Architectural Formation of Growable Light Steel Structure and Its 3D Visualisation Design and Construction Method

Abstract

1. Introduction

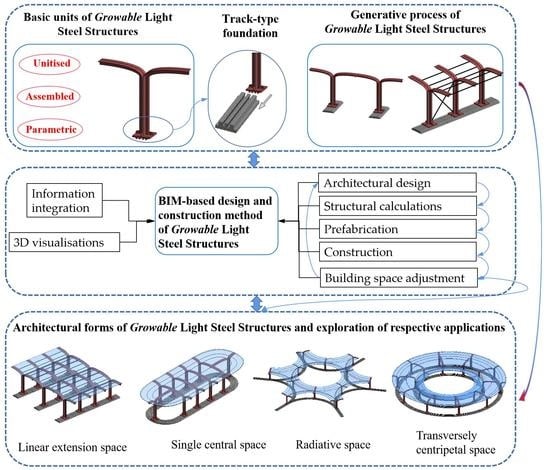

2. Characteristics of the Proposed Novel Type of Growable Light Steel Structure

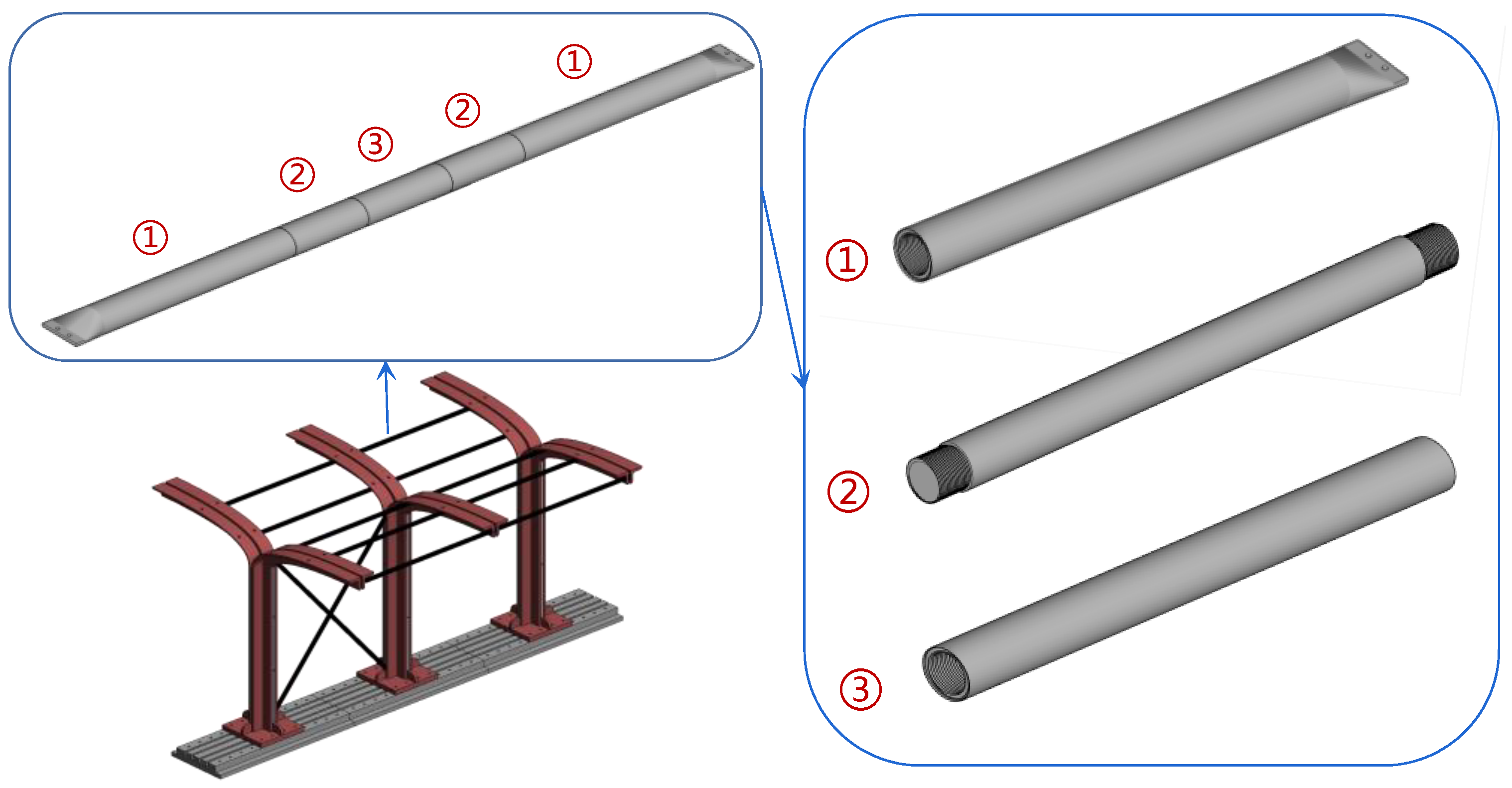

2.1. Proposed Basic Units of Growable Light Steel Structures

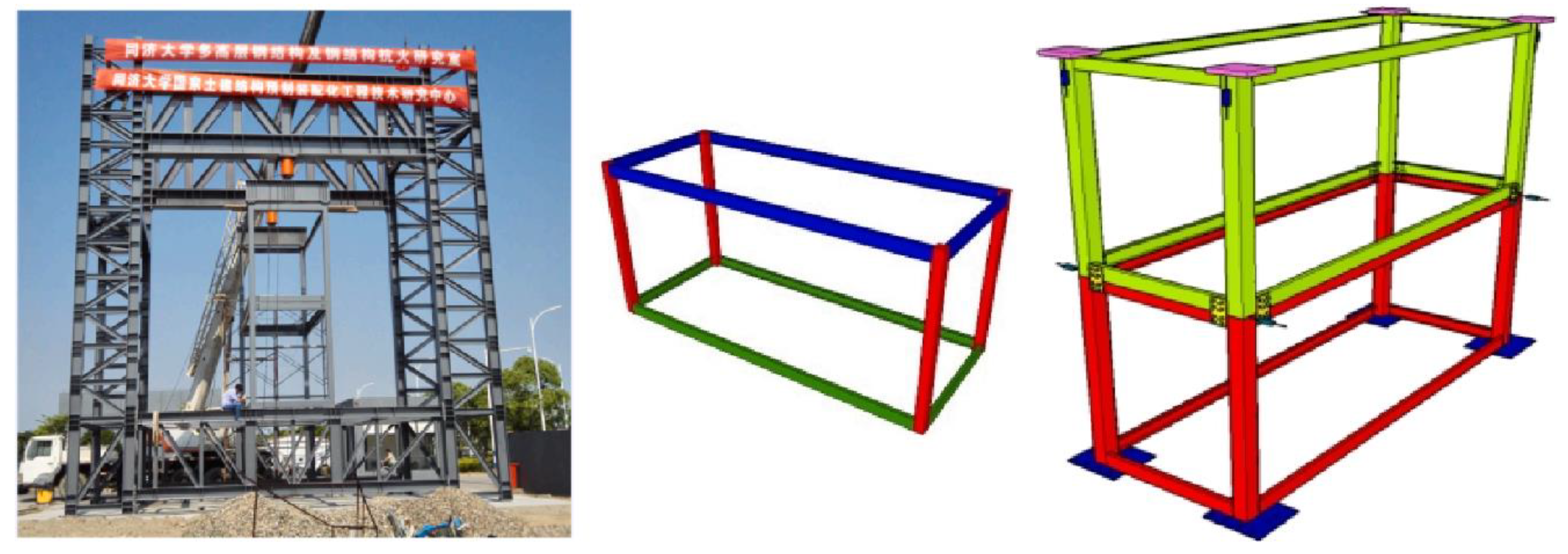

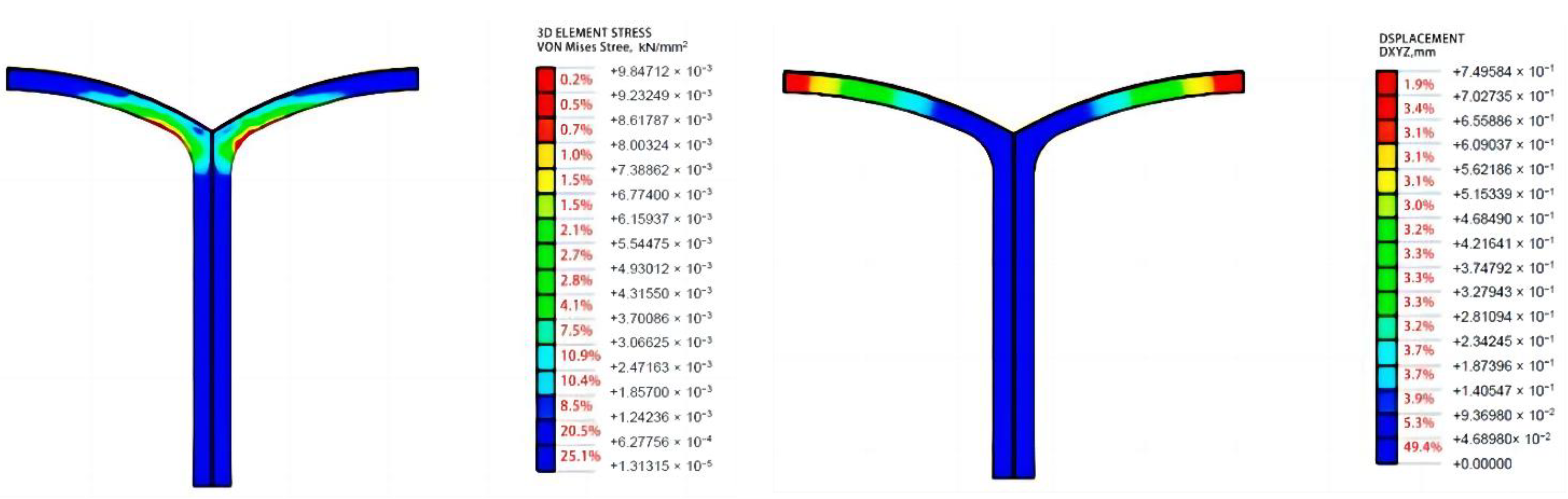

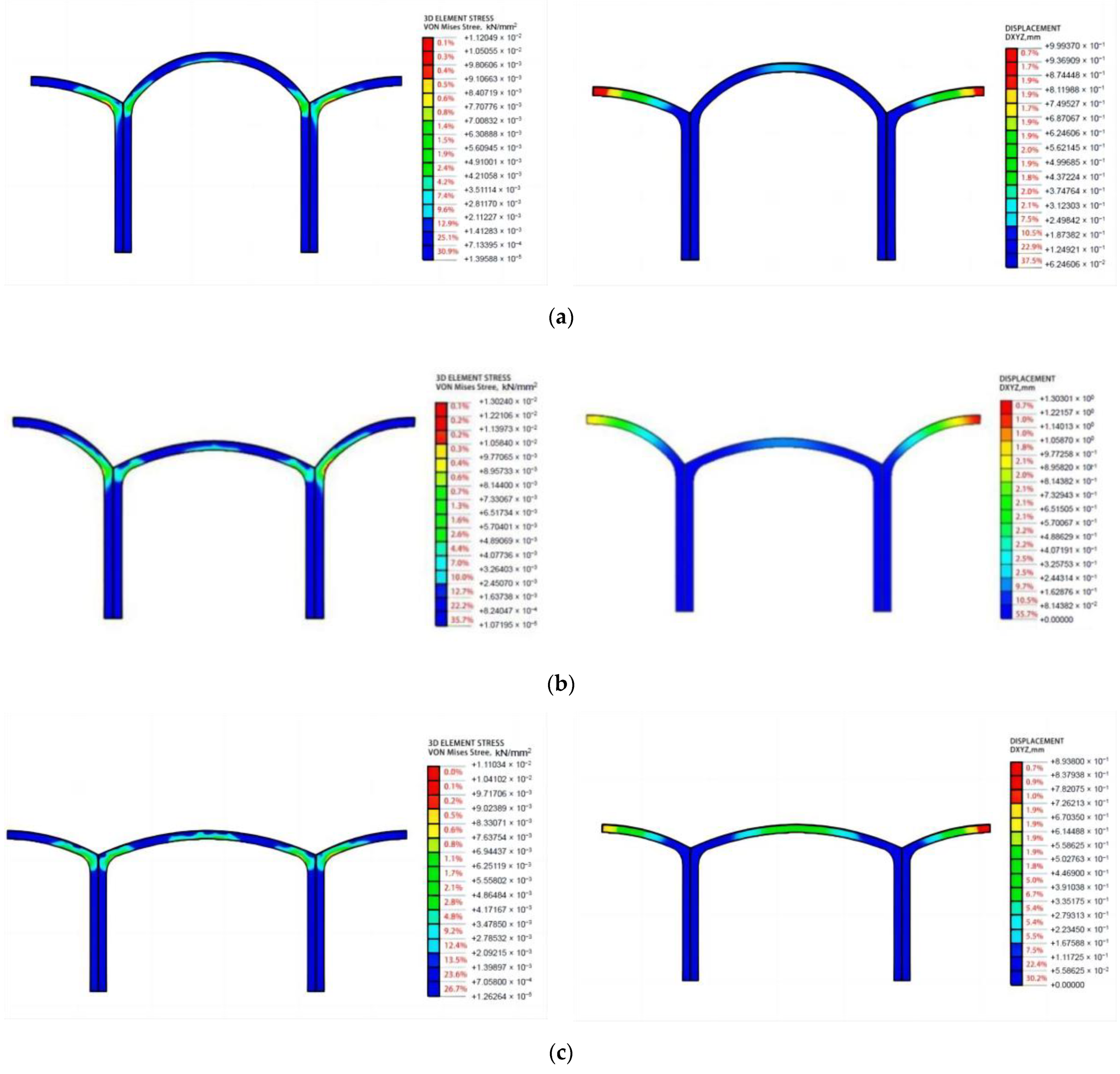

2.2. Characteristics of Basic Units of Growable Light Steel Structure

3. Architectural Formation of Growable Light Steel Structures

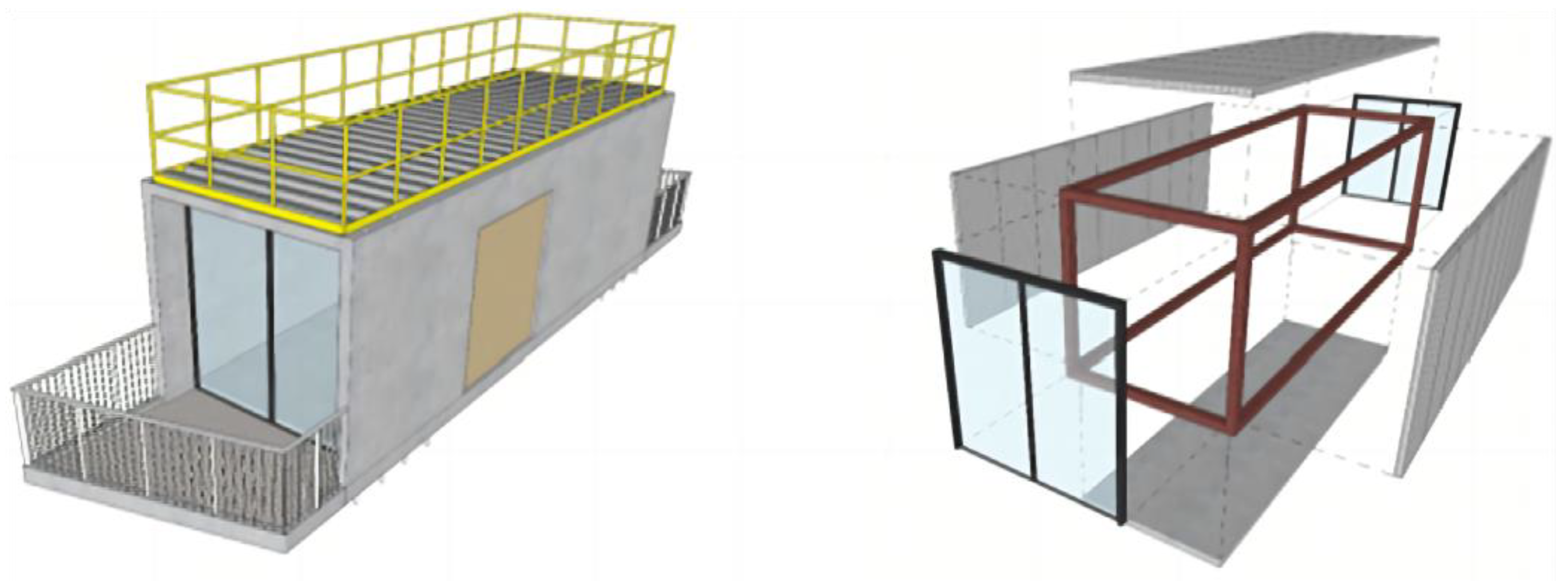

