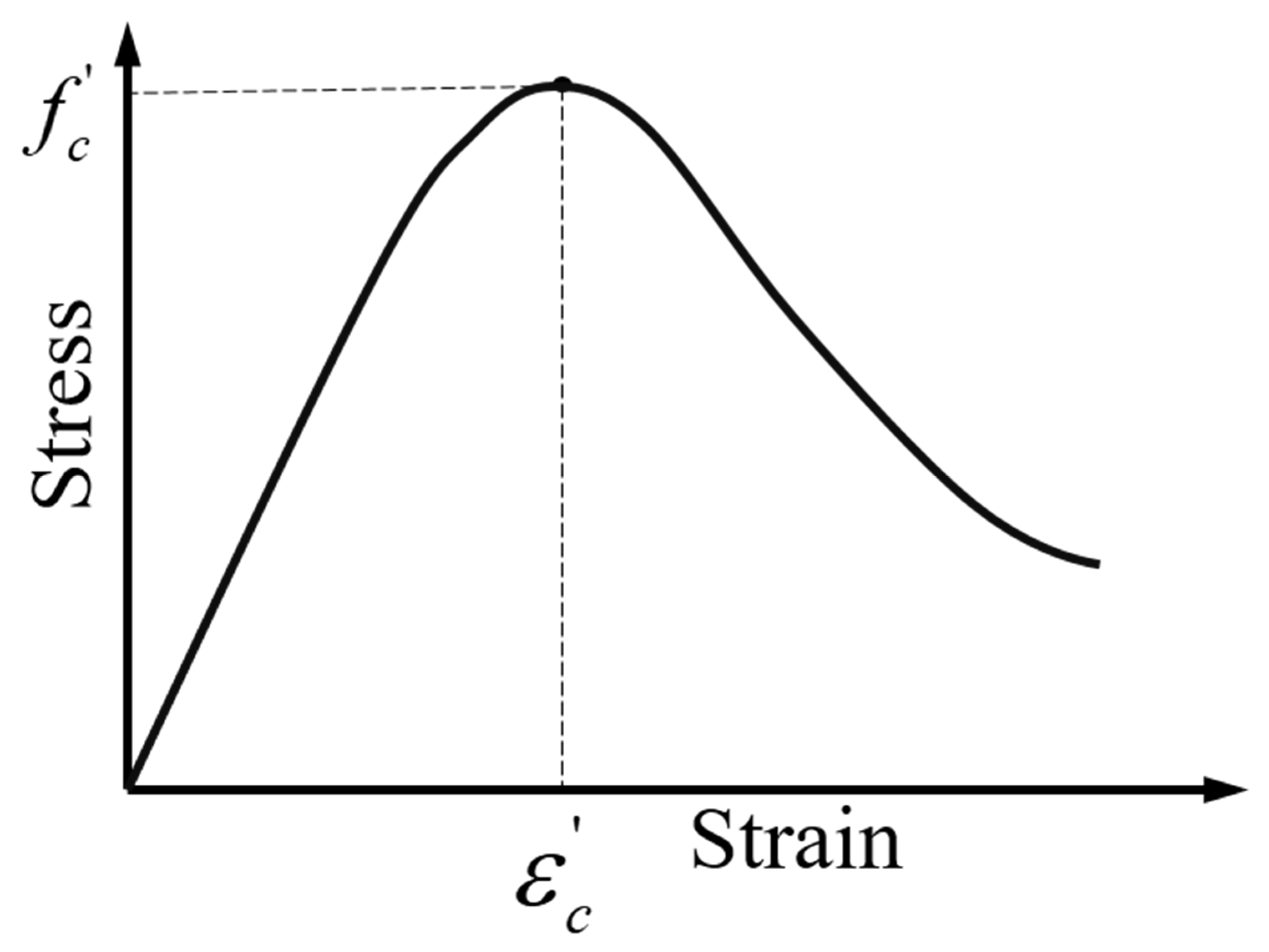

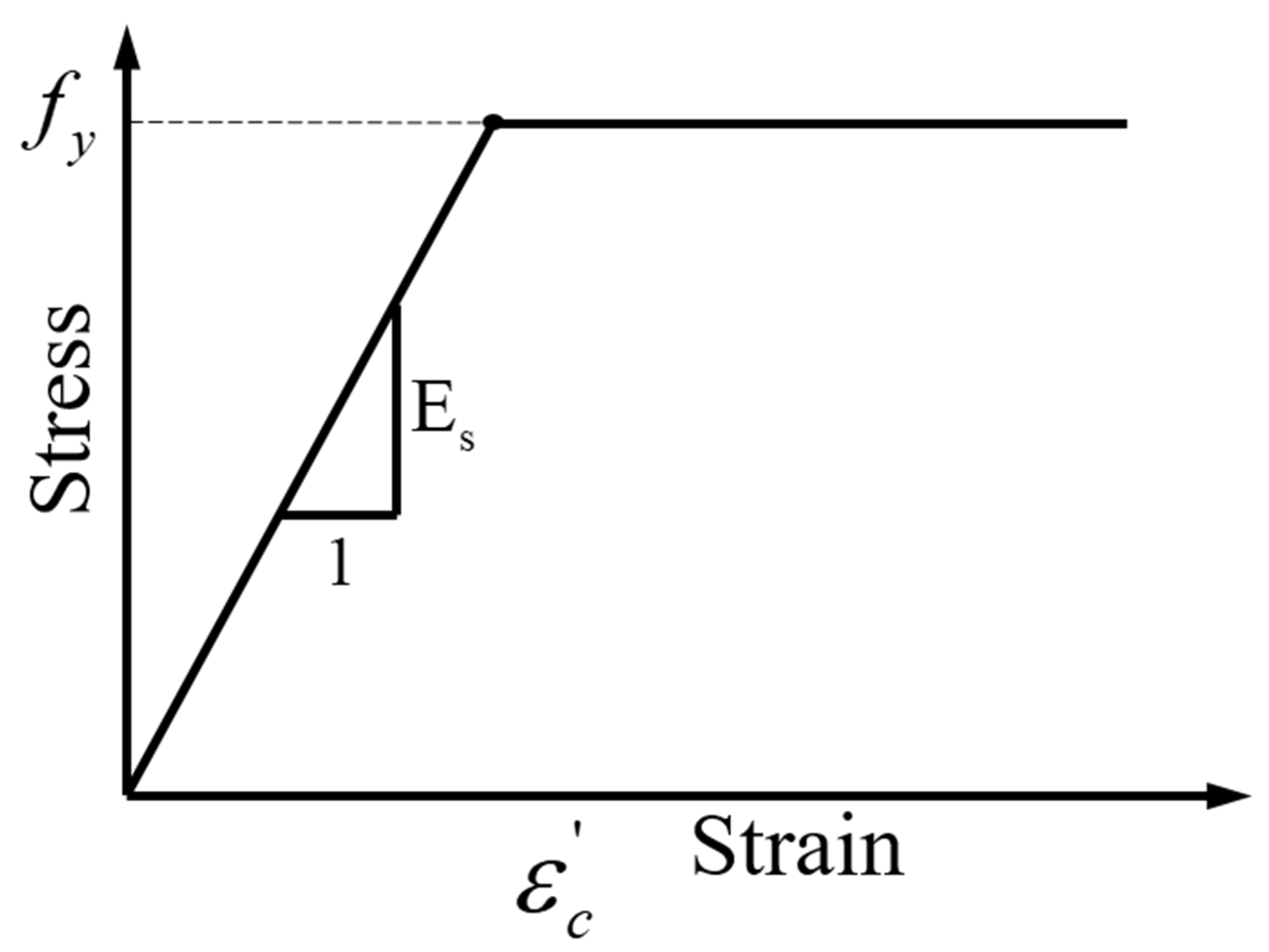

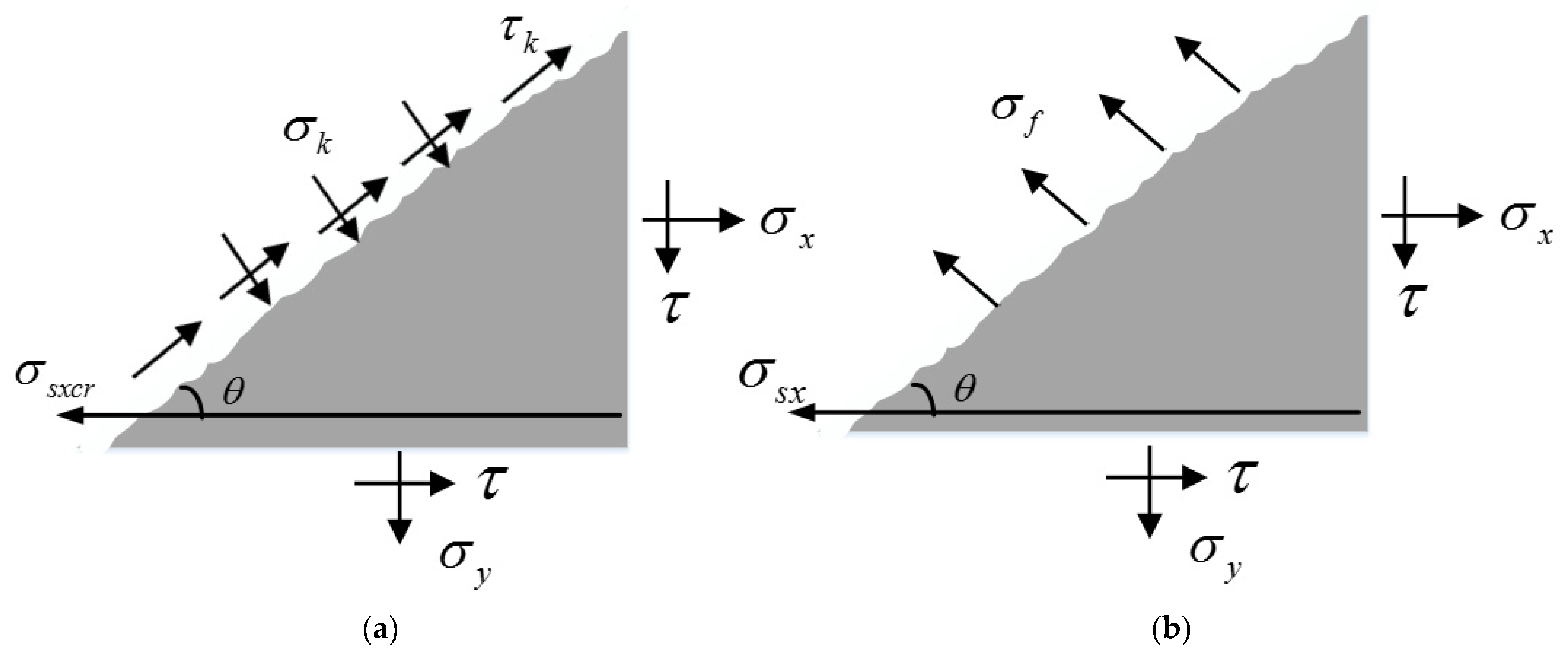

4.1. Modified Compression Field Theory

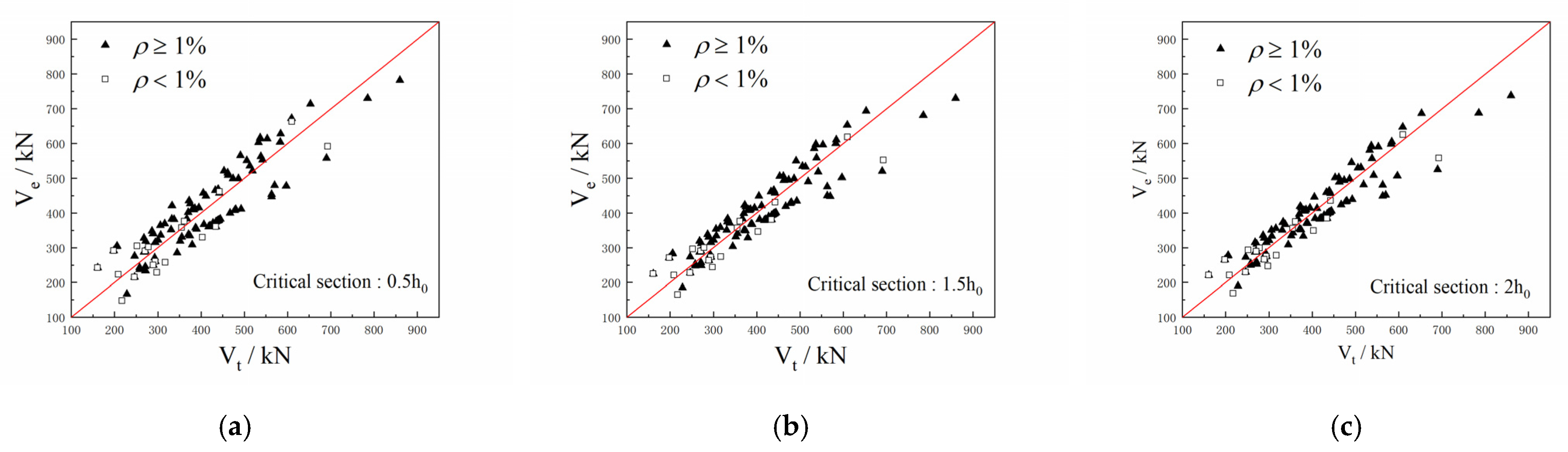

4.2. Calculation Results

5. Conclusions

- (1)

- The database established in this paper has the characteristic of a small amount of extreme data and adequate specimens. It is suitable for the various research aspects of the slab–column joints without punching shear reinforcement in further work.

- (2)

- There are some differences in the parameters included in the design codes. The design codes proposed in this paper all consider the relative of punching shear capacity with the concrete strength. Where only GB50010 [49] uses tensile strength in the equation, the other design codes use compressive strength. Moreover, only EC2 [52] and JSCE [53] consider the effects of reinforcement ratio for punching shear. Other parameters, such as the position of the column, the size effect and the critical perimeter are not the same.

- (3)

- Design codes have different results in predicting punching shear for the database in this paper. ACI318 [50] has a relatively small coefficient of variation and a low degree of discreteness. But the predicting values are visibly higher than the experimental results which indicate conservative results. JSCE [53] has a large coefficient of variation. EC2 [52] has a large dispersion, but the average value is the smallest of other design codes. GB50010 [49] has a small dispersion and average value, but the applicable range of the equation is small.

