Synergies between Mass Customisation and Construction 4.0 Technologies

Abstract

1. Introduction

2. Literature Review

2.1. Mass Customisation

2.2. C4.0 Areas and Technologies

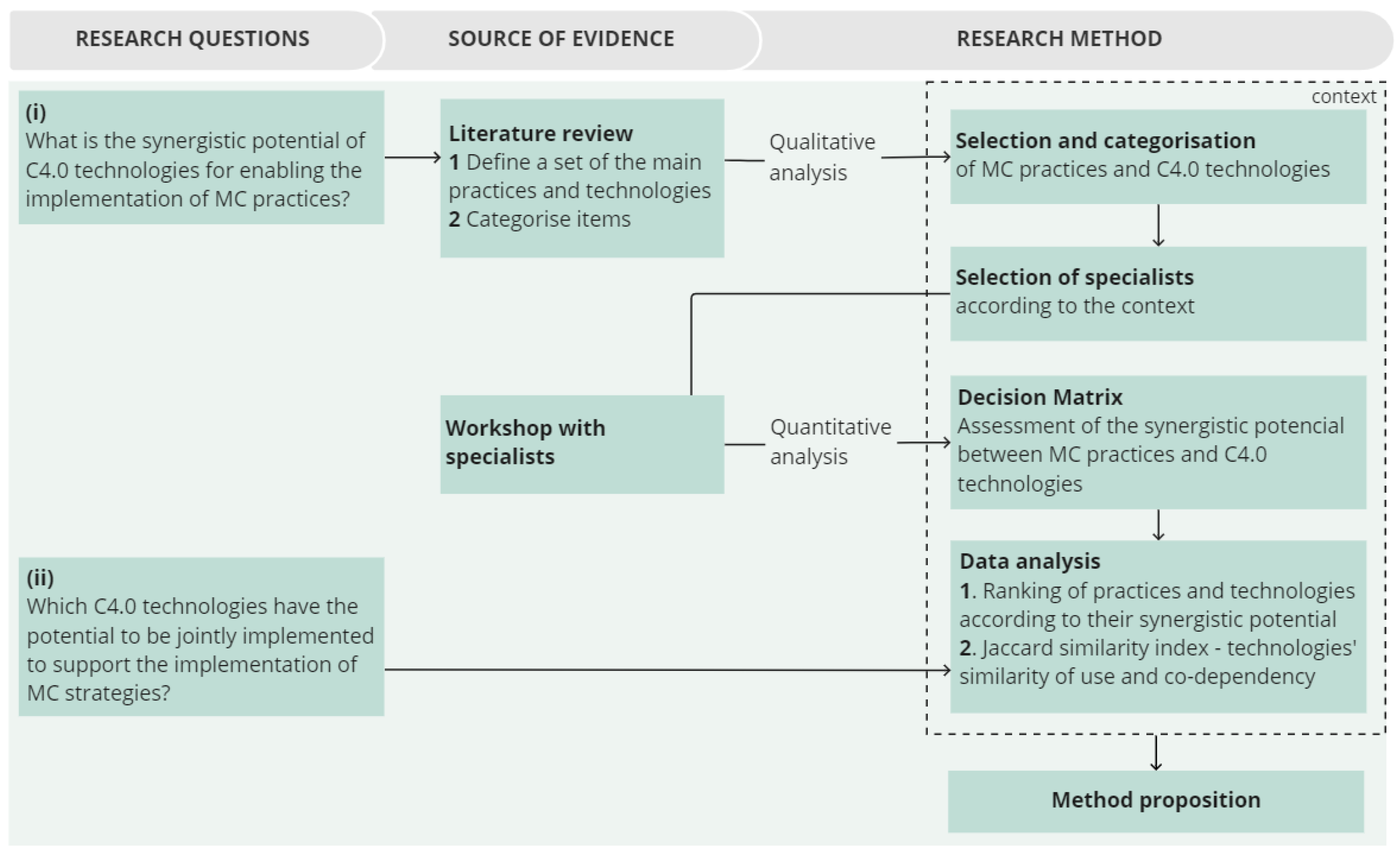

3. Research Method

3.1. Selection and Categorisation of MC Practices and C4.0 Technologies

3.2. Selection of Specialists

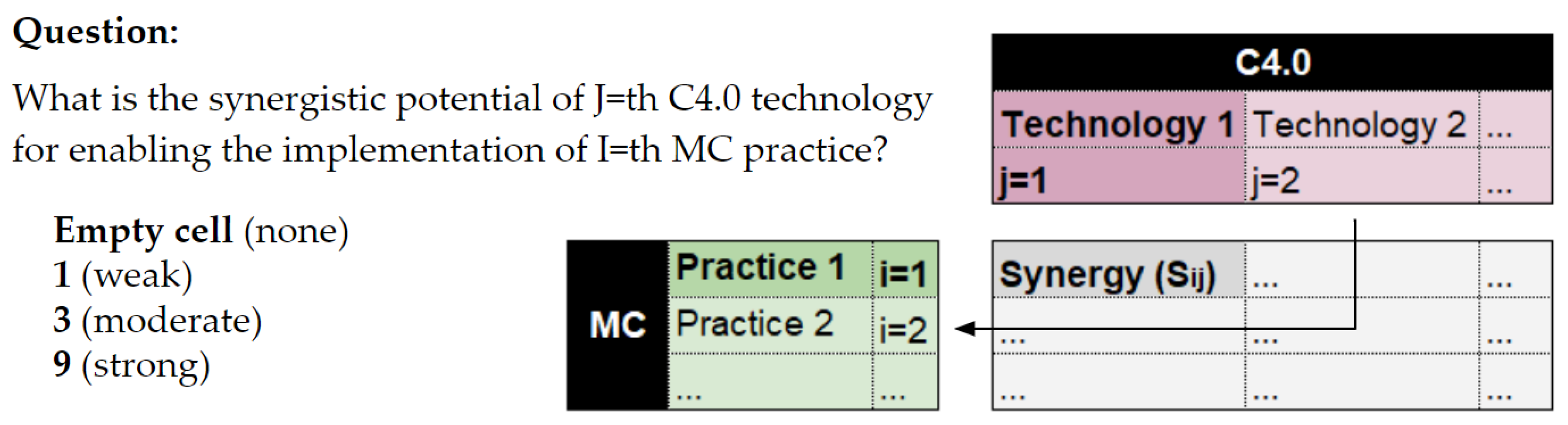

3.3. Decision Matrix Associating MC Practices and C4.0 Technologies

3.4. Data Analysis

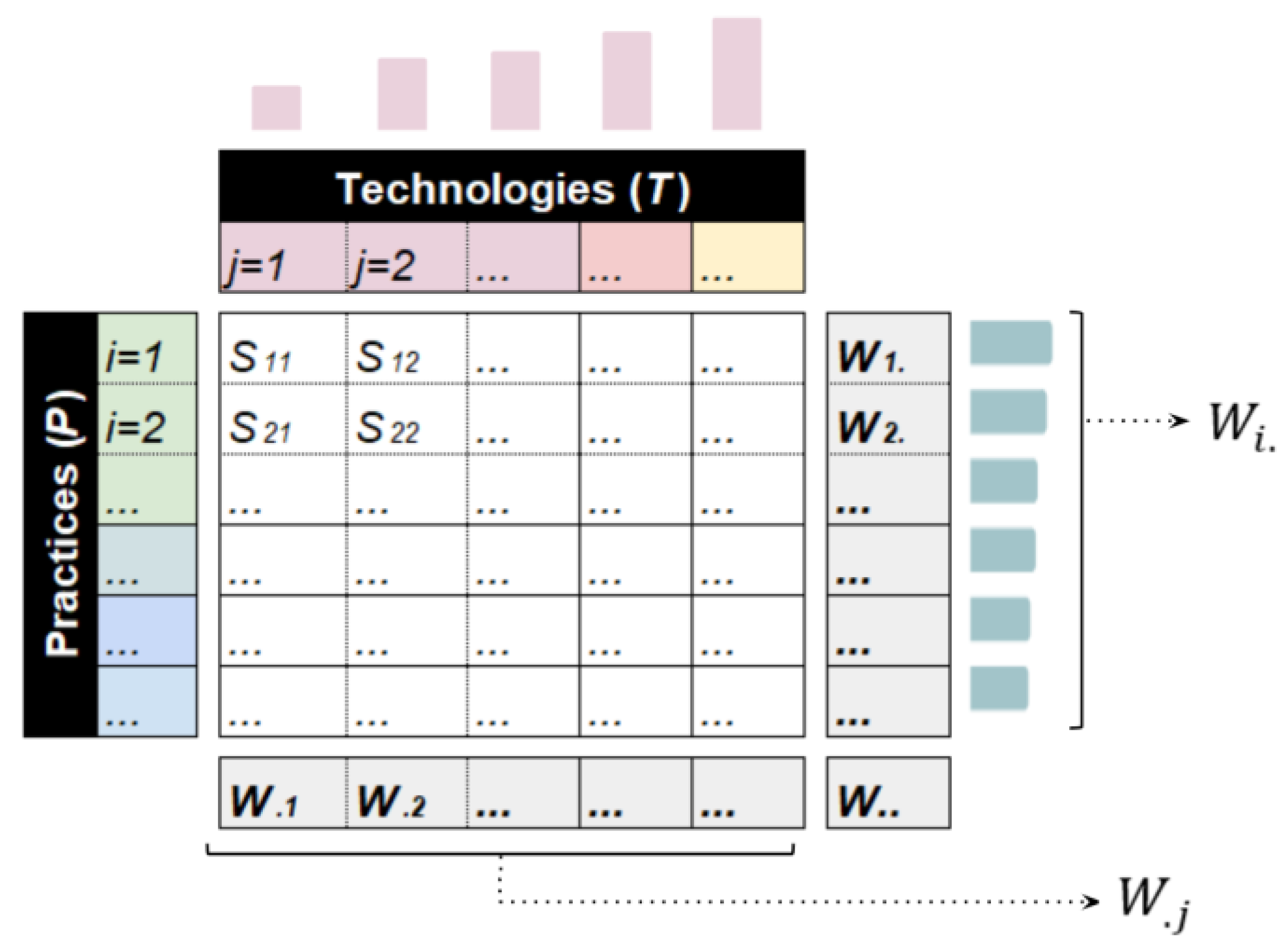

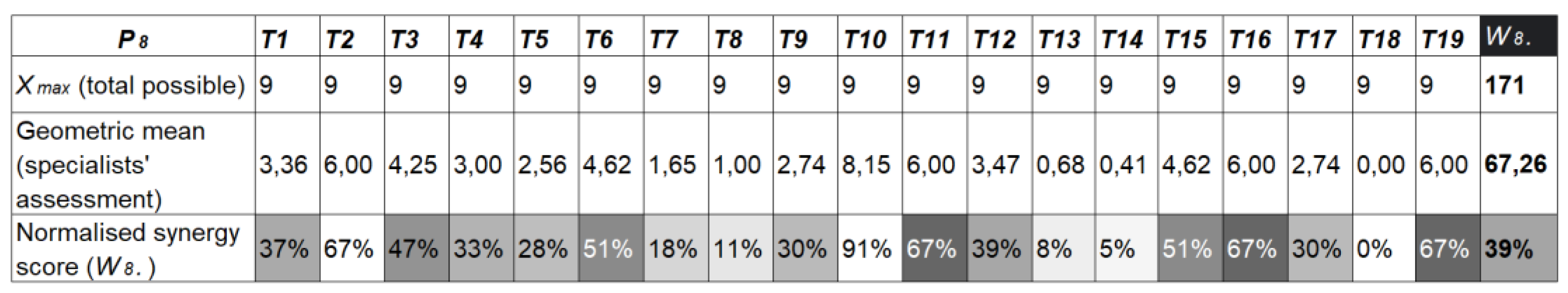

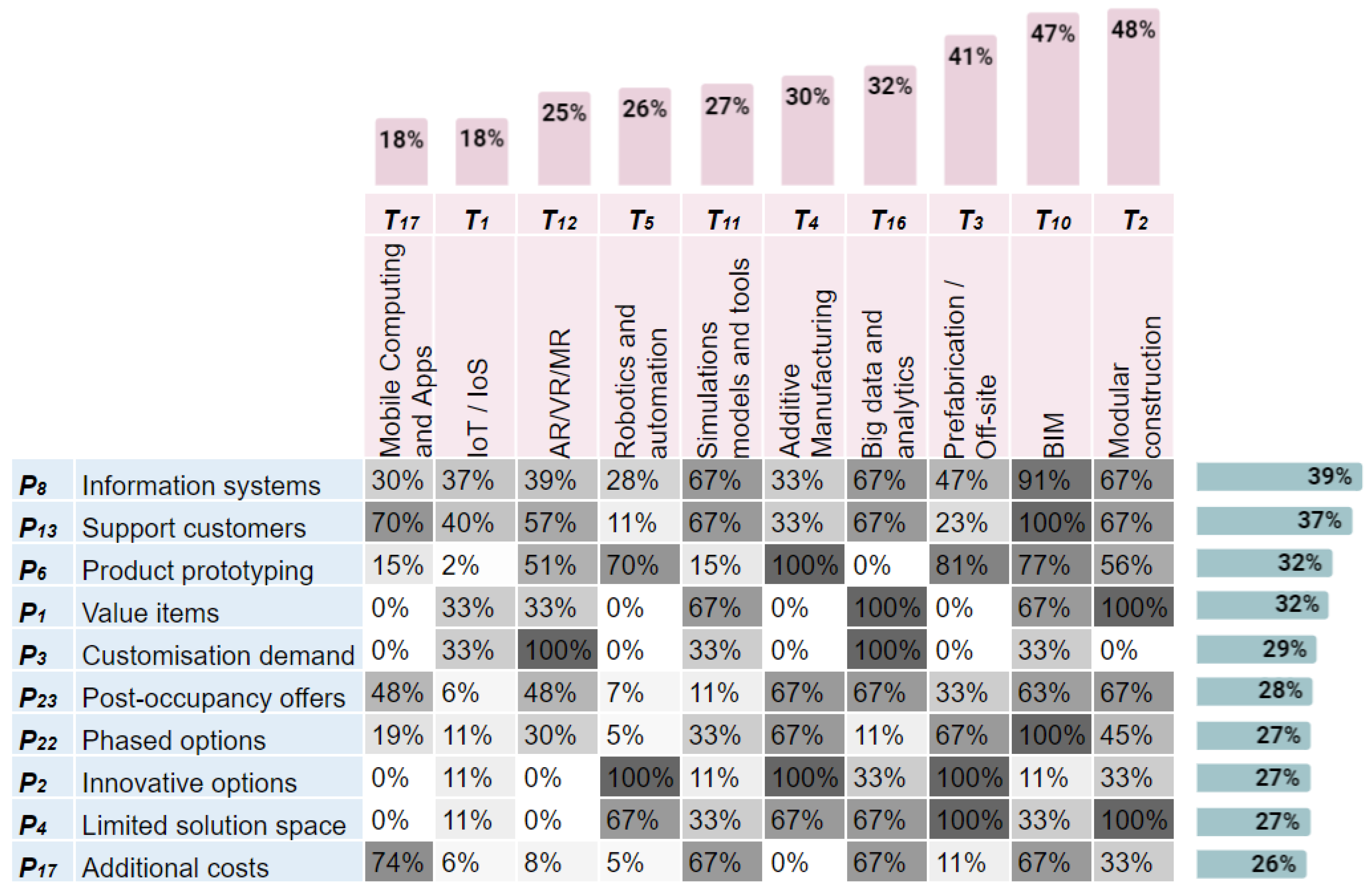

3.4.1. Ranking of Practices and Technologies

| Technology | |

| Synergy scores between P-th practice | |

| : | Global synergies metrics of practices |

| Practice | |

| Synergy scores between J-th technology | |

| : | Global synergies metrics of technologies |

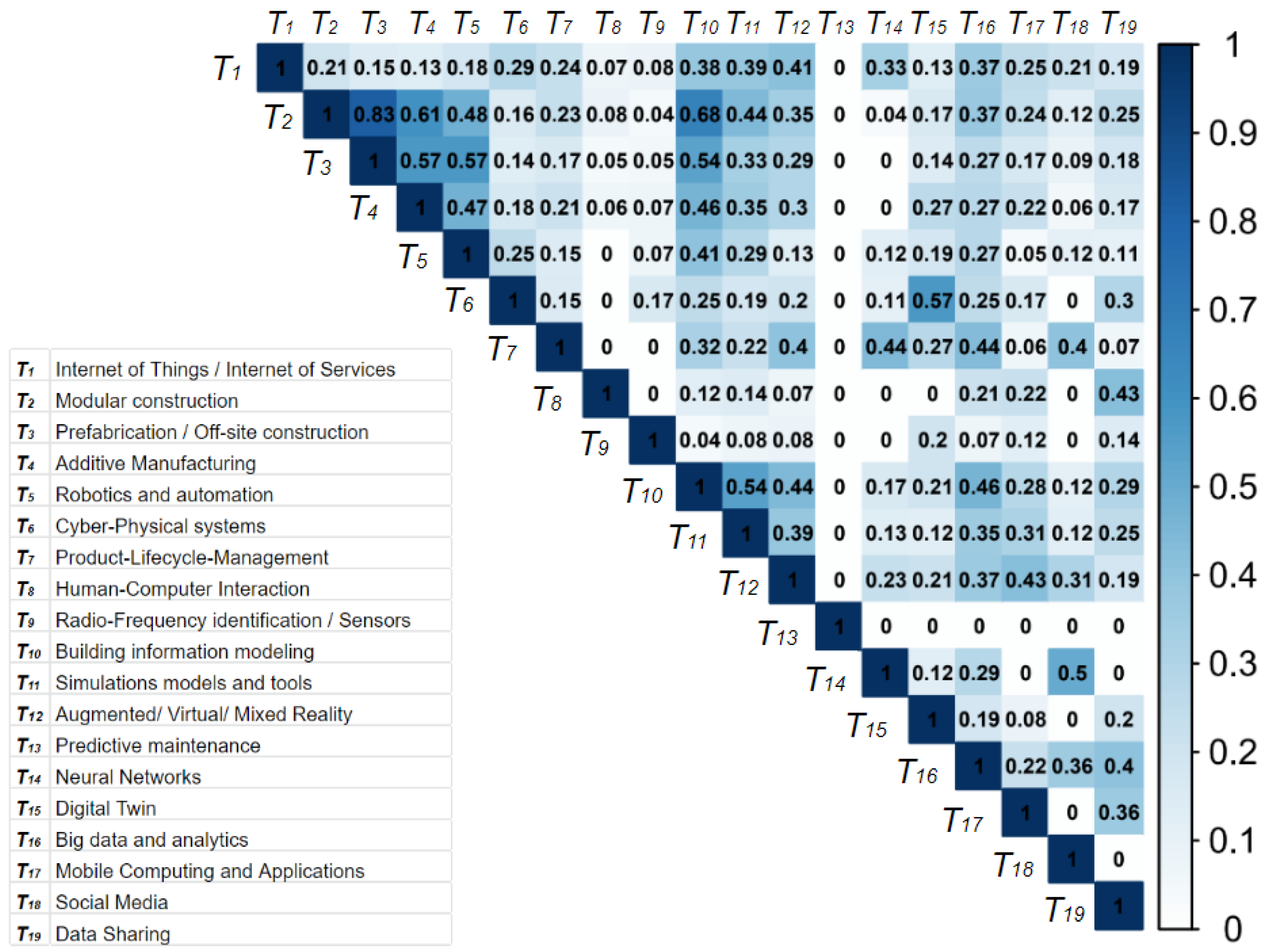

3.4.2. Jaccard Similarity Index

| Technology i | |

| Technology i + 1 | |

| Jaccard similarity index for the technologies |

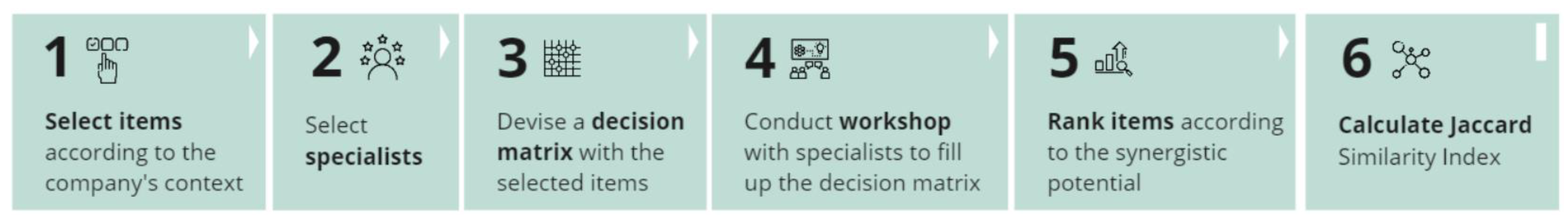

