Reducing Life Cycle Embodied Energy of Residential Buildings: Importance of Building and Material Service Life

Abstract

1. Introduction

1.1. Life Cycle Embodied Energy Assessment

Approaches and Examples of Embodied Energy Assessment

1.2. Building Service Life

1.3. Materials Service Life

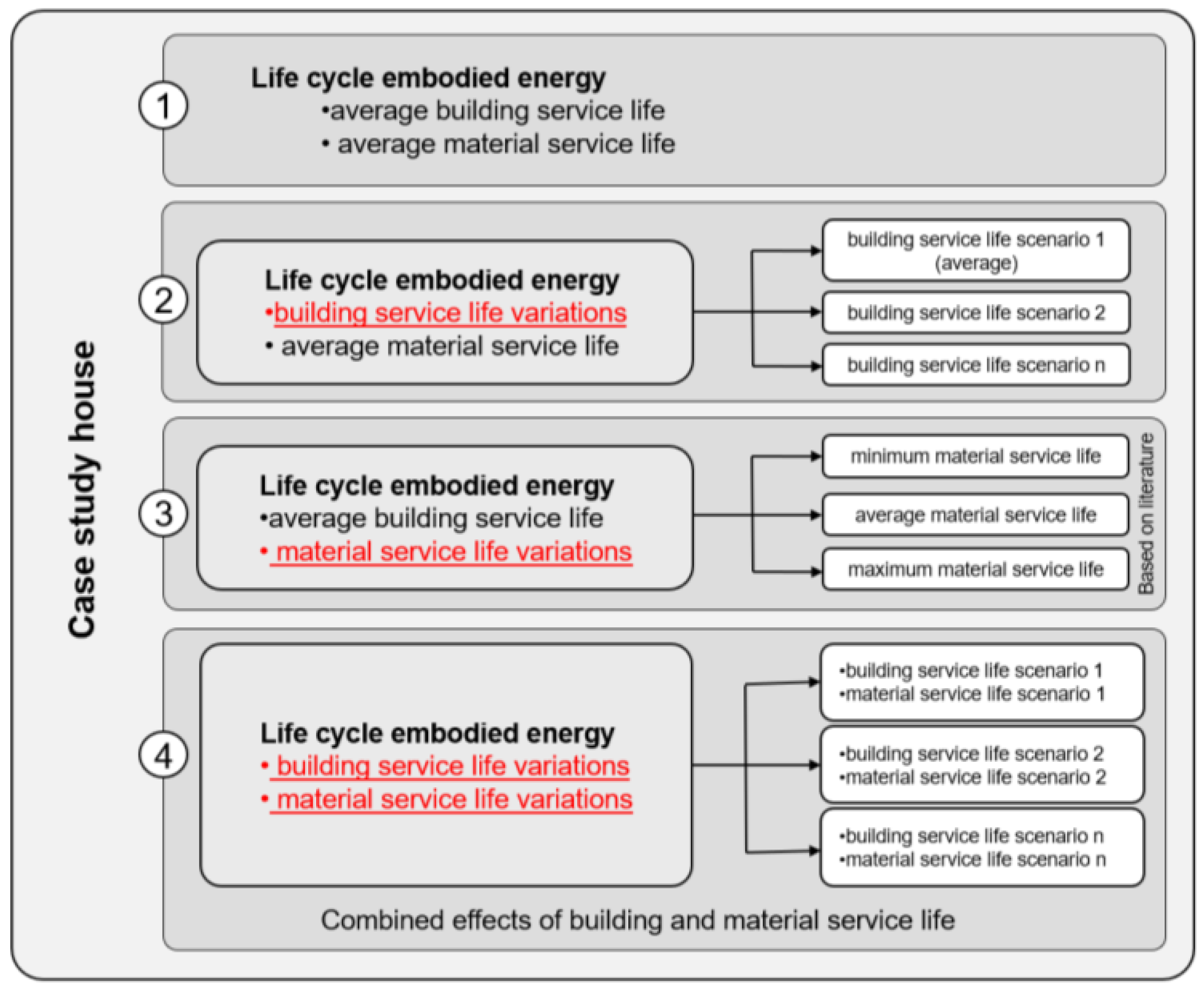

2. Materials and Methods

2.1. Case Study House

2.2. Calculating Initial and Recurrent Embodied Energy

2.2.1. Estimating Average Building Service Life and Additional Scenarios