- (4)

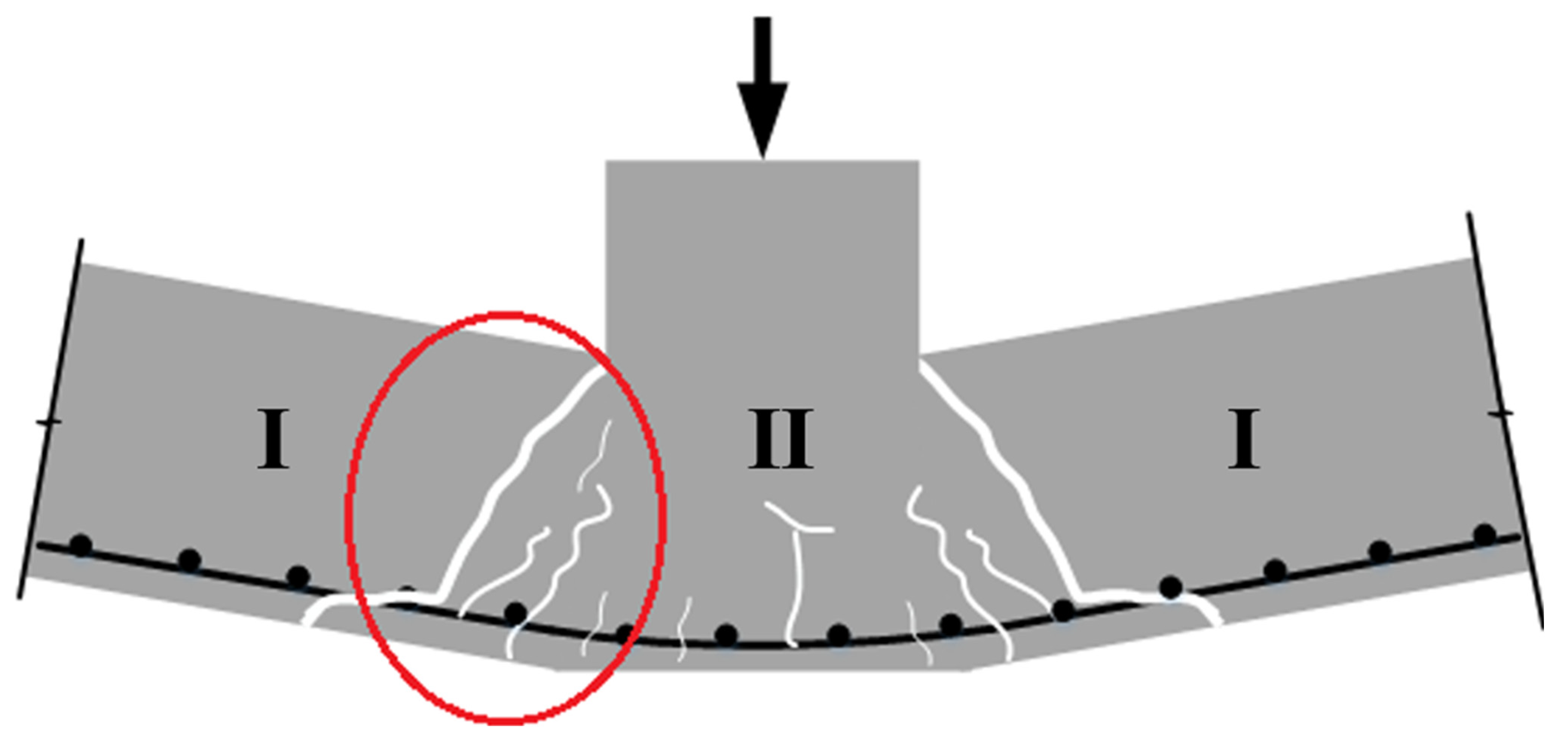

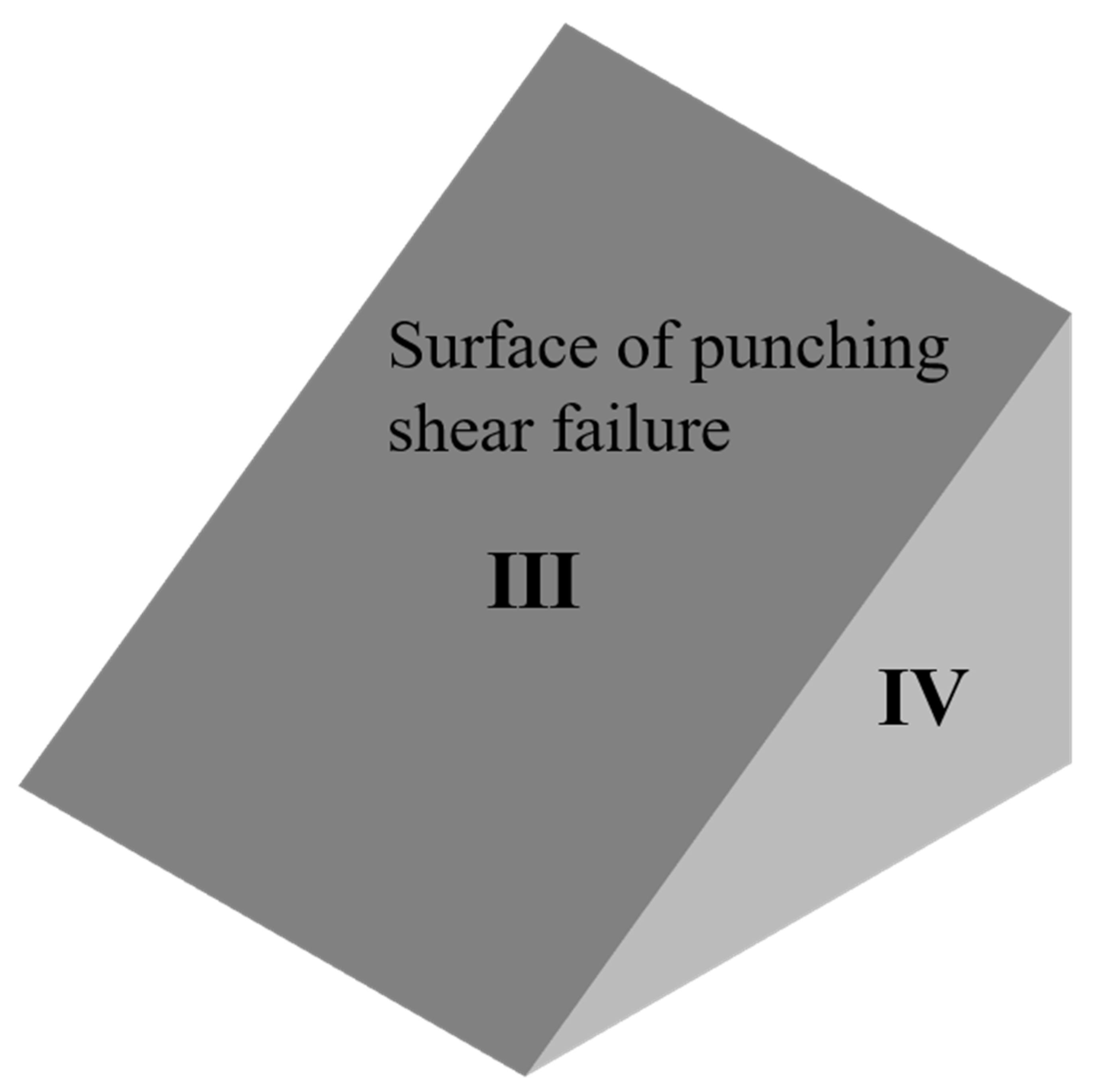

- The punching shear failure criterion of RC slab–column (within vertical load) without punching shear reinforcement proposed are combined the shear diagonal tension failure of RC beams with a large shear-to-span ratio, and the failure is caused by the direct stress and shear stresses in the concrete.

- (5)

- The model of MCFT can be used to predict the punching shear is based on three assumptions, which are essential to transform the three-dimensional mechanics into two-dimensional planar mechanics. The punching shear strength is decided by integrating the stress on the punching surfaces, which is proposed by the stress state of the cracked concrete units in the critical shear crack.

- (6)

- The punching shear capacity equation established based on the MCFT model has limitations before being modified, which is conservative. To ensure the accuracy of the equation, a regression analysis is also applied according to the database. It is shown by the comparison between existing design codes and the proposed model that the model is more accurate when the reinforcement ratio and critical section are considered. The characteristic of the equation established in this paper is that