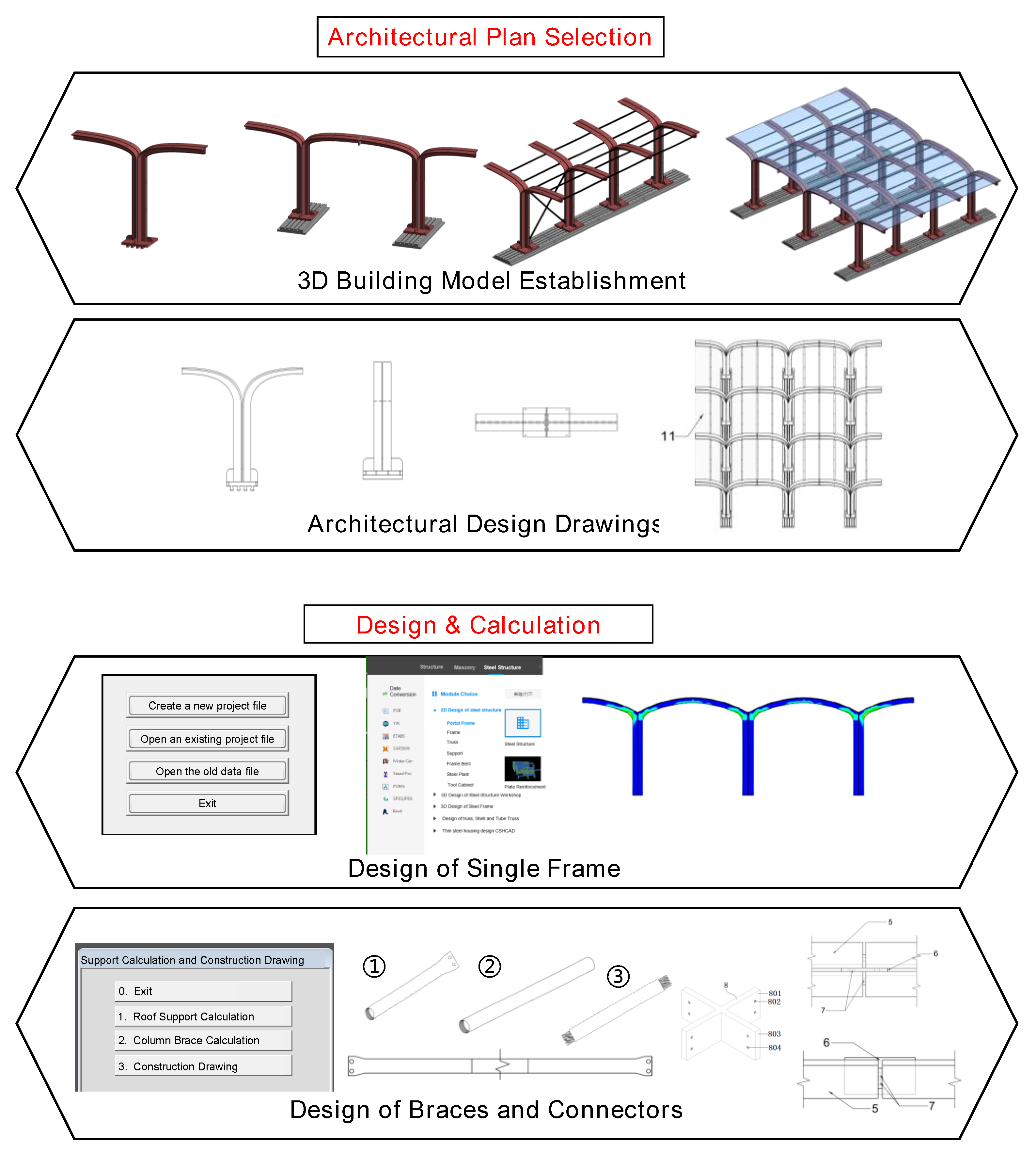

3.1. Superstructure of the Growable Light Steel Building

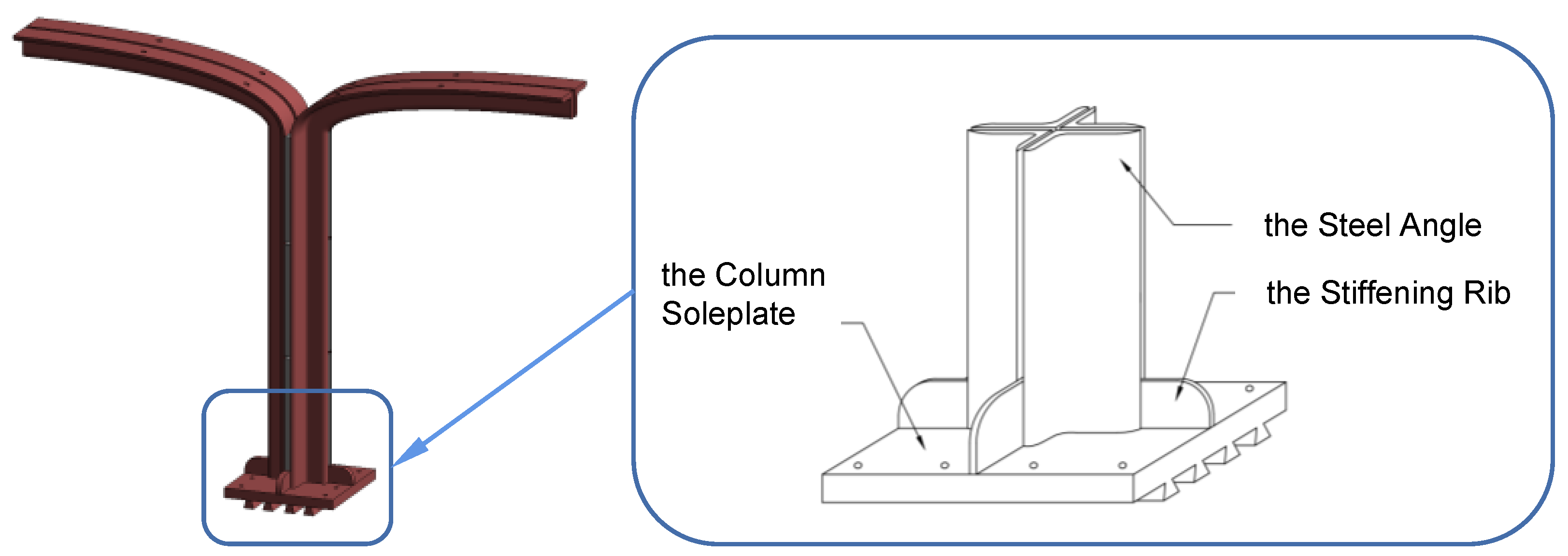

3.2. Foundation of the Growable Light Steel Structure

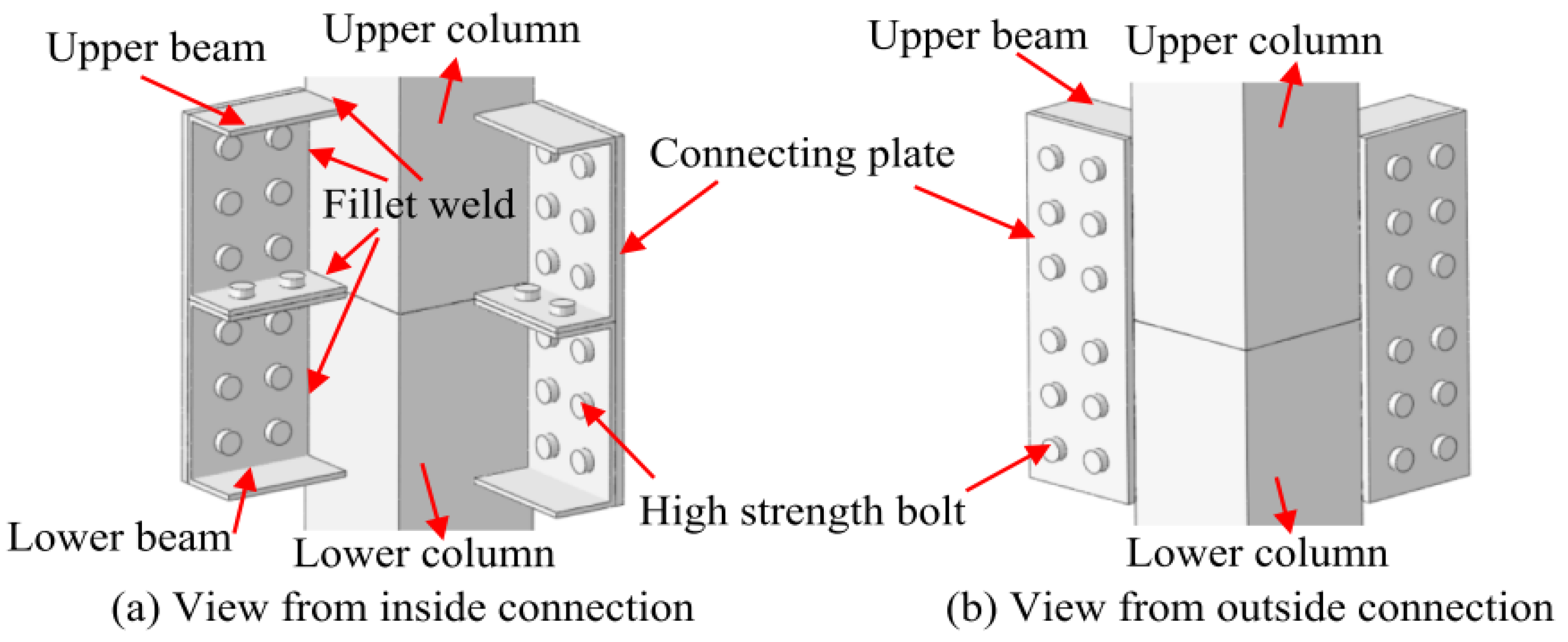

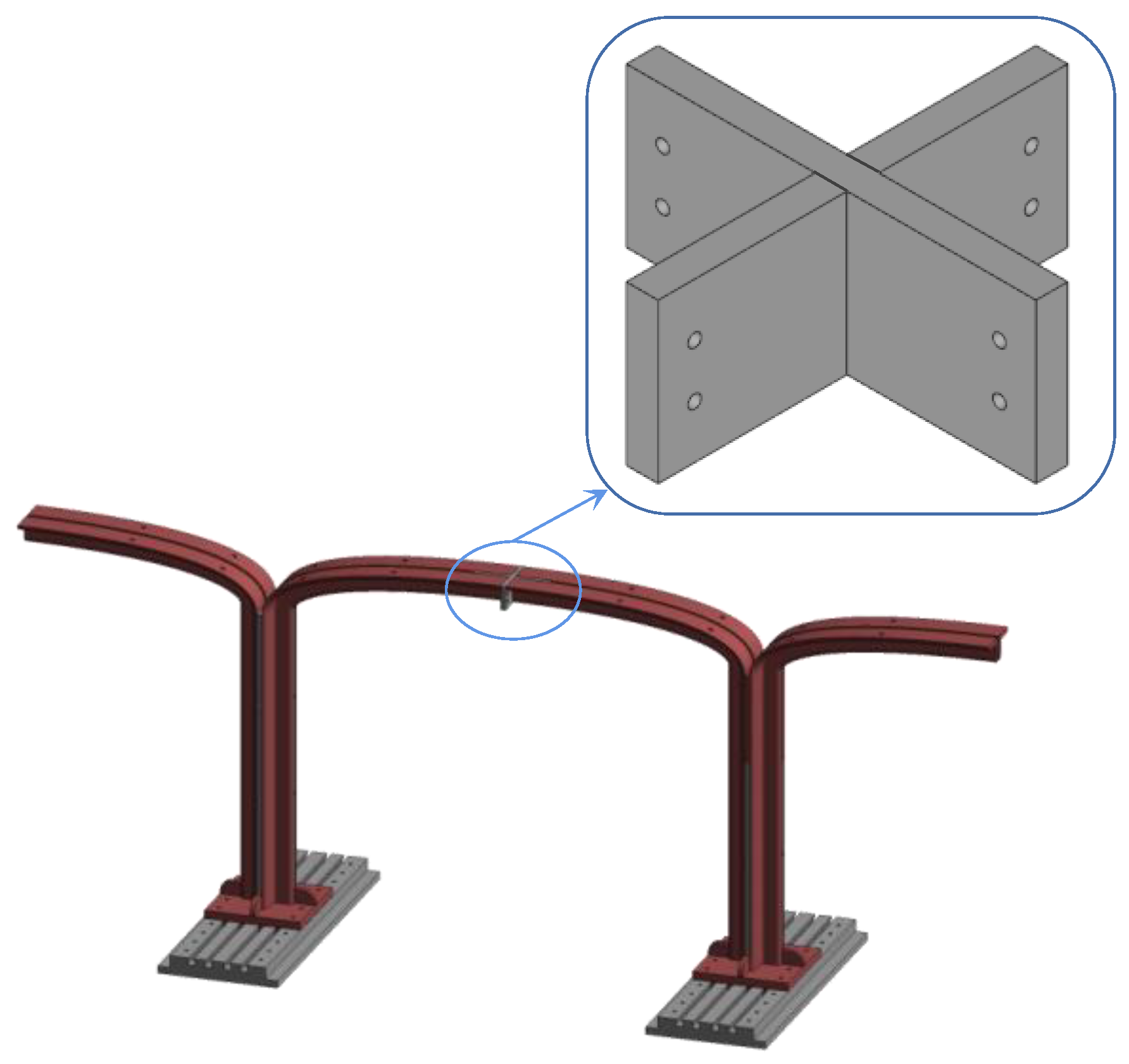

3.3. Braces and Connections

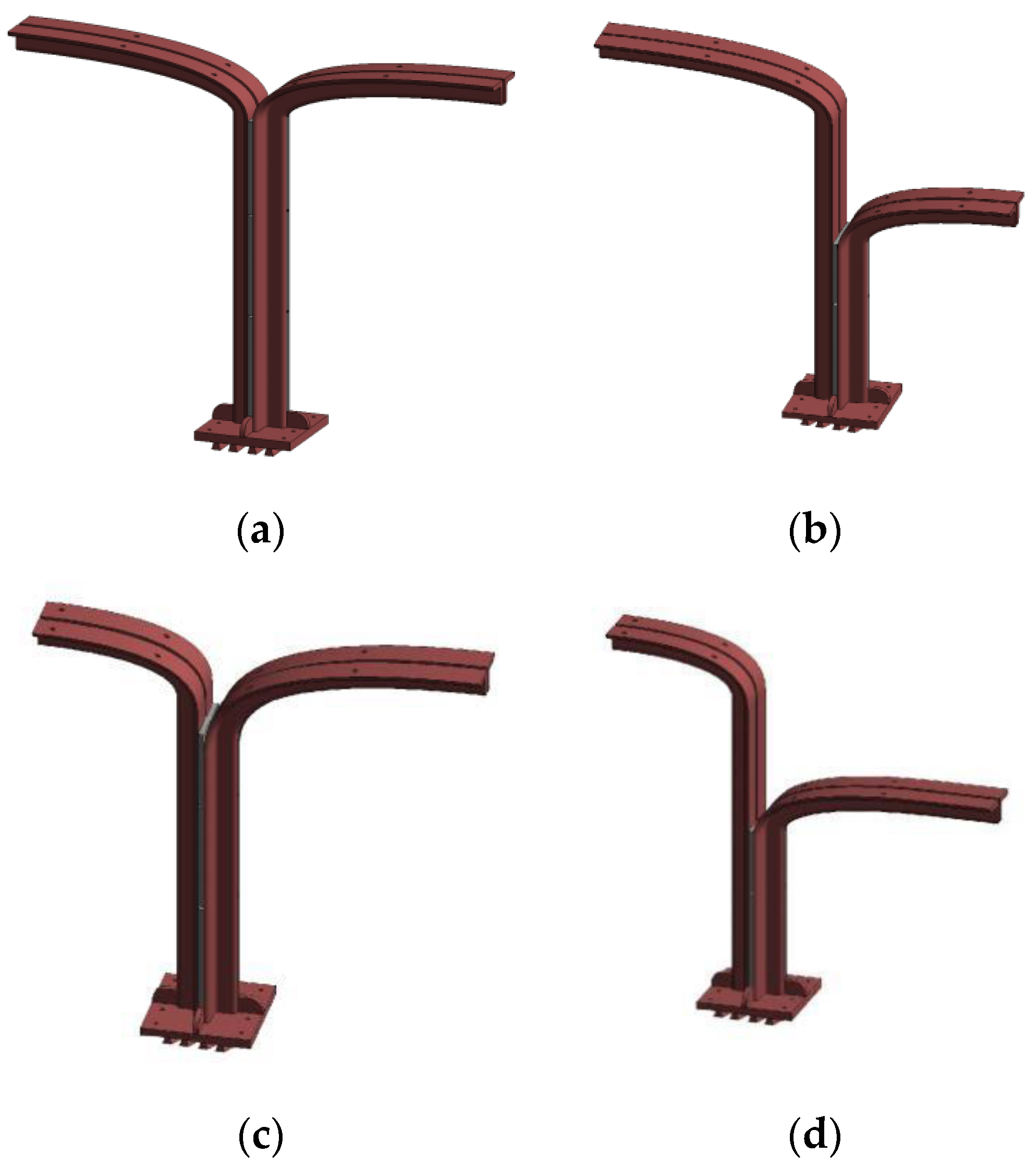

4. Expansions of the Architectural Form of the Diversified Growable Light Steel Units and Structures

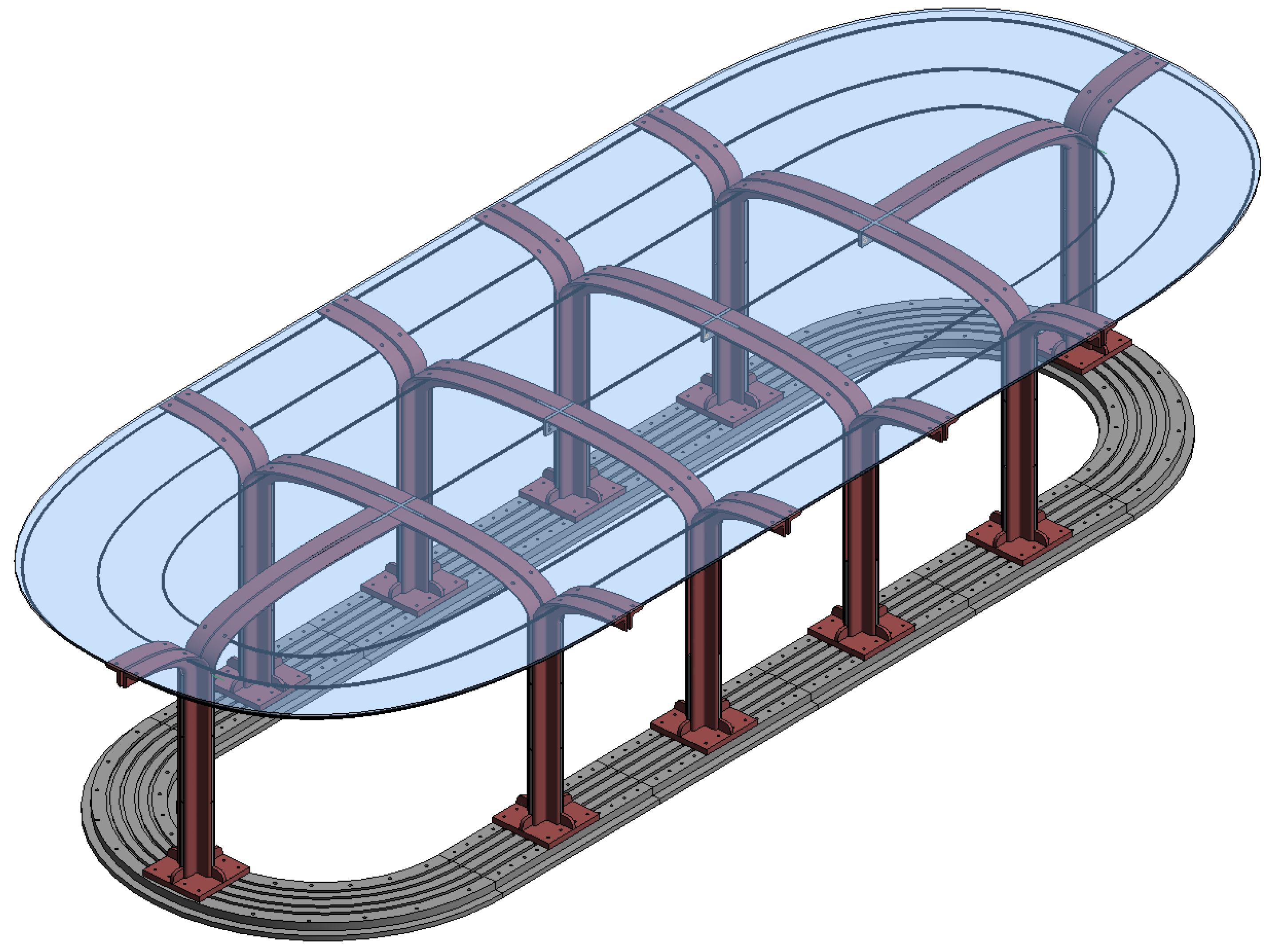

4.1. Linear Extension Space

4.2. Single Central Space

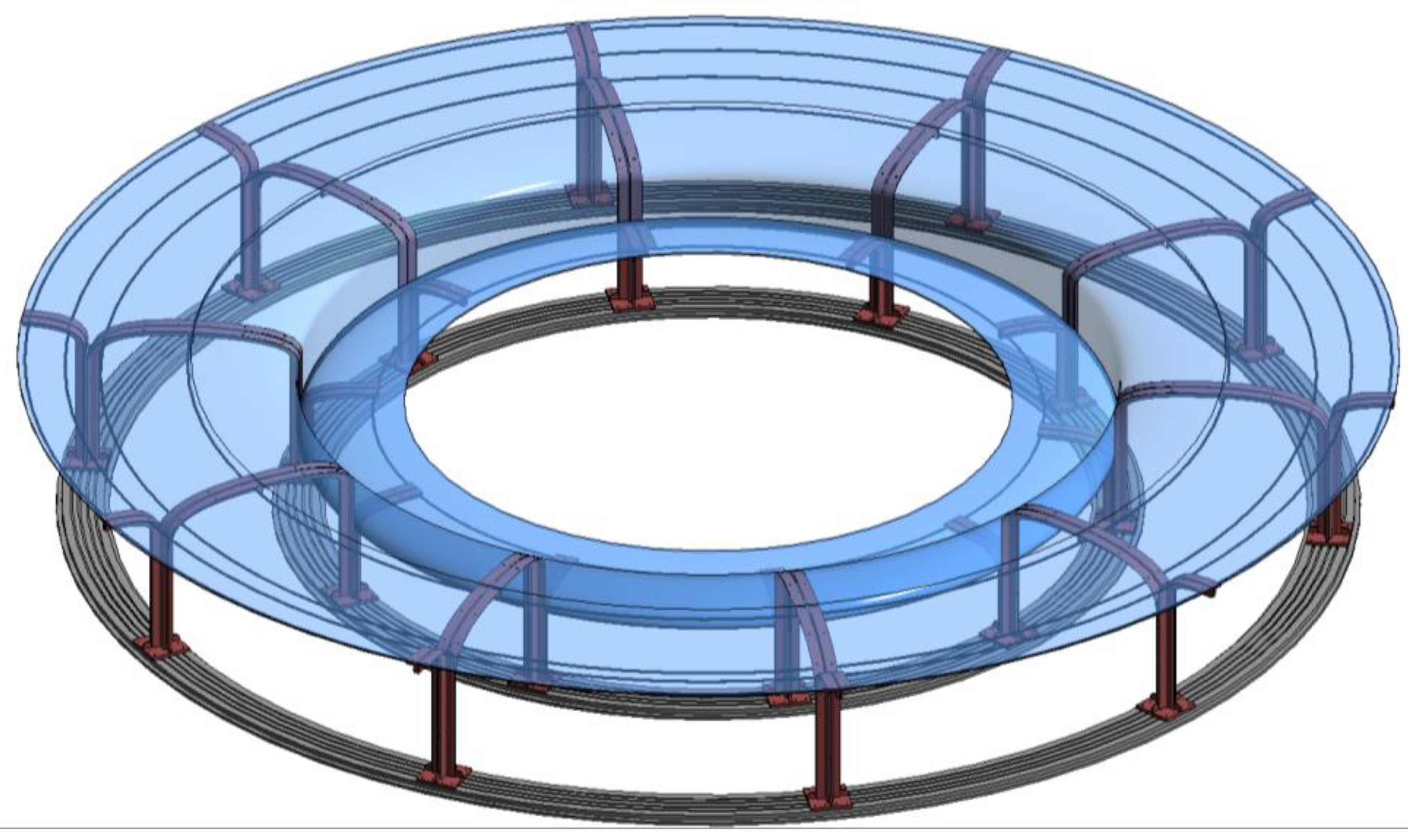

4.3. Transversely Centripetal Space

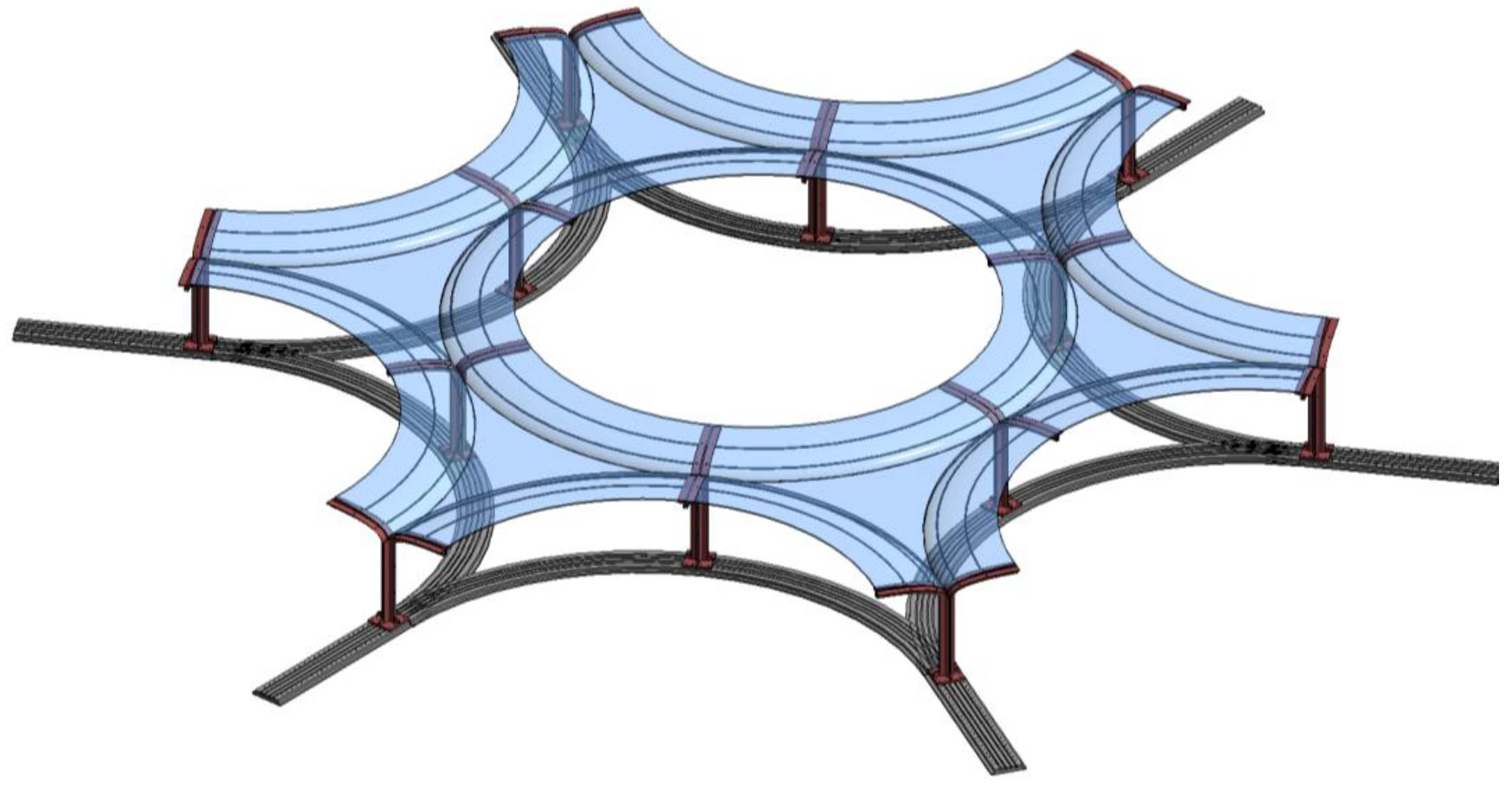

