Abstract

Digital twin (DT) is gaining increasing attention due to its ability to present digital replicas of existing assets, processes and systems. DT can integrate artificial intelligence, machine learning, and data analytics to create real-time simulation models. These models learn and update from multiple data sources to predict their physical counterparts’ current and future conditions. This has promoted its relevance in various industries, including the construction industry (CI). However, recognising the existence of a distinct set of factors driving its adoption has not been established. Therefore, this study aims to identify the drivers and integrate them into a classification framework to enhance its understanding. Utilising popular databases, including Scopus, Web of Science, and ScienceDirect, a systematic literature review of 58 relevant DT adoptions in the CI research was conducted. From the review, the drivers for DT adoption in the CI were identified and classified. The results show that developed countries such as the UK, US, Australia, and Italy have been the top countries in advancing DT adoption in the CI, while developing countries have made commendable contributions. A conceptual framework has been developed to enhance the successful adoption of DT in the CI based on 50 identified drivers. The major categories of the framework include concept-oriented drivers, production-driven drivers, operational success drivers, and preservation-driven drivers. The developed framework serves as a guide to propel DT adoption in the CI. Furthermore, this study contributes to the body of knowledge about DT adoption drivers, which is essential for DT promotion in the CI.

1. Introduction

The computerization and digitalization of activities and processes significantly impact how physical assets are managed [1]. Various technologies, including artificial intelligence (AI), the internet of things (IoT), building information modelling (BIM), digital twins (DTs), blockchain, machine learning, data analytics, deep learning, and the like, are being utilised to enhance productivity across several industries. Several economies are therefore confident in utilising these technologies to enhance their growth and development. For instance, in the UK, the National Infrastructure Commission [2] reported that AI could aid in getting more from infrastructure and add up to 10.3% to the UK economy by 2030. Ding and Drogemuller [3] highlighted that advances in BIM have the potential of achieving a 98% reduction in the time taken for updating databases relating to the operation and maintenance phase of a project. Gartner [4] predicted that half of the large industrial companies would be using DTs by 2021 to achieve a possible 10% improvement in these organisations’ effectiveness. This is possible because DTs align better with other emerging paradigms like cyber-physical systems (CPS) and Industry 4.0. DT helps to integrate the physical world to the digital world and increases productivity using predictive analytics [5,6,7].

The National Aeronautics and Space Administration (NASA) presented the concept of ‘twins’ by building two space vehicles that were identical in nature to determine the conditions of the space vehicle while on mission [8]. Boschert and Rosen [8] further indicated that the vehicle that was on earth was the twin of the vehicle that went on a mission in space. A widely accepted introduction of DT was in 2003, where Michael Grieves presented the digital version of a physical product. In 2006, a variant of the DT known as the “product avatar” was also introduced [9]. DTs have been utilised in several industries or domains, which include the manufacturing, healthcare, aeronautics and aviation, energy, education, agriculture, meteorology, and automotive sectors [10]. Although DT adoption in the construction industry has been quite slow [11], most of its application has been focused on the operation and maintenance phase of projects. For instance, Lu, Xie, Parlikad and Schooling [12] utilised DT to develop a system that could detect anomalies in the conditions of an asset during its operation. The diagnosis of the operational conditions was carried out using the asset’s monitoring dataset. The study showed that a building asset could be continuously monitored using the developed system. Kaewunruen and Lian [13] developed the world’s first 6D BIM for managing the lifecycle of a railway turnout system. They used Revit-2018 software to develop a 3D model of the railway turnout system. The authors established that 6D is geared towards assessing the carbon footprint of the system throughout its whole lifecycle. A conclusion was made that DTs could be used to visualise and prioritise maintenance decisions. Lin and Cheung [14] developed an advanced monitoring and control system for an underground parking garage environment using DT. The authors concluded that the system is visually effective for managing and monitoring environmental conditions. In Australia, the restoration team of the Sydney Opera House designed a unified central data repository to enhance operation and maintenance using some DT concepts [15]. In the UK, the National Infrastructure Commission [2] indicated the need for a national DT to develop a richer understanding and optimization of infrastructure works. The introduction of DT in the construction industry has witnessed several ambiguities due to its similarities with BIM. However, available studies [11,16] have clearly indicated that DT and BIM are different in terms of their purposes, technologies, and end-users. BIM is a static representation of the design of the building or structure to be constructed for the purpose of understanding and communicating the design. In contrast, DT is a real-time representation of the building or structure that is fully or partially completed and developed for the purpose of representing the status and character of the building or structure it mirrors. They also mentioned that, whilst BIM operates on static data, DT utilises real-time or near real-time data. Further, the facility’s lifecycle stages of their applications are also different. Several technologies, including BIM, wireless sensor networks (WSNs), data analytics, and Machine Learning are currently supporting the development of DTs in the construction industry [11,17].

Notwithstanding the efforts and quest for DT in the construction industry, little attention has been geared towards the driving forces for its adoption. The drivers will serve as a blueprint for practitioners and stakeholders to better understand DT and its potential success in the construction industry. Though there have been several reviews [11,18,19,20,21] on the application of DT in the construction industry, they did not pay enough attention to the drivers for DT adoption. Thus, there is yet to be a study that comprehensively reviews the literature on the drivers for DT adoption in the construction industry. There are also disagreements among industry practitioners and researchers on how DT can assist in designing and constructing buildings as well as civil infrastructure projects [22]. These hinder the thorough understanding and readiness to embrace DT to address some of the numerous challenges confronting the construction industry [11]. Therefore, the overarching aim of this study is to comprehensively review the literature on the drivers for DT adoption in the construction industry. The drivers in this study refer to the ‘pull’ as well as ‘push’ factors and the influential factors that will propel the construction industry to adopt DTs. Further, the drivers also include motivations and potential benefits of DT adoption to the construction industry. The following objectives have been articulated to assist in arriving at the aim of the study:

To ascertain the annual publication trends of DT adoption in the construction industry research.

To determine the country/region of authors actively probing into the drivers of DT adoption and assess the impacts on their construction industry.

To identify, classify, and integrate the drivers into a unified construction project lifecycle-based typology (classification framework) to enhance understanding of DT adoption in the construction industry.

