Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study

Abstract

:1. Introduction

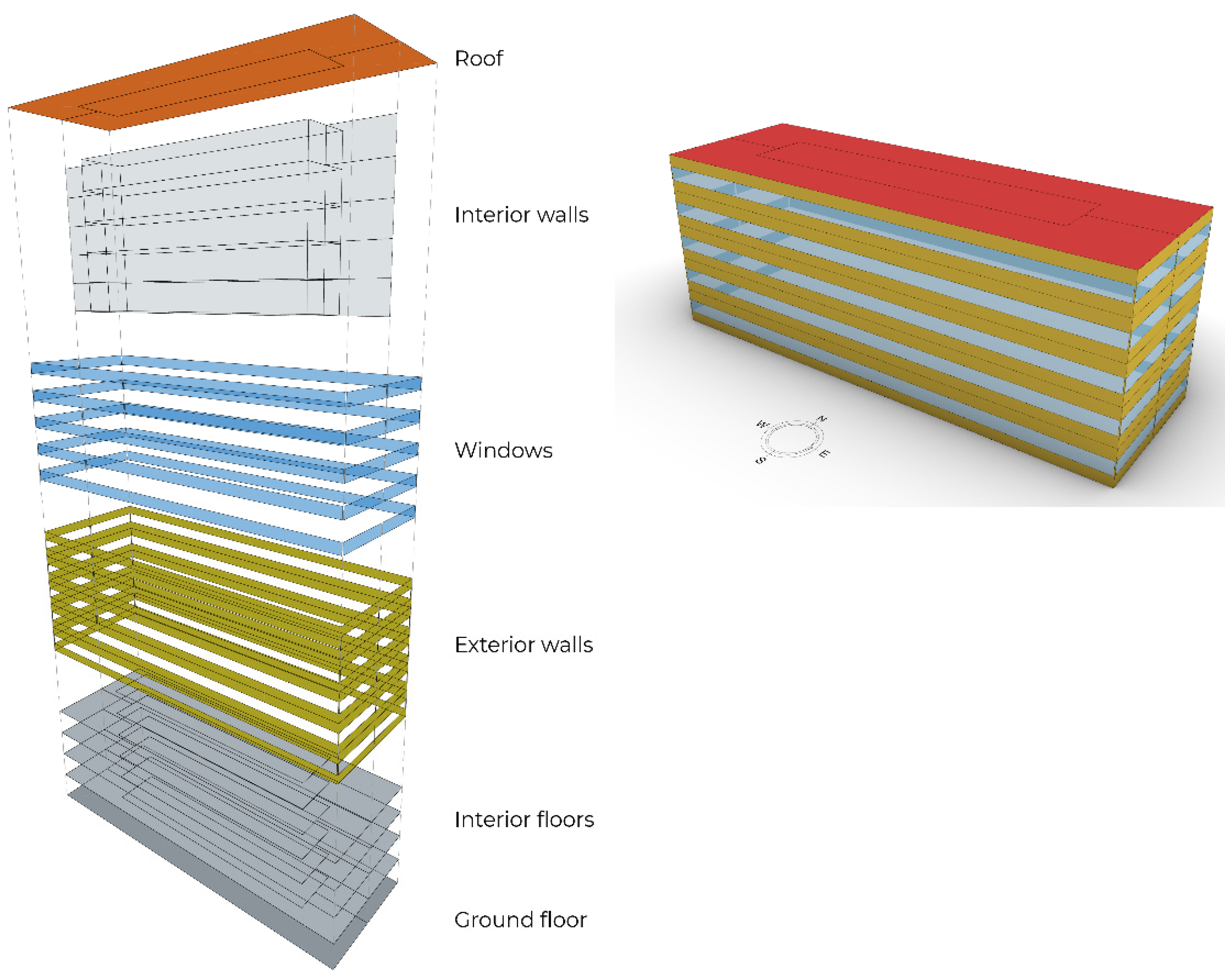

2. Materials and Methods

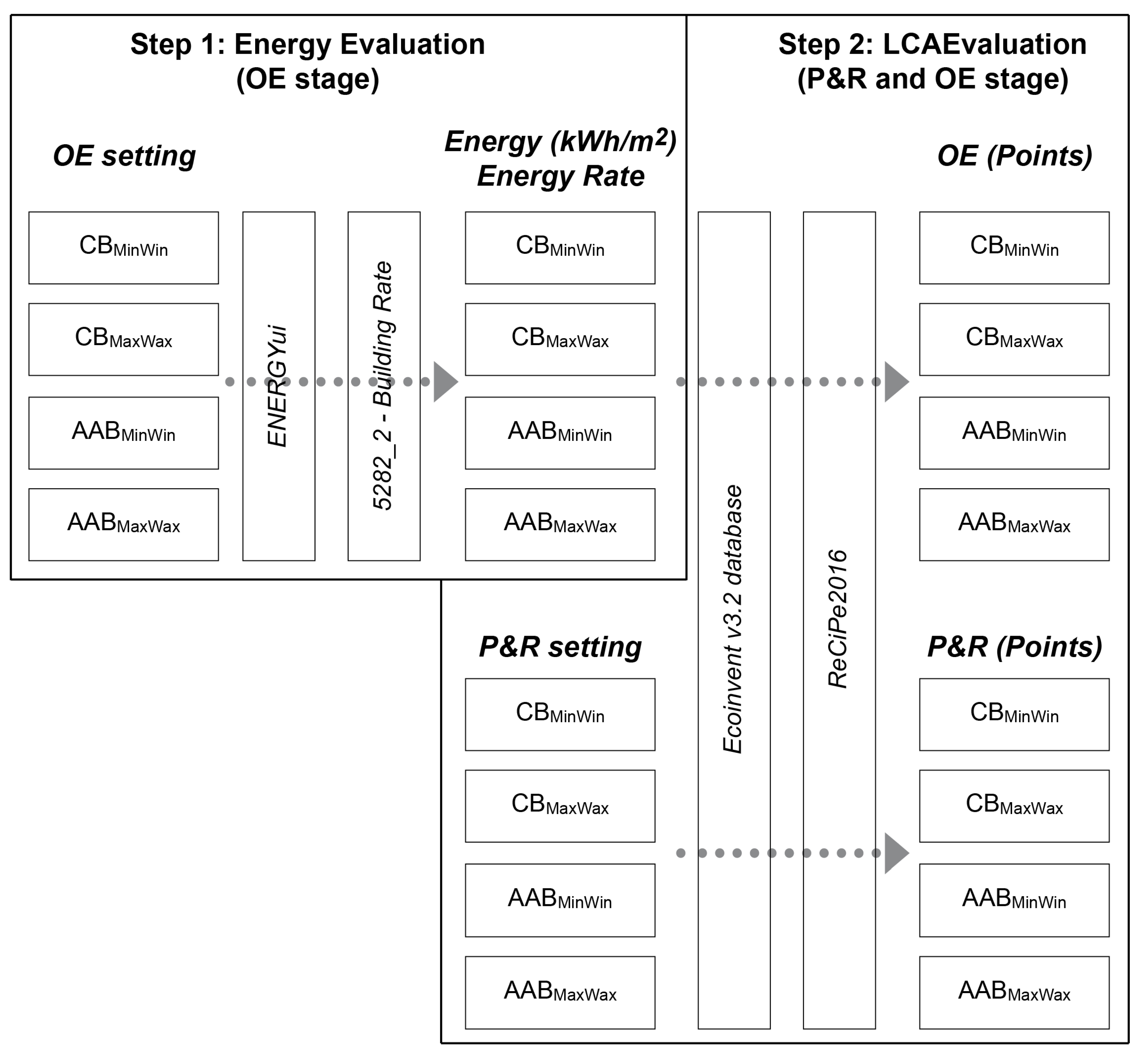

2.1. Research Framework

2.2. Energy Assessment of the OE Stage

2.3. LCA of P&R and OE Stages

2.3.1. Goal and Scope

2.3.2. Life Cycle Inventory (LCI)

2.3.3. Life Cycle Impact Assessment

2.4. Statistical Evaluation

2.4.1. The Design Structure of the ReCiPe2016 Endpoint Single-Score Results and Two-Stage Nested Analysis of Variance (ANOVA) Test