both have reliable theoretical support and summaries of a large number of test results, as well as high prediction accuracy and low dispersion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, H.G.; Choi, K.G.; Lan, C. Strain-based strength model for direct punching shear of interior slab-column connections. Eng. Struct. 2011, 33, 1062–1073. [Google Scholar] [CrossRef]

- Ruiz, M.F.; Muttoni, A. Applications of Critical Shear Crack Theory to Punching of Reinforced Concrete Slabs with Transverse Reinforcement. ACI Struct. J. 2009, 106, 485–494. [Google Scholar] [CrossRef]

- Kadhum, M.M.; Harbi, S.M.; Khamees, S.S.; Abdulraheem Mustafa, S.; Farsangi, E.N. Punching shear behavior of flat slabs utilizing reactive powder concrete with and without flexural reinforcement. Pract. Period. Struct. Des. Constr. 2021, 26, 04020060. [Google Scholar] [CrossRef]

- Menna, D.W.; Genikomsou, A.S. Punching shear response of concrete slabs strengthened with ultrahigh-performance fiber-reinforced concrete using finite-element methods. Pract. Period. Struct. Des. Constr. 2021, 26, 04020057. [Google Scholar] [CrossRef]

- Hueste, M.B.D.; Wight, J.K. Nonlinear punching shear failure model for interior slab-column connections. J. Struct. Eng. 1997, 9, 997–1008. [Google Scholar] [CrossRef]