The significance of this study lies in the fact that it is the first to conduct a comprehensive literature review and bring to light a classified set of drivers for adopting DT in the construction industry. Further, a novel framework has also been developed as a guide to enhance the successful adoption of DT in the construction industry. Practically, the findings will serve as a reference point for enhancing the knowledge of industry practitioners on the benefits of adopting DT in the construction industry. The remainder of the paper is structured as follows: Section 2 presents the methodology adopted for this study. The results and discussion are presented in Section 3. Finally, the paper is concluded in Section 4 with implications for practice, suggestions for further research, and limitations.

2. Research Methodology

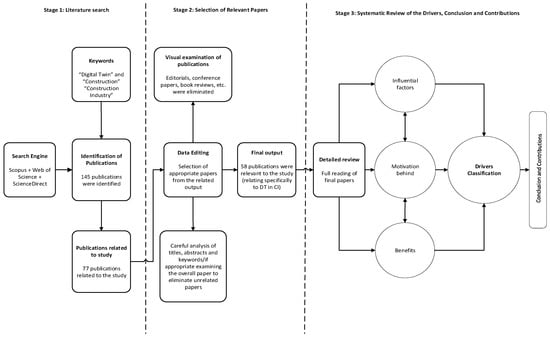

This study is grounded on a systematic review of the literature that focuses on the previous research on the adoption of DT technology in the construction industry. This method aligns with specific principles, including a review that is carried out systematically or the delivery of a transparent method, replicability, as well as updatability, and summarisation and synthesization of the key focus of the study [23]. A similar methodology as utilised by Opoku, Perera, Osei-Kyei and Rashidi [11] and Chan, Tetteh and Nani [24] was adapted to evaluate and thoroughly study the literature within the scope under consideration. This involves an initial search for literature using several databases, filtration of process as well as analysing the content of the identified literature. Figure 1 depicts the entire research process utilised in this study. In the first stage, a search for the literature was conducted using three databases, including Scopus, Web of Science and ScienceDirect. In the second stage, a detailed visual examination was carried-out to identify and select the most appropriate publications for this research. In the final stage, a systematic content analysis was conducted to identify the drivers and crystallise them into categories to enhance their understanding. The subsequent sub-sections comprehensively elaborate on the three stages utilised in this study.

Figure 1.

An overview of the literature review and research process (adapted from [24]).

2.1. Literature Search

The initial search was conducted using the Scopus database. Scopus was used because it has broader coverage than other databases like Google Scholar, PubMed and Web of Science [11,25]. It is also an effectual search engine for literature review [26]. In order to get a substantial number of papers, a comprehensive search was conducted using the keywords with appropriate Boolean operators: ((“digital twin” OR “virtual counterpart” OR “digital replica” OR “virtual twin”) AND (“construction” OR “construction industry”)), with no limitation in terms of the year (search on 7 September 2021). However, “article” or “review” was selected for the type of document since they provide the most reputable as well as influential sources of knowledge [27]. Book reviews, letters to the editors, forums, briefing sheets, discussions/closures, forewords as well as introductions, seminar papers, were all excluded in this study. The study also restricted the language type to English language based on the study aim and objectives. At the end of the initial search, 138 publications were retrieved from this query. An additional search was carried out using Web of Science and ScienceDirect to add to the initially searched publications and yielded 145 papers. The addition of other publications from Web of Science and ScienceDirect was done to ensure that an acceptable number of research papers on the adoption of DT technology in the construction industry were captured and used in the study. In addition, it was to ensure that this study did not leave out any relevant literature. A total of 77 publications from 30 journals and conference proceedings were identified after removing duplicates. The details of the publications included in the study are depicted in Table 1.

Table 1.

Search results of publications relevant to the study.

2.2. Selection of Relevant Papers

The researchers critically and comprehensively examined the 77 papers after stage 1 had been completed. The reason for the examination was to identify those papers that were relevant to the specific research topic. It was also ensured that only refereed journal papers were used in the study to enhance the quality of obtained data [28]. Complete text analysis was carried out if no relevant information was obtained after critically examining the abstracts and conclusions of the potential publications. The publications that referred to digital twins without their adoption in construction or the construction industry were not included in this study. This was done to ensure that only publications that focused on DT adoption in the construction industry were used in this research. This resulted in the final identification of 58 relevant publications for detailed analysis. The number of selected papers, as well as the final relevant publications, are provided in Table 1.

2.3. Identification of DT Adoption in the Construction Industry Drivers

The drivers were identified from the 58 publications used in the study. Whilst some publications stated some of the drivers in tables and charts, other papers required detailed content analysis to discover the drivers. A four-step approach utilised by Zhang, Oo and Lim [80] in conducting content analysis was adopted for the study. Content analysis is a systematic and structured method to put together several textual contents into fewer content categories based on explicit coding rules [81]. This method is helpful in analysing the drivers for DT adoption in the construction industry. Though no methodical rules exist for analysing data in content analysis, the data’s preparation, organisation, and reporting are three essential processes in content analysis [82]. Zhang, Oo and Lim [80] used the four steps: de-contextualisation, re-contextualisation; categorisation and compilation; and consistency assessment. De-contextualisation involves the selection of the unit of analysis and deducing meaning from the data. In this case, themes rather than words and sentences are used as the unit of analysis. Codes are used to represent themes that capture already defined criteria. We established an initial standardised code as the procedure to de-contextualise the text. The codebook included identifying the publication year, authors, title of publication, journal or conference proceeding in which the paper was published and the country in which the research was carried-out. Further, the researchers also identified the driving forces for DT adoption in the construction industry as well as the major findings and contributions that were clearly stated in the publication.

Re-contextualisation relates to openly coding through the condensation of the implications of the themes’ unit of analysis. The coding is based on the homogeneity between the major themes. For example, statements that relate to the concept of the digital twin are coded as concept-oriented drivers. The next step is to categorise and compile the sub-themes. This involves the abstracting and naming of the themes according to content-characteristic words. In this stage, similar or dissimilar sub-themes are put together to form broader sub-themes. Finally, the assessment of consistency stage involves the comparison of different judgements to ensure trustworthiness in the process. This eliminates the subjective judgements and possibilities of differences in judgements among various authors.

