Bayesian Network Models for Evaluating the Impact of Safety Measures Compliance on Reducing Accidents in the Construction Industry

Abstract

1. Introduction

- Top management (i.e., Chief Executive Officer (CEO) and Company Manager (CM)),

- Safety personnel (i.e., the safety managers and safety coordinators),

- Frontline supervisors (i.e., forepersons and superintendents), and

- Workers (i.e., carpenters and pipefitters).

2. Related Construction Industry Safety Literature

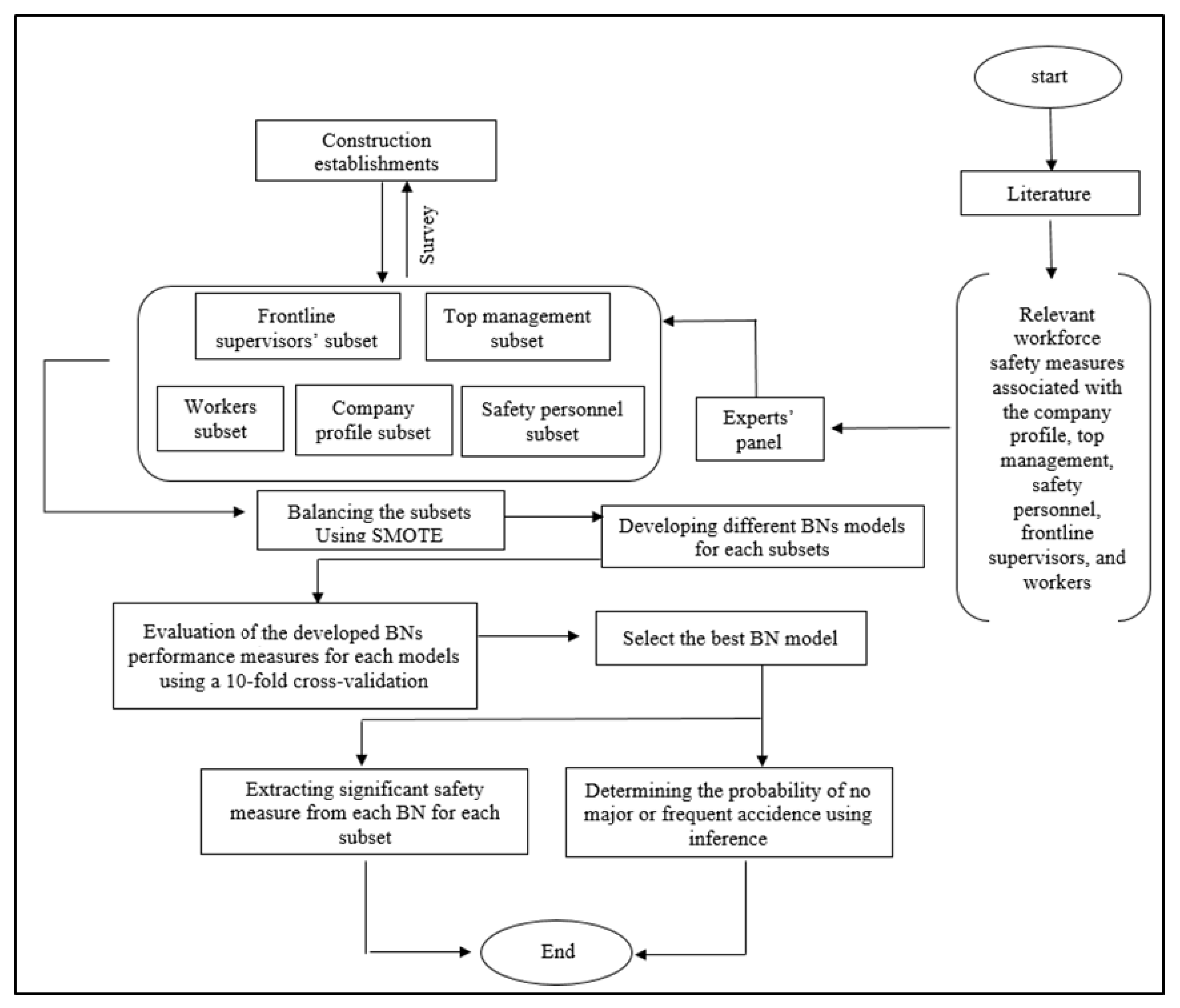

3. Methodology

4. Workforce Safety Measures in the Construction Industry

5. Survey Data Collection and Analysis

5.1. Analysis of the Safety Measures from Survey Results

5.1.1. Part 1—Data: Demographics

5.1.2. Part 2—Data: Top Management

5.1.3. Part 3—Data: Safety Coordinator/Manager

5.1.4. Part 4—Data: Frontline Supervisors

5.1.5. Part 5—Data: Workers

5.2. Defining and Coding Safety Measures Variables

5.3. Analysis of Safety Measures Compliance in the Jordanian Construction Industry

6. Bayesian Network (BN) Modeling

6.1. Balancing Subsets by Oversampling

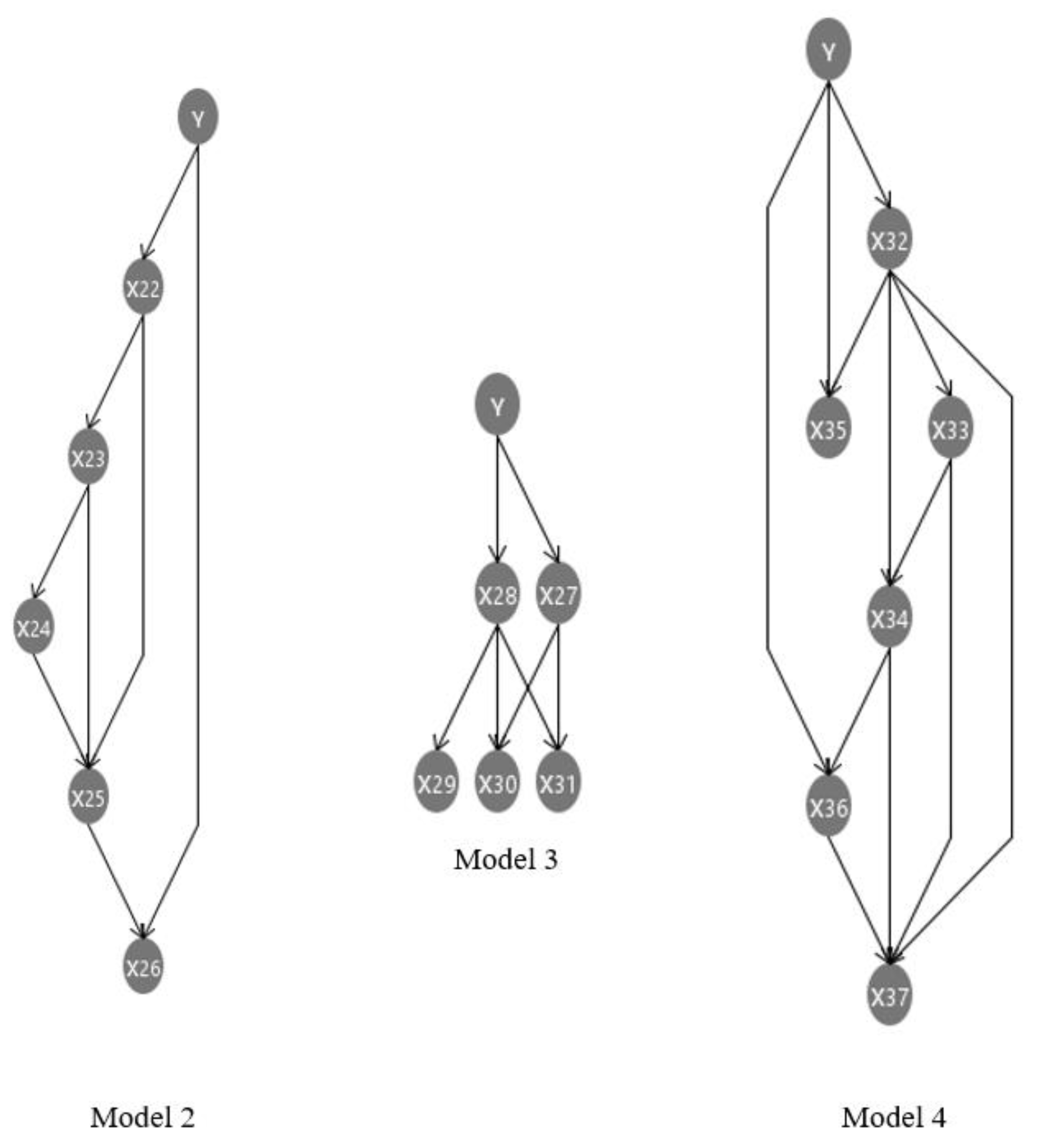

6.2. Safety Measures BN Data Modeling and Evaluation

6.3. Discussion of BN Model and Inference Results

6.3.1. Demographics

6.3.2. Top Management

6.3.3. Safety Coordinator/Manager

6.3.4. Frontline Supervisors

6.3.5. Workers

7. Concluding Remarks and Recommendations

- Company profile: The associated factors are: the type of sector and the yearly estimated revenue of the establishment, where the construction of buildings has the highest probability, which equals 46.85%, and establishments with yearly estimated revenue of more than $10 million have the highest probability which equals around 27.5%.

- Top management: The associated factors are: (1) strong core safety values that they abide by, (2) responding to all incidents in a positive and learning way, (3) a formal safety training program for all new employees, (4) periodic refresher training for each worker, (5) a formal supervisory safety training program for all frontline supervisors, and 6) adequate personal protective equipment and first-aid equipment, and trained emergency personnel with probabilities equal to 89.21%, 83.33%, 62.39%, 52.4%, 62.39%, and 81.31% respectively.

- Safety coordinator/manager: The associated factors are: implementing accident prevention techniques and communicating accident reports to workers to prevent future similar accidents with probabilities equal to 72.81% and 70.15%, respectively.