3.5. Overview of the Method to Identify the Synergistic Potential between MC and C4.0

4. Findings

4.1. Ranking of Practices and Technologies According to Their Synergistic Potential

4.2. Jaccard Similarity Index–Technologies’ Similarity of Use

4.3. Method to Identify the Synergistic Potential between MC and C4.0

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pine, B. Mass Customization: The New Frontier in Business Competition; Harvard Business School Press: Boston, MA, USA, 1993. [Google Scholar]

- Hart, C.W.L. Mass customization: Conceptual underpinnings, opportunities and limits. Int. J. Serv. Ind. Manag. 1995, 6, 36–45. [Google Scholar] [CrossRef]

- Tseng, M.M.; Jiao, J.; Merchant, M.E. Design for mass customization. CIRP Ann. 1996, 45, 153–156. [Google Scholar] [CrossRef]

- Da Silveira, G.; Borenstein, D.; Fogliatto, F.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar] [CrossRef]

- Schreier, M. The value increment of mass-customized products: An empirical assessment. J. Consum. Behav. 2006, 5, 317–327. [Google Scholar] [CrossRef]

- Piller, F.T.; Moeslein, K. From economies of scale towards economies of customer integration: Value creation in mass customization based electronic commerce. In Proceedings of the 15th Bled Electronic Commerce Conference eReality: Constructing the eEconomy, Bled, Slovenia, 17–19 June 2002. [Google Scholar]

- Fatorachian, H.; Kazemi, H. A critical investigation of Industry 4.0 in manufacturing: Theoretical operationalization framework. Prod. Plan. Control 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in offsite construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Munoz-La, F.R.; Mora-Serrano, J.; Oñate, E. Methodological-technological framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28(2), 689–711. [Google Scholar] [CrossRef]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative Industry 4.0: Securing the Future of German Manufacturing Industry; Acatech: Munich, Germany, 2013. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitization and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Maskuriy, R.; Ali, K.N.; Maresova, P.; Selamat, A. Industry 4.0 for the construction industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Gandhi, A.; Magar, C.; Roberts, R. How Technology can Drive the Next Wave of Mass Customization. McKinsey Bus. Technol. 2014, 32, 1–8. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/bto/pdf/mobt32_02-09_masscustom_r4.ashx (accessed on 10 August 2022).

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A.; Ohiomah, I. Construction 4.0: Towards delivering of sustainable houses in South Africa. In Proceedings of the Creative Construction Conference, Ljubljana, Slovenia, 30 June–3 July 2018. [Google Scholar]

- Osunsanmi, T.O.; Oke, A.E.; Aigbavboa, C.O. Survey dataset on fusing RFID with mobile technology for efficient safety of construction professionals. Data Brief 2019, 25, 104290. [Google Scholar] [CrossRef] [PubMed]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Oke, A.E.; Liphadzi, M. Appraisal of stakeholders’ willingness to adopt construction 4.0 technologies for construction projects. Built Environ. Proj. Asset Manag. 2020, 10(4), 547–565. [Google Scholar] [CrossRef]

- Kotha, S. Mass-customization: A strategy for knowledge creation and organisational learning. Int. J. Technol. Manag. 1996, 11, 846–858. [Google Scholar]