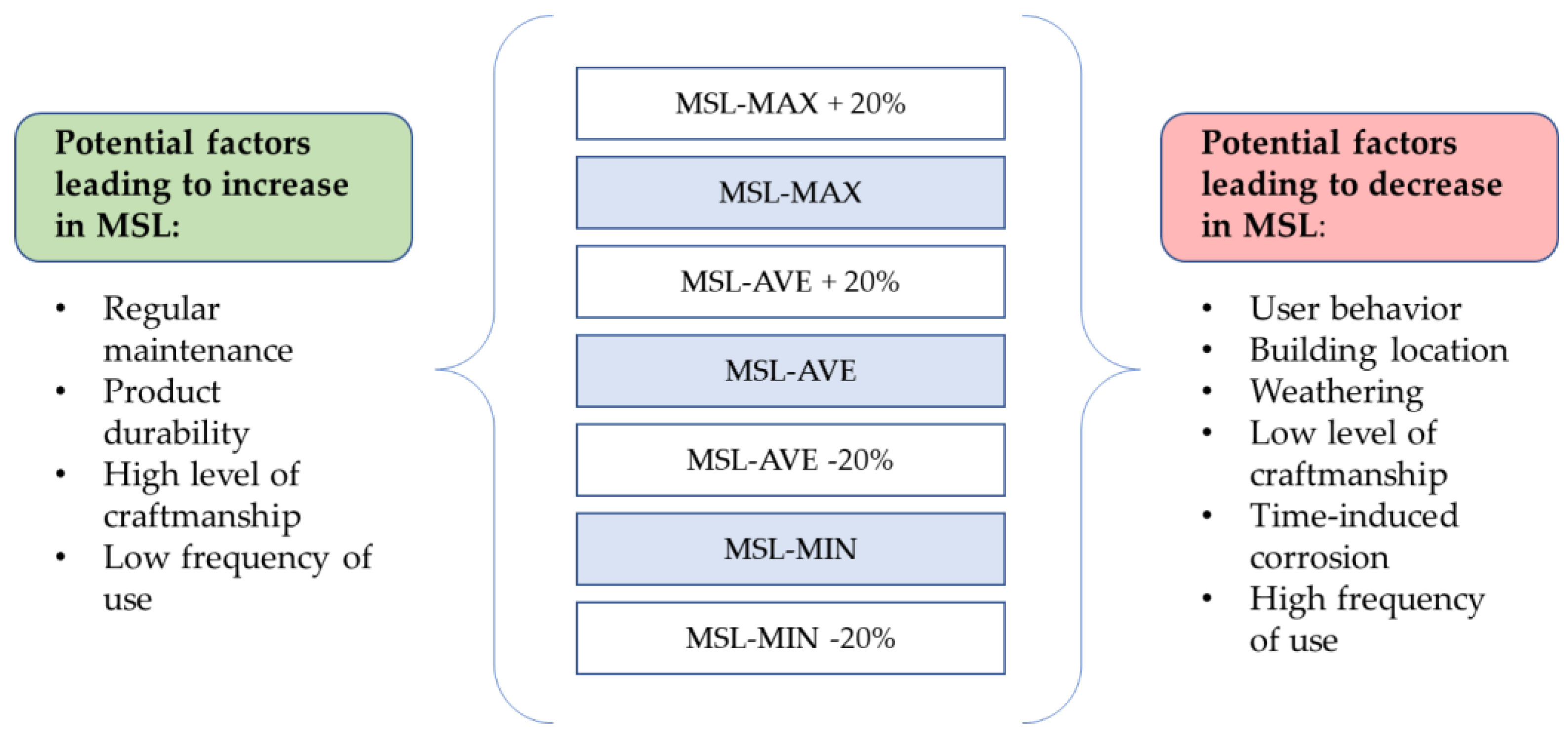

2.2.2. Estimating Material Service Life and Additional Scenarios

3. Results and Discussion

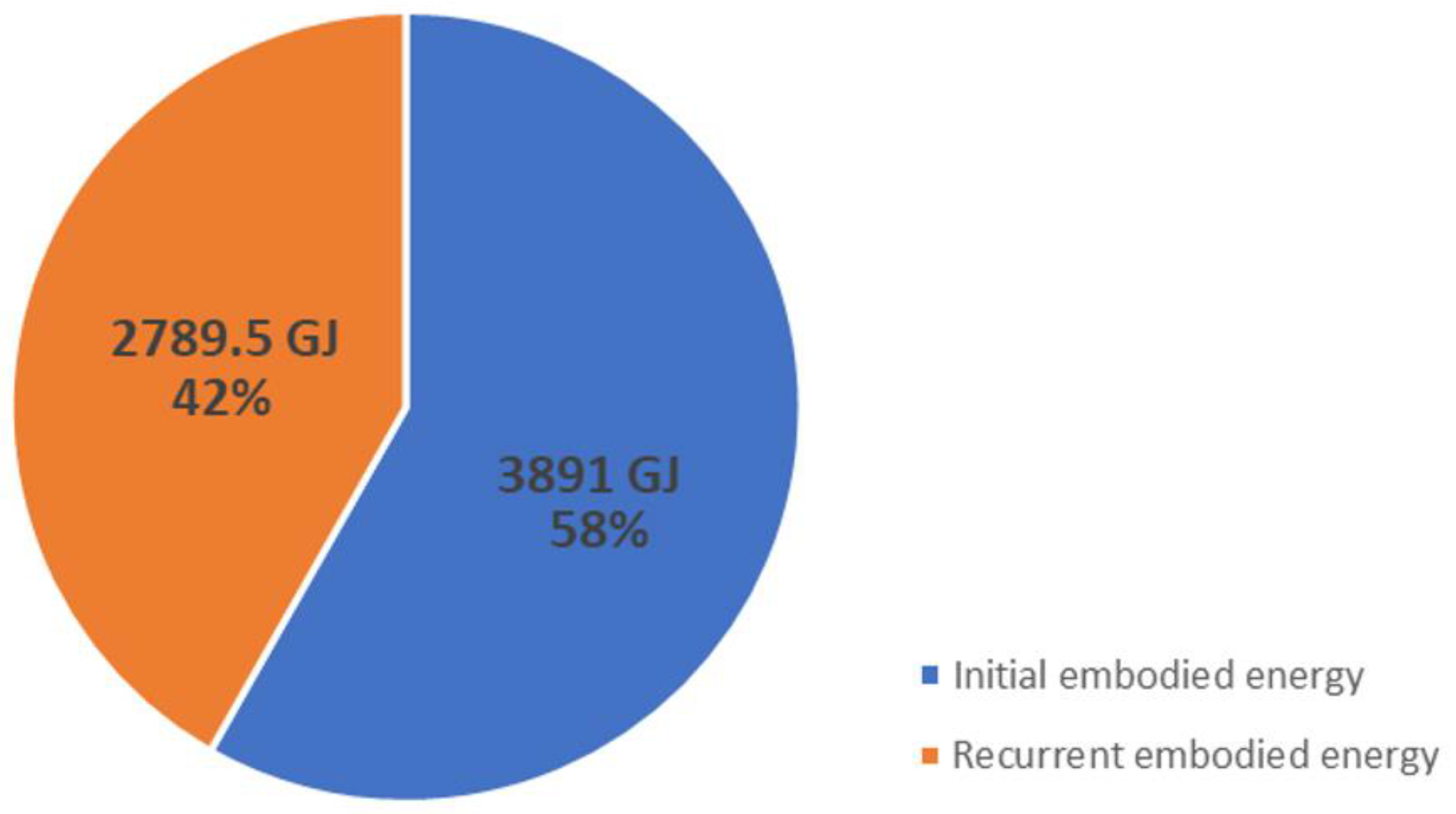

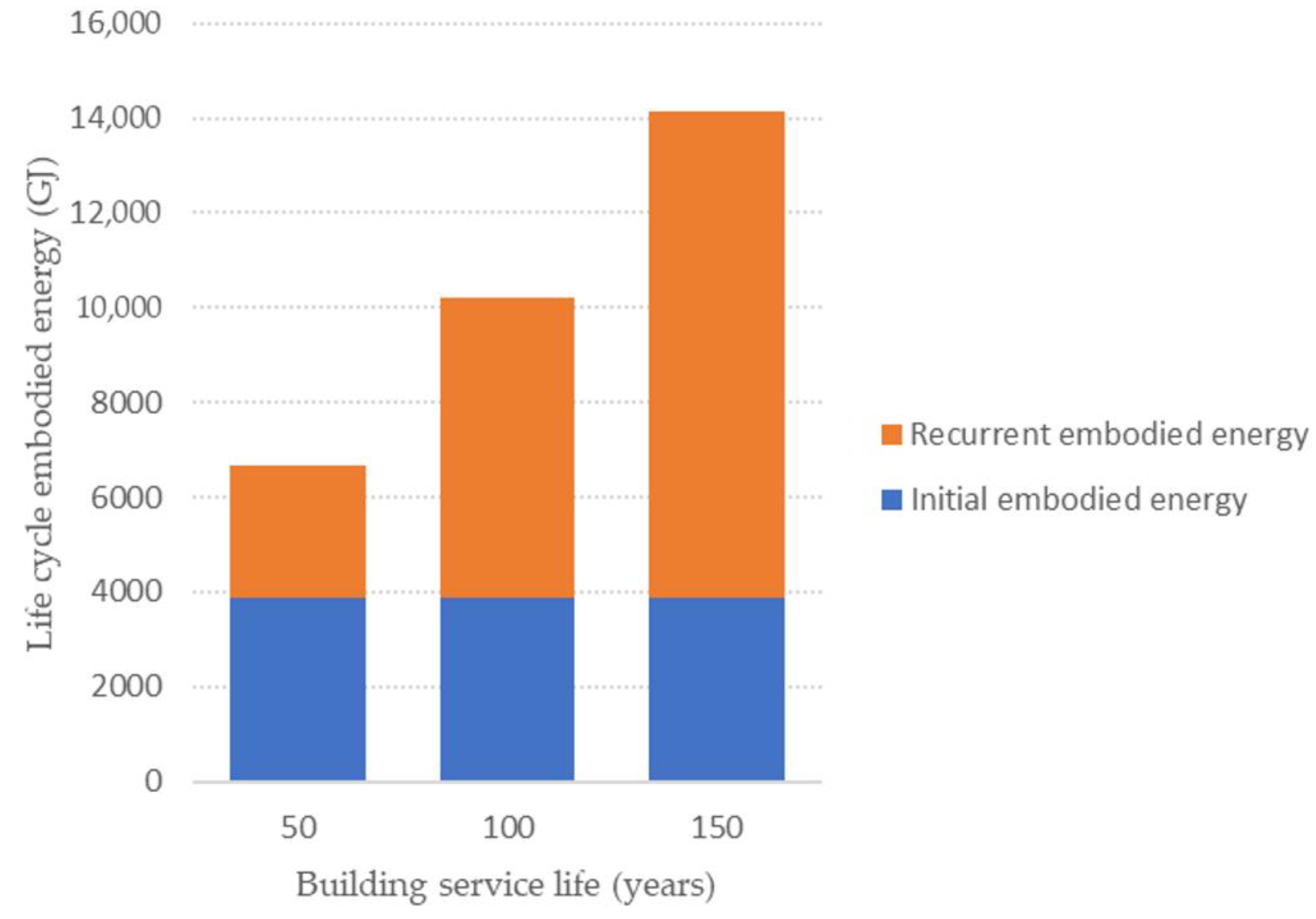

3.1. Base Case Results (with Average Material and Building Service Life)

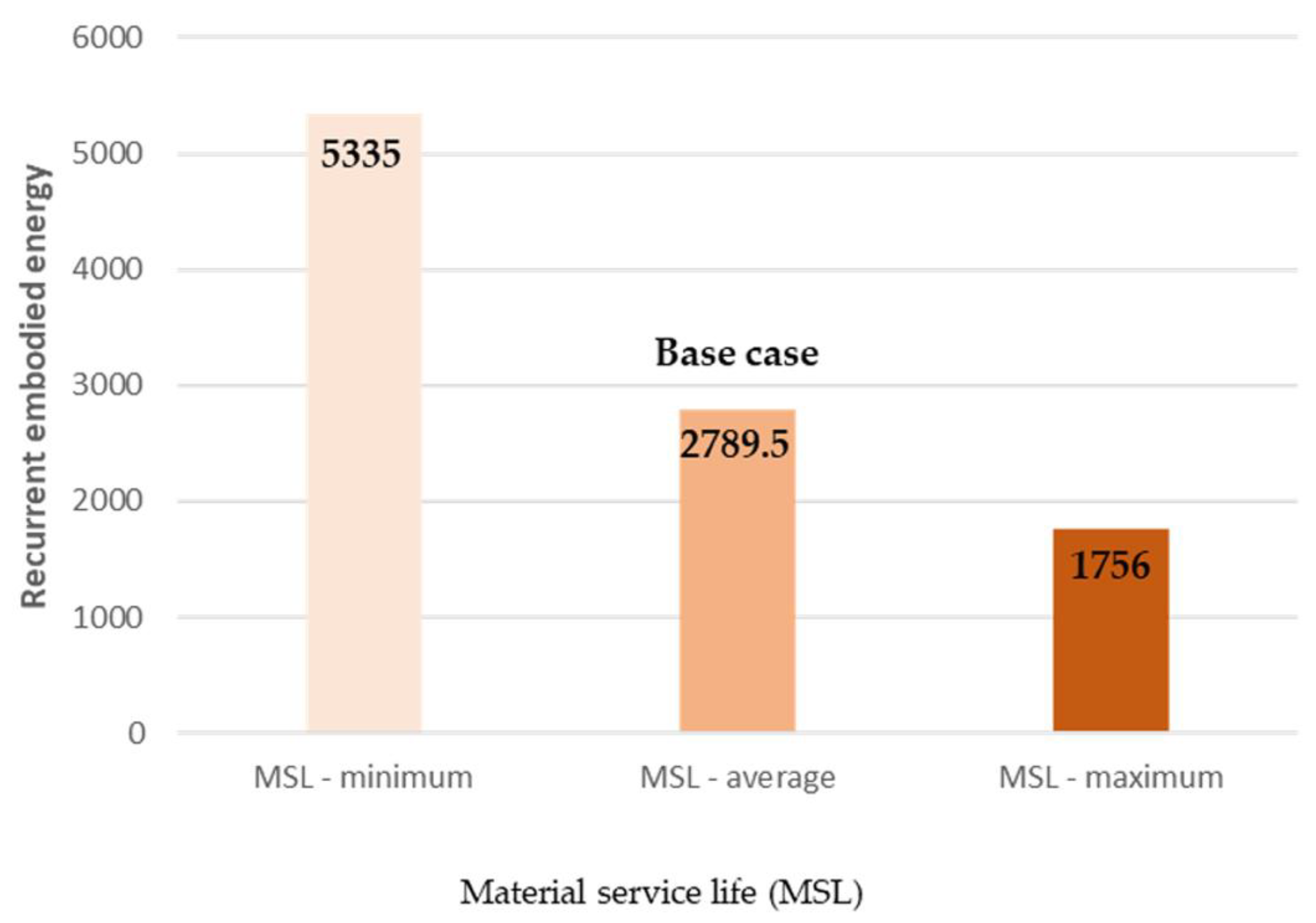

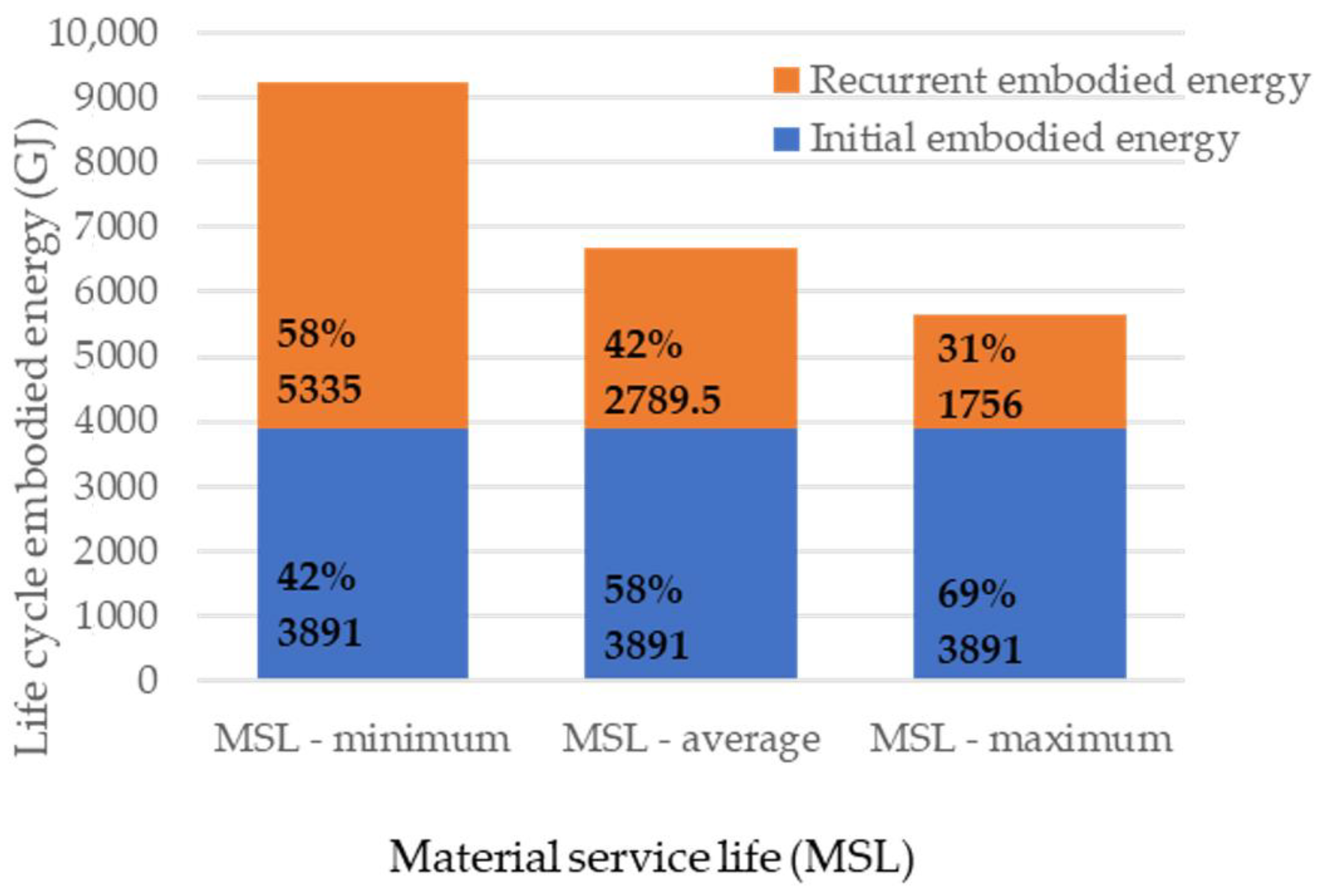

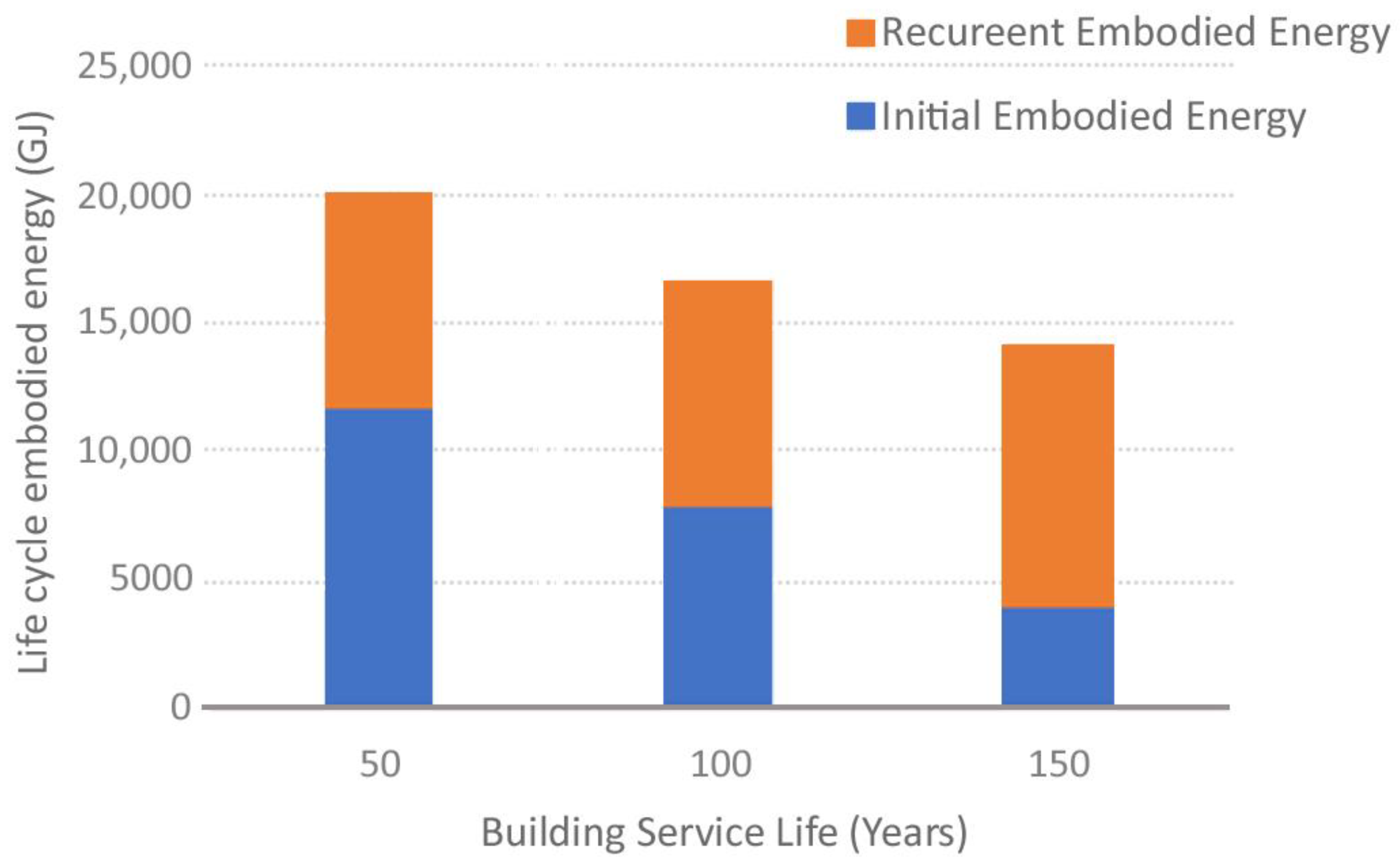

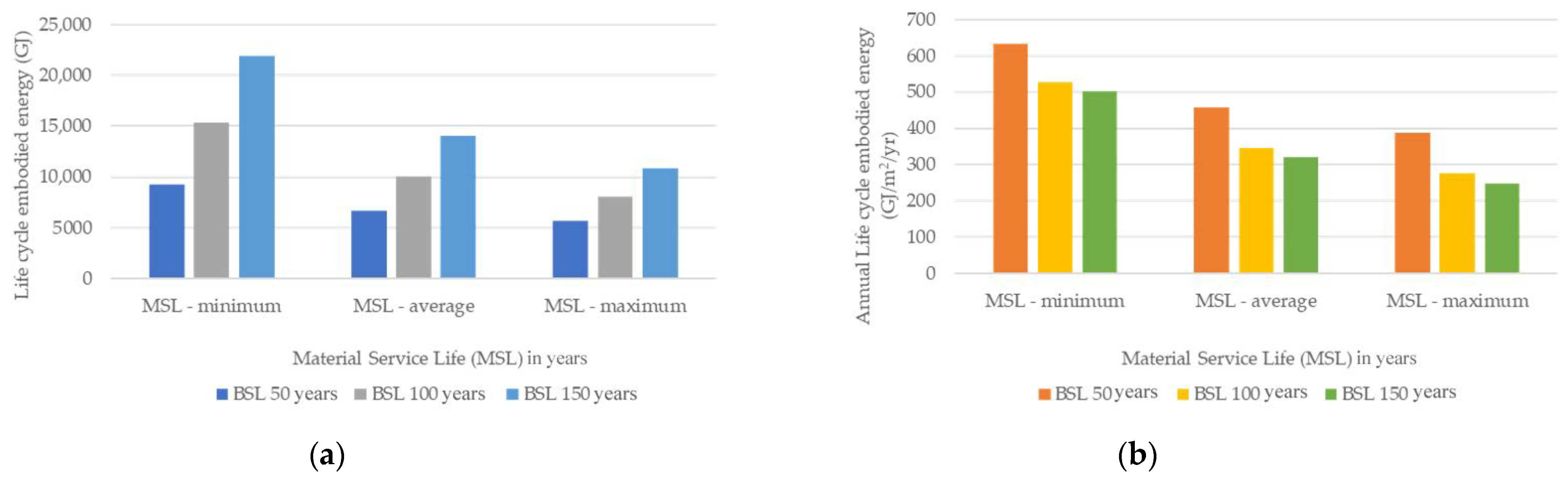

3.2. Effect of Material Service Life Variations