4.4. Radiative Space

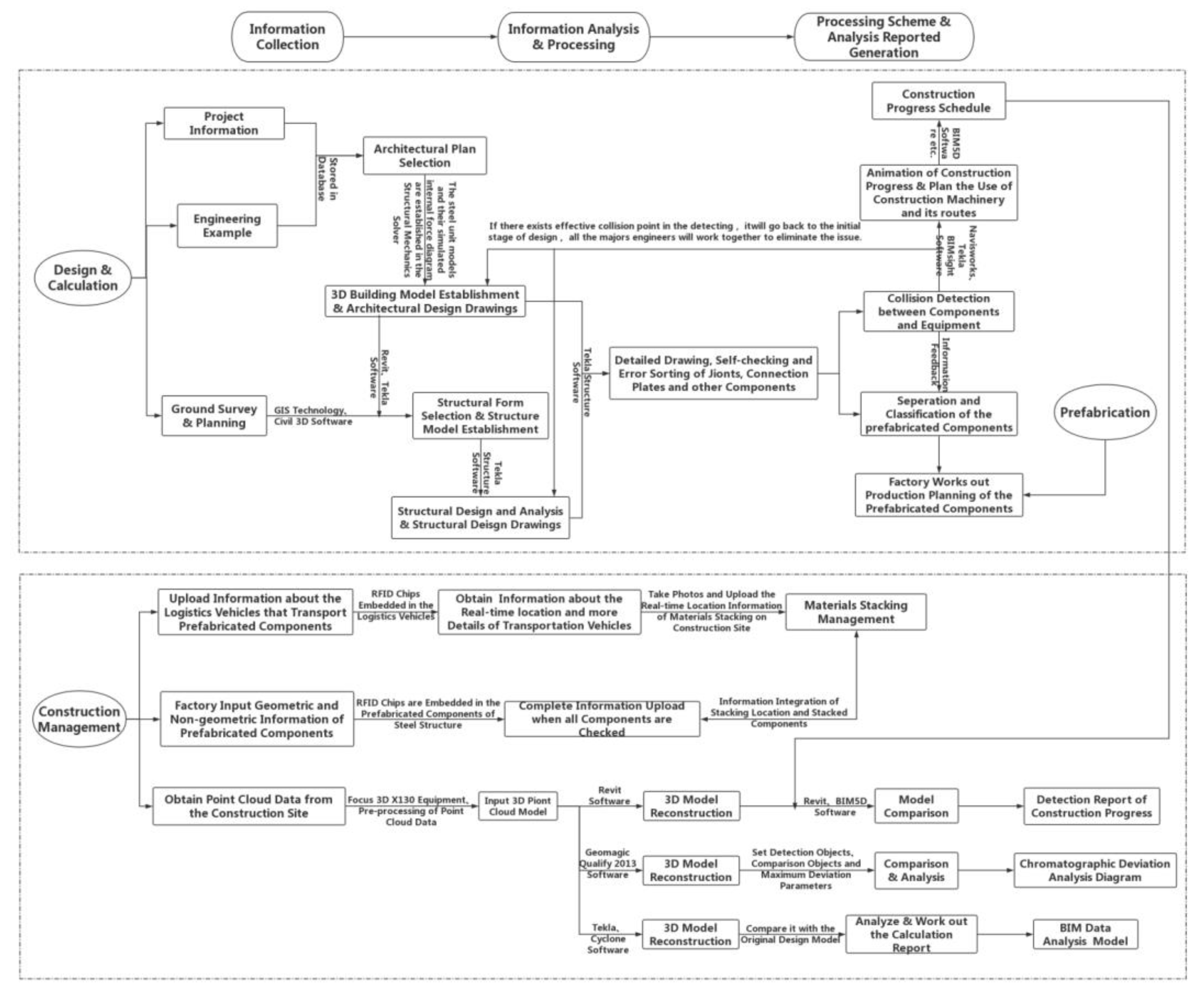

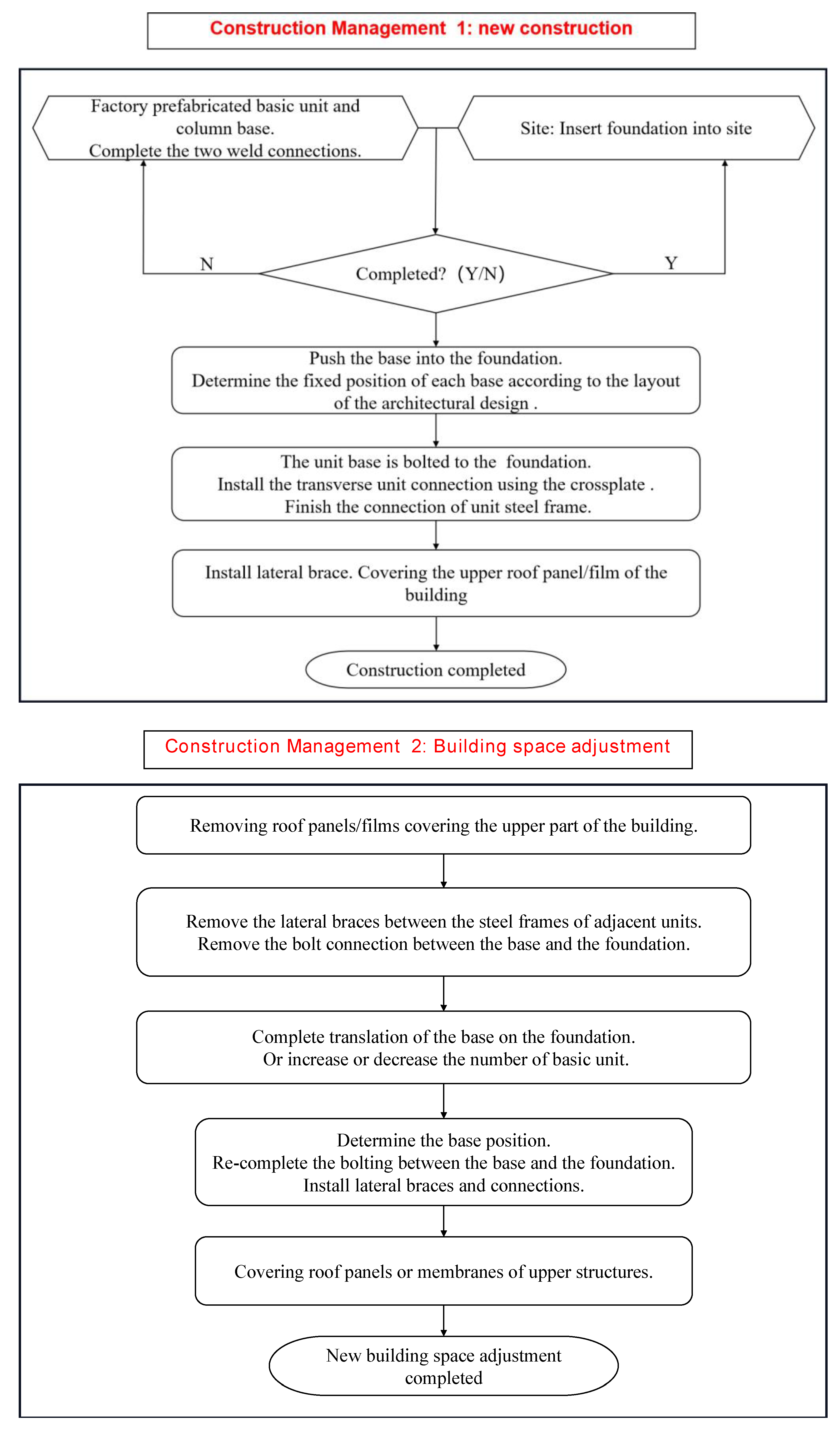

5. Design and Construction Method of the Growable Light Steel Structure Based on BIM Technology

6. Conclusions

- The basic units of light steel structures are proposed, and their good mechanical properties are analysed and verified. The three characteristics of the basic units of growing-type light steel structures, namely utilised, parametric, and assembled, are analysed. Based on the parametric design, reasonable layout of structural units, and practical construction assembly, the diverse growth of light steel-unit structures can be realised;