2.4.2. p-Value Interpretation

3. Results and Discussion

3.1. Energy Assessment of the OE Stage

3.2. LCAs of the P&R and OE Stages

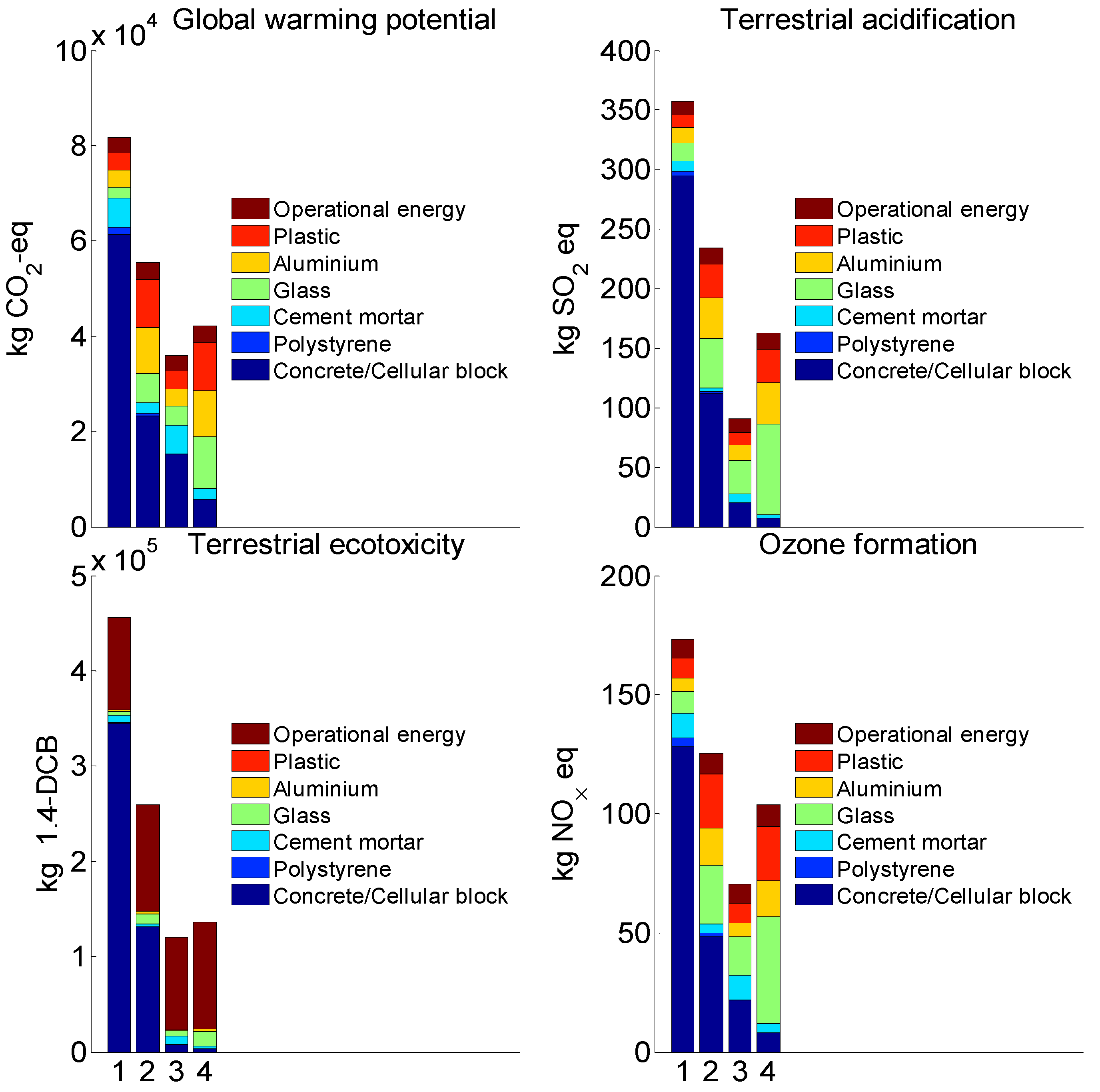

3.2.1. Preparatory Results: Materials and Energy

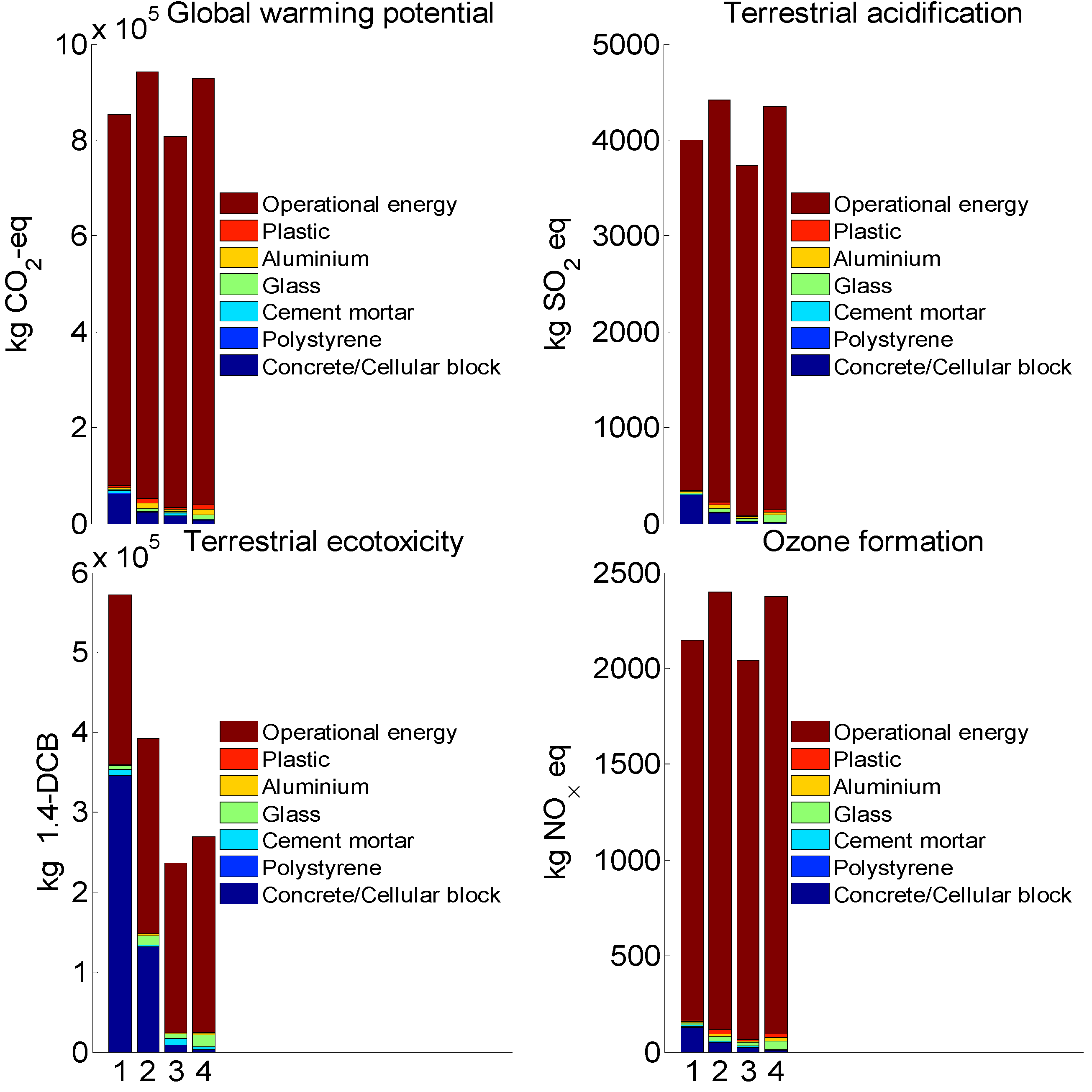

3.2.2. ReCiPe2016 Midpoint Results

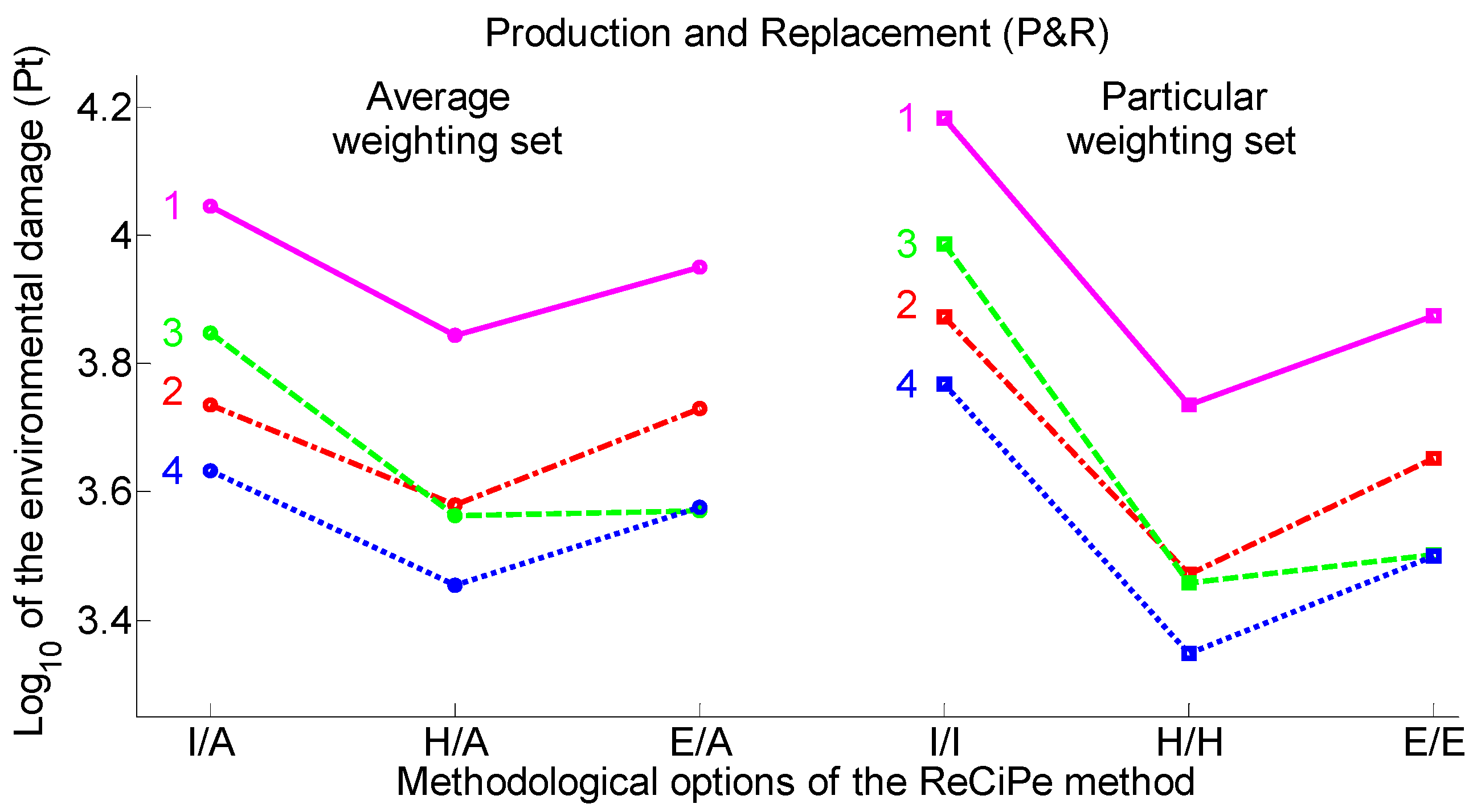

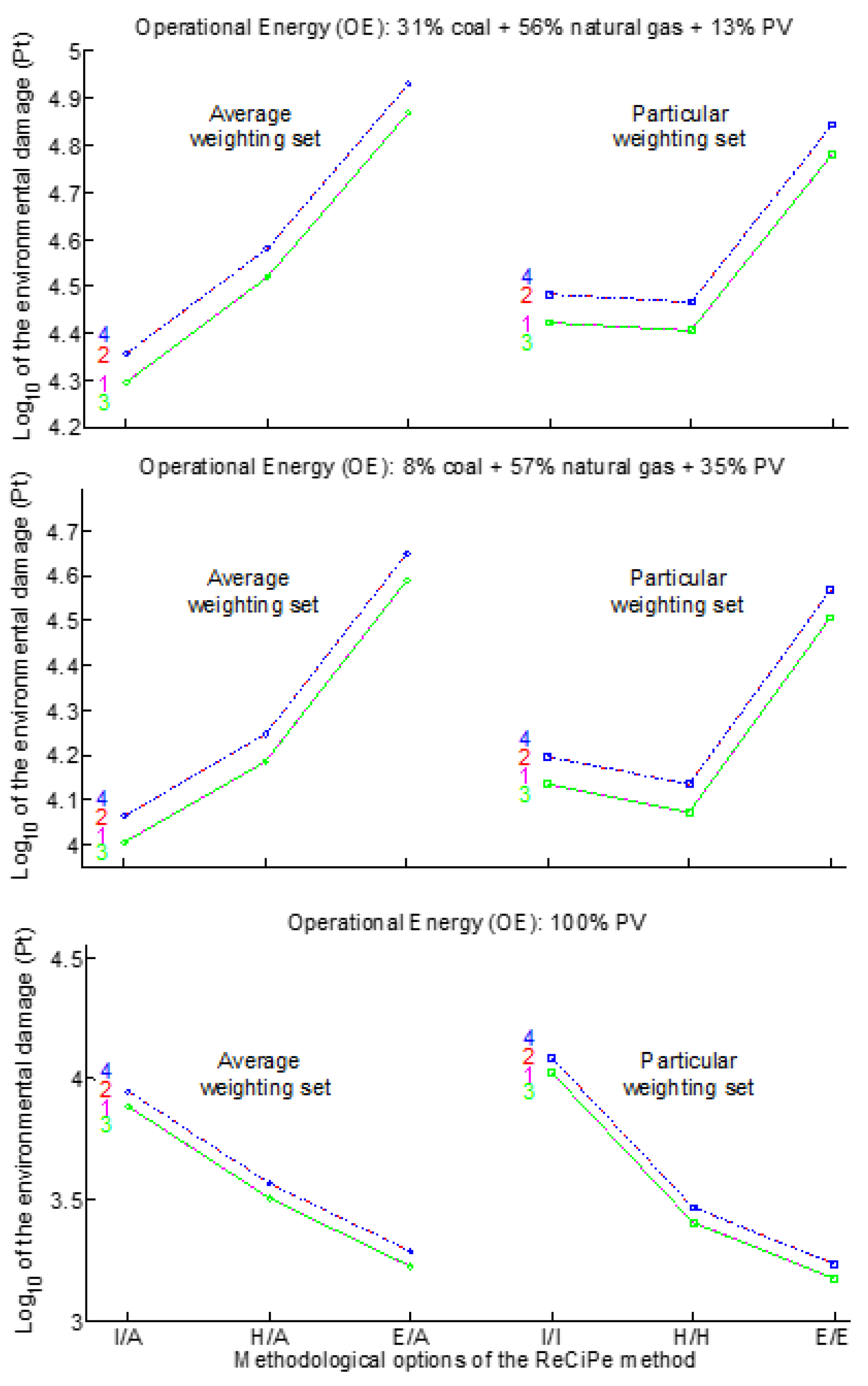

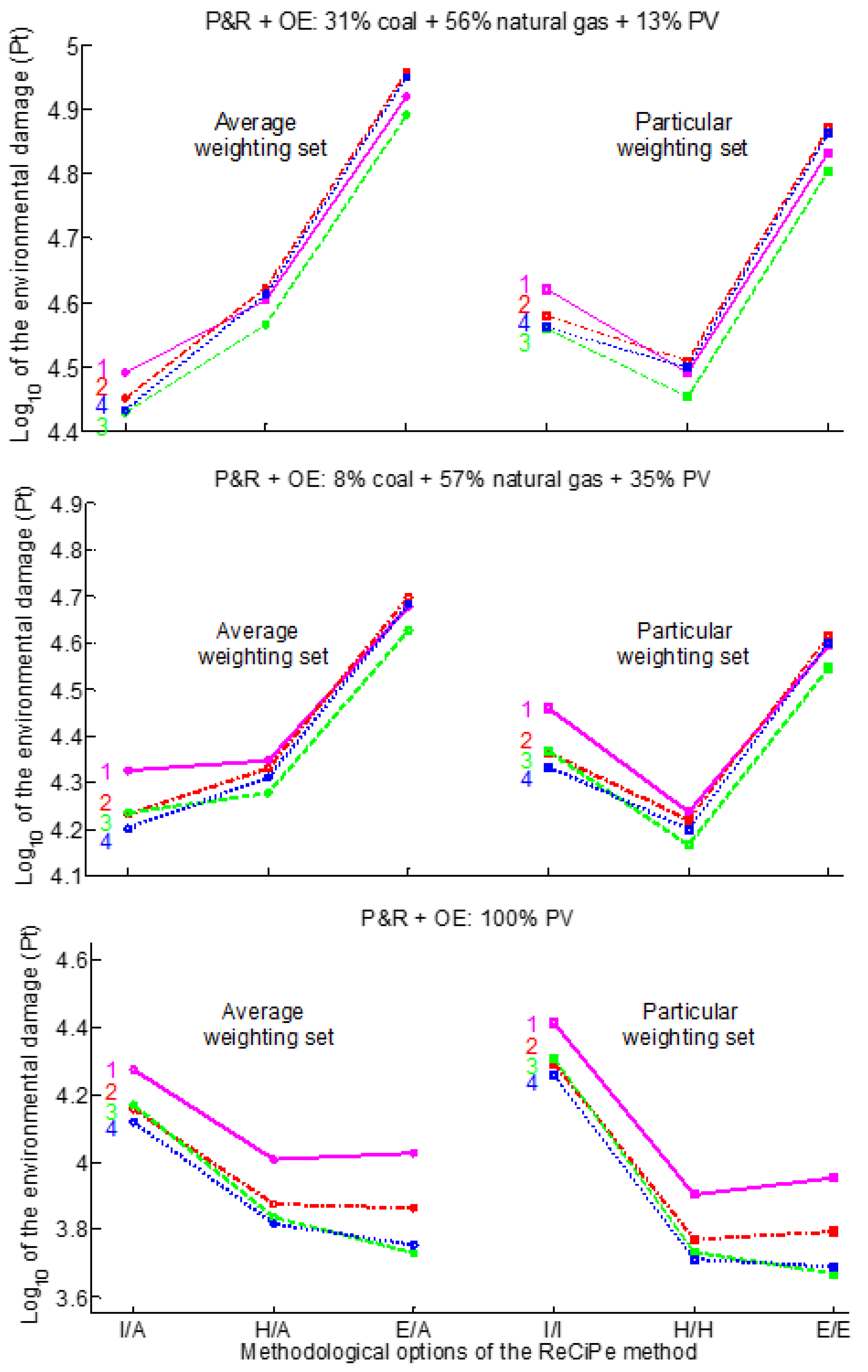

3.2.3. ReCiPe2016 2016 Endpoint Single-Score Results

4. Conclusions

5. Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Directive 2010/31/EU of the European Parliament and of the Council (Recast). Official Journal of the European Union 19 May. 2010. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 15 December 2020).

- Shaviv, E.; Yezioro, A.; Capeluto, I.G. Energy Code for Office Buildings in Israel. Renew. Energy 2008, 33, 99–104. [Google Scholar] [CrossRef]

- Hamed, T.A.; Bressler, L. Energy security in Israel and Jordan: The role of renewable energy sources. Renew. Energy 2019, 135, 378–389. [Google Scholar] [CrossRef]