3.3. Effect of Building Service Life Variations

3.3.1. Initial Embodied Energy

3.3.2. Recurrent Embodied Energy

3.3.3. Life Cycle Embodied Energy

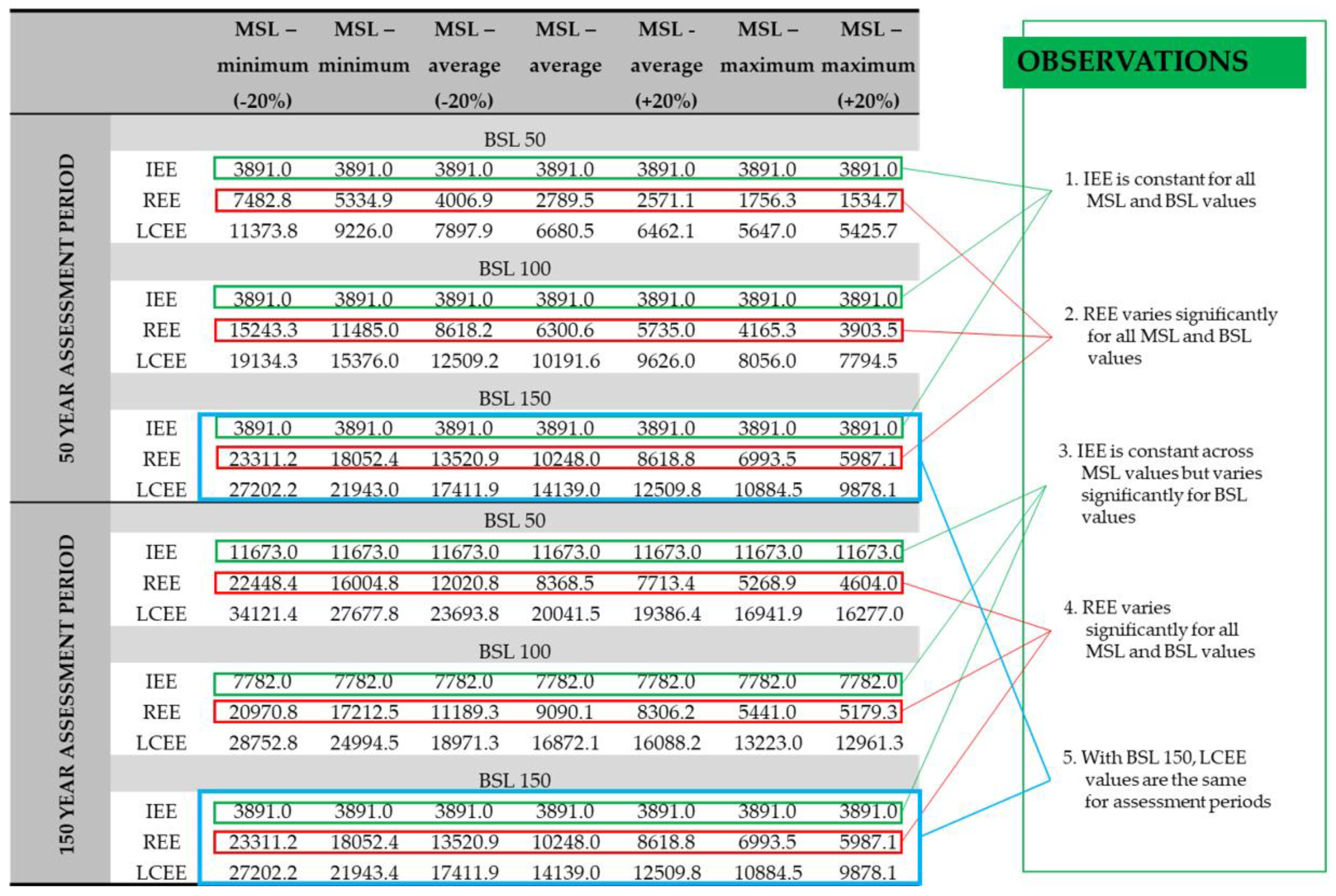

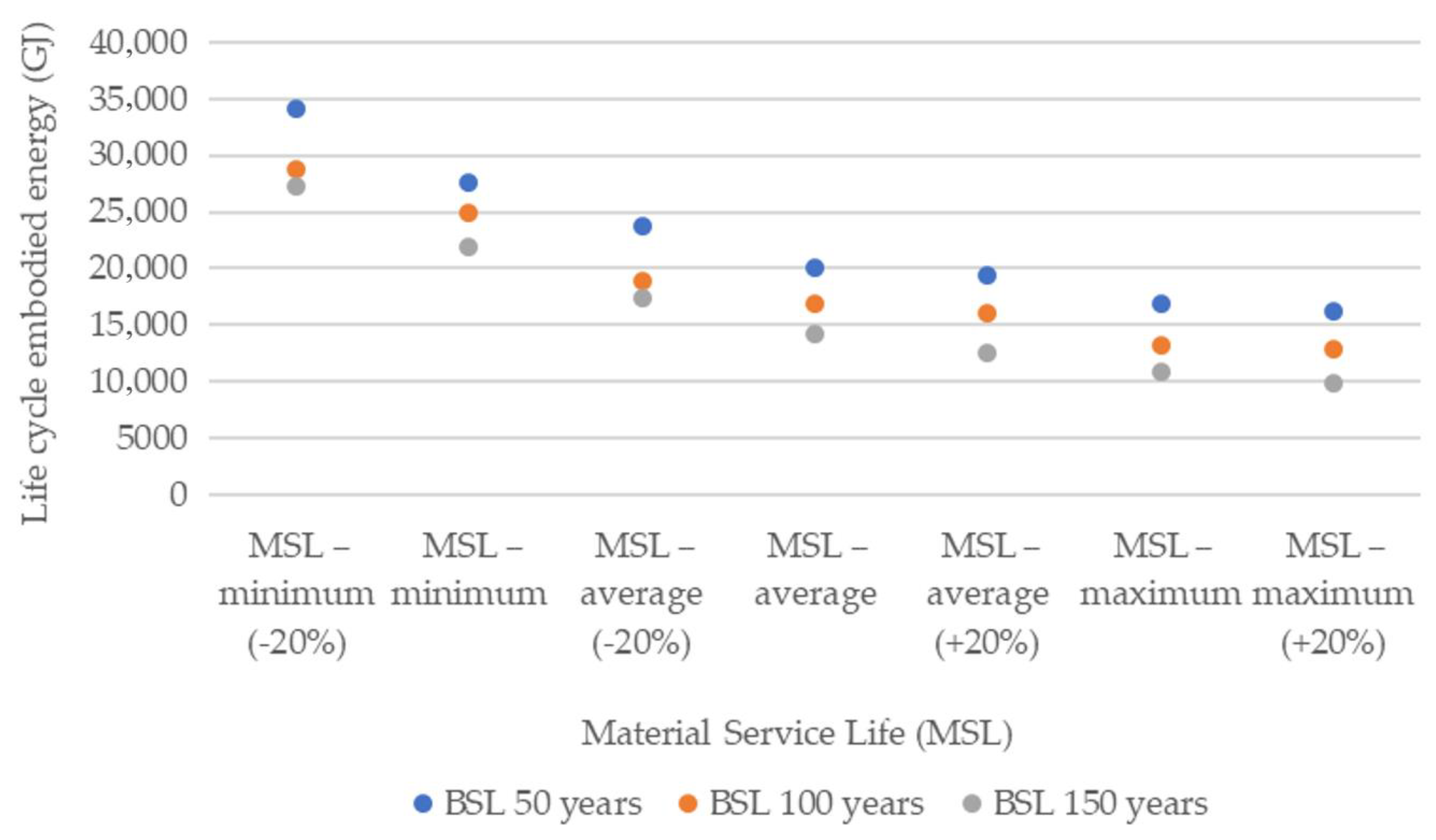

3.4. Combined Effect of Building and Material Service Life

3.5. Sensitivity Analysis

3.5.1. Life Cycle Embodied Energy Variations Based on the 50-Year Assessment Period

3.5.2. Life Cycle Embodied Energy Variations Based on the 150-Year Assessment Period