- Li, D.G.; Shu, Z.F.; Yu, Z.W. Experimental study on the punching shear strength of reinforced concrete slab-column connections without punching shear reinforcement. J. Hunan Univ. 1986, 8, 22–35. [Google Scholar]

- Zhen, J.L.; Zhen, Z.J. Experimental research on punching shear strength of reinforced concrete slab. J. Fuzhou Univ. Nat. Sci. Ed. 1992, 2, 65–69. [Google Scholar]

- Koppitz, R.; Kenel, A.; Keller, T. Effect of punching shear on load-deformation behavior of flat slabs. Eng. Struct. 2014, 80, 444–457. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Instantaneous deflection of light-weight concrete slabs. Front. Struct. Civ. Eng. 2017, 11, 412–423. [Google Scholar] [CrossRef]

- Milligan, G.J.; Polak, M.A.; Zurell, C. Finite element analysis of punching shear behaviour of concrete slabs supported on rectangular columns. Eng. Struct. 2020, 224, 111189. [Google Scholar] [CrossRef]

- Lu, X.; Guan, H.; Sun, H.; Li, Y.; Zuo, L. A preliminary analysis and discussion of the condominium building collapse in surfside, Florida, US, June 24, 2021. Front. Struct. Civ. Eng. 2021, 15, 1097–1110. [Google Scholar] [CrossRef]

- Broms, C.E. Elimination of flat plate punching failure mode. ACI Struct. J. 2000, 1, 94–101. [Google Scholar] [CrossRef]

- Pinto, V.C.; Branco, V.; Oliveira, D.R. Punching in two-way RC flat slabs with openings and L section columns. Eng. Comput. 2019, 36, 2430–2444. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Cao, Z. Size effect in punching shear failure of slabs. ACI Struct. J. 1987, 1, 44–53. [Google Scholar]

- Hallgren, M. Punching Shear Capacity of Reinforced High Strength Concrete Slabs. Ph.D. Thesis, KTH Royal Institute of Technology, Department of Structural Engineering, Stockholm, Sweden, November 1996. [Google Scholar]

- Yankelevsky, D.Z.; Leibowttz, O. Punching shear in concrete slabs. Int. J. Mech. Sci. 1999, 41, 1–15. [Google Scholar] [CrossRef]

- Nielsen, M.P.; Hoang, L.C. Limit Analysis and Concrete Plasticity; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Johansen, K.W. Yield-Line Theory; Cement and Concrete Association: London, UK, 1962. [Google Scholar]

- Silva, R.J.C.; Regan, P.E.; Melo, G.S.S.A. Punching of post-tensioned slabs—Tests and codes. ACI Struct. J. 2007, 104, 123–132. [Google Scholar] [CrossRef]

- Cai, J.; Lin, F. Ultimate punching shear strength for concrete slabs based on twin-shear strength theory. Eng. Mech. 2006, 23, 110–113. [Google Scholar] [CrossRef]

- Huang, C.; Shuang, P.; Ding, B.; Srikanta, P. An analytical punching shear model of RC slab-column connection based on database. J. Intell. Fuzzy Syst. 2018, 35, 469–483. [Google Scholar] [CrossRef]

- Long, A.E. Punching failure of slabs—Transfer of moment and shear. J. Struct. Div. 1973, 8, 665–685. [Google Scholar] [CrossRef]

- Kinnunen, S.; Nylander, H. Punching of Concrete Slabs without Shear Reinforcement; KTH Royal Institute of Technology: Stockholm, Sweden, 1960. [Google Scholar]

- Broms, C.E. Concrete Flat Slabs and Footings—Design Method for Punching and Detailing for Ductility. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2005. [Google Scholar]

- Walraven, J.C. Fundamental analysis of aggregate interlock. J. Struct. Div. 1981, 11, 2245–2270. [Google Scholar] [CrossRef]

- Guandalini, S.; Burdet, O.; Muttoni, A. Punching tests of slabs with low reinforcement ratios. ACI Struct. J. 2009, 106, 87–95. [Google Scholar] [CrossRef]

- Pani, L.; Ftochino, F. Punching of reinforced concrete slab without shear reinforcement: Standard models and new proposal. Front. Struct. Civ. Eng. 2020, 48, 21–34. [Google Scholar] [CrossRef]

- Zaghlool, E.R.F.; Paiva, H.A.R.D. Tests of flat-plate corner column-slab connections. J. Struct. Div. 1973, 3, 551–572. [Google Scholar] [CrossRef]

- Bentz, E.C.; Vecchio, F.J.; Collins, M.P. Simplified modified compression field theory for calculating shear strength of reinforced concrete elements. ACI Struct. J. 2007, 103, 614–624. [Google Scholar]

- Urban, T.; Goldyn, M.; Krawczyk, L.; Sowa, L. Experimental investigations on punching shear of lightweight aggregate concrete flat slabs. Eng. Struct. 2019, 197, 109371. [Google Scholar] [CrossRef]

