Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis

Abstract

:1. Introduction

2. Literature Review

2.1. Construction 4.0 Technologies

2.2. Decision-Making in Construction

3. Materials and Methods

Thematic Analysis

4. Results

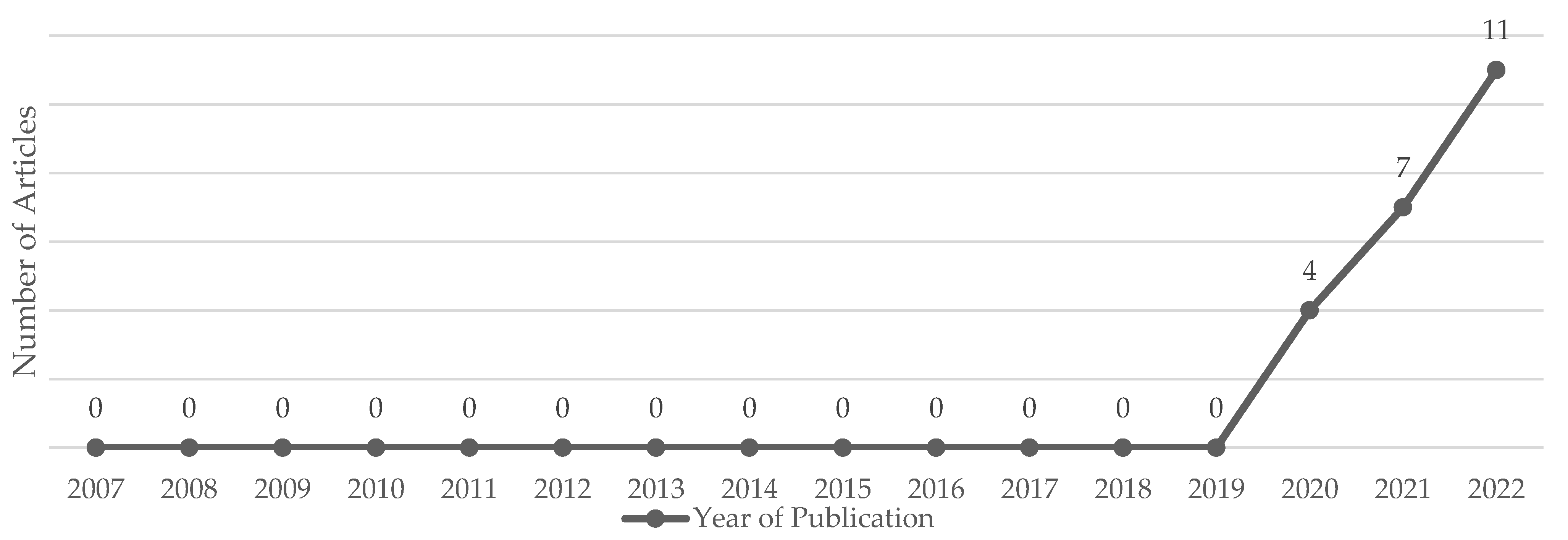

4.1. Overview of the Existing Research

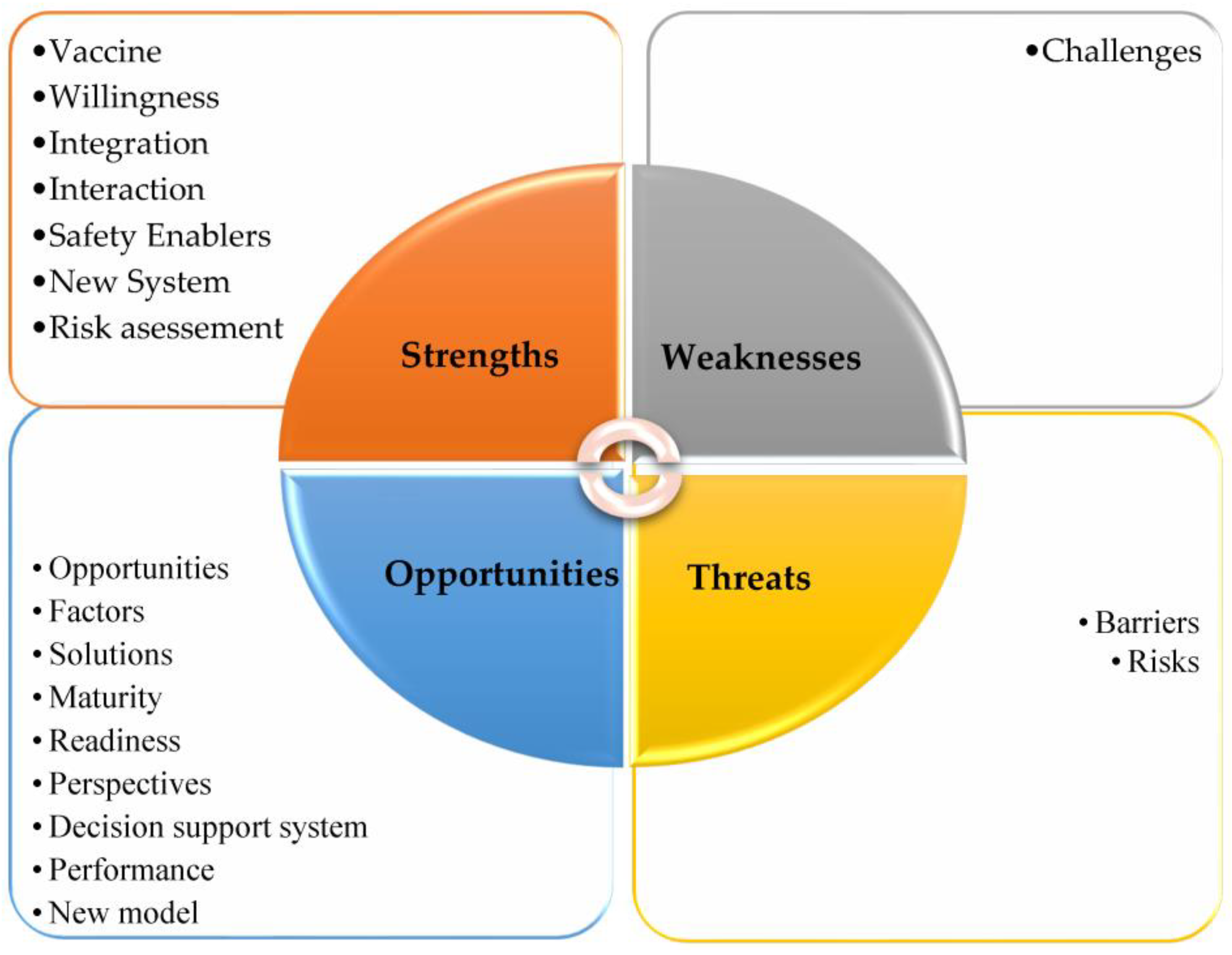

4.2. Thematic Analysis

4.2.1. Strengths

4.2.2. Weaknesses

4.2.3. Opportunities

4.2.4. Threats

5. Discussion

5.1. Characteristics of the Existing Research

5.2. Existing Research Areas, Limitations, and Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajab, I.A.A.; Ishak, H.; Ishak, M.; Rajab, R.S. Is It the Dawn of Industrial Revolution 4.0 in Malaysia. myForesight 2016, 2012, 1–44. [Google Scholar]

- WEF. Shaping the Future of Construction a Breakthrough in Mindset and Technology; World Economic Forum: Cologny, Switzerland, 2016. [Google Scholar]

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A. Construction 4.0: The Future of the Construction Industry in South Africa. Civ. Environ. Eng. 2018, 12, 206–212. [Google Scholar]

- Aripin, I.D.M.; Marinie, E.A.Z.; Ismail, Z. Factors Influencing the Implementation of Technologies Behind Industry 4.0 in the Malaysian Construction Industry. In Proceedings of the International Conference on Built Environment and Engineering 2018—“Enhancing Construction Industry Through IR4.0”, Johor, Malaysia, 29–30 October 2018; Volume 6, pp. 6–11. [Google Scholar]

- Kaufmann, D.; Ruaux, X.; Jacob, M. Digitalization of the Construction Industry: The Revolution is Underway; Oliver Wyman: New York, NY, USA, 2018. [Google Scholar]

- Goi, C.-L. The Impact of Technological Innovation on Building a Sustainable City. Int. J. Qual. Innov. 2017, 3, 6. [Google Scholar] [CrossRef] [Green Version]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef] [Green Version]