- Hentschke, C.; Formoso, C.T.; Echeveste, M.S. A Customer Integration Framework for the Development of Mass Customised Housing Projects. Sustainability 2020, 12(21), 8901. [Google Scholar] [CrossRef]

- Ferguson, S.M.; Olewnik, A.T.; Cormier, P. A review of mass customization across marketing, engineering and distribution domains toward development of a process framework. Res. Eng. Des. 2014, 25, 11–30. [Google Scholar] [CrossRef]

- Piller, F.T. Mass customization: Reflections on the state of the concept. Int. J. Flex. Manuf. Syst. 2004, 16, 313–334. [Google Scholar] [CrossRef]

- Kumar, A.; Gattoufi, S.; Reisman, A. Mass customization research: Trends, directions, diffusion intensity, and taxonomic frameworks. Int. J. Flex. Manuf. Syst. 2007, 19, 637–665. [Google Scholar] [CrossRef]

- Echeveste, M.S.; Rozenfeld, H.; Fettermann, D.C. Customizing practices based on the frequency of problems in new product development process. Concurr. Eng. Res. Appl. 2017, 25, 245–261. [Google Scholar] [CrossRef]

- Gherardi, S. Knowing and learning in practice-based studies: An introduction. Learn. Organ. 2009, 16, 352–359. [Google Scholar] [CrossRef]

- Jiao, J.; Ma, Q.; Tseng, M. Toward high value-added products and services: Mass customization and beyond. Technovation 2003, 23, 809–821. [Google Scholar] [CrossRef]

- Fettermann, D.C.; Tortorella, G.L.; Taboada, C.M. Mass customization process in companies from the housing sector in Brazil. In Managing Innovation in Highly Restrictive Environments; Springer: Cham, Switzerland, 2019; pp. 99–118. [Google Scholar] [CrossRef]

- Linner, T.; Bock, T. Evolution of large-scale industrialisation and service innovation in Japanese prefabrication industry. Constr. Innov. 2012, 12, 156–178. [Google Scholar] [CrossRef]

- Rocha, C.G. A Conceptual Framework for Defining Customisation Strategies in the House-Building Sector. Ph.D. Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2011. [Google Scholar]

- Schoenwitz, M.; Potter, A.; Gosling, J.; Naim, M. Product, process and customer preference alignment in prefabricated house building. Int. J. Prod. Econ. 2017, 183, 79–90. [Google Scholar] [CrossRef]

- Lampel, J.; Mintzberg, H. Customizing customization. Sloan Manag. Rev. 1996, 38, 21–30. [Google Scholar]

- Barlow, J.; Ozaki, R. Achieving ‘customer focus’ in private house-building: Current practice and lessons from other industries. Hous. Stud. 2003, 18, 87–101. [Google Scholar] [CrossRef]

- Noguchi, M.; Hernández-Velasco, C. A ‘mass custom design’ approach toupgrading conventional housing development in Mexico. Habitat Int. 2005, 29, 325–336. [Google Scholar] [CrossRef]

- Schoenwitz, M.; Naim, M.; Potter, A. The nature of choice in mass customized house building. Constr. Manag. Econ. 2012, 30, 203–219. [Google Scholar] [CrossRef]

- Tillmann, P.A. Diretrizes para a Adoção da Customização em Massa na Construção Habitacional para Baixa Renda. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2008. [Google Scholar]

- Valente, C.P. Modelo para Concepção de Dispositivos Visuais na Gestão da Produção na Construção. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2017. [Google Scholar]

- Amorim, L.G. Análise de Práticas Relacionadas à Gestão da Produção para Apoiar a Customização em Massa em Empreendimentos Habitacionais. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2019. [Google Scholar]

- Wikberg, F.; Olofsson, T.; Ekholm, A. Design configuration with architectural objects: Linking customer requirements with system capabilities in industrialized house-building platforms. Constr. Manag. Econ. 2014, 32, 196–207. [Google Scholar] [CrossRef]

- Martinez, E.; Tommelein, I.D.; Alvear, A. Integration of Lean and Information Technology to Enable a Customisation Strategy in Aordable Housing. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017; pp. 95–102. [Google Scholar]

- Machado, A.G.C.; Moraes, W.F.A. De Um framework para a customização. Rev. Alcance Eletrôn. 2010, 17, 295–311. [Google Scholar]

- Formoso, C.T.; Tillmann, P.; Hentschke, C.S. Guidelines for the Implementation of Mass Customization in Affordable House-Building Projects. Sustainability 2022, 14, 4141. [Google Scholar] [CrossRef]

- Barlow, J.; Childerhouse, P.; Gann, D.; Hong-Minh, S.; Naim, M.; Ozaki, R. Choice and delivery in house-building: Lessons from Japan for UK housebuilders. Build. Res. Inf. 2003, 31, 134–145. [Google Scholar] [CrossRef]

- Khalili-Araghi, S.; Kolarevic, B. Development of a framework for dimensional customisation system: A novel method for customer participation. J. Build. Eng. 2016, 5, 231–238. [Google Scholar] [CrossRef]

- Conte, M.; Hentschke, C.S.; Formoso, C.T.; Echeveste, M. Developing a choice menu: An investigation on the definition and offer of customisation units. In Proceedings of the Zero Energy Mass Custom Home (ZEMCH) International Conference, Seoul, Korea, 26–28 November 2019; pp. 1–7. [Google Scholar]

- Randall, T.; Terwiesch, C.; Ulrich, K.T. Principles for user design of customized products. Calif. Manag. Rev. 2005, 47, 68–85. [Google Scholar] [CrossRef]

- Conte, M. Integração do Cliente na Customização de Produtos Habitacionais. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2020. [Google Scholar]

- Dunston, P.S.; Wang, X. Mixed reality-based visualization interfaces for architecture, engineering, and construction industry. J. Constr. Eng. Manag. 2005, 131, 1301–1309. [Google Scholar] [CrossRef]

- Pullman, M.E.; Gross, M.A. Ability of experience design elements to elicit emotions and loyalty behaviors. Decis. Sci. 2004, 35, 551–578. [Google Scholar] [CrossRef]

- Zomerdijk, L.G.; Voss, C.A. Service design for experience-centric services. J. Serv. Res. 2010, 13, 67–82. [Google Scholar] [CrossRef]