- Frontline supervisors: The associated factors are: encouraging the recording and reporting of all near misses, and the frontline supervisors are part of safety procedures reviewing with probabilities equal to 83.33% and 75.49%, respectively.

- Workers: The associated factors are: feeling okay to report unsafe conditions, workers’ actions suggesting that safety training is received well, and workers are part of safety procedures reviewing with probabilities equal to 65.68%, 63.58%, and 70.31%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akcay, E.C.; Arditi, D. Predicting Employer and Worker Responsibilities in Accidents That Involve Falls in Building Construction Sites. Buildings 2022, 12, 464. [Google Scholar] [CrossRef]

- Al-Kasasbeh, M.; Abudayyeh, O.; Olimat, H.; Liu, H.; Al Mamlook, R.; Abu Alfoul, B. A Robust Construction Safety Performance Evaluation Framework for Workers’ Compensation Insurance: A Proposed Alternative to EMR. Buildings 2021, 11, 434. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Fredericks, T.K.; Butt, S.E.; Shaar, A. An investigation of management’s commitment to construction safety. Int. J. Proj. Manag. 2006, 24, 167–174. [Google Scholar] [CrossRef]

- DOS (Departments of Statistics). 2021. Available online: http://dosweb.dos.gov.jo/ar/category/%D8%A7%D9%84%D9%86%D8%A7%D8%AA%D8%AC-%D8%A7%D9%84%D9%85%D8%AD%D9%84%D9%8A-%D8%A7%D9%84%D8%A5%D8%AC%D9%85%D8%A7%D9%84%D9%8A (accessed on 12 January 2022).

- Yiu, N.S.; Chan, D.W.; Shan, M.; Sze, N. Implementation of safety management system in managing construction projects: Benefits and obstacles. Saf. Sci. 2019, 117, 23–32. [Google Scholar] [CrossRef]

- Fang, J.; Kong, G.; Yang, Q. Group Performance of Energy Piles under Cyclic and Variable Thermal Loading. J. Geotech. Geoenviron. Eng. 2022, 148, 04022060. [Google Scholar] [CrossRef]

- Alubaid, F.A.-R.S.; Alhadeethi, R.H.F.; Mohamed, A.J. Assessment: The safety policy management for building construction companies in Jordan. J. Appl. Eng. Sci. 2020, 18, 120–131. [Google Scholar] [CrossRef]

- SSC Social Security Corporation. 2019. Available online: https://www.ssc.gov.jo/en/annual-reports (accessed on 23 August 2021).

- HSE (Health and Safety Executive). 2021. Available online: https://www.hse.gov.uk/construction/index.htm?utm_source=hse.gov.uk&utm_medium=refferal&utm_campaign=construction&utm_content=home-page-info (accessed on 15 February 2021).

- BLS (Bureau of Labor Statistics). 2022. Available online: https://www.bls.gov/iif/oshcfoi1.htm#rates (accessed on 7 July 2022).