- Yap, J.B.H.; Lee, K.P.H.; Wang, C. Safety enablers using emerging technologies in construction projects: Empirical study in Malaysia. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Costin, A.; Kibert, C.; Fu, M. A systematic review of emerging technologies in industrialized construction. J. Build. Eng. 2021, 39, 102265. [Google Scholar] [CrossRef]

- Statsenko, L.; Samaraweera, A.; Bakhshi, J.; Chileshe, N. Construction 4.0 technologies and applications: A systematic literature review of trends and potential areas for development. Constr. Innov. 2022. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in off-site construction: Current status and future direction towards industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Wang, K.; Guo, F.; Zhang, C.; Hao, J.; Schaefer, D. Digital Technology in Architecture, Engineering, and Construction (AEC) Industry: Research Trends and Practical Status toward Construction 4.0. In Proceedings of the Construction Research Congress 2022, Arlington, VA, USA, 9–12 March 2022; pp. 983–992. [Google Scholar] [CrossRef]

- Moshood, T.D.; Adeleke, A.Q.; Nawanir, G.; Ajibike, W.A.; Shittu, R.A. Emerging Challenges and Sustainability of Industry 4.0 Era in the Malaysian Construction Industry. Int. J. Recent Technol. Eng. 2020, 9, 1627–1634. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A proposed framework for Construction 4.0 based on a review of literature. EPiC Ser. Built Environ. 2020, 1, 301–309. [Google Scholar] [CrossRef]

- Wan Mohammad, W.N.S.; Abdullah, M.R.; Ismail, S.; Takim, R. Overview of Building Information Modelling (BIM) adoption factors for construction organisations. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012107. [Google Scholar] [CrossRef]

- CIDB. Construction 4.0 Strategic Plan (2021–2025); CIDB: Kuala Lumpur, Malaysia, 2021.

- Lecat, A. Hot Trends in Construction—A New Era of Opportunities; Roland Berger: Paris, France, 2018. [Google Scholar]

- Gerber, D.; Nguyen, B. Blockchain Technology Timeline: Case Studies in the Built Environment; Arup: London, UK, 2019. [Google Scholar]

- Lu, C.; Liu, J.; Liu, Y.; Liu, Y. Intelligent construction technology of railway engineering in China. Front. Eng. Manag. 2019, 6, 503–516. [Google Scholar] [CrossRef]

- Agarwal, R.; Chandrasekaran, S.; Sridhar, M. The Digital Future of Construction; McKinsey & Company: Singapore, 2016. [Google Scholar]

- Gerbert, P.; Castagnino, S.; Rothballer, C.; Renz, A.; Filitz, R. Digital in Engineering and Construction—The Transformative Power of Building Information Modelling; Boston Consulting Group: Boston, MA, USA, 2016. [Google Scholar]

- Choudhary, A.; Dogne, N. Smart Construction Materials and Techniques. In Proceedings of the National Conference on Alternative & Innovation Construction Materials & Techniques; s TEQIP-II/Civil/AICMT-3; e-Proceeding: MITS under TEQIP-II, Gwalior, India, August 2014; pp. 12–16. [Google Scholar]

- Elbanna, S. Decision Making. In The SAGE Encyclopedia of Political Behavior; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2017; pp. 163–166. [Google Scholar]

- Liu, B.; Huo, T.; Liang, Y.; Sun, Y.; Hu, X. Key Factors of Project Characteristics Affecting Project Delivery System Decision Making in the Chinese Construction Industry: Case Study Using Chinese Data Based on Rough Set Theory. J. Prof. Issues Eng. Educ. Pract. 2016, 142, 05016003. [Google Scholar] [CrossRef]

- Esa, M.; Alias, A.; Abdul-samad, Z. Project Managers′ Cognitive Style in Decision Making: A Perspective from Construction Industry. Int. J. Psychol. Stud. 2014, 6, 65–73. [Google Scholar] [CrossRef] [Green Version]

- Zhong, S.; Elhegazy, H.; Elzarka, H. Key factors affecting the decision-making process for buildings projects in Egypt. Ain Shams Eng. J. 2022, 13, 101597. [Google Scholar] [CrossRef]

- Szafranko, E. Decision problems in management of construction projects. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012048. [Google Scholar] [CrossRef]