- Jiao, J.; Tseng, M. Fundamentals of product family architecture. Integr. Manuf. Syst. 2000, 11, 469–483. [Google Scholar] [CrossRef]

- Salvador, F.; De Holan, P.M.; Piller, F. Cracking the code of mass customization. MIT Sloan Manag. Rev. 2009, 50, 71–78. [Google Scholar]

- Piller, F.T.; Tseng, M.M. New directions for mass customization. In The Customer Centric Enterprise; Springer: Berlin/Heidelberg, Germany, 2003; pp. 19–535. [Google Scholar] [CrossRef]

- Andújar-Montoya, M.D.; Gilart-Iglesias, V.; Montoyo, A.; Marcos-Jorquera, D. A construction management framework for mass customisation in traditional construction. Sustainability 2015, 7, 5182–5210. [Google Scholar] [CrossRef]

- Piller, F.; Schubert, P.; Koch, M.; Möslein, K. Overcoming mass confusion: Collaborative customer co-design in online communities. J. Comput.-Mediat. Commun. 2005, 10, jcmc1042. [Google Scholar] [CrossRef]

- Turowski, K. A virtual electronic call center solution for mass customization. In Proceedings of the 32nd Annual Hawaii International Conference on Systems Sciences, Hawaii, HI, USA, 5–8 January 1999. [Google Scholar]

- Gilmore, J.H.; PINE, B.J. The four faces of mass customization. Harv. Bus. Rev. 1997, 75, 91–102. [Google Scholar]

- Rudberg, M.; Wikner, J. Mass customization in terms of the customer order decoupling point. Prod. Plan. Control 2004, 15, 445–458. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; da Silveira, G.J.C. Mass customisation: A method for market segmentation and choice menu design. Int. J. Prod. Econ. 2008, 111, 606–622. [Google Scholar] [CrossRef]

- Naim, M.; Barlow, J. An innovative supply chain strategy for customized housing. Constr. Manag. Econ. 2002, 21, 593–602. [Google Scholar] [CrossRef]

- Sawhney, A.; Irizarry, J.; Riley, M.; Pérez, C.T. A proposed framework for Construction 4.0 based on a review of literature. In Proceedings of the Associated Schools of Construction Proceedings 56th Annual International Conference, Online Conference, 14-18 April 2020; Leathem, T., Ed.; EPiC Series in Built Environment. Easy-Chair: Manchester, UK, 2020; Volume 1, pp. 301–309. [Google Scholar]

- Tam, V.W.; Tam, C.M.; Zeng, S.X.; Ng, W.C. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Kajati, E.; Papcun, P.; Liu, C.; Zhong, R.Y.; Koziorek, J.; Zolotova, I. Cloud based cyber-physical systems: Network evaluation study. Adv. Eng. Inform. 2019, 42, 100988. [Google Scholar] [CrossRef]

- Pargman, D.S.; Eriksson, E.; Bates, O.; Kirman, B.; Comber, R.; Hedman, A.; Van den Broeck, M. The future of computing and wisdom: Insights from human–computer interaction. Futures 2019, 113, 102434. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modelling for Owners, Managers, Architects, Engineers, Contractors, and Fabricators; John Wiley and Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Craig, A.B.; Sherman, W.R.; Will, J.D. Developing Virtual Reality Applications: Foundations of Effective Design; Morgan Kaufmann: Burlington, MA, USA, 2009. [Google Scholar]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Huang, H.; Chen, X.; Wang, J. Blockchain-based multiple groups data sharing with anonymity and traceability. Sci. China Inf. Sci. 2020, 63, 1–13. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for offsite construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Mansouri, S.; Castronovo, F.; Akhavian, R. Analysis of the synergistic effect of data analytics and technology trends in the AEC/FM industry. J. Constr. Eng. Manag. 2020, 146, 04019113. [Google Scholar] [CrossRef]

- Lukka, K. The constructive research aproach. In Case Study Research in Logistics; Ojala, L., Himola, O.-P., Eds.; Series B1; Turku School of Economics and Business Administration: Turku, Finland, 2003; pp. 83–101. [Google Scholar]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; Productivity Press: New York, NY, USA, 1990. [Google Scholar]

- Hamers, L.; Hemeryck, Y.; Herweyers, G.; Janssen, M.; Keters, H.; Rousseau, R.; Vanhoutte, A. Similaritymeasures in scientometric research: The Jaccard index versus Salton’s cosine formula. Inf. Process. Manag. 1989, 25, 315–318. [Google Scholar] [CrossRef]

- Nahmens, B. Is customization fruitful in industrialized homebuilding industry? J. Constr. Eng. Manag. 2011, 137, 1027–1035. [Google Scholar] [CrossRef]

- Vilutiene, T.; Hosseini, M.R.; Pellicer, E.; Zavadskas, E.K. Advanced BIM applications in the construction industry. Adv. Civ. Eng. 2019, 6356107. [Google Scholar] [CrossRef]

- Li, X.; Wu, P.; Shen, G.Q.P.; Wang, X.Y.; Teng, X. Mapping the knowledge domains of Building Information Modelling (BIM): A bibliometric approach. Autom. Constr. 2017, 84, 195–206. [Google Scholar] [CrossRef]

- Lee, S.; Ha, M. Customer interactive building information modelling for apartment unit design. Autom. Constr. 2013, 35, 424–430. [Google Scholar] [CrossRef]

- Farr, E.R.P.; Piroozfar, P.A.E.; Robinson, D. BIM as a generic configurator for facilitation of customisation in the AEC industry. Autom. Constr. 2014, 45, 119–125. [Google Scholar] [CrossRef]

- Benros, D.; Duarte, J.P. An integrated system for providing mass customized housing. Autom. Constr. 2009, 18, 310–320. [Google Scholar] [CrossRef]

- Zhao, H.; Adzhiev, V.; Pasko, A.; McLoughlin, L. 3D mass customization toolkits design, part I: Survey and an evaluation model. Comput.-Aided Des. Appl. 2018, 16, 204–222. [Google Scholar] [CrossRef]