- Raheem, A.A.; Hinze, J.W. Disparity between construction safety standards: A global analysis. Saf. Sci. 2014, 70, 276–287. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Okun, A.H.; Guerin, R.J.; Schulte, P.A. Foundational workplace safety and health competencies for the emerging workforce. J. Saf. Res. 2016, 59, 43–51. [Google Scholar] [CrossRef]

- Vignoli, M.; Nielsen, K.M.; Guglielmi, D.; Mariani, M.G.; Patras, L.; Peirò, J.M. Design of a safety training package for migrant workers in the construction industry. Saf. Sci. 2021, 136, 105124. [Google Scholar] [CrossRef]

- Al-Bayati, A.J.; Albert, A.; Ford, G. Construction Safety Culture and Climate: Satisfying Necessity for an Industry Framework. Pract. Period. Struct. Des. Constr. 2019, 24, 1–10. [Google Scholar] [CrossRef]

- Al-Shabbani, Z.; Sturgill, R.; Dadi, G.B. Developing a Pre-Task Safety Briefing Tool for Kentucky Maintenance Personnel. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 187–197. [Google Scholar] [CrossRef]

- Awwad, R.; Jabbour, M.; El Souki, O. Safety Practices in the Lebanese Construction Market: Contractors’ Perspective. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Sydney, Australia, 9–11 July 2014. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef] [PubMed]

- Choudhry, R.M.; Fang, D.; Ahmed, S.M. Safety Management in Construction: Best Practices in Hong Kong. J. Prof. Issues Eng. Educ. Pract. 2008, 134, 20–32. [Google Scholar] [CrossRef]

- Nicolaidou, O.; Dimopoulos, C.; Varianou-Mikellidou, C.; Mikellides, N.; Boustras, G. Weak signals management in occupational safety and health: A Delphi study. Saf. Sci. 2022, 146, 105558. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, Y. Bayesian Approach for Probabilistic Site Characterization Using Cone Penetration Tests. J. Geotech. Geoenviron. Eng. 2013, 139, 267–276. [Google Scholar] [CrossRef]

- Han, L.; Wang, L.; Zhang, W. Quantification of statistical uncertainties of rock strength parameters using Bayesian-based Markov Chain Monte Carlo method. IOP Conf. Ser. Earth Environ. Sci. 2020, 570, 032051. [Google Scholar] [CrossRef]

- Mujalli, R.O.; Garach, L.; López, G.; Al-Rousan, T. Evaluation of Injury Severity for Pedestrian–Vehicle Crashes in Jordan Using Extracted Rules. J. Transp. Eng. Part A Syst. 2019, 145, 04019028. [Google Scholar] [CrossRef]

- Alkilani, S.Z.; Jupp, J.; Sawhney, A. Issues of construction health and safety in developing countries: A case of Jordan. Constr. Econ. Build. 2013, 13, 141–156. [Google Scholar] [CrossRef]

- Hiyassat, M.A.S.; Talhoni, B.T. Construction Safety in Developing Countries: A Case Study of Jordan; Abhath Al-Yarmouk, Basic Sciences and Engineering Series; Yarmouk University: Irbid, Jordan, 2000; Volume 9, pp. 133–147. [Google Scholar]

- Mohammad, S.; Al-Smadi, B.M.; Hyari, K.H.; Rababeh, S.M. Safety Management in the Jordanian Construction Industry. Jordan J. Civ. Eng. 2010, 4, 47–54. [Google Scholar]

- Assbeihat, M.; Jamal, A. Construction Safety in Jordan—Conditions and Obstacles. Int. J. Oper. Logist. Manag. 2015, 4, 193–203. [Google Scholar]

- Al-Smadi, S.A.-D.W.; Supeni, E.E.; Voon, W.S. A Study on Safety and Health Good Practices at Construction Sector in Jordan. East Afr. J. Eng. 2021, 3, 57–71. [Google Scholar] [CrossRef]

- Al-Aubaidy, N.A.; Caldas, C.H.; Mulva, S.P. Assessment of underreporting factors on construction safety incidents in US construction projects. Int. J. Constr. Manag. 2019, 22, 103–120. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, J.; Soh, J.; Jeong, J. Quantitative Analysis of the Accident Prevention Costs in Korean Construction Projects. Buildings 2022, 12, 1536. [Google Scholar] [CrossRef]

- Bamfo-Agyei, E.; Thwala, D.W.; Aigbavboa, C. Performance Improvement of Construction Workers to Achieve Better Productivity for Labour-Intensive Works. Buildings 2022, 12, 1593. [Google Scholar] [CrossRef]

- Azmat, Y.; Saad, N. The Safety Policies Practiced in the Construction Industry of Saudi Arabia. J. Ergon. 2018, 8, 1–14. [Google Scholar] [CrossRef]

- Sarireh, M.; Tarawneh, S. Safety Concept, Value and Cost in Construction Projects in Jordan. Civ. Environ. Res. 2014, 6, 1–13. [Google Scholar]

- Al-Bayati, A.J.; Al-Kasasbeh, M.; Awolusi, I.; Abudayyeh, O.; Umar, T. Trends of Occupational Fatal and Nonfatal Injuries in Electrical and Mechanical Specialty Contracting Sectors: Necessity for a Learning Investigation System. J. Constr. Eng. Manag. 2021, 147, 04021069. [Google Scholar] [CrossRef]

- Al-Refaie, A. Factors affect companies’ safety performance in Jordan using structural equation modeling. Saf. Sci. 2013, 57, 169–178. [Google Scholar] [CrossRef]

- Prati, G.; Pietrantoni, L.; Fraboni, F. Using data mining techniques to predict the severity of bicycle crashes. Accid. Anal. Prev. 2017, 101, 44–54. [Google Scholar] [CrossRef]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic Minority Over-sampling Technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar] [CrossRef]

- Bradley, A.P. The use of the area under the ROC curve in the evaluation of machine learning algorithms. Pattern Recognit. 1997, 30, 1145–1159. [Google Scholar] [CrossRef]

- Oh, T.K.; Kwon, Y.J.; Oh, B.-H.; Gwon, Y.-I.; Yoon, H.-K. Suggestions for safety coordinator’s roles at each construction stage (client, designer, supervisor, and contractor) to improve safety and health activities in South Korea. Saf. Sci. 2021, 133, 104994. [Google Scholar] [CrossRef]

- Jazayeri, E.; Liu, H.; Dadi, G.B. Assessing and Evaluating Subcontractor Management Safety Policies. In Proceedings of the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018. [Google Scholar] [CrossRef]