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbas, B.; Khamis, W.; Abdullah Ahmed, M.; Shà, H.; Mohammed, M. Environmental Pollution with the Heavy Metal Compound. Res. J. Pharm. Technol. 2018, 11, 4035–4041. [Google Scholar] [CrossRef]

- Ebadi, A.G.; Toughani, M.; Najafi, A.; Babaee, M. A Brief Overview on Current Environmental Issues in Iran. Cent. Asian J. Environ. Sci. Technol. Innov. 2020, 1, 1–11. [Google Scholar] [CrossRef]

- Qadri, H.; Bhat, R.; Mehmood, M.; Hamid Dar, G. Fresh Water Pollution Dynamics and Remediation; Springer: Singapore, 2019; ISBN 9789811382765. [Google Scholar]

- Anser, M.; Hanif, I.; Vo, X.; Alharthi, M. The Long-Run and Short-Run Influence of Environmental Pollution, Energy Consumption, and Economic Activities on Health Quality in Emerging Countries. Environ. Sci. Pollut. Res. 2020, 27, 32518–32532. [Google Scholar] [CrossRef] [PubMed]

- Sarkodie, S.A.; Ahmed, M.Y.; Owusu, P.A. Ambient Air Pollution and Meteorological Factors Escalate Electricity Consumption. Sci. Total Environ. 2021, 795, 148841. [Google Scholar] [CrossRef]