- Hassenzahl, M. Experience Design: Technology for All the Right Reasons. Synth. Lect. Hum. Cent. Inform. 2010, 3, 1–95. [Google Scholar] [CrossRef]

- Gupta, S.; Vajic, M. The Contextual and Dialectical Nature of Experiences. In New Service Development: Creating Memorable Experiences; SAGE: Thousand Oaks, CA, USA, 2000. [Google Scholar] [CrossRef]

- Gutek, B.A.; Bhappu, A.D.; Liao-Troth, M.A.; Cherry, B. Distinguishing between service relationships and encounters. J. Appl. Psychol. 1999, 84, 218. [Google Scholar] [CrossRef]

- Koskela, L.; Pikas, E.; Gomes, D.; Biotto, C. Towards Shared Understanding on Common Ground, Boundary Objects and Other Related Concepts. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016. [Google Scholar]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Meisel, N.A.; Watson, N.; Sven, G.B.; Duarte, J.P.; Nazarian, S. Design and System Considerations for Construction-Scale Concrete Additive Manufacturing in Remote Environments via Robotic Arm Deposition. 3d Print. Addit. Manuf. 2022, 9, 35–45. [Google Scholar] [CrossRef]

- Shukla, M.; Todorov, I.; Kapletia, D. Application of additive manufacturing for mass customisation: Understanding the interaction of critical barriers. Prod. Plan. Control 2018, 29, 814–825. [Google Scholar] [CrossRef]

- Slywotzky, A.J. The age of the choiceboard. Harv. Bus. Rev. 2001, 78, 40. [Google Scholar]

- Abdollahpouri, H.; Adomavicius, G.; Burke, R.; Guy, I.; Jannach, D.; Kamishima, T.; Krasnodebski, J.; Pizzato, L. Beyond personalization: Research directions in multistakeholder recommendation. arXiv 2009, arXiv:1905.01986v1. [Google Scholar]

- Trentin, A.; Perin, E.; Forza, C. Increasing the consumer-perceived benefits of a mass-customization experience through sales-configurator capabilities. Comput. Ind. 2014, 65, 693–705. [Google Scholar] [CrossRef]

- Hentschke, C.S. A method for Capturing Customers’ Preferences for Housing Customisation. Ph.D. Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2021. [Google Scholar]

- Hentschke, C.S.; Echeveste, M.S.; Formoso, C.T.; Ribeiro, J.L.D. Method for capturing demands for housing customisation: Balancing value for customers and operations costs. J. Hous. Built Environ. 2022, 37, 311–337. [Google Scholar] [CrossRef]

- Jensen, P.; Olofsson, T.; Sandberg, M.; Malmgren, L. Reducing complexity of customized prefabricated buildings through modularization and IT support. In Proceedings of the International Conference on Informations Technology in Construction, Santiago, Chile, 15–17 July 2008; pp. 429–437. [Google Scholar]

- Feldmann, F.G.; Birkel, H.; Hartmann, E. Exploring barriers towards modular construction—A developer perspective using fuzzy DEMATEL. J. Clean. Prod. 2022, 367, 133023. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in offsite construction: Current status and future direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Pan, M.; Yang, Y.; Zheng, Z.; Pan, W. Artificial Intelligence and Robotics for Prefabricated and Modular Construction: A Systematic Literature Review. J. Constr. Eng. Manag. 2022, 148, 03122004. [Google Scholar] [CrossRef]

- Neelamkavil, J. Automation in the prefab and modular construction industry. In Proceedings of the 26th Symposium on Construction Robotics ISARC, Austin, TX, USA, 24–27 June 2009. [Google Scholar]

- Viana, D.D.; Tommelein, I.D.; Formoso, C.T. Using modularity to reduce complexity of industrialized building systems for mass customization. Energies 2017, 10, 1622. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuserb, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

| Decision Categories | Code | Practice | Short Name | Based on |

|---|---|---|---|---|

| Core Categories | P1 | Identify customisable items of greater value-added capabilities | Value items | [4,24,25] |

| P2 | Offer innovative customisation units, such as those related to sustainability and automation | Innovative options | [18,26] | |

| P3 | Adopt methods for identifying the demand for customisation, consumers preferences, and market segmentation to define solution spaces | Customisation demand | [4,18,24,27,28] | |

| P4 | Define a limited solution space to achieve economies of scale | Limited solution space | [18,27,29,30,31,32] | |

| P5 | Define different levels of customisation with specific customisation units according to customers’ preferences, distinct market segments, and projects | Customisation levels | [18,28,33] | |

| P6 | Use product prototyping to test and communicate technical and design solutions to stakeholders | Product prototyping | [18,34,35] | |

| P7 | Create a database of customers orders for customising housing units shared within departments | Orders database | [4,18,24,25,27] | |

| P8 | Use specialised information systems for managing production management of customised products | Information systems | [18,35,36,37] | |

| P9 | Use choice menus as a learning tool, to understand customers’ needs and preferences and provide feedback to new product development | Choice menu learnings | [18,37] | |

| P10 | Manage information about customisation orders to create knowledge for the company | Knowledge creation | [18,26,27,30,33] | |

| P11 | Create metrics that can be used to analyse the trade-offs between flexibility–productivity | Trade-offs metrics | [18,27,38] | |

| P12 | Develop and refine products in partnership with the supply chain | Supply chain partnership | [4,35,39] | |

| Customer integration | P13 | Adopt information technology tools, choice menus, or online configurator systems to support customers’ choice and product configuration | Support customers | [18,25,31,36,40,41,42] |

| P14 | Build physical or virtual prototypes, virtual or augmented reality, or showrooms for showing the product alternatives | Product alternatives | [18,25,39,43] | |

| P15 | Use augmented, virtual, or mixed reality to present product alternatives to customers | Present options | [44,45] | |

| P16 | Prepare the relational context, including training employees for technical assistance during the customer’s decision-making process | Relational context | [43,44,46] | |

| P17 | Use tools, lists, and databases that communicate additional costs and suppliers’ information for customisation to support customer decision-making during configuration, enabling negotiation and increasing transparency | Additional costs | [3,18,31,35,42,44] | |

| P18 | Monitor customers’ buying experience to feedback on the process | Buying experience | [44] | |