- Tam, C.; Fung, I.W. Effectiveness of safety management strategies on safety performance in Hong Kong. Constr. Manag. Econ. 1998, 16, 49–55. [Google Scholar] [CrossRef]

- Hon, C.K.; Hinze, J.; Chan, A.P. Safety climate and injury occurrence of repair, maintenance, minor alteration and addition works. Facilities 2014, 32, 188–207. [Google Scholar] [CrossRef]

- Collins, B.; Dixon, J.; Smibert, D. PW 0388 Construction safety culture in canada: Assess and intervene. Abstracts 2018, 24, A209. [Google Scholar] [CrossRef]

- A review of metro construction in China: Organization, market, cost, safety and schedule. Front. Eng. Manag. 2017, 4, 4–19. [CrossRef]

- Lozano-Díez, R.V.; López-Zaldívar, O.; del Cura, S.H.; Verdú-Vázquez, A. Analysis of the impact of health and safety coordinator on construction site accidents: The case of Spain. J. Saf. Res. 2019, 68, 149–156. [Google Scholar] [CrossRef]

- Oswald, D.; Sherratt, F.; Smith, S. Problems with safety observation reporting: A construction industry case study. Saf. Sci. 2018, 107, 35–45. [Google Scholar] [CrossRef]

| Subset | Variable | Variable Code | Categories | Categories Codes | Count | Percentage |

|---|---|---|---|---|---|---|

| Part 1: Company profile | Type of sector for the establishment work | X1 | Civil and Heavy Street or Road Construction | 1 | 6 | 10.7 |

| Construction of Buildings | 2 | 28 | 50.0 | |||

| Residential—Apartment Complex | 3 | 7 | 12.5 | |||

| Residential—Single-family | 4 | 5 | 8.9 | |||

| Special Trades Contract | 5 | 10 | 17.9 | |||

| Total | 56 | 100.0 | ||||

| Role of the establishment work | X2 | General Contractor | 1 | 48 | 85.7 | |

| Sub-Contractor | 2 | 8 | 14.3 | |||

| Total | 56 | 100.0 | ||||

| The yearly estimated revenue of the establishment | X3 | Less than $100 K | 1 | 8 | 14.3 | |

| $100 K– $500 K | 2 | 11 | 19.6 | |||

| $500 K– $1 million | 3 | 6 | 10.7 | |||

| More than $1 million, but less than $10 million | 4 | 14 | 25.0 | |||

| More than $10 million | 5 | 17 | 30.4 | |||

| Total | 56 | 100.0 | ||||

| Number of the daily workers working at the establishment | X7 | Less than 10 | 1 | 9 | 16.1 | |

| 10–50 | 2 | 11 | 19.6 | |||

| 50–100 | 3 | 7 | 12.5 | |||

| 100–250 | 4 | 8 | 14.3 | |||

| More than 250 | 5 | 21 | 37.5 | |||

| Total | 56 | 100.0 | ||||

| Number of employees working at the establishment | X8 | Less than 10 | 1 | 5 | 8.9 | |

| 10–50 | 2 | 8 | 14.3 | |||

| 50–100 | 3 | 10 | 17.9 | |||

| 100–250 | 4 | 10 | 17.9 | |||

| More than 250 | 5 | 23 | 41.1 | |||

| Total | 56 | 100.0 | ||||

| The establishment has a full-time safety coordinator/manager | X9 | No | 0 | 16 | 28.6 | |

| Yes | 1 | 40 | 71.4 | |||

| Total | 56 | 100.0 | ||||

| Part 2: Top management | The top management has strong core safety values that they abide by all | X10 | No | 0 | 4 | 7.1 |

| Yes | 1 | 52 | 92.9 | |||

| Total | 56 | 100.0 | ||||

| The top management responds to all incidents in a positive, learning way. | X11 | No | 0 | 8 | 14.3 | |

| Yes | 1 | 48 | 85.7 | |||

| Total | 56 | 100.0 | ||||

| The top management allocates time and funds when corrective safety actions are required. | X12 | No | 0 | 4 | 7.1 | |

| Yes | 1 | 52 | 92.9 | |||

| Total | 56 | 100.0 | ||||

| The top management adheres to safety requirements and procedures | X13 | No | 0 | 6 | 10.7 | |

| Yes | 1 | 50 | 89.3 | |||

| Total | 56 | 100.0 | ||||

| The top management considers safety an integral part of the job, which receives the same amount of attention as other aspects | X14 | No | 0 | 9 | 16.1 | |

| Yes | 1 | 47 | 83.9 | |||

| Total | 56 | 100.0 | ||||

| The top management has a formal safety training program for all new employees | X15 | No | 0 | 20 | 35.7 | |

| Yes | 1 | 36 | 64.3 | |||

| Total | 56 | 100.0 | ||||

| The top management has periodic refresher training for each worker | X16 | No | 0 | 24 | 42.9 | |

| Yes | 1 | 32 | 57.1 | |||

| Total | 56 | 100.0 | ||||

| The top management has a formal supervisory safety training program for all frontline supervisors | X17 | No | 0 | 21 | 37.5 | |

| Yes | 1 | 35 | 62.5 | |||

| Total | 56 | 100.0 | ||||

| The top management has a program of regular site visits by safety coordinator/manager to review and control job hazards | X18 | No | 0 | 14 | 25.0 | |

| Yes | 1 | 42 | 75.0 | |||

| Total | 56 | 100.0 | ||||

| The top management provides adequate personal protective equipment, first-aid equipment, and trained emergency personnel | X19 | No | 0 | 9 | 16.1 | |

| Yes | 1 | 47 | 83.9 | |||

| Total | 56 | 100.0 | ||||

| The top management establishes a procedure for the emergency evacuation of injured workers | X20 | No | 0 | 13 | 23.2 | |

| Yes | 1 | 43 | 76.8 | |||

| Total | 56 | 100.0 | ||||

| The top management has provisions for maintaining safety records and reporting accidents in compliance with safety regulations requirements | X21 | No | 0 | 18 | 32.1 | |

| Yes | 1 | 38 | 67.9 | |||

| Total | 56 | 100.0 | ||||

| Part 3: Safety coordinator/manager | The safety coordinator/manager tries to implement accident prevention techniques. | X22 | No | 0 | 3 | 5.4 |

| Yes | 1 | 43 | 76.8 | |||

| NA | 3 | 10 | 17.9 | |||

| Total | 56 | 100.0 | ||||

| The safety coordinator/manager clearly communicates safety regulations and expectations | X23 | No | 0 | 4 | 7.1 | |