- Bakht, M.N.; El-Diraby, T.E.M. ASCE Synthesis of Decision-Making Research in Construction. J. Constr. Eng. Manag. 2015, 141, 04015027. [Google Scholar] [CrossRef]

- Lee, Z.P.; Rahman, R.A.; Doh, S.I. Application of decision support tool in design-build projects: A quasi-experiment with novice decision makers. Built Environ. Proj. Asset Manag. 2022, 12, 537–555. [Google Scholar] [CrossRef]

- Lamé, G. Systematic Literature Reviews: An Introduction. In Proceedings of the 22nd International Conference on Engineering Design (ICED19), Delf, The Netherlands, 5–8 August 2019. [Google Scholar]

- Page, M.J.; Mckenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews Systematic reviews and Meta-Analyses. BMJ 2021, 372, 89. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Reprint-Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. BMJ Phys. Ther. 2009, 89, 873–880. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015: Elaboration and explanation. BMJ 2015, 349, g7647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Sytematic Rev. 2015, 4, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Chang-richards, A.Y.; Pelosi, A.; Yang, N. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Archit. Manag. 2021, 29, 3181–3209. [Google Scholar] [CrossRef]

- Shahruddin, S.; Zairul, M. BIM Requirements across a Construction Project Lifecycle: A PRISMA-Compliant Systematic Review and Meta-Analysis. Int. J. Innov. Creat. Chang. 2020, 12, 569–590. [Google Scholar]

- Regona, M.; Yigitcanlar, T.; Xia, B. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Hong, Y.; Chan, D.W.M. Research trend of joint ventures in construction: A two-decade taxonomic review. J. Facil. Manag. 2014, 12, 118–141. [Google Scholar] [CrossRef] [Green Version]

- Radzi, A.R.; Rahman, R.A.; Doh, S.I. Decision making in highway construction: A systematic review and future directions. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Ghaleb, H.; Alhajlah, H.H.; Bin Abdullah, A.A.; Kassem, M.A.; Al-Sharafi, M.A. A Scientometric Analysis and Systematic Literature Review for Construction Project Complexity. Buildings 2022, 12, 482. [Google Scholar] [CrossRef]

- Li, S.; Fang, Y.; Wu, X. A systematic review of lean construction in Mainland China. J. Clean. Prod. 2020, 257, 120581. [Google Scholar] [CrossRef]

- Palmatier, R.W.; Houston, M.B.; Hulland, J. Review articles: Purpose, process, and structure. J. Acad. Mark. Sci. 2018, 46, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry: Review of Management Perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef]

- Franco, B.; Domingues, A.M.; Africano, N.D.A.; Deus, R.M.; Aparecida, R.; Battistelle, G. Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities. Infrastructures 2022, 7, 43. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction Industry 4.0 and Sustainability: An Enabling Framework. IEEE Trans. Eng. Manag. 2021, 1–19. [Google Scholar] [CrossRef]

- Boton, C.; Rivest, L.; Ghnaya, O.; Chouchen, M. What is at the Root of Construction 4.0: A Systematic Review of the Recent Research Effort. Arch. Comput. Methods Eng. 2021, 28, 2331–2350. [Google Scholar] [CrossRef]

- Hindiyeh, R.I.; Ocloo, W.K.; Cross, J.A. Systematic Review of Research Trends in Engineering Team Performance. EMJ—Eng. Manag. J. 2022, 1–25. [Google Scholar] [CrossRef]

- Farouk, A.M.; Rahman, R.A.; Romali, N.S. Non-revenue water reduction strategies: A systematic review. Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Rani, H.A.; Farouk, A.M.; Anandh, K.S.; Almutairi, S.; Rahman, R.A. Impact of COVID-19 on Construction Projects: The Case of India. Buildings 2022, 12, 762. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Thwala, W.D.D.; Molusiwa, R. Modelling construction 4.0 as a vaccine for ensuring construction supply chain resilience amid COVID-19 pandemic. J. Eng. Des. Technol. 2022, 20, 132–158. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Emmanuel Oke, A.; Liphadzi, M. Appraisal of stakeholders’ willingness to adopt construction 4.0 technologies for construction projects. Built Environ. Proj. Asset Manag. 2020, 10, 547–565. [Google Scholar] [CrossRef]

- Kor, M.; Yitmen, I.; Alizadehsalehi, S. An investigation for integration of deep learning and digital twins towards Construction 4.0. Smart Sustain. Built Environ. 2022. [Google Scholar] [CrossRef]