3. Results and Discussion

3.1. Annual Publication Trends on Drivers for DT Adoption in the Construction Industry

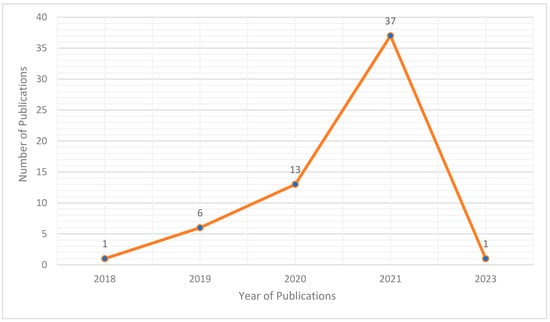

This section discusses the research findings, together with the descriptive analysis and categories of the identified drivers using content analysis. Figure 2 shows the annual publication on the driving forces for digital twin adoption in the construction industry, with an increasing growth since 2018. The first relevant paper was published in 2018 (see Figure 2). It is understandable since the DT concept in technologically advanced industries such as manufacturing was at its infancy and other areas like the construction industry were now contextualising the concept [83]. Since then, relevant annual publications have increased from one in 2018 to six in 2019.

Figure 2.

Number of relevant publications published annually from 2018 to 2023.

Furthermore, there was a progressive increase in the number of relevant papers published annually, resulting in 13 published in 2020 despite the COVID-19 pandemic. Similarly, 37 relevant papers were published in 2021 (i.e., peak year) (see Figure 2). The growing interest in the adoption of DT in the construction industry is evident in this review, where one paper on its driving forces has already seen its publication in 2023. Further, the exponential increase in the number of relevant publications showed that researchers and practitioners had recognised the prowess of digital twins in solving some of the numerous challenges confronting the construction industry, especially in operation and maintenance phase of a project [11].

3.2. Geographical Considerations of DT Adoption in the Construction Industry

The study identified the countries or regions actively involved in the adoption of DT in the construction industry related studies and presented them in Table 2. The 58 publications covered nineteen countries or regions, which included both developed and developing countries. The majority of the publications focused on the United Kingdom (UK), United States (US), Australia, and Italy, with nine, seven, six, and six publications. Thirteen publications focused on multi-country analysis (for instance, Australia and UK, China and Singapore, Canada and UK, UK and Pakistan). Therefore, it can be deduced from the results that most developed countries, such as the UK, US, Australia, and Italy, have the highest number of researchers contributing to the probing of the driving forces for the adoption of DT in the construction industry. In the same vein, developing countries like Brazil, China, and South Africa have contributed to the DT adoption in the construction industry drivers research with at least one publication. The construction industries of these developed countries are benefitting significantly from the adoption of DT. For instance, the UK, through the Centre for Digital Built Britain (CDBB), is running the National Digital Twin Programme (NDTp) to access high-quality and secure data to improve how infrastructure is built, managed, operated and decommissioned [84]. Further, in Australia, the restoration team of the Sydney Opera House designed a unified central data repository to enhance operation and maintenance using some DT concepts [15]. This evidence proves the potential of DT adoption in the construction industry.

Table 2.

Distribution of selected papers by country or region.

3.3. Drivers of DT Adoption in the Construction Industry

After completing the four-step approach, a total of 50 drivers were identified and presented in Table 3. Table 3 also presents the number of studies that relates to each of the identified sub-themes. In this study, all the identified drivers for digital twin adoption in the construction industry are presented in detail. It is worthy to note that the identified drivers are mostly the expectations of researchers in their studies and that few are based on practical evidence.

Table 3.

Drivers for DT adoption in construction industry identified in the literature.

3.4. Classification of the DT in Construction Industry Drivers

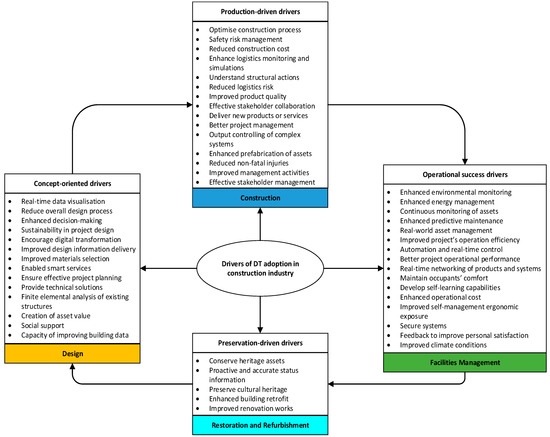

The lifecycle philosophy of construction projects is critical to the successful adoption of DT due to the integrated activities on design, construction, operation and maintenance, and preservation [11]. The construction project lifecycle phases as described by Guo, Li and Skitmore [85] is adopted for this study. In this study, the planning and design phases are referred to as design; construction and commissioning phases are referred to as construction; utilization and maintenance phases are referred to as facilities management; finally, decommissioning phase is referred to as restoration and refurbishment.

The study consolidated either similar or dissimilar variables into broader higher-order categories. The purpose of the consolidation was to enhance the understanding, clarity and simplicity of the identified drivers. The study adopted the classification technique utilised by Ghobadi [86] and Chan, Tetteh and Nani [24]. This technique defines the categories based on four robust codified logic. For instance, Ghobadi [86] adopted this approach to develop a framework for classifying the driving forces for knowledge sharing in software teams using the change perspective of organisations. Chan, Tetteh and Nani [24] also utilised the same approach to develop a conceptual framework to guide, determine and assess the success of international construction joint ventures. The codified logic involves, firstly, identifying the interrelationships between the identified factors. Secondly, comparing the results to ensure consistency within the categorisation of the factors. Thirdly, establishing a relationship between classifications of previous studies and the current results and, lastly, finalising the categorisation of the factors using focus group discussions. This study resorted to four academics who have extensive knowledge on the adoption of DTs in the construction industry to finalise the categorisation of the driving forces. The classification process resulted in the 50 drivers being classified into four major categories. These categories include concept-oriented drivers, production-driven factors, operational success, and preservation-driven drivers (see Table 4). Furthermore, these categories have also been ranked to establish the most frequent usage of DT in the construction industry.

Table 4.

Typology of Drivers for DT adoption in CI ranking.