- Goldyn, M.; Krawczyk, L.; Ryzynski, W.; Urban, T. Experimental inverstigations on punching shear of falt slabs made from lightweight aggregate concrete. Arch. Civ. Eng. 2018, 64, 293–306. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.J.; Yang, Q.N.; Mao, M.J.; Zhang, W.B. Effect of punching shear-span ratio on punching strength of reinforced concrete slab. Ind. Constr. 2018, 48, 84–88. [Google Scholar] [CrossRef]

- Caratelli, A.; Imperatore, S.; Meda, A.; Rinaldi, Z. Punching shear behavior of lightweight fiber reinforced concrete slabs. Compos. Part B Eng. 2016, 99, 257–265. [Google Scholar] [CrossRef]

- Carmo, R.N.F.; Costa, H.; Rodrigues, M. Experimental study of punching failure in LWAC slabs with different strengths. Mater. Struct. 2016, 49, 2611–2626. [Google Scholar] [CrossRef]

- Youm, K.S.; Kim, J.J.; Moon, J. Punching shear failure of slab with lightweight aggregate concrete (LWAC) and low reinforcement ratio. Constr. Build. Mater. 2014, 65, 92–102. [Google Scholar] [CrossRef]

- Peng, J. Experimental Research on Punching Shear Resistance of Reinforced Concrete Slab-Column Joints. Master’s Thesis, Hunan University, Changsha, China, 2013. [Google Scholar]

- Yang, J.M.; Yoon, Y.S.; Cook, W.D.; Mitchell, D. Punching shear behavior of two-way slabs reinforced with high-strength steel. ACI Strcutural J. 2010, 4, 468–475. [Google Scholar] [CrossRef]

- Widianto; Bayrak, O.; Jirsa, J.O. Two-way shear strength of slab-column connections: Reexamination of ACI 318 provisions. ACI Struct. J. 2009, 106, 160–170. [Google Scholar]

- Zhang, Y.W. Experimental Research on Punching Shear Resistance of Reinforced Concrete Slabs. Master’s Thesis, Hunan University, Changsha, China, 2010. [Google Scholar]

- Lee, J.-H.; Yoon, Y.-S.; Lee, S.-H.; Cook, W.D.; Mitchell, D. Enhancing performance of slab-column connections. J. Struct. Eng. 2008, 3, 448–457. [Google Scholar] [CrossRef]

- Teng, S.; Cheong, H.K.; Kuang, K.L.; Geng, J.Z. Punching shear strength of slabs with openings and supported on rectangular columns. ACI Struct. J. 2004, 5, 678–687. [Google Scholar] [CrossRef]

- Ospina, C.E.; Alexander, S.D.; Roger, C.J.J. Punching of two-way concrete slabs with fiber-reinforced polymer reinforcing bars or grids. ACI Struct. J. 2003, 82, 431–446. [Google Scholar] [CrossRef]

- Reineck, K.H.; Kuchma, D.A.; Kang, S.K.; Marx, S. Shear database for reinforced concrete members without shear reinforcement. ACI Struct. 2003, 2, 240–249. [Google Scholar] [CrossRef]

- Liu, G.Y.; Liu, X.D. Experimental research on punching problem of plate with anti-punching bent ribs. J. Harbin Inst. Civ. Eng. Archit. 1994, 3, 47–52. [Google Scholar]

- An, Y.J.; Zhao, G.F. Experimental research on the punching shear resistance of reinforced steel fiber concrete slabs. J. Build. Struct. 1994, 2, 11–14. [Google Scholar]

- Marzouk, A.H.H. Punching shear analysis of reinforced high-strength concrete slabs. Can. J. Civ. Eng. 1991, 5, 954–963. [Google Scholar] [CrossRef]

- Regan, P.E. Symmetric punching of reinforced concrete slabs. Mag. Concr. Res. 1986, 136, 115–128. [Google Scholar] [CrossRef]

- Mowrer, R.D.; Vanderbilt, M.D. Shear strength of lightweight aggregate reinforced concrete flat plates. ACI Struct. J. 1967, 64, 722–729. [Google Scholar] [CrossRef]

- GB50010-2010 (2015); Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development: Beijing, China, 2015.

- ACI-318 (2019); Committee 318—Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary on Building Code Requirements. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- CSA (2019); Design of Concrete Structures. Canadian Standards Association: Rexdale, ON, Canada, 2019.

- EC2 (2004); EN 1992-1-1:2004: Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. National Standards Authority of Ireland: Dublin, Ireland, 2014.