- Bayhan, H.G.; Demirkesen, S.; Zhang, C.; Tezel, A. A lean construction and BIM interaction model for the construction industry. Prod. Plan. Control 2021, 1–28. [Google Scholar] [CrossRef]

- Wang, N.; Issa, R.R.A.; Anumba, C.J. NLP-based query-answering system for information extraction from building information models. J. Comput. Civ. Eng. 2022, 36, 04022004. [Google Scholar] [CrossRef]

- Sadeghi, M.; Mahmoudi, A.; Deng, X. Blockchain technology in construction organizations: Risk assessment using trapezoidal fuzzy ordinal priority approach. Eng. Constr. Archit. Manag. 2022. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef]

- Amade, B.; Nwakanma, C.I. Identifying Challenges of Internet of Things on Construction Projects Using Fuzzy Approach. J. Eng. Proj. Prod. Manag. 2021, 11, 215–227. [Google Scholar] [CrossRef]

- Nagy, O.; Papp, I.; Szabó, R.Z. Construction 4.0 organisational level challenges and solutions. Sustainability 2021, 13, 12312. [Google Scholar] [CrossRef]

- Bademosi, F.; Issa, R.R.A. Factors Influencing Adoption and Integration of Construction Robotics and Automation Technology in the US. J. Constr. Eng. Manag. 2021, 147, 04021075. [Google Scholar] [CrossRef]

- Law, K.K.; Chang, S.; Siu, M.-F.F. Factors Influencing Adoption of Construction Robotics in Hong Kong’s Industry: A Multistakeholder Perspective. J. Manag. Eng. 2022, 38, 04021096. [Google Scholar] [CrossRef]

- Razkenari, M.; Kibert, C.J. A Framework for Assessing Maturity and Readiness Towards Industrialized Construction. J. Archit. Eng. 2022, 28, 04022003. [Google Scholar] [CrossRef]

- Mansour, H.; Aminudin, E.; Mansour, T. Implementing industry 4.0 in the construction industry- strategic readiness perspective. Int. J. Constr. Manag. 2021, 1–14. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Li, J.; Costin, A.; Kibert, C.; Qian, S. Investigating U.S. industry practitioners’ perspectives towards the adoption of emerging technologies in industrialized construction. Buildings 2020, 10, 85. [Google Scholar] [CrossRef]

- Afolabi, A.O.; Nnaji, C.; Okoro, C. Immersive Technology Implementation in the Construction Industry: Modeling Paths of Risk. Buildings 2022, 12, 363. [Google Scholar] [CrossRef]

- Hussain, A.H.; Alam, M.R.A.; Eni, S.; Ani, A.I.C.; Roslan, A.F. Assessing the organisations decision for digital transformation through BIM implementation in Malaysia. MCRJ Spec. Issue 2020, 11, 16–33. [Google Scholar]

- Mahmoudi, A.; Sadeghi, M.; Deng, X. Performance measurement of construction suppliers under localization, agility, and digitalization criteria: Fuzzy Ordinal Priority Approach. Environ. Dev. Sustain. 2022, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.; Parente, M.; Moutinho, J.; Sampaio, M. Fuel consumption prediction for construction trucks: A noninvasive approach using dedicated sensors and machine learning. Infrastructures 2021, 6, 157. [Google Scholar] [CrossRef]

- Sadeghi, M.; Mahmoudi, A.; Deng, X. Adopting distributed ledger technology for the sustainable construction industry: Evaluating the barriers using Ordinal Priority Approach. Environ. Sci. Pollut. Res. 2022, 29, 10495–10520. [Google Scholar] [CrossRef] [PubMed]

- Yap, J.B.H.; Lam, C.G.Y.; Skitmore, M.; Talebian, N. Barriers To the Adoption of New Safety Technologies in Construction: A Developing Country Context. J. Civ. Eng. Manag. 2022, 28, 120–133. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Digital technology utilisation decisions for facilitating the implementation of Industry 4.0 technologies. Constr. Innov. 2020, 21, 476–489. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Adepoju, O.O.; Aigbavboa, C.O. Assessing knowledge and skills gap for construction 4.0 in a developing economy. J. Public Aff. 2021, 21, e2264. [Google Scholar] [CrossRef]