| P19 | Define interactions with customers and display them in a customer journey representation | Customers interaction | [18,25,40,42,47] | |

| P20 | Prepare customers for decision-making process | Decision- process | [25,44] | |

| Product Design | P21 | Use modular components that allow product variations according to customers’ requirements | Modular components | [18,31,32,38,40] |

| P22 | Offer customisation options according to the execution stage of the work | Phased options | [29,33,35] | |

| P23 | Offer additional customisation units after occupancy or replace previously chosen components according to customers emerging needs | Post-occupancy offers | [18,25,26] | |

| P24 | Use standardisation methods for (communalisation) | Standardisation | [25,48] | |

| Operations management | P25 | Translate customers’ requests for design and production instructions | Production instructions | [4,25] |

| P26 | Build a prototype or a model apartment to guide the execution of works’ team and enable continuous improvement | Guiding prototype | [34,35] | |

| P27 | Define customisation levels according to the decoupling point in long-term planning | Decoupling points | [33,35,39] | |

| P28 | Processes that allow customisation postponement | Customisation postponement | [27,35,39] | |

| P29 | Automation in the production of components | Automation | [26,35] | |

| P30 | More flexible production arrangements to contribute to the production of custom items | Flexible production | [3,25] | |

| P31 | Industrialisation or prefabrication of components for production in short lead times | Short lead times | [35] |

| Area | Code | Technology | Description |

|---|---|---|---|

| Physical Domain | T1 | Internet of Things (IoT)/Internet of Services (IoS) | Connects digital BIM models with physical devices for on-site control and monitoring, optimising communication, and construction logistics in general [9] |

| T2 | Modular Construction | A system’s capacity to be subdivided into smaller, independent modules (subsystems), linked and assembled using standardised rules [9] | |

| T3 | Prefabrication/Offsite construction | Practice of producing construction components in a manufacturing factory, transporting them to construction sites, and assembling them to construct buildings [59] | |

| T4 | Additive Manufacturing | The additive process of depositing successive thin layers of material upon each other, producing a final three-dimensional product through a wide variety of materials [60] | |

| T5 | Robotics and automation | Machines that can be programmed to interact autonomously with objects to perform tasks of different kinds [9] | |

| T6 | Cyber-Physical Systems (CPS)/Embedded systems | Ecosystem that entangles the network and physical worlds through real-time communication and cooperation between value network participants such as devices, systems, organisations, and people [61] | |

| T7 | Product-Lifecycle-Management (PLM) | Deals with the integration of all information produced throughout all phases of the whole lifecycle of a company’s product (Sudarsan et al., 2005) through integrated IT solutions, involving customers, suppliers, and resources [9] | |

| T8 | Human–Computer Interaction (HCI) | Studies the interaction between humans and computers in all forms, and engaged with understanding the relationship between humans and emerging technologies [62] | |

| T9 | Radio-Frequency identification (RFID)/Sensors/Worker sensors | Use of electromagnetic fields, radio frequency waves, to automatically detect, identify, geolocate, and track tags affixed to objects [9] | |

| Simulation and Modelling | T10 | Building information modelling (BIM) | Tools, processes and technologies that are facilitated by digital, machine-readable documentation about a building, its performance, its planning, its construction and its operation [63] |

| T11 | Simulations models and tools | Replicate and thus predict the behaviour of systems and processes, i.e., analyse structures during the design phase, predict energy consumption, simulate fire evacuations [9] | |

| T12 | Augmented/Virtual/Mixed Reality (AR/VR/MR) | AR creates connections between the physical world and digital information by providing an immediate, simple interface to a digitally enhanced physical world (Schmalstieg and Hollerer, 2016). VR generates a view that appears to the user’s senses similar to the real world through a computer simulation [64] | |

| T13 | Predictive maintenance | Use simulations or early detection of key indicators to predict future failures in installations, systems, or equipment [9] | |

| T14 | Neural Networks | Computational models inspired by biological neural networks that use interconnected nodes that process information to generate automatic predictions and learning [9] | |

| T15 | Digital Twin | Virtual replica of a physical system that allows different simulation disciplines characterised by the synchronisation between the virtual and actual system [9] | |

| Digitalisation and Virtualisation | T16 | Big data and analytics | Concerned with the understanding of the big data, provides insights to transform companies through data-driven decision-making [65] |

| T17 | Mobile Computing and Applications | Use of mobile devices to support communication and collaboration during the construction process [11] | |

| T18 | Social Media | Used as a platform for collaboration, interactions, and information sharing among the different project participants [11] | |

| T19 | Data Sharing | Sharing of data between stakeholders for cooperative purposes [66] |

| Specialist | Background | Education | Area of Expertise | Years in Industry | Years in Academia |

|---|---|---|---|---|---|

| 1 | Civil Engineer | PhD | CM, MC | 3 | 38 |

| 2 | Architect and Urbanist | PhD | MC | - | 16 |

| 3 | Civil Engineer | PhD Candidate | DT, CM | 14 | 12 |

| 4 | Architect and Urbanist | PhD | MC, CM | - | 10 |

| 5 | Civil Engineer | PhD Candidate | DT, CM | 9 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conte, M.; Echeveste, M.E.S.; Formoso, C.T.; Bazzan, J. Synergies between Mass Customisation and Construction 4.0 Technologies. Buildings 2022, 12, 1896. https://doi.org/10.3390/buildings12111896

Conte M, Echeveste MES, Formoso CT, Bazzan J. Synergies between Mass Customisation and Construction 4.0 Technologies. Buildings. 2022; 12(11):1896. https://doi.org/10.3390/buildings12111896

Chicago/Turabian StyleConte, Manoela, Marcia E. S. Echeveste, Carlos T. Formoso, and Jordana Bazzan. 2022. "Synergies between Mass Customisation and Construction 4.0 Technologies" Buildings 12, no. 11: 1896. https://doi.org/10.3390/buildings12111896

APA StyleConte, M., Echeveste, M. E. S., Formoso, C. T., & Bazzan, J. (2022). Synergies between Mass Customisation and Construction 4.0 Technologies. Buildings, 12(11), 1896. https://doi.org/10.3390/buildings12111896