- JSCE Concrete Committee. Standard Specifications for Concrete Structures—2007; Japan Society of Civil Engineers: Tokyo, Japan, 2007. [Google Scholar]

- El-Gendy, M.G.; El-Salakawy, E.F. GFRP shear reinforcement for slab-column edge connections subjected to reversed cyclic lateral load. J. Compos. Constr. 2020, 24, 04020003. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Jafarian, N.; Naderi, A.; Mostofinejad, A.; Salehi, M. Effects of openings on the punching shear strength of reinforced concrete slabs. Structures 2020, 25, 760–773. [Google Scholar] [CrossRef]

- Hassan, M.; Fam, A.; Benmokrane, B.; Ferrier, E. Effect of column size and reinforcement ratio on shear strength of glass fiber-reinforced polymer reinforced concrete two-way slabs. Struct. J. 2017, 114, 937–950. [Google Scholar] [CrossRef]

- Zhao, J.; Yi, W.J. Calculation and study on punching bearing capacity of slab-column joints without shear reinforcement. Build. Struct. 2019, 13, 120–131. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M.P. The modified compression-field theory for reinforced concrete elements subjected to shear. ACI J. Proc. 1986, 2, 219–231. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M.P. Predicting the response of reinforced concrete beams subjected to shear using modified compression field theory. ACI Struct. J. 1988, 3, 258–268. [Google Scholar] [CrossRef]

- Eladawy, M.; Hassan, M.; Benmokrane, B.; Ferrier, E. Lateral cyclic behavior of interior two-way concrete slab-column connections reinforced with GFRP bars. Eng. Struct. 2020, 209, 109978. [Google Scholar] [CrossRef]

- Li, Z.P.; Mao, M.J.; Yang, Q.N. Effect of reinforcement ratio on punching capacity of reinforced concrete bridge deck. Ind. Constr. 2020, 50, 44–51. [Google Scholar] [CrossRef]

- Chen, W.J.; Bian, J.J.; Wang, N.; Su, Y.P. Punching shear capacity analysis of a slab-column connection considering the effect of different reinforcement ratios. China Earthq. Eng. J. 2016, 38, 525–532. [Google Scholar] [CrossRef]

- Yi, W.J.; Hong, F.; Peng, J. Experimental investigation of punching shear failure of reinforced concrete slab-column conections. Build. Struct. 2016, 46, 11–18. [Google Scholar] [CrossRef]

| Design Codes | Punching Shear Strength | |

|---|---|---|

| GB50010 [49] | ||

| ACI318 [50] | ||

| CSA [51] | ||

| JSCE [53] | ||

| EC2 [52] | ||

| Parameter | ACI318 [50] | GB50010 [49] | EC2 [52] | CSA [51] | JSCE [53] |

|---|---|---|---|---|---|

| Compressive strength of concrete | |||||

| Ratio of flexure reinforcement | / | / | / | ||

| Location of critical section | |||||

| Size effect | √ | / | √ | / | √ |

| Column position | √ | √ | / | √ | / |

| Design Codes | Average Value of | Standard Deviation | Coefficient of Variation | Max | Min | Value of Max–Min | Over-Average Percentage |

|---|---|---|---|---|---|---|---|

| ACI318 [50] | 1.4369 | 0.1797 | 0.1200 | 1.8539 | 1.0784 | 0.7575 | 39.04% |

| GB50010 [49] | 1.2118 | 0.1489 | 0.1227 | 1.5718 | 0.7178 | 0.8540 | 32.67% |

| EC2 [52] | 1.1839 | 0.1708 | 0.1443 | 1.6838 | 0.8725 | 0.8113 | 36.65% |

| CSA [51] | 1.2457 | 0.1609 | 0.1292 | 1.7034 | 0.8549 | 0.8485 | 35.46% |

| JSCE [53] | 1.1826 | 0.1744 | 0.1475 | 1.8124 | 0.9758 | 0.8366 | 40.63% |

| Critical Section Position | Average Ratio | Standard Deviation | Coefficient Of Variation | Over-Average Percentage | |

|---|---|---|---|---|---|

| 2.60 | 1.00 | 0.180247 | 0.180247 | 39.8% | |

| 1.56 | 1.00 | 0.148922 | 0.148922 | 42.3% | |

| 1.30 | 1.00 | 0.139113 | 0.139113 | 42.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Huang, T.; Tong, Y.; Liang, S. A Modified Compression Field Theory Based Analytical Model of RC Slab-Column Joint without Punching Shear Reinforcement. Buildings 2022, 12, 226. https://doi.org/10.3390/buildings12020226

Wu L, Huang T, Tong Y, Liang S. A Modified Compression Field Theory Based Analytical Model of RC Slab-Column Joint without Punching Shear Reinforcement. Buildings. 2022; 12(2):226. https://doi.org/10.3390/buildings12020226

Chicago/Turabian StyleWu, Linfeng, Tiancan Huang, Yili Tong, and Shixue Liang. 2022. "A Modified Compression Field Theory Based Analytical Model of RC Slab-Column Joint without Punching Shear Reinforcement" Buildings 12, no. 2: 226. https://doi.org/10.3390/buildings12020226

APA StyleWu, L., Huang, T., Tong, Y., & Liang, S. (2022). A Modified Compression Field Theory Based Analytical Model of RC Slab-Column Joint without Punching Shear Reinforcement. Buildings, 12(2), 226. https://doi.org/10.3390/buildings12020226