| Yes | 1 | 43 | 76.8 | |||

| NA | 3 | 9 | 16.1 | |||

| Total | 56 | 100.0 | ||||

| The safety coordinator/manager is approachable and receptive | X24 | No | 0 | 3 | 5.4 | |

| Yes | 1 | 47 | 83.9 | |||

| NA | 3 | 6 | 10.7 | |||

| Total | 56 | 100.0 | ||||

| The safety coordinator/manager strives to improve overall site safety | X25 | No | 0 | 4 | 7.1 | |

| Yes | 1 | 46 | 82.1 | |||

| NA | 3 | 6 | 10.7 | |||

| Total | 56 | 100.0 | ||||

| The safety coordinator/manager communicates accidents reports to workers in order to prevent future similar accidents | X26 | No | 0 | 6 | 10.7 | |

| Yes | 1 | 42 | 75.0 | |||

| NA | 3 | 8 | 14.3 | |||

| Total | 56 | 100.0 | ||||

| Part 4: Frontline supervisors | Frontline supervisors encourage the recording and reporting of all near misses | X27 | No | 0 | 8 | 14.3 |

| Yes | 1 | 48 | 85.7 | |||

| Total | 56 | 100.0 | ||||

| Frontline supervisors are part of safety procedures reviewing | X28 | No | 0 | 12 | 21.4 | |

| Yes | 1 | 44 | 78.6 | |||

| Total | 56 | 100.0 | ||||

| Frontline supervisors correct unsafe conditions quickly | X29 | No | 0 | 4 | 7.1 | |

| Yes | 1 | 52 | 92.9 | |||

| Total | 56 | 100.0 | ||||

| Frontline supervisors lead by example when it comes to safety | X30 | No | 0 | 8 | 14.3 | |

| Yes | 1 | 48 | 85.7 | |||

| Total | 56 | 100.0 | ||||

| Frontline supervisors always ensure that workers are following proper safety regulations | X31 | No | 0 | 10 | 17.9 | |

| Yes | 1 | 46 | 82.1 | |||

| Total | 56 | 100.0 | ||||

| Part 5: Workers | Workers feel okay with reporting unsafe conditions | X32 | No | 0 | 17 | 30.4 |

| Yes | 1 | 39 | 69.6 | |||

| Total | 56 | 100.0 | ||||

| Workers know how/where to file an incident report | X33 | No | 0 | 17 | 30.4 | |

| Yes | 1 | 39 | 69.6 | |||

| Total | 56 | 100.0 | ||||

| Workers follow all safety policies and procedures | X34 | No | 0 | 17 | 30.4 | |

| Yes | 1 | 39 | 69.6 | |||

| Total | 56 | 100.0 | ||||

| Workers’ actions suggest that safety training is received well | X35 | No | 0 | 18 | 32.1 | |

| Yes | 1 | 38 | 67.9 | |||

| Total | 56 | 100.0 | ||||

| Workers are part of safety procedures reviewing | X36 | No | 0 | 17 | 30.4 | |

| Yes | 1 | 39 | 69.6 | |||

| Total | 56 | 100.0 | ||||

| Workers feel confident that safety issues will be corrected if they reported them. | X37 | No | 0 | 12 | 21.4 | |

| Yes | 1 | 44 | 78.6 | |||

| Total | 56 | 100.0 | ||||

| Y | No major/frequent accidents occurred in the establishment during the last 5 years (no safety penalties during the last 5 years) (Y) | Y | No | 0 | 6 | 10.7 |

| Yes | 1 | 41 | 73.2 | |||

| NA | 3 | 9 | 16.1 | |||

| Total | 56 | 100.0 |

| No accidents Occurrence in the Establishment during the Last Five Years (Y) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Independent Variables | Categories | 0 | 1 | NA | Total | ||||

| Count | Percentage | Count | Percentage | Count | Percentage | Count | Percentage | |||

| Model 0 | X1 | 1 | 0 | 0.0 | 4 | 7.1 | 2 | 3.6 | 6.0 | 10.7 |

| 2 | 3 | 5.4 | 21 | 37.5 | 4 | 7.1 | 28.0 | 50.0 | ||

| 3 | 2 | 3.6 | 4 | 7.1 | 1 | 1.8 | 7.0 | 12.5 | ||

| 4 | 0 | 0.0 | 4 | 7.1 | 1 | 1.8 | 5.0 | 8.9 | ||

| 5 | 1 | 1.8 | 8 | 14.3 | 1 | 1.8 | 10.0 | 17.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X2 | 1 | 5 | 8.9 | 34 | 60.7 | 9 | 16.1 | 48.0 | 85.7 | |

| 2 | 1 | 1.8 | 7 | 12.5 | 0 | 0.0 | 8.0 | 14.3 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X3 | 1 | 1 | 1.8 | 5 | 8.9 | 2 | 3.6 | 8.0 | 14.3 | |

| 2 | 2 | 3.6 | 7 | 12.5 | 2 | 3.6 | 11.0 | 19.6 | ||

| 3 | 0 | 0.0 | 6 | 10.7 | 0 | 0.0 | 6.0 | 10.7 | ||

| 4 | 0 | 0.0 | 13 | 23.2 | 1 | 1.8 | 14.0 | 25.0 | ||

| 5 | 3 | 5.4 | 10 | 17.9 | 4 | 7.1 | 17.0 | 30.4 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X7 | 1 | 1 | 1.8 | 4 | 7.1 | 4 | 7.1 | 9.0 | 16.1 | |

| 2 | 1 | 1.8 | 8 | 14.3 | 2 | 3.6 | 11.0 | 19.6 | ||

| 3 | 1 | 1.8 | 5 | 8.9 | 1 | 1.8 | 7.0 | 12.5 | ||

| 4 | 0 | 0.0 | 8 | 14.3 | 0 | 0.0 | 8.0 | 14.3 | ||

| 5 | 3 | 5.4 | 16 | 28.6 | 2 | 3.6 | 21.0 | 37.5 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100 | ||

| X8 | 1 | 2 | 3.6 | 3 | 5.4 | 0 | 0.0 | 5.0 | 8.9 | |

| 2 | 0 | 0.0 | 4 | 7.1 | 4 | 7.1 | 8.0 | 14.3 | ||

| 3 | 1 | 1.8 | 6 | 10.7 | 3 | 5.4 | 10.0 | 17.9 | ||

| 4 | 0 | 0.0 | 10 | 17.9 | 0 | 0.0 | 10.0 | 17.9 | ||

| 5 | 3 | 5.4 | 18 | 32.1 | 2 | 3.6 | 23.0 | 41.1 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100 | ||