- He, P.; Liang, J.; Qiu, Y.; Li, Q.; Xing, B. Increase in Domestic Electricity Consumption from Particulate Air Pollution. Nat. Energy 2020, 5, 985–995. [Google Scholar] [CrossRef]

- Koondhar, M.A.; Houjian, L.; Wang, H.; Sanchir, B.; Kong, R. Looking Back over the Past Two Decades on the Nexus between Air Pollution, Energy Consumption, and Agricultural Productivity in China: A Qualitative Analysis Based on the ARDL Bounds Testing Model. Environ. Sci. Pollut. Res. Int. 2020, 27, 13575–13589. [Google Scholar] [CrossRef]

- Guzmán-Luna, P.; Gerbens-Leenes, P.W.; Vaca-Jiménez, S.D. The Water, Energy, and Land Footprint of Tilapia Aquaculture in Mexico, a Comparison of the Footprints of Fish and Meat. Resour. Conserv. Recycl. 2021, 165, 105224. [Google Scholar] [CrossRef]

- Dharmala, N.; Kholod, N.; Chaturvedi, V.; Ghosh, P.P.; Mathur, R.; Bali, S.; Behera, A.; Chamola, S.; Clarke, L.; Evans, M.; et al. Win-Win Transportation Strategies for India: Linking Air Pollution and Climate Mitigation. Energy Clim. Chang. 2022, 3, 100072. [Google Scholar] [CrossRef]

- Musa, K.S.; Maijama’a, R. Economic Growth, Energy Consumption and Environmental Pollution in Nigeria: Evidence from ARDL Approach. Energy Econ. Lett. 2020, 7, 61–73. [Google Scholar] [CrossRef]

- Nazir, M.S.; Mahdi, A.J.; Bilal, M.; Sohail, H.M.; Ali, N.; Iqbal, H.M.N. Environmental Impact and Pollution-Related Challenges of Renewable Wind Energy—A Review. Sci. Total Environ. 2019, 683, 436–444. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, T.; Liu, S.; Wang, K.; Rogers, T.; Yao, L.; Zhao, P. Reducing Energy Consumption and Pollution in the Urban Transportation Sector: A Review of Policies and Regulations in Beijing. J. Clean. Prod. 2021, 285, 125339. [Google Scholar] [CrossRef]

- Wang, X.-C.; Klemeš, J.J.; Dong, X.; Fan, W.; Xu, Z.; Wang, Y.; Varbanov, P.S. Air Pollution Terrain Nexus: A Review Considering Energy Generation and Consumption. Renew. Sustain. Energy Rev. 2019, 105, 71–85. [Google Scholar] [CrossRef]

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive Assessment of Embodied Environmental Impacts of Buildings Using Normalized Environmental Impact Factors. J. Clean. Prod. 2022, 334, 130083. [Google Scholar] [CrossRef]

- Li, L.; Sun, W.; Hu, W.; Sun, Y. Impact of Natural and Social Environmental Factors on Building Energy Consumption: Based on Bibliometrics. J. Build. Eng. 2021, 37, 102136. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the Embodied Energy and Carbon of Buildings: A Systematic Literature Review and Meta-Analysis of Life Cycle Assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- International Energy Agency (IEA); United Nations Environment Programme (UNEP). 2018 Global Status Report: Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2018; pp. 1–73. [Google Scholar]

- World Energy Council (WEC). World Energy Issues Monitor 2020: Decoding New Signals of Change; World Energy Council: London, UK, 2020; pp. 1–179. [Google Scholar]

- Zuev, V. Setting Up a Global System for Sustainable Energy Governance. In The Geopolitics of the Global Energy Transition; Lecture Notes in Energy; Hafner, M., Tagliapietra, S., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 365–381. ISBN 978-3-030-39066-2. [Google Scholar]

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Prospects 2019—Highlights; United Nations: New York City, NY, USA, 2019; ISBN 978-92-1-148316-1. [Google Scholar]

- Chen, H.; Tackie, E.A.; Ahakwa, I.; Musah, M.; Salakpi, A.; Alfred, M.; Atingabili, S. Does Energy Consumption, Economic Growth, Urbanization, and Population Growth Influence Carbon Emissions in the BRICS? Evidence from Panel Models Robust to Cross-Sectional Dependence and Slope Heterogeneity. Environ. Sci. Pollut. Res. 2022, 29, 37598–37616. [Google Scholar] [CrossRef]

- Warsame, A.A. The Impact of Urbanization on Energy Demand: An Empirical Evidence from Somalia. Int. J. Energy Econ. Policy 2022, 12, 383–389. [Google Scholar] [CrossRef]

- Fatourehchi, D.; Noguchi, M.; Doloi, H. Review of the Existing Energy Policies and Challenges of Energy Consumption to Achieve a Sustainable Behavioural Change among Iranian Households. In Proceedings of the 4th International Conference on Smart Villages and Rural Development, Smart Villages Lab (SVL) (COSVARD 2021), Webinar, Melbourne, VIC, Australia, 13–14 December 2021. [Google Scholar]

- Fatourehchi, D.; Noguchi, M.; Doloi, H. Iranian Household Electricity Use Compared to Selected Countries. Encyclopedia 2022, 2, 1637–1665. [Google Scholar] [CrossRef]

- Birgisdottir, H.; Moncaster, A.; Wiberg, A.H.; Chae, C.; Yokoyama, K.; Balouktsi, M.; Seo, S.; Oka, T.; Lützkendorf, T.; Malmqvist, T. IEA EBC Annex 57 ‘Evaluation of Embodied Energy and CO2eq for Building Construction. Energy Build. 2017, 154, 72–80. [Google Scholar] [CrossRef]

- Mirabella, N.; Roeck, M.; Ruschi Mendes SAADE, M.; Spirinckx, C.; Bosmans, M.; Allacker, K.; Passer, A. Strategies to Improve the Energy Performance of Buildings: A Review of Their Life Cycle Impact. Buildings 2018, 8, 105. [Google Scholar] [CrossRef]

- Danish Government. Strategy for Energy Renovation of Buildings—The Route to Energy-Efficient Buildings in Tomorrow’s Denmark; Danish Government: Copenhagen, Denmark, 2014; pp. 1–54. [Google Scholar]

- Amran, Y.A.; Amran, Y.M.; Alyousef, R.; Alabduljabbar, H. Renewable and Sustainable Energy Production in Saudi Arabia According to Saudi Vision 2030; Current Status and Future Prospects. J. Clean. Prod. 2020, 247, 119602. [Google Scholar] [CrossRef]

- UAE Government. UAE Energy Strategy 2050—The Official Portal of the UAE Government. Available online: https://u.ae/en/about-the-uae/strategies-initiatives-and-awards/federal-governments-strategies-and-plans/uae-energy-strategy-2050 (accessed on 11 October 2020).

- International Bank for Reconstruction and Development. The World Bank Tracking SDG 7: The Energy Progress Report (2020); International Bank for Reconstruction and Development: Washington DC, USA, 2020; pp. 1–204. [Google Scholar]

- United Nations, Department of Economic and Social Affairs. Global Sustainable Development Report 2019|The Future Is Now: Science for Achieving Sustainable Development; United Nations: New York, NY, USA, 2019; pp. 1–252. [Google Scholar]

- Rauf, A.; Attoye, D.E.; Crawford, R.H. Life Cycle Energy Analysis of a House in UAE. In Proceedings of the ZEMCH 2021 International Conference, ZEMCH Network, Dubai, United Arab Emirates, 26–28 October 2021; pp. 13–23. [Google Scholar]

- Tabet Aoul, K.A.; Hagi, R.; Abdelghani, R.; Akhozheya, B.; Karaouzene, R.; Syam, M. The Existing Residential Building Stock in UAE: Energy Efficiency and Retrofitting Opportunities. In Proceedings of the 6th Annual International Conference on Architecture and Civil Engineering, ACE, Singapore, 14–15 May 2018. [Google Scholar]