- Israel Electricity Authority. Electricity Status Report. 2020. Available online: https://www.gov.il/BlobFolder/generalpage/dochmeshek/he/Files_Netunei_hashmal_doch_reshut_hasmal_2020_malle_n.xlsx.pdf (accessed on 15 December 2020). (In Hebrew)

- Halasah, S.A.; Pearlmutter, D.; Feuermann, D. Field installation versus local integration of photovoltaic systems and their effect on energy evaluation metrics. Energy Pol. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Ministry of Energy. Sustainable Energy. Available online: https://www.gov.il/BlobFolder/news/energy_2030/en/National_Energy_Efficiacy_Program.pdf (accessed on 15 December 2020).

- Giordano, R.; Serra, V.; Tortalla, E.; Valentini, V.; Aghemo, C. Embodied Energy and Operational Energy Assessment in the Framework of Nearly Zero Energy Building and Building Energy Rating. Energy Procedia 2015, 78, 3204–3209. [Google Scholar] [CrossRef] [Green Version]

- Lessard, Y.; Anand, C.; Blanchet, P.; Frenette, C.; Amor, B. LEED v4: Where Are We Now? Critical Assessment through the LCA of an Office Building Using a Low Impact Energy Consumption Mix. J. Ind. Ecol. 2017, 22, 1105–1116. [Google Scholar] [CrossRef]

- Amiri, A.; Emami, N.; Ottelin, J.; Sorvari, J.; Marteinsson, B.; Heinonen, J.; Junnila, S. Embodied emissions of buildings—A forgotten factor in green building certificates. Energy Build. 2021, 241, 110962. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pèreza, G.; Castella, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the life cycle energy of buildings: Review and analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Capeluto, I.G.; Yezioro, A.; Shaviv, E. What are the required conditions for heavy structure buildings to be thermally effective in a hot humid climate? J. Sol. Energy Eng. 2004, 126, 886–892. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energy Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- Dong, Y.; Ng, S.T.; Liu, P. A comprehensive analysis towards benchmarking of life cycle assessment of buildings based on systematic review. Build. Environ. 2021, 204, 108162. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. Environmental damage from wall technologies for residential buildings in Israel. J. Green Build. 2016, 11, 98–106. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. Life-Cycle Assessment of the Energy Code for Office Buildings Using the Prescriptive Approach in Israel. In Proceedings of the International Conference on Sustainable Infrastructure 2017 (ASCE) Methodology, 26–28 October 2017; Soibelman, L., Peña-Mora, F., Eds.; American Society of Civil Engineers: New York, NY, USA, 2017; pp. 207–217. ISBN 978-1-5108-5274-7. [Google Scholar]

- Yezioro, A.; Capeluto, I.G. Energy Rating of Buildings to Promote Energy-Conscious Design in Israel. Buildings 2021, 11, 59. [Google Scholar] [CrossRef]

- US Department of Energy. EnergyPlus. Available online: https://energyplus.net/downloads (accessed on 10 November 2021).