| X9 | 0 | 2 | 3.6 | 10 | 17.9 | 4 | 7.1 | 16.0 | 28.6 | |

| 1 | 4 | 7.1 | 31 | 55.4 | 5 | 8.9 | 40.0 | 71.4 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100 | ||

| Model 1 | X10 | 0 | 0 | 0.0 | 4 | 7.1 | 0 | 0.0 | 4.0 | 7.1 |

| 1 | 6 | 10.7 | 37 | 66.1 | 9 | 16.1 | 52.0 | 92.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X11 | 0 | 0 | 0.0 | 6 | 10.7 | 2 | 3.6 | 8.0 | 14.3 | |

| 1 | 6 | 10.7 | 35 | 62.5 | 7 | 12.5 | 48.0 | 85.7 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X12 | 0 | 0 | 0.0 | 4 | 7.1 | 0 | 0.0 | 4.0 | 7.1 | |

| 1 | 6 | 10.7 | 37 | 66.1 | 9 | 16.1 | 52.0 | 92.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X13 | 0 | 0 | 0.0 | 6 | 10.7 | 0 | 0.0 | 6.0 | 10.7 | |

| 1 | 6 | 10.7 | 35 | 62.5 | 9 | 16.1 | 50.0 | 89.3 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X14 | 0 | 1 | 1.8 | 7 | 12.5 | 1 | 1.8 | 9.0 | 16.1 | |

| 1 | 5 | 8.9 | 34 | 60.7 | 8 | 14.3 | 47.0 | 83.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X15 | 0 | 1 | 1.8 | 13 | 23.2 | 6 | 10.7 | 20.0 | 35.7 | |

| 1 | 5 | 8.9 | 28 | 50.0 | 3 | 5.4 | 36.0 | 64.3 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X16 | 0 | 0 | 0.0 | 18 | 32.1 | 6 | 10.7 | 24.0 | 42.9 | |

| 1 | 6 | 10.7 | 23 | 41.1 | 3 | 5.4 | 32.0 | 57.1 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X17 | 0 | 0 | 0.0 | 17 | 30.4 | 4 | 7.1 | 21.0 | 37.5 | |

| 1 | 6 | 10.7 | 24 | 42.9 | 5 | 8.9 | 35.0 | 62.5 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X18 | 0 | 1 | 1.8 | 10 | 17.9 | 3 | 5.4 | 14.0 | 25.0 | |

| 1 | 5 | 8.9 | 31 | 55.4 | 6 | 10.7 | 42.0 | 75.0 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X19 | 0 | 0 | 0.0 | 8 | 14.3 | 1 | 1.8 | 9.0 | 16.1 | |

| 1 | 6 | 10.7 | 33 | 58.9 | 8 | 14.3 | 47.0 | 83.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X20 | 0 | 1 | 1.8 | 11 | 19.6 | 1 | 1.8 | 13.0 | 23.2 | |

| 1 | 5 | 8.9 | 30 | 53.6 | 8 | 14.3 | 43.0 | 76.8 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X21 | 0 | 1 | 1.8 | 15 | 26.8 | 2 | 3.6 | 18.0 | 32.1 | |

| 1 | 5 | 8.9 | 26 | 46.4 | 7 | 12.5 | 38.0 | 67.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| Model 2 | X22 | 0 | 0 | 0.0 | 3 | 5.4 | 0 | 0.0 | 3.0 | 5.4 |

| 1 | 6 | 10.7 | 31 | 55.4 | 6 | 10.7 | 43.0 | 76.8 | ||

| 3 | 0 | 0.0 | 7 | 12.5 | 3 | 5.4 | 10.0 | 17.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X23 | 0 | 1 | 1.8 | 3 | 5.4 | 0 | 0.0 | 4.0 | 7.1 | |

| 1 | 5 | 8.9 | 31 | 55.4 | 7 | 12.5 | 43.0 | 76.8 | ||

| 3 | 0 | 0.0 | 7 | 12.5 | 2 | 3.6 | 9.0 | 16.1 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X24 | 0 | 0 | 0.0 | 3 | 5.4 | 0 | 0.0 | 3.0 | 5.4 | |

| 1 | 5 | 8.9 | 35 | 62.5 | 7 | 12.5 | 47.0 | 83.9 | ||

| 3 | 1 | 1.8 | 3 | 5.4 | 2 | 3.6 | 6.0 | 10.7 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X25 | 0 | 1 | 1.8 | 3 | 5.4 | 0 | 0.0 | 4.0 | 7.1 | |

| 1 | 5 | 8.9 | 34 | 60.7 | 7 | 12.5 | 46.0 | 82.1 | ||

| 3 | 0 | 0.0 | 4 | 7.1 | 2 | 3.6 | 6.0 | 10.7 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X26 | 0 | 0 | 0.0 | 4 | 7.1 | 2 | 3.6 | 6.0 | 10.7 | |

| 1 | 6 | 10.7 | 31 | 55.4 | 5 | 8.9 | 42.0 | 75.0 | ||

| 3 | 0 | 0.0 | 6 | 10.7 | 2 | 3.6 | 8.0 | 14.3 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| Model 3 | X27 | 0 | 0 | 0.0 | 7 | 12.5 | 1 | 1.8 | 8.0 | 14.3 |

| 1 | 6 | 10.7 | 34 | 60.7 | 8 | 14.3 | 48.0 | 85.7 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X28 | 0 | 0 | 0.0 | 10 | 17.9 | 2 | 3.6 | 12.0 | 21.4 | |

| 1 | 6 | 10.7 | 31 | 55.4 | 7 | 12.5 | 44.0 | 78.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X29 | 0 | 0 | 0.0 | 4 | 7.1 | 0 | 0.0 | 4.0 | 7.1 | |

| 1 | 6 | 10.7 | 37 | 66.1 | 9 | 16.1 | 52.0 | 92.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X30 | 0 | 1 | 1.8 | 7 | 12.5 | 0 | 0.0 | 8.0 | 14.3 | |

| 1 | 5 | 8.9 | 34 | 60.7 | 9 | 16.1 | 48.0 | 85.7 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X31 | 0 | 0 | 0.0 | 8 | 14.3 | 2 | 3.6 | 10.0 | 17.9 | |