- Mawed, M.; Al Bairam, I.; Al-Hajj, A. Linking Between Sustainable Development and Facilities Management Strategies: An Integrated Approach for Evaluating the Sustainability of Existing Building in the UAE. In Proceedings of the ICSF 2017, Manama, Bahrain, 26–27 November 2017; p. 33. [Google Scholar]

- Crawford, R.H. Post-Occupancy Life Cycle Energy Assessment of a Residential Building in Australia. Archit. Sci. Rev. 2014, 57, 114–124. [Google Scholar] [CrossRef]

- Rauf, A. The Effect of Building and Material Service Life on Building Life Cycle Embodied Energy. Ph.D. Thesis, The University of Melbourne, Melbourne, VIC, Australia, 2016. [Google Scholar]

- Rauf, A.; Attoye, D.E.; Crawford, R. Embodied and Operational Energy of a Case Study Villa in UAE with Sensitivity Analysis. Buildings 2022, 12, 1469. [Google Scholar] [CrossRef]

- Singh, A.; Vaddy, P.; Biligiri, K.P. Quantification of Embodied Energy and Carbon Footprint of Pervious Concrete Pavements through a Methodical Lifecycle Assessment Framework. Resour. Conserv. Recycl. 2020, 161, 104953. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Ilori, O.M. Changing Significance of Embodied Energy: A Comparative Study of Material Specifications and Building Energy Sources. J. Build. Eng. 2019, 23, 324–333. [Google Scholar] [CrossRef]

- Crawford, R.H.; Czerniakowski, I.; Fuller, R.J. A Comprehensive Framework for Assessing the Life-Cycle Energy of Building Construction Assemblies. Archit. Sci. Rev. 2010, 53, 288–296. [Google Scholar] [CrossRef]

- Janjua, S. Sustainability Implication of Residential Building Materials Considering Service Life Variability. Ph.D. Thesis, Curtin University, Bentley, WA, Australia, 2021. [Google Scholar]

- Rauf, A.; Crawford, R.H. Building Service Life and Its Effect on the Life Cycle Embodied Energy of Buildings. Energy 2015, 79, 140–148. [Google Scholar] [CrossRef]

- Rauf, A.; Crawford, R.H. The Relationship between Material Service Life and the Life Cycle Energy of Contemporary Residential Buildings in Australia. Archit. Sci. Rev. 2013, 56, 252–261. [Google Scholar] [CrossRef]

- Dixit, M.K. Life Cycle Recurrent Embodied Energy Calculation of Buildings: A Review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- Tavares, V.; Lacerda, N.; Freire, F. Embodied Energy and Greenhouse Gas Emissions Analysis of a Prefabricated Modular House: The “Moby” Case Study. J. Clean. Prod. 2019, 212, 1044–1053. [Google Scholar] [CrossRef]

- Venkatraj, V.; Dixit, M.K. Life Cycle Embodied Energy Analysis of Higher Education Buildings: A Comparison between Different LCI Methodologies. Renew. Sustain. Energy Rev. 2021, 144, 110957. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Boquera, L.; Chàfer, M.; Vérez, D. Embodied Energy and Embodied Carbon of Structural Building Materials: Worldwide Progress and Barriers through Literature Map Analysis. Energy Build. 2021, 231, 110612. [Google Scholar] [CrossRef]

- Dascalaki, E.G.; Argiropoulou, P.; Balaras, C.A.; Droutsa, K.G.; Kontoyiannidis, S. Analysis of the Embodied Energy of Construction Materials in the Life Cycle Assessment of Hellenic Residential Buildings. Energy Build. 2021, 232, 110651. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied Energy and Carbon of Building Insulating Materials: A Critical Review. Clean. Environ. Syst. 2021, 2, A100032. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A Review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on Buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Marzouk, M.; Elshaboury, N. Science Mapping Analysis of Embodied Energy in the Construction Industry. Energy Rep. 2022, 8, 1362–1376. [Google Scholar] [CrossRef]

- Venkatraj, V.; Dixit, M.K. Challenges in Implementing Data-Driven Approaches for Building Life Cycle Energy Assessment: A Review. Renew. Sustain. Energy Rev. 2022, 160, 112327. [Google Scholar] [CrossRef]

- Weththasinghe, K.K.; Stephan, A.; Francis, V.; Tiwari, P. Improving Material Selection in Shopping Centres through a Parametric Life Cycle Embodied Flow and Material Cost Analysis Model. Renew. Sustain. Energy Rev. 2022, 165, 112530. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organisation for Standardization: Geneva, Switzerland, 2006.

- Almeida, M.; Ferreira, M.; Barbosa, R. Relevance of Embodied Energy and Carbon Emissions on Assessing Cost Effectiveness in Building Renovation—Contribution from the Analysis of Case Studies in Six European Countries. Buildings 2018, 8, 103. [Google Scholar] [CrossRef]

- Dixit, M.K.; Singh, S. Embodied Energy Analysis of Higher Education Buildings Using an Input-Output-Based Hybrid Method. Energy Build. 2018, 161, 41–54. [Google Scholar] [CrossRef]

- Garcia, R.; Calantone, R. A Critical Look at Technological Innovation Typology and Innovativeness Terminology: A Literature Review. J. Prod. Innov. Manag. Int. Publ. Prod. Dev. Manag. Assoc. 2002, 19, 110–132. [Google Scholar] [CrossRef]

- Giordano, R.; Giovanardi, M.; Guglielmo, G.; Micono, C. Embodied Energy and Operational Energy Evaluation in Tall Buildings According to Different Typologies of Façade. Energy Procedia 2017, 134, 224–233. [Google Scholar] [CrossRef]

- Koezjakov, A.; Urge-Vorsatz, D.; Crijns-Graus, W.; Van den Broek, M. The Relationship between Operational Energy Demand and Embodied Energy in Dutch Residential Buildings. Energy Build. 2018, 165, 233–245. [Google Scholar] [CrossRef]

- Omrany, H.; Soebarto, V.; Sharifi, E.; Soltani, A. Application of Life Cycle Energy Assessment in Residential Buildings: A Critical Review of Recent Trends. Sustainability 2020, 12, 351. [Google Scholar] [CrossRef]

- Dixit, M.K.; Culp, C.H.; Lavy, S.; Fernandez-Solis, J. Recurrent Embodied Energy and Its Relationship with Service Life and Life Cycle Energy: A Review Paper. Facilities 2014, 32, 22. [Google Scholar] [CrossRef]

- Crawford, R.H. Life Cycle Assessment in the Built Environment; Routledge: Abingdon, UK, 2011. [Google Scholar]

- Dixit, M.K. Life Cycle Embodied Energy Analysis of Residential Buildings: A Review of Literature to Investigate Embodied Energy Parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Crawford, R.H. Validation of a Hybrid Life-Cycle Inventory Analysis Method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Omar, W.M.S.W. A Hybrid Life Cycle Assessment of Embodied Energy and Carbon Emissions from Conventional and Industrialised Building Systems in Malaysia. Energy Build. 2018, 167, 253–268. [Google Scholar] [CrossRef]

- Treloar, G.J.; Love, P.E.; Holt, G.D. Using National Input/Output Data for Embodied Energy Analysis of Individual Residential Buildings. Constr. Manag. Econ. 2001, 19, 49–61. [Google Scholar] [CrossRef]

- Baird, G.; Alcorn, A.; Haslam, P. The Energy Embodied in Building Materials-Updated New Zealand Coefficients and Their Significance. Trans. Inst. Prof. Eng. New Zealand Civ. Eng. Sect. 1997, 24, 46–54. [Google Scholar]

- Wang, J.; Yu, C.; Pan, W. Life Cycle Energy of High-Rise Office Buildings in Hong Kong. Energy Build. 2018, 167, 152–164. [Google Scholar] [CrossRef]

- Crawford, R.H.; Hollingsbee, T. 5x4: A Case Study in Low Energy Infill Housing. In Proceedings of the World Sustainable Building Conference, Barcelona, Spain, 28–30 October 2014. [Google Scholar]