- To adapt to the growable light steel-unit structures, new track-type foundations are adopted, which not only bear and transfer the loadings from the upper light steel-unit structure but also promote the arrangement of the positions of light steel units through mechanical transmission. The track-type foundations can be divided into individual components. The transmission rails and supporting column foot panels can be prefabricated, which realises the integration of the building construction industry, mechanical engineering, and environmental protection, and reduces the damage to the construction site environment. It can also be recycled for energy saving and efficiency, further promoting the industrialisation and automation process;

- Based on the characteristics of the growable light steel-unit structures, combined with the changes in the form of the basic tracks, the extension and contraction of the architectural space are realised, the structural form and service space are adjusted, the secondary reorganisation and optimisation of the structural space are completed, and the architectural forms with various service spaces are further expanded. This study explores the application of growability in new light steel structure buildings, which shows great advantages and potential in various aspects, such as enriching the use function of the building, making efficient use of site resources, and improving the utilisation rate of structural space;

- Finally, this study explores the implementation method of the design and construction of growable light steel buildings based on BIM technology, systematically analyses the relevant information among the design calculations, component prefabrications, and construction process of the new growable light steel buildings, and executes the operations required in individual stages. By using highly integrated information interaction and 3D visual expression form, the design, construction efficiency, and project benefits of steel buildings are greatly improved.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.; Deng, K. Lightweight reconfigurable structure system (LRSS): Rethinking temporary buildings. In Proceedings of the Eco-Architecture 2018, New Forest, UK, 2–4 October 2018; Available online: https://www.wessex.ac.uk/conferences/2018/eco-architecture-2018 (accessed on 28 July 2020).

- Li, H.; Lin, J.; Lian, H.; Chen, K.; Lyu, Y.; Chen, Y.; Ren, L.; Zheng, L.; Lin, Z.; Yu, X.; et al. The Performance of Mobile Cabin Hospital in Combatting COVID-19 in China. 2020. Available online: https://search.bvsalud.org/global-literature-on-novel-coronavirus-2019-ncov/resource/en/ppmedrxiv-20162206 (accessed on 28 July 2020).