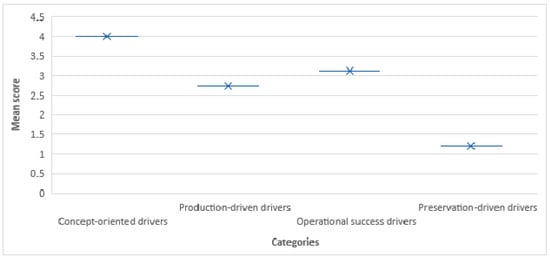

Table 4 shows the identified four main categories and their associated driving forces for DT adoption in the construction industry. For instance, conserve heritage assets, proactive and accurate status information, preserve cultural heritage, enhanced building retrofit, and improved renovation work form the preservation-driven drivers for adopting DT in the construction industry. The conceptual framework for DT adoption in the construction industry drivers’ classification is presented in Figure 3. In addition to Table 4, the mean scores for each of the categories are graphically presented in Figure 4.

Figure 3.

A conceptual framework for classification of the main drivers for DT adoption in construction industry.

Figure 4.

Graphical representation of the mean scores of the categories.

3.4.1. Concept-Oriented Drivers

The concept-oriented drivers are drivers that form the baseline for DT adoption in the construction industry. These drivers are generally realised at the concept or design and engineering stage of the project. They set the pace for adopting DT in the construction industry. Within this construct, 14 drivers were identified to include real-time data visualisation, reduce overall design process, enhanced decision-making, sustainability in project design, encourage digital transformation, improved design information delivery, improved materials selection, enabled smart services, ensure effective project planning, provide technical solutions, finite elemental analysis of existing structures, creation of asset value, social support, and capacity of improving building data. This is the initial decision-making stage; the decision on whether to adopt DT is very critical [87]. The behaviour rule of the physical entity is reflected in a DT and would be kept updated throughout the lifecycle of the construction project. The concept-oriented drivers are therefore essential in ensuring that the most critical decisions are made regarding the project. Designers are, therefore, provided with efficient information during the design of the project. Hence, a complete digital project footprint will be available to designers to aid them in making informed decisions once they have a DT [88].

According to the individual citations’ frequencies documented in this review, the top four variables with high scores identified include real-time data visualisation, reduced overall design process, enhanced decision-making, and sustainability in project design. This category was ranked first out of four with a 4.00, as calculated by the mean of the citation frequencies of the factors underlying the category. It is worth noting that most of the factors underlying this category form more than 50% of the papers that were reviewed in this study. For example, 18 out of 58 different publications identified real-time data visualisation, constituting more than 30% of the total number of articles reviewed. Several studies have presented some justifications to support this driving force [34,42,61,77]. The need to possess the ability to visualise project data in real-time has pushed for the adoption of DT in the construction industry. Although available technologies like building information modeling (BIM) existed, accessibility to real-time data was impossible, since BIM deals with static data [11,16]. Agostinelli, Cumo, Guidi and Tomazzoli [49] found out that DT presents buildings with the capability to enrich their knowledge and data available, receive sensor signals for continuous monitoring and utilise artificial intelligence (AI) techniques to develop self-learning and predictivity capabilities. The authors highlighted that real-time data visualisation through DT improves energy management systems in both small and large-scale (apartments to district) projects. Similarly, urban-scale energy modelling for optimization is possible through DT [50]. The real-time visualised data in the DT can inform decisions regarding energy distributions, demand, cost savings and emissions from buildings.

Regarding the design process for a building project, DT can aid in reducing the overall design process. This is possible since at the designing of a project, DT can inform the designers’ decision as to which hereditary components, as well as information, can be used from a previous project or rejected during the redesign and re-engineering of the project. Lydon, Caranovic, Hischier and Schlueter [53] stated that DT could reduce the high planning resources needed to implement the elements of multifunctional buildings. The authors further mentioned that the application of DT could resolve issues related to building systems performance during the design and support the various methods employed in digital fabrication during the construction of the project. DT plays a significant role in minimising the duration of the overall design process. For instance, Opoku, Perera, Osei-Kyei and Rashidi [11] mentioned that DT ensures an iterative optimisation of the information and product physical models and, therefore, reduces the overall design process. This can help in reducing the possibilities of incurring additional costs during rework.

Furthermore, decision-making can be enhanced once a what-if analysis is conducted using the DT of the building [52]. Further, the project’s sustainability is enhanced through the adoption of DT in the design of the project. DT presents the opportunity to secure the sustainability of the building project. Several purpose-driven factors and considerations relating to sustainable decision-making in establishing the need, planning, designing, construction, operation, as well as maintenance, are possible through DT adoption in the construction industry [57]. This can enhance the overall sustainability of the construction project.

3.4.2. Production-Driven Drivers

The production-driven drivers focus on bringing the construction project into being. This is the stage where the industry receives its finished product. The production-driven driving forces ensure that the integrity of the project’s structural system is achieved [45]. Considering the definition and theoretical background of the production-driven drivers, 15 drivers were classified under this category to include optimise construction process, safety risk management, reduced construction cost, enhance logistics monitoring and simulations, understand structural actions, reduced logistics risk, improved product quality, effective stakeholder collaboration, deliver new products or services, better project management, output controlling of complex systems, enhanced prefabrication of assets, reduced non-fatal injuries, improved management activities, and effective stakeholder management. The strength of PD drivers lies in its ability to bring into being the building project [11,53,71,72]. Notwithstanding this assumption, this category was ranked third considering the frequency of citations with a mean value of 2.73. It is worthy to note that the underlining factors of the PDD are very significant in the adoption of DT in the construction industry.

DTs can provide support for various methods of construction related to the digital fabrication of the building project [53]. Macchi, Roda, Negri and Fumagalli [89] confirmed that, in the absence of design drawings, DTs are relevant in preparing the as-built drawings; this can enhance and optimise the whole construction process. Safety risk management is a key aspect for consideration in the construction industry. Liu, Meng, Xing and Jiang [73] developed a framework for managing prefabricated building hoisting safety risk using a DT. The DT presented the opportunity to realise the virtual-real interaction in the entire hoisting process and the visualisation of the time-varying information. The authors further indicated that DT could improve safety management as well as construction methods. The construction logistics can also be monitored and simulated using DTs. Several potential risks associated with construction logistics can be predicted using DTs to enhance the coordination effectiveness of the supply chain as well as just-in-time delivery of construction modules [33]. This can, therefore, reduce the overall cost associated with the construction process for the building project. Opoku, Perera, Osei-Kyei and Rashidi [11] indicated that, although the adoption of DT is dependent on the level of knowledge regarding its development, there could be a significant reduction in the overall cost resulting from the application of DT. In the modern construction industry, stakeholders expect buildings to be structurally safe whilst achieving value for money; this is possible through the adoption of DTs. Therefore, DT adoption in the construction industry is an outmost priority. According to Madni, Madni and Lucero [90], the adoption of DTs in the construction of projects presents a significant return on investments throughout the projects’ lifecycle.