- Stephan, A.; Crawford, R.H. The Relationship between House Size and Life Cycle Energy Demand: Implications for Energy Efficiency Regulations for Buildings. Energy 2016, 116, 1158–1171. [Google Scholar] [CrossRef]

- Azzouz, A.; Borchers, M.; Moreira, J.; Mavrogianni, A. Life Cycle Assessment of Energy Conservation Measures during Early Stage Office Building Design: A Case Study in London, UK. Energy Build. 2017, 139, 547–568. [Google Scholar] [CrossRef]

- Wen, T.J.; Siong, H.C.; Noor, Z.Z. Assessment of Embodied Energy and Global Warming Potential of Building Construction Using Life Cycle Analysis Approach: Case Studies of Residential Buildings in Iskandar Malaysia. Energy Build. 2015, 93, 295–302. [Google Scholar] [CrossRef]

- Lolli, N.; Fufa, S.M.; Inman, M. A Parametric Tool for the Assessment of Operational Energy Use, Embodied Energy and Embodied Material Emissions in Building. Energy Procedia 2017, 111, 21–30. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An Embodied Carbon and Energy Analysis of Modern Methods of Construction in Housing: A Case Study Using a Lifecycle Assessment Framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, H.; Long, Z. A Distributed Computing Framework for Wind Speed Big Data Forecasting on Apache Spark. Sustain. Energy Technol. Assess. 2020, 37, 100582. [Google Scholar] [CrossRef]

- ISO 15686-1:2011; Buildings and Constructed—Service Life Planning—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2011. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/04/57/45798.html (accessed on 10 February 2022).

- Athena Institute; Morrison Hersfield. Service Life Considerations in Relation to Green Building Rating Systems; Athena Sustainable Materials Institute: Merrickville, ON, Canada, 2006; pp. 1–49. [Google Scholar]

- S478-95 (R2007); Standard Guideline on Durability in Buildings S478-95 (R2007). Canadian Standards Association: Toronto, ON, Canada, 1995; pp. 1–101.

- Public Works and Government Services Canada. Durability Guidelines for Building Wall Envelopes; Public Works and Government Services Canada: Toronto, ON, Canada, 1997. [Google Scholar]

- ISO 15686-1:2011; Buildings and Constructed Assets—Service Life Planning—Part 2 Service Life Prediction Procedures. International Organization for Standardization: Geneva, Switzerland, 2011. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/04/57/45798.html (accessed on 10 February 2022).

- Silva, A.; de Brito, J. Service Life of Building Envelopes: A Critical Literature Review. J. Build. Eng. 2021, 44, 102646. [Google Scholar] [CrossRef]

- Tabet Aoul, K.A.; Hagi, R.; Abdelghani, R.; Syam, M.; Akhozheya, B. Building Envelope Thermal Defects in Existing and Under-Construction Housing in the UAE; Infrared Thermography Diagnosis and Qualitative Impacts Analysis. Sustainability 2021, 13, 2230. [Google Scholar] [CrossRef]

- Huijbregts, M.A. Application of Uncertainty and Variability in LCA. Int. J. Life Cycle Assess. 1998, 3, 273–280. [Google Scholar] [CrossRef]

- Wang, E.; Shen, Z. A Hybrid Data Quality Indicator and Statistical Method for Improving Uncertainty Analysis in LCA of Complex System—Application to the Whole-Building Embodied Energy Analysis. J. Clean. Prod. 2013, 43, 166–173. [Google Scholar] [CrossRef]

- Grant, A.; Ries, R.; Kibert, C. Life Cycle Assessment and Service Life Prediction. J. Ind. Ecol. 2014, 18, 187–200. [Google Scholar] [CrossRef]

- Riahinezhad, M.; Hallman, M.; Masson, J.F. Critical Review of Polymeric Building Envelope Materials: Degradation, Durability and Service Life Prediction. Buildings 2021, 11, 299. [Google Scholar] [CrossRef]

- Xu, Q.; Shi, D.; Shao, W. Service Life Prediction of RC Square Piles Based on Time-Varying Probability Analysis. Constr. Build. Mater. 2019, 227, 116824. [Google Scholar] [CrossRef]

| Method | Strength | Weakness | Source |

|---|---|---|---|

| Process Analysis | Combines process, product, and location-specific data Classified as the most accurate | Details of major production data is sometimes unavailable Complex procedure due to upstream supply chain associated with the approach 59% truncation error reported | [36,45,64,65,66] |

| Input–output analysis | Energy is quantified based on economic data of product production processes Considered to be systemically complete and very comprehensive | Complicated by aggregation of dissimilar products Applicability is limited to a single product Prone to errors due to the use of economic data Multiple-time counting of energy embodied associated with delivered fuels | [36,62,63,65,66,67] |

| Category | Design Service Life for Category | Examples |

|---|---|---|

| Temporary - | Up to ten years | Non-permanent construction buildings, sale offices, bunkhouses, temporary exhibition buildings |

| Medium Life | 25–49 years | Most industrial buildings, most parking structures |

| Long Life | 50–99 years | Most residential, commercial and office buildingsHealth and education buildings Parking structures below buildings designed for long life category |

| Permanent | Minimum period, 100 years | Monumental or heritage buildings (national museums, art galleries, archives) |

| Quantity | Wastage Factor | Delivered Quantity | Unit | Embodied Energy Coefficient (GJ/Unit) | Embodied Energy (GJ) | |

|---|---|---|---|---|---|---|

| Concrete 20 MPa | 52 | 1.15 | 59.54 | m3 | 4.44 | 264.13 |

| Steel | 5.18 | 1.05 | 5.44 | t | 85.46 | 464.61 |

| Timber—Softwood for wall frame | 8.11 | 1.02 | 8.27 | m3 | 10.925 | 90.37 |

| Bricks | 82.89 | 1.05 | 87.03 | m2 | 0.56 | 48.78 |

| concrete roof tile (20 mm) | 378 | 1.10 | 415.61 | m2 | 0.251 | 104.46 |

| carpet—nylon | 240.51 | 1.05 | 252.53 | m2 | 0.683 | 172.54 |

| Paint—water based | 1294 | 1.05 | 1358.70 | m2 | 0.096 | 130.96 |

| Ceramic tiles | 57.1 | 1.05 | 59.96 | m2 | 0.293 | 17.58 |

| Plasterboard 10 mm | 683.15 | 1.05 | 717.31 | m2 | 0.207 | 148.31 |

| Material | Service Life (Minimum) | Service Life (Average) | Service Life (Maximum) |

|---|---|---|---|

| Concrete roof tiles | 30 | 40 | 60 |

| Bricks | Lifetime | Lifetime | Lifetime |

| Aluminum-framed windows | 10 | 25 | 40 |

| Concrete slab | Lifetime | Lifetime | Lifetime |

| Wall framing | Lifetime | Lifetime | Lifetime |

| Ceramic wall and floor tiles | 20 | 60 | 100 |

| Nylon carpet | 7 | 10 | 20 |

| Paint (interior) | 5 | 10 | 15 |

| Gypsum plasterboard | 20 | 35 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rauf, A. Reducing Life Cycle Embodied Energy of Residential Buildings: Importance of Building and Material Service Life. Buildings 2022, 12, 1821. https://doi.org/10.3390/buildings12111821

Rauf A. Reducing Life Cycle Embodied Energy of Residential Buildings: Importance of Building and Material Service Life. Buildings. 2022; 12(11):1821. https://doi.org/10.3390/buildings12111821

Chicago/Turabian StyleRauf, Abdul. 2022. "Reducing Life Cycle Embodied Energy of Residential Buildings: Importance of Building and Material Service Life" Buildings 12, no. 11: 1821. https://doi.org/10.3390/buildings12111821

APA StyleRauf, A. (2022). Reducing Life Cycle Embodied Energy of Residential Buildings: Importance of Building and Material Service Life. Buildings, 12(11), 1821. https://doi.org/10.3390/buildings12111821