- PRé Consultants. SimaPro; Version 9.1. 0.35; PRé Consultants: Amersfoort, The Netherlands, 2019. [Google Scholar]

- Hart, J.; D’Amico, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2001, 25, 403–418. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Asif, M. An empirical study on life cycle assessment of double-glazed aluminium-clad timber windows. Int. J. Build. Pathol. Adapt. 2019, 37, 547–564. [Google Scholar] [CrossRef]

- Jia, X.; Lv, F.; Li, P.; Wang, W. Life-cycle assessment of p-type multi-Si back surface field (BSF) solar module in China of 2019. Sol. Energy 2020, 196, 207–216. [Google Scholar] [CrossRef]

- Pushkar, S. Using Eco-Indicator 99 to evaluate building technologies under Life cycle assessment uncertainties. J. Architect. Eng. 2014, 20, 04013010. [Google Scholar] [CrossRef]

- Verbitsky, O.; Pushkar, S. Eco-Indicator 99, ReCiPe, and ANOVA for evaluating building technologies under LCA uncertainties. Environ. Eng. Manag. J. 2018, 17, 2549–2559. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Picquelle, S.J.; Mier, K.L. A practical guide to statistical methods for comparing means from two-stage sampling. Fish. Res. 2011, 107, 1–13. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Final collapse of the Neyman-Pearson decision theoretic framework and rise of the neoFisherian. Ann. Zool. Fenn. 2009, 46, 311–349. [Google Scholar] [CrossRef]

- Gotelli, N.J.; Ellison, A.M. A Primer of Ecological Statistics, 2nd ed.; Sinauer Associates: Sunderland, MA, USA, 2004; p. 638. ISBN 1605350648. [Google Scholar]

- Beninger, P.G.; Boldina, I.; Katsanevakis, S. Strengthening statistical usage in marine ecology. J. Exp. Mar. Biol. Ecol. 2012, 426, 97–108. [Google Scholar] [CrossRef]

- Fisher, R.A. Statistical Methods and Scientific Inference; Oliver and Boyd: Edinburgh, UK, 1956; p. 175. [Google Scholar]

- Altman, D.G. Practical Statistics for Medical Research; Chapman and Hall: London, UK, 1991; p. 623. [Google Scholar]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Solano-Olivares, K.; Martínez, E.; García, E.O.; Santoyo, E. Life cycle assessment for a grid-connected multi-crystalline silicon photovoltaic system of 3 kWp: A case study for Mexico. J. Clean. Prod. 2021, 316, 128314. [Google Scholar] [CrossRef]

| Parameters | Settings | |

|---|---|---|

| Location | Tel Aviv | |

| Structure (5 stories) | Typical floor | 844.6 m2 |

| Main façade orientation | North–south | |

| Loads | People | 12 people/m2 |

| Constant | 0.4 W/m2 | |

| Non-constant | 8 W/m2 | |

| Lighting | 12 W/m2 | |

| Mechanical system | Ideal system heating/cooling load calculation | |

| Setpoint | Heating | 20 °C |

| Cooling | 24 °C | |

| Infiltration | 1 ach | |

| Seasons | All | |

| Components (U-Value (W/m2K)) | Alternatives | |||

|---|---|---|---|---|

| CBMinWin | CBMaxWin | AABMinWin | AABMaxWin | |

| Composite Materials (Thickness (m)) | ||||

| Roof (U = 0.7) | Bitumen (0.05 m), light concrete (0.05 m), polystyrene (0.045 m), concrete (0.14 m), lime–cement mortar (0.02 m) | |||

| Ground floor (U = 0.72) | Cement mortar (0.025 m), concrete (0.14 m), polystyrene (0.04 m), light concrete (0.05 m), sand (0.03 m), cement mortar (0.02), marble (0.04 m) | |||

| Internal floor (U = 3.53) | Cement mortar (0.025 m), concrete (0.15 m), cement mortar (0.02 m), ceramic tile (0.02 m) | |||

| Interior walls (U = 2.66) | Lime–cement mortar (0.015 m), concrete block (0.10 m), lime–cement mortar (0.015 m) | |||

| Exterior walls (U = 053 a; U = 0.54 b) | a Cement mortar (0.025 m), polystyrene (0.03 m), concrete block (0.23 m), lime–cement mortar (0.02 m) | b Cement mortar (0.025 m), autoclaved aerated block (0.2 m) lime–cement mortar (0.02 m) | ||