3.4.3. Operational Success Drivers

The operational success drivers establish the relationship between the construction project and its users. This is the point where the project’s reliability, as well as its convenience, are of utmost importance to its users. Several stakeholders operate the construction project and, therefore, prevent the data integration between different stakeholders and the project. The adoption of DT at a project’s operation and maintenance stage is usually centred on facilities and maintenance management [11,16,22]. The flow of information among the different stakeholders could also be improved through the application of DT. The operational success drivers category is the second highest ranked category, with a mean value of 3.13, and is explained by sixteen different drivers. The OSD category includes enhanced environmental monitoring, enhanced energy management, continuous monitoring of assets, enhanced predictive maintenance, real-world asset management, improved projects’ operation efficiency, automation and real-time control, better project operational performance, real-time networking of products and systems, maintain occupants’ comfort, develop self-learning capabilities, enhanced operational cost, improved self-management ergonomic exposure, secure systems, feedback to improve personal satisfaction, and improved climate conditions. It is worth to noting that this category has been identified as one of the most significant determinants for adopting DTs in the construction industry, as reported by Opoku, Perera, Osei-Kyei and Rashidi [11]. The critical variables under this category are enhanced environmental monitoring, enhanced energy management, continuous monitoring of assets, and enhanced predictive maintenance [19,30,34,43]. Ensuring building occupants comfort has become an area of great concern in recent times. Facilities managers are, therefore, confronted with the challenge of making critical decisions regarding the operation and maintenance of the building to ensure occupants’ comfort. Khajavi, Motlagh, Jaribion, Werner and Holmström [16] concluded that the DT improves the buildings’ operational efficiency based on collected real-time data, enhancing well-informed decision-making.

With the adoption of DTs in the construction industry, various environmental parameters, including ambient and room temperatures, relative humidity, lux and decibel levels within buildings, can be monitored to improve the environmental conditions. Lin and Cheung [14] developed an advanced monitoring and control system for an underground parking garage environment using DT. The authors concluded that the system is visually effective for managing and monitoring environmental conditions. Many studies have affirmed that the predominant factor for DT adoption in the construction industry is to continuously monitor construction assets [11,21,34,45,63,70]. For instance, Meža, Mauko Pranjić, Vezočnik, Osmokrović and Lenart [63] developed a fully functioning DT of a road constructed using secondary raw materials. As a result, the road could be continuously monitored, and the authors established the prowess of DT in addressing challenges in infrastructure projects. DT also enables intelligent optimisation and automation of energy management systems in buildings. For example, Agostinelli, Cumo, Guidi and Tomazzoli [49] developed a DT-based real-time methodology for monitoring the energy performance of buildings. The authors established that the methodology could reduce the gap between the buildings’ simulated and actual energy performance. In terms of predictive maintenance of buildings, DT presents an excellent and enhanced opportunity. D’Addona, Ullah and Matarazzo [91] indicated that DT provides the platform to identify and evaluate anticipatory measures relating to the predictive maintenance of assets. Further, DT enhances predictive maintenance and ensures well-informed decisions regarding the facility [11,16].

3.4.4. Preservation-Driven Drivers

Different from the regular use of DT in the construction industry, the preservation-driven drivers focus on preserving or conserving the construction asset for future use. Per the definition of the PR drivers and its theoretical background, five out of the fifty drivers were classified under this category, which include conserve heritage assets, proactive and accurate status information, preserve cultural heritage, enhanced building retrofit, and improved renovation works. As Opoku et al. (2021) indicated, researchers have geared little attention towards the demolition and recovery phase of projects regarding the adoption of DT in the construction industry. However, an important area of DT application is that of the preservation of heritage assets, which may possibly be demolished later. The PRD construct is the least ranked among the four categories based the frequency of citations, with a mean value of 1.20.

Notwithstanding, the drivers underlying this category are important for the sustainability together with the continuous evolution of the construction industry [45,92]. In the construction industry, heritage buildings are very significant assets that aid in creating sustainable communities. Furthermore, these assets present additional value to the regeneration of construction projects. Comparatively, heritage buildings present better environmental and economic advantages in terms of reuse than a new build. This is because these buildings provide additional character to the city districts. Further, the culture of the locality is preserved through the reuse of heritage assets; this can be harnessed through the adoption of DT. According to Göçer, Hua and Göçer [93], DT can present a pre-retrofit model of an existing asset that collect and integrate various data regarding assets; this can provide an enhanced understanding of the requirements of the asset to be renovated. In addition, building retrofit decision-making is improved since the labour-intensive and time-consuming activities are catered for using DTs [94]. This explains the relevance of DT for the preservation and conservation of existing buildings.

4. Conclusions

This study identified the main driving forces for DT adoption in the construction industry by systematically reviewing 58 journal and conference publications. The descriptive analysis indicates a growing interest in DT adoption in the construction industry among researchers with studies from both developed as well as developing countries. The findings indicate that majority of the developed countries, which includes the UK, US, Australia and Italy, have the highest number of researchers contributing to the probing of the driving forces for the adoption of DT in the construction industry. In the same vein, developing countries like Brazil, China, and South Africa have also contributed to the DT adoption in the construction industry. The comprehensive content analysis resulted in the identification of 50 drivers for the adoption of DT in the construction industry. The 50 driving forces were extracted, classified and integrated in a framework. The classification framework includes four key categories, specifically: concept-oriented drivers, operational success drivers, production-driven drivers, and preservation-driven drivers. A detailed analysis of these categories of drivers have been conducted and presented in this study.