| 1 | 6 | 10.7 | 33 | 58.9 | 7 | 12.5 | 46.0 | 82.1 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| Model 4 | X32 | 0 | 0 | 0.0 | 12 | 21.4 | 5 | 8.9 | 17.0 | 30.4 |

| 1 | 6 | 10.7 | 29 | 51.8 | 4 | 7.1 | 39.0 | 69.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X33 | 0 | 1 | 1.8 | 12 | 21.4 | 4 | 7.1 | 17.0 | 30.4 | |

| 1 | 5 | 8.9 | 29 | 51.8 | 5 | 8.9 | 39.0 | 69.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X34 | 0 | 1 | 1.8 | 13 | 23.2 | 3 | 5.4 | 17.0 | 30.4 | |

| 1 | 5 | 8.9 | 28 | 50.0 | 6 | 10.7 | 39.0 | 69.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X35 | 0 | 0 | 0.0 | 14 | 25.0 | 4 | 7.1 | 18.0 | 32.1 | |

| 1 | 6 | 10.7 | 27 | 48.2 | 5 | 8.9 | 38.0 | 67.9 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X36 | 0 | 1 | 1.8 | 14 | 25.0 | 2 | 3.6 | 17.0 | 30.4 | |

| 1 | 5 | 8.9 | 27 | 48.2 | 7 | 12.5 | 39.0 | 69.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| X37 | 0 | 0 | 0.0 | 10 | 17.9 | 2 | 3.6 | 12.0 | 21.4 | |

| 1 | 6 | 10.7 | 31 | 55.4 | 7 | 12.5 | 44.0 | 78.6 | ||

| Total | 6 | 10.7 | 41 | 73.2 | 9 | 16.1 | 56.0 | 100.0 | ||

| Class variable Categories Count and Percentage | |||

|---|---|---|---|

| Dataset | No | Yes | Total |

| Imbalanced | 6 (11%) | 50 (89%) | 56 |

| Balanced | 48 (49%) | 50 (51%) | 98 |

| BN Model Algorithm | Performance Measure Average of 10 Runs (Standard Deviation) | Best Algorithm | |||||

|---|---|---|---|---|---|---|---|

| Safety Measure Subset Model | Accuracy | TPR | TNR | F1-Score | AUC | ||

| Model 0 | 1. Hillclimber+Bdeu | 0.872 (0.010) | 0.915 (0.116) | 0.830 (0.162) | 0.877 (0.098) | 0.907 (0.089) | 3 |

| 2. Hillclimber+MDL | 0.847 (0.010) | 0.915 (0.116) | 0.782 (0.180) | 0.857 (0.093) | 0.860 (0.110) | ||

| 3. Hillclimber+AIC | 0.886 (0.092) | 0.915 (0.116) | 0.858 (0.154) | 0.888 (0.090) | 0.895 (0.104) | ||

| 4. K2+Bdeu | 0.863 (0.010) | 0.915 (0.116) | 0.812 (0.175) | 0.869 (0.093) | 0.909 (0.097) | ||

| 5. K2+MDL | 0.856 (0.011) | 0.915 (0.116) | 0.800 (0.191) | 0.865 (0.099) | 0.908 (0.099) | ||

| 6. K2+AIC | 0.879 (0.011) | 0.915 (0.116) | 0.844 (0.183) | 0.884 (0.101) | 0.893 (0.103) | ||

| Best performance | 6 | 0 | 3 | 3 | 3 | ||

| Model 1 | 1. Hillclimber+Bdeu | 0.778 (0.011) | 0.988 (0.051) | 0.580 (0.214) | 0.820 (0.082) | 0.805 (0.116) | 6 |

| 2. Hillclimber+MDL | 0.746 (0.011) | 1.000 (0.000) | 0.504 (0.214) | 0.800 (0.073) | 0.730 (0.143) | ||

| 3. Hillclimber+AIC | 0.782 (0.011) | 0.992 (0.042) | 0.582 (0.209) | 0.822 (0.080) | 0.783 (0.120) | ||

| 4. K2+Bdeu | 0.799 (0.011) | 0.979 (0.065) | 0.628 (0.215) | 0.832 (0.082) | 0.799 (0.109) | ||

| 5. K2+MDL | 0.790 (0.011) | 0.979 (0.065) | 0.610 (0.210) | 0.825 (0.082) | 0.781 (0.123) | ||

| 6. K2+AIC | 0.805 (0.010) | 0.979 (0.065) | 0.640 (0.199) | 0.836 (0.077) | 0.798 (0.108) | ||

| Best performance | 6 | 3 | 6 | 6 | 3 | ||

| Model 2 | 1. Hillclimber+Bdeu | 0.624 (0.095) | 1.000 (0.000) | 0.264 (0.186) | 0.726 (0.053) | 0.622 (0.127) | 4 |

| 2. Hillclimber+MDL | 0.600 (0.089) | 1.000 (0.000) | 0.216 (0.174) | 0.712 (0.049) | 0.611 (0.138) | ||

| 3. Hillclimber+AIC | 0.599 (0.088) | 1.000 (0.000) | 0.214 (0.174) | 0.712 (0.049) | 0.610 (0.137) | ||

| 4. K2+Bdeu | 0.653 (0.010) | 1.000 (0.000) | 0.320 (0.199) | 0.742 (0.062) | 0.658 (0.107) | ||

| 5. K2+MDL | 0.622 (0.094) | 1.000 (0.000) | 0.260 (0.183) | 0.724 (0.054) | 0.619 (0.099) | ||

| 6. K2+AIC | 0.623 (0.095) | 1.000 (0.000) | 0.262 (0.186) | 0.725 (0.055) | 0.619 (0.099) | ||

| Best performance | 4 | 0 | 4 | 4 | 4 | ||

| Model 3 | 1. Hillclimber+Bdeu | 0.644 (0.011) | 1.000 (0.000) | 0.304 (0.206) | 0.737 (0.063) | 0.650 (0.128) | 5, 6 |

| 2. Hillclimber+MDL | 0.606 (0.010) | 1.000 (0.000) | 0.230 (0.194) | 0.717 (0.057) | 0.611 (0.125) | ||

| 3. Hillclimber+AIC | 0.638 (0.099) | 1.000 (0.000) | 0.292 (0.194) | 0.734 (0.059) | 0.648 (0.125) | ||

| 4. K2+Bdeu | 0.662 (0.010) | 1.000 (0.000) | 0.340 (0.204) | 0.748 (0.065) | 0.660 (0.112) | ||