- Yang, K.; Sunindijo, R.Y.; Wang, C.C. Identifying Leadership Competencies for Construction 4.0. Buildings 2022, 12, 1434. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Ibrahim, F.S.; Esa, M.; Rahman, R.A. The Adoption of Iot in the Malaysian Construction Industry: Towards construction 4.0. Int.J. Sustain. Constr. Eng. Technol. 2021, 12, 56–67. [Google Scholar] [CrossRef]

| Journal Title | No. of Articles | Source |

|---|---|---|

| Journal of Engineering, Design, and Technology | 2 | [51,52] |

| Built Environment Project and Asset Management | 1 | [53] |

| Innovative and Sustainable Built Environment | 1 | [54] |

| Production Planning and Control | 1 | [55] |

| Journal of Computing in Civil Engineering | 1 | [56] |

| Engineering, Construction, and Architectural Management | 1 | [57] |

| International Journal of Environmental Research and Public Health | 1 | [58] |

| Sustainability (Switzerland) | 1 | [59] |

| Journal of Engineering, Project, and Production Management | 1 | [60] |

| Journal of Construction Engineering and Management | 1 | [61] |

| Journal of Management in Engineering | 1 | [62] |

| Journal of Architectural Engineering | 1 | [63] |

| International Journal of Construction Management | 1 | [64] |

| Buildings | 2 | [65,66] |

| Malaysian Construction Research Journal | 1 | [67] |

| Environment, Development, and Sustainability | 1 | [68] |

| Infrastructures | 1 | [69] |

| Environmental Science and Pollution Research | 1 | [70] |

| Journal of Civil Engineering and Management | 1 | [71] |

| Source | Purpose | Area | Subtheme | Theme |

|---|---|---|---|---|

| [52] | Modeling technologies | Decision process | Vaccine | Strength |

| [53] | Adoption technologies | Decision process | Willingness | |

| [54] | Investigation technologies | Integrated technologies | Integration | |

| [55] | Synergy | Integrated technologies | Interaction | |

| [51] | Adoption technologies | Integrated technologies | Safety enablers | |

| [56] | Virtual systems | One technology | New system | |

| [57] | Management frameworks | One technology | Risk assessment | |

| [58] | Implementation technologies | Key factor | Challenges | Weaknesses |

| [59] | Implementation technologies | Key factor | Challenges | |

| [60] | Implementation technologies | Key factor | Challenges | |

| [58] | Implementation technologies | Key factor | Opportunities | Opportunities |

| [61] | Adoption technologies | Key factor | Factors | |

| [62] | Adoption technologies | Key factor | Factors | |

| [59] | Implementation technologies | Key factor | Solutions | |

| [63] | Adoption technologies | Decision process | Maturity | |

| [63] | Adoption technologies | Decision process | Readiness | |

| [64] | Implementation technologies | Decision support tool | Readiness | |

| [65] | Adoption technologies | Key factor | Perspectives | |

| [67] | Implementation technologies | Decision process | Decision | |

| [72] | Implementation technologies | Decision support tool | Decision | |

| [68] | Criteria measurement | Integrated technologies | Performance | |

| [69] | Implementation technologies | One technology | Prediction | |

| [70] | Adoption technologies | Key factor | Barriers | Threats |

| [71] | Adoption technologies | Key factor | Risk | |

| [66] | Adoption technologies | Key factor | Barriers |

| Theme | Subtheme | Research Limitation | Future Research Direction |

|---|---|---|---|

| Strength |

|

|

|

| Weaknesses |

|

|

|

| Opportunities |

|

|

|

| Threats |

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafei, H.; Radzi, A.R.; Algahtany, M.; Rahman, R.A. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings 2022, 12, 2206. https://doi.org/10.3390/buildings12122206

Shafei H, Radzi AR, Algahtany M, Rahman RA. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings. 2022; 12(12):2206. https://doi.org/10.3390/buildings12122206

Chicago/Turabian StyleShafei, Hazwani, Afiqah R. Radzi, Mohammed Algahtany, and Rahimi A. Rahman. 2022. "Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis" Buildings 12, no. 12: 2206. https://doi.org/10.3390/buildings12122206

APA StyleShafei, H., Radzi, A. R., Algahtany, M., & Rahman, R. A. (2022). Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings, 12(12), 2206. https://doi.org/10.3390/buildings12122206