4.1. Practical Implications and Future Research Recommendations

The developed conceptual framework provides an industry-specific lens for identifying the driving forces for DT adoption in the construction industry. This can aid industry practitioners and other stakeholders interested in adopting DTs in tackling most of the numerous challenges confronting the construction industry. As highlighted in most studies regarding the slow advancement of innovation in the construction industry, especially with its adoption of digital technologies [11,95]. This can help enlighten the understanding of DT applications in the construction industry, as well as the promotion of its adoption. This study can also facilitate the continued inquiry into the cutting-edge abilities of DT in tackling most of the challenges in the construction industry. For instance, the results suggest that fertile grounds for conducting empirical investigations into how the industry can benefit from DT adoption and devise strategies that could enhance the purposes of applying DTs in the construction industry. This would enhance decision-making regarding DT adoption in the industry. This study recommends further research using the case studies approach since most of the driving forces identified are based on the opinions of the researchers whose works have been utilised in the study. This study also suggests that future empirical investigations could explore the inter-relationships among the driving forces and propose strategies for improving the adoption of DTs in the construction industry.

4.2. Limitations of the Research

Despite the contributions of this research, the researchers acknowledge the fact that only Scopus, Web of Science, as well as ScienceDirect databases, were utilised in this study. This could have resulted in overlooking relevant publications regarding the driving forces for DT adoption in the construction industry. Based on this, the findings of the research might not entirely reflect the completely available literature on the drivers for DT adoption in the construction industry. Furthermore, although the most significant publications were carefully selected, the literature search may not have included all keywords. Finally, the researchers also admit the likely limitation regarding the sampling approach used in this study. Hence, the results are subject to the sampling approach employed.

Notwithstanding those mentioned above, there is enough justification, since it is practically impossible to consider all publications related to the drivers of DT adoption in the construction industry in a single review study. It must be noted that the identified driving forces have not been tested empirically and would therefore require future research to undertake detailed surveys empirically from different geographical perspectives to ascertain the most significant driving forces that need vital considerations. Nevertheless, the study is ground-breaking, as it is the first to bring to light a classified set of drivers for adopting DT in the construction industry.

Author Contributions

Conceptualization, D.-G.J.O., S.P., R.O.-K. and M.R.; methodology, D.-G.J.O., S.P. and R.O.-K.; software, T.F. and M.R.; validation, S.P., R.O.-K., M.R. and T.F.; formal analysis, D.-G.J.O.; investigation, D.-G.J.O.; resources, S.P., R.O.-K. and M.R.; data curation, D.-G.J.O. and T.F.; writing—original draft preparation, D.-G.J.O.; writing—review and editing, S.P., R.O.-K., M.R., T.F. and K.B.; visualization, T.F.; supervision, S.P., R.O.-K. and M.R.; project administration, S.P., R.O.-K., M.R. and D.-G.J.O.; funding acquisition, D.-G.J.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Western Sydney University Postgraduate Research Scholarship provided by Western Sydney University, Australia and in-kind funding from the Centre for Smart Modern Construction (c4SMC).

Institutional Review Board Statement

The study was conducted according to the guidelines of the National Statement on Ethical Conduct in Human Research 2007 (Updated 2018), Australia, and approved by the Western Sydney University Human Research Ethics Committee (H14101 and 13 November 2020).

Informed Consent Statement

Not applicable.

Data Availability Statement

Data supporting the findings in this study can be accessed through https://www.scopus.com/, https://www.webofscience.com/ and https://www.sciencedirect.com/ (accessed on 7 September 2021).

Acknowledgments

This study forms part of a large-scope study on digitally optimising energy consumption in buildings. The authors also admit that this study shares a similar background and methodology with other related papers but with different scopes and objectives. Finally, special appreciations also go to the Editors and anonymous Reviewers whose constructive and invaluable comments and suggestions enhanced the quality of this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modeling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Data for the Public Good. Available online: https://nic.org.uk/app/uploads/Data-for-the-Public-Good-NIC-Report.pdf (accessed on 20 November 2021).

- Ding, L.; Drogemuller, R. Towards sustainable facilities management. In Technology, Design and Process Innovation in the Built Environment; Spon Press: London, UK, 2009; pp. 399–418. [Google Scholar]

- Available online: https://www.gartner.com/smarterwithgartner/prepare-for-the-impact-of-digital-twins (accessed on 20 November 2021).

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.-A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Warke, V.; Kumar, S.; Bongale, A.; Kotecha, K. Sustainable Development of Smart Manufacturing Driven by the Digital Twin Framework: A Statistical Analysis. Sustainability 2021, 13, 10139. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Weyrich, M. Digital Twin of manufacturing systems: A case study on increasing the efficiency of reconfiguration. at-Automatisierungstechnik 2020, 68, 435–444. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect; Springer International Publishing: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Hribernik, K.A.; Rabe, L.; Thoben, K.-D.; Schumacher, J. The product avatar as a product-instance-centric information management concept. Int. J. Prod. Lifecycle Manag. 2006, 1, 367. [Google Scholar] [CrossRef]

- Kumar, S.; Patil, S.; Bongale, A.; Kotecha, K.; Bongale, A.K.M. Demystifying Artifificial Intelligence based Digital Twins in Manufacturing—A Bibliometric Analysis of Trends and Techniques. Libr. Philos. Pract. 2020, 2020, 1–21. [Google Scholar]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Cheung, W.-F. Developing WSN/BIM-Based Environmental Monitoring Management System for Parking Garages in Smart Cities. J. Manag. Eng. 2020, 36, 04020012. [Google Scholar] [CrossRef]

- CRC Construction. Adopting BIM for Facilities Management: Solutions for Managing the Sydney Opera House; Cooperative Research Center for Construction Innovation: Brisbane, Australia, 2007. [Google Scholar]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.; Tan, Y.; Wang, X. Literature Review of Digital Twins Applications in Construction Workforce Safety. Appl. Sci. 2021, 11, 339. [Google Scholar] [CrossRef]

- Ozturk, G.B. Digital Twin Research in the AECO-FM Industry. J. Build. Eng. 2021, 40, 102730. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Alshammari, K.; Beach, T.; Rezgui, Y. Cybersecurity for digital twins in the built environment: Current research and future directions. J. Inf. Technol. Constr. 2021, 26, 159–173. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Cent. Eng. 2020, 1. [Google Scholar] [CrossRef]