- Chen, D.; Wang, G.; Chen, G. Lego architecture: Research on a temporary building design method for post-disaster emergency. Front. Archit. Res. 2021, 10, 758–770. [Google Scholar] [CrossRef]

- Kronenburg, R.; Lim, R.; Chii, W.Y. Transportable Environments; Taylor & Francis: London, UK, 2003. [Google Scholar]

- Hosseini, S.M.A.; Farahzadi, L.; Pons, O. Assessing the sustainability index of different post-disaster temporary housing unit configuration types. J. Build. Eng. 2021, 42, 102806. [Google Scholar] [CrossRef]

- Yun, B.Y.; Kang, Y.; Kim, U.Y.; Wi, S.; Kim, S. Practical solutions with PCM for providing thermal stability of temporary house, school and hospital in disaster situations. Build. Environ. 2022, 207, 108540. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Wi, S.; Cho, M.H.; Park, J.H.; Yun, Y.B.; Kim, S. Developing energy-efficient temporary houses for sustainable urban regeneration: Manufacturing homes with loess, pearlite, and vermiculite. Sustain. Cities Soc. 2020, 61, 102287. [Google Scholar] [CrossRef]

- Grosso, M.; Thiebat, F. Life cycle environmental assessment of temporary building constructions. Energy Procedia 2015, 78, 3180–3185. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, Y.; Chen, S.; Sun, Y. Numerical study on the thermal performance of lightweight temporary building integrated with phase change materials. Appl. Therm. Eng. 2018, 138, 35–47. [Google Scholar] [CrossRef]

- Zheng, P.; Wu, H.; Liu, Y.; Ding, Y.; Yang, L. Thermal comfort in temporary buildings: A review. Build. Environ. 2022, 221, 109262. [Google Scholar] [CrossRef]

- Ye, R.; Wang, J.; Jiang, H.; Xie, N. Numerical study on thermal comfort and energy-saving potential of a prefabricated temporary house integrated with composite phase change materials. Energy Build. 2022, 268, 112169. [Google Scholar] [CrossRef]

- Köhler, D. The Mereological City: A Reading of the Works of Ludwig Hilberseimer; Transcript: Bielefeld, Germany, 2016. [Google Scholar]

- Wang, L. Study on Operation Performance of Green Public Buildings in Dalian Affected by Epidemic Situation. Master’s Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar]

- He, L.; Zhang, L. A bi-objective optimization of energy consumption and investment cost for public building envelope design based on the E-constraint method. Energy Build. 2022, 266, 112133. [Google Scholar] [CrossRef]

- Guo, C.; Bian, C.; Liu, Q.; You, Y.; Li, S.; Wang, L. A new method of evaluating energy efficiency of public buildings in China. J. Build. Eng. 2022, 46, 103776. [Google Scholar] [CrossRef]

- BCA Committee. Design for Manufacturing and Assembly (DfMA): Prefabricated Prefinished Volumetric Construction; Building and Construction Authority (BCA): Singapore, 2020.

- Aziz, S.; Nasir, S.N.C.M.; Hatrom, R.; Bazuli, L.A.; Abdullah, M.R. Modular construction system (MCS) in Malaysia: Mass customization through combinatorial. IOP Conf. Ser. Earth Environ. Sci. 2019, 385, 012030. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Lyu, Y.-F.; Li, G.-Q.; Cao, K.; Zhai, S.-Y.; Li, H.; Chen, C.; Wang, Y.-Z. Behavior of splice connection during transfer of vertical load in full-scale corner-supported modular building. Eng. Struct. 2021, 230, 111698. [Google Scholar] [CrossRef]

- Lyu, Y.-F.; Li, G.-Q.; Cao, K.; Zhai, S.-Y.; Wang, Y.-B.; Mao, L.; Ran, M.-M. Bending behavior of splice connection for corner-supported steel modular buildings. Eng. Struct. 2022, 250, 113460. [Google Scholar] [CrossRef]

- Zhai, S.-Y.; Lyu, Y.-F.; Cao, K.; Li, G.-Q.; Wang, W.-Y.; Chen, C. Experimental study on bolted-cover plate corner connections for column-supported modular steel buildings. J. Constr. Steel Res. 2022, 189, 107060. [Google Scholar] [CrossRef]

- Zhou, Y. Research on growable and changable educational buildings: A conceptual design of reconstruction of educational buildings after disaster. Ind. Constr. 2020, 40, 36–38. [Google Scholar]

- Graziano, A.; Bettucci, E. Growing Architecture: Iterative Growth and Cells Differentiation. 2022. Available online: https://www.iaacblog.com/programs/growing-architecture-syllabus-faculty/ (accessed on 5 April 2022).

- Angeletou, K. Modifiable Public Space: A System of Public Movable Structures to Enable Space Customization by the User. 2018. Available online: https://futurearchitectureplatform.org/projects/50411ca0-5b32-4a67-8ac1-52b6cd65d253/ (accessed on 5 April 2022).

- Song, F.; Chen, H. Sustainable utilization of detachable building. Des. Technol. 2018, 2, 17–24. [Google Scholar] [CrossRef]

- Peng, Z. Temporary Building’s Design Method Research Based on Rapid Construction. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2015. [Google Scholar]

- Yan, H.; Luo, D. Discuss on demountable building. Hous. Sci. 2015, 35, 24–28. [Google Scholar] [CrossRef]

- Jia, Y. Research on the Newbud LGS System and Geometric Evolution. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2012. [Google Scholar]

- Cao, Y. The Function and Research Value of Temporary Landscape in Urban Public Space. Ph.D. Thesis, Shanghai University, Shanghai, China, 2019. [Google Scholar]

- Wu, S.; Wang, L.; Han, S. Application of BIM technology in design and construction of multi-storey fabricated steel structure residential buildings. Build. Constr. 2019, 41, 691–693. [Google Scholar] [CrossRef]

- Yao, X.; Chen, H.; Jia, S.; Zhao, W. Application of 3D laser scanning and BIM technology in deformation monitoring of super high-rise steel structure. Ind. Constr. 2019, 49, 189–193. [Google Scholar] [CrossRef]

- Xie, H. The Application Research of 3D Laser Scanning Technology on Architecture Field. Master’s Thesis, Hefei University of Technology, Hefei, China, 2017. [Google Scholar]

| Types of Parameter Variation | Height of Middle Span (m) | Height of Side Span (m) | Span of Middle Span (m) | Span of Side Span (m) |

|---|---|---|---|---|

| Different heights of the same span (Internal cantilevers are taller) | 6 | 4.5 | 7.2 | 3.6 |

| Different heights of the same span (External cantilevers are taller) | 4.5 | 6.0 | 7.2 | 3.6 |

| Different spans of the same height (Internal cantilevers are longer) | 4.5 | 4.5 | 9.0 | 3.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Liu, Z.; Zhang, B.; Song, Y.; Zhang, X. Architectural Formation of Growable Light Steel Structure and Its 3D Visualisation Design and Construction Method. Buildings 2022, 12, 2041. https://doi.org/10.3390/buildings12112041

Jia H, Liu Z, Zhang B, Song Y, Zhang X. Architectural Formation of Growable Light Steel Structure and Its 3D Visualisation Design and Construction Method. Buildings. 2022; 12(11):2041. https://doi.org/10.3390/buildings12112041

Chicago/Turabian StyleJia, Huijuan, Zhiyuan Liu, Binsheng Zhang, Yongsheng Song, and Xian Zhang. 2022. "Architectural Formation of Growable Light Steel Structure and Its 3D Visualisation Design and Construction Method" Buildings 12, no. 11: 2041. https://doi.org/10.3390/buildings12112041

APA StyleJia, H., Liu, Z., Zhang, B., Song, Y., & Zhang, X. (2022). Architectural Formation of Growable Light Steel Structure and Its 3D Visualisation Design and Construction Method. Buildings, 12(11), 2041. https://doi.org/10.3390/buildings12112041