| 5. K2+MDL | 0.662 (0.010) | 1.000 (0.000) | 0.340 (0.204) | 0.748 (0.065) | 0.661 (0.112) | ||

| 6. K2+AIC | 0.662 (0.010) | 1.000 (0.000) | 0.340 (0.204) | 0.748 (0.065) | 0.661 (0.111) | ||

| Best performance | 4, 5, 6 | 0 | 4, 5, 6 | 4, 5, 6 | 5, 6 | ||

| Model 4 | 1. Hillclimber+Bdeu | 0.755 (0.011) | 0.979 (0.065) | 0.540 (0.216) | 0.801 (0.076) | 0.764 (0.107) | 4 |

| 2. Hillclimber+MDL | 0.709 (0.011) | 0.985 (0.053) | 0.444 (0.204) | 0.773 (0.075) | 0.714 (0.124) | ||

| 3. Hillclimber+AIC | 0.747 (0.011) | 0.981 (0.061) | 0.522 (0.209) | 0.796 (0.080) | 0.749 (0.123) | ||

| 4. K2+Bdeu | 0.756 (0.011) | 0.979 (0.065) | 0.542 (0.217) | 0.802 (0.075) | 0.755 (0.123) | ||

| 5. K2+MDL | 0.729 (0.011) | 0.989 (0.046) | 0.480 (0.205) | 0.786 (0.074) | 0.743 (0.126) | ||

| 6. K2+AIC | 0.752 (0.011) | 0.979 (0.065) | 0.534 (0.215) | 0.799 (0.078) | 0.750 (0.128) | ||

| Best performance | 3 | 5 | 4 | 4 | 1 | ||

| Setting Evidence to Y = Yes | Setting Evidence to Y = Yes | ||||||

|---|---|---|---|---|---|---|---|

| Model | Independent Variables | Categories | Probability of Categories in Variables after Setting Evidence to the Response Variable | Model | Independent Variables | Categories | Probability of Categories in Variables after Setting Evidence to the Response Variable |

| Model 0 | X1 | 1 | 0.1312 | Model 2 | X22 | 0 | 0.0679 |

| 2 | 0.4685 | 1 | 0.7281 | ||||

| 3 | 0.0999 | 3 | 0.2038 | ||||

| 4 | 0.1122 | X23 | 0 | 0.0676 | |||

| 5 | 0.1879 | 1 | 0.764 | ||||

| X2 | 1 | 0.8491 | 3 | 0.1682 | |||

| 2 | 0.1508 | X24 | 0 | 0.0629 | |||

| X3 | 1 | 0.145 | 1 | 0.826 | |||

| 2 | 0.1789 | 3 | 0.111 | ||||

| 3 | 0.1281 | X25 | 0 | 0.0878 | |||

| 4 | 0.2751 | 1 | 0.7955 | ||||

| 5 | 0.2727 | 3 | 0.1166 | ||||

| X7 | 1 | 0.1366 | X26 | 0 | 0.1407 | ||

| 2 | 0.1723 | 1 | 0.7015 | ||||

| 3 | 0.1093 | 3 | 0.1576 | ||||

| 4 | 0.1113 | Model 3 | X27 | 0 | 0.1666 | ||

| 5 | 0.4703 | 1 | 0.8333 | ||||

| X8 | 1 | 0.0995 | X28 | 0 | 0.245 | ||

| 2 | 0.1356 | 1 | 0.7549 | ||||

| 3 | 0.1591 | X29 | 0 | 0.079 | |||

| 4 | 0.1411 | 1 | 0.9209 | ||||

| 5 | 0.4644 | X30 | 0 | 0.1507 | |||

| X9 | 0 | 0.2715 | 1 | 0.8492 | |||

| 1 | 0.7284 | X31 | 0 | 0.1921 | |||

| Model 1 | X10 | 0 | 0.1078 | 1 | 0.8078 | ||

| 1 | 0.8921 | Model 4 | X32 | 0 | 0.3431 | ||

| X11 | 0 | 0.1666 | 1 | 0.6568 | |||

| 1 | 0.8333 | X33 | 0 | 0.2714 | |||

| X12 | 0 | 0.1 | 1 | 0.7287 | |||

| 1 | 0.8999 | X34 | 0 | 0.2689 | |||

| X13 | 0 | 0.1284 | 1 | 0.731 | |||

| 1 | 0.8715 | X35 | 0 | 0.3641 | |||

| X14 | 0 | 0.152 | 1 | 0.6358 | |||

| 1 | 0.8479 | X36 | 0 | 0.2968 | |||

| X15 | 0 | 0.376 | 1 | 0.7031 | |||

| 1 | 0.6239 | X37 | 0 | 0.2211 | |||

| X16 | 0 | 0.4759 | 1 | 0.7788 | |||

| 1 | 0.524 | ||||||

| X17 | 0 | 0.408 | |||||

| 1 | 0.5919 | ||||||

| X18 | 0 | 0.2492 | |||||

| 1 | 0.7507 | ||||||

| X19 | 0 | 0.1868 | |||||

| 1 | 0.8131 | ||||||

| X20 | 0 | 0.2132 | |||||

| 1 | 0.7867 | ||||||

| X21 | 0 | 0.3459 | |||||

| 1 | 0.654 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Kasasbeh, M.; Mujalli, R.O.; Abudayyeh, O.; Liu, H.; Altalhoni, A. Bayesian Network Models for Evaluating the Impact of Safety Measures Compliance on Reducing Accidents in the Construction Industry. Buildings 2022, 12, 1980. https://doi.org/10.3390/buildings12111980

Al-Kasasbeh M, Mujalli RO, Abudayyeh O, Liu H, Altalhoni A. Bayesian Network Models for Evaluating the Impact of Safety Measures Compliance on Reducing Accidents in the Construction Industry. Buildings. 2022; 12(11):1980. https://doi.org/10.3390/buildings12111980

Chicago/Turabian StyleAl-Kasasbeh, Maha, Randa Oqab Mujalli, Osama Abudayyeh, Hexu Liu, and Amr Altalhoni. 2022. "Bayesian Network Models for Evaluating the Impact of Safety Measures Compliance on Reducing Accidents in the Construction Industry" Buildings 12, no. 11: 1980. https://doi.org/10.3390/buildings12111980

APA StyleAl-Kasasbeh, M., Mujalli, R. O., Abudayyeh, O., Liu, H., & Altalhoni, A. (2022). Bayesian Network Models for Evaluating the Impact of Safety Measures Compliance on Reducing Accidents in the Construction Industry. Buildings, 12(11), 1980. https://doi.org/10.3390/buildings12111980