- Briner, R.B.; Denyer, D. Systematic review and evidence synthesis as a practice and scholarship tool. In Oxford Handbook of Evidence-Based Management; Rousseau, D.M., Ed.; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Chan, A.P.C.; Tetteh, M.O.; Nani, G. Drivers for international construction joint ventures adoption: A systematic literature review. Int. J. Constr. Manag. 2020, 1–13. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P.C. Review of studies on the Critical Success Factors for Public–Private Partnership (PPP) projects from 1990 to 2013. Int. J. Proj. Manag. 2015, 33, 1335–1346. [Google Scholar] [CrossRef]

- Tober, M. PubMed, ScienceDirect, Scopus or Google Scholar—Which is the best search engine for an effective literature research in laser medicine? Med. Laser Appl. 2011, 26, 139–144. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Grilo, A. Bibliometric analysis and review of Building Information Modelling literature published between 2005 and 2015. Autom. Constr. 2017, 80, 118–136. [Google Scholar] [CrossRef]

- Noor, B.A.; Yi, S. Review of BIM literature in construction industry and transportation: Meta-analysis. Constr. Innov. 2018, 18, 433–452. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Digital Twin and Web-Based Virtual Gaming Technologies for Online Education: A Case of Construction Management and Engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Porsani, G.B.; Del Valle de Lersundi, K.; Gutiérrez, A.S.-O.; Bandera, C.F. Interoperability between Building Information Modelling (BIM) and Building Energy Model (BEM). Appl. Sci. 2021, 11, 2167. [Google Scholar] [CrossRef]

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building Information Modelling and Internet of Things Integration for Facility Management—Literature Review and Future Needs. Appl. Sci. 2021, 11, 3062. [Google Scholar] [CrossRef]

- Coupry, C.; Noblecourt, S.; Richard, P.; Baudry, D.; Bigaud, D. BIM-Based Digital Twin and XR Devices to Improve Maintenance Procedures in Smart Buildings: A Literature Review. Appl. Sci. 2021, 11, 6810. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Love, P.E.D.; Matthews, J. The ‘how’ of benefits management for digital technology: From engineering to asset management. Autom. Constr. 2019, 107, 102930. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2020, 122, 103517. [Google Scholar] [CrossRef]

- Lu, Q.; Chen, L.; Li, S.; Pitt, M. Semi-automatic geometric digital twinning for existing buildings based on images and CAD drawings. Autom. Constr. 2020, 115, 103183. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Liang, C.-J.; Kamat, V.R.; Menassa, C.C. Teaching robots to perform quasi-repetitive construction tasks through human demonstration. Autom. Constr. 2020, 120, 103370. [Google Scholar] [CrossRef]

- Marocco, M.; Garofolo, I. Integrating disruptive technologies with facilities management: A literature review and future research directions. Autom. Constr. 2021, 131, 103917. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Yang, A.; Gao, J. Digital Twin-Based Ecogreen Building Design. Complexity 2021, 2021, 1391184. [Google Scholar] [CrossRef]

- Angjeliu, G.; Coronelli, D.; Cardani, G. Development of the simulation model for Digital Twin applications in historical masonry buildings: The integration between numerical and experimental reality. Comput. Struct. 2020, 238, 106282. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the void: Digital twins for construction site logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Al-Saeed, Y.; Edwards, D.J.; Scaysbrook, S. Automating construction manufacturing procedures using BIM digital objects (BDOs): Case study of knowledge transfer partnership project in UK. Constr. Innov. 2020, 20, 345–377. [Google Scholar] [CrossRef]

- Bosch-Sijtsema, P.; Claeson-Jonsson, C.; Johansson, M.; Roupe, M. The hype factor of digital technologies in AEC. Constr. Innov. 2021, 21, 899–916. [Google Scholar] [CrossRef]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Bass, B.; New, J.; Copeland, W. Potential Energy, Demand, Emissions, and Cost Savings Distributions for Buildings in a Utility’s Service Area. Energies 2021, 14, 132. [Google Scholar] [CrossRef]

- O’Grady, T.M.; Brajkovich, N.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Circular Economy and Virtual Reality in Advanced BIM-Based Prefabricated Construction. Energies 2021, 14, 4065. [Google Scholar] [CrossRef]

- Demianenko, M.; De Gaetani, C.I. A Procedure for Automating Energy Analyses in the BIM Context Exploiting Artificial Neural Networks and Transfer Learning Technique. Energies 2021, 14, 2956. [Google Scholar] [CrossRef]

- Lydon, G.P.; Caranovic, S.; Hischier, I.; Schlueter, A. Coupled simulation of thermally active building systems to support a digital twin. Energy Build. 2019, 202, 109298. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Ghobadi, M.; Shirowzhan, S.; Edwards, D.J.; Delzendeh, E. Metrics development and modelling the mixed reality and digital twin adoption in the context of Industry 4.0. Eng. Constr. Arch. Manag. 2021, 28, 1355–1376. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Xu, N. Digital Twin for Sustainability Evaluation of Railway Station Buildings. Front. Built Environ. 2018, 4, 77. [Google Scholar] [CrossRef] [Green Version]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven Metaphors to Understand Digital Twins of Built Assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. A Framework for Using Data as an Engineering Tool for Sustainable Cyber-Physical Systems. IEEE Access 2021, 9, 22876–22882. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, L.; Fu, C.; Chen, Y.-W. Transparent Digital Twin for Output Control Using Belief Rule Base. IEEE Trans. Cybern. 2021, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Trans. Ind. Inform. 2021, 17, 746–756. [Google Scholar] [CrossRef]

- Rausch, C.; Lu, R.; Talebi, S.; Haas, C. Deploying 3D scanning based geometric digital twins during fabrication and assembly in offsite manufacturing. Int. J. Constr. Manag. 2021. [Google Scholar] [CrossRef]

- Antonino, M.; Nicola, M.; Claudio, D.M.; Luciano, B.; Fulvio, R.C. Office building occupancy monitoring through image recognition sensors. Int. J. Saf. Secur. Eng. 2019, 9, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Xue, F.; Lu, W.; Chen, Z.; Webster, C.J. From LiDAR point cloud towards digital twin city: Clustering city objects based on Gestalt principles. ISPRS J. Photogramm. Remote Sens. 2020, 167, 418–431. [Google Scholar] [CrossRef]