| Window area | 673.8 m2 | 1817.1 m2 | 673.8 m2 | 1817.1 m2 |

| Window type (U = 3.14 c; U = 3.95 d) | c Single LowE glass (aluminum frame: 10% of window area) | d Double clear glass (aluminum frame: 10% of window area) | ||

| Shading | Internal dynamic (plastic blinds) | External dynamic (plastic blinds) | Internal dynamic (plastic blinds) | External dynamic (plastic blinds) |

| Materials/Energy | Data Source |

|---|---|

| P&R Stage | |

| Concrete blocks | Lightweight concrete block, at plant/CH |

| Cellular blocks | Autoclaved aerated concrete block, at plant/CH |

| Polystyrene | Polystyrene foam slab, at plant/RER |

| Cement mortar | Cement mortar, at plant/CH |

| Glass | Flat glass, coated/uncoated, at plant/RER |

| Aluminum | Aluminum extrusion profile/RER |

| Plastic | Polyethylene, LDPE, at plant/RER |

| OE Stage | |

| Operational energy | Electricity, hard coal, at power plant/ES |

| Electricity, natural gas, at power plant/ES | |

| Electricity, PV, at 3 kWp flat roof installation, multi-Si/CH |

| Alternative | Energy (kWh/m2∙year) | Building Rate | |||||

|---|---|---|---|---|---|---|---|

| Floor 1 | Floor 2 | Floor 3 | Floor 4 | Floor 5 | Building | ||

| CBMinWin | 27.1 | 27.9 | 28.5 | 28.4 | 31.2 | 28.6 | C |

| CBMaxWin | 30.6 | 32.8 | 32.8 | 32.8 | 35.4 | 32.9 | D |

| AABMinWin | 27.1 | 27.9 | 28.5 | 28.4 | 31.2 | 28.6 | C |

| AABMaxWin | 30.6 | 32.8 | 32.8 | 32.8 | 35.4 | 32.9 | D |

| Materials/Energy | Alternatives | |||

|---|---|---|---|---|

| CBMinWin | CBMaxWin | AABMinWin | AABMaxWin | |

| Production Stage | ||||

| Concrete/cellular blocks (kg) | 152,228 | 57,563 | 36,770 | 13,904 |

| Polystyrene (kg) | 331 | 125 | – | – |

| Cement mortar (kg) | 31,622 | 11,957 | 31,622 | 11,957 |

| Glass (kg) | 2021 | 5451 | 4043 | 10,903 |

| Aluminum (kg) | 1455 | 3925 | 1455 | 3925 |

| Plastic (kg) | 1617 | 4361 | 1617 | 4361 |

| Operational Energy Stage | ||||

| Energy (kWh/floor∙50 year) | 1,203,555 | 1,385,144 | 1,203,555 | 1,385,144 |

| Alternative | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Production Stage | ||||

| 1 | X | 0.0019 | 0.0012 | 0.0008 |

| 2 | X | 0.2057 | 0.0081 | |

| 3 | X | 0.0082 | ||

| 4 | X | |||

| Alternative | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| OE stage with 31% coal, 56% natural gas, and 13% PV-based electricity | ||||

| 1 | X | 0.0746 | 1.0000 | 0.0746 |

| 2 | X | 0.0746 | 1.0000 | |

| 3 | X | 0.0746 | ||

| 4 | X | |||

| OE stage with 8% coal, 57% natural gas, and 35% PV-based electricity | ||||

| 1 | X | 0.0570 | 1.0000 | 0.0570 |

| 2 | X | 0.0570 | 1.0000 | |

| 3 | X | 0.0570 | ||

| 4 | X | |||

| OE stage with 100% PV-based electricity | ||||

| 1 | X | 0.0020 | 1.0000 | 0.0020 |

| 2 | X | 0.0020 | 1.0000 | |

| 3 | X | 0.0020 | ||

| 4 | X | |||

| Alternative | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| OE stage with 31% coal, 56% natural gas, and 13% PV-based electricity | ||||

| 1 | X | 0.7693 | 0.1219 | 0.7361 |

| 2 | X | 0.1036 | 0.5548 | |

| 3 | X | 0.1660 | ||

| 4 | X | |||

| OE stage with 8% coal, 57% natural gas, and 35% PV-based electricity | ||||

| 1 | X | 0.1601 | 0.0371 | 0.0656 |

| 2 | X | 0.1063 | 0.2709 | |

| 3 | X | 0.3224 | ||

| 4 | X | |||

| OE stage with 100% PV-based electricity | ||||

| 1 | X | 0.0043 | 0.0018 | 0.0017 |

| 2 | X | 0.0223 | 0.0148 | |

| 3 | X | 0.1481 | ||

| 4 | X | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S.; Yezioro, A. Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study. Buildings 2022, 12, 157. https://doi.org/10.3390/buildings12020157

Pushkar S, Yezioro A. Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study. Buildings. 2022; 12(2):157. https://doi.org/10.3390/buildings12020157

Chicago/Turabian StylePushkar, Svetlana, and Abraham Yezioro. 2022. "Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study" Buildings 12, no. 2: 157. https://doi.org/10.3390/buildings12020157

APA StylePushkar, S., & Yezioro, A. (2022). Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study. Buildings, 12(2), 157. https://doi.org/10.3390/buildings12020157