- Meža, S.; Mauko Pranjić, A.; Vezočnik, R.; Osmokrović, I.; Lenart, S. Digital Twins and Road Construction Using Secondary Raw Materials. J. Adv. Transp. 2021, 2021, 8833058. [Google Scholar] [CrossRef]

- Oliveira, P.P. Digital twin development for airport management. J. Airpt. Manag. 2020, 14, 246–259. [Google Scholar]

- Hasan, S.M.; Lee, K.; Moon, D.; Kwon, S.; Jinwoo, S.; Lee, S. Augmented reality and digital twin system for interaction with construction machinery. J. Asian Arch. Build. Eng. 2021. [Google Scholar] [CrossRef]

- Tran, H.; Nguyen, T.N.; Christopher, P.; Bui, D.-K.; Khoshelham, K.; Ngo, T.D. A digital twin approach for geometric quality assessment of as-built prefabricated façades. J. Build. Eng. 2021, 41, 102377. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. J. Clean. Prod. 2021, 278, 123505. [Google Scholar] [CrossRef]

- Züst, S.; Züst, R.; Züst, V.; West, S.; Stoll, O.; Minonne, C. A graph based Monte Carlo simulation supporting a digital twin for the curatorial management of excavation and demolition material flows. J. Clean. Prod. 2021, 310, 127453. [Google Scholar] [CrossRef]

- Babalola, A.; Musa, S.; Akinlolu, M.T.; Haupt, T.C. A bibliometric review of advances in building information modeling (BIM) research. J. Eng. Des. Technol. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Akanmu, A.A.; Anumba, C.J.; Ogunseiju, O.O. Towards next generation cyber-physical systems and digital twins for construction. J. Inf. Technol. Constr. 2021, 26, 505–525. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Don Ranasinghe, G.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a Digital Twin at Building and City Levels: Case Study of West Cambridge Campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Steyn, W.J.V.D.M.; Broekman, A. Development of a Digital Twin of a Local Road Network: A Case Study. J. Test. Eval. 2021, 51. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, X.; Xing, Z.; Jiang, A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors 2021, 21, 3583. [Google Scholar] [CrossRef]

- Ogunseiju, O.R.; Olayiwola, J.; Akanmu, A.A.; Nnaji, C. Digital twin-driven framework for improving self-management of ergonomic risks. Smart Sustain. Built Environ. 2021, 10, 403–419. [Google Scholar] [CrossRef]

- Shim, C.-S.; Dang, N.-S.; Lon, S.; Jeon, C.-H. Development of a bridge maintenance system for prestressed concrete bridges using 3D digital twin model. Struct. Infrastruct. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Omer, M.; Margetts, L.; Hadi Mosleh, M.; Hewitt, S.; Parwaiz, M. Use of gaming technology to bring bridge inspection to the office. Struct. Infrastruct. Eng. 2019, 15, 1292–1307. [Google Scholar] [CrossRef] [Green Version]

- Kaewunruen, S.; Peng, S.; Phil-Ebosie, O. Digital Twin Aided Sustainability and Vulnerability Audit for Subway Stations. Sustainability 2020, 12, 7873. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean Practices Using Building Information Modeling (BIM) and Digital Twinning for Sustainable Construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Ma, W.; Phil-Ebosie, O. Digital Twin Aided Vulnerability Assessment and Risk-Based Maintenance Planning of Bridge Infrastructures Exposed to Extreme Conditions. Sustainability 2021, 13, 2051. [Google Scholar] [CrossRef]

- Zhang, Q.; Oo, B.L.; Lim, B.T.H. Drivers, motivations, and barriers to the implementation of corporate social responsibility practices by construction enterprises: A review. J. Clean. Prod. 2019, 210, 563–584. [Google Scholar] [CrossRef]

- Drisko, J.W.; Maschi, T. Content analysis. In Pocket Guides to Social Work R; Oxford University Press: New York, NY, USA, 2016. [Google Scholar]

- Assarroudi, A.; Heshmati Nabavi, F.; Armat, M.R.; Ebadi, A.; Vaismoradi, M. Directed qualitative content analysis: The description and elaboration of its underpinning methods and data analysis process. J. Res. Nurs. 2018, 23, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manufac. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Available online: https://www.cdbb.cam.ac.uk/what-we-do/national-digital-twin-programme (accessed on 5 December 2021).

- Guo, H.L.; Li, H.; Skitmore, M. Life-Cycle Management of Construction Projects Based on Virtual Prototyping Technology. J. Manag. Eng. 2010, 26, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Ghobadi, S. What drives knowledge sharing in software development teams: A literature review and classification framework. Inf. Manag. 2015, 52, 82–97. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Mousavi, V.; Karami, A.; Yu, Y.; Samali, B. Quality Evaluation of Digital Twins Generated Based on UAV Photogrammetry and TLS: Bridge Case Study. Remote Sens. 2021, 13, 3499. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef] [Green Version]

- Macchi, M.; Roda, I.; Negri, E.; Fumagalli, L. Exploring the role of Digital Twin for Asset Lifecycle Management. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- D’Addona, D.M.; Ullah, A.S.; Matarazzo, D. Tool-wear prediction and pattern-recognition using artificial neural network and DNA-based computing. J. Intell. Manufac. 2015, 28, 1285–1301. [Google Scholar] [CrossRef]

- Jouan, P.; Hallot, P. Digital Twin: Research Framework to Support Preventive Conservation Policies. ISPRS Int. J. Geo-Inf. 2020, 9, 228. [Google Scholar] [CrossRef] [Green Version]

- Göçer, Ö.; Hua, Y.; Göçer, K. A BIM-GIS integrated pre-retrofit model for building data mapping. Build. Simul. 2016, 9, 513–527. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.H. Lessons learned from the Existing Building Energy Optimization workshop: An initiative for the analysis-driven retrofit decision making. KSCE J. Civ. Eng. 2017, 21, 1059–1068. [Google Scholar] [CrossRef]

- Agarwal, R.; Chandrasekaran, S.; Sridhar, M. Imagining Construction’s Digital Future; McKinsey & Company: Mumbai, India, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).